Installation

WBD1

WashBar™ Duo

Table of Contents

Safety Information .............................................................2

Supplies Required .............................................................2

Components ...................................................................3-4

Dimensions .....................................................................5-8

Structural Rough-Ins ..........................................................9

Plumbing and Electrical Rough-Ins ................................. 10

WashBar Installation ........................................................11

Aerator Installation ........................................................... 11

Attach Soap Motor and Soap Container Bracket ............12

Control Box and Valve Installation ............................. 13-14

Soap Installation .............................................................. 15

Electrical Connections ..................................................... 16

Adjust Temperature with Water Running ......................... 16

Master Control Box .....................................................17-21

Cleaning and Maintenance .........................................22-23

215-1890 Rev. D; ECO 19-08-012

© 2019 Bradley

Page 1 of 23 7/21/2019

Menomonee Falls, WI 53052 USA

P.O. Box 309

800 BRADLEY (800 272 3539)

+1 262 251 6000

bradleycorp.com

WBD1 Installation

WARNING

Make sure that all water supply lines have been flushed and then completely turned off before beginning

installation. Debris in supply lines can cause valves to malfunction.

Turn OFF electrical power to the electrical outlets, then unplug all electrical units prior to installation. Electrical

power MUST remain off until installation is complete.

Installer's hardware must be appropriate for wall construction. Wall anchors must have a minimum pull-out

rating of 1,000 pounds.

IMPORTANT

Read this entire installation manual to ensure proper installation. When finished with the installation, file this

manual with the owner or maintenance department. Compliance and conformity to local codes and ordinances

is the responsibility of the installer. Product warranties may be found under “Products” on our Web site at

www.bradleycorp.com.

Separate parts from packaging and make sure all parts are accounted for before discarding any packaging

material. If any parts are missing, do not begin installation until you obtain the missing parts.

For standard height mounting, do not exceed the recommended 33.5" distance from the fixture rim to the

finished floor.

Troubleshooting and internal maintenance must be performed by qualified service personnel.

Supplies Required

• (4) #10 fasteners and wall anchors for soap tank brackets (minimum pull-out rating of 100 lbs.)

• 1/2" hot/cold or tempered stub-out

• (1) Dedicated 120V ac, 20A GFCI outlet

• Drill

• Basin Wrench

• Tape Measure

• Phillips Screw Driver

• Flat Head Screw Driver

• 5/16" nut driver

• 5/16" socket (with or without extension)

2 7/21/2019 Bradley • 215-1890 Rev. D; ECO 19-08-012

Installation WBD1

Components

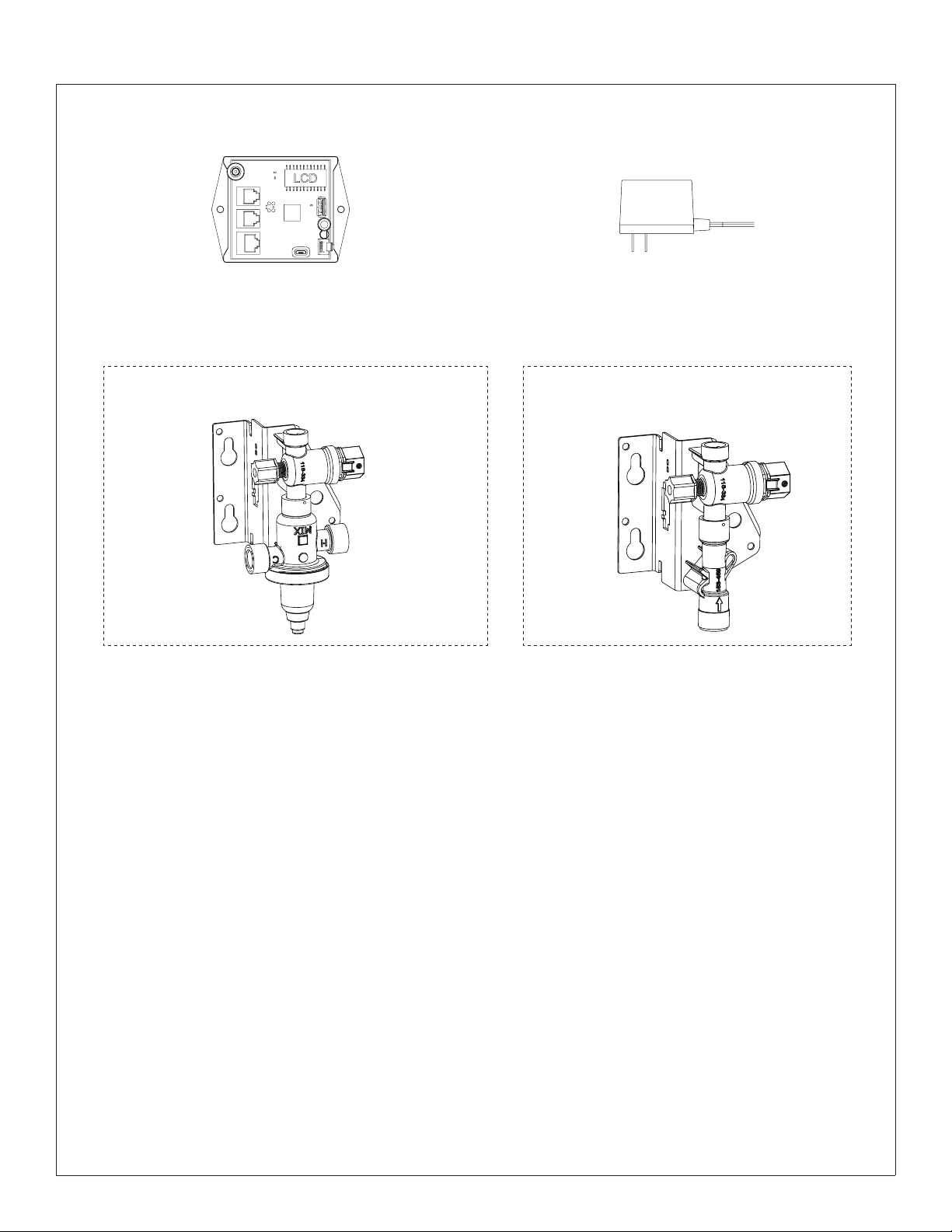

Master Control Box

(S39-845)

#10 x 3/8" Screw (2x)

(P18-054)

DC Lead Free Valve

Assembly, Single TMA

(S08-2401TMA)

Hose/90 Stop Lead Free TMA

(S45-2730)

DC Power

Adapter

(261-147)

DC Lead Free Valve

Assembly, Single TL

(S08-2401TL)

Hose/90 Stop Lead Free TL

(S45-2731)

Bradley • 215-1890 Rev. D; ECO 19-08-012 7/21/2019 3

WBD1 Installation

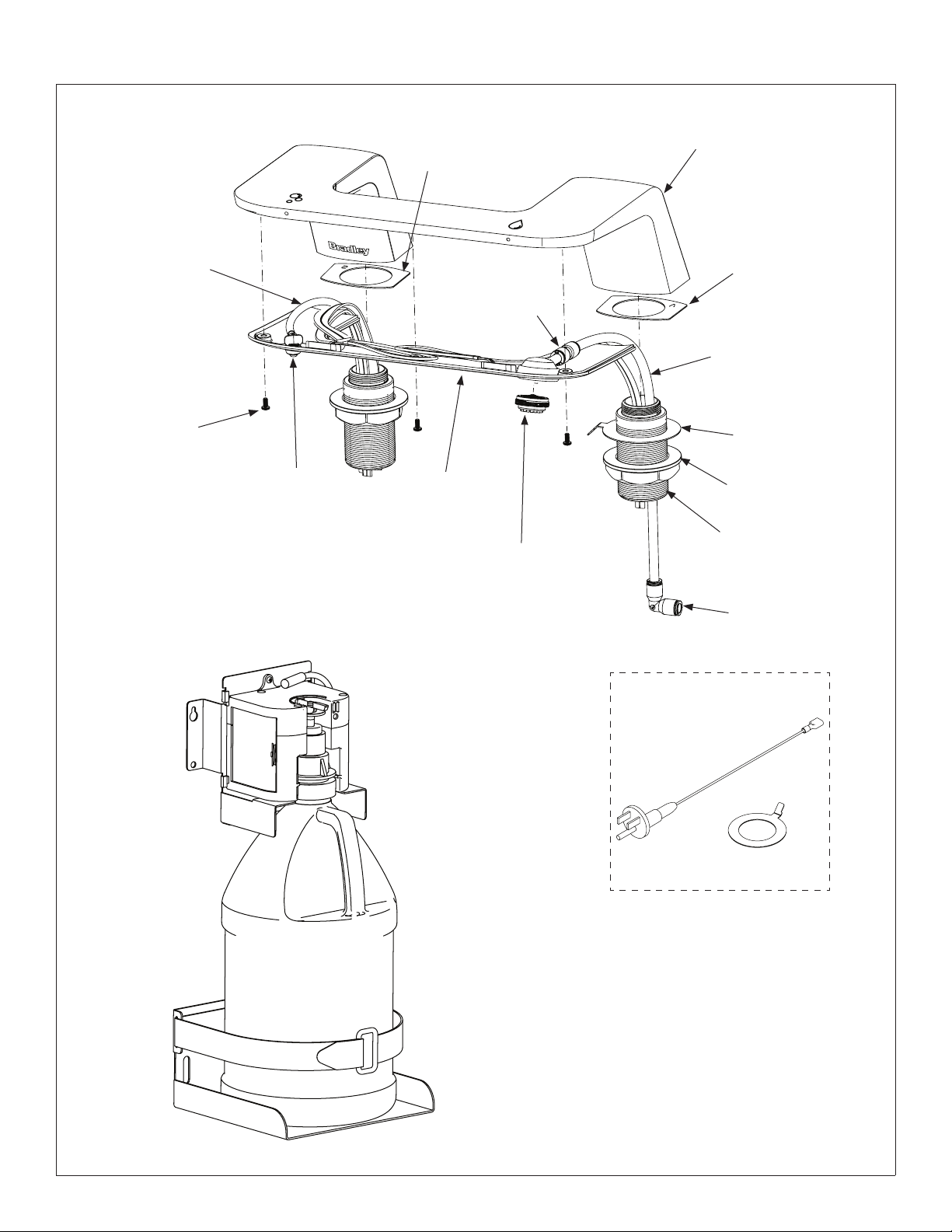

Components

Soap Tube

.20mm OD x 27cm long

(269-2684)

Kit Screws, WBD1

Access Plate (S65-494)

Elbow, 1/4 x 3.4mm

Hose Barb (145-221)

Gasket, WashBar Deck,

Soap Side (124-101)

Union Tube, 1/4" OD

(269-624)

Access Plate and

Hardware Kit (S04-124)

Aerator .50 GPM (S05-175)

Aerator .35 GPM (S05-215)

(Aerators are shipped loose

in bag with red service key)

Casting ASM. WashBar

(WBD1), Chrome w/ LED

(S05-217F01)

Gasket, WashBar Deck,

Faucet Side (124-102)

Union Tube,

1/4" OD x 12"

(269-547E)

WashBar Ground .25"

QC (230-035)

Nut, WashBar,

1-3/8-18

(110-256)

Shank WashBar,

1-3/8" OD

(109-055)

Union Elbow, 1/4"

(269-2531)

Control Box Assembly with

Liquid Pump (S52-166)

Control Box Assembly with

Foam Pump (S52-167)

Liquid Pump with External

Rubber Sleeve Connection

(269-2518)

Foam Pump with Internal

Press Fit Connection

(269-2519)

Gallon Jug

(Supplied by Others)

Hook and Loop Strap

(269-2574)

Grounding Kit, WashBar

(S65-493)

Ground Wire Asembly

1/4" Quick Type B Outlet

(S83-423)

Grounding Washer

1/4" QC (230-035)

Soap Tank Bracket

(140-1171)

4 7/21/2019 Bradley • 215-1890 Rev. D; ECO 19-08-012

Installation WBD1

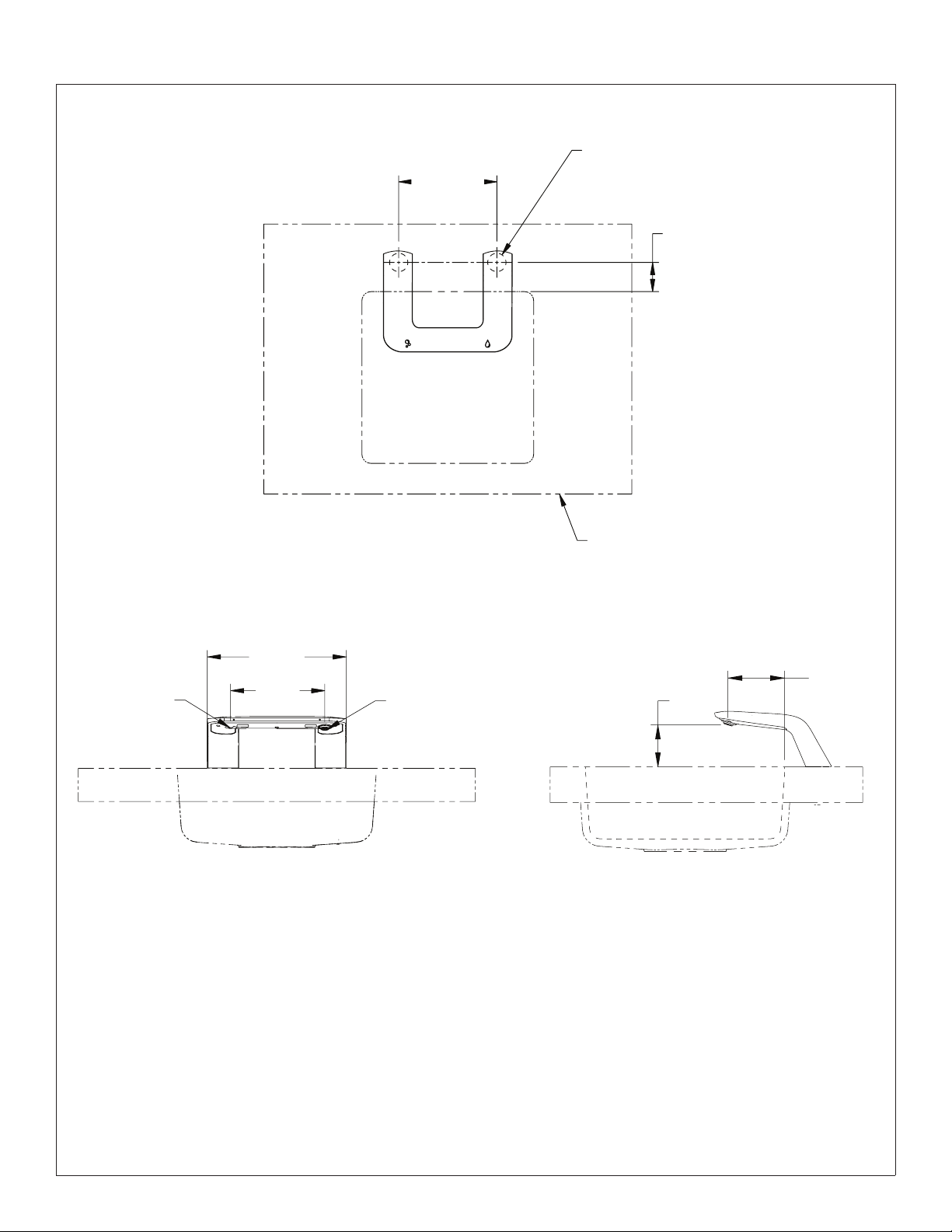

Dimensions - Customer Supplied Countertop with WBD1

ø 1-7/16" (37)

Top View

1-Station shown. Other

configurations are similar.

8" Set"

(203)

Thru Deck (2) Places

(mm)

2-1/2"

(64)

Front View

Soap

10-1/2"

(267)

7-1/8"

(181)

Water

Side View

Lav Deck By Others

3"

(76)

4"

(102)

Bradley • 215-1890 Rev. D; ECO 19-08-012 7/21/2019 5

WBD1 Installation

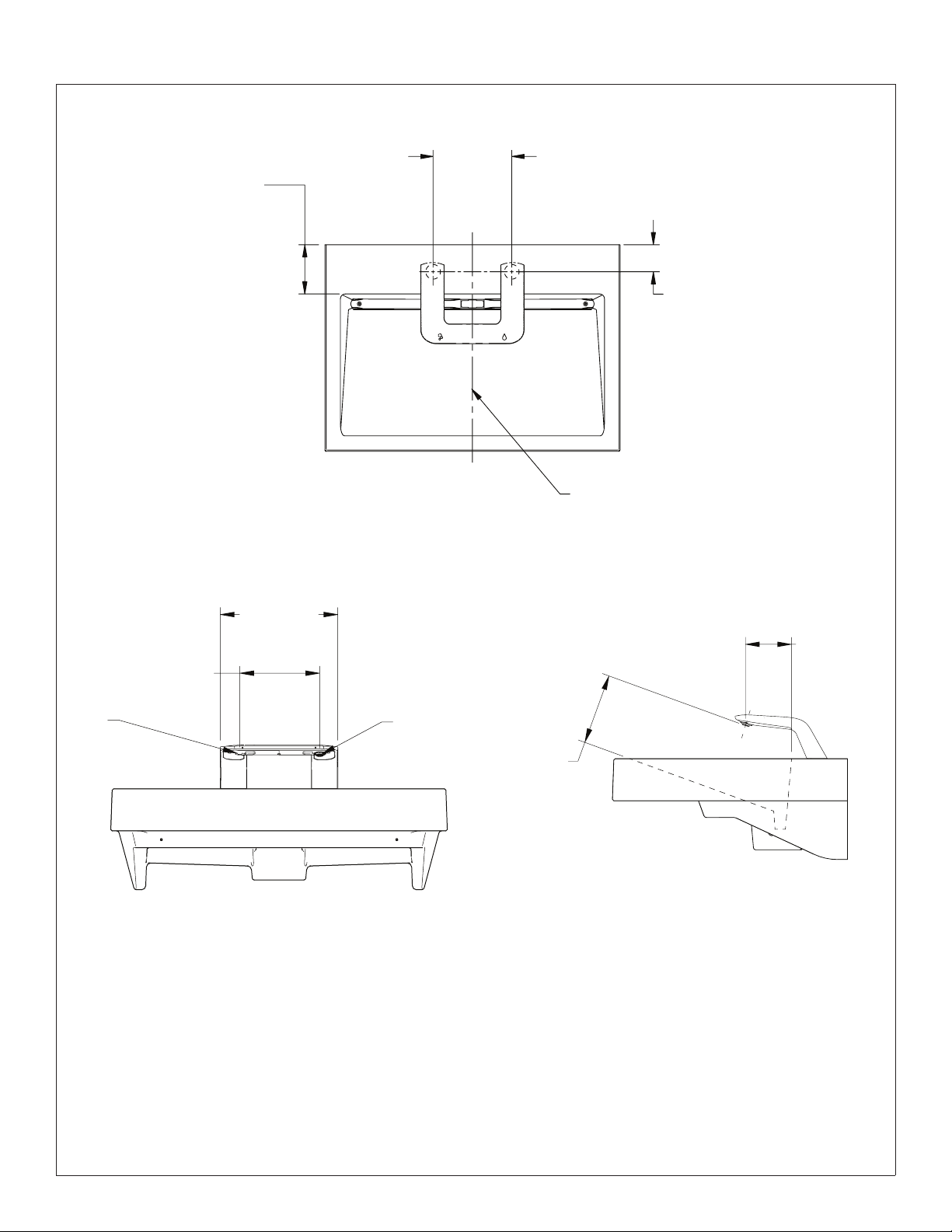

Dimensions - Verge® LVA-Series with WBD1

Top View

1-Station shown. Other

configurations are similar.

5"

(127)

8" Set

(203)

(mm)

2-3/4"

(70)

Lav Centerline

Front View

Soap

7-1/8"

(181)

10-1/2"

(267)

Side View

4-1/8"

(105)

Water

6-3/8"

(160)

6 7/21/2019 Bradley • 215-1890 Rev. D; ECO 19-08-012

Installation WBD1

Dimensions - Verge LVA-Series with WBD1

Side View with Soap

4-1/4"

(107)

6-1/4"

(158)

13-1/2"

(343)

7"

(178)

Bradley • 215-1890 Rev. D; ECO 19-08-012 7/21/2019 7

WBD1 Installation

Dimensions - LD-3010 with WBD1

Top View

1-Station shown. Other

configurations are similar.

5"

(127)

8" Set

(203)

(mm)

3"

(76)

Lav Centerline

Front View

Soap

10-1/2"

(267)

7-1/8"

(181)

Side View

4-1/2"

(114)

Water

6-1/8"

(157)

8 7/21/2019 Bradley • 215-1890 Rev. D; ECO 19-08-012

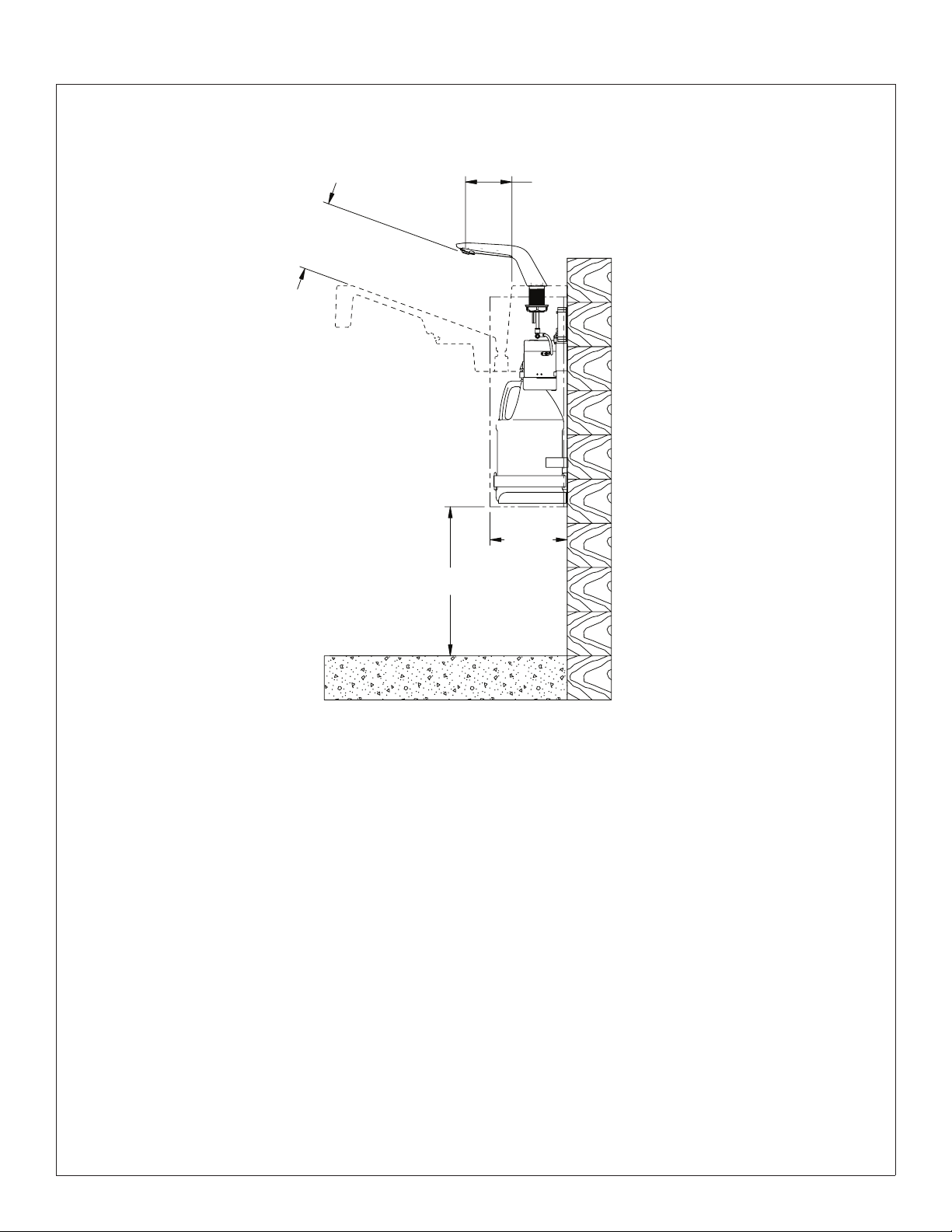

Installation WBD1

Structural Rough-Ins

Standard ADA height shown. Subtract or

add for other accessibility guidelines.

S

5"

(127)

12-7/8"

(327)

C

C

28"

(723)

max.

10-3/8"

(264)

5-1/2"

(140)

(mm)

Typical rough-ins for single

C

L

S

S1S1

3-1/2"

(89)

10-3/8"

(264)

3/4"

(19)

C

C

3-1/4"

(83)

bowl are shown. Other

multiple-bowl rough-ins are

similar.

33-1/2"

(851)

Deck Height

15-5/8"

(396)

Finished Floor

CODE DESCRIPTION QTY.

C*

S #10 Wall Anchors for Soap Control Box Bracket 4

S1 #10 Wall Anchors for Soap Tank Bracket (100 lb pull out force) 4

* "C" roughins for access panel brackets is not needed for customer supplied countertop.

Install wall anchor with a minimum pull-out force of 100 lbs. per local codes at locations shown

RIM HEIGHT VERTICAL HEIGHT ADJUSTMENTS FIXTURE STYLE

34" No Adjustment Standard Height, ADA, TAS

31 Subtract 3" Juvenile, ADA and TAS

33-1/16" Subtract 15/16" OBC

34-1/16" Add 1/16" BCBC and QBC

33-7/8" Subtract 1/8" CSA

4

Bradley • 215-1890 Rev. D; ECO 19-08-012 7/21/2019 9

WBD1 Installation

Plumbing and Electrical Rough-Ins

Standard ADA height shown. Subtract or add for other

accessibililty guidelines.

C

L

(25)

W

H

C

1"

(mm)

9"

(229)

E

33-1/2"

(851)

Deck Height

Tempered

Supply

Finished Floor

1"

(25)

2-1/4"

(57)

17-1/2"

(444)

23-3/4"

(603)

CODE DESCRIPTION QTY.

A 1½" NPT Drain, Stub-out 2" from wall 1

E Dedicated 120V ac, 20A GFCI outlet properly grounded and no more than 4 ft. from the GFCI Outlet. 1

H,C 1/2" nominal (5/8" O.D. Comp.) Hot/Cold supplies, stub-out 2" from wall

* If no GFCI outlet is provided, contact a licensed electrician to assure proper electrical connections in accordance with local building codes.

10 7/21/2019 Bradley • 215-1890 Rev. D; ECO 19-08-012

Installation WBD1

1

WashBar Installation

WashBar comes pre-assembled, with the

exception of the aerator.

Single station shown; multi-station similar.

Assemble WashBar

through deck WashBar

A

holes. Run cables and

tubes as shown.

WashBar

Attach the 1/4" supply

tube to the 1/4" union

elbow after WashBar is

D

assembled to deck.

Connect grounding wire spade

terminal end to grounding washer

tab. Attach grounding wire plug

B

adapter to wall outlet.

2

Aerator Installation

Carefully thread the aerator into

the WashBar casting using the red

service key provided. Ensure no

A

leaks after installation.

Soap Tube (Clear),

LED Cable (Gray),

Soap Sensor Cable (Shorter Cable)

Secure to the underside with nuts.

C

Red Service Key

Aerator

(0.35 gpm or

0.5 gpm)

Bradley • 215-1890 Rev. D; ECO 19-08-012 7/21/2019 11

WBD1 Installation

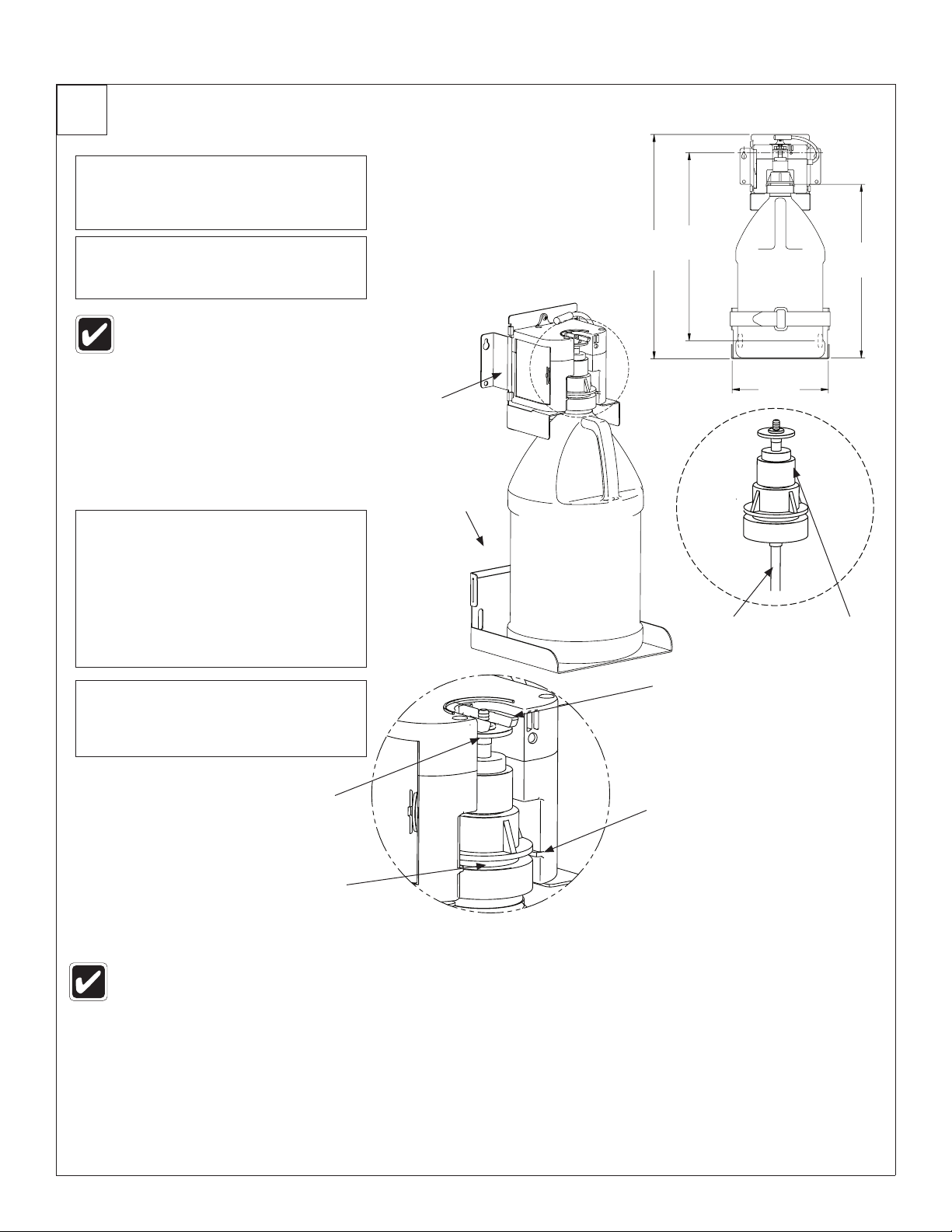

3

Attach Soap Motor and Soap Container Bracket

Attach soap motor control box and

soap container bracket to wall using

#10 fasteners at locations shown in

A

Structural Rough-In drawing.

Install the soap pump onto gallon

container opening (supplied by

B

others).

The liquid soap pump has a rubber

sleeve that fits over the soap

container opening. The foam soap

pump has an interior white cylinder

that fits into the soap container.

This fit up may be tight. Move the

soap pump laterally while applying

pressure to seat into soap container

opening.

To check soap fitup, slide gallon jug

with soap pump into soap motor

control box. Ensure soap pump flange

is positioned below motor control box

lever and soap control box flange

C

is positioned in soap pump groove.

Gallon jug should rest on soap

container bracket without soap pump

pulling off of container.

Soap Motor

Control Box

Soap

Container

Bracket

15-1/2"

(394)

13"

(330)

Soap Supply

Tube

12"

(305)

6-5/8"

(168)

Liquid soap pump

shown. Foam soap

pump similar.

Once fitup is correct, remove soap

container with pump attached and set

D

aside. Soap container will be installed

in a later step.

Soap Pump

Flange

Soap Pump

Groove

Reference LVA Series and LD-3010 Series installation manuals for instructions on

bracket assembly, drain assembly, p-trap assembly and access panel assembly.

Motor Control

Box Lever

Soap Control

Box Flange

12 7/21/2019 Bradley • 215-1890 Rev. D; ECO 19-08-012

Installation WBD1

4a

B

Control Box and Valve Installation - Customer Supplied Countertop

3" (76mm) max

6-3/4"

(172)

9-3/4"

(249)

Attach 1/4" supply tube from the

WashBar to the 1/4" supply valve

outlet. Loosen the compression

nut on the valve body. Push the

1/4" supply tube firmly into the

tube connector until it is fully

seated. Tighten the compression

nut by hand.

Secure master control box

to wall at this approximate

location using #10

A

fasteners (supplied by

installer).

12-1/4"

(314)

16"

(406)

max

Bradley • 215-1890 Rev. D; ECO 19-08-012 7/21/2019 13

WBD1 Installation

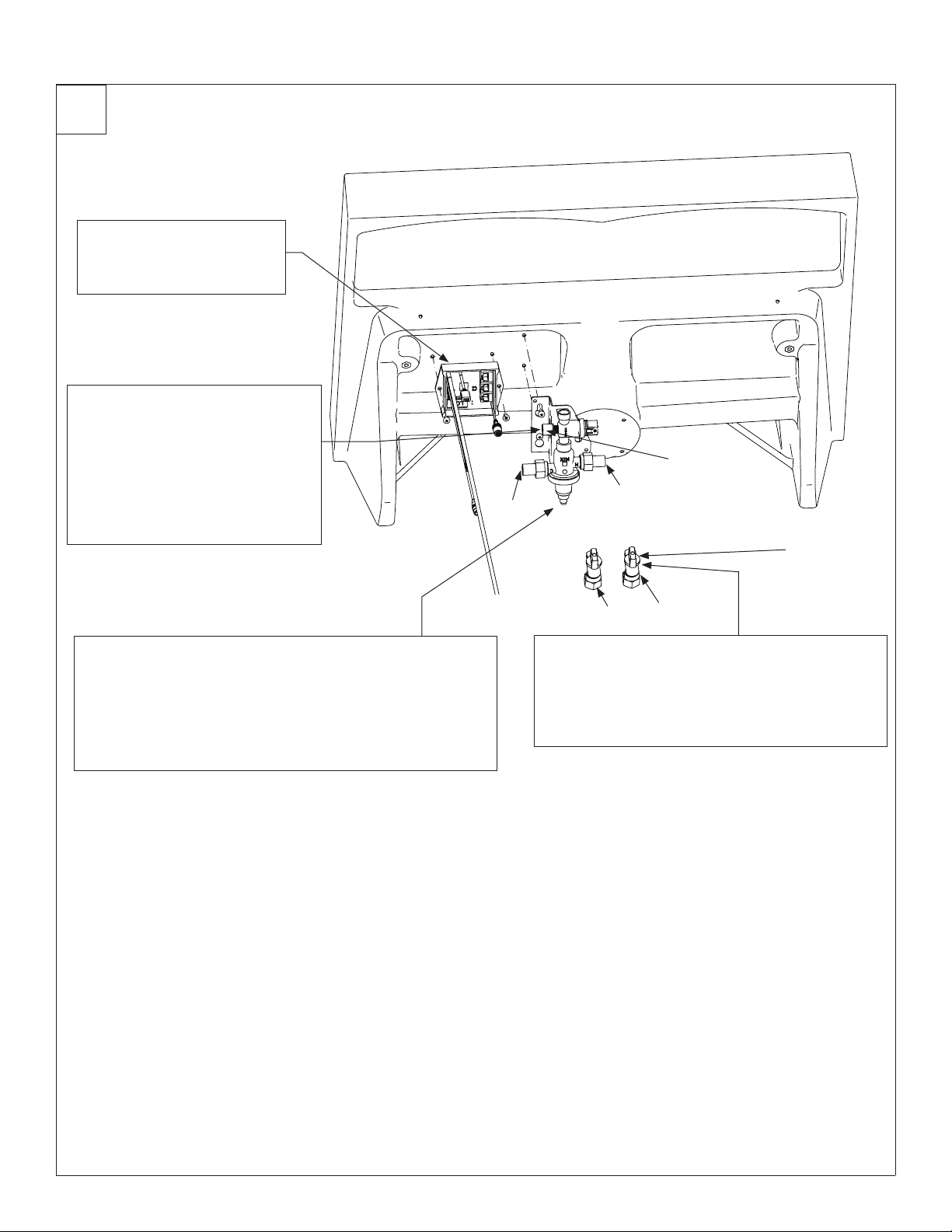

4b

B

Control Box and Valve Installation - LVA and LD-3010 Decks

LVA is shown. LD-3010 is similar.

Secure control box to

underside of bowl using

A

(2) #10 x 1/2" long screws

provided.

Attach 1/4" supply tube from the

WashBar to the 1/4" supply valve

outlet. Loosen the compression

nut on the valve body. Push the

1/4" supply tube firmly into the

tube connector until it is fully

seated. Tighten the compression

nut by hand.

Cold

Hot

1/4" Water Supply

Outlet with

Compression Nut

3/8"

Compression

Nut

For thermostatic mixing valve installation, secure 1/2" supply

hose to hot water supply valve inlet. Secure the other supply

hose from cold water supply to cold water supply valve inlet.

Secure valve to bowl using (2) #10 x 1/2" long screws.

C

For tempered line installation, secure 1/2" supply hose

to tempered water supply and TL valve inlet (not shown).

Secure valve to bowl using (2) #10 x 1/2" long screws.

Hot Supply/Stop Valve

Remove 3/8" compression nut/sleeve from the

hot and cold supply stop valves. Connect 3/8"

end of flexible supply hose to 3/8" compression

D

on supply stop valve. Ensure hot and cold supply

hoses are connected to hot and cold supply stop

valve. For TL option, only connect cold supply.

Cold Supply/

Stop Valve

14 7/21/2019 Bradley • 215-1890 Rev. D; ECO 19-08-012

Installation WBD1

5

Soap Installation

Attach soap supply tube from the

WashBar to the top of the soap pump.

A

Attach soap pump with supply tubes

attached into gallon jug.

B

Slide gallon jug with soap pump into

soap motor control box. Ensure soap

pump flange is positioned below motor

control box lever and soap control

box flange is positioned in soap pump

C

groove. Gallon jug should rest on soap

container bracket without soap pump

pulling off of container.

Use the hook and loop strap provided

to secure container to soap bracket.

Feed end of cable tie (smooth side

facing you) through the right side slot

D

of bracket flange at top. Feed through

left side flange slot and wrap around

jug. Secure with hook and loop end.

The soap system is designed to be used with a standard

U.S. gallon soap container. For accurate low soap

indication, user needs to set soap type (see configuration

mode at the end of this manual on how to set soap type.

Soap cycle count defaults to liquid soap configuration. If

you have the foam soap option, please see Setting the

Soap Type under Configuration Mode towards the end of

this manual.

Attach Soap Supply Tube Here

Soap Pump

Ensure Soap Pump

Flange is Positioned

Below Control Box Lever

Ensure that the soap tube is not

kinked. Position hand above soap

E

motor control box and adjust tube if

needed.

To manually prime the soap, press

down on the control box lever arm 6

F

to 8 times.

For ease of soap container

removal, pull tank while rotating

bottom of tank out.

Top Flange

Cable Tie Slot

Control Box

Flange

Soap Pump

Groove

Hook and Loop Strap

Soap Container

Bracket

Bradley • 215-1890 Rev. D; ECO 19-08-012 7/21/2019 15

WBD1 Installation

6

Air/Water Sensor

Board Connector

WashBar (Shorter

Cables - Red)

Board Connector

- From WashBar

Sensor Cables)

Electrical Connections

Each WashBar requires the same connections.

Connect DC power adapter male barrel

plug into master control female barrel

B

plug. Plug the DC power adapter into

the GFCI wall outlet.

(Red) - From

of 2 Sensor

Soap Sensor

(Longer of 2

LED Board

Connector - From

WashBar

(Gray Cable)

Not Used

USB for Software

Upgrades

Connector Plug

to DC Valve Plug

Make barrel plug and

connector plug connections

C

as shown.

Female Barrel

Plug to Soap

Motor Control Box

Male Barrel Plug

Make (3) connections from

the WashBar assembly as

shown (Water Sensor, Soap

A

Sensor and LED)

7

Adjust Temperature with Water Running

WARNING This valve is NOT factory

preset. Upon installation,

the temperature of this

valve must be checked and

adjusted to ensure delivery

of a safe water temperature.

Water in excess of 110°F

(43°C) may cause scalding.

After all connections are made,

reference Master Control Box:

System Startup section later in

D

this manual.

Loosen Cap Screw about 1/4" (4-6

turns) and lift up cover (do not

A

remove).

Using cover, turn cartridge gently until

desired water temperature is reached.

B

Do not turn past stops as this may

damage unit. Push cover down and

tighten screw.

Connector Plug to

Dryer Motor

(Gray Cable)

(Not Used for WBD1)

H

C

16 7/21/2019 Bradley • 215-1890 Rev. D; ECO 19-08-012

Installation WBD1

Master Control Box

Scan to watch maintenance and

troubleshooting videos for the WashBar!

6V Power LED Over Current LED LCD

12V 2A

Barrel Plug

Status LED

Sensor Board 1

Connector

Sensor Board 2

Connector

LED Board

Connector

System Startup

Before providing power to WashBar, make sure the area under the WashBar is clear of any obstructions and

that sensors are clear.

USB Connector

Soap Cable

Water Valve Cable

(Female)

Proximity Cable (USB

1.1 Mini B, Female)

The first time the WashBar is powered up, there is a sequence of LEDs that will light up.

• Within 5-10 seconds of receiving power, the WashBar will cycle it's LED lights RED, GREEN and then BLUE. Once

the LEDs turn blue, the WashBar is in Standy/Idle Mode.

If any of the WashBar LEDs flash RED, check for sensor obstruction. Once obstruction is removed or

cleaned, the WashBar LEDs will return to blue indicating that the WashBar is in Standby/Idle Mode.

• The power LED on the master control box will be GREEN indicating the unit has power.

The first time the WashBar is powered up, there is a series of items displayed on the LCD screen.

• Control software revisions (ex. "000")

• Control software type ("2-1" is for a system with no dryer, "3-1" is for a system with a dryer).

The control box can be configured for either system. See website for instructions on how to change system

"FLAG" or contact Bradley customer service.

Bradley • 215-1890 Rev. D; ECO 19-08-012 7/21/2019 17

WBD1 Installation

Master Control Box: Operation Modes

Standby/Idle Mode

Standby/Idle mode is automatically activated when the WashBar is not in use. All of the sensors (soap, water) are active in this

mode. When any sensor is activated (soap, water or approach), the WashBar will exit Standby/Idle Mode.

LED Indicators Meaning

All blue dimmed Default/normal

All blue User option, See Configuration Mode

All Off User option, See Configuration Mode

Only Soap LED solid red Low soap (Reset: Hold hand under soap sensor until red

LED turns off, approximately 13 seconds.)

Only Water LED solid red Sensor board error

Soap and water LED solid

red

Any Flashing Red LED Water or soap has timed-out. This is caused by a obstructed

Low soap and sensor board error

sensor. Remove obstruction or wipe sensors with microfiber

cloth to prevent from scratching sensor. System will return

operational automatically once cleared.

Operation Mode

Operation mode is the normal dispensing/washing mode automatically activated when the WashBar is in use. All of the sensors

(soap, water) are active in this mode.

While in operating mode:

• The soap and water can activate at the same time.

• When a water sensor is still detecting an object after 30 seconds, the water will shut off and wait for a no-detect before

becoming ready again.

• To reset low soap, hold hand under soap for 13 seconds (see table below for low soap indicator LED).

• When a soap sensor is still detecting an object after 15 seconds, the soap will prime for 30 seconds or until a no-detect

occurs before becoming ready again. If an object continues to block the soap sensor after the prime cycle the LED will flash

red until obstruction is removed. An obstruction can be a dirty sensor window.

LED Indicators Meaning

All blue bright Ready Mode

Green bright Dispensing soap or water

Only Soap LED solid red Low soap (Reset: Hold hand under soap sensor until red

LED turns off, approximately 13 seconds)

Only Water LED solid red Sensor board error

Soap and water LED solid red Low soap and sensor board error

Any Flashing Red LED Water or soap has timed-out. This is caused by a

obstructed sensor. Remove obstruction or wipe sensors

with microfiber cloth to prevent from scratching sensor.

System will return operational automatically once

cleared.

18 7/21/2019 Bradley • 215-1890 Rev. D; ECO 19-08-012

Installation WBD1

WashBar Sensor Location

12

Underside of WashBar

Sensor

Sensor

Cleaning Mode

Cleaning mode temporarily locks out the WashBar for approximately 30 seconds. All of the sensors (soap, water) are inactive in

this mode. After 30 seconds, the WashBar will exit Cleaning Mode and return to Standby/Idle Mode. Use a soft cloth and ethyl

alcohol or water to clean WashBar access plates/sensor windows.

To activate Cleaning Mode:

1. Place a hand under the water sensor and then immediately (within 1 second) under the soap sensor and hold hands

under both water and soap sensors for approximately 5 seconds until all LED lights turn solid white. Some water and

soap will dispense during the initial 5 seconds needed to enter Cleaning Mode. To avoid soap or water on hands, block

sensors located just to the left of the water nozzle and right of the soap nozzle.

2. Remove hands only when all LED lights turn solid white.

LED lights may flash and cycle different colors. To activate this mode, only remove hands once all LED lights

are solid white.

Configuration Mode

Configuration Mode is when the user can configure the WashBar or obtain cycle counts for soap and water. All of the sensors

(soap, water) are active in this mode. After 10 seconds of no use, the WashBar will slow flash all LEDs green and then return to

Standby/Idle Mode.

To activate Configuration Mode:

1. Place a hand under the water sensor and then immediately (within 1 second) under the soap sensor and hold hands

under both water and soap sensors for approximately 10 seconds until all LED lights turn solid red. Some water and soap

will dispense during the initial 5 seconds needed to enter Configuration Mode. To avoid soap or water on hands, block the

sensors located just to the left of the water nozzle and right of the soap nozzle.

2. Remove hands only when all LED lights turn solid red.

LED lights may flash and cycle different colors. To activate this mode, only remove hands once all LED lights

are solid red.

While in Configuration Mode, LED lights will be solid red unless changing configurations.

Setting the Soap Type

If the WashBar is set to the correct soap type, the low soap indicator will display low soap at 80% empty as intended. If not set

correctly, a liquid soap system will be empty before indicator lights up if set to foam and a foam soap system will be 60% empty if

set to liquid.

To set soap type, while in Configuration Mode:

1. Hold hand under soap sensor for 5 seconds to start selection process. Selection options will cycle until hand is removed.

2. Continue to hold hand under soap until desired setting color is shown then remove hand while color is being displayed.

• Red LED: Liquid Soap (3200 dispensing cycles occur before low soap counter needs to be reset. This is the Default

setting when WashBar is reset.)

• Blue LED: Foam Soap (4000 dispensing cycles occur before low soap counter needs to be reset.)

Bradley • 215-1890 Rev. D; ECO 19-08-012 7/21/2019 19

WBD1 Installation

Setting the LED Lights ON (Bright) / ON (Low) / OFF for Standby/Idle Mode

To set the LED lights to ON (Bright) / ON (Low) / OFF for Standby/Idle Mode, while in Configuration Mode:

1. Hold hand under water sensor for 5 seconds to start the selection process. Selection options will cycle until hand is

removed.

2. Continue to hold hand under water until desired setting color is shown then remove hand while color is being displayed.

• Blue LED (Bright): standby LEDs ON (default when WashBar is reset)

• Blue LED (Low): Standby LEDs slightly dimmer

• LED Off: standby LEDs OFF

Reset Mode

Reset mode is when the user can reset all WashBar settings back to their default settings. This removes all custom configuration

options but does not reset counters. Counters cannot be reset. All of the sensors (soap, water) are active in this mode. Once the

WashBar has been reset, it will automatically return to Standby/Idle Mode.

To reset the WashBar:

1. Place a hand under the water and then immediately (within 1 second) under the soap sensor and hold hands under both

water and soap sensors for approximately 20 seconds until all LED lights turn solid green.

2. Remove hands once all LED lights turn solid green. WashBar has now been reset and will return to Standby/Idle Mode. If

foam soap is being used, the soap type will need to be set to foam. If this step is not done, the low soap indicator will not

be accurate. See Configuration section "Setting the Soap Type."

LED lights may flash and cycle different colors. To reset the WashBar, only remove hands once all LED lights

are solid green.

24 Hour Water Purge

If water has not been used within 24 hours, the WashBar will automatically run water for 5 seconds. This is not configurable by the user.

Software Update

Software revisions can be found at

www.bradleycorp.com/software-updates/washbar

The master control board software can be updated using a USB flash drive. To update

the software:

1. Download the desired software revision into the ROOT directory of a USB

flashdrive (do not copy file in any folder).

2. Place the USB flash drive containing the desired software into the master

control board.

3. DO NOT REMOVE FLASH DRIVE until status LED on master control board

turns off and LED lights on WashBar turn all BLUE to indicate update is

complete.

LEDs may turn off after ALL have flashed BLUE if standby LED setting is set to "OFF". RED LEDs may be

solid if low soap or board error has occurred or Flashing RED if sensor is blocked.

4. Remove USB flash drive if desired. Leaving USB flash drive in master control board will not affect WashBar performance.

Software version will display on the LCD screen. Software can be reversed to a previous version by having

only an earlier version of the software on the USB flash drive.

LCD Display

USB Port

Status LED

20 7/21/2019 Bradley • 215-1890 Rev. D; ECO 19-08-012

Installation WBD1

Displaying Software Revision and Cycle Counts on LCD Display

The master control board has an LCD screen that continuously displays information about the software version and cycle counts

for the soap and water. To view the LCD display:

5. Open the access panel.

6. Locate the LCD screen on the master control board. The display will cycle through the software revision and counts.

Cycle counts are displayed x1000 (ex. 65 = 65,000)

• REV followed by the software revision

• SOP followed by the soap cycle count

• H2O followed by the water cycle count

Bradley • 215-1890 Rev. D; ECO 19-08-012 7/21/2019 21

WBD1 Installation

Cleaning and Maintenance for Terreon

Material Description: Terreon is a densified solid surface material composed of bio based resin and is resistant to chemicals,

stains, burns and impact. Surface can be easily repaired with everyday cleansers or fine grit abrasives. Because Terreon is a

unique cast material, its aggregate flow and distribution, and shades of color can vary from product to product creating natural

characteristics.

Routine Cleaning: For regular cleaning, use mild neutral base cleaners.

Stubborn Stains: Remove tough stains with Soft-Scrub® and a green Scotch-Brite® pad or lightly sand in a circular motion with

240 grit wet/dry sandpaper. The finish can then be renewed with a maroon Scotch-Brite pad.

Scratches: Remove scratches with a green Scotch-Brite pad. The finish can then be renewed with a maroon Scotch-Brite pad.

Hard Water Deposits: Remove hard water deposits with a mild solution of vinegar and water. Always rinse the unit thoroughly

after cleaning.

Restoring the surface:

colors may require additional care and maintenance. For complete instructions on this additional maintenance, visit bradleycorp.com.

Repair Kits: Terreon repair kits are available. Contact your Bradley representative or distributor for part numbers and pricing.

Repair kits are made to order and have a shelf life of 30 days.

Use Hope’s® Perfect Countertop to refresh and protect the Terreon Solid Surface material. Dark Terreon

®

NOTICE! Do not use strong acid or alkaline chemicals and cleaners to clean Terreon. If these chemicals

come in contact with the surface, wipe them off immediately and rinse with soapy water. Avoid

contact with harsh chemicals such as paint remover, bleach, acetone, etc. Avoid contact with hot

pans and objects.

Cleaning and Maintenance for Stainless Steel

Material Description: Stainless steel is extremely durable, and maintenance is simple and inexpensive. Proper care, particularly

under corrosive conditions, is essential. Always start with the simplest solution and work your way toward the more complicated.

Routine cleaning: Daily or as often as needed use a solution of warm water and soap, detergent, or ammonia. Apply the

cleaning solution per the manufacturer's instructions and always use a soft cloth or sponge to avoid damaging the finish.

Stubborn Stains: To remove stains from stainless steel use a stainless steel cleaner and polish such as Ball® stainless steel

cleaner or a soft abrasive. Always follow the manufacturer's instructions and apply in the same direction as the polish lines.

NOTICE! Never use ordinary steel wool or steel brushes on stainless steel. Always use stainless steel wool

or stainless steel brushes.

Fingerprints and Smears: To remove fingerprints or smears use a high quality stainless steel cleaner and polish in accordance

with the manufacturer's instructions. Many of these products leave a protective coating that helps prevent future smears and

fingerprints.

Grease and Oil: To remove grease and oil use a quality commercial detergent or caustic cleaner. Apply in accordance to the

manufacturer's instructions and in the direction of the polish lines.

Precautions: Avoid prolonged contact with chlorides (bleaches, salts), bromides (sanitizing agents), thiocyanates (pesticides,

photography chemicals, and some foods), and iodides on stainless steel equipment, especially if acid conditions exist.

NOTICE! Do not permit salty solutions to evaporate and dry on stainless steel.

The appearance of rust streaks on stainless steel leads to the belief that the stainless steel is rusting. Look for the actual source

of the rust in some iron or steel particles which may be touching, but not actually a part of the stainless steel structure.

NOTICE! Strongly acidic or caustic cleaners may attack the steel causing a reddish film to appear. The use

of these cleaners should be avoided.

Brand Names

Use of brand names is intended only to indicate a type of cleaner. This does not constitute an endorsement, nor does the

omission of any brand name cleaner imply inadequacy. Many products named are regional in distribution, and can be found in

local supermarkets, department and hardware stores, or through your cleaning service. It is emphasized that all products should

be used in strict accordance with package instructions.

22 7/21/2019 Bradley • 215-1890 Rev. D; ECO 19-08-012

Installation WBD1

Cleaning and Maintenance for WashBar

Wipe top and underside of WashBar with a mild neutral based cleaner. Dry with a soft cloth to avoid micro scratches in the

WashBar finish and sensor plates.

Cleaning and Maintenance for Trench Drain

Depending on application and usage, it is recommended that the drain cap and strainer be removed for regular trench drain

cleaning 2-3 times a month.

Liquid Soap Recommendations and Dispenser Maintenance

Overview

Quality soap dispensers require good quality soap and periodic maintenance to properly operate. Bradley soap dispensers will

provide dependable, consistent operation over the long term when soap with reasonable viscosity and pH levels are used and

when a minimal amount of periodic maintenance is performed on the valves. Most soap dispenser problems are caused by soap

that is too thick or corrosive, or by a lack of maintenance. Many soaps come in concentrate form which must be diluted with water.

Often, the soap is improperly diluted or used straight out of the bottle, which causes clogging and valve failure. If proper soap is

being used, valves that have never been cleaned are usually the source of dispensing problems. With proper maintenance and

soap, Bradley dispensers will provide long term, trouble free operation.

Viscosity

Soap thickness is determined by a measurement called viscosity. Soap viscosity should be between 100 cps (centipoise) and

2500 cps for all Bradley soap dispensers. Thick soaps flow slower and inhibit the “flushing” action of the valves, which allows the

soap to congeal in the valve and cause clogs.

pH Level

The pH (acid) level of the soap should be in the range of 6.5 to 8.5. More acidic soaps (pH levels lower than 6.5) will corrode

metal parts (even stainless steel!!) and degrade rubber and plastic components. They will also cause skin irritation. Most

inexpensive soaps (typically the pink lotion type) fall into this acidic category and will eventually cause valve failure and metal

corrosion.

CAUTION Base soaps (pH levels higher than 8.5) will cause skin irritation and swelling or degradation of

rubber and plastic parts.

Soap Valves

Valves must also be maintained (cleaned) to function properly. At the very minimum, hot water should be pumped through valves

periodically to clear out soap residue. Ideally, valves should occasionally be soaked for 30 minutes in hot water or a soap valve

cleaning solution. The valve should be pumped at least 20 times while it is soaking to clear any clogs. The soap reservoir should

also be flushed with hot water. In cases of extreme clogging, the valve should be disassembled and the parts should be soaked

in hot water or cleaning solution to restore proper functioning. Generally, any quality soap meeting the viscosity and pH guidelines

above will work well with Bradley soap dispensers. PCMX or Isopropanol based antibacterial soaps (within viscosity and pH limits)

will also work with Bradley dispensers. Soaps satisfying these basic guidelines will provide consistent flow and reduce clogs.

Bradley • 215-1890 Rev. D; ECO 19-08-012 7/21/2019 23

Loading...

Loading...