BRAND Hydraulics DS User Manual

DS DIRECTIONAL CONTROL VALVES

INSTALLATION & USER GUIDE

SPECIFICATIONS:

• Coils: - 12 VDC, 3.5 ohms, 40 watts, & 3.5 amps

- 24 VDC, 14 ohms, 40 watts, and 1.75 amps

- 120 VAC, 300 ohms, 40 watts, and 0.40 amps

• Port Sizes: - #8 SAE (3/4-16) all ports

- #10 SAE (7/8-14) all ports

- #12 SAE (1-1/16-12) all ports

- #4 SAE (7/16-20) drain port

• Weight: 10.0 lbs (4.55 kg).

• 10 Micron Filtration Recommended.

MOUNTING, & ASSEMBLY INSTRUCTIONS:

Mounting – Valve can be mounted in any orientation. Valve must be mounted on a flat surface. Special attention should

be paid to not bend or twist the casting when mounting. Doing so may cause the valve to fail.

Handle Assembly – If the enclosed lever handle is desired, the handle actuator will already be installed on the valve.

When you receive the valve, simply screw the supplied lever handle into the threaded handle actuator.

FREQUENTLY ASKED QUESTIONS:

Q: Can I paint the valve?

A: Painting valves is acceptable as long as the following precautions are taken:

1- All ports must be plugged

2- Spool must be masked or taped off completely.

Any paint on the spool will cause leakage when it chips off. Warranty is void if any valve is returned with paint on

the spool

Q: When do I need an external drain?

A: The external drain is only used on Electrically Actuated “DS” valves where operating

pressures are greater than 3600 psi (248 bar) but does not exceed 4500 psi (310 bar). The internal drain plug can be swapped

out with the external drain plug (opposite the coil) if the spool seems to “stick” at higher pressures. Note: pilot, knob, and

lever actuated valves are rated to 4500 psi (310 bar).

Q: What pilot pressure is required for the pilot operated version of the valve?

A: Valve requires 150 psi pilot pressure.

Q: When are “unused open-port” spools (types F&G) beneficial?

A: In selector spools F and G, the unused ports are open to prevent line cavitation during motor freewheel.

Q: When are closed cross-over spools used as opposed to open cross-over?

A: Closed cross-over transient position spools are recommended for switching flow between cylinders to help prevent

cylinders from shifting while in the transient position.

Q: What kits are available for this valve?

A: There is a replacement seal kit for each variation of valve (Electric = P/N#: DS-EK, Knob& Lever=P/N#: DS-K, Manual

Lever=P/N#: DS-HL, Pilot=P/N# DS-PK). There are also a number of different kits available for this valve depending on the

spool action, and handle option the valve is equipped with. Please contact factory for specific kit numbers relating to different

spool actions, and handle options.

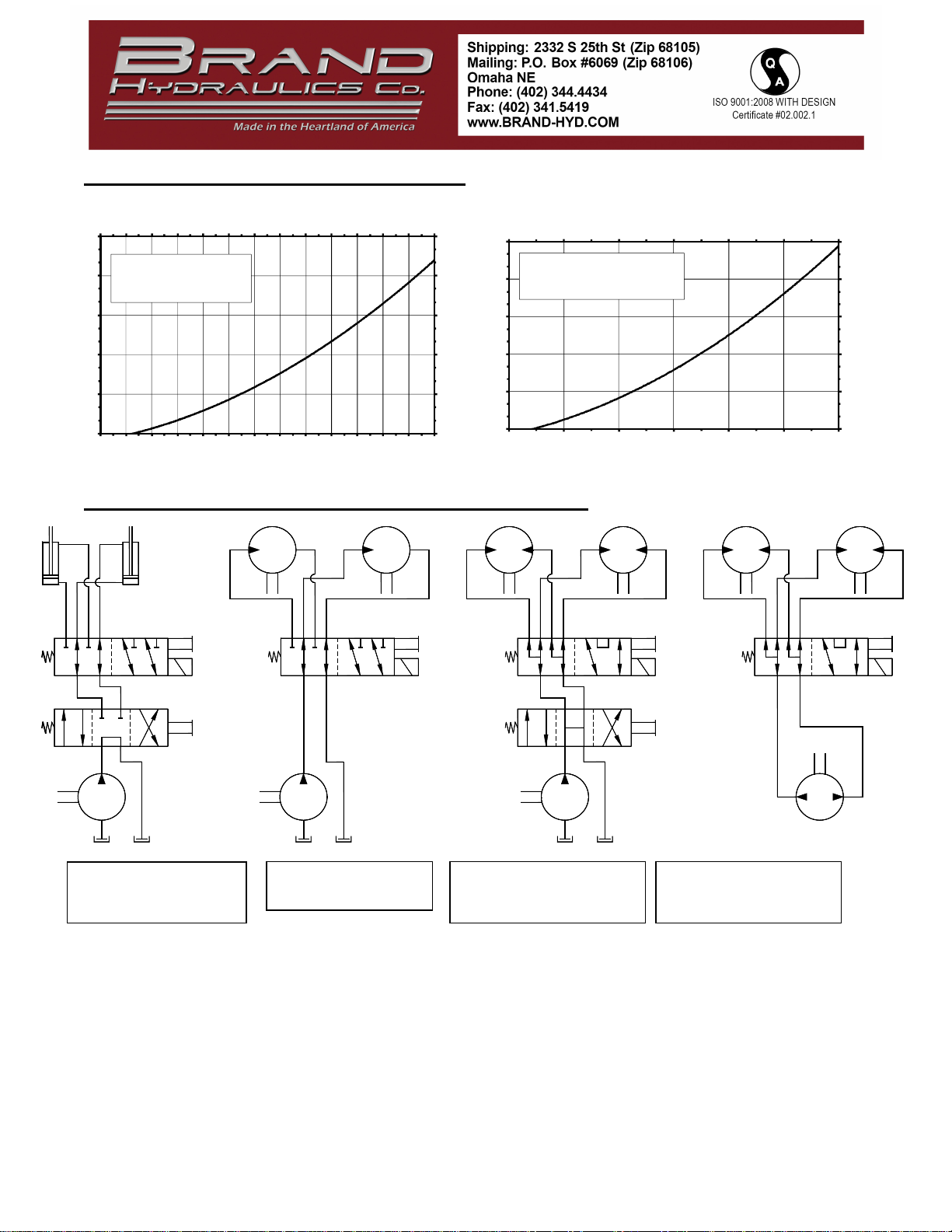

• Flow and pressure ratings for Pilot, Lever and

Knob actuated valves

#8 SAE – 10gpm (38 lpm) & 4500 psi (310 bar)

#10 SAE –18gpm (68 lpm) & 4500 psi (310 bar)

#12 SAE –30gpm (114lpm) & 4500 psi (310 bar)

05/14

Selector

spool – used to

directional control valve

Selector

spool – used to

motors individually

Series/Parallel

spool

– used to

directional control valve

Series/Parallel spool

–

used

with one bi

-

directional pump

FLOW & PRESSURE INFORMATION:

0 8 15 23 30 38 45 53 60 68 76 83 91 98

150

120

90

Pressure vs. Flow for Electric DS

Flow (lpm)

This line represents the total

pressure drop across valve.

De-energized (Pd-Pf) + (Pb-Pc)

Energized (Pd-Pe) + (Pa-Pc)

60

Pressure (psi)

30

0

0 2 4 6 8 10 12 14 16 18 20 22 24 26

Flow (gpm)

10

150

8

120

6

4

2

0

90

60

Pressure (psi)

Pressure (bar)

30

0

Pressure vs. Flow for Manual/Pilot DS

0 19 38 57 76 95 113

This line represents the total pressure

drop across valve. Total pressure

drop equals (Pd-Pf) + (Pb-Pc)

or (Pd-Pe) + (Pa-Pc)

0 5 10 15 20 25 30

COMMON DOUBLE SELECTOR APPLICATIONS:

extend and retract two

separate cylinders with one

rotate two uni-directional

rotate two bi-directional motors

in series or parallel with one

Flow (lpm)

Flow (gpm)

to rotate two bi-directional

motors in series or parallel

10

8

6

4

Pressure (bar)

2

0

05/14

Loading...

Loading...