BRAND Hydraulics FC51, FC55, FCR51, FCB51 User Manual

FC FLOW CONTROL (FC51, FC55, FCR51 & FCB51 )

INSTALLATION & USER GUIDE

SPECIFICATIONS:

Rated for 3000 psi (207 bar).

Weighs 7- ¾ lbs. (3.52 kg).

FEATURES:

CF port (Controlled Flow) - Flow coming from the CF port is pressure compensated and proportional to the side lever

rotation. CF flow can vary from closed to wide open.

EX port (Excess Flow) - Flow coming from the EX port is also pressure compensated. Note: When side lever is set to 0,

entire flow will exit valve via EX port.

MOUNTING & ADJUSTMENT INSTRUCTIONS:

Mounting – Valve can be mounted in any orientation. Valve must be mounted on a flat surface. Special attention should

be paid to not bend or twist the casting when mounting. Doing so may cause the compensator spool to bind, causing

valve to fail. It is recommended to install washers between casting and mounting surface.

Relief Adjustment (FCR & FCB valves) –Relief setting is factory preset to 1500 psi, unless otherwise noted within

model code. Relief valve can be set anywhere within the range of 500 psi to 3000psi.

To adjust relief pressure: First, remove acorn nut and then turn the relief adjustment set screw clockwise to

increase the pressure setting. One complete turn of set screw increases/decreases pressure by 300 psi. EX port

MUST be plumbed back to tank for relief function to operate.

FREQUENTLY ASKED QUESTIONS:

Q: Can the CF port be blocked or plugged?

A: No. If the CF port is blocked or plugged for any reason the compensation spool will attempt to compensate for increasing

pressure, and shift thus blocking the EX port as well, and rendering valve inoperable. DO NOT BLOCK CF PORT.

Q: Can the EX port be blocked or plugged?

A: The EX port can be blocked or plugged, but doing so requires a pressure compensated or load sense pump. Plugging the

EX port may create instability issues that can be remedied by switching the compensator spool to a different spool. (Part #

XDC609)

Q: Can flow be sent in reverse through valve.

A: Yes, If valve number begins with a FC55. If you’re unsure of your valve’s model number, please contact factory for

assistance.

Q: Can I add a relief to my standard FC51 valve?

A: It is not possible to add a built-in relief to a standard FC51 or FC55 valve. The casting is different, which prevents this.

Q: What kits are available for this valve?

A: There is a replacement seal kit for the FC51 & FC55 (Part # FC-K) A replacement seal kit for the FCR51 (Part # FCR-K).

Seal replacement kit for the FCB51 (Part # FCB-K) Relief kit for FCB51 (TS-B)

30-Micron Filtration Recommended.

Torque to turn side lever spool.

35 in*lbs with 3000 psi (207 bar) on EX Port.

04/14

TROUBLESHOOTING:

Problem: Valve chatters or has stability issues. Instability generally occurs when the valve sees an application that has

rapidly changing loads. (ie: Fan, Vibration, etc.) Because of these changing loads the compensator spool tries to compensate

rapidly. This causes the valve to become unstable, as well as begin to make noises, including a chatter.

Solution: Most instability issues can be solved by using a different compensator spool. A replacement spool designed for

load changing applications can be ordered. (Part #: XDC609)

GENERAL INFORMATION:

Pipe Thread Sealant - Warranty is void when Teflon tape is used to seal pipe threads. This is because Teflon tape is a

friction reducing agent which allows customers to over-torque fittings. We recommend using a sealant that does not include

friction reducing agents i.e. Lead Plate.

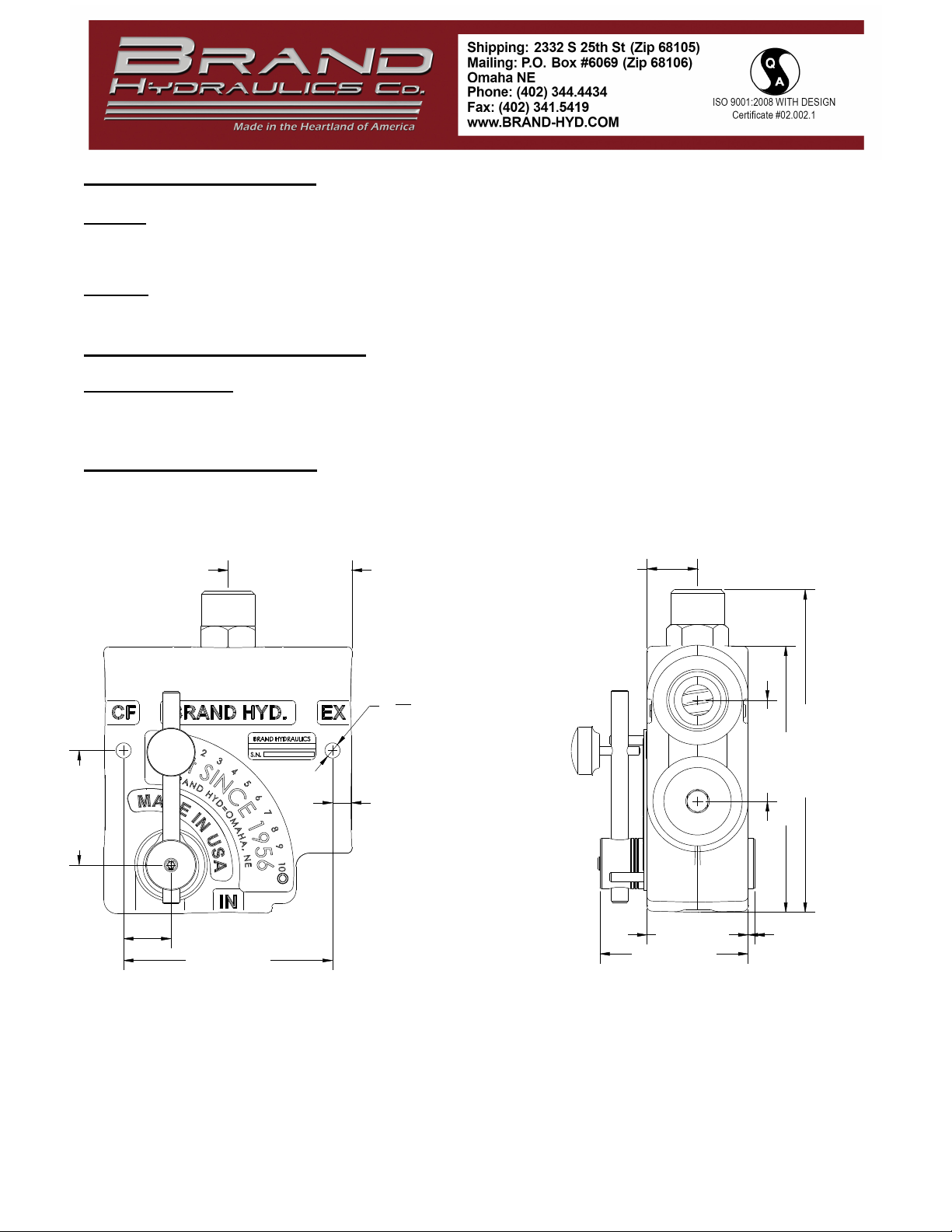

DIMENSIONAL DATA:

FCR51 & FC51 DIMENSIONAL DATA (FCR51 SHOWN)

2.30" [58.5] REF.

9

Ø

" [Ø7.1] THRU

32

(2 PLACES)

0.35" [8.9] REF.

2.13" [54.0]

0.88" [22.4]

3.88" [98.4]

0.94" [23.8] REF.

1.88" [47.6]

1.88" [47.6] 0.12" [3.2]

2.75" [69.8]

5.99" [152.1]

4.94" [125.6]

04/14

Loading...

Loading...