Bradley Terreon TDB3103, Terreon Extra Height WF3203 Installation Manual

Installation

TDB3103

Terreon® 36" Semi-circular Deep Bowl

Washfountain with Infrared Control

TDB3103 with

Infrared Control

TDB3103 avec

commande à infrarouge

Modelo TDB3103 con

control infrarrojo

Terreon Lavabo fontaine 914 mm (36")

à cuvette profonde semi-circulaire avec

commande à infrarouge

Fuente de lavado semicircular con

palangana profunda Terreon de 914 mm

(36") con control infrarrojo

WF3203

Terreon Extra Height 36" Semi-Circular

Classic Washfountain with 9" Deep Bowl

and Infrared Control

Terreon Lavabo fontaine 914 mm (36") à

hauteur supplémentaire classique semicirculaire à cuvette profonde de 229 mm

(9") et commande à infrarouge

Fuente de lavado clásica semicircular

Terreon de altura adicional de 914 mm

(36") con palangana profunda de 229 mm

(9") y control infrarrojo

215-1332 Rev. V; ECN 12-00-004

© 2013 Bradley

Page 1 of 56 1/15/2013

WF3203 with

Infrared Control

WF3203 avec

commande à infrarouge

Modelo WF3203 con

control infrarrojo

P.O. Box 309, Menomonee Falls, WI USA 53052-0309

PHONE 800.BRADLEY (800.272.3539) FAX 262.251.5817

bradleycorp.com

TDB3104, WF3204 Installation

Table of Contents

Pre-Installation Information ...............................................................................3

Semi-Circular Washfountain Dimensions ..................................................................4-5

Rough-In Specifications............................................................................... 6-7

Installing the Drain......................................................................................8

Bowl/Pedestal Mounting and Assembly .....................................................................8

Installing Drain Spud in Bowl..............................................................................9

Connect Supply Stops, Sprayhead Supply Tubing and P-Trap ....................................................9

Sprayhead, IR Module and Thermostatic Mixing Valve Installation................................................10

Electrical Connections for Adaptive Infrared .................................................................11

Adjust the Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cleaning and Maintenance ...........................................................................13-14

Soap Valve Parts List and Maintenance .................................................................15-16

Sprayhead Parts List and Troubleshooting ..................................................................17

IR Module Troubleshooting ..............................................................................18

Adaptive IR Troubleshooting .............................................................................19

Thermostatic Mixing Valve Troubleshooting..................................................................20

Sommaire

Informations sur la pré-installation ........................................................................21

Dimensions du lavabo fontaine semi-circulaire ............................................................22-23

Spécifications de mise en place des tuyauteries ......................................................... 24-25

Mise en place des tuyauteries de drain et d’alimentation .......................................................26

Montage de l’ensemble cuvette et socle....................................................................26

Installation de l’ergot de drain dans la cuvette ...............................................................27

Raccorder les robinets d’arrêt d’alimentation, la tubulure d’alimentation et le siphon en P .............................27

Installation du bec diffuseur, du module IR et du robinet mélangeur thermostatique..................................28

Connexions électriques pour infrarouge Adaptive.............................................................29

Faire couler l’eau pour régler la température ................................................................30

Instructions de nettoyage/d’entretien....................................................................31-32

Nomenclature et conseils d’entretien pour le savon ........................................................33-34

Nomenclature et Suggestions pour réparer le bec diffuseur.....................................................35

Dépannage IR Adaptive ................................................................................36

Dépannage du bouton-poussoir électromagnétique ...........................................................37

Dépannage du robinet mitigeur thermostatique ..............................................................38

Índice

Información previa a la instalación ........................................................................39

Dimensiones de fuentes de lavado semicirculares.........................................................40-41

Especificaciones técnicas para colocación de tuberías empotradas ...........................................42-43

Desagüe y suministros empotrados .......................................................................44

Montaje y ensamblaje de palangana/pedestal ...............................................................44

Instalación del embudo de desagüe en la palangana..........................................................45

Conecte las válvulas de cierre de suministro, la tubería de suministro de la boquilla rociadora y el sifón en P. .............45

Instalación de la boquilla rociadora, el módulo infrarrojo y la válvula mezcladora termostática .........................46

Conexiones eléctricas para el dispositivo infrarrojo Adaptive ....................................................47

Ajuste la temperatura con el agua corriendo ................................................................48

Instrucciones de limpieza/mantenimiento ................................................................49-50

Lista de piezas y mantenimiento de los dispensadores de jabón..............................................51-52

Lista de piezas y solución de problemas de las boquillas rociadoras .............................................53

Localización de fallas del dispositivo IR Adaptive.............................................................54

Solución de problemas de la válvula de solenoide............................................................55

Solución de problemas de la válvula mezcladora termostática ..................................................56

2 1/15/2013 Bradley • 215-1332 Rev. V; ECN 12-00-004

Installation TDB3104, WF3204

IMPORTANT!

Installation

Read this entire installation manual to ensure proper installation. When finished with the

installation, file this manual with the owner or maintenance department.

Separate parts from packaging and make sure all parts are accounted for before discarding

Packing List

•

•

any packaging material. If any parts are missing, do not begin installation until you obtain

•

THIS

SIDE

•

UP

the missing parts.

Make sure that all water supply lines have been flushed and then completely turned off

before beginning installation. Debris in supply lines can cause valves to malfunction.

Hardware supplied by installer must be appropriate for wall construction. Wall anchors used

must have a minimum pull-out rating of 1,000 lbs.

The Adaptive® Infrared control must be connected with a 24 VAC Class II transformer.

Connections to 110 VAC can cause personal injury and will result in damage to the

electronics.

Product warranties may be found under “Product” on our web site

at www.bradleycorp.com.

Supplies Required by Installer

• (4) 1/2" lag bolts, screws or other fasteners to anchor washfountain pedestal

• 1/2" nominal copper tubing for hot and cold water supply lines.

• Standard P-trap

• 1-1/2" drain lines and fittings

• Teflon tape or pipe dope

• 110 VAC GFI power source for 110/24 VAC UL Class II transformer supplied

• OPTIONAL: Bradley recommends installing an electrical cut off switch to the unit. This feature allows no accidental

water delivery during regular maintenance and service.

Pre-Installation Information

Terreon Material

The Washfountain is constructed of Terreon®, a densified solid surface material composed of polyester resin. Terreon is resistant to

chemicals, stains, burns and impact. Surface damage can be easily repaired with everyday cleaners or fine-grit abrasives. Terreon

is NAHB certified to meet ANSI Z124.3, Z124.6 and ANSI/ICPA SS-1-2001.

Adaptive Infrared

The sprayhead is controlled by a solenoid valve, allowing the user to activate a flow of water. The Infrared sensor will take a few

minutes to adapt to its environment when the unit is powered up.

Bradley • 215-1332 Rev. V; ECN 12-00-004 1/15/2013 3

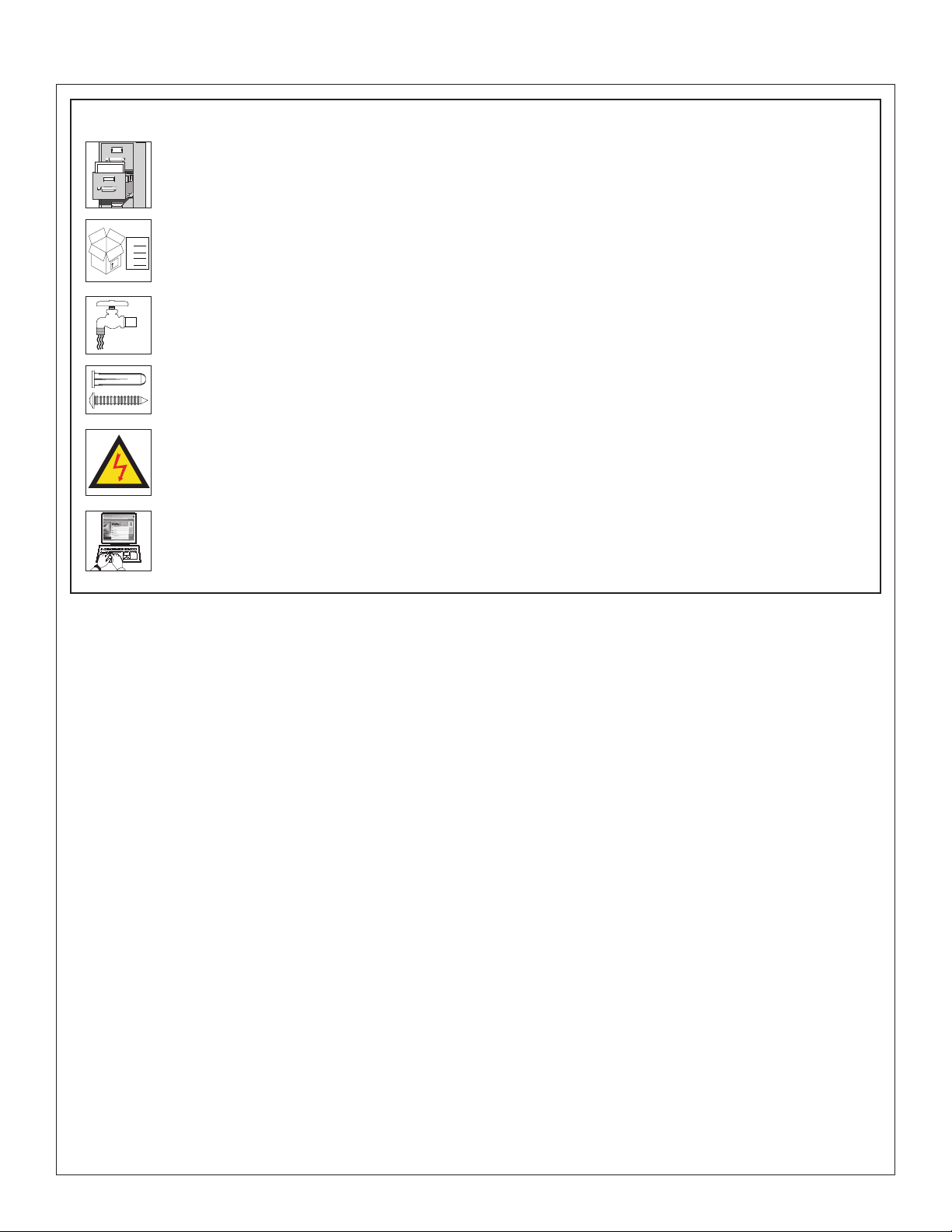

TDB3104, WF3204 Installation

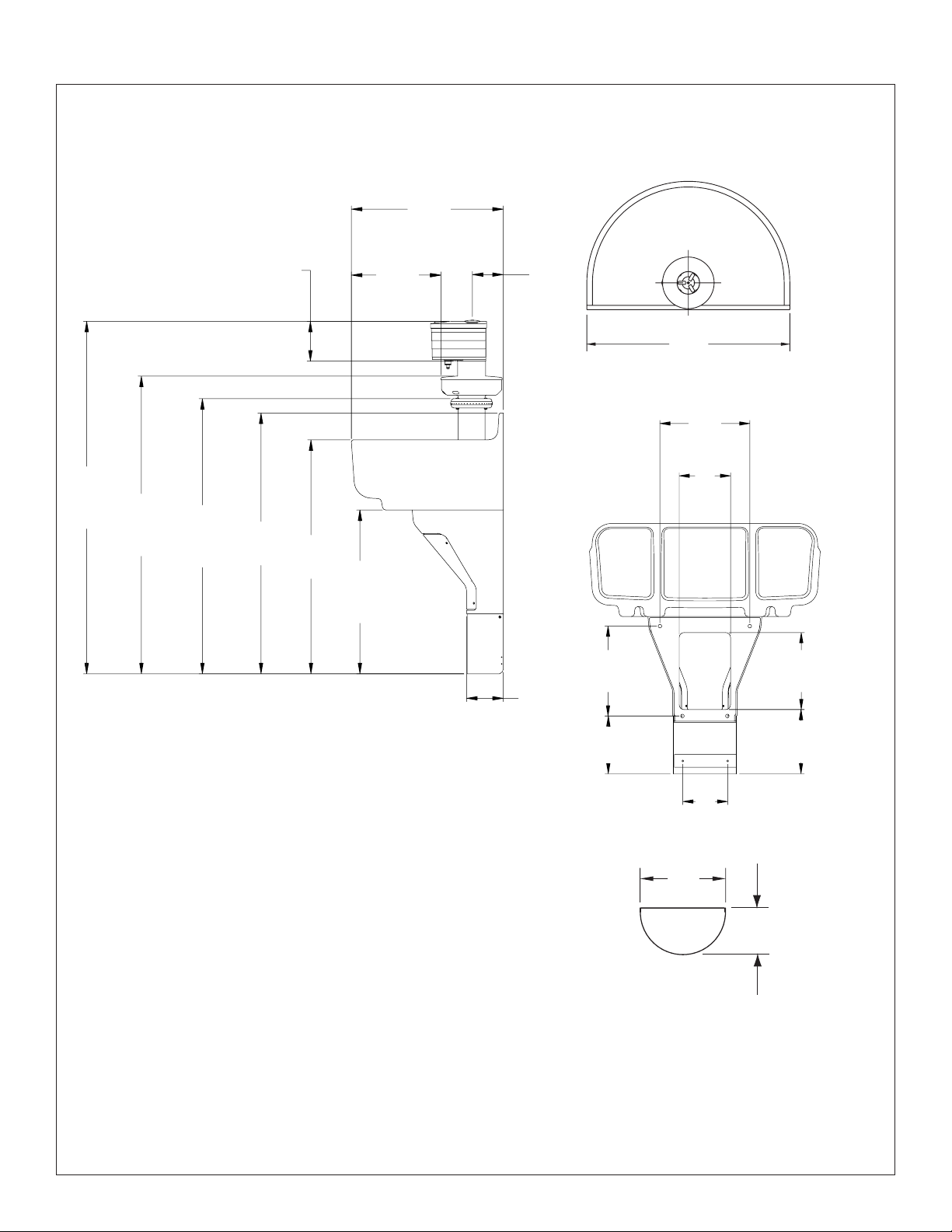

Semi-Circular Washfountain Dimensions

Model TDB3103

36" Semi-circular - side view

*53-1/4"

(1353)

*44-7/8"

(1140)

*41-1/4"

(1048)

*34"

(864)

*38"

(965)

*30-3/8"

(772)

6"

(152)

*24-1/2"

(622)

13-1/2"

(343)

22-3/4"

(577)

14-1/16"

(357)

4-3/4"

(121)

Top View

Back View

36"

(914)

14"

(356)

8"

(203)

Optional equipment may not comply with all

ADA dimensional guidelines

5-1/2"

(140)

*Adjustments to Vertical Dimensions

for Various Rim Heights

Rim Height Application Adjustment

34" Adult Height ADA, TAS Adult Height None, as shown

32" TAS Ages 11 thru 14 or 15, Grades 6 thru 8 or 9 Subtract 2"

30" TAS Ages 4 thru 10 or 11, Grades 6 thru 8 or 9

& Proposed Juvenile Height ADA

Subtract 4"

14"

(356)

*9"

(229)

Bottom View

12"

(305)

*10"

(254)

7"

(178)

10"

(254)

5-1/2"

(140)

4 1/15/2013 Bradley • 215-1332 Rev. V; ECN 12-00-004

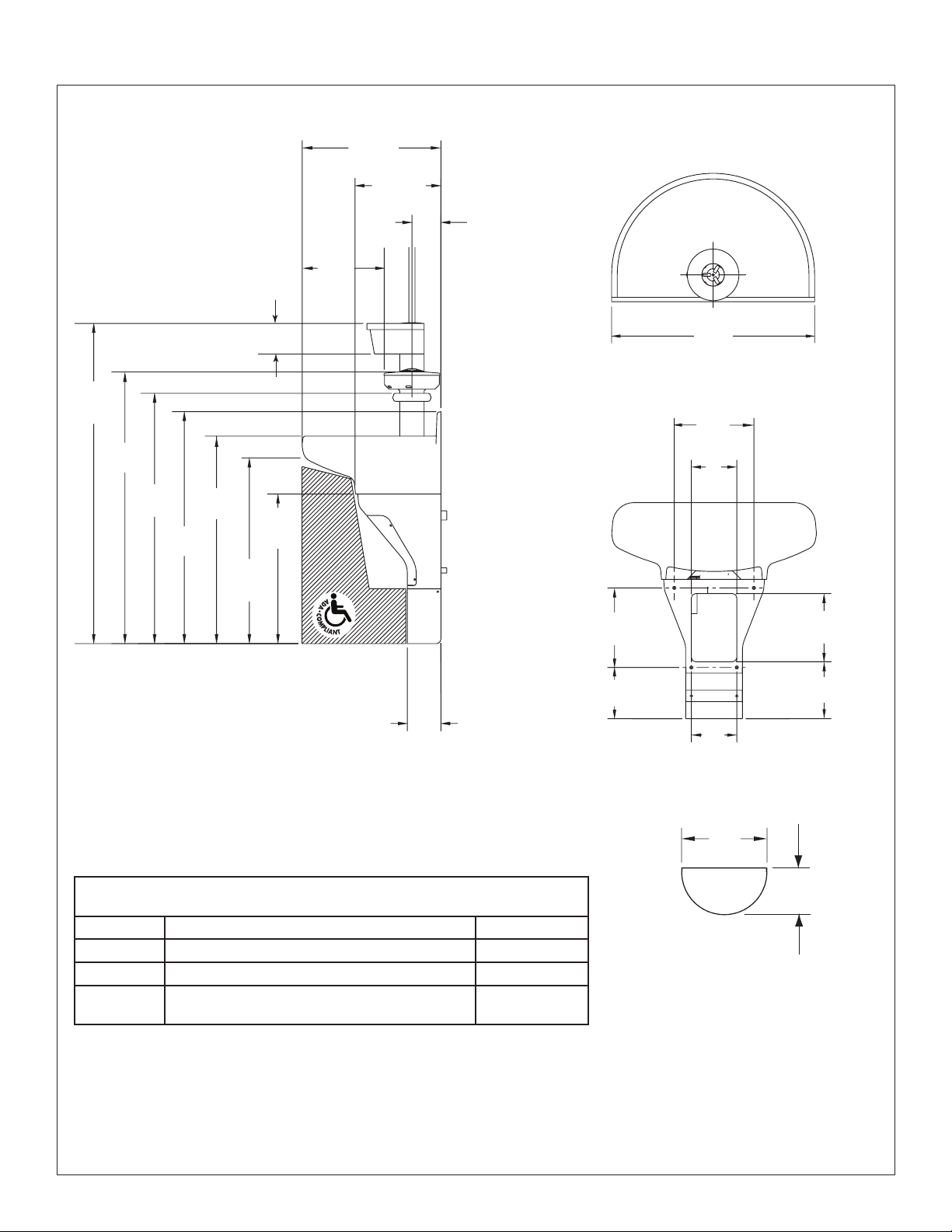

Installation TDB3104, WF3204

Semi-Circular Washfountain Dimensions

Model WF3203

36" Semi-circular - side view

22-3/4"

(577)

Top View

52-11/16"

(1339)

44-1/2"

(1131)

41-1/8"

(1046)

39"

(991)

6"

(151)

35"

(889)

24-1/2"

(662)

13-3/8"

(340)

4-5/8"

(118)

Back View

5-1/2"

(140)

14"

(356)

9"

(229)

36"

(914)

14"

(356)

8"

(203)

12"

(305)

10"

(254)

7"

(178)

Bottom View

10"

(254)

5-1/2"

(140)

Bradley • 215-1332 Rev. V; ECN 12-00-004 1/15/2013 5

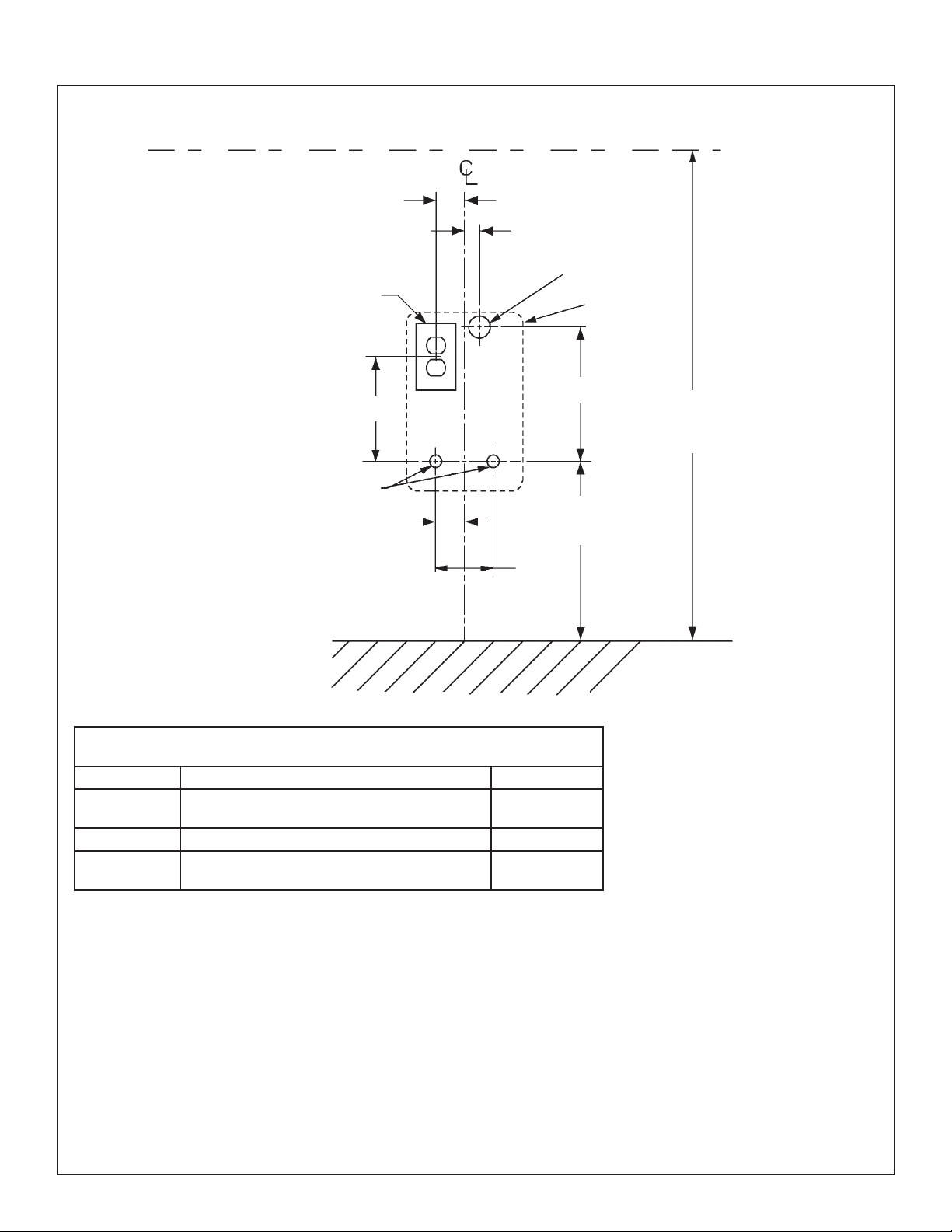

TDB3104, WF3204 Installation

Semi-Circular Washfountian Rough-Ins

2" (51)

1" (25)

Location of Electrical Outlet (Check

Local Codes - Outlet may be Required

to be in a Remove Location)

7"

(178)

Hot Cold

1/2" Nominal Copper

Tubing for Supply Lines,

Stub Out 1" from Wall

2"

(51)

(102)

4"

1-1/2" NPT

Drain from

the Wall

Pedestal

Opening at Wall

9"

(229)

12" (305)*

See Table

Below

(mm)

34" (864)

Rim Height*

See Table

Below

Finished Floor

*Adjustments to Vertical Dimensions

for Various Rim Heights

Rim Height Application Adjustment

34"

35" (WF3203)

32" TAS Ages 11 thru 14 or 15, Grades 6 thru 8 or 9 Subtract 2"

30" TAS Ages 4 thru 10 or 11, Grades Pre-K thru 5

Adult Height ADA, TAS Adult Height None, as shown

Subtract 4"

or 6 & Proposed Juvenile Height ADA

6 1/15/2013 Bradley • 215-1332 Rev. V; ECN 12-00-004

Installation TDB3104, WF3204

Rough-In Specifications

Type A Drain

- Supplies through wall

- Vented through wall

off-drain

4"

(102)

Clearance Hole

*17-21"

(432 - 533)

Trap for Wall Outlet Only

*12"

(305)

1" (25)

2"

(51)

2"

(51)

4-3/4"

(121)

Drain through Wall

Supplies through Wall

Drain P-Trap and supplies by others.

1/2" Nominal Copper

Tubing for Cold Supply,

Through Wall

1-1/2" NPT Drain

36" Bowl

(914)

5" R. Bottom Access

1/2" Nominal Copper

Tubing for Hot Supply,

Through Wall

*Adjustments to Vertical Dimensions

for Various Rim Heights

Rim Height Application Adjustment

34"

35" (WF3203)

32" TAS Ages 11 thru 14 or 15, Grades

30" TAS Ages 4 thru 10 or 11, Grades

Adult Height ADA, TAS Adult Height None, as shown

Subtract 2"

6 thru 8 or 9

Subtract 4"

Pre-K thru 5 or 6 & Proposed

Juvenile Height ADA

(mm)

Type O Drain

- Supplies from above

- Vented through wall

off drain

1-1/2" NPT Drain

Through Wall

(Stub Out to Suit

Trap Dimensions)

1/2" Nominal Copper Tubing

Trap for Wall Outlet Only

4"

(102)

Clearance Hole

*17-21"

(432 - 533)

Wall

1"

(25)

Supplies from Above

4-3/4"

(121)

Drain through Wall

4"

(102)

13" R Top Access

Tra p

1-1/2" NPT Drain

Cold

7/8"

(22)

7/8"

(22)

Hot

36" (914) Bowl

7-3/8" R. Bottom Access

Bradley • 215-1332 Rev. V; ECN 12-00-004 1/15/2013 7

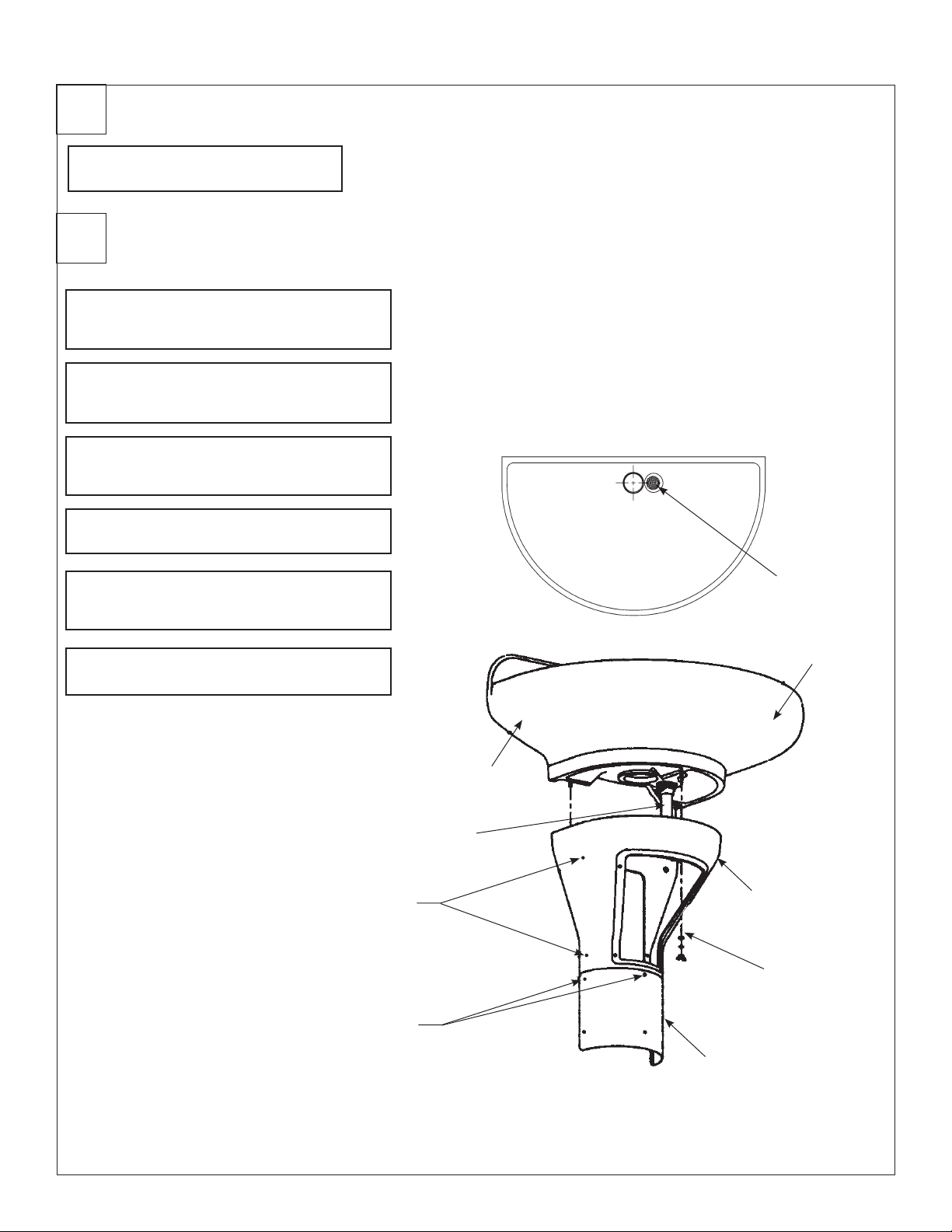

TDB3104, WF3204 Installation

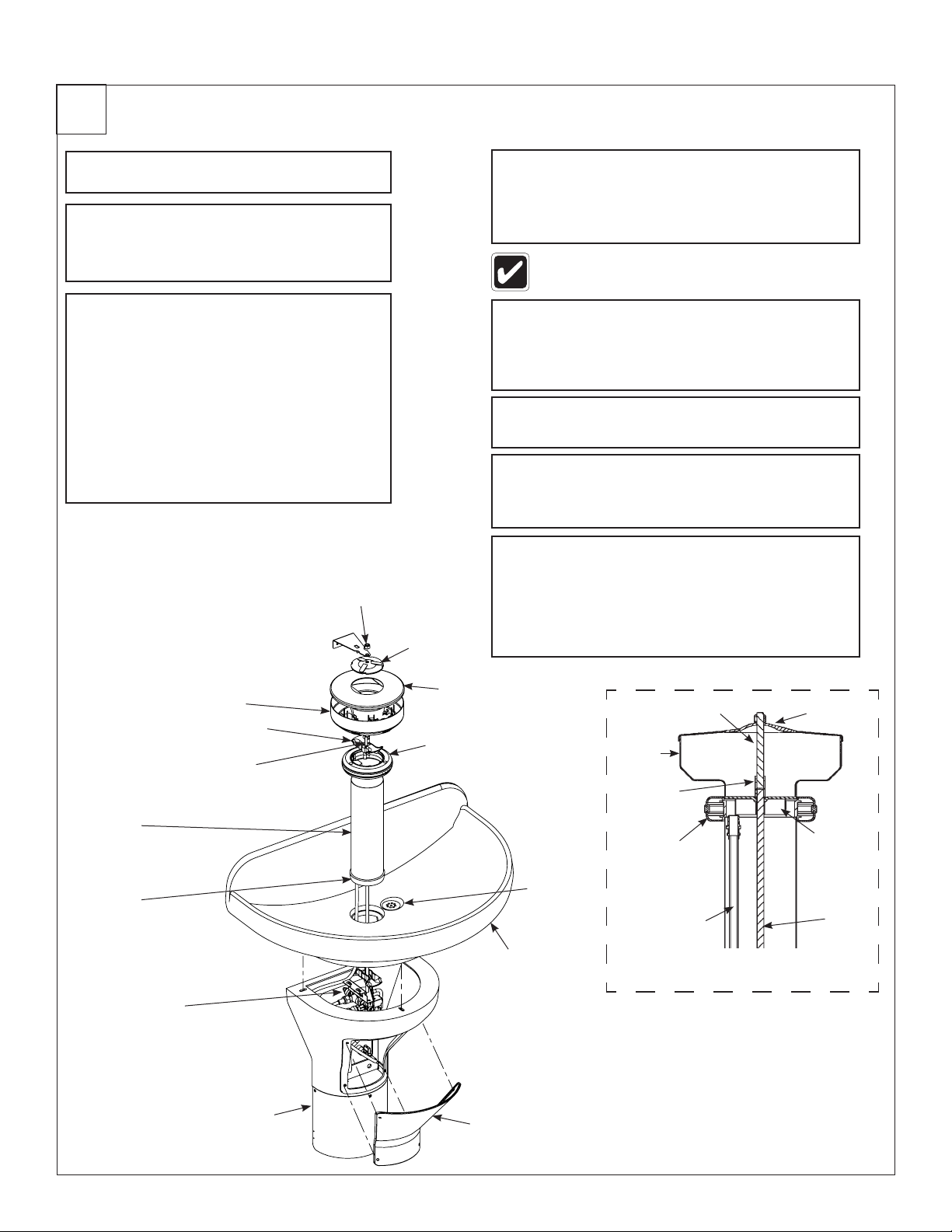

1

2

A

B

C

D

Rough-in Drain and Supplies

Rough in supply and drain piping

A

as required for your installation.

Bowl/Pedestal Mounting and Assembly

Attach the stainless steel pedestal base

to the pedestal using supplied screws and

finishing washers.

Position the pedestal at the desired location

and mark the position of the (4) pedestal

wall mounting locations.

Secure pedestal to wall with suitable

fasteners, 1/2" anchors and 1/2" bolts

(supplied by installer).

Using two people, carefully lift bowl onto

pedestal.

A location to plug in the 24 VAC Tramsformer is

required. Refer to drawing for Outlet Rough-In.

Before attaching 1/4" wing nuts and washer to

threaded rod, remove red protective caps from

threaded rods. Discard sleeve caps after removal.

CAUTION! Bowl surface is very smooth. Approximate

weight of bowl is 75 pounds. Handle with Care!

Top View

Position the bowl so that the threaded rods

in the bowl mate with the slotted holes in

E

the pedestal.

Using 1/4" wing nuts and washers, secure

F

the bowl to the pedestal, three places.

Wall Mounting

Locations

(Typical)

#10 - 24 Screw (3)

(160-248)

Finish Washers (3)

(142-002CA)

Front View

Place Hands

Here When

Lifting Bowl

Drain

Drain

Place Hands

Here When

Lifting Bowl

Pedestal

(219-039)

Threaded Rod

(Secured by 1/4"

wing nut and

washer)

Base Assembly, Standard Height

(S17-281)

Base Assembly, TAS (S17-284)

Base Assembly, Juvenile Height

(S17-285)

Shell, Wall Mounted - Trim Piece

(186-1306)

8 1/15/2013 Bradley • 215-1332 Rev. V; ECN 12-00-004

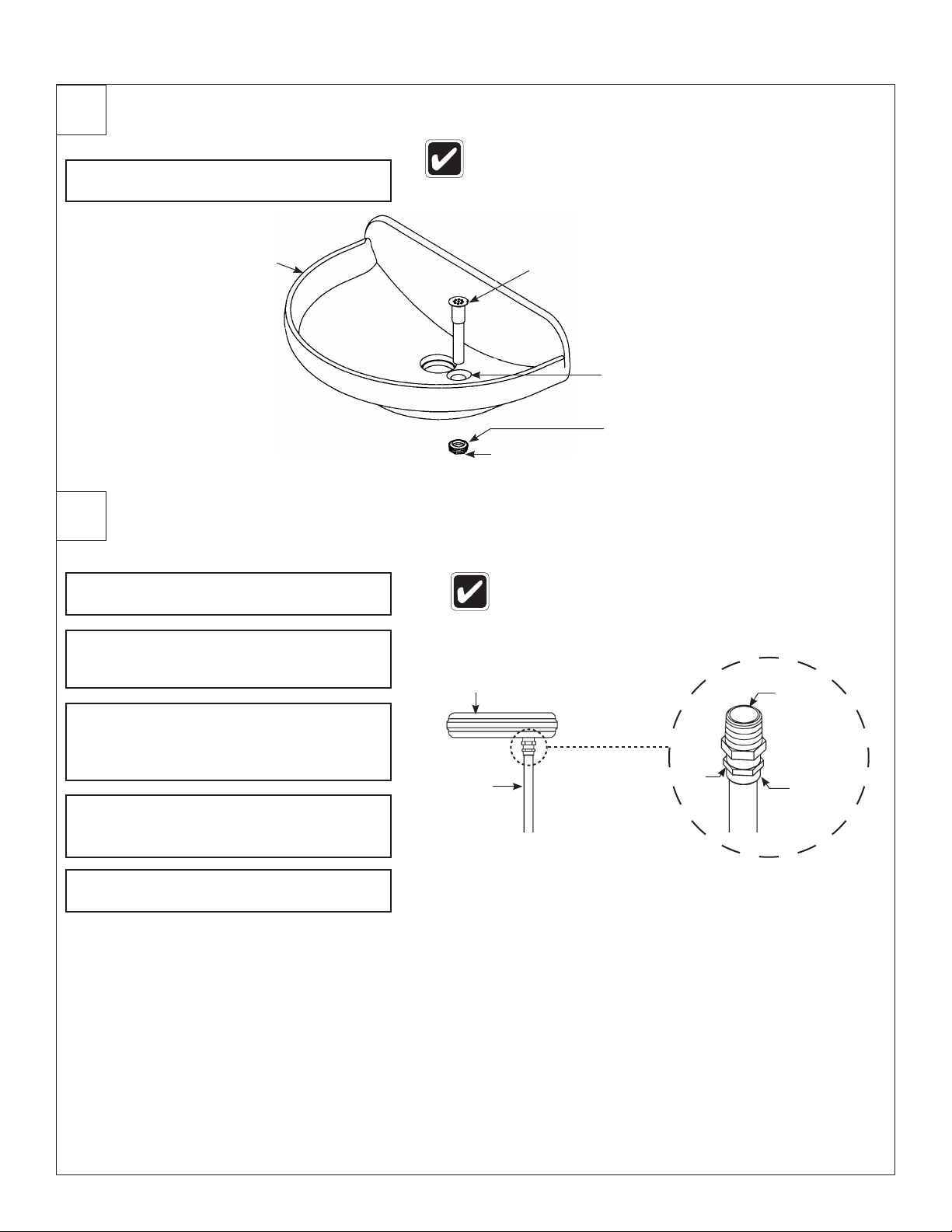

Installation TDB3104, WF3204

3

A

4

Installing Drain Spud in Bowl

Secure drain spud with lock nut and washers.

Bowl

Drain Pre-Pack

(S45-273)

Connect Supply Stops, Sprayhead Supply Tubing and P-Trap

Seal between drain spud and drain hole with

plumber’s putty (supplied by installer).

Strainer and Spud

Apply Plumber's Putty Here

Fiber Washer

Locknut

Connect supply stops onto stub-outs.

A

Using a sharp knife, cut tubing squarely and

remove any burrs. Do not pinch or crush end

B

of tubing.

Loosen nut on fitting. Moisten end of tube

and push into fitting until it is firmly seated.

C

Tighten nut to secure tube to fitting (make

sure nut is securely tightened).

If connector leaks, reseat tubing. If leaking

persists, replace the male connector, or call

D

your bradley representative for assistance.

Connect p-trap (supplied by installer) to

E

tailpiece and drain outlet.

Sprayhead

Tubing

Flush supply lines before making connections.

Do not use pipe sealant on compression fittings.

Male 3/8"

Tube

Connector

(145-105)

Nut

Tubing

Bradley • 215-1332 Rev. V; ECN 12-00-004 1/15/2013 9

TDB3104, WF3204 Installation

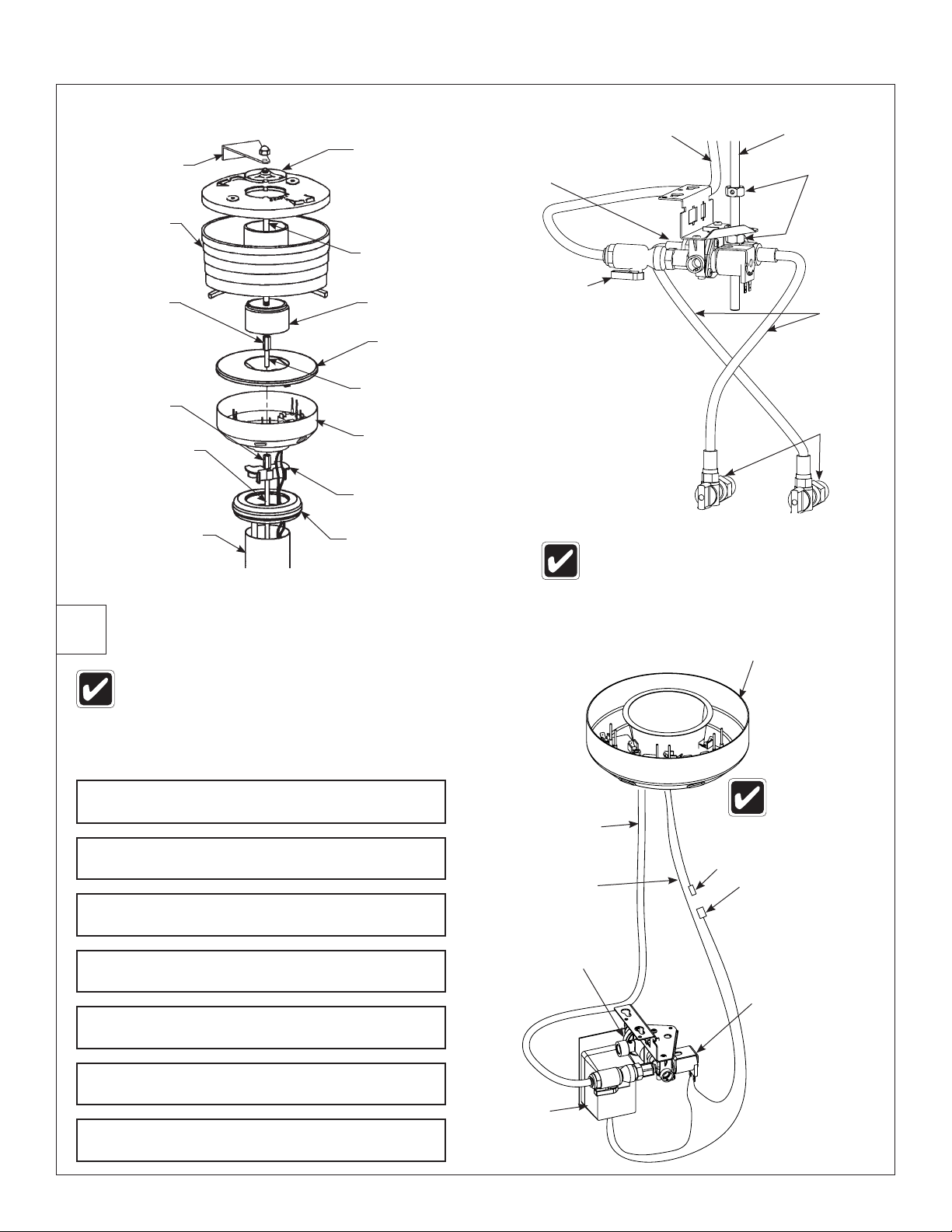

5

Sprayhead, IR Module and Thermostatic Mixing Valve Installation

Install hemmed end (not sharp end) of

support tube with gasket onto bowl.

A

Place sprayhead with 3/8" tubing onto

support tube. Run the tubing down through

B

the support tube. Make sure the spray holes

point away from the wall.

Place the upper tie bar (notched at both

corners of each end) on top of sprayhead

parallel to wall. Connect the two threaded

tie rods together using the coupling nut

with hex head set screws. Run the tie rod

down through upper tie bar and secure

C

from underneath the bowl using the lower

tie bar (no notches) and hex nut with socket

head set screw. A minimum of 2-1/4" of

threaded tie rod should protrude below the

lower tie bar; this will be required to attach

the valving.

Tie Rod Pre-Pack

(S45-1336)

Top Cover

(107-099 (A))

(107-179 (O))

Place the infrared module assembly on top of

sprayhead. Rotate until infrared module locks in

with tie bar. Drop two infrared module wires down

D

to valve assembly. Make sure infrared module

windows are facing away from the wall.

Skip to step F for units without soap.

For units with soap option, install the spacer, soap

dispenser and cover using the couping nut, third

tie rod (8-5/8" long) and second coupling nut.

E

Secure with sprayhead restraining bracket, acorn

nut and socket head screw.

Secure infrared module cover and top cover with

F

acorn nut and socket head set screw.

Holding the valve assembly outside of pedestal,

connect 3/8" tubing from sprayhead to valve

G

assembly tube connector. Connect the two flexible

hoses to the valve assembly.

Thread one supplied 3/8" nut onto the tie rod.

Slide valve assembly on next and secure with

another 3/8" nut. Connect flexible hoses to supply

stops. Make sure the hot supply is connected to

H

the hot inlet on the valve (marked with the letter

"H") and the cold supply is connected to the cold

inlet on the valve (marked with the letter "C").

IR Module Assembly

Support Tube

(S57-006)

Support

Tube Gasket

(125-011)

Valve

Assembly

Pedestal Assembly (S17-287)

(S50-367)

Tie Bar

Tie Rod

(176-008A)

Module Cover

(S04-083)

Sprayhead

(S05-054B)

Terreon® Semi-Circular

Deep Bowl (ADA Bowl

Shown, Classic Bowl is

your local Bradley Rep

Access Panel

Drain

(269-1597)

Optional)

(Part No. Varies with

color of bowl. Contact

for assistance)

(186-1260)

Infrared

Module

Assembly

Coupling

Nut and Set

Screw

Sprayhead

Supply Tube

A/O Units

(A Shown)

Tie Rod Pre-Pack

Section View of

A/O Unit Assembly

Cover

Tie Bar

Tie Rod

10 1/15/2013 Bradley • 215-1332 Rev. V; ECN 12-00-004

Installation TDB3104, WF3204

Unit with "A" Drain and IR Module Shown,

Also Available with "O" Drain

Restraining Bracket

(140-128)

Soap

Dispenser

Coupling Nut

and Set Screw

Coupling Nut

and Set Screw

21-5/8" Tie Rod

(176-008A)

Support Tube

Top

Cover

8-5/8"

Tie Rod

Spacer

Module

Cover

4-1/4" Tie Rod

(176-118)

IR Module

Assembly

Tie Bar

Sprayhead

(S05-054B)

3/8" Tubing from Sprayhead

I.R. Valve with Thermostatic

Mixing Valve (Shown) (S45-2504)

Volume

Control

I.R. Valve with

Tempered Line Not

Shown (S45-2505)

Do not apply pipe sealant

to compression fittings.

Valve Assembly

Hot

Tie

Rod

Tie Rod Nut

(110-064)

Flexible

Hose

(269-2053)

Stop

(S27-340)

Cold

6

Electrical connections for Adaptive Infrared

START-UP NOTE: Do not use for two minutes after making

power connection. The sensors will take up to eight minutes

(without being used) to adapt to the bowl if another object is

detected during the two-minute start-up period.

Attach infrared female connect wire from infrared

A

module to solenoid.

3/8" Tubing from

Attach the infrared male connect wire from the

B

infrared module to the transformer lead wire.

Attach the remaining transformer lead wire to the

C

solenoid.

Connect 24 VAC transformer provided to power

D

source.

Turn supplies on. Open stop valves completely.

E

Open volume control valve completely and check

F

piping installation for leaks.

Pass your hand in front of each sensor until air is

G

purged from the lines.

Sprayhead

Infrared

Module Female

Connect Wire

I.R. Valve with

Thermostatic Mixing Valve

(Shown) (S45-2504)

24 VAC

Transformer

(S83-134)

Infrared Module

(S50-367)

Male

Connect

Female

Connect

Solenoid

Tempered Line Not

Shown (S45-2505)

Do not apply

pipe sealant to

compression

fittings.

Valve

I.R. Valve with

Bradley • 215-1332 Rev. V; ECN 12-00-004 1/15/2013 11

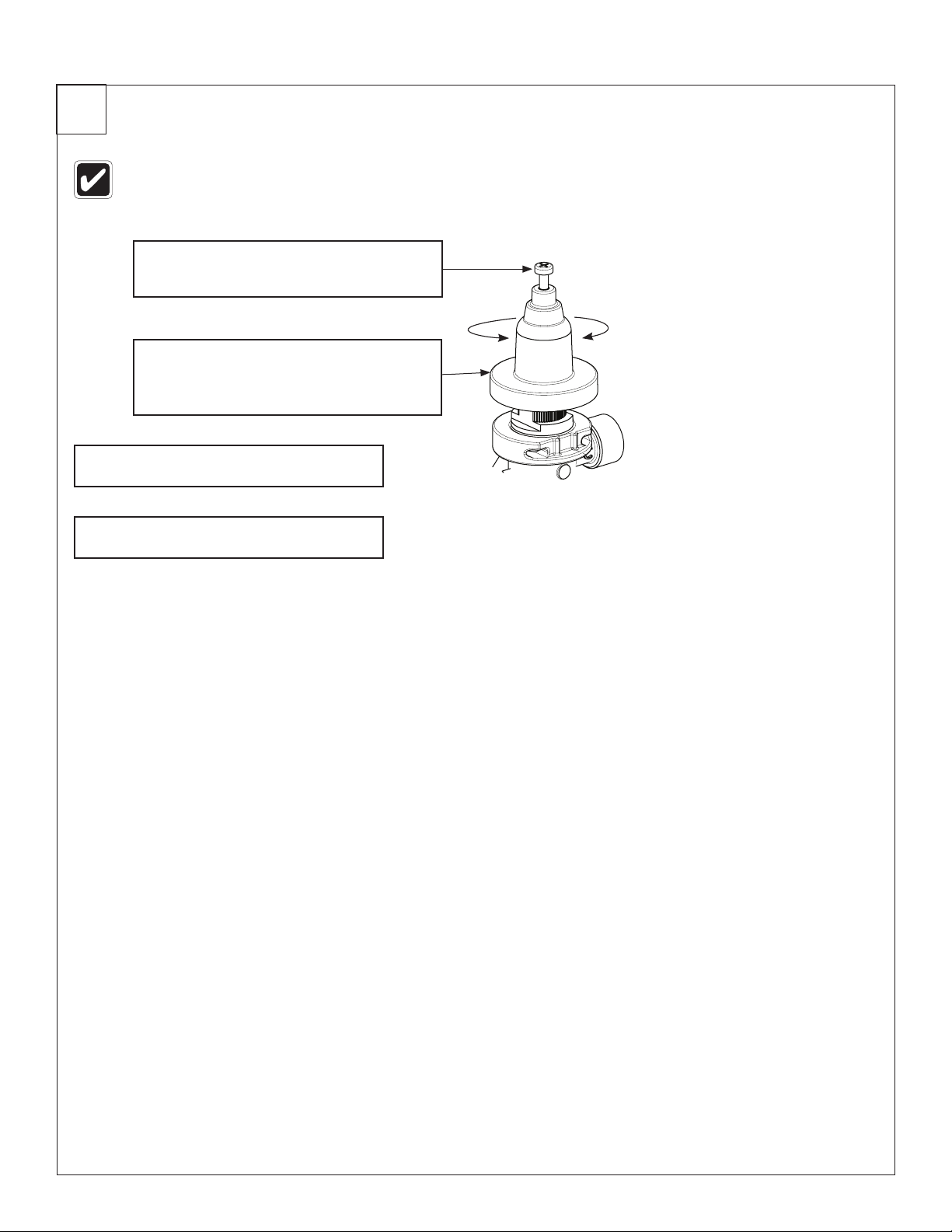

TDB3104, WF3204 Installation

7

Adjust the Temperature

This valve is NOT factory preset. Upon installation, the temperature of this

valve must be checked and adjusted to ensure delivery of a safe water

temperature. Water in excess of 110°F (43°C) may cause scalding.

Loosen Cap Screw about 1/4" (4-6 turns)

and lift up cover (do not remove).

A

Using cover, turn cartridge gently until

desired water temperature is reached. Do

B

not turn past stops as this may damage

unit. Push cover down and tighten screw.

Clean sprayhead, if necessary. Adjust the

volume control to control the flow of water.

C

Attach pedestal access panel with

hardware provided.

D

H

C

12 1/15/2013 Bradley • 215-1332 Rev. V; ECN 12-00-004

Installation TDB3104, WF3204

Cleaning and maintenance instructions for Terreon

Material Description: Terreon® is an NAHB Certified densified solid surface material composed of polyester resin and is resistant

to chemicals, stains, burns and impact. Surface damage can be easily repaired with everyday cleansers or fine grit abrasives.

Routine Cleaning: Clean daily or as often as conditions require using a standard commercial or household cleaner such as

Formula 409® or Windex®.

Stubborn Stains: Remove tough stains with Ajax®, Comet®, or Soft-Scrub® and a green Scotch-Brite® pad or lightly sand in a

circular motion with 240 grit wet/dry sandpaper. The finish can be renewed with a maroon Scotch-Brite pad.

®

Special Situations for Material

Scratches: Remove scratches with a green Scotch-Brite® pad. The finish can then be renewed with a maroon Scotch-Brite® pad.

Hard Water Deposits: Remove hard water deposits with a mild solution of vinegar and water. Always rinse the unit thoroughly

after cleaning.

Restoring the surface: Use Hope’s® Solid Surface cleaner and polish to refresh and protect the Terreon Solid Surface material.

Bradley recommends additional care and maintenance for the darker colored Terreon. For complete instructions on this additional

maintenance see Bradley document #1505.

NOTICE! Do not use strong acid or alkaline chemicals and cleansers to clean Terreon. If these chemicals

come in contact with the Terreon surface, wipe them off immediately and rinse with soapy water.

Avoid contact with harsh chemicals such as paint remover, bleach, acetone, etc. Avoid contact with

hot pans and objects.

Repair Kits: Terreon repair kits are available. Contact your Bradley representative or distributor for part numbers and pricing.

Repair kits are made to order and have a shelf life of 30 days.

Brand Names: Use of brand names is intended only to indicate a type of cleaner. This does not constitute an endorsement, nor

does the omission of any brand name cleaner imply its inadequacy. Many products named are regional in distribution, and can be

found in local supermarkets, department and hardware stores, or through your cleaning service. It is emphasized that all products

should be used in strict accordance with package instructions.

Cleaning/Maintenance Instructions for Gel-coated Fiberglass

Material Description: The Terreon Washfountains referenced in this installation manual use a gel-coated fiberglass pedestal.

Routine Cleaning: The gel-coated pedestal should be cleaned daily or as often as needed with a mild solution of detergent and

water. Always use a soft cloth to avoid damage to the finish.

Repair Kits: There are no repair kits available for fiberglass materials. However, replacement parts are available, contact your

Bradley representative for pricing and part numbers.

NOTICE! Do not expose gel-coated fiberglass to solvents as they will damage the material and may create

harmful fumes.

Brand Names: Use of brand names is intended only to indicate a type of cleaner. This does not constitute an endorsement, nor

does the omission of any brand name cleaner imply its inadequacy. Many products named are regional in distribution, and can be

found in local supermarkets, department and hardware stores, or through your cleaning service. It is emphasized that all products

should be used in strict accordance with package instructions.

Bradley • 215-1332 Rev. V; ECN 12-00-004 1/15/2013 13

TDB3104, WF3204 Installation

Cleaning and maintenance instructions for stainless steel

Material Description: Stainless steel is extremely durable, and maintenance is simple and inexpensive. Proper care, particularly

under corrosive conditions, is essential. Always start with the simplest solution and work your way toward the more complicated.

Routine cleaning: Daily or as often as needed use a solution of warm water and soap, detergent, or ammonia. Apply the cleaning

solution per the manufacturer’s instructions and always use a soft cloth or sponge to avoid damaging the finish.

Stubborn Stains: To remove stains from stainless steel use a stainless steel cleaner and polish such as Ball® stainless steel

cleaner or a soft abrasive. Always follow the manufacturer’s instructions and apply in the same direction as the polish lines.

NOTICE! Never use ordinary steel wool or steel brushes on stainless steel. Always use stainless steel wool

or stainless steel brushes.

Special Situations for Material

Fingerprints and Smears: To remove fingerprints or smears use a high quality stainless steel cleaner and polish in accordance

with the manufacturer’s instructions. Many of these products leave a protective coating that helps prevent future smears and

fingerprints.

Grease and Oil : To remove grease and oil use a quality commercial detergent or caustic cleaner. Apply in accordance to the

manufacturer’s instructions and in the direction of the polish lines.

Precautions: Avoid prolonged contact with chlorides (bleaches, salts), bromides (sanitizing agents), thiocyanates (pesticides,

photography chemicals, and some foods), and iodides on stainless steel equipment, especially if acid conditions exist.

NOTICE! Do not permit salty solutions to evaporate and dry on stainless steel.

The appearance of rust streaks on stainless steel leads to the belief that the stainless steel is rusting. Look for the actual source

of the rust in some iron or steel particles which may be touching, but not actually a part of the stainless steel structure.

NOTICE! Strongly acidic or caustic cleaners may attack the steel, causing a reddish film to appear. The use

of these cleaners should be avoided.

Brand Names: Use of brand names is intended only to indicate a type of cleaner. This does not constitute an endorsement, nor

does the omission of any brand name cleaner imply its inadequacy. Many products named are regional in distribution, and can be

found in local supermarkets, department and hardware stores, or through your cleaning service. It is emphasized that all products

should be used in strict accordance with package instructions.

14 1/15/2013 Bradley • 215-1332 Rev. V; ECN 12-00-004

Installation TDB3104, WF3204

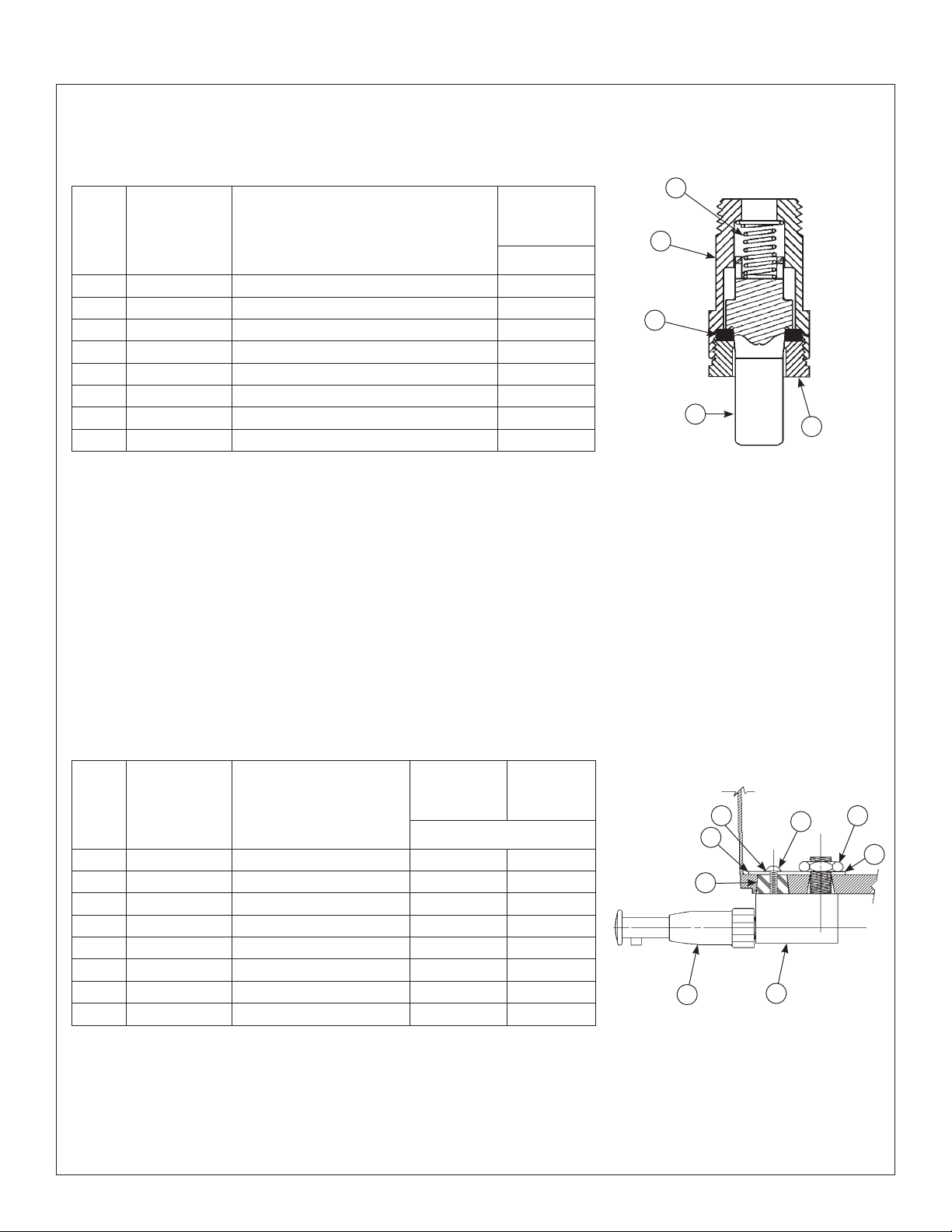

Soap Valve — Liquid — S09-007S

Parts List

Attaching

Parts

S09-007S

Item Part No. Description

1 118-025 Valve Body 1

2 110-007 Packing Nut 1

3 135-001L Spring 1

4 125-001BU Washer 1

5 119-028 Plunger 1

* 161-014 Nut 1

* 124-001D Washer 2

* 142-002AH Washer - Stainless Steel 1

* Not Illustrated

This valve delivers a measured amount of soap with each upward stroke. The soap

dispenser has been standard on washfountains since 1983 and is not well-suited for

very thick lotion soaps.

Qty

NOTICE! Lotion soap will clog liquid soap valves. Use only lotion soap

valves with lotion soap.

3

1

4

5

2

Soap Valve — Lotion — S09-057S

Parts List

Valve

Assembly

S09-057

Item Part No. Description

1 124-001D Washer — 1

2 110-057 Nut — 1

3 125-001AN Stopper — 1

4 159-114 Reinforcing Plate — 1

5 124-001AT Washer — 1

6 160-176 Screw — 1

7 S09-040 Valve 1 1

8 S53-045 Adaptor 1 1

Qty

Attaching

Parts

S09-057S

5

4

3

7

6

8

2

1

Bradley • 215-1332 Rev. V; ECN 12-00-004 1/15/2013 15

TDB3104, WF3204 Installation

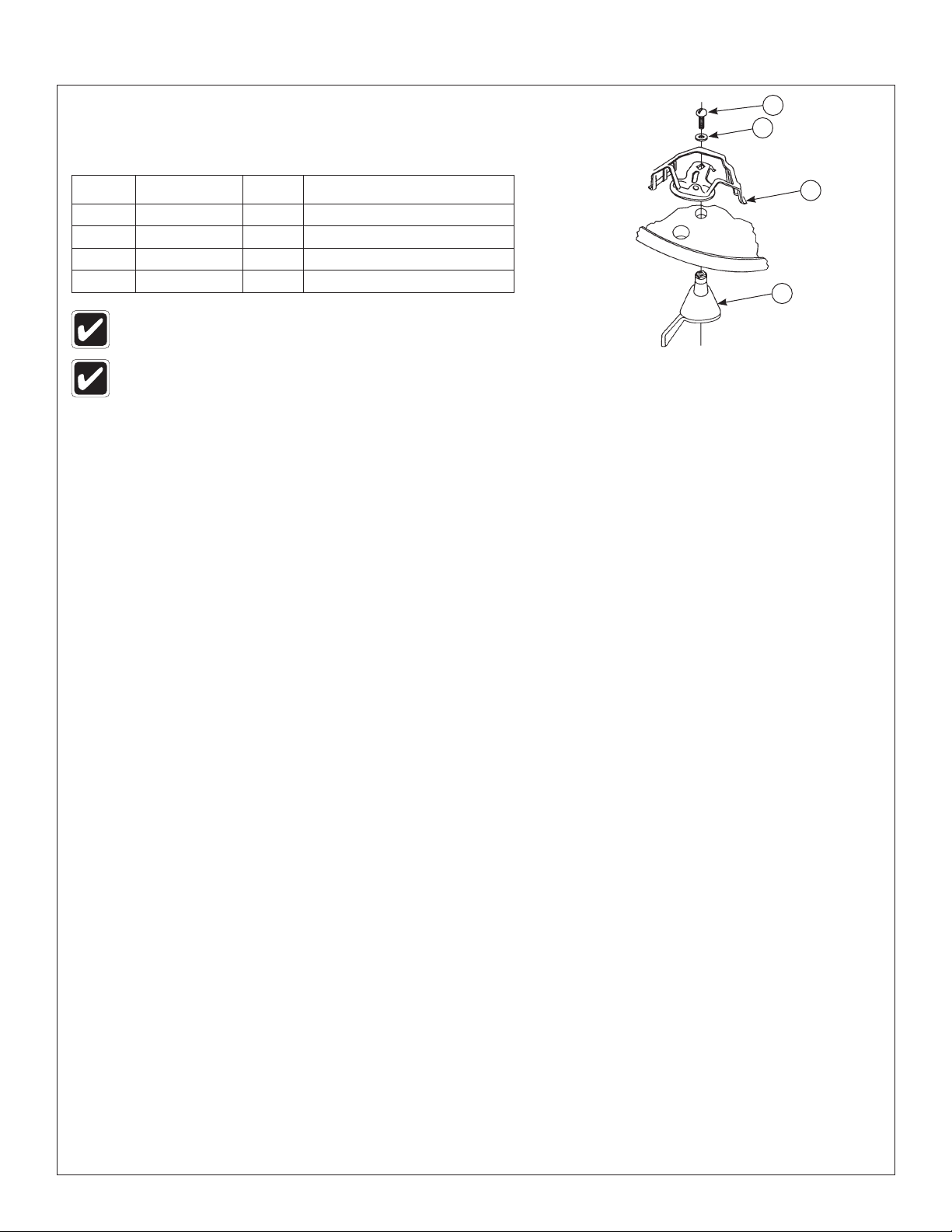

Soap Valve — Powdered — S09-010A

1

2

Parts List

Item Part No. Qty Description

1 160-069 1 Screw, 1/4-20 RD

2 142-002X 1 Washer, 1/4 Split-Lock

3 S62-002 1 Agitator / Slide Assy.

4 192-004 1 Lever - Powdered Soap

Reducer plugs are available for use with fine granulated

soap to reduce the flow.

Valves can be changed from powdered to liquid by plugging the innermost, or “bearing” hole with rubber plug,

part number 125-001AK. To change from liquid to powdered, the plug must be removed. If none is present, it

will be necessary to drill out the bearing hole with a 1/2" or 5/8" drill. The plastic container configuration forms

a natural template for locating the bearing hole.

3

4

Soap Maintenance Tips

Soap Recommendations

Quality soap dispensers require good quality soap and periodic maintenance to properly operate. Bradley soap dispensers will

provide dependable, consistent operation over the long term when soap with reasonable viscosity and pH levels are used and

when a minimal amount of periodic maintenance is performed on the valves.

Soap thickness is determined by a measurement called viscosity. Soap viscosity should be between 100 cps (centerpoise) and

2500 cps for all Bradley soap dispensers. Thinner soaps are perceived by the users as being “watered down” so users tend to

take more than they need, resulting in waste. Thick soaps flow slower and inhibit the “flushing” action of the valves, which

allows the soap to congeal in the valve and cause clogs.

The pH (acid) level of the soap should be in the range of 6.5 to 8.5. More acidic soaps (pH levels lower than 6.5) will corrode

metal parts (even stainless steel!!) and degrade rubber and plastic components. They will also cause skin irritation. Most

inexpensive soaps (typically the pink lotion type) fall into this acidic category and will eventually cause valve failure and

metal corrosion. Base soaps (pH levels higher than 8.5) will cause swelling or degradation of rubber and plastic parts and skin

irritation.

Generally, any quality soap meeting the viscosity and pH guidelines above will work well with Bradley soap dispensers. PCMX

or Isapropanol based antibacterial soaps (within viscosity and pH limits) will also work with Bradley dispensers. Soaps satisfying

these basic guidelines will provide consistent flow and reduce clogs.

Most soap dispenser problems are caused by soap that is too thick or corrosive, or by a lack of maintenance. Many soaps come

in concentrate form which must be diluted with water. Often, the soap is improperly diluted or used straight out of the bottle, which

causes clogging and valve failure. If proper soap is being used, valves that have never been cleaned are usually the source of

dispensing problems. Bradley has entered into an agreement with Champion Brand Products to provide additional customer

service for purchasers of our dispensers regarding soap issues. They are very helpful and can get to the bottom of almost any

soap dispenser related problem. They also sell an excellent “Bradley approved” soap. Please see

for details about soap valve cleaning or how to contact Champion. With proper maintenance and soap, Bradley dispensers will

provide long term, trouble free operation.

Soap Instruction Sheet 215-1286

Soap Dispenser Maintenance Instructions

Bradley soap dispensers will provide dependable, consistent operation over the long term when the proper soap is used and when

a minimal amount of periodic maintenance is performed on the valves. Valves must be maintained (cleaned) to function properly.

To ensure proper operation of your soap dispenser, follow these instructions:

• Once per month, unscrew valve from reservoir and soak it for 30 minutes in hot water.

• Push valve at least 20 times while it is soaking.

• Flush soap reservoir with hot water while valve is soaking.

In cases of extreme clogging, the valve should be disassembled and the parts should be soaked in hot water or cleaning solution

to restore proper functioning. Soap dispensers that will not be used for extended periods of time (schools during summer break,

etc.) should be drained, cleaned and left empty until put back into service. Soap left on the outside of dispensers can cause

discoloration and corrosion of the reservoir (even on stainless steel units). All soap should be wiped or scrubbed off daily, then the

outside of the dispenser should be rinsed with clear water and dried with a soft cloth.

16 1/15/2013 Bradley • 215-1332 Rev. V; ECN 12-00-004

Installation TDB3104, WF3204

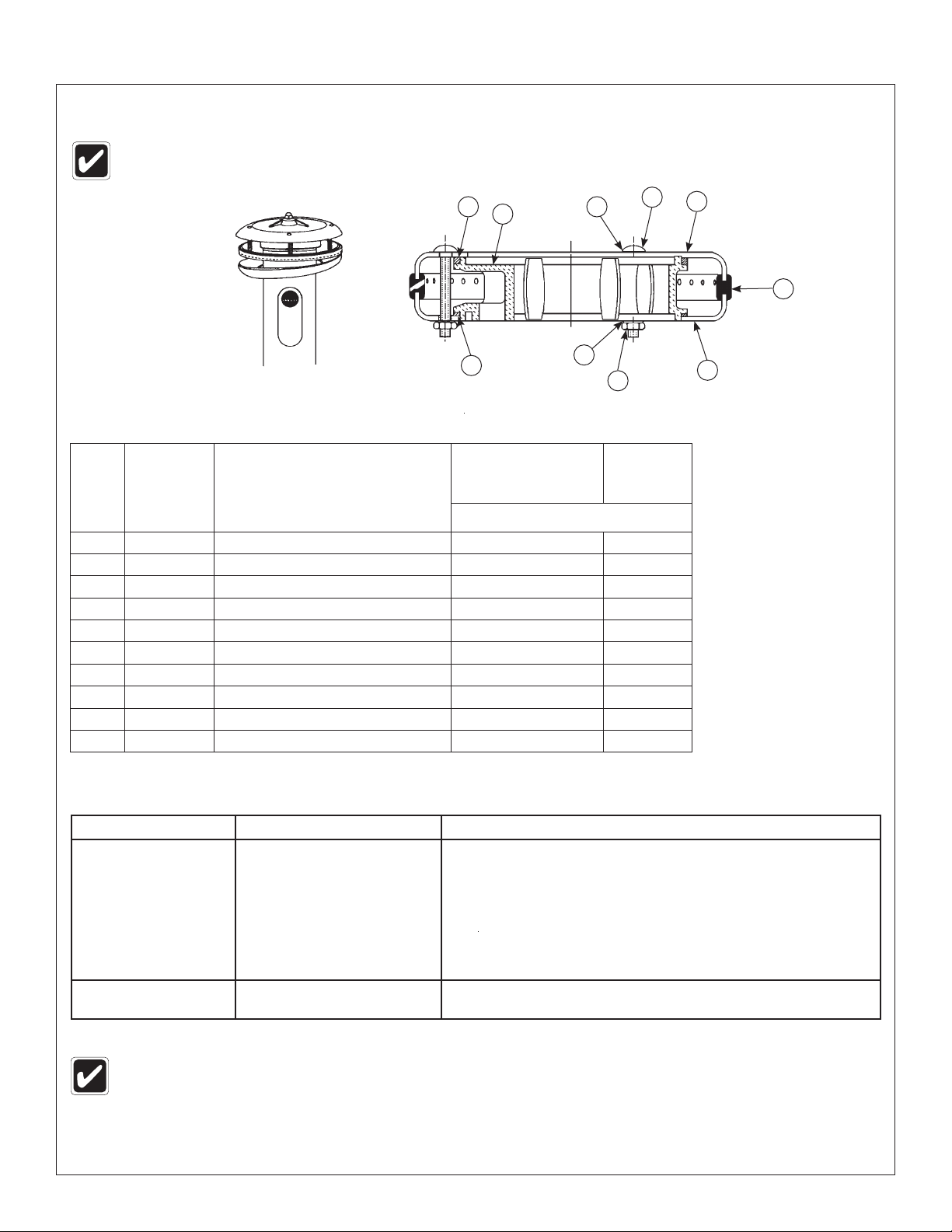

Sprayheads — Standard w/Neoprene Spray Ring Grommet

Repair kit does not include sprayhead

grommet. Order as a separate item.

4

1

2

3

5

9

10

7

Parts List

Sprayhead

Assembly

S05-054B

Item Part No. Description

1 125-001DE Neoprene Washer - Top 1 1

2 139-031 Sprayhead Manifold 1 —

3 124-001AL Washer 3 4

4 160-211 Carriage Bolt 3 4

5 115-061 Sprayhead - Top 1 —

6 116-008 Sprayhead - Bottom 1 —

7 124-001AT Washer 3 4

8 161-025 Nut 3 4

9 124-020D Sprayhead Grommet - Semi-Circle 1 —

10 125-001DF Neoprene Washer - Bottom 1 1

Qty

Sprayhead Service Suggestions

8

Repair

Kit

S45-051

6

Problem Possible Cause Solution

Water splashes over the

rim of the bowl.

Water flow diminishes

from the sprayhead.

Foreign matter has reduced

the size of the sprayhead slots,

causing greater pressure at the

open slots.

Strainer portion of the stopstrainer-check valve is plugged.

Clean the sprayhead:

1. Disassemble the sprayhead and dislodge any dirt, lime buildup and foreign debris with a wire brush.

2. Sprayheads with rubber grommet spray rings may be cleaned

by rubbing a coin over the grommet.

3. Throttle down the volume control (water spray should strike

the bowl without splashing outside of the bowl).

Remove and clean the strainer screen from the stop-strainer-check

valve.

The sprayhead shown above includes a perforated neoprene spray ring grommet that is self-cleaning. The

water pressure flexes the spray holes which slows accumulation of foreign matter and tends to “break loose”

any such deposits that may have accumulated.

Bradley • 215-1332 Rev. V; ECN 12-00-004 1/15/2013 17

Loading...

Loading...