Page 1

Installation

Installation

Instalación

TDB3108

Terreon®54" Circular Deep Bowl Washfountain with

Infrared Control

Terreon®Lavabo fontaine 1372 mm (54") à cuvette

profonde circulaire avec commande à infrarouge

Fuente de lavado circular con palangana profunda

Terreon®de 1372 mm (54") con control infrarrojo

WF3208

Terreon®Extra Height 54" Circular Classic

Washfountain with 9" Deep Bowl and Infrared Control

Terreon®Lavabo fontaine 1372 mm (54") à hauteur

supplémentaire classique circulaire à cuvette

profonde de 229 mm (9") et commande à infrarouge

Fuente de lavado clásica circular Terreon®de altura

adicional de 1372 m (54") con palangana profunda de

229 mm (9") y control infrarrojo

P.O. Box 309, Menomonee Falls, WI 53052-0309

Phone: 1-800-BRADLEY Fax: (262) 251-5817

http:\\www.bradleycorp.com

215-1187 Rev N; EN 06-915B

© 2007 Bradley Corporation

Page 1 of 85 4/6/2007

IMPORTANT!

Read this entire installation manual to ensure

proper installation. When finished with the

installation, file this manual with the owner

or maintenance department.

Separate parts from packaging and make

sure all parts are accounted for before

discarding any packaging material. If any

parts are missing, do not begin installation

until you obtain the missing parts.

Make sure that all water supply lines have

been flushed and then completely turned off

before beginning installation. Debris in

supply lines can cause valves to

malfunction.

Hardware supplied by installer must be

appropriate for wall construction. Wall

anchors used must have a minimum pull-out

rating of 1,000 lbs.

The Adaptive® Infrared control must be

connected with a 24 VAC Class II

transformer. Connections to 110 VAC can

cause personal injury and will result in

damage to the electronics.

Product warranties may be found under

“Product Information” on our web site at

www.bradleycorp.com.

IMPORTANT !

Lire ce manuel d’installation dans son

intégralité pour garantir une installation

appropriée. Une fois celle-ci terminée,

classer ce manuel auprès du service à la

clientèle ou d’entretien.

Séparer les pièces de l’emballage et veiller à

bien avoir toutes les pièces avant de jeter le

matériau d’emballage. Le cas échéant, ne

pas commencer l’installation avant d’avoir

obtenu les pièces manquantes.

Veiller à bien vidanger et fermer toutes les

conduites d’eau avant de commencer

l’installation. Tout débris dans les conduites

d’alimentation risque de provoquer un

mauvais fonctionnement des soupapes.

La quincaillerie fournie par l’installateur doit

être appropriée pour la construction des

murs. Les dispositifs d’ancrage muraux

doivent avoir un indice d’arrachement

minimum de 454 kg (1 000 lbs.).

La commande à infrarouge Adaptive® doit

être connectée avec un transformateur

24 V c.a. Classe II. Des connexions à du

110 V c.a. peuvent provoquer des blessures

personnelles et endommager les

composants électroniques.

Les garanties du produit figurent sous la

rubrique « Informations techniques » sur

notre site Internet à www.bradleycorp.com.

¡IMPORTANTE!

Lea todo este manual para garantizar su

instalación adecuada. Cuando haya

terminado la instalación, preséntelo al dueño

o al Departamento de Mantenimiento.

Separe las piezas del empaque y asegúrese

de que no falte ninguna antes de desechar el

material del empaque. Si falta alguna pieza,

no comience con la instalación hasta que

obtenga las faltantes.

Asegúrese de que todas las tuberías de

suministro de agua hayan sido lavadas y

cerradas completamente antes de comenzar

la instalación. Los desechos en las tuberías

de suministro pueden causar averías en las

válvulas.

Las piezas metálicas proporcionadas por el

instalador deben ser adecuadas para la

construcción en la pared. Las sujeciones de

pared usadas deben tener una capacidad

mínima de extracción de 454 kg (1.000

libras).

El control infrarrojo Adaptive® debe

conectarse con un transformador clase II de

24 V CA. Las conexiones a 110 V CApueden

causar lesiones personales y producirán

daños a los componentes electrónicos.

Se pueden encontrar garantías de los

productos en Product Information

(Información sobre productos) en nuestro

sitio Web en www.bradleycorp.com.

A

D

A

C

O

M

P

L

I

A

N

T

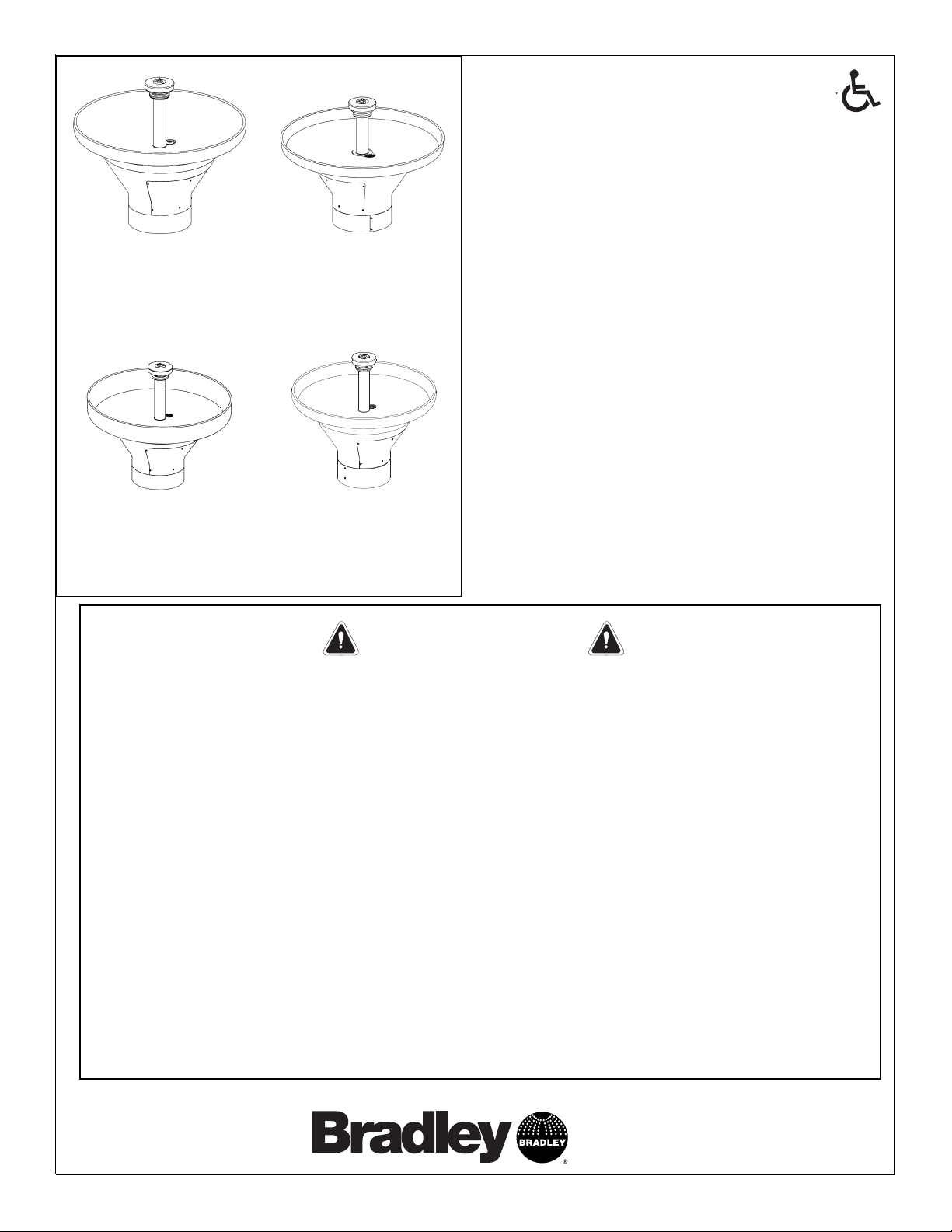

TDB3108

with Infrared Control

TDB3108

avec commande à infrarouge

Modelo TDB3108

con control infrarrojo

TDB3108 Juvenile

with Infrared Control

TDB3108 Enfant

avec commande à infrarouge

Modelo infantil TDB3108

con control infrarrojo

WF3208

with Infrared Control

WF3208

avec commande à infrarouge

Modelo WF3208

con control infrarrojo

TDB3108 TAS Height

with Infrared Control

TDB3108 Hauteur TAS

avec commande à infrarouge

Altura TAS del modelo TDB3108

con control infrarrojo

Page 2

TDB3108, WF3208 Terreon®54" Circular Installation

2 4/6/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

Table of Contents

Pre-Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Model TDB3108 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Model WF3208 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Washfountain Rough-Ins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-19

Terreon® Cleaning/Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Gel-Coated Fiberglass Cleaning/Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Stainless Steel Cleaning/Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Soap Dispensing Valve Repair Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22-23

Soap Recommendations and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Sprayhead Troubleshooting/Repair Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Manual Mixing Valve (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Volume Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Vernatherm™ Thermostatic Mixing Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28-29

Supplies Required by Installer

• (4) 1/2" lag bolts, screws or other fasteners to anchor washfountain pedestal

• 1" hot and cold water supply lines and fittings (refer to rough-ins on pages 7-8)

• Reducing fittings and 1/2" nom. copper tubing supply lines for types with supplies from above

• Standard P-trap (refer to rough-ins on pages 7-8) (vented trap supplied by Bradley when required)

• 2" drain lines and fittings (refer to rough-ins on pages 7-8)

• 1-1/2" vent or tie pipe on fixtures vented through washfountain column (see page 9 for lengths required)

• Teflon tape or pipe dope

• 110 VAC GFI power source for 110/24 VAC UL Class II transformer supplied

• OPTIONAL: Bradley recommends installing an electrical cut-off switch to the unit. This feature

allows no accidental water delivery during regular maintenance and service.

Pre-Installation Information

Terreon®Material

The Washfountain is constructed of Terreon®, a densified solid surface material composed of polyester

resin. Terreon

®

is resistant to chemicals, stains, burns and impact. Surface damage can be easily

repaired with everyday cleaners or fine-grit abrasives. Terreon

®

is NAHB certified to meet ANSI

Z124.3, Z124.6 and ANSI/ICPA SS-1-2001.

Adaptive Infrared

The sprayhead is controlled by a solenoid valve, allowing the user to activate a flow of water. The

Infrared sensor will take a few minutes to adapt to its environment when the unit is powered up.

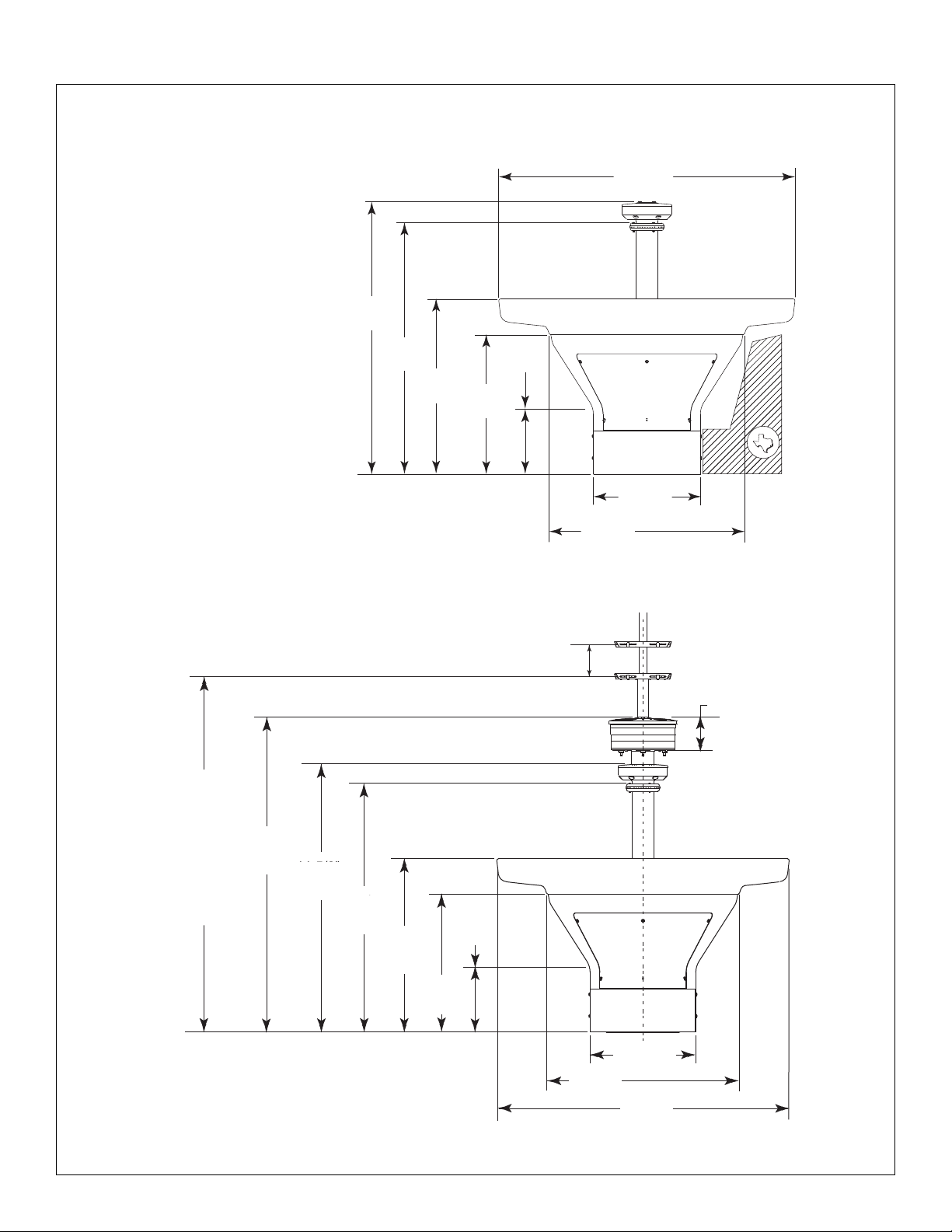

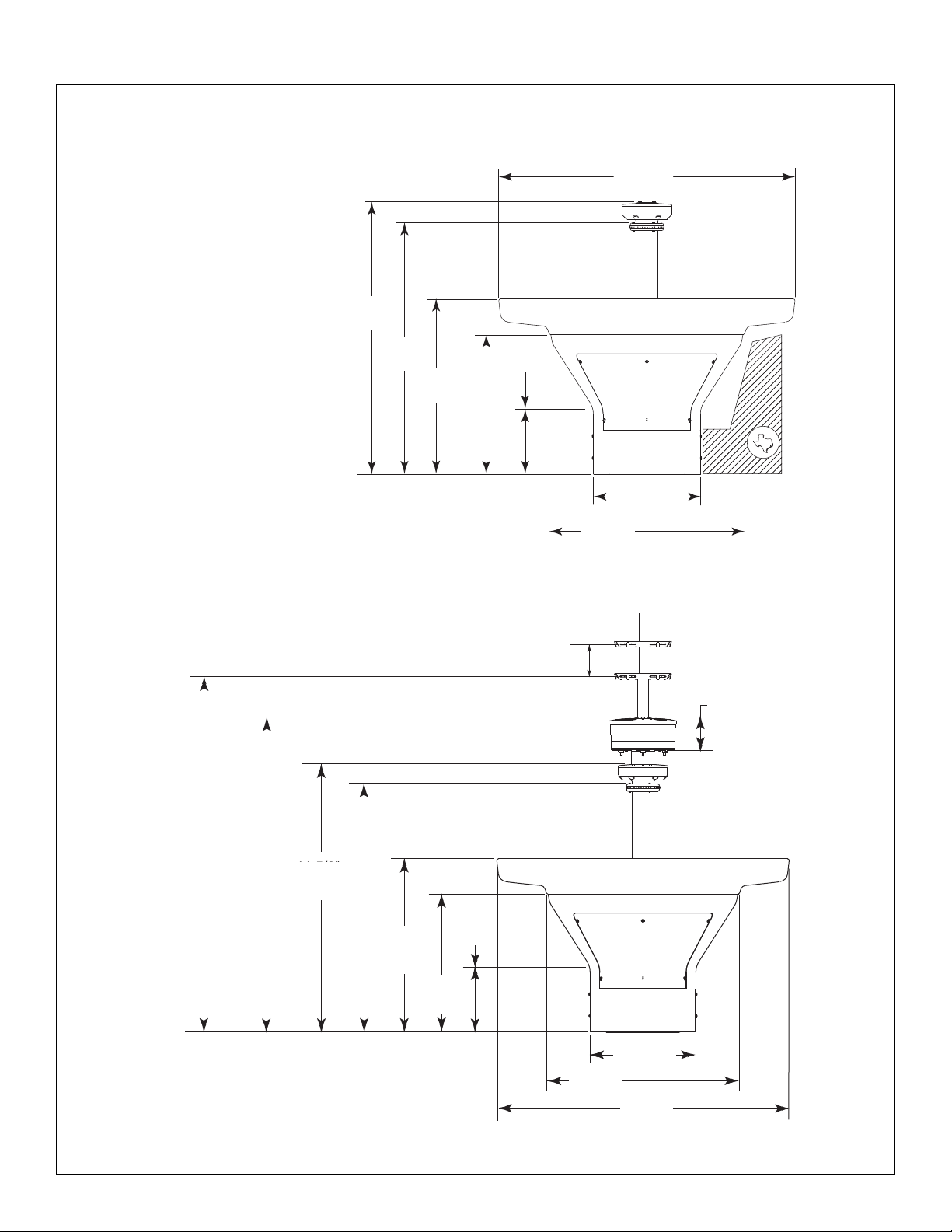

Page 3

Installation TDB3108, WF3208 Terreon®54" Circular

3Bradley Corporation • 215-1187 Rev. N; EN 06-915B 4/6/2007

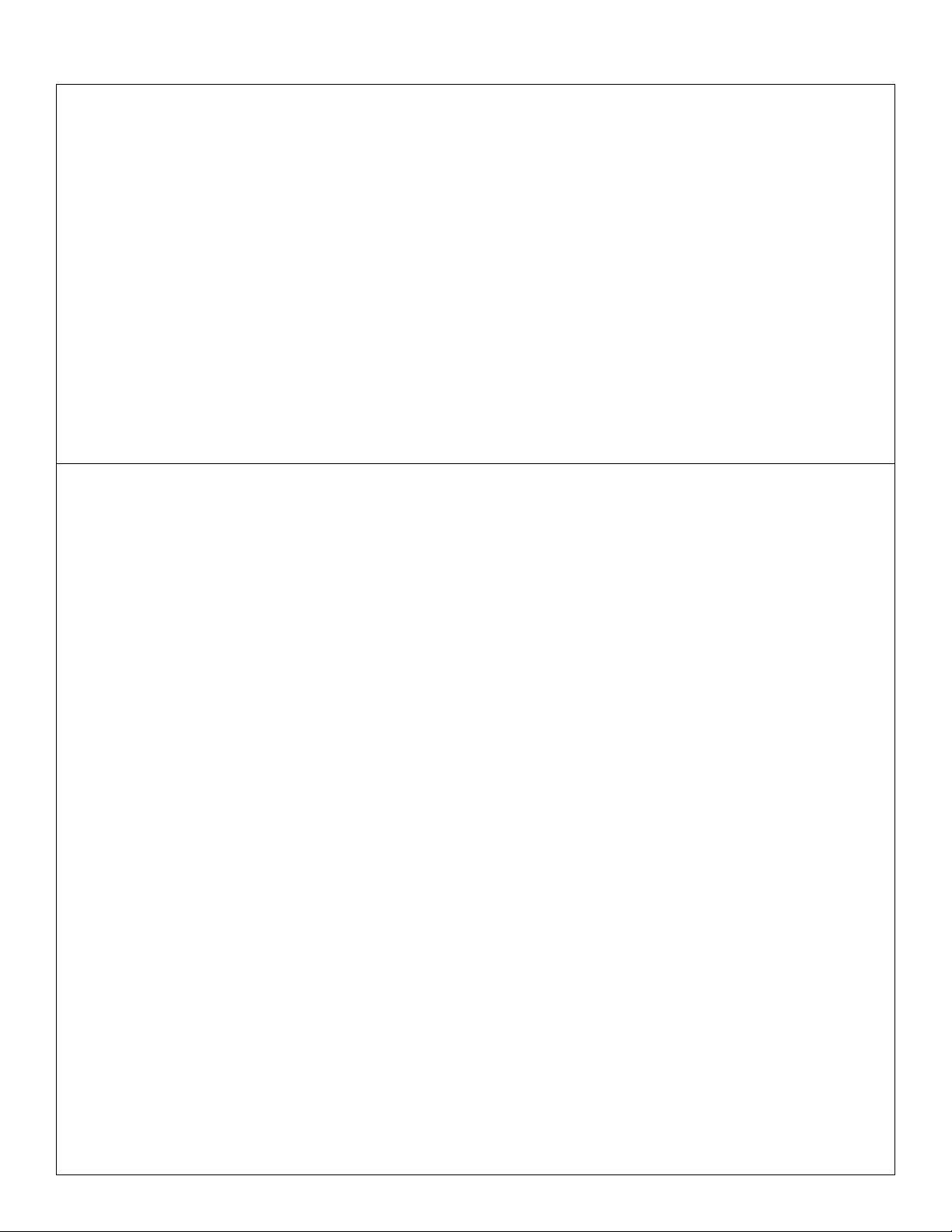

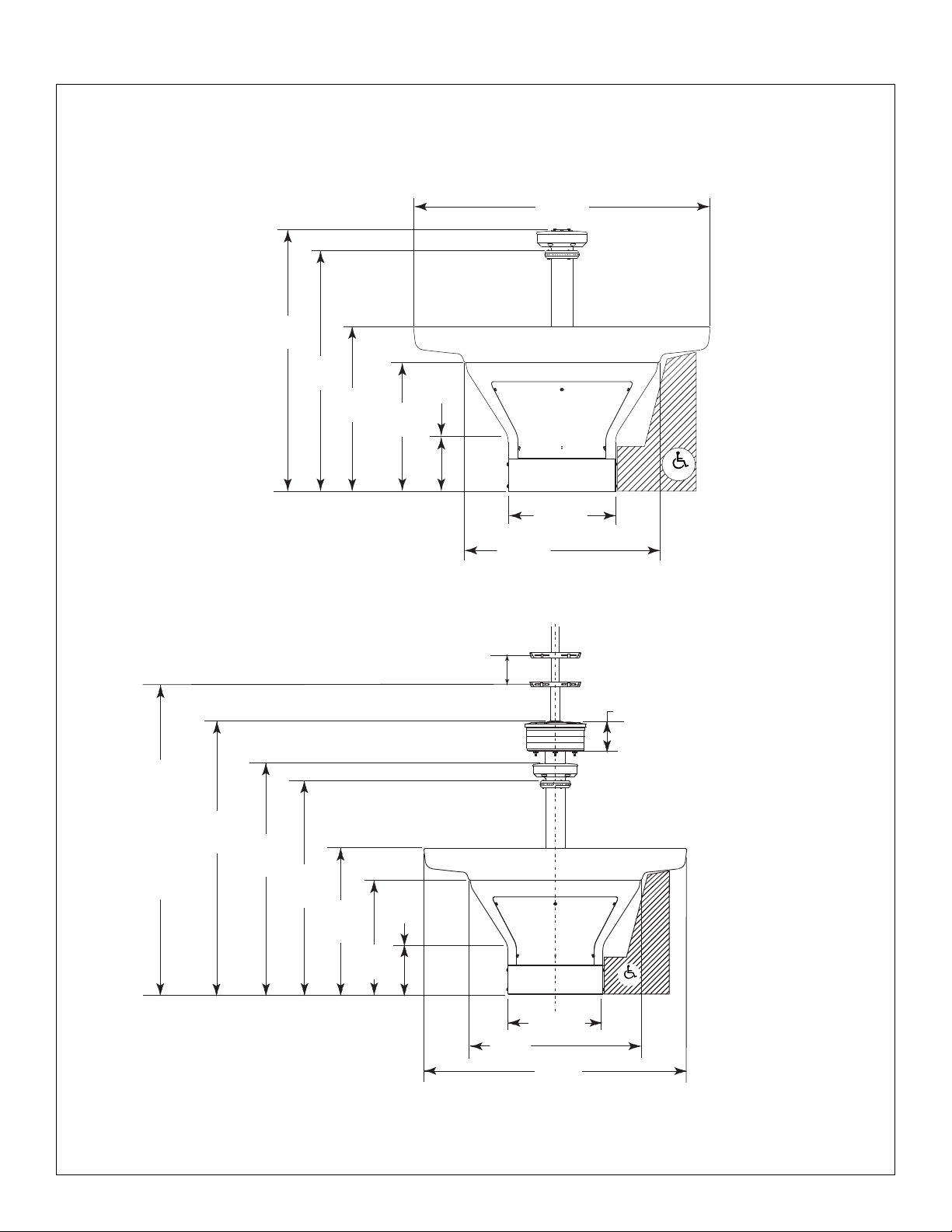

Model TDB3108 is ADA compliant.

Optional equipment may not comply with

all ADA dimensional guidelines

Model TDB3108 - 54" Circular

Model TDB3108 - 54" Circular

with optional accessories

Figure 1a

Figure 1b

54"

(1372)

47-1/4"

(1200)

43-3/4"

(1111)

34"

(864)

23-1/2"

(597)

10"

(254)

A

D

A

•

C

O

M

T

P

N

L

I

A

63-5/8"

(1616)

WITH

SOAP

55-1/8"

(1400)

WITHOUT

SOAP

55-3/4"

(1416)

47-1/4"

(1200)

43-3/4"

(1111)

34"

(864)

19-1/2"

(495)

36"

(914)

Adjust to towel dispenser

mounting holes

6" (152)

10"

(254)

23-1/2"

(597)

36"

(914)

19-1/2"

(495)

54"

(1372)

Page 4

TDB3108, WF3208 Terreon®54" Circular Installation

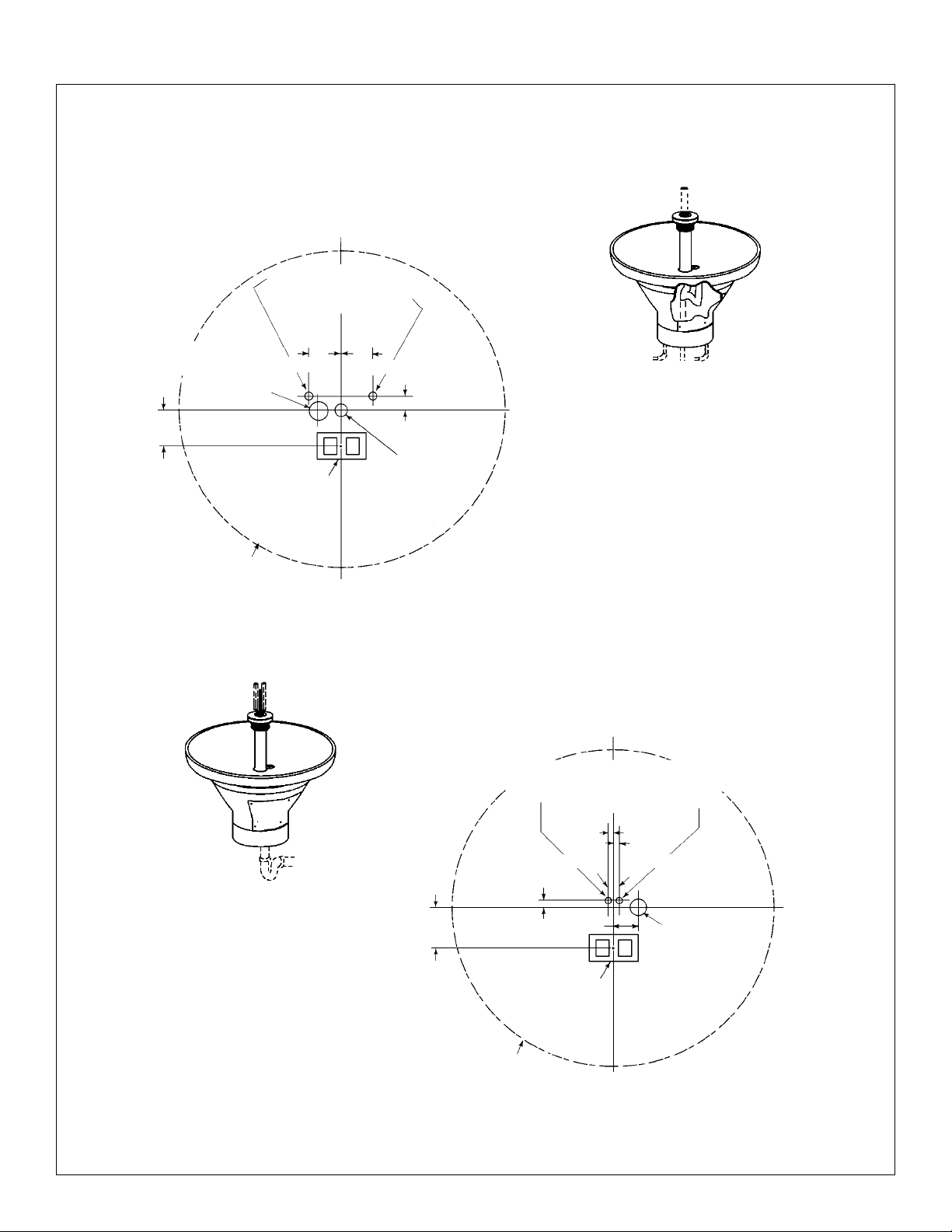

4 4/6/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

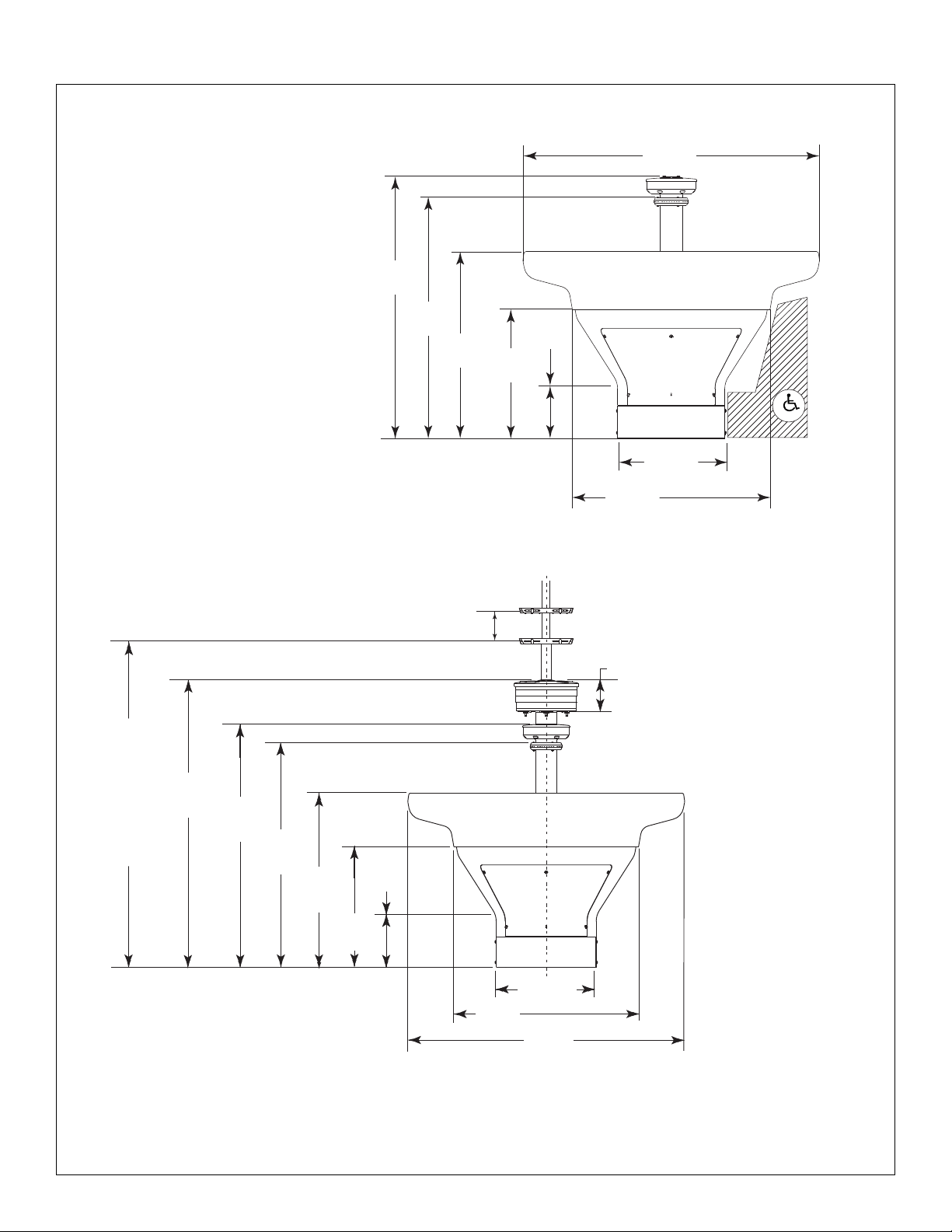

Circular Washfountain Dimensions (TAS intermediate)

TAS

54"

(1372)

19-1/2"

(495)

35-1/2"

(902)

25-1/2"

(648)

12"

(305)

32"

(813)

41-1/8"

(1045)

44-5/8"

(1133)

Model TDB3108

54" Circular - TAS Height

Model TDB3108

54" Circular - TAS Height with

optional accessories

Figure 1c

Figure 1d

Optional equipment may not comply with

all TAS dimensional guidelines

61"

(1549)

WITH

SOAP

52-1/2"

(1334)

WITHOUT

SOAP

53-1/4"

(1353)

44-5/8"

(1143)

41-1/8"

(1045)

32"

(813)

Adjust to towel dispenser

mounting holes

12"

(305)

25-1/2"

(648)

35-1/2"

(902)

6" (152)

19-1/2"

(495)

54"

(1372)

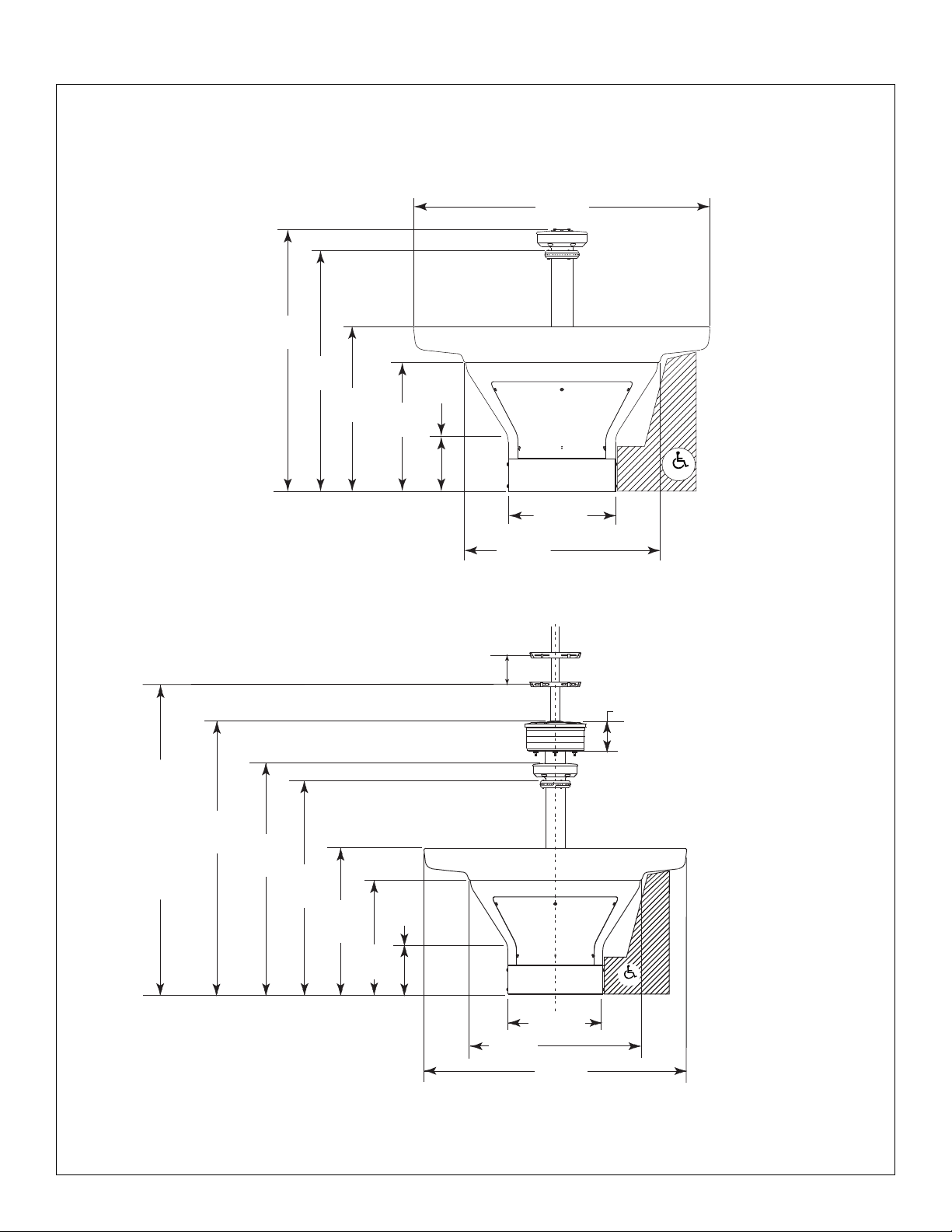

Page 5

Installation TDB3108, WF3208 Terreon®54" Circular

5Bradley Corporation • 215-1187 Rev. N; EN 06-915B 4/6/2007

Circular Washfountain Dimensions (juvenile height)

A

D

A

•

C

O

M

P

L

I

A

N

T

54"

(1372)

19-1/2"

(495)

35-1/2"

(902)

23-1/2"

(597)

10"

(254)

30"

(762)

39-1/8"

(994)

42-5/8"

(1083)

Model TDB3108

54" Circular - Juvenile Height

Model TDB3108

54" Circular - Juvenile Height

with optional accessories

Figure 1e

Figure 1f

Optional equipment may not comply with

all ADA or TAS dimensional guidelines

59-1/8"

(1502)

WITH

SOAP

50-5/8"

(1286)

WITHOUT

SOAP

51-1/4"

(1303)

42-5/8"

(1033)

39-1/8"

(994)

30"

(762)

Adjust to towel dispenser

mounting holes

10"

(254)

23-1/2"

(597)

35-1/2"

(902)

19-1/2"

(495)

54"

(1372)

6" (152)

A

D

A

•

C

O

M

T

P

N

L

I

A

Optional equipment may not

comply with all ADA

dimensional guidelines

Page 6

TDB3108, WF3208 Terreon®54" Circular Installation

6 4/6/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

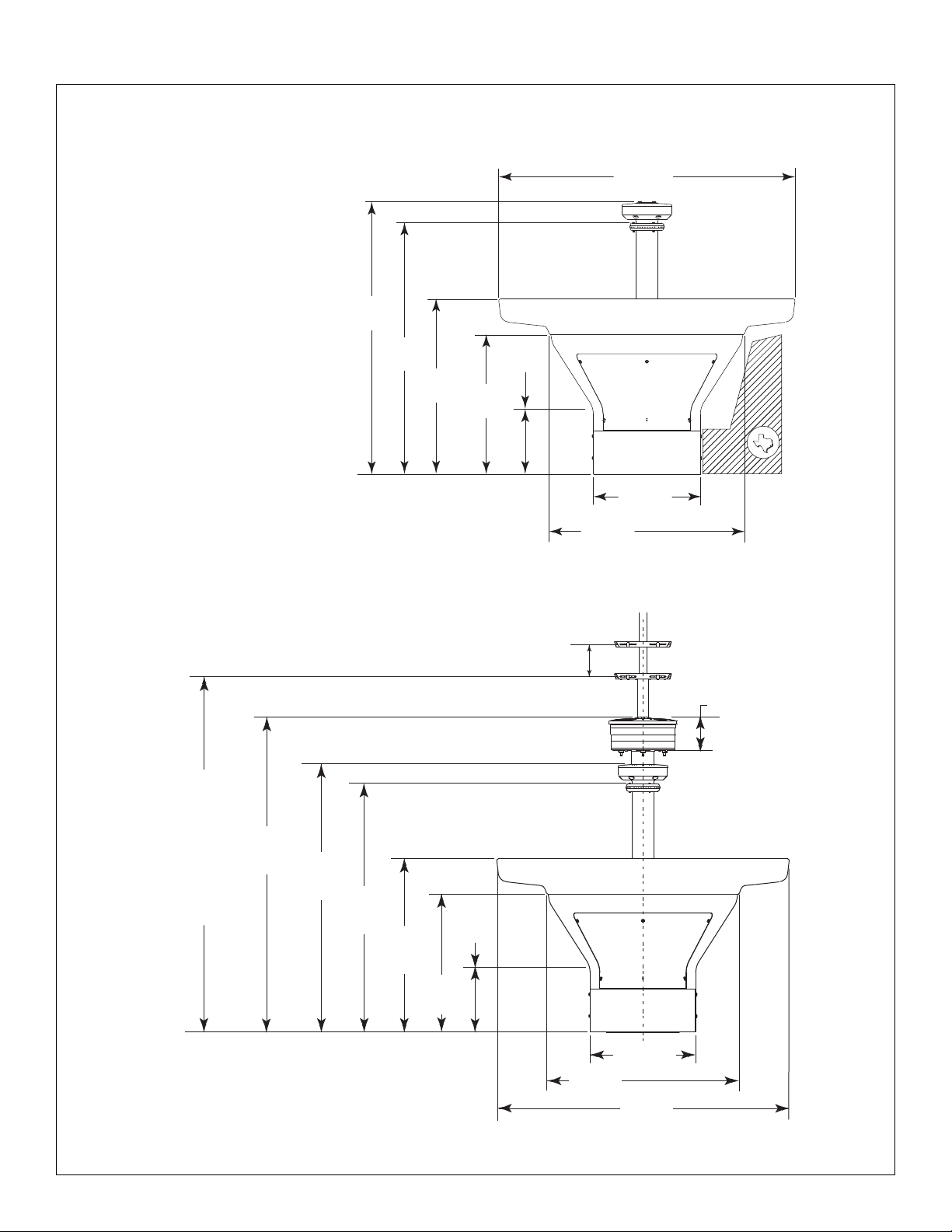

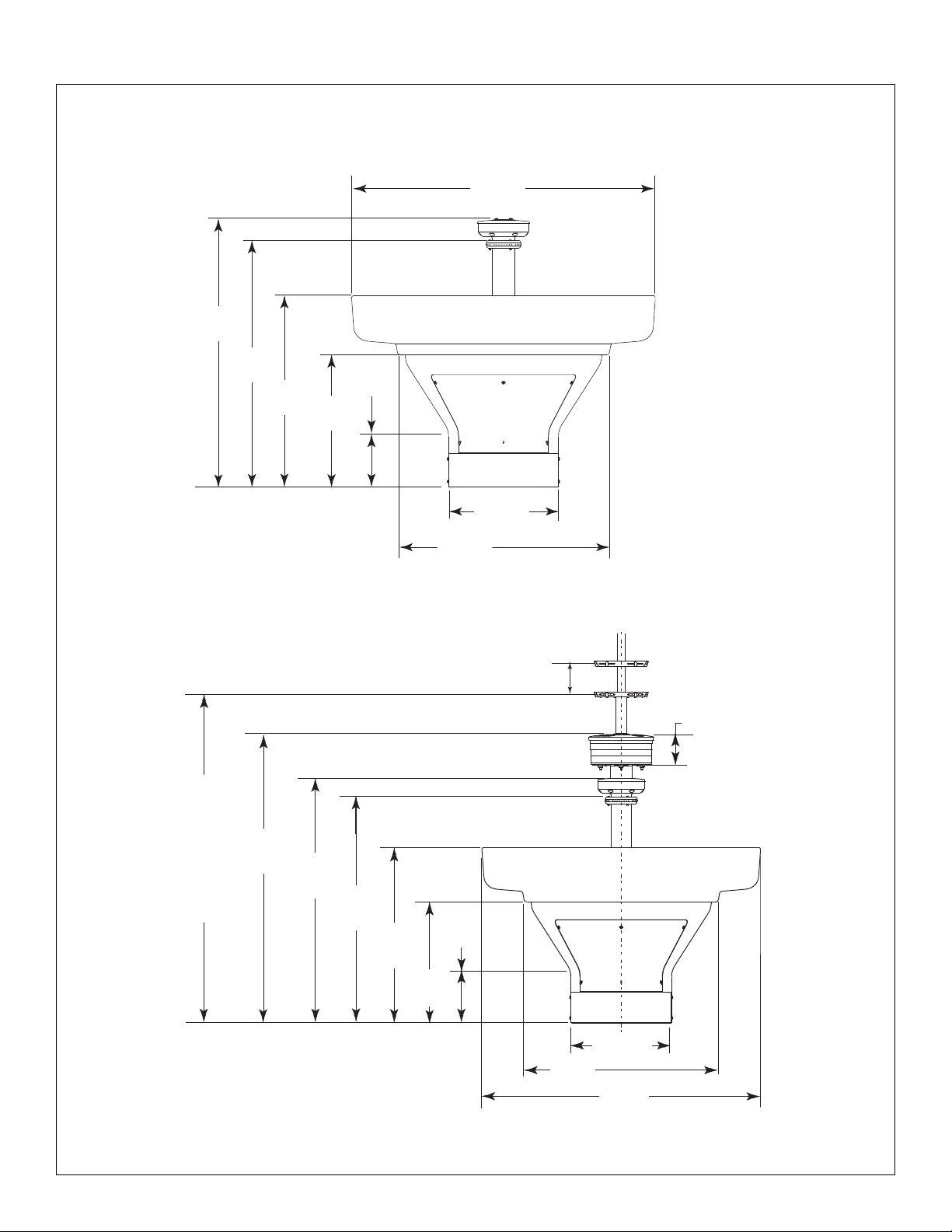

Circular Washfountain Dimensions

54"

(1372)

19-1/2"

(495)

37-1/2"

(953)

23-1/2"

(597)

10"

(254)

34"

(864)

43-3/4"

(1111)

47-1/4"

(1200)

Model WF3208 is not ADA compliant.

Model WF3208 - 54" Circular

Model WF3208 - 54" Circular

with optional accessories

Figure 1g

Figure 1h

63-5/8"

(1616)

WITH

SOAP

55-1/8"

(1400)

WITHOUT

SOAP

55-3/4"

(1416)

47-1/4"

(1200)

43-3/4"

(1111)

34"

(864)

Adjust to towel dispenser

mounting holes

6" (152)

10"

(254)

23-1/2"

(597)

37-1/2"

(953)

19-1/2"

(495)

54"

(1372)

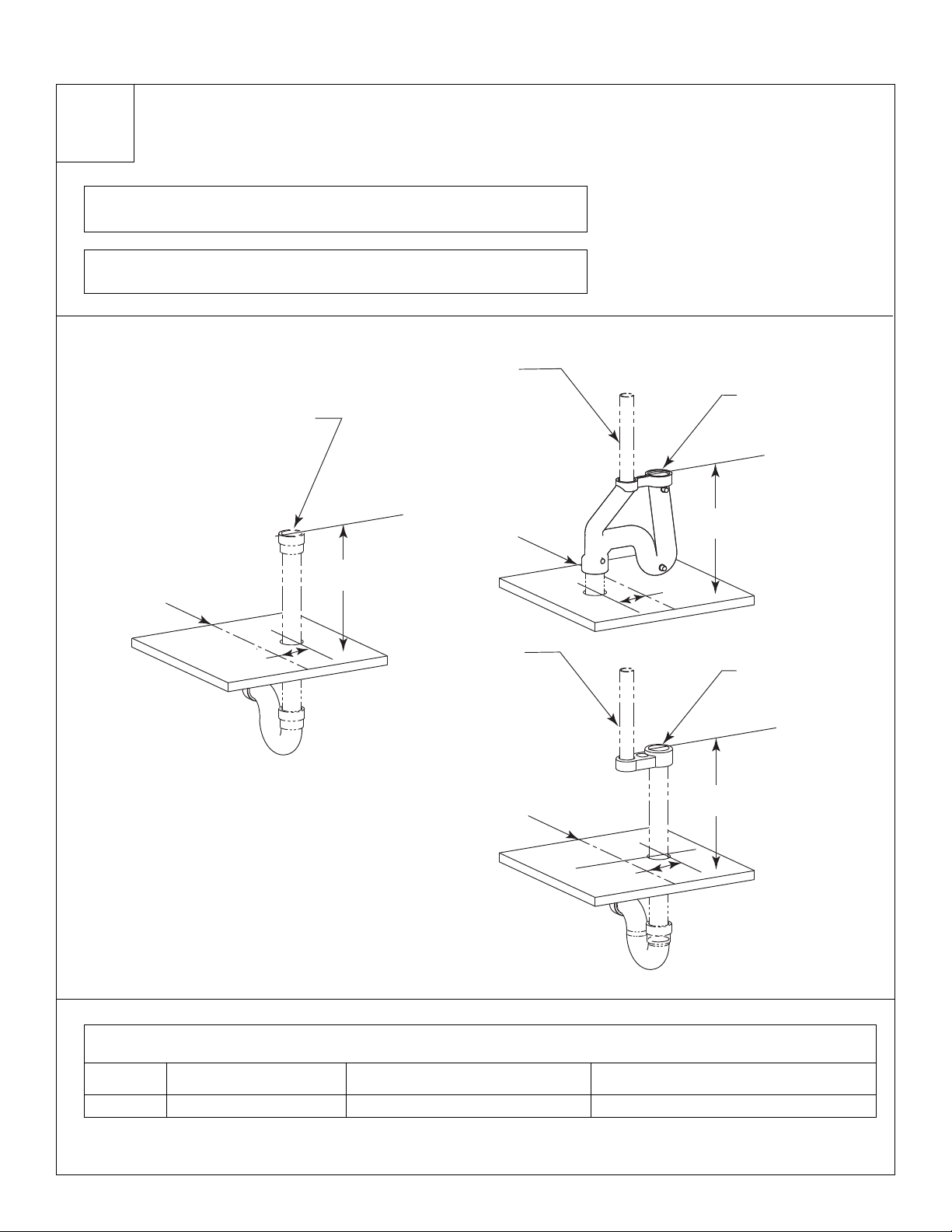

Page 7

Installation TDB3108, WF3208 Terreon®54" Circular

7Bradley Corporation • 215-1187 Rev. N; EN 06-915B 4/6/2007

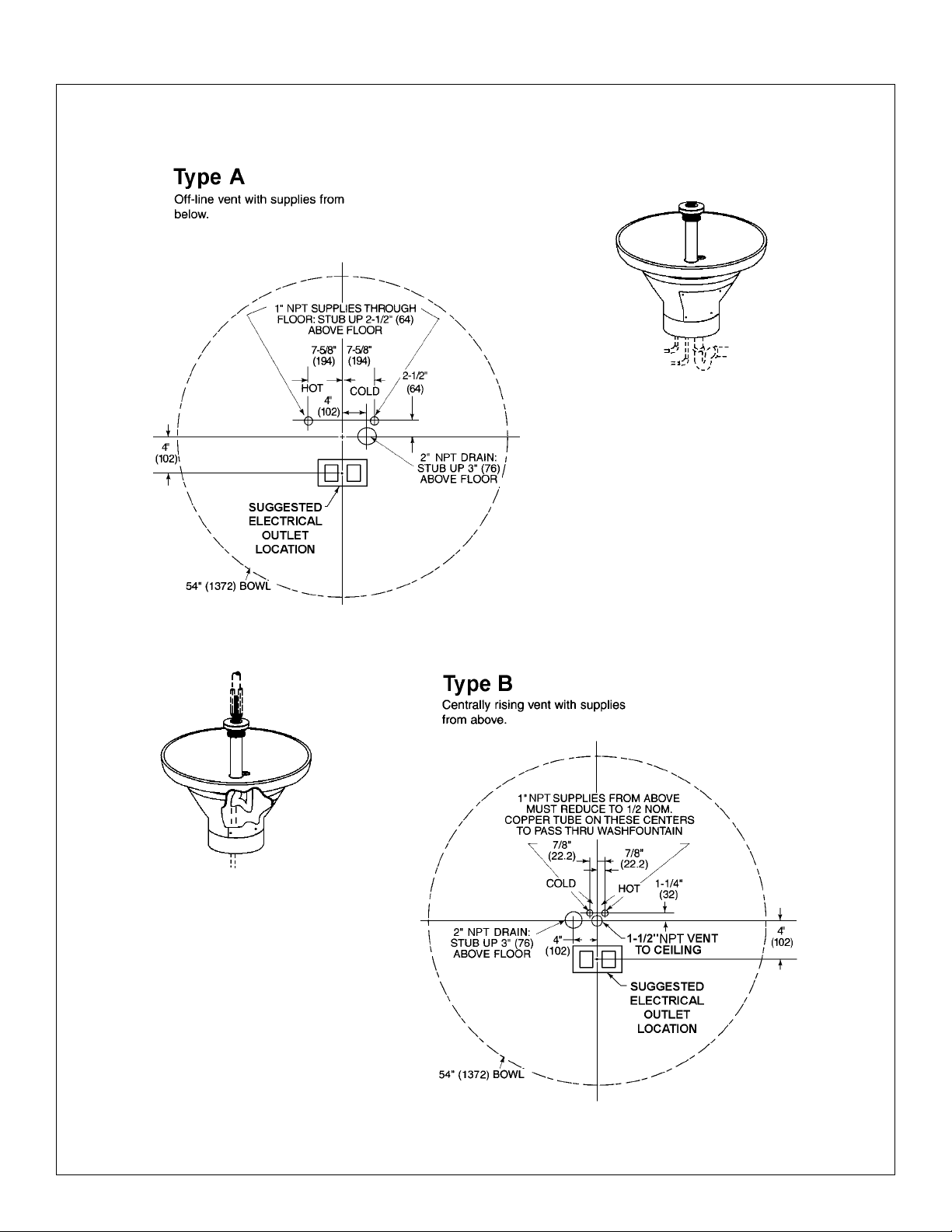

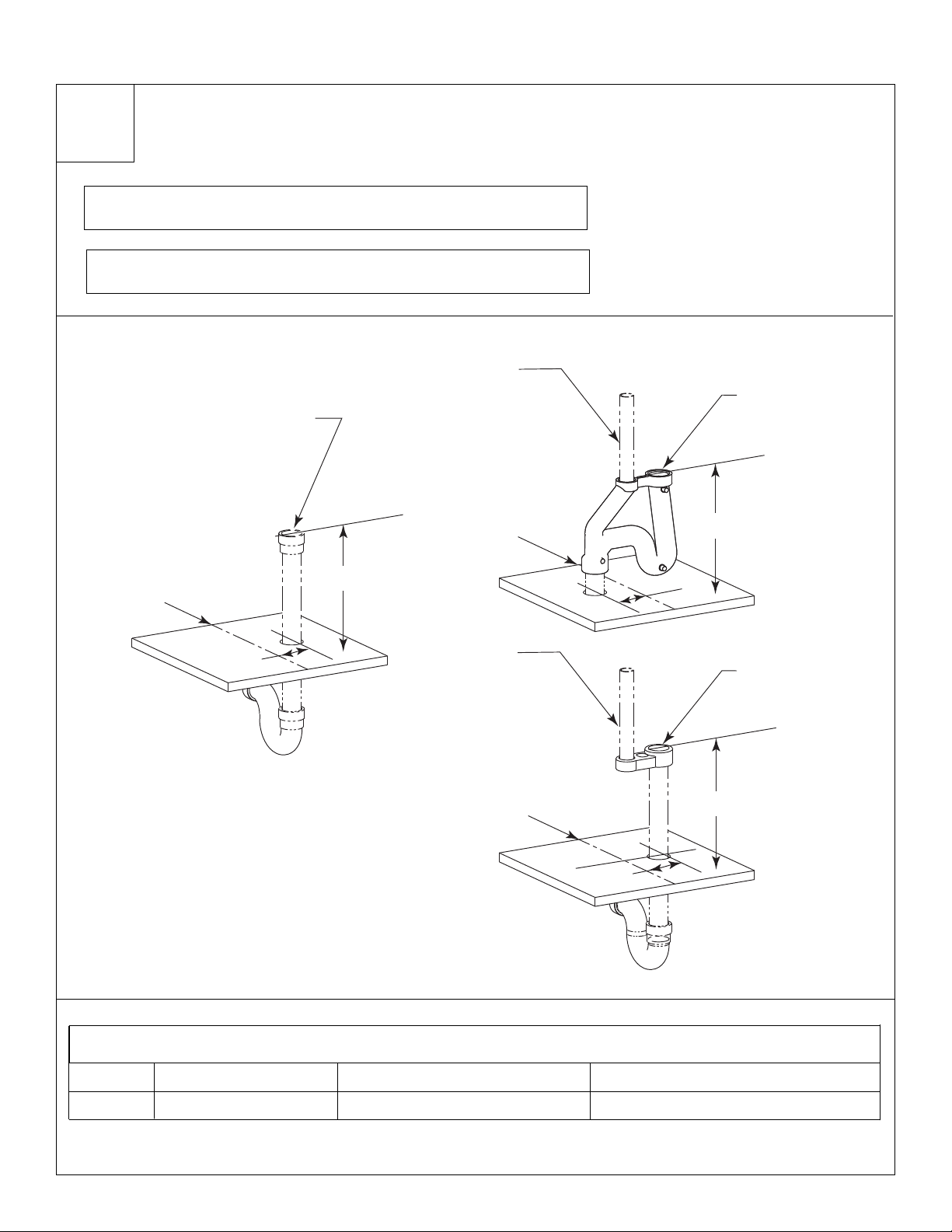

Rough-In Specifications

NOTE: Supply lines for one to two

washfountains should be 1"; for

three washfountains, 1-1/4". For

more than three washfountains,

pipe sizes should be increased

proportionately.

NOTE: Supply lines for one to two

washfountains should be 1"; for

three washfountains, 1-1/4". For

more than three washfountains,

pipe sizes should be increased

proportionately.

Figure 2a

Figure 2b

Page 8

TDB3108, WF3208 Terreon®54" Circular Installation

8 4/6/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

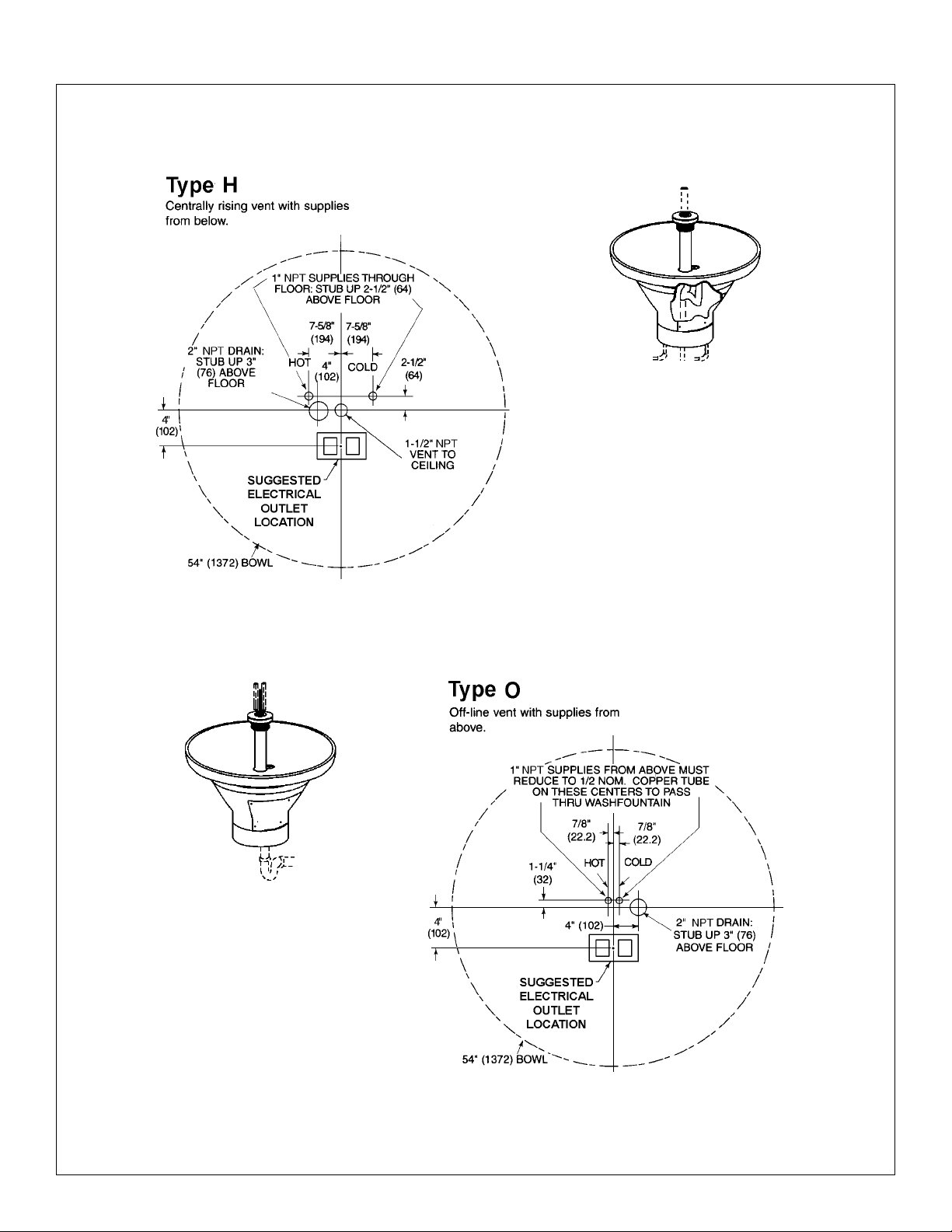

Rough-In Specifications continued . . .

NOTE: Supply lines for one to two

washfountains should be 1"; for

three washfountains, 1-1/4". For

more than three washfountains,

pipe sizes should be increased

proportionately.

NOTE: Supply lines for one to two

washfountains should be 1"; for

three washfountains, 1-1/4". For

more than three washfountains,

pipe sizes should be increased

proportionately.

Figure 2c

Figure 2d

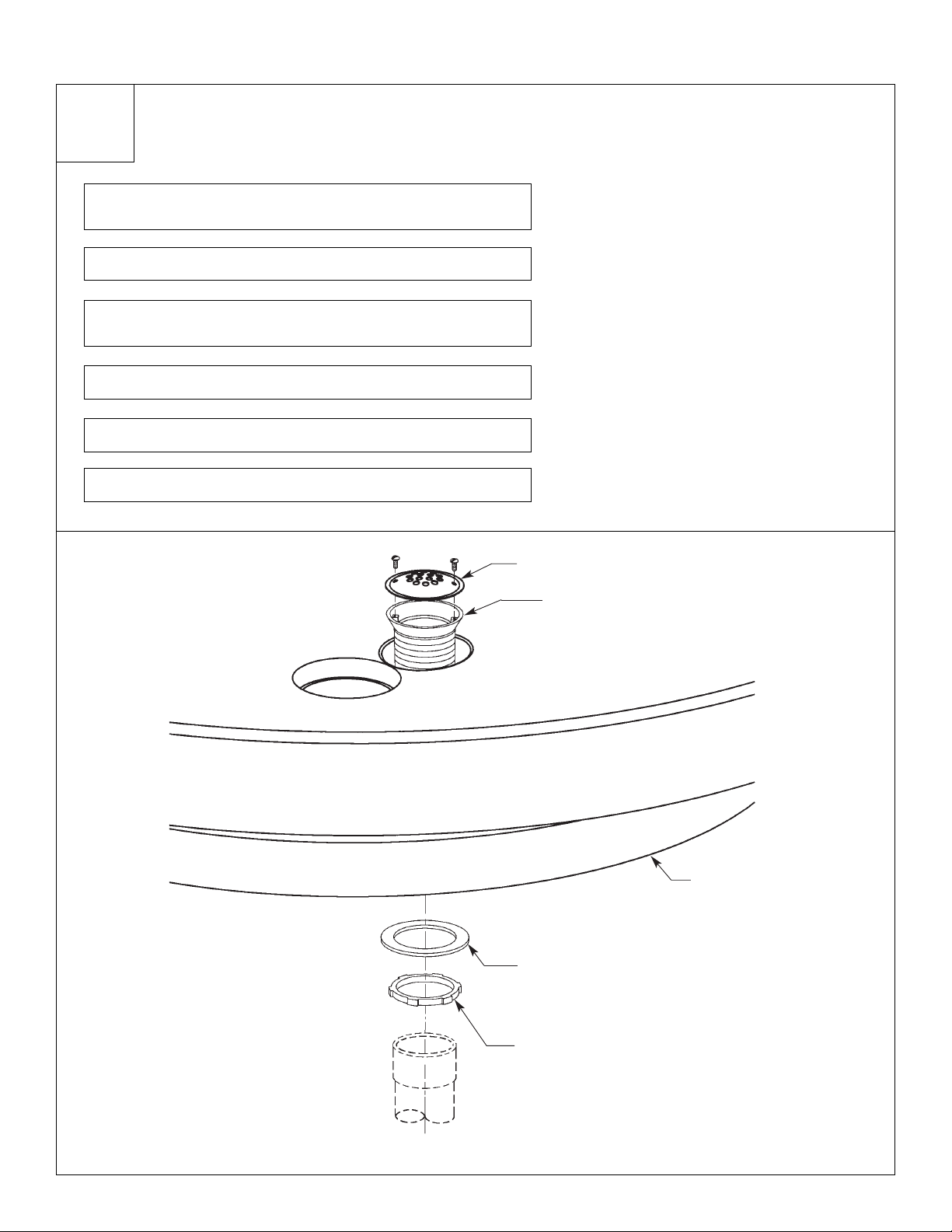

Page 9

Installation TDB3108, WF3208 Terreon®54" Circular

9Bradley Corporation • 215-1187 Rev. N; EN 06-915B 4/6/2007

1

Installing the drain

NOTE:

All piping shown in dotted lines

to be supplied by installer.

ROUGH IN SUPPLYAND DRAIN PIPING AS REQUIRED FOR YOUR INSTALLATION (SEE

PAGES 7-8 FOR ROUGH-INS OF OPTIONAL INSTALLATIONS)

A

ASSEMBLE THE DRAIN TO THE DIMENSION SHOWN IN FIGURE 3 FOR THE BOWL

YOU ARE INSTALLING.

B

t

Figure 3

Dim Standard Height Juvenile Height TAS

B 23-3/8" (594mm) 22-1/2" (572mm) 24-1/2" (622mm)

Table 1 — “B” Trap Dimensions

Centerline of

Washfountain

Vent

Tie Pipe

2" NPT Coupling if Tie

Pipe is not required

(Supplied by Installer)

B – See Table 1

(Supplied by Installer)

Centerline of

Washfountain

or

Types B, H

Vented T rap

(111-024)

B – See Table 1

4"

(102)

4"

(102)

(Supplied by Installer)

T ypes A, O

See rough-ins

on Pages 7-8

for dimensions

not shown

Vent

or

Tie Pipe

Centerline of

Washfountain

B – See Table 1

4"

(102)

Optional

Tie Pipe Bracke

(S70-082)

T ypes A, O

With Tie Pipe

Bracket Option

Page 10

TDB3108, WF3208 Terreon®54" Circular Installation

10 4/6/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

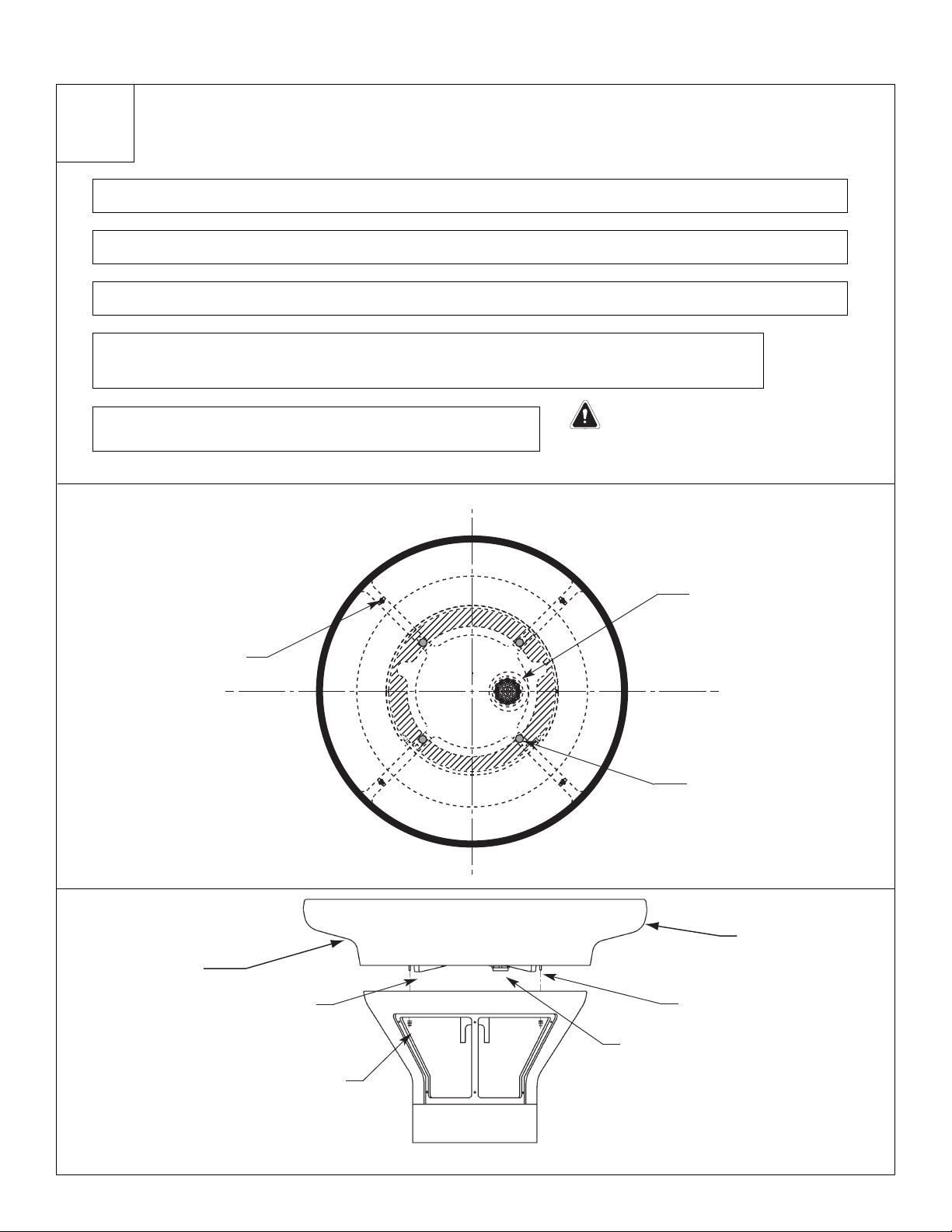

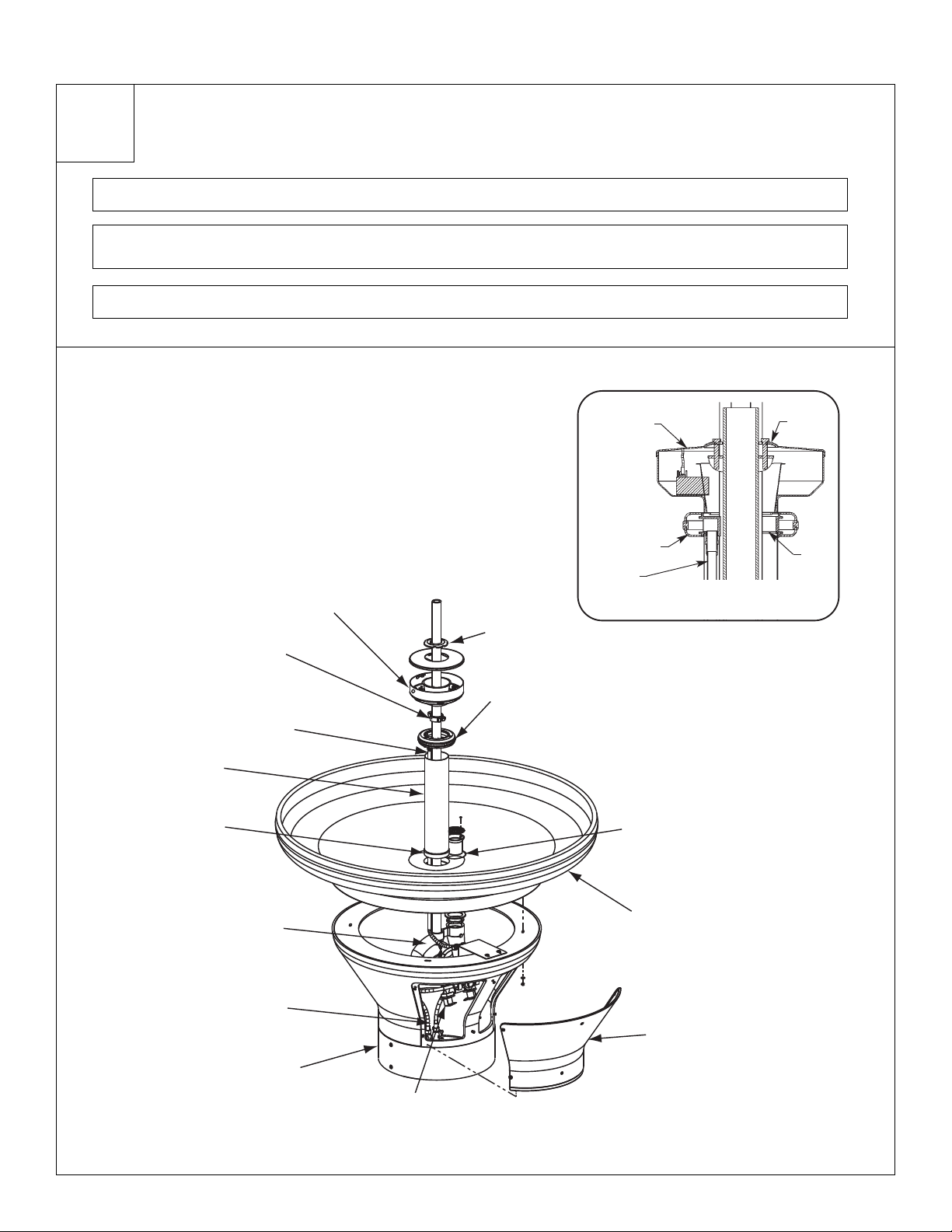

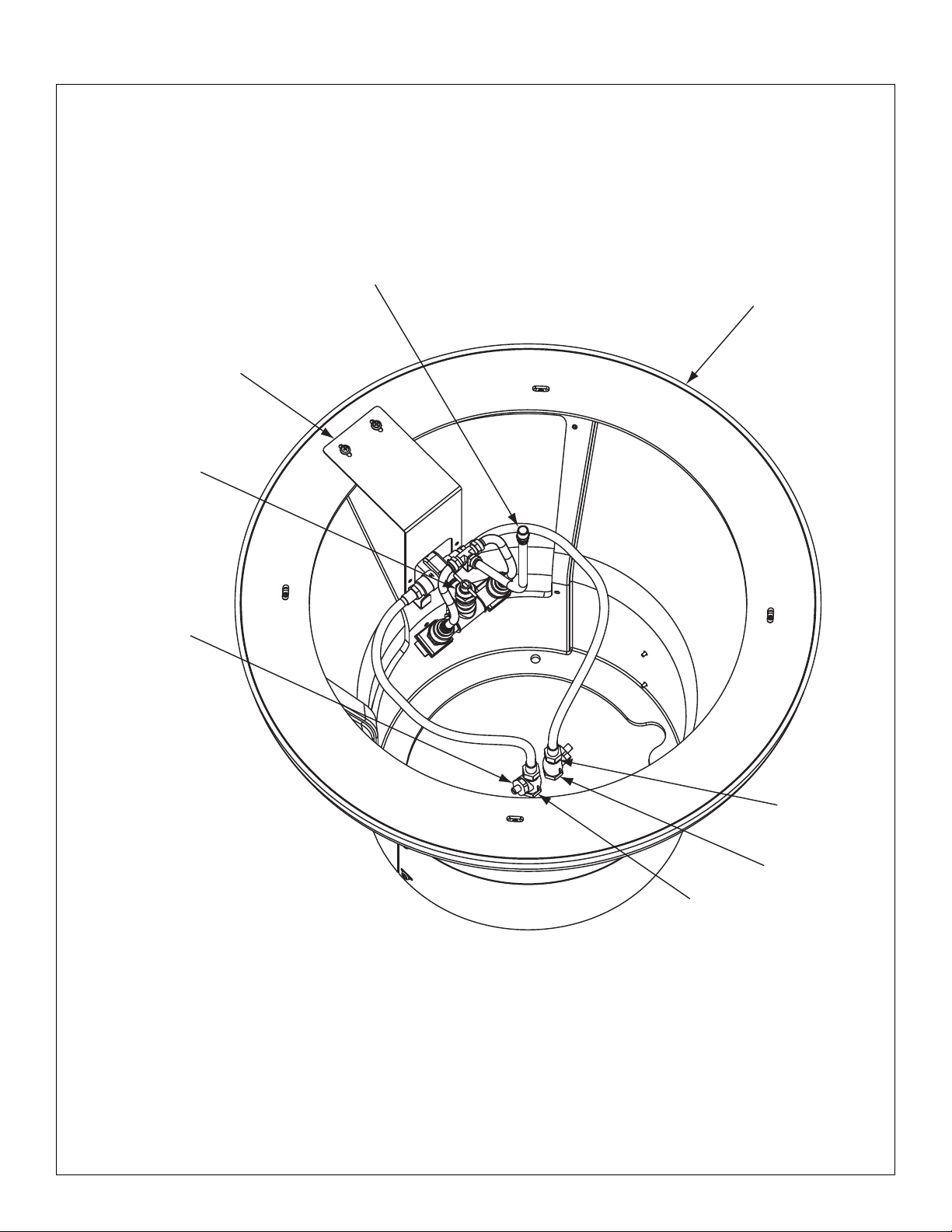

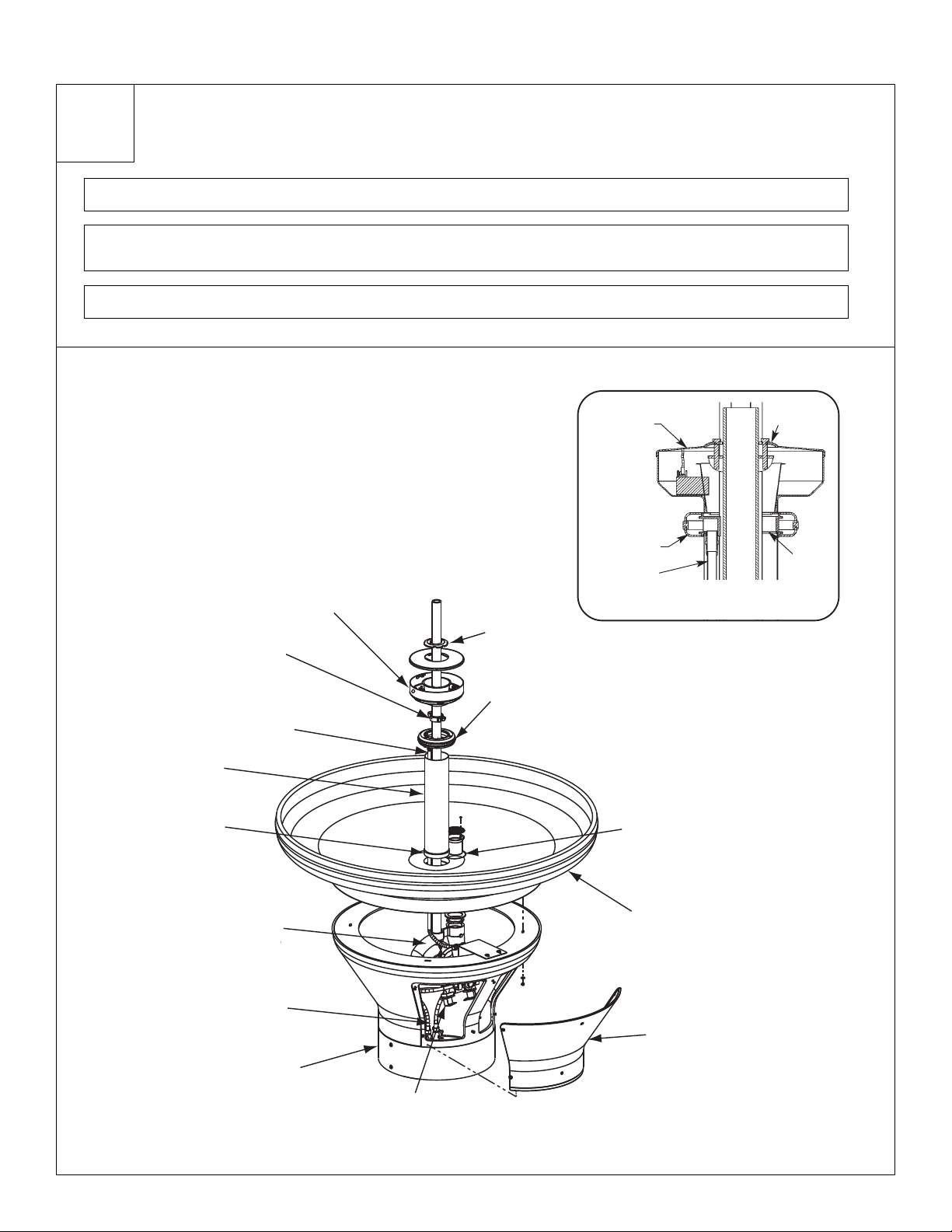

2

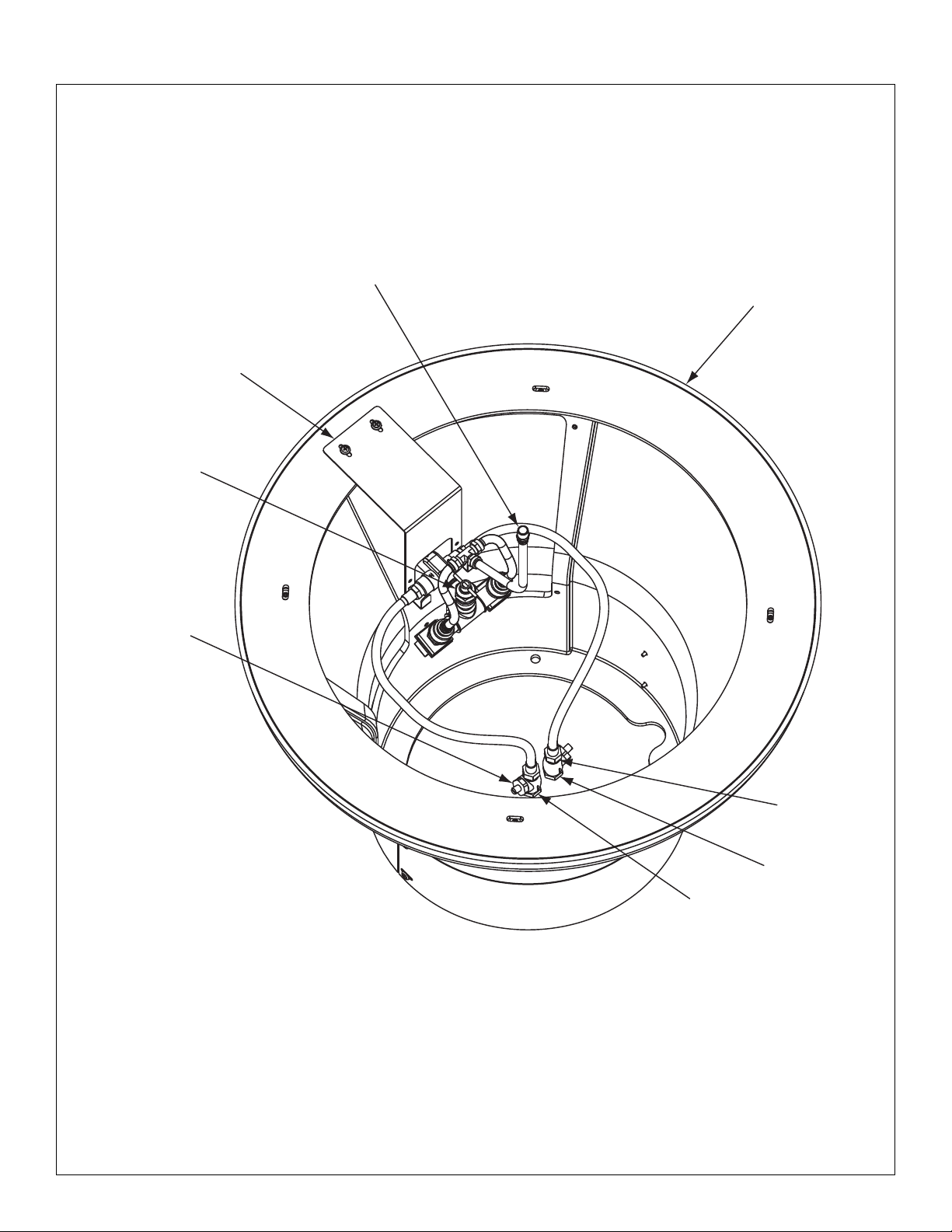

Bowl/pedestal mounting and assembly

CAUTION:

Bowl surface is very smooth. Approximate

weight of bowl is 190 pounds. Handle with Care!

POSITION THE PEDESTALAT DESIRED LOCATION AND MARK THE POSITION OF THE (4) MOUNTING LOCATIONS (SEE FIGURE 4A).

PLACE TAS SPACER ON FLOOR OVER THE MOUNTING HOLES. PLACE PEDESTAL ON TOP OF THE SPACER.

A

SECURE PEDESTALTO FLOOR WITH SUITABLE FASTENERS, 1/2" ANCHORS AND BOLTS (SUPPLIED BY INSTALLER). DO NOT OVERTIGHTEN.

B

USING THREE OR FOUR PEOPLE, CAREFULLYLIFT BOWL (SEE FIGURE 4B) ON TO PEDESTAL MAKING SURE DRAIN

HOLES LINE UP WITH FLOOR DRAIN AND MATE THREAD RODS WITH SLOTTED HOLES IN PEDESTAL USING

LOCATOR RIBS.

C

TAS OPTION:

USING 1/4" WING NUTS AND WASHERS, SECURE THE BOWLTO THE

PEDESTAL IN FOUR PLACES.

D

DRAIN

TOP VIEW

FRONT VIEW

TDB 3108 BOWL - 190 LBS.

THREADED RODS

(4) PLACES

LOCATOR RIBS

(4) PLACES

1/4" WASHERS

AND WING NUTS

(4) PLACES

THREADED RODS

(4) PLACES

FLOOR MOUNTING

(4) PLACES

DRAIN

PLACE HANDS

HERE WHEN

LIFTING BOWL

PLACE HANDS

HERE WHEN

LIFTING BOWL

Figure 4a

Figure 4b

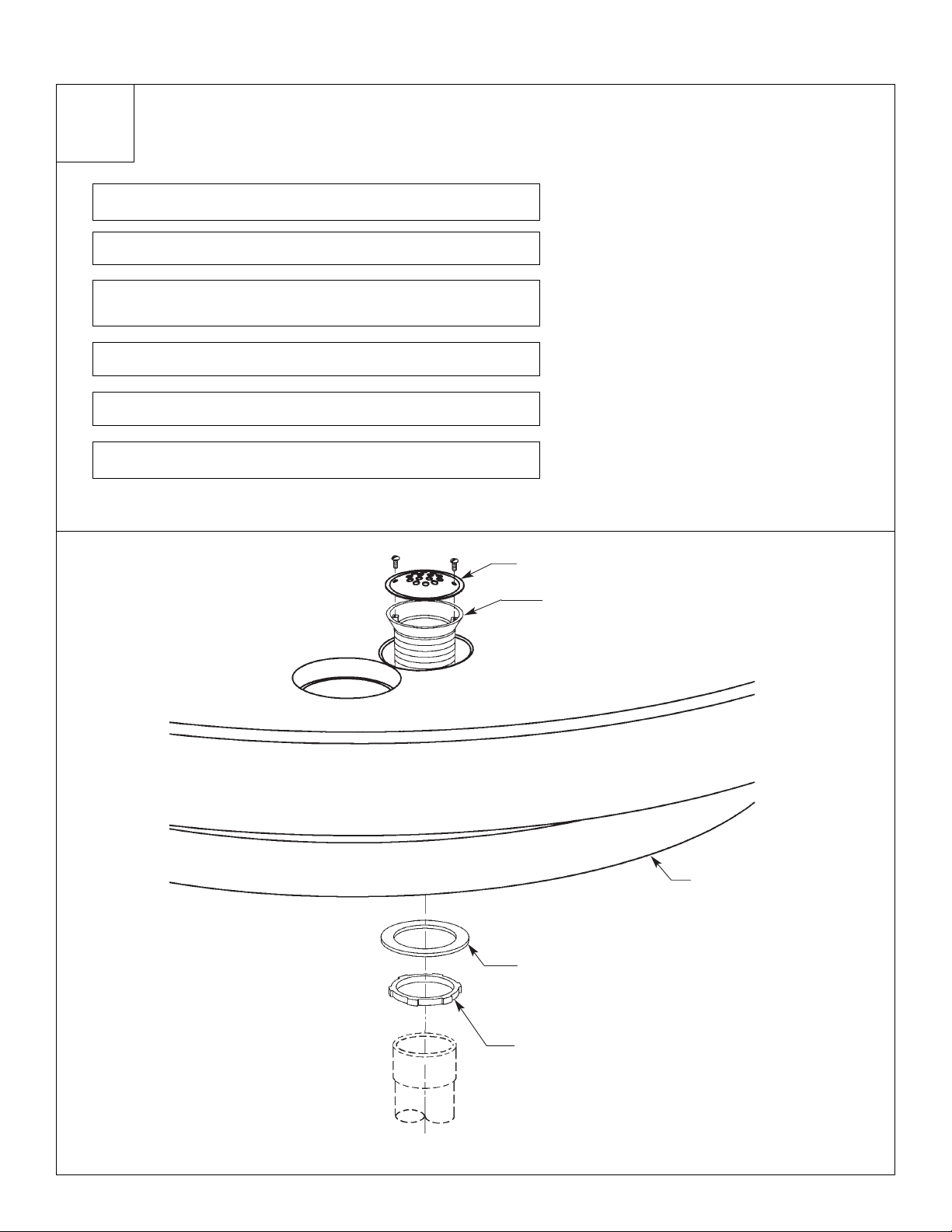

Page 11

Installation TDB3108, WF3208 Terreon®54" Circular

11Bradley Corporation • 215-1187 Rev. N; EN 06-915B 4/6/2007

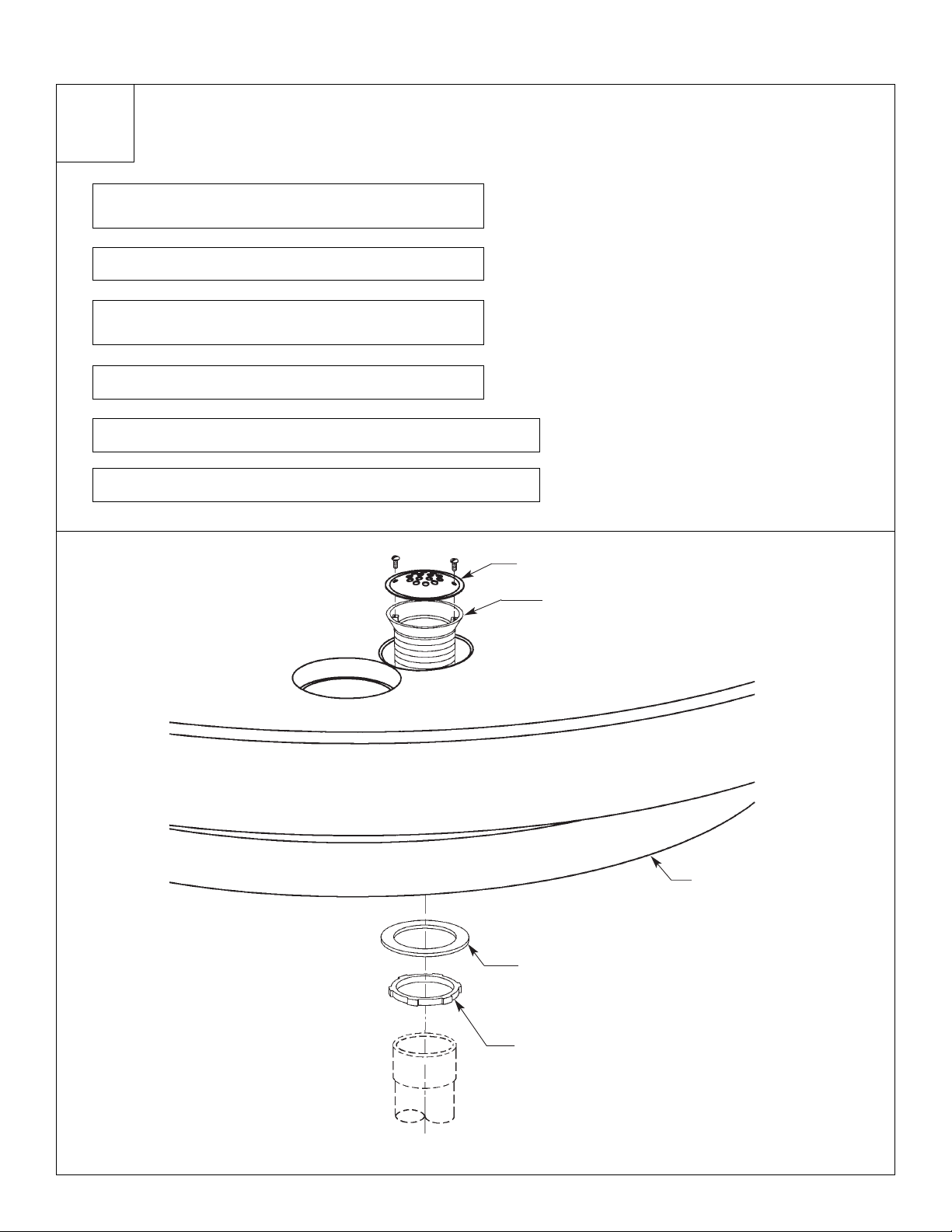

3

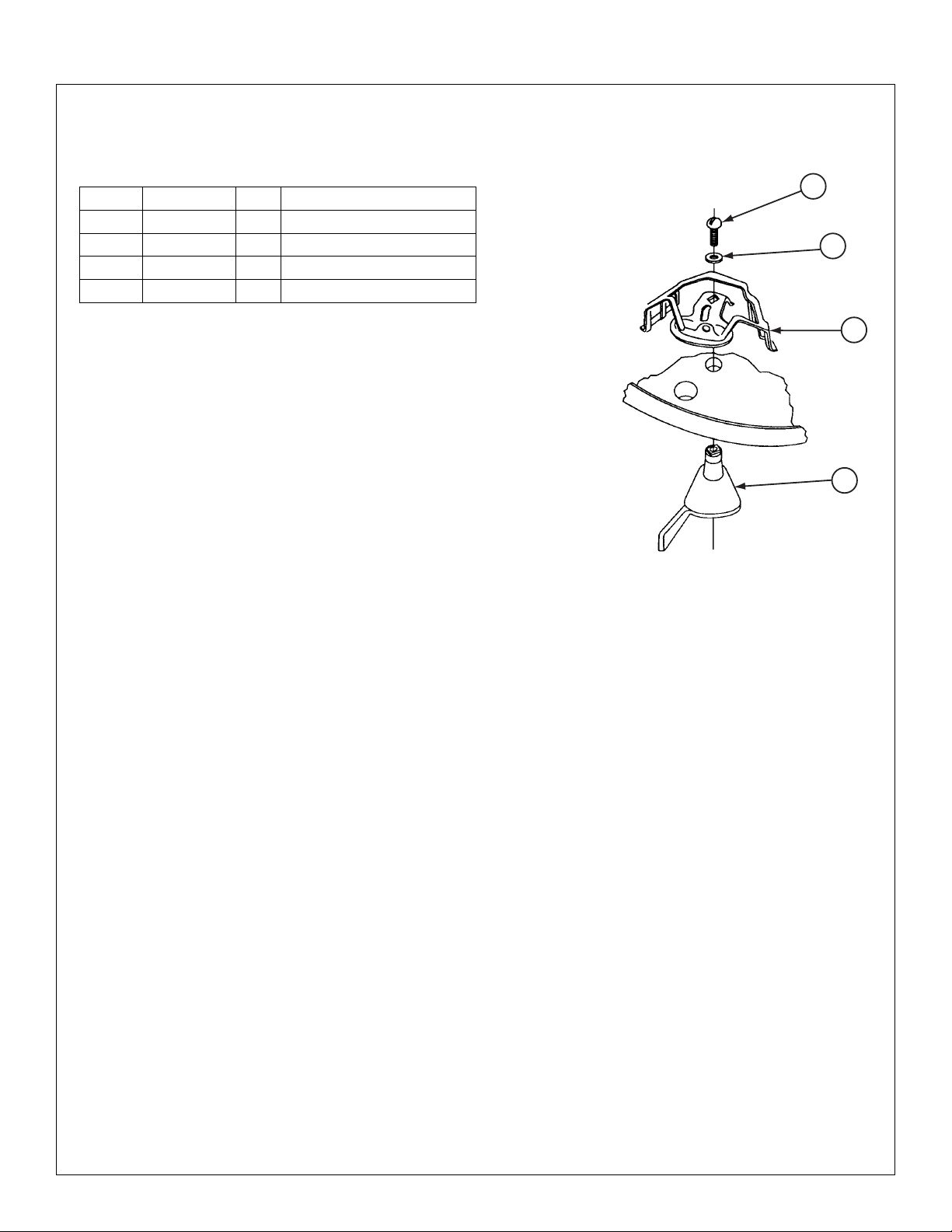

Installing drain spud in bowl

NOTE!

Seal between drain spud and drain hole with

plumber’s putty (supplied by installer).

LOOSELYATTACH THE DRAIN SPUD TO THE BOWL WITH THE

LOCKNUT AND WASHER AS SHOWN IN FIGURE 5.

A

TIGHTEN THE SPUD AND LOCK NUT AGAINST THE BOWL.

B

SECURE THE STRAINER TO DRAIN SPUD WITH THE SCREWS PROVIDED.

C

CONNECT SPUD (OR B TRAP OR TIE PIPE BRACKET) TO DRAIN.

D

ATTACH B TRAP TO DRAIN SPUD.

B TRAP OPTION:

ATTACH TIE PIPE BRACKET TO

DRAIN SPUD.

TIE PIPE OPTION:

STRAINER

S45-067

SPUD

112-015

BOWL

WASHER

142-068

LOCKNUT

161-021

DRAIN PRE-PACK

S45-273

Figure 5

Page 12

TDB3108, WF3208 Terreon®54" Circular Installation

12 4/6/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

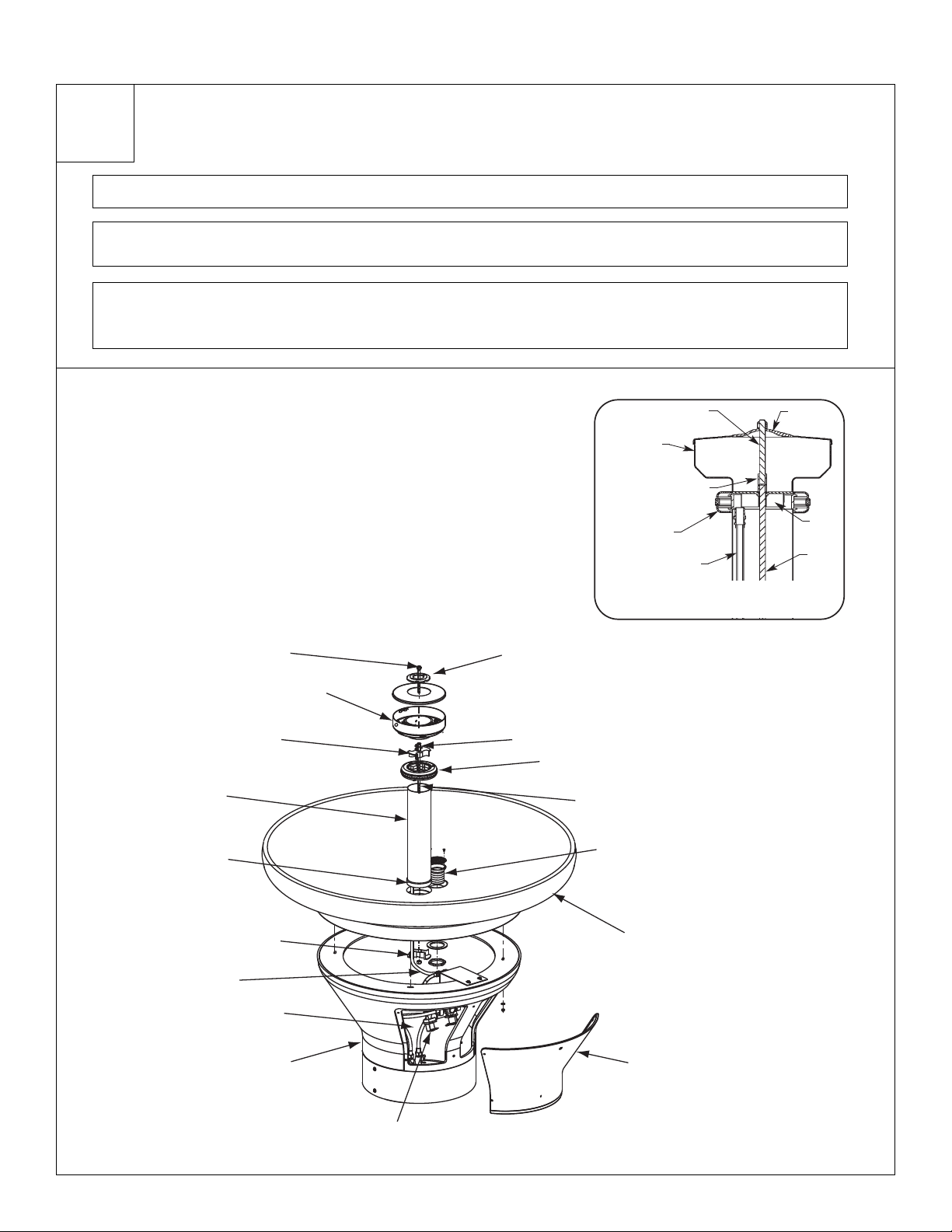

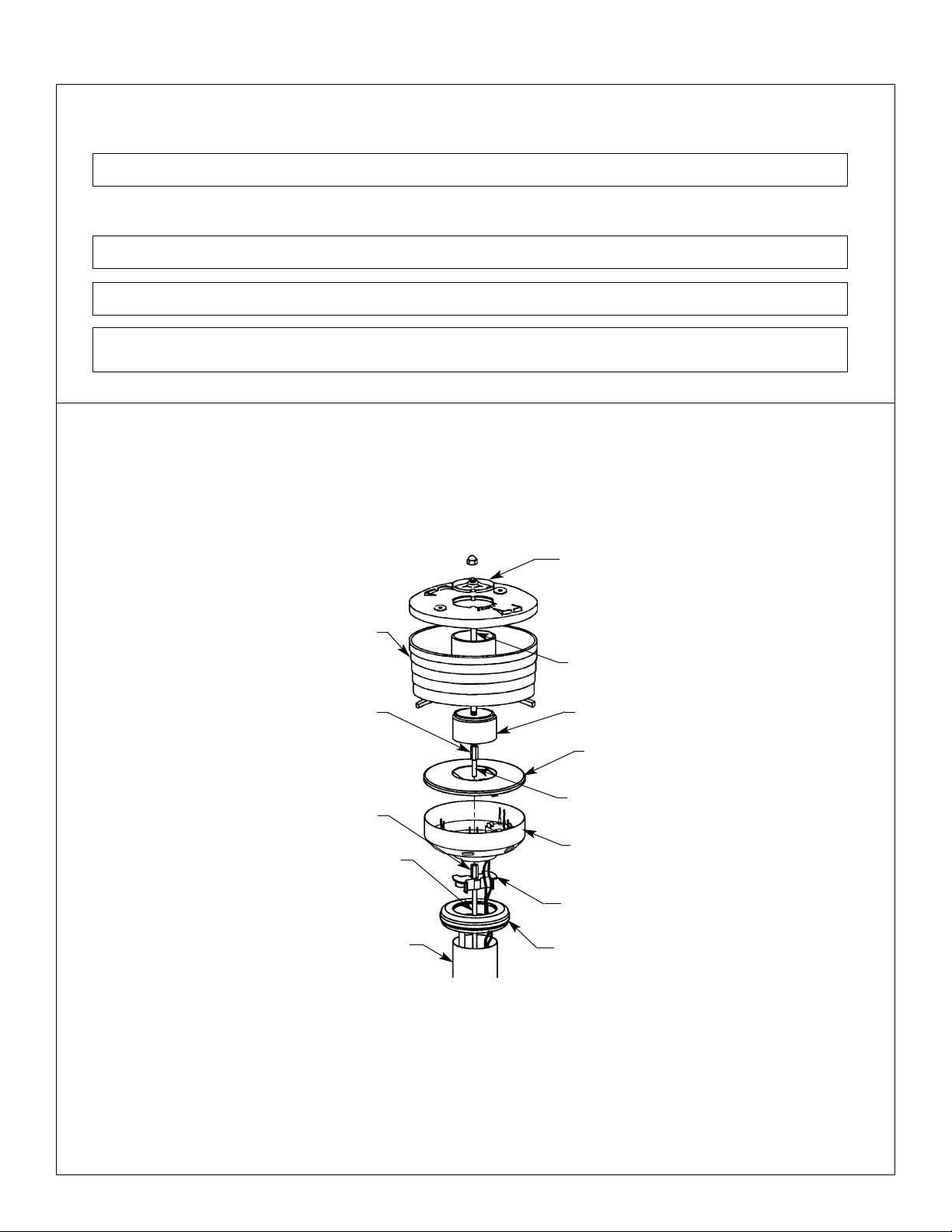

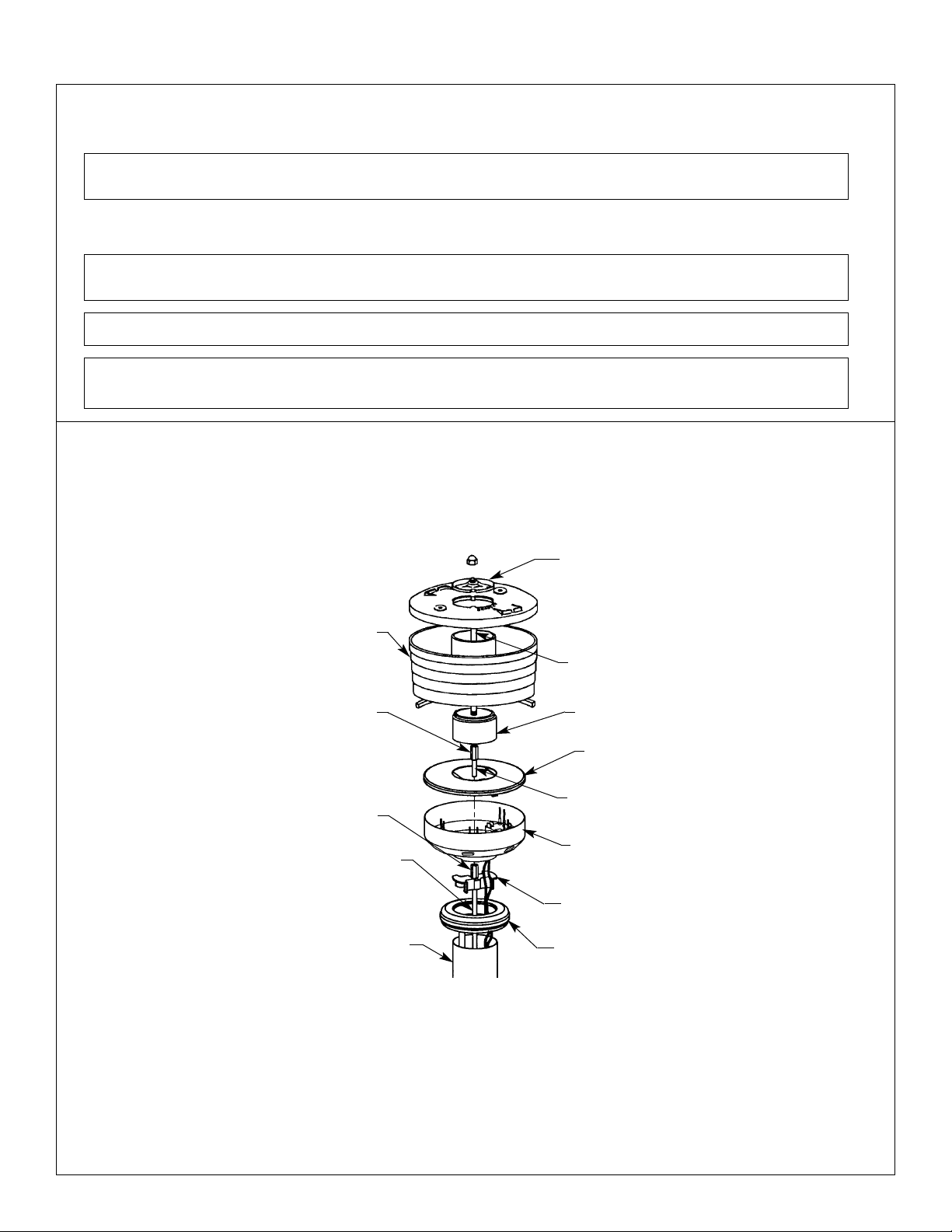

Adaptive infrared assembly for A drain and O drain units

without Tie Pipe option

4a

Figure 6

INSTALL HEMMED END (NOT SHARP END) OF SUPPORT TUBE WITH GASKET ONTO BOWL (SEE FIGURE 6).

A

CONNECT 1/2" SUPPLYTUBING TO SPRAYHEAD WITH 3/8" NPT TO 1/2" TUBE CONNECTOR AND PLACE SPRAYHEAD ONTO

SUPPORT TUBE. RUN THE TUBING DOWN THROUGH THE SUPPORT TUBE AND CONNECT TO VALVE TUBE CONNECTOR.

B

PLACE THE UPPER TIE BAR (NOTCHED AT BOTH CORNERS OF EACH END) ON TOP OF SPRAYHEAD. CONNECT THE LONGER TIE

ROD TO THE 4-1/4" TIE ROD USING THE COUPLING NUT WITH HEX HEAD SET SCREWS. RUN THE TIE ROD ASSEMBLY DOWN

THROUGH UPPER TIE BAR (SEE FIGURE 6 INSET) AND SECURE FROM UNDERNEATH THE BOWL USING LOWER TIE BAR (NO

NOTCHES) AND HEX NUT WITH SOCKET HEAD SET SCREW.

C

COVER

TIE

ROD

ACTUATOR

MODULE

ASSY.

SPRAYHEAD

SUPPLYTUBE

TIE ROD

PRE-PACK

COUPLING

NUT

SECTION VIEW OF

A/O UNIT ASSEMBLY

TIE

BAR

TIE ROD PRE-PACK

I.R. MODULE ASSY.

SUPPORT TUBE

(STD) S57-005

(JUV) S57-006

SUPPORT TUBE

GASKET

125-011

PRE-PACK

1/2" SUPPLY TUBE

PRE-PACK

S45-1466

PEDESTAL ASSY.

S45-1336

TIE BAR

S45-055

S17-242

COVER

107-099 (A)

107-179 (O)

S50-344

NUT

SPRAYHEAD

S05-054

TIE ROD

176-008A

DRAIN

S45-273

TERREON® DEEP BOWL

(ADA bowl shown, classic

bowl is optional)

Part No. varies with color of bowl.

Contact your local Bradley Rep.

for assistance

ACCESS PANEL

186-1456

VALVE ASSY.

S50-369

A/O

(A shown)

Page 13

Installation TDB3108, WF3208 Terreon®54" Circular

13Bradley Corporation • 215-1187 Rev. N; EN 06-915B 4/6/2007

Installation Instructions continued . . .

TOP COVER

Figure 7

I.R. MODULE

ASSEMBLY

S50-344

SPRAYHEAD

S05-054

SUPPORT TUBE

(STD.) S57-005

(JUV.) S57-006

COUPLING

NUT

SPACER

SOAP

DISPENSER

TIE ROD

(STD.) 21-5/8"

(JUV.) 18-1/8"

UNIT WITH “A” DRAIN AND I.R. MODULE

SHOWN, ALSO AVAILABLE WITH “O” DRAIN

COUPLING

NUT

4-1/4"

TIE ROD

8-5/8"

TIE ROD

MODULE

COVER

TIE BAR

PLACE THE INFRARED MODULE ASSEMBLY ON TOP OF SPRAYHEAD. ROTATE UNTIL INFRARED MODULE LOCKS IN WITH TIE BAR.

DROP TWO INFRARED MODULE WIRES DOWN TO VALVE ASSEMBLY.

D

SECURE INFRARED MODULE COVER AND TOP COVER WITH ACORN NUT AND SET SCREW.

E

FOR O UNIT: INSTALL 1/2" NOMINAL COPPER TUBING SUPPLYLINES (PASS THEM THROUGH HOLES IN COVER DOWN

THROUGH SUPPORT COLUMN) AND CONNECT TO STOPS USING SUITABLE FITTINGS.

F

FOR UNITS WITH SOAP OPTION, INSTALL THE SPACER, SOAP DISPENSER AND COVER USING THE THIRD TIE ROD (8-5/8" LONG)

AND SECOND COUPLING NUT AS SHOWN (SEE FIGURE 7). SECURE WITH ACORN NUT AND SET SCREW.

•

NOTE! Skip to step E for units without soap.

Page 14

TDB3108, WF3208 Terreon®54" Circular Installation

14 4/6/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

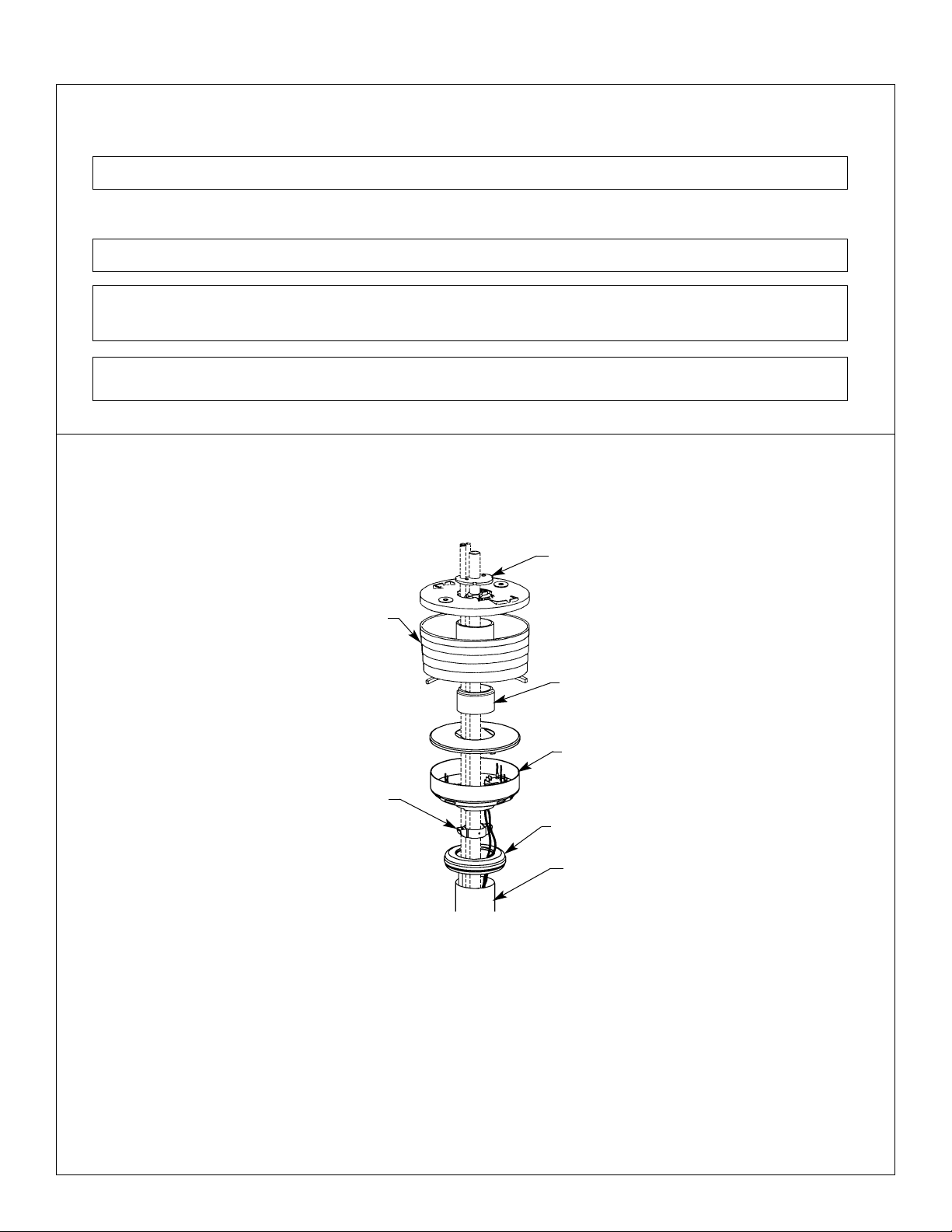

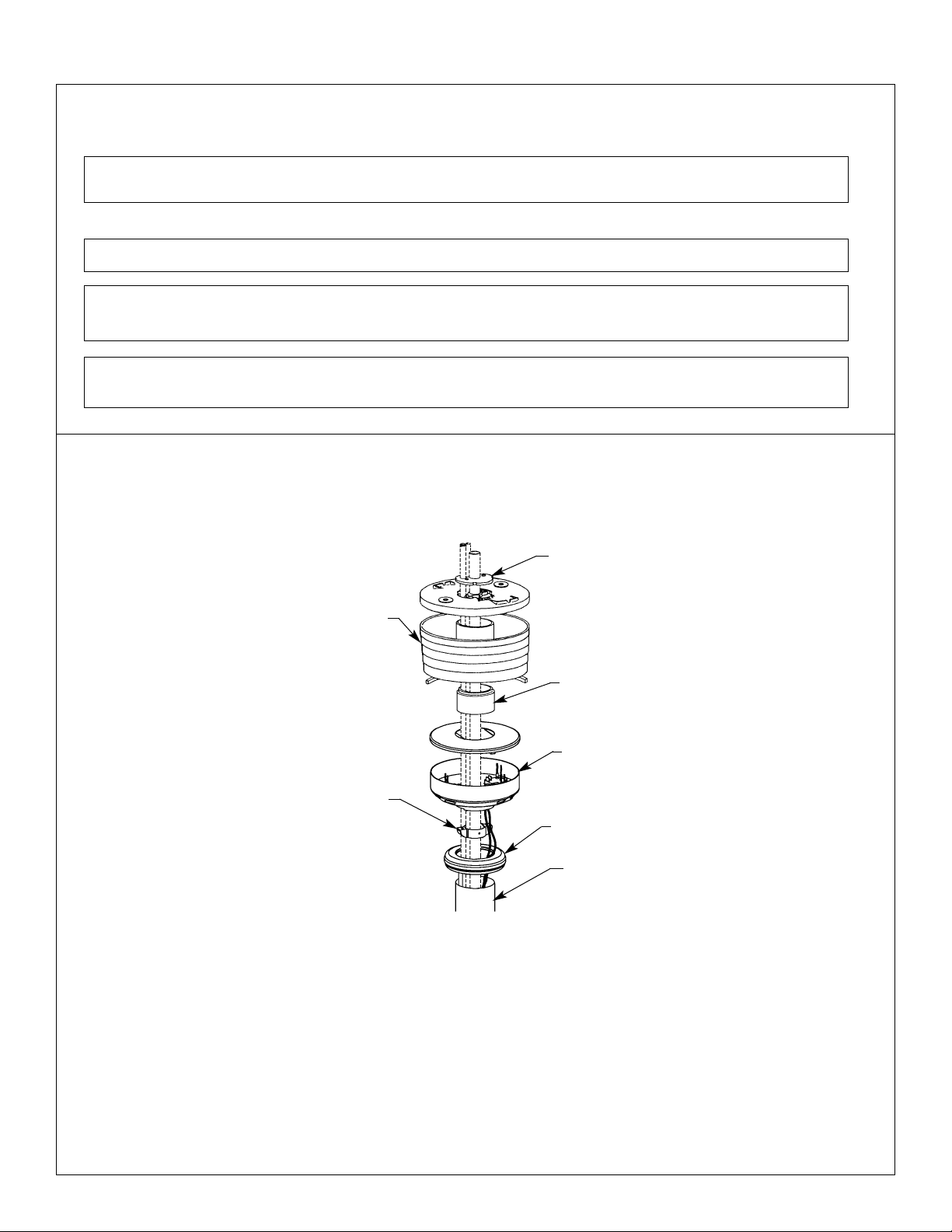

Adaptive infrared assembly for B drain and H drain units

with Tie Pipe option

4b

SUPPORT TUBE

GASKET

125-011

SUPPORT TUBE

(STD) S57-005

(JUV) S57-006

PRE-PACK

S45-1466

VENTED TRAP

111-024

TIE BAR

PRE-PACK

S45-056

PEDESTAL ASSY.

S17-242

COVER

107-185 (B)

107-048 (H)

I.R. MODULE ASSY.

S50-344

1/2" SUPPLY TUBE

SPRAYHEAD

S05-054

DRAIN

S45-273

VALVE ASSY.

S50-369

ACCESS PANEL

186-1456

TERREON® DEEP BOWL

(ADA bowl shown, classic bowl

is optional) Part No. varies with color

of bowl. Contact your Bradley Rep.

for assistance.

B/H

(B shown)

COVER

SECTION VIEW OF

B/H UNIT ASSEMBLY

SPRAYHEAD

ACTUATOR

MODULE

ASSY.

TIE

BAR

SUPPLY

TUBE

Figure 8

INSTALL HEMMED END (NOT SHARP END) OF SUPPORT TUBE WITH GASKET ONTO BOWL (SEE FIGURE 8).

A

CONNECT 1/2" SUPPLYTUBING TO SPRAYHEAD WITH 3/8" NPT TO 1/2" TUBE CONNECTOR AND PLACE SPRAYHEAD ONTO

SUPPORT TUBE. RUN THE TUBING DOWN THROUGH THE SUPPORT TUBE AND CONNECT TO VALVE TUBE CONNECTOR.

B

INSERT THE 1-1/2" VENT PIPE (SUPPLIED BY INSTALLER) DOWN THROUGH THE SUPPORT TUBE AND THREAD INTO VENTED TRAP.

C

Page 15

Installation TDB3108, WF3208 Terreon®54" Circular

15Bradley Corporation • 215-1187 Rev. N; EN 06-915B 4/6/2007

Installation Instructions continued . . .

Figure 9

INFRARED

MODULE

ASSEMBLY

S50-344

SPRAYHEAD

S05-054

SUPPORT TUBE

(STD.) S57-005

(JUV.) S57-006

SPACER

SOAP

DISPENSER

TIE BAR

UNIT WITH “B” DRAIN AND I.R. MODULE

SHOWN, ALSO AVAILABLE WITH “H” DRAIN

TOP COVER

PLACE THE INFRARED MODULE ASSEMBLY ON TOP OF SPRAYHEAD. ROTATE UNTIL INFRARED MODULE LOCKS IN WITH TIE BAR.

DROP TWO INFRARED MODULE WIRES DOWN TO VALVE ASSEMBLY.

D

POSITION THE UPPER TIE BAR SLIGHTLYBELOW THE MODULE (SEE FIGURE 8 INSET ON PREVIOUS PAGE) OR SOAP DISPENSER

(SEE FIGURE 9) AND FASTEN SECURELY TO VENT PIPE WITH SET SCREWS PROVIDED. SECURE TOP COVER TO TIE BAR WITH TWO

CAP SCREWS PROVIDED.

E

FOR B UNIT: INSTALL 1/2" NOMINAL COPPER TUBING SUPPLYLINES (PASS THEM THROUGH HOLES IN COVER DOWN

THROUGH SUPPORT COLUMN) AND CONNECT SUPPLY LINES TO STOPS USING SUITABLE FITTINGS.

F

FOR UNITS WITH SOAP OPTION, SLIDE THE SPACER AND SOAP DISPENSER OVER THE 1-1/2" PIPE.

•

NOTE! Skip to step E for units without soap.

Page 16

TDB3108, WF3208 Terreon®54" Circular Installation

16 4/6/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

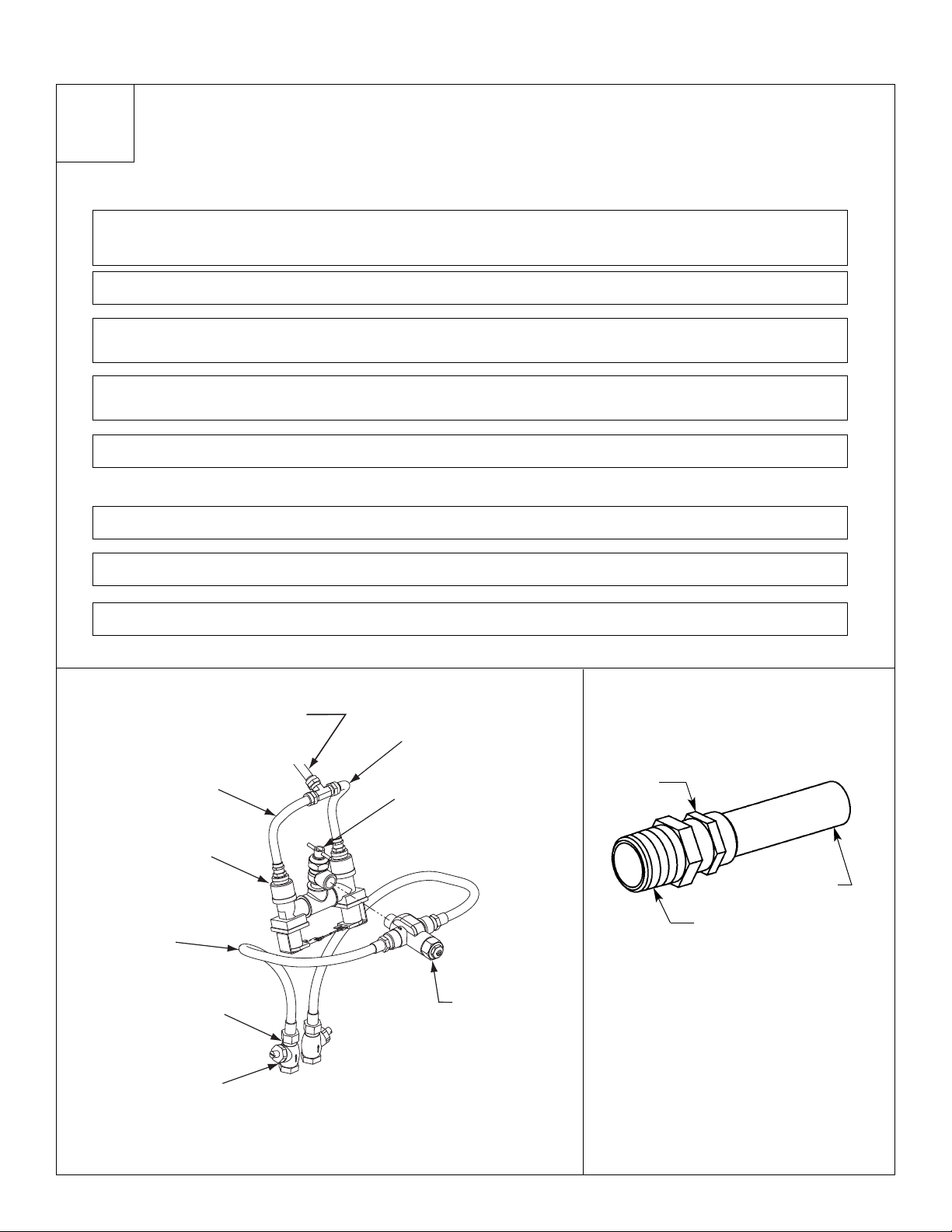

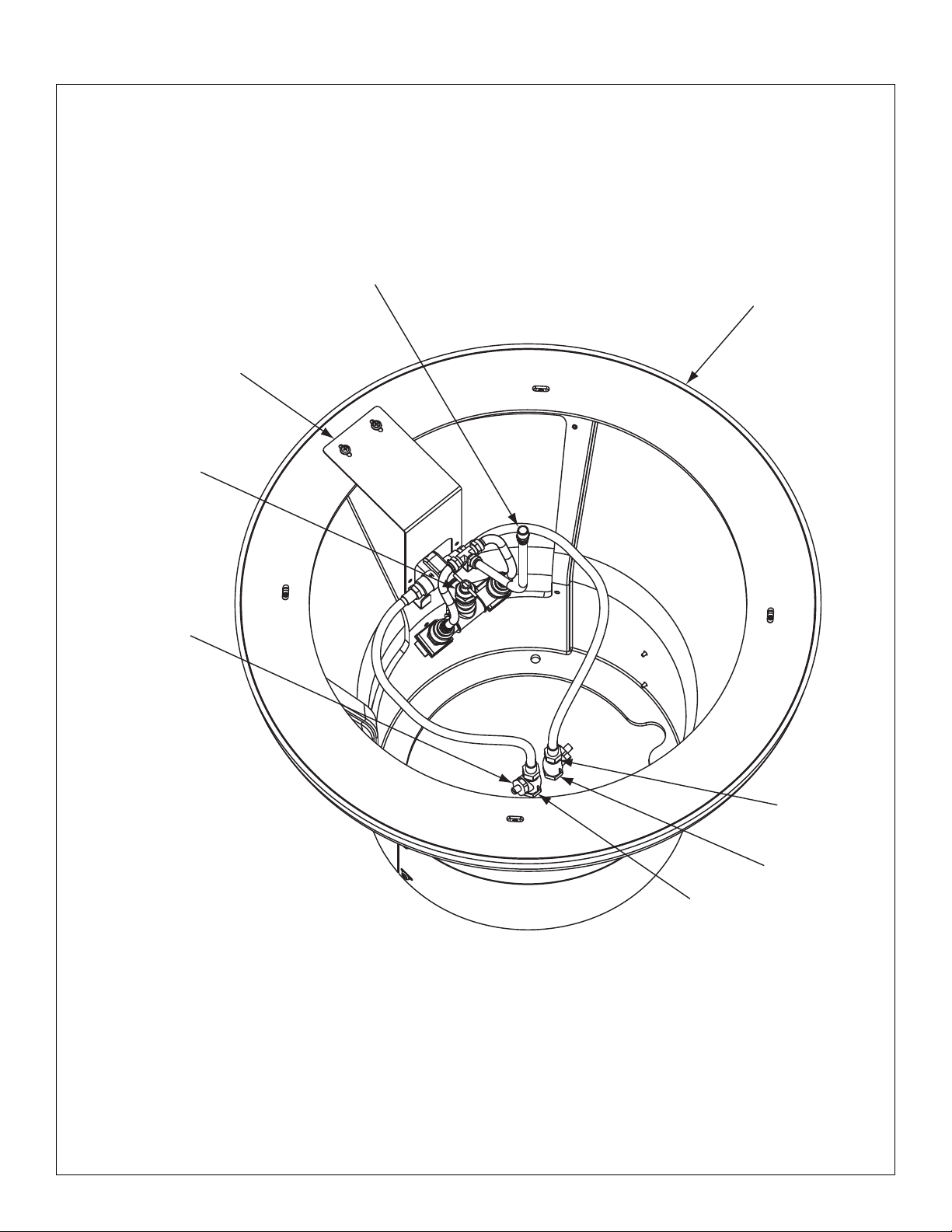

5

Valve and tubing connections

Figure 10a

Figure 10b

NUT

MALE TUBE

CONNECTOR

TUBING

V ALVE ASSEMBLY S50-369

NOTE: Flush supply lines before making connections.

Do not apply pipe sealant to compression fittings.

CONNECT 1/2" DIA. TUBING TO TEE AND SOLENOID ASSEMBLY, TWO PLACES. THE MALE CONNECTOR

(FIGURE 10B) FOR THE VALVE ASSEMBLY WILL REMAIN TIGHT AND LEAKPROOF WHEN TUBING IS CUT AND INSTALLED PROPERLY.

FOLLOW THE PROCEDURES BELOW WHEN INSTALLING TUBING TO ENSURE THAT YOU ACHIEVE A LEAKPROOF SEAL.

A

USING A SHARP RAZOR, CUT TUBING SQUARELY AND REMOVE ANY BURRS. DO NOT PINCH OR CRUSH END OF TUBING.

•

LOOSEN NUT ON FITTING. MOISTEN END OF TUBE AND PUSH INTO FITTING UNTIL IT IS FIRMLY SEATED. TIGHTEN NUT TO SECURE

TUBE TO FITTING (MAKE SURE NUT IS SECURELY TIGHTENED).

•

IF CONNECTOR LEAKS, RESEAT TUBING ACCORDING TO ABOVE PROCEDURE. IF LEAKING PERSISTS, REPLACE MALE

CONNECTOR, OR CALL YOUR BRADLEY REPRESENTATIVE FOR ASSISTANCE.

•

HANG VALVE ASSEMBLY ON PEDESTAL BRACKET (SEE FIGURE 11 ON PAGE 17). USE WIRE TIE TO SECURE VALVES.

B

CONNECT THE 1/2" NPT FEMALE END OF THE STOP/CHECK VALVES TO THE ROUGH-INS.

C

ATTACH FLEXIBLE HOSING TO THERMOSTATIC MIXING VALVE, TWO PLACES.

D

INSERT THE FILTER WASHERS (PROVIDED) INTO THE SWIVEL NUT AT THE END OF THE SUPPLY HOSES AND CONNECT TO THE

STOP/CHECK VALVES.

E

NOTE! For “O” and “B” units (overhead supplies) Skip steps C through E

1/2" DIA. TUBE

FROM SPRAYHEAD

1/2" DIA. TUBE

R68-600012

SOLENOID

ASSY.

S08-055

FLEXIBLE

HOSE

FILTER WASHER

TEE

269-764

VOLUME CONTROL

S02-045

THERMOSTATIC

MIXING VALVE

ASSEMBLY

S67-597

STOP/CHECK

VALVE

Page 17

Installation TDB3108, WF3208 Terreon®54" Circular

17Bradley Corporation • 215-1187 Rev. N; EN 06-915B 4/6/2007

Installation Instructions continued . . .

VALVE AND TUBING CONNECTIONS - ADAPTIVE INFRARED OPTION

NOTE: FLUSH SUPPLY LINES BEFORE MAKING CONNECTIONS.

Figure 11

1/2" TUBE FROM

SPRAYHEAD

VALVE

BRACKET

VOLUME

CONTROL

PEDESTAL

CHECK/STOP

VALVE

FILTER

WASHER

COLD

SUPPLY

HOT

SUPPLY

Page 18

TDB3108, WF3208 Terreon®54" Circular Installation

18 4/6/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

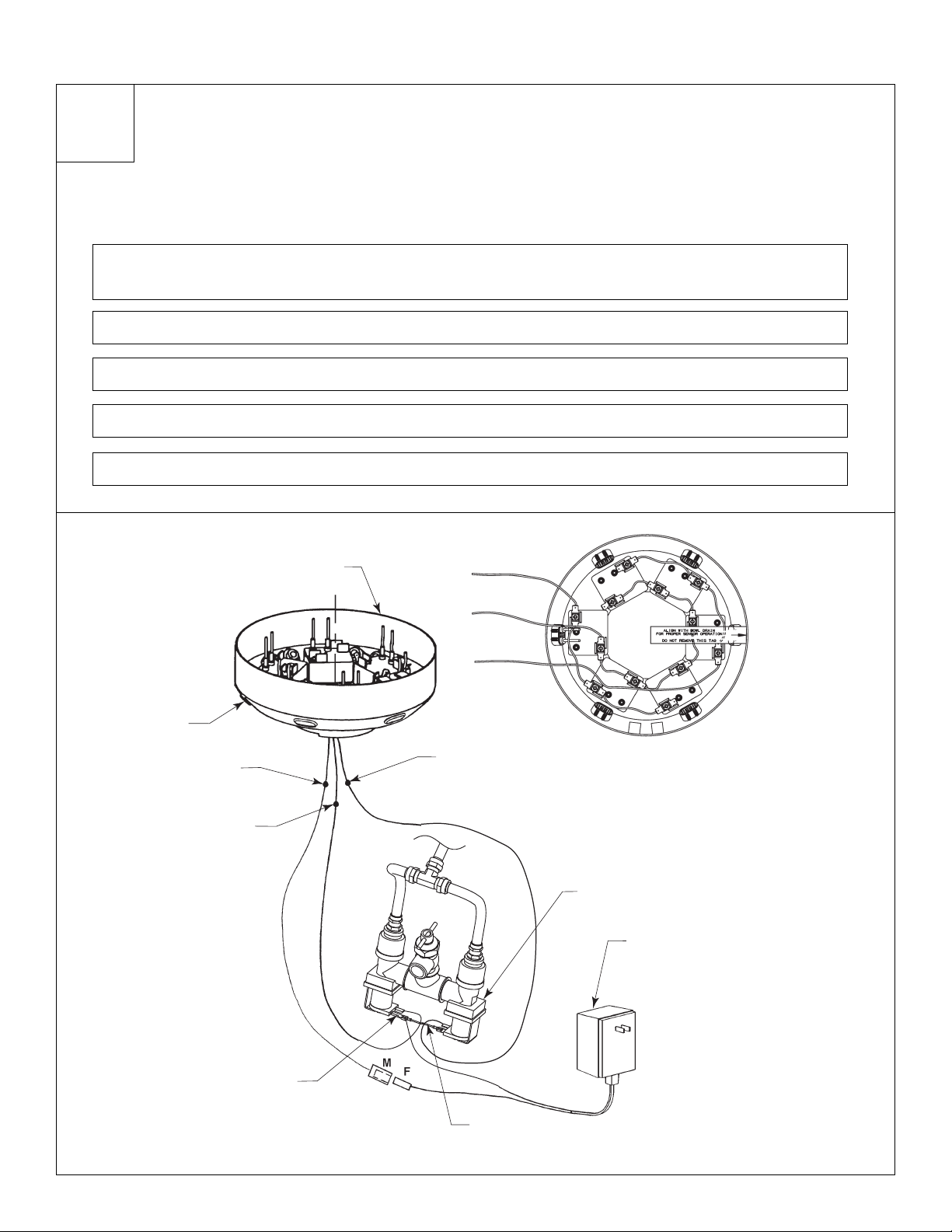

6

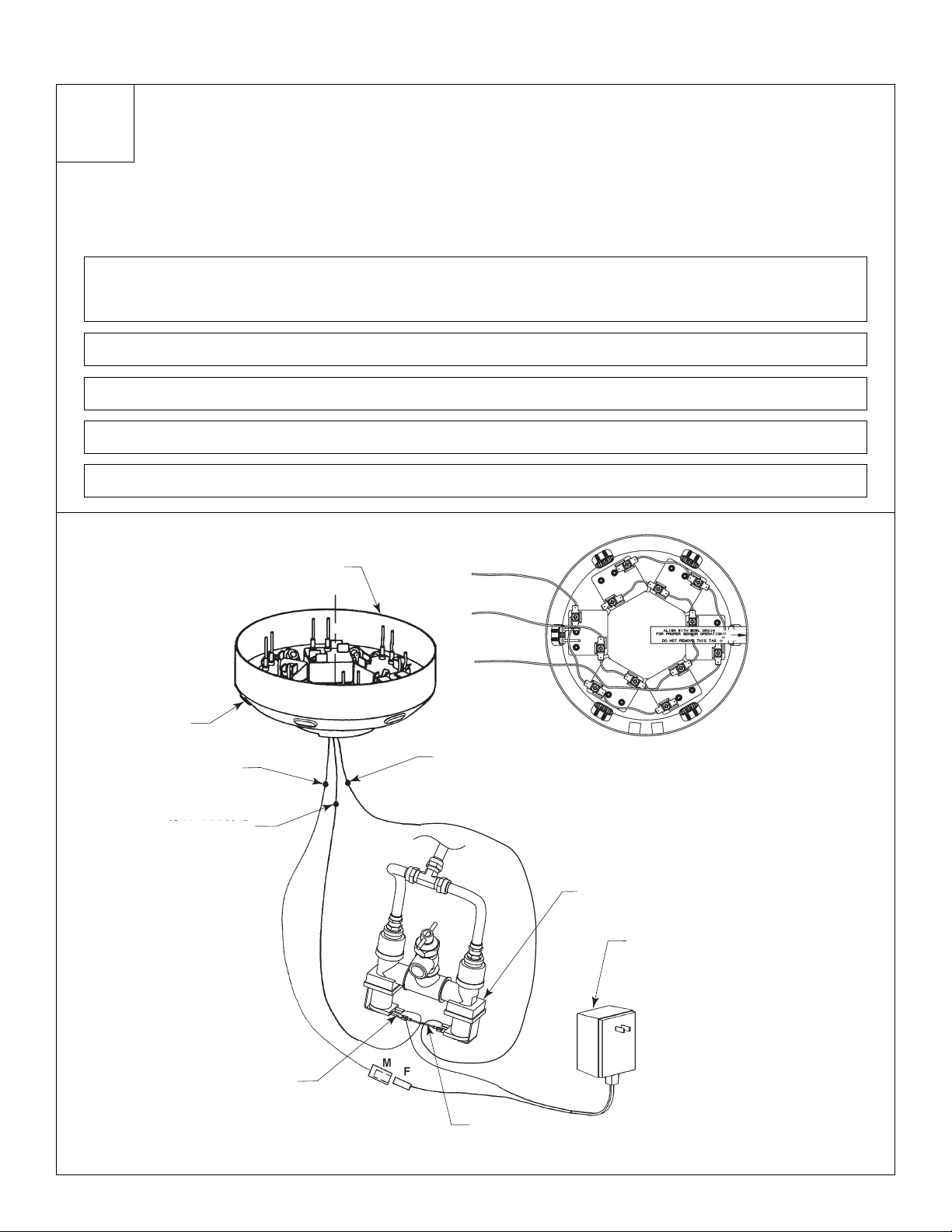

Electrical connections for Adaptive Infrared

START-UP NOTE: Do not use for two minutes after making power connection. The sensors will take up

to eight minutes (without being used) to adapt to the bowl if another object is detected during the

two-minute start-up period.

I.R. MODULE

S50-344

TOP VIEW MODULE

ASSEMBLY

CONNECT WIRES

AS SHOWN

VALVE ASSY.

S50-369

110/24 VAC

TRANSFORMER

S83-134

F = FEMALE CONNECT

M = MALE CONNECT

WIRE

ADAPTER

269-620

S53-261

(S53-261A) C

RED

(S53-261A) A

RED

(S53-272) B

BLACK

WINDOW

269-1351

Figure 12

CONNECT THE THREE WIRES FROM THE INFRARED MODULE ASSEMBLY TO THE VALVE ASSEMBLY. ATTACH TWO OF THE FEMALE

CONNECT WIRES TO THE SOLENOIDS AS SHOWN IN FIGURE 12. ATTACH THE MALE CONNECT WIRE TO ONE OF THE 24 VAC

TRANSFORMER LEADS. ATTACH THE REMAINING TRANSFORMER LEAD TO THE SOLENOID WIRE ADAPTER (SEE FIGURE 12).

A

CONNECT 24 VAC TRANSFORMER PROVIDED TO POWER SOURCE.

B

TURN SUPPLIES ON. OPEN CHECK/STOP VALVES COMPLETELY.

C

OPEN VOLUME CONTROL VALVE COMPLETELY AND CHECK PIPING INSTALLATION FOR LEAKS.

D

PASS YOUR HAND IN FRONT OF EACH SENSOR UNTILAIR IS PURGED FROM THE LINES.

E

Page 19

Installation TDB3108, WF3208 Terreon®54" Circular

19Bradley Corporation • 215-1187 Rev. N; EN 06-915B 4/6/2007

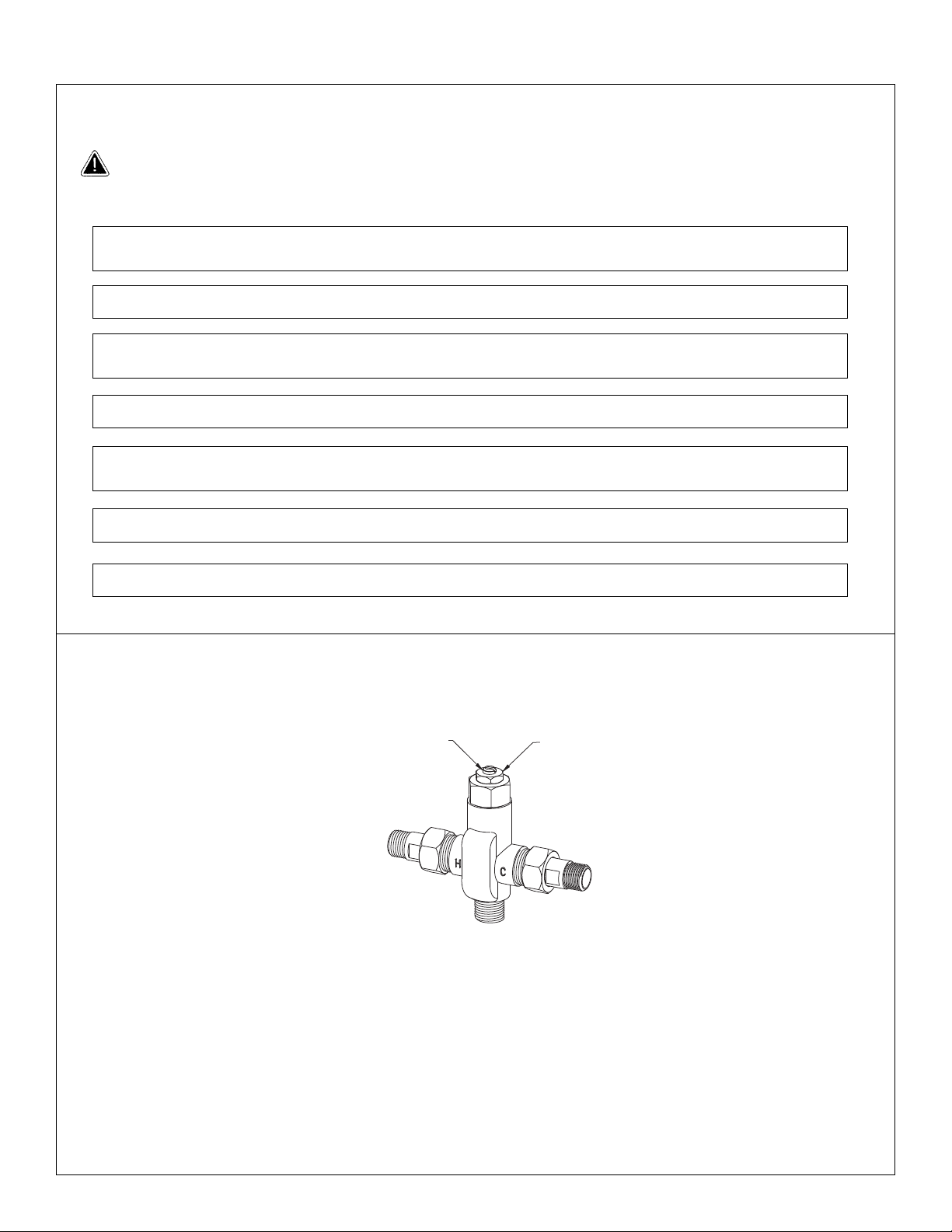

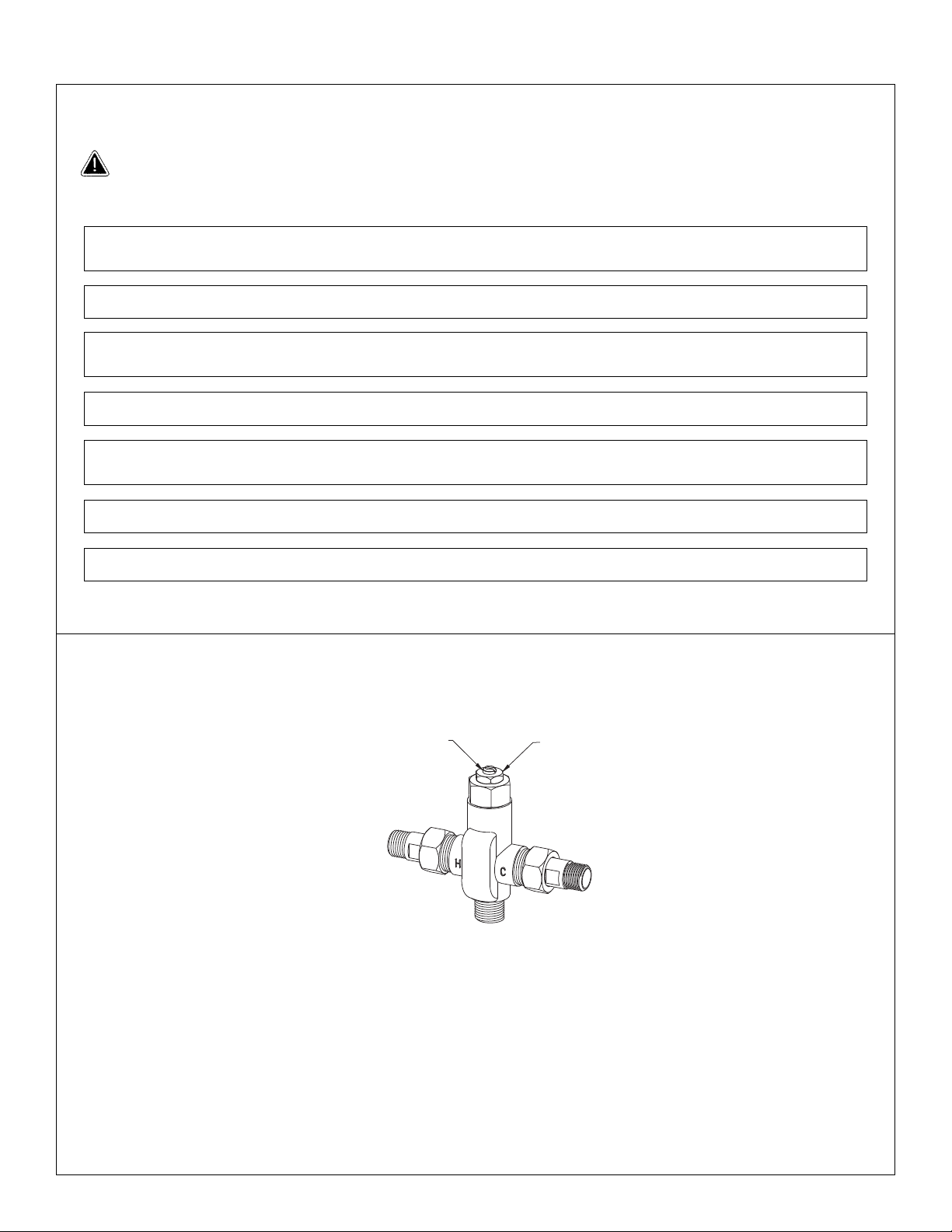

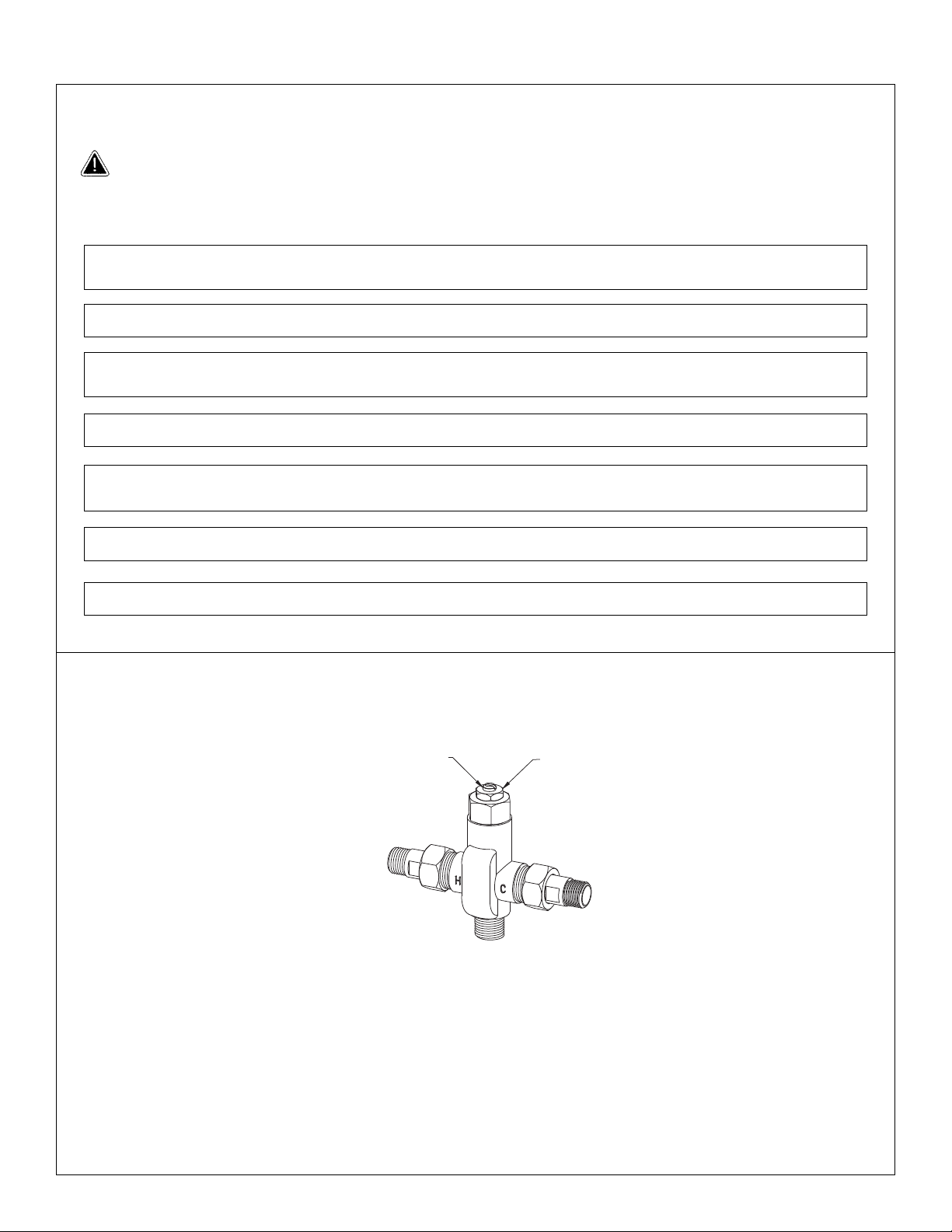

Vernatherm Ajustment Instructions

NOTE: The Vernatherm TMA valve is NOT factory preset. Upon installation, the temperature

of this valve must be checked and adjusted to ensure delivery of a safe water temperature.

Water in excess of 110°F (43°C) may cause scalding.

TEMPERATURE

ADJUSTMENT

STEM

TEMPERATURE

LOCKING

NUT

Figure 13

CHECK THE TEMPERATURE AND ADJUST IF NECESSARY (THE RANGE OF THE VALVE IS 95°F–115°F (35°C–43°C). TO ADJUST THE

TEMPERATURE, FOLLOW THE PROCEDURE BELOW:

F

CLEAN SPRAYHEAD IF NECESSARY. SEE PAGE 25 FOR SPRAYHEAD MAINTENANCE AND REPAIR PARTS. ADJUST THE VOLUME

CONTROL VALVE, IF NECESSARY, TO CONTROL THE FLOW OF WATER.

G

ATTACH PEDESTALACCESS PANEL WITH HARDWARE PROVIDED.

H

ATTACH KICK PLATE TO PEDESTAL BASE WITH HARDWARE PROVIDED.

I

LOOSEN TEMPERATURE LOCKING NUT WITH WRENCH.

•

ONCE DESIRED TEMPERATURE IS REACHED, TIGHTEN NUT TO PREVENT TEMPERATURE CHANGE.

•

USING A BLADE SCREWDRIVER, TURN THE ADJUSTMENT STEM COUNTERCLOCKWISE TO INCREASE THE TEMPERATURE OR

CLOCKWISE TO DECREASE THE TEMPERATURE (FIGURE 13).

•

Page 20

TDB3108, WF3208 Terreon®54" Circular Installation

20 4/6/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

Cleaning/Maintenance Instructions for Terreon®

Material Description: Terreon® is a NAHB Certified densified solid surface material composed of polyester

resin and is resistant to chemicals, stains, burns and impact. Surface damage can be easily repaired with

everyday cleansers or fine grit abrasives.

Routine Cleaning: Clean daily or as often as conditions require using a standard commercial or household

cleaner such as Formula 409

®

or Windex®.

Stubborn Stains: Remove tough stains with Ajax

®

, Comet®, or Soft-Scrub®and a green Scotch-Brite®pad or

lightly sand in a circular motion with 240 grit wet/dry sandpaper. The finish can be renewed with a maroon

Scotch-Brite pad.

Special Situations for Material

Scratches: Remove scratches with a green Scotch-Brite®pad. The finish can then be renewed with a maroon

Scotch-Brite

®

pad.

Hard Water Deposits: Remove hard water deposits with a mild solution of vinegar and water. Always rinse

the unit thoroughly after cleaning.

Restoring the Surface: Use Hope’s

®

Solid Surface cleaner and polish to refresh and protect the Terreon

Solid Surface material. Bradley recommends additional care and maintenance for the darker colored Terreon,

for complete instructions on this additional maintenance see Bradley document #1505.

IMPORTANT:

DO NOT USE STRONG ACID OR ALKALINE CHEMICALS AND CLEANSERS TO

CLEAN TERREON. IF THESES CHEMICALS COME IN CONTACT WITH THE TERREON

SURFACE WIPE THEM OFF IMMEDIATELY AND RINSE WITH SOAPY WATER. AVOID CONTACT

WITH HARSH CHEMICALS SUCH AS PAINT REMOVER, BLEACH, ACETONE, ETC. AVOID

CONTACT WITH HOT PANS AND OBJECTS.

Repair Kits: Terreon®repair kits are available. Contact your Bradley representative or distributor for part

numbers and pricing.

NOTE: Repair kits are made to order and have a shelf life of 30 days.

Brand Names: Use of brand names is intended only to indicate a type of cleaner. This does not constitute an

endorsement, nor does the omission of any brand name cleaner imply its inadequacy. Many products named

are regional in distribution, and can be found in local supermarkets, department and hardware stores, or

through your cleaning service. It is emphasized that all products should be used in strict accordance with

package instructions.

Cleaning/Maintenance Instructions for Gel-coated Fiberglass

Material Description: The Terreon®Washfountains referenced in this installation manual use a gel-coated

fiberglass pedestal.

Routine Cleaning: The gel-coated pedestal should be cleaned daily or as often as needed with a mild solution

of detergent and water. Always use a soft cloth to avoid damage to the finish.

Repair Kits: There are no repair kits available for fiberglass materials. However, replacement parts are

available, contact your Bradley representative for pricing and part numbers.

IMPORTANT: DO NOT EXPOSE GEL-COATED FIBERGLASS TO SOLVENTS AS THEY

WILL DAMAGE THE MATERIAL AND MAY CREATE HARMFUL FUMES.

Brand Names: Use of brand names is intended only to indicate a type of cleaner. This does not constitute an

endorsement, nor does the omission of any brand name cleaner imply its inadequacy. Many products named are

regional in distribution, and can be found in local supermarkets, department and hardware stores, or through your

cleaning service. It is emphasized that all products should be used in strict accordance with package instructions.

Page 21

Installation TDB3108, WF3208 Terreon®54" Circular

21Bradley Corporation • 215-1187 Rev. N; EN 06-915B 4/6/2007

Cleaning and Maintenance Instructions for Stainless Steel

Material Description: Stainless steel is extremely durable, and maintenance is simple and inexpensive.

Proper care, particularly under corrosive conditions, is essential. Always start with the simplest solution and

work your way toward the more complicated.

Routine Cleaning: Daily or as often as needed use a solution of warm water and soap, detergent, or

ammonia. Apply the cleaning solution per the manufacture’s instructions and always use a soft cloth or

sponge to avoid damaging the finish.

Stubborn Stains: To remove stains from stainless steel use a stainless steel cleaner and polish such as Ball

®

stainless steel cleaner or a soft abrasive. Always follow the manufacture’s instructions and apply in the same

direction as the polish lines.

IMPORTANT: NEVER USE ORDINARY STEEL WOOL OR STEEL BRUSHES ON STAINLESS

STEEL. ALWAYS USE STAINLESS STEEL WOOL OR STAINLESS STEEL BRUSHES.

Special Situations for Material

Finger Prints and Smears: To remove fingerprints or smears use a high quality stainless steel cleaner and

polish in accordance with the manufacture’s instructions. Many of these products leave a protective coating

the helps prevent future smears and fingerprints.

Grease and Oil: To remove grease and oil use a quality commercial detergent or caustic cleaner. Apply in

accordance to the manufacture’s instructions and in the direction of the polish lines.

Precautions: Avoid prolonged contact with chlorides (bleaches, salts), bromides (sanitizing agents),

thiocyanates (pesticides, photography chemicals, and some foods), and iodides on stainless steel equipment,

especially if acid conditions exist.

IMPORTANT: DO NOT PERMIT SALTY SOLUTIONS TO EVAPORATE AND DRY ON

STAINLESS STEEL.

The appearance of rust streaks on stainless steel leads to the belief that the stainless steel is rusting. Look for the

actual source of the rust in some iron or steel particles which may be touching, but not actually a part of the

stainless steel structure.

NOTE: Strongly acidic or caustic cleaners may attack the steel causing a reddish film to appear. The use of

these cleaners should be avoided.

Brand Names: Use of brand names is intended only to indicate a type of cleaner. This does not constitute an

endorsement, nor does the omission of any brand name cleaner imply its inadequacy. Many products named are

regional in distribution, and can be found in local supermarkets, department and hardware stores, or through your

cleaning service. It is emphasized that all products should be used in strict accordance with package instructions.

Page 22

TDB3108, WF3208 Terreon®54" Circular Installation

22 4/6/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

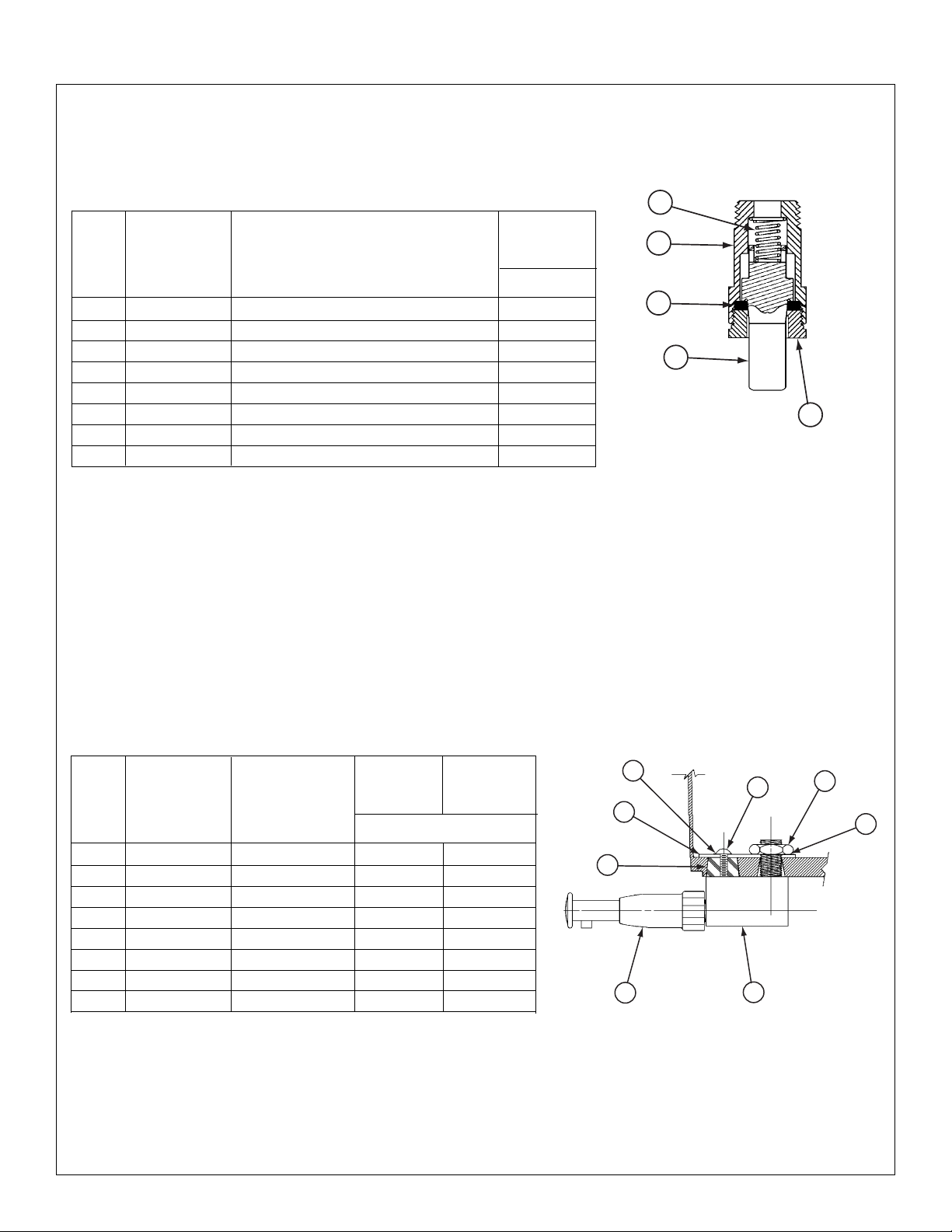

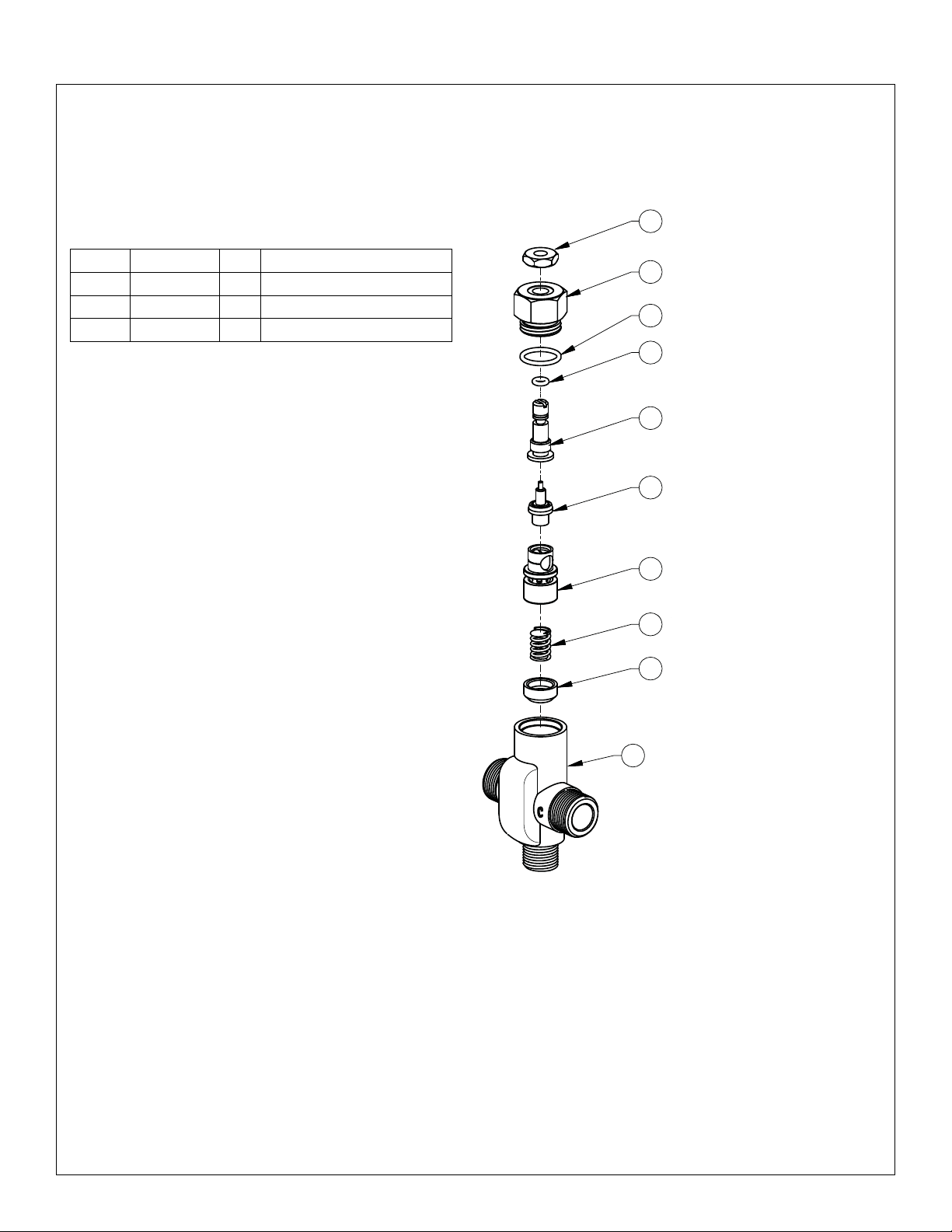

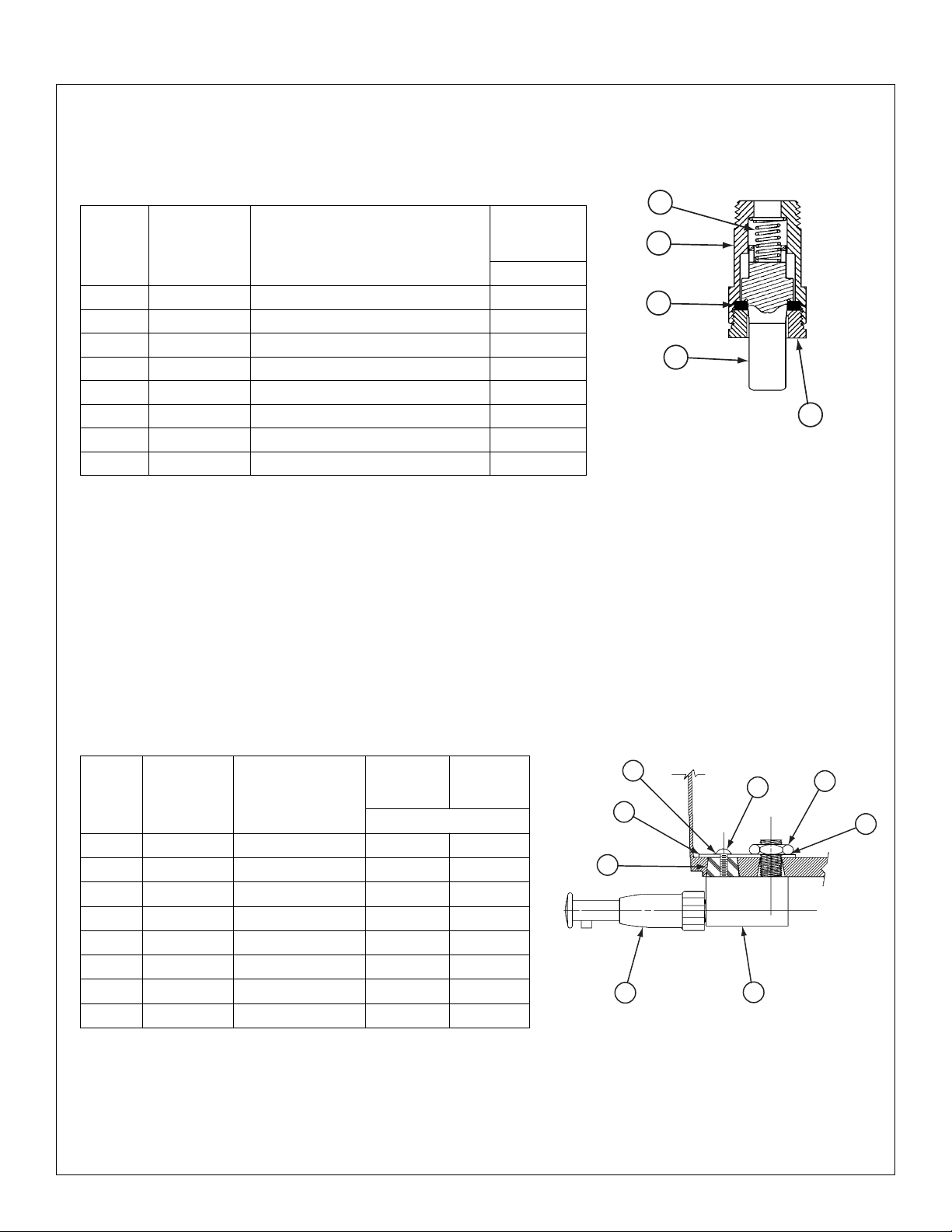

1 118-025 Valve Body 1

2 110-007 Packing Nut 1

3 135-001L Spring 1

4 125-001BU Washer 1

5 119-028 Plunger 1

* 161-014 Nut 1

* 124-001D Washer 2

* 142-002AH Washer - Stainless Steel 1

Attaching

Parts

S09-007S

Item Part No. Description Qty

Parts List

Soap Valve — Liquid — S09-007S

* Not Illustrated

3

1

5

4

2

This valve delivers a measured amount of soap with each upward stroke. The soap dispenser has

been standard on washfountains since 1983 and is not well-suited for very thick lotion soaps.

NOTE: Lotion soap will clog liquid soap valves. Use only lotion soap valves with lotion soap.

Soap Valve — Lotion — S09-057S

1 124-001D Washer — 1

2 110-057 Nut — 1

3 125-001AN Stopper — 1

4 159-114 Reinforcing Plate — 1

5 124-001AT Washer — 1

6 160-176 Screw — 1

7 S09-040 Valve 1 1

8 S53-045 Adaptor 1 1

Valve Attaching

Assembly Parts

S09-057 S09-057S

Item Part No. Description Qty

Parts List

3

2

1

4

5

7

6

8

Page 23

Installation TDB3108, WF3208 Terreon®54" Circular

23Bradley Corporation • 215-1187 Rev. N; EN 06-915B 4/6/2007

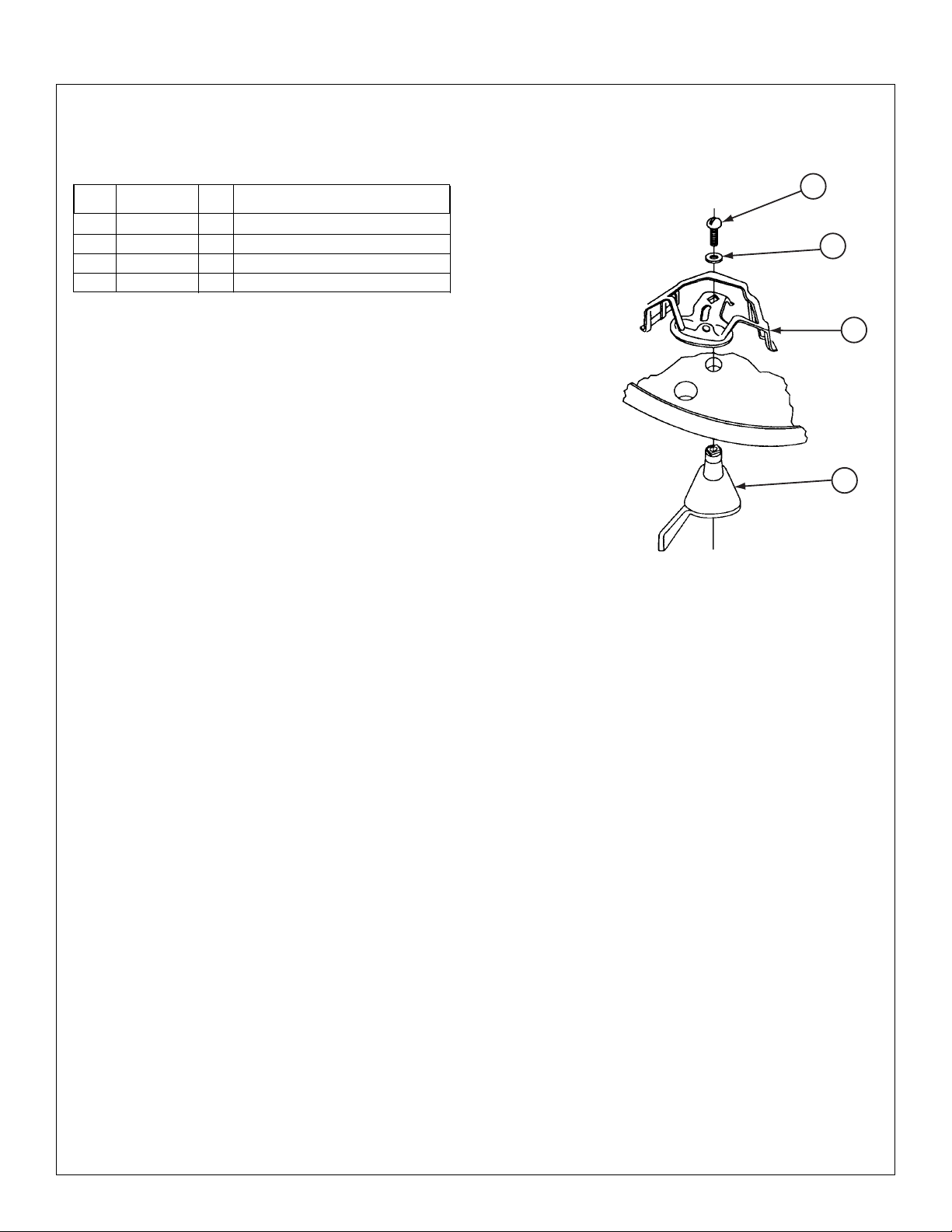

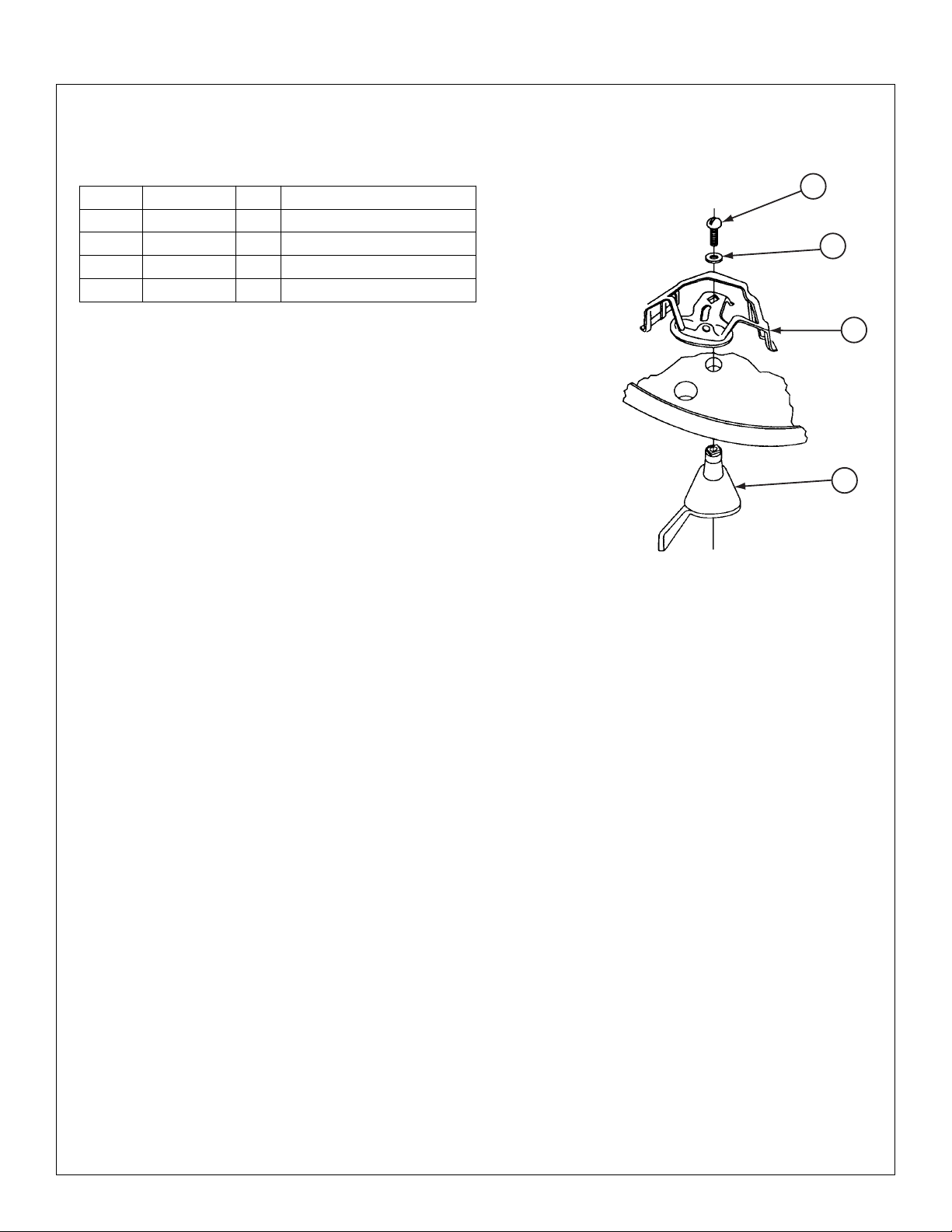

Soap Valve — Powdered — S09-010A

3

2

1

4

1 160-069 1 Screw, 1/4-20 RD

2 142-002X 1 Washer, 1/4 Split-Lock

3 S62-002 1 Agitator / Slide Assy.

4 192-004 1 Lever - Powdered Soap

Item Part No. Qty Description

Parts List

NOTE: Reducer plugs are available for use with fine granulated

soap to reduce the flow.

NOTE: Valves can be changed from powdered to liquid by plugging

the innermost, or “bearing” hole with rubber plug, part number

125-001AK. To change from liquid to powdered, the plug must be

removed. If none is present, it will be necessary to drill out the

bearing hole with a 1/2" or 5/8" drill. The plastic container

configuration forms a natural template for locating the bearing

hole.

Page 24

TDB3108, WF3208 Terreon®54" Circular Installation

24 4/6/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

SOAP

RECOMMENDA

TIONS

Quality soap dispensers require good quality soap and periodic maintenance to properly operate. Bradley soap

dispensers will provide dependable, consistent operation over the long term when soap with reasonable

viscosity and pH levels are used and when a minimal amount of periodic maintenance is performed on the

valves.

Soap thickness is determined by a measurement called viscosity. Soap viscosity should be between 100 cps

(centerpoise) and 2500 cps for all Bradley soap dispensers. Thinner soaps are perceived by the users as being

“watered down” so users tend to take more than they need, resulting in waste. Thick soaps flow slower and

inhibit the “flushing” action of the valves, which allows the soap to congeal in the valve and cause clogs.

The pH (acid) level of the soap should be in the range of 6.5 to 8.5. More acidic soaps (pH levels lower than

6.5) will corrode metal parts (even stainless steel!!) and degrade rubber and plastic components. They will also

cause skin irritation. Most inexpensive soaps (typically the pink lotion type) fall into this acidic category and

will eventually cause valve failure and metal corrosion.

Base soaps (pH levels higher than 8.5) will cause

swelling or degradation of rubber and plastic parts and skin irritation.

Generally, any quality soap meeting the viscosity and pH guidelines above will work well with Bradley soap

dispensers. PCMX or Isapropanol based antibacterial soaps (within viscosity and pH limits) will also work

with Bradley dispensers. Soaps satisfying these basic guidelines will provide consistent flow and reduce clogs.

Most soap dispenser problems are caused by soap that is too thick or corrosive, or by a lack of maintenance.

Many soaps come in concentrate form which must be diluted with water. Often, the soap is improperly diluted

or used straight out of the bottle, which causes clogging and valve failure. If proper soap is being used, valves

that have never been cleaned are usually the source of dispensing problems. Bradley has entered into an

agreement with Champion Brand Products to provide additional customer service for purchasers of our

dispensers regarding soap issues. They are very helpful and can get to the bottom of almost any soap dispenser

related problem. They also sell an excellent “Bradley approved” soap. Please see Soap Instruction Sheet 215-

1286 for details about soap valve cleaning or how to contact Champion. With proper maintenance and soap,

Bradley dispensers will provide long term, trouble free operation.

SOAP DISPENSER MAINTENANCE INSTRUCTIONS

Bradley soap dispensers will provide dependable, consistent operation over the long term when the proper

soap is used and when a minimal amount of periodic maintenance is performed on the valves. Valves must be

maintained (cleaned) to function properly.

To ensure proper operation of your soap dispenser, follow these instructions:

• Once per month, unscrew valve from reservoir and soak it for 30 minutes in hot water.

• Push valve at least 20 times while it is soaking.

• Flush soap reservoir with hot water while valve is soaking.

In cases of extreme clogging, the valve should be disassembled and the parts should be soaked in hot water or

cleaning solution to restore proper functioning. Soap dispensers that will not be used for extended periods of

time (schools during summer break, etc.) should be drained, cleaned and left empty until put back into service.

Soap left on the outside of dispensers can cause discoloration and corrosion of the reservoir (even on stainless

steel units). All soap should be wiped or scrubbed off daily, then the outside of the dispenser should be rinsed

with clear water and dried with a soft cloth.

Soap Maintenance Tips

Page 25

Installation TDB3108, WF3208 Terreon®54" Circular

25Bradley Corporation • 215-1187 Rev. N; EN 06-915B 4/6/2007

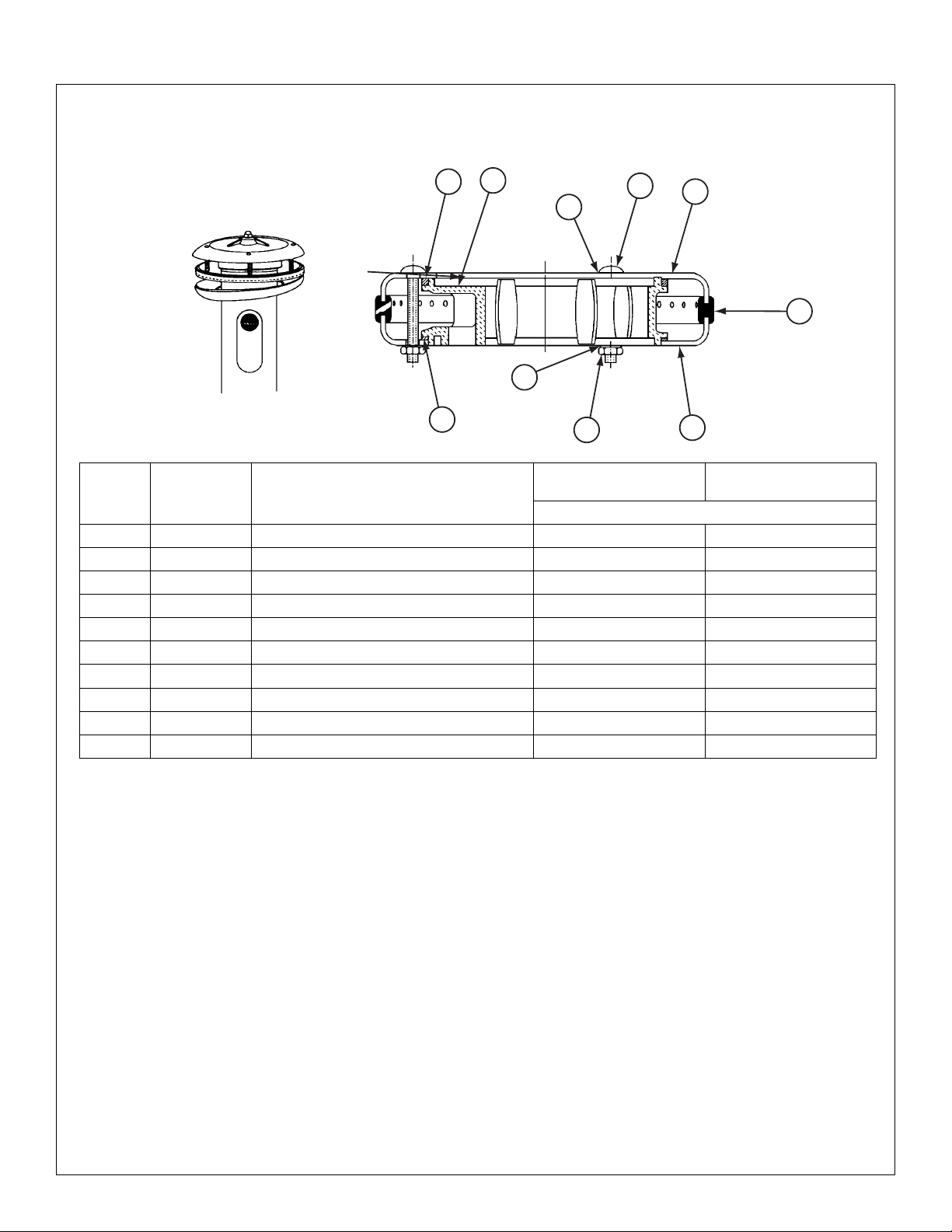

Sprayheads — Standard w/Neoprene Spray Ring Grommet

3

2

1

10

4

5

7

6

8

9

1 125-001DE Neoprene Washer-Top 1 1

2 139-031 Sprayhead Manifold 1 —

3 124-001AL Washer 3 4

4 160-211 Carriage Bolt 3 4

5 115-061 Sprayhead Top 1 —

6 116-008 Sprayhead Bottom 1 —

7 124-001AT Washer 3 4

8 161-025 Nut 3 4

9 124-020D Sprayhead Grommet - Semi-circle 1 —

10 125-001DF Neoprene Washer-Bottom 1 1

Sprayhead Repair Kit

Assembly S05-054B S45-051

Item Part No. Description Qty

Parts List

NOTE: Repair kit does not include sprayhead

grommet. Order as a separate item.

Sprayhead Service Suggestions

Problem: Water splashes over the rim of the bowl.

Cause: Foreign matter has reduced the size of the sprayhead slots, causing greater pressure at the open slots.

Solution: Clean the sprayhead:

1. Disassemble the sprayhead and dislodge any dirt, lime build-up and foreign debris with a wire brush.

2. Sprayheads with rubber grommet spray rings may be cleaned by rubbing a coin over the grommet.

3. Throttle down the volume control (water spray should strike the bowl without splashing outside of the bowl).

Problem: Water flow diminishes from the sprayhead.

Cause: Strainer portion of the stop-strainer-check valve is plugged.

Solution: Remove and clean the strainer screen from the stop-strainer-check valve.

NOTE: The sprayhead shown above includes a perforated neopreme spray ring gr ommet that is self-cleaning. The water pressure flexes

the spray holes which slows accumulation of foreign matter and tends to “br eak loose” any such deposits that may have accumulated.

Page 26

TDB3108, WF3208 Terreon®54" Circular Installation

26 4/6/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

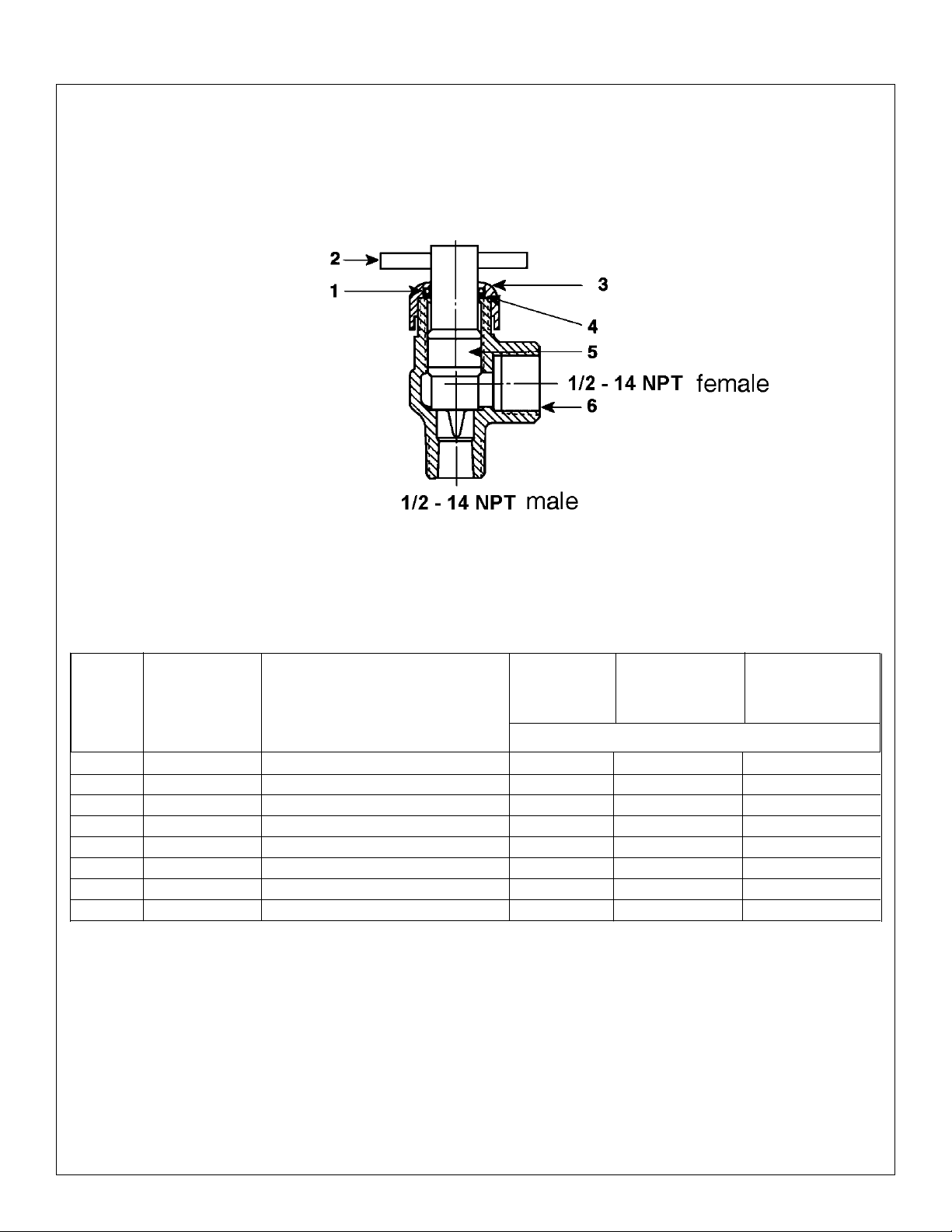

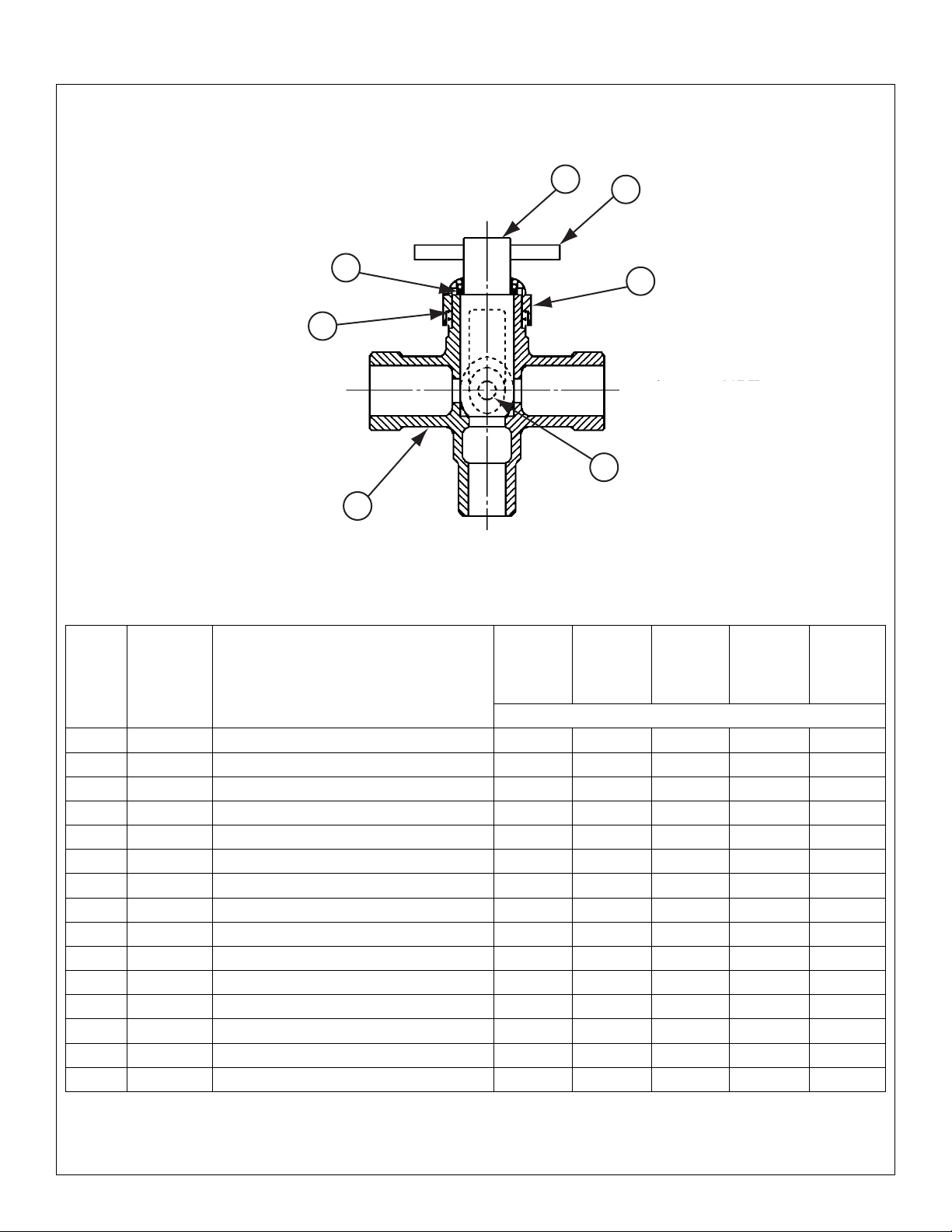

Mixing Valve — Manual — S01-038

5

6

7

2

3

4

1

1-1/16 - 14 NPT

1/2 - 14 NPT

1 118-034 Mixing Valve Body - Brass 1 1 — — —

1 118-034A Mixing Valve Body - Chrome — — 1 1 —

2 124-001BD Fiber Washer 1 1 1 1 1

3 125-001BC O-Ring 1 1 1 1 1

4 119-059 Mixing Valve Core 1 1 1 1 1

5 152-038 Roll Pin 1 1 1 1 1

6 121-016 Bonnet - Brass 1 1 — — 1

6 121-016A Bonnet - Chrome — — 1 1 —

7 160-197 Screw - Brass 1 1 — — —

7 160-189 Screw - Stainless Steel — — 1 1 —

* 129-007 Tailpiece - Brass — 2 — — —

* 110-005 Tailpiece Nut - Brass — 2 — — —

* 129-007A Tailpiece - Chrome — — — 2 —

* 110-005A Tailpiece Nut - Chrome — — — 2 —

* 124-001AF Tailpiece Washer — 2 — 2 2

Valve Valve Valve Valve

Assembly Assembly Assembly Assembly Repair Kit

S01-038 S01-038S S01-038A S01-038AS S45-197

Item Part No. Description Qty

Manual Mixing Valve Parts List

* Parts not shown

Page 27

Installation TDB3108, WF3208 Terreon®54" Circular

27Bradley Corporation • 215-1187 Rev. N; EN 06-915B 4/6/2007

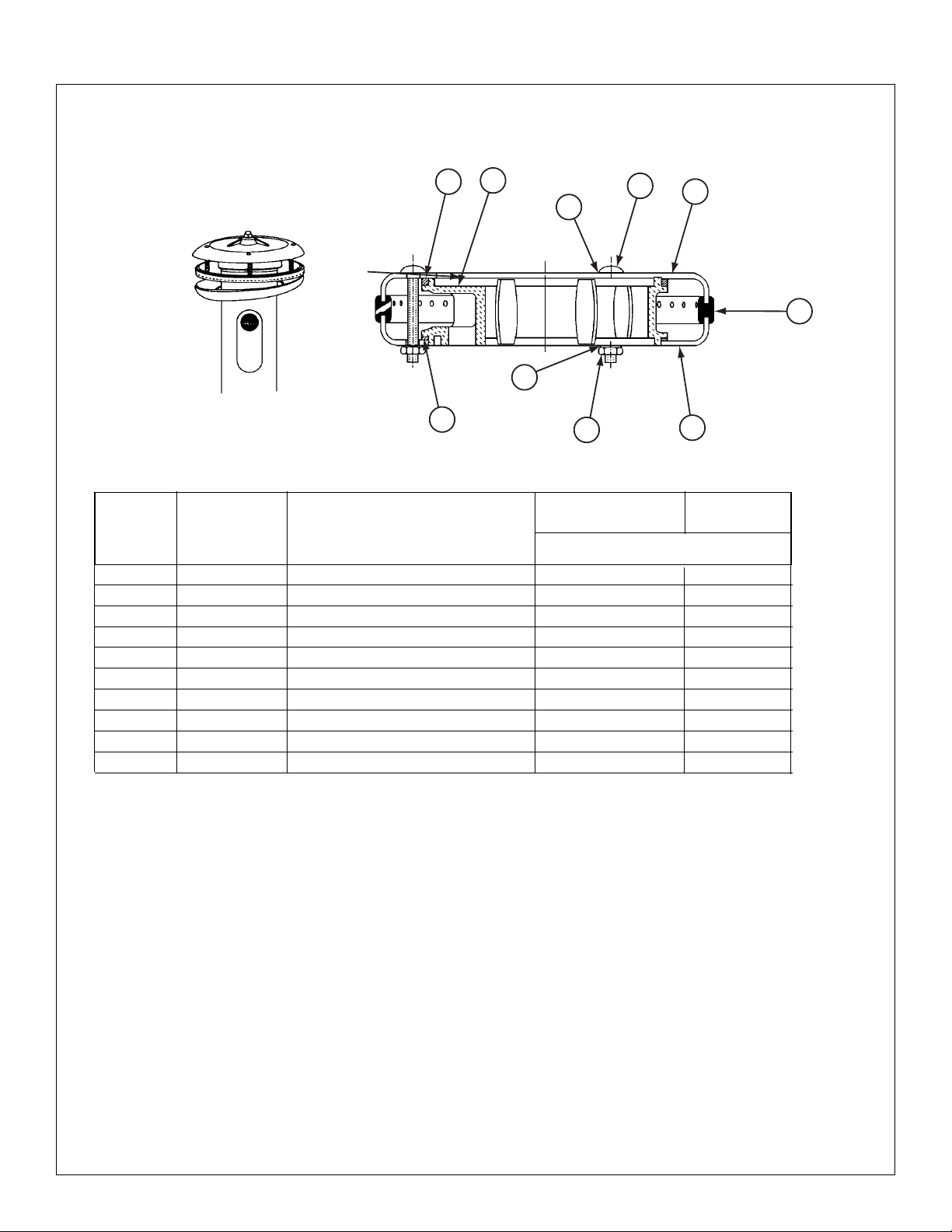

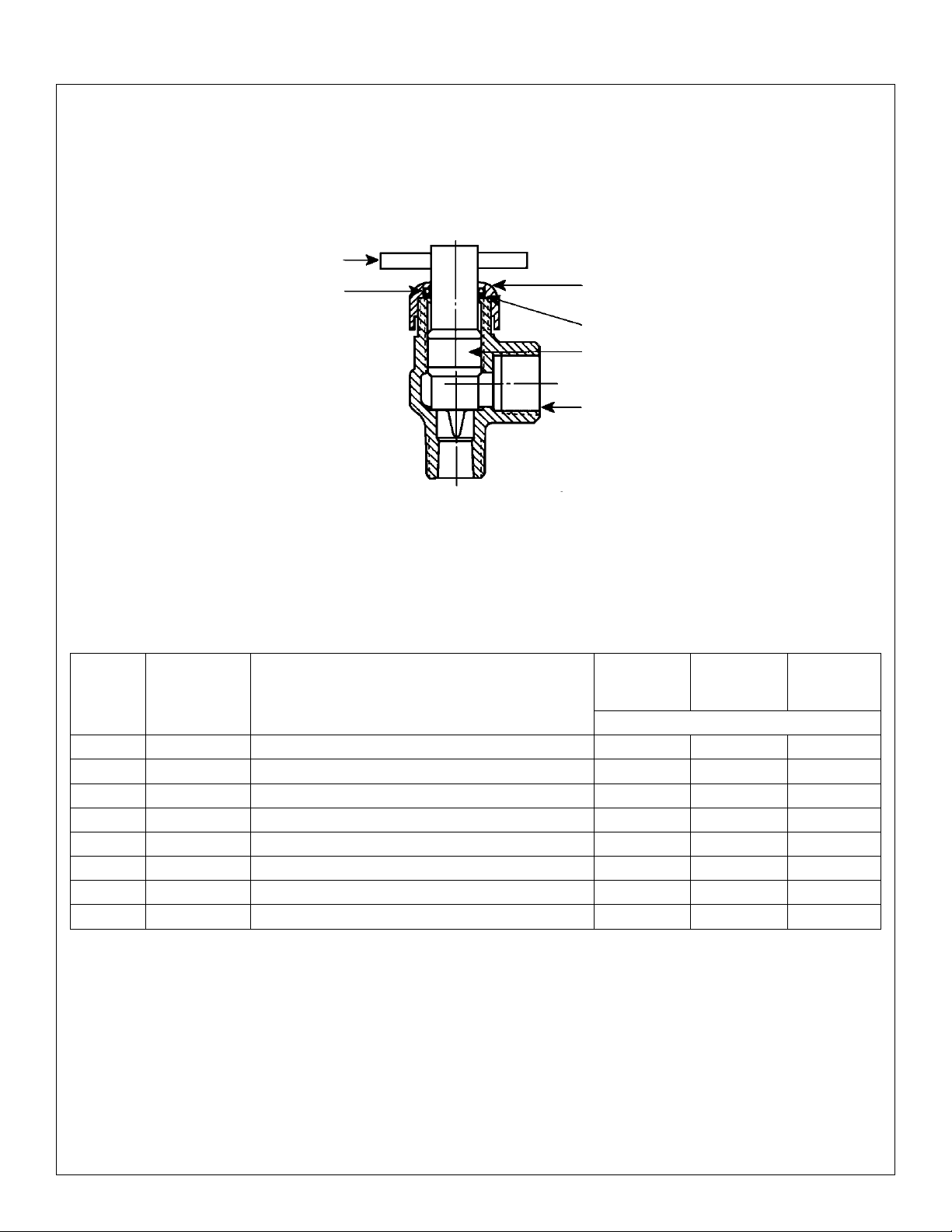

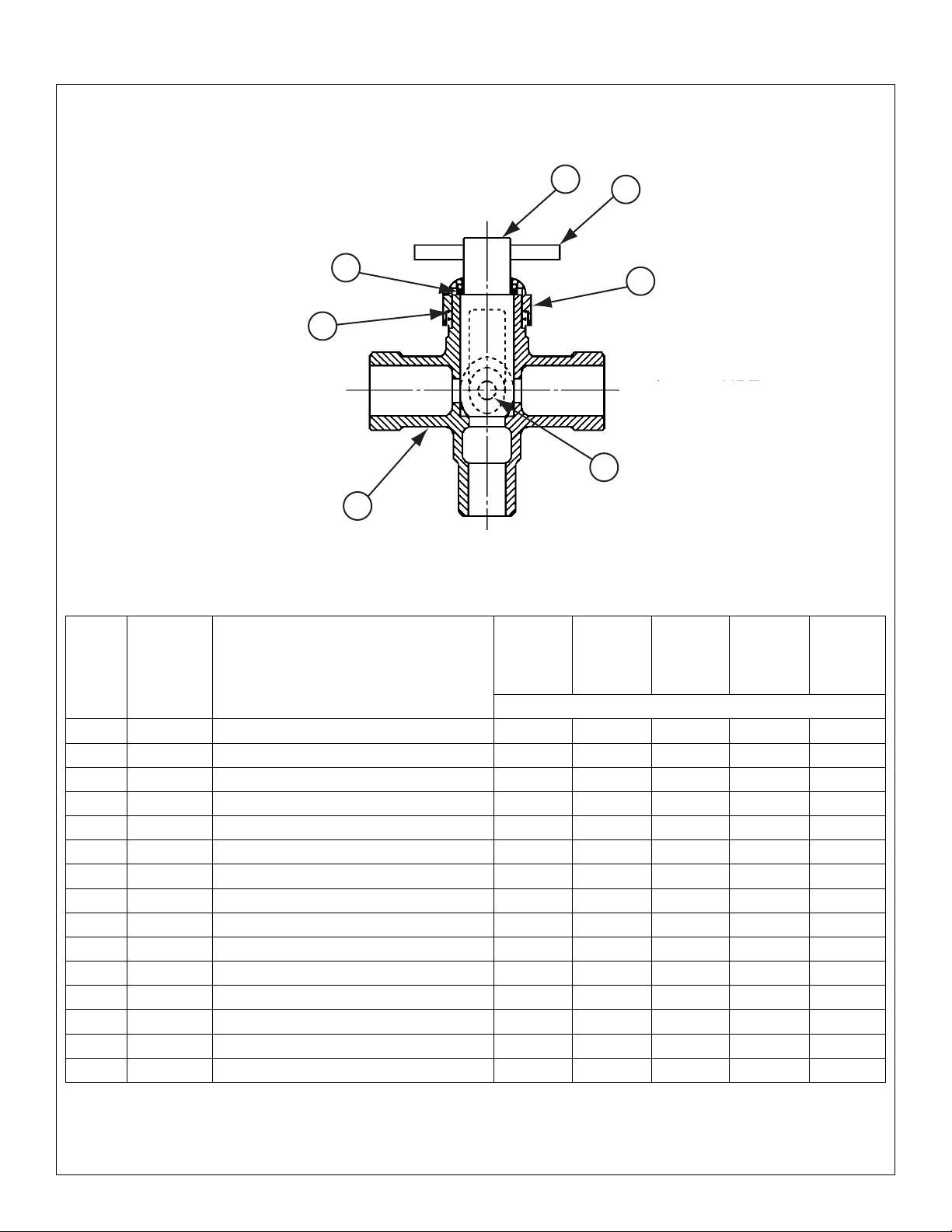

Volume Control Valve Repair Parts — S02-045

1 125-001BC O-Ring 1 1 1

2 152-038 Roll Pin 1 1 1

3 121-016 Bonnet 1 — 1

3 121-016A Bonnet — 1 —

4 124-001BD Fiber Washer 1 1 1

5 119-060 Valve Core 1 1 1

6 118-033 Valve Body 1 — —

6 118-033B Valve Body — 1 —

Brass Chrome

Valve Valve Repair Kit

S02-045 S02-045A S45-198

Item Part No. Description Qty

Volume Control Valve Parts List

Page 28

TDB3108, WF3208 Terreon®54" Circular Installation

28 4/6/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

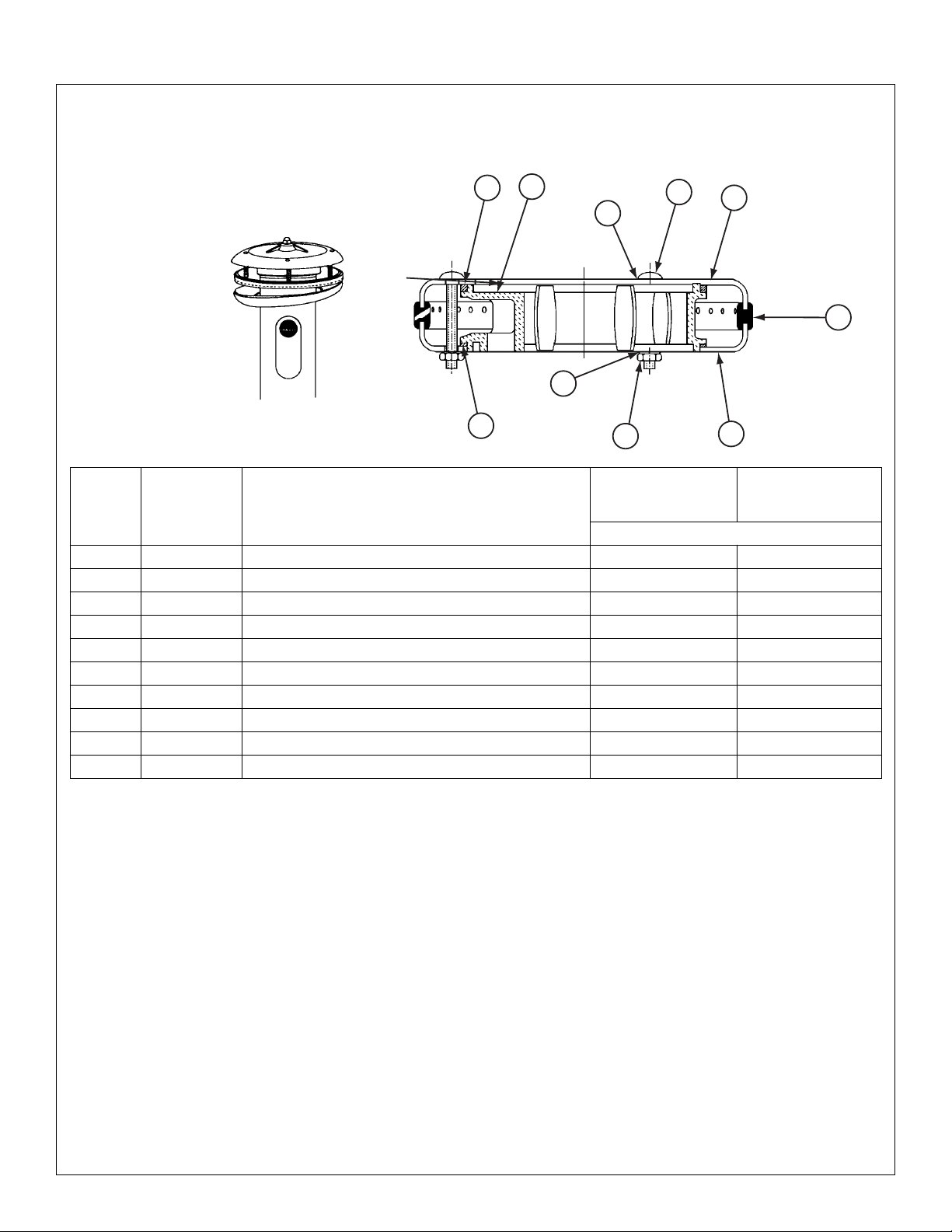

Thermostatic Mixing Valve Troubleshooting

NOTE: Before attempting to troubleshoot the valve or disassemble the components, check for the

following conditions:

• If stop/check valves are used, make sure that they are fully open.

• Make sure that the hot and cold inlet pipes are connected properly, and that there are no crossconnections or leaking stop/check valves.

• Check the hot water heater output to make sure that it is at least 20° F above the set

temperature.

Be sure to close the appropriate shut-off valves prior to disassembly of the valve and reopen the

valves after inspection and repair is complete.

Problem: Limited water flow

Cause: Dirt and debris have built up in the valve or strainer.

1. Remove and clean strainer. If strainer needs to be replaced, order Bradley part no. 173-028.

2. Check the piston for smooth movement.

To check the valve’s piston for free and smooth movement, follow the procedures outlined below:

1. Remove the valve’s cap and thermostat (see Figure 14 on Page 29).

2. Push down on the piston with your finger (the piston should move freely). If the movement is

not as it should be, the piston needs to be cleaned. Follow the method outlined below for

cleaning the piston and valve body:

• Remove the thermostat.

• Lift the piston out with a needle-nose pliers and remove the spring.

• Any cleaner suitable for brass and stainless steel may be used (if cleaning with suitable cleaner

is not sufficient to remove debris, a 400-grit sandpaper may be used to polish and hone the

piston and valve body).

• Snap spring into piston (will detent) and reassemble into the valve body. Retest the piston.

3. If, after a thorough cleaning, the piston does not move freely, the piston must be replaced.

Contact your Bradley representative and ask for Repair Kit (part number S65-259).

Problem: External leaks in the system

Cause: O-rings have been damaged.

Solution: Replace O-rings where necessary. For replacement of the O-rings, contact your

Bradley representative and ask for Repair Kit (part number S65-259).

Problem: Improper water temperature or temperature fluctuation

Cause: Thermostat is slowly failing or not working at all.

Solution: Check the thermostat for proper operation.

1. At room temperature (80° F or less) remove cap and thermostat.

2. Place thermostat into container with 115° F water. The pushrod should pop out of the

thermostat approximately 1/10".

3. If thermostat pushrod does not pop out, the thermostat must be replaced. Contact your Bradley

representative and ask for Repair Kit (part number S65-259).

Cause: Valve temperature is not properly set.

Solution: Adjust the temperature. Using a blade screwdriver, turn the adjustment stem

counterclockwise to increase the temperature or clockwise to decrease the temperature.

Page 29

Installation TDB3108, WF3208 Terreon®54" Circular

29Bradley Corporation • 215-1187 Rev. N; EN 06-915B 4/6/2007

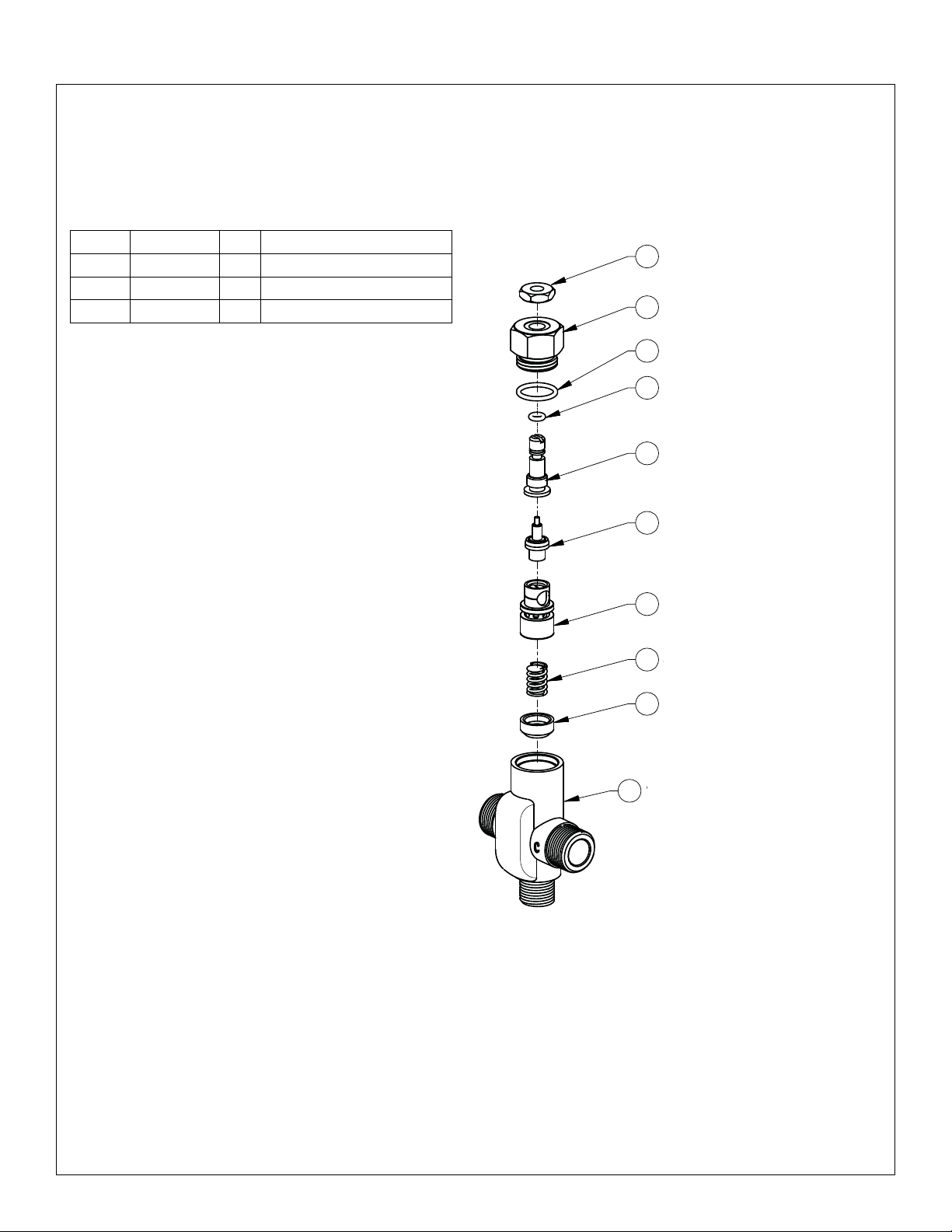

9

6

5

4

3

2

7

8

Spring

Thermostat

Piston

Stem

O-Ring

O-Ring

Cap

Nut 3/8-24 Hex Jam

10

Seal Cup

1

Valve Body

Figure 14

Vernatherm Thermostatic Mixing Valve (S01-525) Parts List — Rep air Kit S65-259

5 S39-413 1 Thermostat

7 125-001BX 1 O-Ring

8 125-157 1 O-Ring

Item Part No. Qty Description

Parts List S65-259 Valve Repair Kit

Page 30

TDB3108, WF3208 Terreon®1372 mm (54") Circulaire Installation

30 6/4/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

Sommaire

Informations sur la pré-installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Modèle TDB3108 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31-33

Modèle WF3208 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Mises en place des tuyauteries du lavabo fontaine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35-36

Information sur l’installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37-47

Nettoyage/Entretien Terreon

®

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Nettoyage/Entretien fibre de verre à enduit gélifié . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Nettoyage/Entretien acier inoxydable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Pièces de réparation de robinet distributeur de savon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50-51

Recommandations de savon et conseils d’entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Guide de dépannage du bec diffuseur et Pièces de réparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Robinet mélangeur manuel (en option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Soupape de régulation de débit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Robinet mélangeur thermostatique Vernatherm™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56-57

Fournitures requises par l’installateur

• (4) tire-fond de 1/2", vis ou autres fixations pour ancrer le socle du lavabo fontaine

• conduites d’alimentation d’eau chaude et d’eau froide de 1" et raccords (consulter les mises en place des

tuyauteries sur les pages 35-36)

• Diminution des raccords et conduites d’alimentation en tubulure de cuivre de 1/2" nom. pour types de

fournitures ci-dessus

• Siphon en P standard (consulter les mises en place de tuyauteries aux pages 35-36, siphon à ventilation

fourni par Bradley le cas échéant)

• conduites de vidange de 2" et raccords (consulter les mises en place des tuyauteries aux pages 35-36)

• Tuyau d’aération ou canalisation de liaison de 1-1/2" sur appareils aérés par le biais de la colonne de

lavabo fontaine (consulter la page 37 pour les longueurs requises)

• Ruban Téflon ou pâte lubrifiante

• Source d’alimentation GFI (interrupteur de défaut à la terre) de 110 V c.a. pour transformateur de

110/24 V c.a. UL Classe II fourni

• EN OPTION : Bradley recommande d’installer un coupe-circuit électrique sur l’unité. Cette fonction

empêche toute distribution d’eau accidentelle durant l’entretien ou les réparations standard.

Informations sur la pré-installation

Matériau Terreon

®

Le lavabo fontaine est construit en Terreon®, matériau de surface massif densifié composé de résine de

polyester. Terreon

®

résiste aux produits chimiques, aux taches, aux brûlures et à l’impact. Les dommages de

surface peuvent être facilement réparés à l’aide de produits nettoyants ordinaires ou d’abrasifs à grains fins.

Terreon

®

est certifié NAHB pour être conforme aux normes ANSI Z124.3, Z124.6 et ANSI/ICPASS-1-2001.

Infrarouge Adaptive

Le bec diffuseur est contrôlé par un robinet électromagnétique, permettant à l’utilisateur d’activer un débit

d’eau. Le détecteur à infrarouge prendra quelques minutes à s’adapter à son environnement lorsque l’unité est

mise sous tension.

Page 31

Installation TDB3108, WF3208 Terreon®1372 mm (54") Circulaire

31Bradley Corporation • 215-1187 Rev. N; EN 06-915B 6/4/2007

Le modèle TDB3108 est conforme ADA.

L’équipement optionnel risque de ne pas

être conforme à toutes les directives

dimensionnelles ADA

Modèle TDB3108 - 1372 mm (54") Circulaire

Modèle TDB3108 - 1372 mm (54")

Circulaire avec accessoires en option

Figure 1a

Figure 1b

1372 mm

(54")

495 mm

(19-1/2")

914 mm

(36")

597 mm

(23-1/2")

254 mm

(10")

1616 mm

(63-5/8")

AVEC

SAVON

1400 mm

(55-1/8")

SANS

SAVON

864 mm

(34")

1111 mm

(43-3/4")

1200 mm

(47-1/4")

152 mm (6")

864 mm

(34")

1111 mm

(43-3/4")

1200 mm

(47-1/4")

1416 mm

(55-3/4")

597 mm

(23-1/2")

254 mm

(10")

495 mm

(19-1/2")

914 mm

(36")

1372 mm

(54")

RÉGLAGE DES TROUS DE FIXATION

DU DISTRIBUTEUR D’ESSUIE-MAINS

54"

(1372)

47-1/4"

(1200)

43-3/4"

(1111)

34"

(864)

23-1/2"

(597)

10"

(254)

A

D

A

•

C

O

M

T

P

N

L

I

A

Adjust to towel dispenser

63-5/8"

(1616)

WITH

SOAP

55-1/8"

(1400)

WITHOUT

SOAP

55-3/4"

(1416)

47-1/4"

(1200)

43-3/4"

(1111)

34"

(864)

10"

(254)

mounting holes

19-1/2"

36"

(914)

6" (152)

(495)

23-1/2"

(597)

36"

(914)

19-1/2"

(495)

54"

(1372)

Page 32

TDB3108, WF3208 Terreon®1372 mm (54") Circulaire Installation

32 6/4/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

Dimensions du lavabo fontaine circulaire (TAS intermédiaire)

TAS

54"

(1372)

19-1/2"

(495)

35-1/2"

(902)

25-1/2"

(648)

12"

(305)

32"

(813)

41-1/8"

(1045)

44-5/8"

(1133)

Modèle TDB3108

1372 mm (54") Circulaire - Hauteur TAS

Modèle TDB3108

1372 mm (54") Circulaire - Hauteur

TAS avec accessoires en option

Figure 1c

Figure 1d

L’équipement optionnel risque de ne pas

être conforme à toutes les directives

dimensionnelles TAS

1372 mm

(54")

495 mm

(19-1/2")

902 mm

(35-1/2")

648 mm

(25-1/2")

305 mm

(12")

1549 mm

(61")

AVEC

SAVON

1334 mm

(52-1/2")

SANS

SAVON

813 mm

(32")

1045 mm

(41-1/8")

1133 mm

(44-5/8")

152 mm (6")

813 mm

(32")

1045 mm

(41-1/8")

1143 mm

(44-5/8")

1353 mm

(53-1/4")

648 mm

(25-1/2")

305 mm

(12")

495 mm

(19-1/2")

902 mm

(35-1/2")

1372 mm

(54")

RÉGLAGE DES TROUS DE FIXATION

DU DISTRIBUTEUR D'ESSUIE-MAINS

Adjust to towel dispenser

mounting holes

61"

(1549)

WITH

SOAP

52-1/2"

(1334)

WITHOUT

SOAP

53-1/4"

(1353)

44-5/8"

(1143)

41-1/8"

(1045)

32"

(813)

25-1/2"

(648)

12"

(305)

35-1/2"

(902)

19-1/2"

(495)

54"

(1372)

6" (152)

Page 33

Installation TDB3108, WF3208 Terreon®1372 mm (54") Circulaire

33Bradley Corporation • 215-1187 Rev. N; EN 06-915B 6/4/2007

Dimensions du lavabo fontaine circulaire (hauteur enfant)

A

D

A

•

C

O

M

P

L

I

A

N

T

54"

(1372)

19-1/2"

(495)

35-1/2"

(902)

23-1/2"

(597)

10"

(254)

30"

(762)

39-1/8"

(994)

42-5/8"

(1083)

Modèle TDB3108

1372 mm (54") Circulaire - Hauteur enfant

Modèle TDB3108

1372 mm (54") Circulaire -

Hauteur enfant avec

accessoires en option

Figure 1e

Figure 1f

L’équipement optionnel risque de ne pas

être conforme à toutes les directives

dimensionnelles ADA ou TAS

1372 mm

(54")

495 mm

(19-1/2")

902 mm

(35-1/2")

597 mm

(23-1/2")

254 mm

(10")

1502 mm

(59-1/8")

AVEC

SAVON

1286 mm

(50-5/8")

SANS

SAVON

762 mm

(30")

994 mm

(39-1/8")

1083 mm

(42-5/8")

762 mm

(30")

994 mm

(39-1/8")

1033 mm

(42-5/8")

1303 mm

(51-1/4")

597 mm

(23-1/2")

254 mm

(10")

495 mm

(19-1/2")

902 mm

(35-1/2")

1372 mm

(54")

RÉGLAGE DES TROUS DE FIXATION

DU DISTRIBUTEUR D’ESSUIE-MAINS

L’équipement optionnel risque de

ne pas être conforme à toutes les

directives dimensionnelles ADA.

152 mm (6")

59-1/8"

(1502)

WITH

SOAP

50-5/8"

(1286)

WITHOUT

SOAP

51-1/4"

(1303)

42-5/8"

(1033)

39-1/8"

(994)

Adjust to towel dispenser

10"

23-1/2"

(597)

(254)

30"

(762)

mounting holes

35-1/2"

(902)

19-1/2"

(495)

54"

(1372)

6" (152)

A

D

A

•

C

O

M

T

P

N

L

I

A

Optional equipment may not

comply with all ADA

dimensional guidelines

Page 34

TDB3108, WF3208 Terreon®1372 mm (54") Circulaire Installation

34 6/4/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

Dimensions du lavabo fontaine circulaire

54"

(1372)

19-1/2"

(495)

37-1/2"

(953)

23-1/2"

(597)

10"

(254)

34"

(864)

43-3/4"

(1111)

47-1/4"

(1200)

Le modèle WF3208 n’est

pas conforme ADA

Modèle WF3208 -

1372 mm (54") Circulaire

Modèle TDB3208 - 1372 mm (54")

Circulaire avec accessoires en option

Figure 1g

Figure 1h

1372 mm

(54")

495 mm

(19-1/2")

953 mm

(37-1/2")

597 mm

(23-1/2")

254 mm

(10")

1616 mm

(63-5/8")

AVEC

SAVON

1400 mm

(55-1/8")

SANS

SAVON

864 mm

(34")

1111 mm

(43-3/4")

1200 mm

(47-1/4")

864 mm

(34")

1111 mm

(43-3/4")

1200 mm

(47-1/4")

1416 mm

(55-3/4")

597 mm

(23-1/2")

254 mm

(10")

495 mm

(19-1/2")

953 mm

(37-1/2")

1372 mm

(54")

RÉGLAGE DES TROUS DE FIXATION

DU DISTRIBUTEUR D’ESSUIE-MAINS

152 mm (6")

Adjust to towel dispenser

mounting holes

6" (152)

63-5/8"

(1616)

WITH

SOAP

55-1/8"

(1400)

WITHOUT

SOAP

55-3/4"

(1416)

47-1/4"

(1200)

43-3/4"

(1111)

34"

(864)

23-1/2"

(597)

10"

(254)

37-1/2"

(953)

19-1/2"

(495)

54"

(1372)

Page 35

Installation TDB3108, WF3208 Terreon®1372 mm (54") Circulaire

35Bradley Corporation • 215-1187 Rev. N; EN 06-915B 6/4/2007

Spécifications de mise en place des tuyauteries

REMARQUE : Les conduites

d’alimentation pour un ou deux

lavabos fontaines doivent être de

1" ; pour trois lavabos fontaines,

de 1-1/4". Pour plus de trois

lavabos fontaines, augmenter les

dimensions de tuyaux

proportionnellement.

REMARQUE : Les conduites

d’alimentation pour un ou deux

lavabos fontaines doivent être de

1" ; pour trois lavabos fontaines,

de 1-1/4". Pour plus de trois

lavabos fontaines, augmenter les

dimensions de tuyaux

proportionnellement.

Figure 2a

Figure 2b

Type B

Aération montante centralement avec

alimentations du dessus.

194 mm

(7-5/8")

194 mm

(7-5/8")

EAU CHAUDE

EAU FROIDE

102 mm

(4")

64 mm

(2-1/2")

EMPLACEMENT

CONSEILLÉ POUR

PRISE ÉLECTRIQUE

DRAIN DE 2" NPT :

ERGOT DE

76 mm (3")

AU-DESSUS DU SOL

CUVETTE DE

1372 mm (54")

22,2 mm

(7/8")

ALIMENTATIONS DE 1" NPT DE

DESSUS DOIVENT SE RÉDUIRE À

TUBE EN CUIVRE DE 1/2" NOM. SUR

CES CENTRES POUR PASSER PAR

LE LAVABO FONTAINE

22,2 mm

(7/8")

EAU FROIDE EAU CHAUDE

102 mm

(4")

32 mm

(1-1/4")

DRAIN DE 2" NPT :

ERGOT DE 76 mm

(3") AU-DESSUS

DU SOL

EMPLACEMENT

CONSEILLÉ

POUR PRISE

ÉLECTRIQUE

CUVETTE DE

1372 mm (54")

102 mm

(4")

AÉRATION DE 1-1/2" NPT

AU PLAFOND

102 mm

(4")

Type A

Aération hors canalisation avec

alimentations de dessous.

ALIMENTATIONS DE 1" NPT

DANS LE SOL : ERGOT DE

64 mm (2-1/2") AU-DESSUS

DU SOL

Page 36

TDB3108, WF3208 Terreon®1372 mm (54") Circulaire Installation

36 6/4/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

Spécifications de mise en place des tuyauteries suite . . .

REMARQUE : Les conduites

d’alimentation pour un ou deux

lavabos fontaines doivent être de

1" ; pour trois lavabos fontaines,

de 1-1/4". Pour plus de trois

lavabos fontaines, augmenter les

dimensions de tuyaux

proportionnellement.

REMARQUE : Les conduites

d’alimentation pour un ou deux

lavabos fontaines doivent être de

1" ; pour trois lavabos fontaines,

de 1-1/4". Pour plus de trois

lavabos fontaines, augmenter les

dimensions de tuyaux

proportionnellement.

Figure 2c

Figure 2d

22,2 mm

(7/8")

ALIMENTATIONS DE 1" NPT DE

DESSUS DOIVENT SE RÉDUIRE À

TUBE EN CUIVRE DE 1/2" NOM. SUR

CES CENTRES POUR PASSER PAR

LE LAVABO FONTAINE

22,2 mm

(7/8")

EAU CHAUDE EAU FROIDE

32 mm (1-1/4")

102 mm

(4")

102 mm (4")

DRAIN DE 2" NPT :

ERGOT DE 76 mm

(3") AU-DESSUS

DU SOL

EMPLACEMENT

CONSEILLÉ POUR

PRISE

ÉLECTRIQUE

CUVETTE DE

1372 mm (54")

Type O

Aération hors canalisation avec

alimentations du dessus.

Type H

Aération montante centralement avec

alimentations de dessous.

194 mm

(7-5/8")

194 mm

(7-5/8")

EAU CHAUDE

102 mm

(4")

EMPLACEMENT

CONSEILLÉ

POUR PRISE

ÉLECTRIQUE

CUVETTE DE

1372 mm (54")

AÉRATION DE

1-1/2" NPT AU

PLAFOND

102 mm

(4")

EAU FROIDE

64 mm

(2-1/2")

DRAIN DE 2"

NPT : ERGOT

DE 76 mm (3")

AU-DESSUS

DU SOL

ALIMENTATIONS DE 1" NPT

DANS LE SOL : ERGOT DE

64 mm (2-1/2") AU-DESSUS

DU SOL

Page 37

Installation TDB3108, WF3208 Terreon®1372 mm (54") Circulaire

37Bradley Corporation • 215-1187 Rev. N; EN 06-915B 6/4/2007

1

Installation du drain

REMARQUE :

Toutes les canalisations

indiquées en lignes discontinues

doivent être fournies par

l’installateur.

METTRE EN PLACE CANALISATIONS D’ALIMENTATION ET DE DRAIN TEL QUE

REQUIS POUR L’INSTALLATION (VOIR PAGES 35-36 POUR MISES EN PLACE DES

TUYAUTERIES DES INSTALLATIONS EN OPTION).

A

ASSEMBLER LE DRAIN À LA DIMENSION INDIQUÉE À LA FIGURE 3 POUR LA

CUVETTE À INSTALLER.

B

t

Figure 3

Table 1 — Dimensions du siphon B

Dim Hauteur standard Hauteur enfant TAS

B 594 mm (23-3/8") 572 mm (22-1/2") 622 mm (24-1/2")

Siphon à aération

(111-024)

Console de canalisation

de liaison en option

(S70-082)

Raccordement de 2" NPT si canalisation de

liaison n’est pas requise (fourni par installateur)

Voir mises en place

de tuyauteries en pages 35-36

pour dimensions non illustrées

Types B, H

Types A, O

Avec console de

canalisation de

liaison en option

Types A, O

B – Voir Table 1

102 mm

(4")

B – Voir Table 1

102 mm

(4")

B – Voir Table 1

102 mm

(4")

Axe du lavabo fontaine

Axe du lavabo fontaine

Axe du lavabo fontaine

Tuyau d’aération ou

canalisation de liaison

(fournis par installateur)

Tuyau d’aération ou

canalisation de liaison

(fournis par installateur)

2" NPT Coupling if Tie

Pipe is not required

(Supplied by Installer)

Centerline of

Washfountain

B – See Table 1

Vent

or

Tie Pipe

(Supplied by Installer)

Centerline of

Washfountain

Types B, H

B – See Table 1

4"

(102)

Vented T rap

(111-024)

4"

(102)

Vent

or

Tie Pipe

(Supplied by Installer)

Centerline of

T ypes A, O

See rough-ins

on Pages 7-8

for dimensions

Washfountain

4"

(102)

B – See Table 1

not shown

Optional

Tie Pipe Bracke

(S70-082)

T ypes A, O

With Tie Pipe

Bracket Option

Page 38

TDB3108, WF3208 Terreon®1372 mm (54") Circulaire Installation

38 6/4/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

2

Montage de l’ensemble cuvette et socle

ATTENTION :

La surface de la cuvette est très lisse. La cuvette

pèse approximativement 86,2 kg (190 lbs.)

Manipuler avec soin !

POSITIONNER LE SOCLE À L’EMPLACEMENT SOUHAITÉ ET MARQUER LA POSITION DES (4) EMPLACEMENTS DE MONTAGE (VOIR

FIGURE 4A).

PLACER L’ENTRETOISE TAS SUR LE SOL SUR LES TROUS DE FIXATION. PLACER LE SOCLE SUR L’ENTRETOISE.

A

FIXER LE SOCLE AU SOL À L’AIDE DE FIXATIONS ADÉQUATES, DE DISPOSITIFS D’ANCRAGE DE 1/2" ET DE BOULONS (FOURNIS PAR

L’INSTALLATEUR). NE PAS SERRER EXCESSIVEMENT .

B

AVEC TROIS OU QUATRE PERSONNES, SOULEVER SOIGNEUSEMENT LA CUVETTE (VOIR FIGURE 4B) SUR LE

SOCLE EN S’ASSURANT QUE LES TROUS DE DRAIN S’ALIGNENT SUR LE DRAIN AU SOL ET ACCOUPLER LES TIGES

FILETÉES AVEC LES ORIFICES ALLONGÉS DANS LE SOCLE À L’AIDE DES NERVURES DE REPÈRE.

C

OPTION TAS :

À L’AIDE DES ÉCROUS À OREILLES DE 1/4" ET DES RONDELLES, FIXER

LA CUVETTE SUR LE SOCLE, À QUATRE ENDROITS.

D

DRAIN

TOP VIEW

FRONT VIEW

TDB 3108 BOWL - 190 LBS.

THREADED RODS

(4) PLACES

LOCATOR RIBS

(4) PLACES

1/4" WASHERS

AND WING NUTS

(4) PLACES

THREADED RODS

(4) PLACES

FLOOR MOUNTING

(4) PLACES

DRAIN

PLACE HANDS

HERE WHEN

LIFTING BOWL

PLACE HANDS

HERE WHEN

LIFTING BOWL

Figure 4a

Figure 4b

DRAIN

VUE DE DESSUS

VUE DE FACE

(4) EMPLACEMENTS DE

MONTAGE AU SOL

PLACER LES MAINS ICI POUR

SOULEVER LA CUVETTE

(4) EMPLACEMENTS DE

TIGES FILETÉES

PLACER LES MAINS

ICI POUR SOULEVER

LA CUVETTE

(4) EMPLACEMENTS

DE NERVURES

REPÈRES

DRAIN

(4) EMPLACENTS

RONDELLES DE 1/4" ET

ÉCROUS À OREILLES

TDB3108 CUVETTE – 86,2 kg (190 lbs.)

(4) EMPLACEMENTS DE

TIGES FILETÉES

Page 39

Installation TDB3108, WF3208 Terreon®1372 mm (54") Circulaire

39Bradley Corporation • 215-1187 Rev. N; EN 06-915B 6/4/2007

3

Installation de l’ergot de drain dans la

cuvette

REMARQUE !

Appliquer du mastic (fourni par

l’installateur) entre l’ergot de drain et

l’orifice de drain.

ATTACHER SANS SERRER L’ERGOT DE DRAIN À LA CUVETTE À L’AIDE DU

CONTRE-ÉCROU ET DE LA RONDELLE COMME L’INDIQUE LAFIGURE 5.

A

SERRER L’ERGOT ET LE CONTRE-ÉCROU CONTRE LA CUVETTE.

B

FIXER LA CRÉPINE À L’ERGOT DE DRAIN À L’AIDE DES VIS FOURNIES.

C

RACCORDER L’ERGOT (OU LE SIPHON B OU LE SUPPORT DE

CANALISATION DE LIAISON) AU DRAIN.

D

ATTACHER LE SIPHON B À L’ERGOT DE

DRAIN.

OPTION SIPHON B :

ATTACHER LE SUPPORT DE

CANALISATION DE LIAISON À

L’ERGOT DE DRAIN.

OPTION CANALISATION

DE LIAISON :

STRAINER

S45-067

SPUD

112-015

BOWL

WASHER

142-068

LOCKNUT

161-021

DRAIN PRE-PACK

S45-273

Figure 5

CRÉPINE

S45-067

TUBULURE

112-015

CUVETTE

RONDELLE

142-068

CONTRE-ÉCROU

161-021

PRÉ-CONDITIONNEMENT

DRAIN

S45-273

Page 40

TDB3108, WF3208 Terreon®1372 mm (54") Circulaire Installation

40 6/4/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

Ensemble à infrarouge Adaptive pour unités à drain A ou

à drain O sans option de canalisation de liaison

4a

Figure 6

INSTALLER L’EXTRÉMITÉ OURLÉE (NON TRANCHANTE) DU TUBE-SUPPORT AVEC LE JOINT DANS LA CUVETTE (VOIR FIGURE 6).

A

CONNECTER LA TUBULURE D’ALIMENTATION DE 1/2" AU BEC DIFFUSEUR AVEC UN CONNECTEUR DE 3/8" NPT AU TUBE DE 1/2" ET

PLACER LE BEC DIFFUSEUR SUR LE TUBE-SUPPORT. FAIRE PASSER LA TUBULURE PAR LE TUBE-SUPPORT ET RACCORDER AU

CONNECTEUR DE TUBE DE ROBINET.

B

PLACER LE FER DE LIAISON SUPÉRIEUR (AVEC LE CRAN AUX DEUX COINS DE CHAQUE EXTRÉMITÉ) SUR LE BEC DIFFUSEUR.

CONNECTER LA TRINGLERIE LA PLUS LONGUE À LA TRINGLERIE DE 4-1/4" À L’AIDE DE L’ÉCROU-RACCORD AVEC LES VIS

CALANTES À TÊTE HEXAGONALE. FAIRE PASSER L’ENSEMBLE DE TRINGLERIE PAR LE FER DE LIAISON SUPÉRIEUR (VOIR ENCART

DE FIGURE 6) ET FIXER DU DESSOUS DE LA CUVETTE À L’AIDE DU FER DE LIAISON INFÉRIEUR (SANS CRANS) ET DE L’ÉCROU

HEXAGONAL AVEC LA VIS CALANTE À TÊTE CREUSE.

C

COUVERCLE

107-099 (A)

107-179 (O)

PRÉ-CONDITIONNEMENT TRINGLERIE

S45-1336

PRÉ-CONDITIONNEMENT

S45-1466

JOINT DE TUBE-SUPPORT

(STD) S57-005

(ENFANT) S57-006

TUBE D’ALIMENTATION DE 1/2"

BEC DIFFUSEUR

S05-054

JOINT DE

TUBE-SUPPORT

125-011

DRAIN

S45-273

ENSEMBLE MODULE I.R.

S50-344

PANNEAU D’ACCÈS

186-1456

A/O

(A illustrée)

ENSEMBLE

MODULE

ACTIONNEUR

BEC DIFFUSEUR

TUBE

D’LIMENTATION

COUVERCLE

FER DE

LIAISON

VUE EN SECTION DE

L’ENSEMBLE D’UNITÉ A/O

PRÉ-CONDITIONNEMENT

TRINGLERIE

ÉCROU-

RACCORD

TRINGLERIE

FER DE LIAISON

PRÉ-CONDITIONNEMENT

FER DE LIAISON

S45-055

ENSEMBLE SOUPAPE

S50-369

TRINGLERIE

176-008A

ÉCROU

ENSEMBLE SOCLE

S17-242

CUVETTE PROFONDE EN TERREON

®

(Cuvette ADAillustrée, cuvette classique en

option) Référence varie en fonction de la couleur

de la cuvette. Contacter représentant Bradley

local pour assistance

ACTUATOR

MODULE

SPRAYHEAD

TIE ROD

PRE-PACK

ASSY.

COUPLING

SUPPLYTUBE

A/O UNIT ASSEMBLY

NUT

SECTION VIEW OF

COVER

TIE

ROD

TIE

BAR

TIE ROD PRE-PACK

S45-1336

I.R. MODULE ASSY.

S50-344

TIE BAR

SUPPORT TUBE

(STD) S57-005

(JUV) S57-006

SUPPORT TUBE

1/2" SUPPLY TUBE

GASKET

125-011

PRE-PACK

S45-055

PRE-PACK

S45-1466

PEDESTAL ASSY.

S17-242

COVER

107-099 (A)

107-179 (O)

NUT

SPRAYHEAD

S05-054

TIE ROD

176-008A

DRAIN

S45-273

TERREON® DEEP BOWL

(ADA bowl shown, classic

bowl is optional)

Part No. varies with color of bowl.

Contact your local Bradley Rep.

for assistance

ACCESS PANEL

186-1456

A/O

(A shown)

VALVE ASSY.

S50-369

Page 41

Installation TDB3108, WF3208 Terreon®1372 mm (54") Circulaire

41Bradley Corporation • 215-1187 Rev. N; EN 06-915B 6/4/2007

Instructions relatives à l’installation suite . . .

COUVERCLE SUPÉRIEUR

Figure 7

ENSEMBLE

MODULE I.R.

S50-344

BEC DIFFUSEUR

S05-054

TUBE-SUPPORT

(STD.) S57-005

(ENFANT) S57-006

ÉCROU-

RACCORD

ENTRETOISE

DISTRIBUTEUR

DE SAVON

TRINGLERIE

(STD.) 21-5/8"

(ENFANT) 18-1/8"

UNITÉ AVEC DRAIN « A » ET MODULE I.R. ILLUSTRÉE,

ÉGALEMENT DISPONIBLE AVEC DRAIN « O »

ÉCROU-

RACCORD

TRINGLERIE

DE 4-1/4"

TRINGLERIE

DE 8-5/8"

COUVERCLE

DE MODULE

FER DE LIAISON

PLACER L’ENSEMBLE DU MODULE À INFRAROUGE SUR LE BEC DIFFUSEUR. FAIRE TOURNER JUSQU’À CE QUE LE MODULE À

INFRAROUGE SE BLOQUE AVEC LE FER DE LIAISON. FAIRE GLISSER DEUX FILS DU MODULE À INFRAROUGE DANS L’ENSEMBLE DU

ROBINET.

D

FIXER LE DESSUS DU MODULE À INFRAROUGE ET LE DESSUS SUPÉRIEUR À L’AIDE DE L’ÉCROU BORGNE ET DE LA VIS CALANTE.

E

POUR UNITÉ O : INSTALLER DES CONDUITES D’ALIMENTATION EN TUBULURE DE CUIVRE DE 1/2" NOMINAL (EN LES FAISANT

PASSER PAR LES TROUS DANS LE DESSUS À TRAVERS LE COLONNE-SUPPORT) ET CONNECTER AUX ROBINETS D’ARRÊT À L’AIDE

DE RACCORDS ADÉQUATS.

F

POUR LES UNITÉS AVEC L’OPTION SAVON, INSTALLER L’ENTRETOISE, LE DISTRIBUTEUR DE SAVON ET LE COUVERCLE À L’AIDE DU

TROISIÈME FER DE LIAISON (LONG DE 8-5/8") ET DU SECOND ÉCROU-RACCORD COMME IL L’EST INDIQUÉ (VOIR FIGURE 7). FIXER

AVEC L’ÉCROU BORGNE ET LA VIS CALANTE.

•

REMARQUE ! Passer à l’étape E pour les unités sans savon.

Page 42

TDB3108, WF3208 Terreon®1372 mm (54") Circulaire Installation

42 6/4/2007 Bradley Corporation • 215-1187 Rev. N; EN 06-915B

Ensemble à infrarouge Adaptive pour unités à drain B ou

à drain H avec option de canalisation de liaison

4b

SUPPORT TUBE

GASKET

125-011

SUPPORT TUBE

(STD) S57-005

(JUV) S57-006

PRE-PACK

S45-1466

VENTED TRAP

111-024

TIE BAR

PRE-PACK

S45-056

PEDESTAL ASSY.

S17-242

COVER

107-185 (B)

107-048 (H)

I.R. MODULE ASSY.

S50-344

1/2" SUPPLY TUBE

SPRAYHEAD

S05-054

DRAIN

S45-273

VALVE ASSY.

S50-369

ACCESS PANEL

186-1456

TERREON® DEEP BOWL

(ADA bowl shown, classic bowl

is optional) Part No. varies with color

of bowl. Contact your Bradley Rep.

for assistance.

B/H

(B shown)

COVER

SECTION VIEW OF

B/H UNIT ASSEMBLY

SPRAYHEAD

ACTUATOR

MODULE

ASSY.

TIE

BAR

SUPPLY

TUBE

Figure 8