Page 1

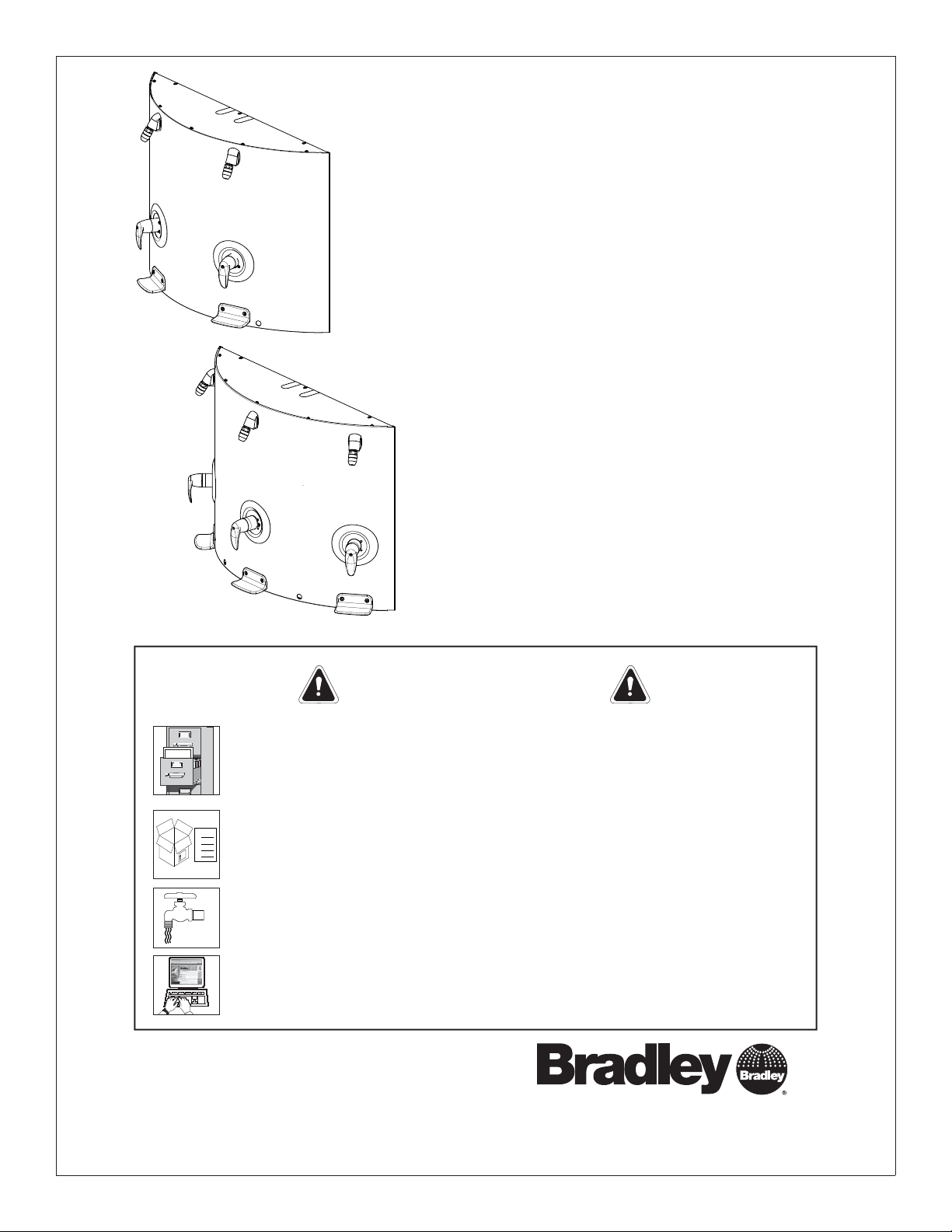

WS-2WMD

Installation

Wall-Saver Shower

WS-2WMD, WS-3WMT

Supplies Required ................................................. 2

Dimensions ............................................................ 2

Installation ............................................................. 3

Optional Vertical Shroud Installation ...................... 3

Optional Horizontal Shroud Installation ................. 4

Cleaning Instructions ............................................. 4

WS-3WMT

Installation

Packing List

•

•

•

THIS

SIDE

•

UP

IMPORTANT!

Read this entire installation manual to ensure proper installation. When

fi nished with the installation, fi le this manual with the owner or maintenance

department. Compliance and conformity to local codes and ordinances is

the responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for

before discarding packaging material. If any parts are missing, do not begin

installation until you obtain the missing parts.

Make sure that all water supply lines have been fl ushed and then completely

turned off before beginning installation. Debris in supply lines can cause

valves to malfunction.

Product warranties may be found under “Products” on our web site at

bradleycorp.com.

215-1706 Rev. A EN 11-03-001A

© 2011 Bradley Corporation

Page 1 of 4 8/23/2011

P.O. Box 309, Menomonee Falls, WI USA 53052-0309

PHONE 800.BRADLEY (800.272.3539) FAX 262.251.5817

bradleycorp.com

Page 2

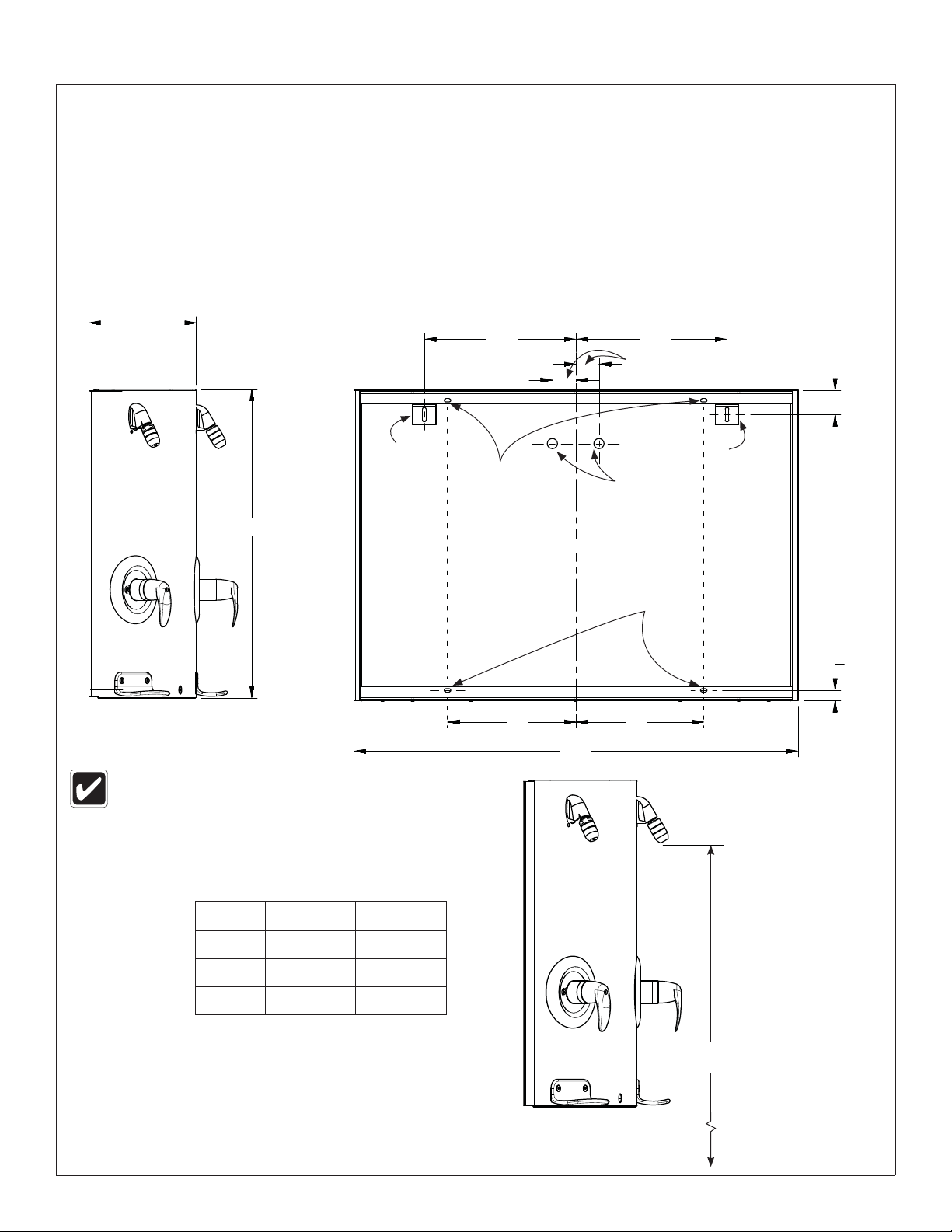

WS-2WMD, WS-3WMT Installation

Supplies required for installation:

• Water supply inlets for 3/4" nom. type “L” copper tube

• (4) Wall anchors and 1/4" diameter bolts for mounting support

brackets

• (OPTIONAL) 1/4" diameter screws for mounting shroud brackets

• (OPTIONAL) 3/4" union

Dimensions (mm)

9"

(229)

13"

(330)

2"

(51)

13"

(330)

2"

(51)

Mounting

Bracket

26-3/4"

(679)

Rough in supply lines before making connections.

Use the Cold Inlet for Tempered Supply.

Recommended Shower Height

(from Showerhead tip to fi nished fl oor)

Anchor

Holes

11"

(279)

C

L

38-1/4"

(972)

Supply

from Wall

11"

(279)

Anchor

Holes

Mounting

Bracket

Standard S24-038

Showerhead Shown

7/8"

(17)

Age Male Female

Adult 6'0" (1.83m) 5'6" (1.68m)

Teen 6'0" (1.83m) 5'6" (1.68m)

Pre-Teen 5'6" (1.68m) 5'6" (1.68m)

Distance to

fi nished fl oor

2 8/23/2011 Bradley Corporation • 215-1706 Rev. A; EN 11-03-001A

Page 3

Installation WS-2WMD, WS-3WMT

Install Shower

1

Remove top and bottom covers.

A

Supplies may be brought in from

back of shower unit or through

knock- outs located on top of

shower unit.

Measure from top of unit to tip of showerhead.

Subtract 2" and add the total to the desired

B

mounting height (see page 2). Mark the wall

with level horizontal line.

Drill 1/4" holes on marked line and attach

mounting brackets to wall using suitable hardware.

C

Hang unit on brackets. Fasten to wall at the four

anchor holes, using suitable hardware.

Mounting

Bracket

Top Cover

Bottom

Cover

X 8

Supply

Knockouts

Mounting

Bracket

X 8

Connect water supply to copper tubes inside the

shower unit. Turn on water to your shower and

D

check for leaks. Attach top and bottom covers.

Installing Optional Vertical Shroud

Position Bracket on top of shower and secure

A

to wall with 1/4" screws (provided by installer).

Position Slip Ring on top of shower against

ceiling and secure to wall with 1/4" screws

B

(provided by installer).

Position Shroud and secure to lower bracket with

screws provided. Using holes on top of shroud

C

as guides, drill and tap #10-24 holes in Slip Ring.

Secure Shroud to Slip Ring.

Slots for 1/4"

Dia. Screws

(supplied by

installer)

Bracket

Top of

Wall Saver

Shower

1" (25)

Ceiling

Slip Ring

6-1/2"

(165)

10-24 x 1/2"

Allen Button

Head Screws

(mm)

4" (102)

6-1/2"

(165)

Shroud

Bradley Corporation • 215-1706 Rev. A; EN 11-03-001A 8/23/2011 3

Page 4

WS-2WMD, WS-3WMT Installation

(mm)Installing Optional Horizontal Shroud

Slots for 1/4"

Dia. Screws

#10-24

Holes

Bracket

(supplied by

installer)

Position Bracket and Slip Ring on wall and

A

secure with 1/4" screws (provided by installer).

Slip

Ring

10-24 x 1/2"

Allen Button

Head Screws

Position Shroud over the bracket and secure with

B

screws provided.

Using shroud as guides, drill and tap #10-24

holes in Slip Ring. Secure Shroud to Slip Ring.

C

Shrouds

Cleaning Stainless Steel

Material Description: Stainless steel is extremely durable, and maintenance is simple and inexpensive. Proper care, particularly under corrosive

conditions, is essential. Always start with the simplest solution and work your way toward the more complicated.

Routine cleaning: Daily or as often as needed use a solution of warm water and soap, detergent, or ammonia. Apply the cleaning solution per the

manufactures instructions and always use a soft cloth or sponge to avoid damaging the fi nish.

Stubborn Stains: To remove stains from stainless steel, use a stainless steel cleaner and polish such as Ball® stainless steel cleaner or a soft

abrasive. Always follow the manufactures instructions and apply in the same direction as the polish lines.

Never use ordinary steel wool or steel brushes on stainless steel.

Always use stainless steel wool or stainless steel brushes.

Special Situations for Material

Fingerprints and Smears: To remove fi ngerprints or smears use a high quality stainless steel cleaner and polish in accordance with the

manufactures instructions. Many of these products leave a protective coating that helps prevent future smears and fi ngerprints.

Grease and Oil: To remove grease and oil, use a quality commercial detergent or caustic cleaner. Apply in accordance to the manufactures

instructions and in the direction of the polish lines.

Precautions: Avoid prolonged contact with chlorides (bleaches, salts), bromides (sanitizing agents), thiocyanates (pesticides, photography chemicals,

and some foods), and iodides on stainless steel equipment, especially if acid conditions exist.

Do not permit salty solutions to dry and evaporate on stainless steel.

The appearance of rust streaks on stainless steel leads to the belief that the stainless steel is rusting. Look for the actual source of the rust in some

iron or steel particles which may be touching, but not actually a part of the stainless steel structure.

Strongly acidic or caustic cleaners may attack the steel causing a

reddish fi lm to appear. The use of these cleaners should be avoided.

Brand Names: Use of brand names is intended only to indicate a type of cleaner. This does not constitute an endorsement, nor does the omission of any brand name cleaner imply its

inadequacy. Many products named are regional in distribution, and can be found in local supermarkets, department and hardware stores, or through your cleaning service. It is emphasized

that all products should be used in strict accordance with package instructions.

4 8/23/2011 Bradley Corporation • 215-1706 Rev. A; EN 11-03-001A

Loading...

Loading...