Page 1

This product is supplemental and does

not fulfill the requirements of an eye or

eye/face wash product.

Ce produit est additionnel et ne remplit

pas les exigences d’un produit de

douche oculaire/faciale.

Este producto es complementario y no

cumple los requisitos de un producto

lavaojos o lavaojos/lavacara.

Installation

S1944011CBC

Hand-Held Drench Hose (with 12'

Hose)

Douchette à boyau mobile (boyau

spiralé de 12')

Manguera rociadora de mano

(manguera con retroceso de 12')

S1944011CBD

Hand-Held Drench Hose (with 25'

Hose)

Douchette à boyau mobile (boyau

spiralé de 25')

Manguera rociadora de mano

(manguera con retroceso de 25')

Table of Contents

Pre-Installation Information ........................... 2

Installation Instructions .............................. 3

Components and Parts List ........................... 4

215-1691 Rev. D; ECN 14-05-013

© 2014 Bradley

Page 1 of 10 7/29/2014

Table des matières

Avant l’installation .................................. 5

Instructions d’installation ............................. 6

Composantes et Liste des pièces ...................... 7

Contenido

Información previa a la instalación ..................... 8

Instrucciones de instalación .......................... 9

Componentes y Lista de piezas ...................... 10

P.O. Box 309, Menomonee Falls, WI USA 53052-0309

PHONE 800.BRADLEY (800.272.3539) FAX 262.251 5817

bradleycorp.com

Page 2

S1944011CBC, S1944011CBD Installation

IMPORTANT

Installation

R

WI 53051

alls,

HENTLICH ZU

WEEK

WÖC

P.O. Box 309, Menomonee F

DAIRE

e(s) each week and sign

UNIT EACH

y malfunctions immediatel

hentlich im

TEST THIS

hrift. Jeglic

DIESES GERÄT 1ST

ESSAI HEBDOMA

Test-operate valv

Report an

Ventil(e) wöc

t immédiatement.

durch Untersc

Test le fonctionnement des v

signe en bas. S'il y à quelqu

un rappor

Date

Datum

Date

114-051

PRÜFEN.

Testbetrieb prüfen,

he Störung sofor

Signed

Unterschrift

below.

bestätigt

t melden.

y.

alves chaque semaine et

e chose qui ne v

Date Signed

Signe

THIS

SIDE

UP

a pas fait

Signed

Signed

Date

Date

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

Packing List

•

•

•

•

Read this installation manual completely to ensure proper installation, then file it with the

owner or maintenance department. Compliance and conformity to drain requirements and

other local codes and ordinances is the responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for before discarding

any packaging material. If any parts are missing, do not begin installation until you obtain

the missing parts.

Flush the water supply lines before beginning installation and after installation is complete.

Test the unit for leaks and adequate water flow. Main water supply to the eyewash should be

“ON” at all times. Provisions shall be made to prevent unauthorized shutoff.

The ANSI Z358.1 standard requires an uninterrupted supply of flushing fluid. Bradley

plumbed emergency fixtures require a minimum of 30 PSI (0.21 MPa) flowing pressure.

Flushing fluid should be tepid per ANSI Z358.1.

The inspection and testing results of this equipment should be recorded weekly to verify

proper operation. This equipment should be inspected annually to ensure compliance with

ANSI Z358.1.

Workers who may come in contact with potentially hazardous materials should be trained

regarding the placement and proper operation of emergency equipment per ANSI Z358.1.

For questions regarding the operation or installation of this product, visit www.bradleycorp.

com or call 800.BRADLEY (800.272.3539).

Product warranties and service parts information may also be found under ”Products” on our

web site at bradleycorp.com.

2

7/29/2014 Bradley • 215-1691 Rev. D; ECN 14-05-013

Page 3

Installation S1944011CBC, S1944011CBD

Installation

NOTICE! Avoid cleaners containing organic solvents,

alcohols, and hydrocarbons. Rinse with water

after cleaning.

Supplies Required:

• Teflon tape and/or pipe sealant

• ½" NPT water supply inlet (30–90 psi)

• (2) ¼-20 screws (stainless steel recommended)

and anchors

• Backflow prevention device as required by UPC,

IPC and/or local plumbing codes

Local codes may require the installation of a backflow

prevention valve to complete proper installation.

Compliance with local codes is the responsibility of the

installer. Valve must be tested annually to verify that it

is functioning properly. Backflow prevention valves are

not included with the fixture and may be supplied by the

contractor or purchased from Bradley Corporation.

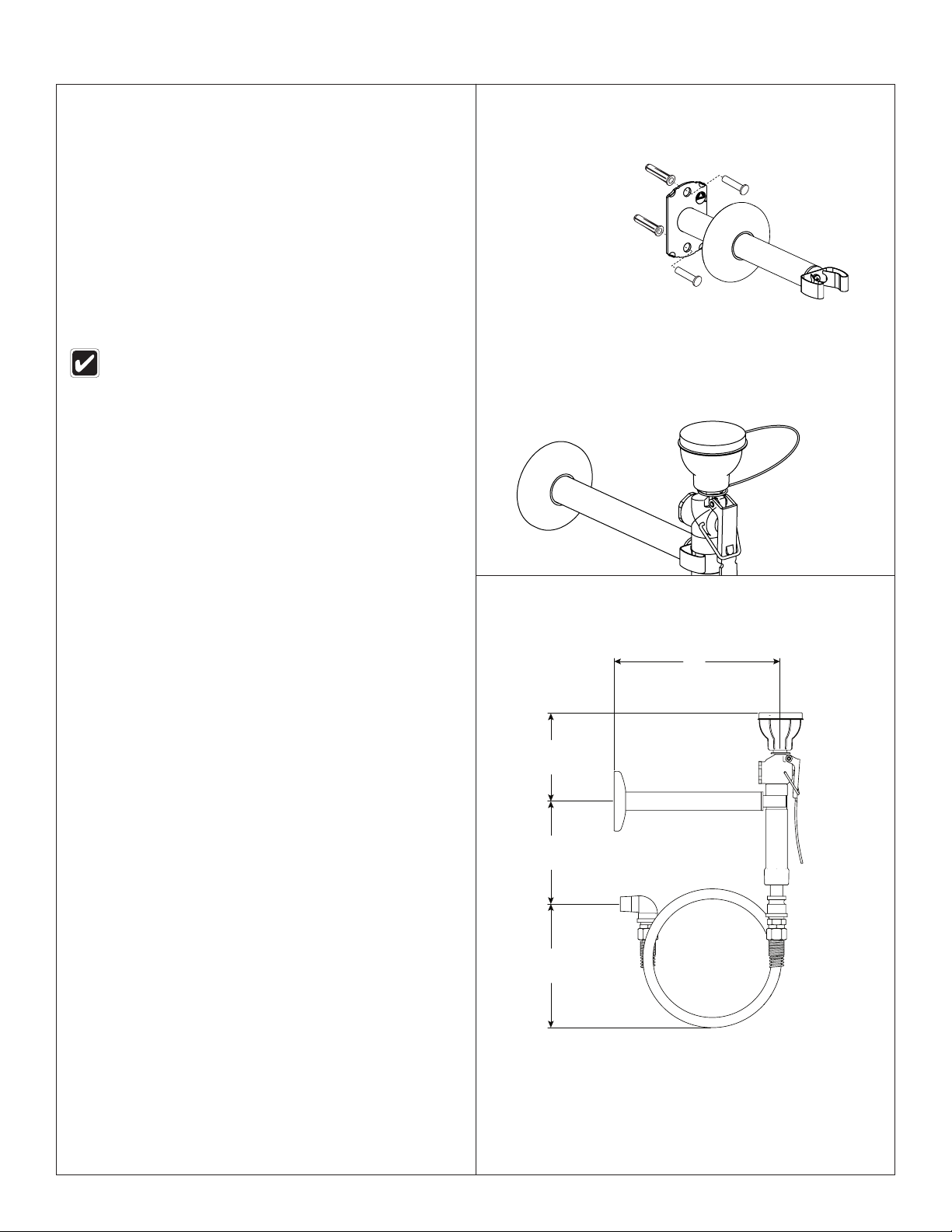

Step 1: Mount the bracket to the wall

Wall

1. Rough in ½" NPT supply piping (by installer) from the

wall where the drench hose is desired.

2. Using the bracket flange as a template, mark the

anchor/screw locations on the wall.

3. Mount the bracket to the wall with two suitable anchors

and ¼-20 screws (supplied by installer).

Step 2: Connect the hose assembly

Apply pipe sealant (supplied by installer) to all male

threaded pipe joints.

1. Connect rigid end of the drench hose to the ½" NPT

elbow.

2. Connect the ½" NPT elbow (provided) to the ½" NPT

supply from the wall.

3. Install the valve body onto the swivel end of the hose.

4. Open the water supply line. Test for leaks and adequate

water flow.

9"

(229mm)

7-1/2"

(191mm)

5-1/2"

(140mm)

6-3/4"

(171mm)

Bradley • 215-1691 Rev. D; ECN 14-05-013 7/29/2014

3

Page 4

S1944011CBC, S1944011CBD Installation

Assembly of Components and Parts List

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Date

Signe

Date

1.2

1.3

1.1

1.4

1

2

7

R

5

Signed

Signed

Swivel End

Water flow rate: 2.2–2.7 gallons (8.3–10.2 liters) per minute.

Item Part No. Qty. Description

1 S39-817 1 Sprayhead Assembly

1.1 S27-332 1 Valve, Hose Spray

1.2 S45-2453 1 Service Kit EFW - Black

Sprayheads

1.3 S53-063 1 Dust Cover

1.4 128-182 1 Handle, Drench Hose

2 S70-175 1 Wall-Mount Assembly

4

6

3

Rigid End

Item Part No. Qty. Description

3 169-078 1

4 269-053 1 Recoil Hose, 12' (S1944011CBC)

269-054 1 Recoil Hose, 25' (S1944011CBD)

5 113-1225 1 Pipe Extension

6 169-639 1 Elbow, ½" NPT

7 204-421 1 Emergency Inspection Tag

Reducing Coupling, ½" x ³⁄₈"

4

7/29/2014 Bradley • 215-1691 Rev. D; ECN 14-05-013

Page 5

Installation S1944011CBC, S1944011CBD

IMPORTANT

Installation

R

WI 53051

alls,

HENTLICH ZU

WEEK

WÖC

P.O. Box 309, Menomonee F

DAIRE

e(s) each week and sign

UNIT EACH

y malfunctions immediatel

hentlich im

TEST THIS

hrift. Jeglic

DIESES GERÄT 1ST

ESSAI HEBDOMA

Test-operate valv

Report an

Ventil(e) wöc

t immédiatement.

durch Untersc

Test le fonctionnement des v

signe en bas. S'il y à quelqu

un rappor

Date

Datum

Date

Lire ce manuel d’installation dans son intégralité pour garantir une installation appropriée.

Une fois celle-ci terminée, classer ce manuel auprès du service à la clientèle ou d’entretien.

L’installateur est responsable de la conformité de l’installation aux codes pour des drain et

codes et règlements en vigueur.

Packing List

•

•

•

THIS

SIDE

•

UP

Assurez-vous que toutes les pièces sont incluses dans l’emballage et qu’il n’en manque

aucune avant de jeter l’emballage. Ne commencez pas l’assemblage avant de recevoir les

pièces manquantes.

Rincez la conduite d’alimentation avant et apres l’installation. Assurez-vous que le débit d’eau

est adéquat et qu’il n’y a pas de fuites. L’alimentation principale en eau doit être toujours

OUVERTE. On devra prévoir des dispositions pour empêcher tout arrêt non autorisé.

La norme ANSI Z358.1 prévoit une alimentation ininterrompue du liquide de rinçage. Les

appareils d’urgence Bradley raccordés au réseau nécessitent une pression d’écoulement d’au

moins 30 PSI (0,21 MPa). Selon ANSI Z358.1, le liquide de rinçage doit être tiède.

Inspectez et testez cet équipement une fois par semaine pour en assurer le bon fonctionement.

Notez les dates d’inspection. Ce matériel doit être inspecté une fois par an pour assurer sa

below.

PRÜFEN.

bestätigt

t melden.

y.

a pas fait

Testbetrieb prüfen,

he Störung sofor

alves chaque semaine et

Signed

e chose qui ne v

Signed

Date Signed

Date

Date

Signed

Unterschrift

Signe

conformité à la norme ANSI Z358.1.

Les ouvriers susceptibles d’entrer en contact avec des matières potentiellement dangereuses

doivent recevoir une formation sur la mise en place et le bon fonctionnement du matériel

d’urgence conformément à la norme ANSI Z358.1.

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

Pour toute question concernant le fonctionnement ou l’installation de ce produit, consulter le

site www.bradleycorp.com ou appeler le 800.BRADLEY (800.272.3539).

Les garanties de produits figurent sous la rubrique « Informations techniques » sur notre site

Internet à www.bradleycorp.com.

Bradley • 215-1691 Rev. D; ECN 14-05-013 7/29/2014

5

Page 6

S1944011CBC, S1944011CBD Installation

Installation

AVIS ! Éviter les nettoyants qui contiennent des

solvants organiques, de l’alcool et de

l’hydrocarbure. Rincer avec de l’eau après le

nettoyage.

Fournitures nécessaires :

• Produit d’étanchéité pour tuyaux

• Tuyauterie d’alimentation en eau de ½" NPT

(30–90 psi)

• (2) vis de ¼-20 (l’emploi de vis en acier

inoxydable est conseillé) et chevilles

• Dispositif de prévention de reflux tel que requis

par les UPC, IPC et/ou codes de plomberie

locaux

Les codes locaux peuvent exiger l’ installation d’une

soupape de prévention d’écoulement de retour pour

réaliser une installation appropriée. L’installateur est

responsable de la conformité aux codes locaux. La

soupape doit être testée une fois par an pour vérifier

qu’elle fonctionne correctement. Les soupapes de

prévention d’écoulement de retour ne sont pas

fournies avec l’appareil et peuvent être fournies

par l’entrepreneur ou achetées auprès de Bradley

Corporation.

Mur

Étape 1 : Installez du support mural

1. Installez rudimentairement un tuyau NPT de ½" sur le

mur où du boyau spiralé fixé.

2. En vous servant de la bride de montage du support

mural comme gabarit, marquez l’emplacement des

chevilles et des vis.

3. Installez du support mural dans le mur avec deux

chevilles pour vis ¼-20 et des chevilles (non fournies).

Étape 2 : Brancher l’alimentation en eau

Mettez du produit d’étanchéité (non fourni) sur tous les

filetages mâles.

1. Raccorder le côté rigide du rideau d’eau à un coude de

1/2 po NPT.

2. Raccordez le coude NPT de ½" (fourni) sur le tuyau

d’alimentation NPT de ½" sortant du mur.

3. Monter le corps de vanne sur le côté pivotant du tuyau.

4. Ouvrir l’alimentation en eau. Vérifier s’il y a des fuites et

si le débit d’eau est adéquat.

9"

(229mm)

7-1/2"

(191mm)

5-1/2"

(140mm)

6-3/4"

(171mm)

6

7/29/2014 Bradley • 215-1691 Rev. D; ECN 14-05-013

Page 7

Installation S1944011CBC, S1944011CBD

Assemblage des composantes et liste des pièces

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Date

Signe

Date

1.2

1.3

1.1

1.4

1

2

7

R

5

Signed

Signed

3

Côté pivotant

Le débit de l’eau : 2.2–2.7 gal/mn (8.3–10.2 l/mn).

Pièce Réf. Qté. Description

1 S39-817 1 Assemblage du gicleur

1.1 S27-332 1 Robinet

1.2 S45-2453 1 Trousse d’entretien EFW Diffuseurs noirs

1.3 S53-063 1 Bouchon antipoussière

1.4 128-182 1 Manette

2 S70-175 1 Support mural

4

6

Côté rigide

Pièce Réf. Qté. Description

3 169-078 1

4 269-053 1 Boyau, 12' (S1944011CBC)

269-054 1 Boyau, 25' (S1944011CBD)

5 113-1225 1 Tuyau

6 169-639 1 Coude ½" NPT

7 204-421 1 Etiquette d’inspection

Réducteur de couplage, ½" x ³⁄₈"

Bradley • 215-1691 Rev. D; ECN 14-05-013 7/29/2014

7

Page 8

S1944011CBC, S1944011CBD Installation

IMPORTANTE

Installation

R

WI 53051

alls,

HENTLICH ZU

WEEK

WÖC

P.O. Box 309, Menomonee F

DAIRE

e(s) each week and sign

UNIT EACH

y malfunctions immediatel

hentlich im

TEST THIS

hrift. Jeglic

DIESES GERÄT 1ST

ESSAI HEBDOMA

Test-operate valv

Report an

Ventil(e) wöc

durch Untersc

Test le fonctionnement des v

signe en bas. S'il y à quelqu

un rappor

Date

Datum

114-051

PRÜFEN.

Testbetrieb prüfen,

t immédiatement.

Date

y.

he Störung sofor

alves chaque semaine et

Signed

Unterschrift

Signe

below.

bestätigt

t melden.

e chose qui ne v

Date Signed

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

THIS

SIDE

UP

a pas fait

Signed

Date

Date

TEL: 1-800-BRADLEY FAX: (262-251-5817)

Lea en su totalidad este manual de instalación para garantizar una instalación adecuada.

Una vez que termine la instalación, entregue este manual al propietario o al Departamento

de Mantenimiento. Es responsabilidad de quien instale el equipo cumplir con los códigos

para desagüe y otra códigos y ordenanzas locales.

Packing List

•

•

•

•

Separar todas las piezas del material de embalaje y asegurarse que todas las piezas estén

incluídas antes de desechar cualquier material de embalaje. Si faltase alguna pieza, no

intentar instalar la unidad combinada Bradley hasta obtener las piezas faltantes.

Aclarar el conducto del suministro de agua antes y después de la instalación. Verificar que

no haya fugas y que el flujo de agua sea adecuado. El suministro principal de agua a la

unidad debe estar siempre en posición “ON” (abierto). Se deben tomar medidas a fin de

evitar el corte no autorizado del suministro.

La norma ANSI Z358.1 exige un suministro ininterrumpido de líquido de limpieza. Los

equipos de emergencia con tuberías de Bradley requieren una presión de flujo mínima de

0,21 MPa (30 PSI). El líquido de limpieza debe estar tibio en conformidad con la norma ANSI

Z358.1.

Este equipo se debe inspeccionar, probar y anotar semanalmente para mantener un

Signed

funcionamiento adecuado

. Se debe revisar este equipo anualmente para asegurarse de que

cumpla con la norma ANSI Z358.1.

Los trabajadores que puedan tener contacto con materiales potencialmente peligrosos

deben recibir capacitación sobre la ubicación y operación adecuada de los equipos de

http://www.bradleycorp.com

emergencia en conformidad con la norma ANSI Z358.1.

Para consultas sobre la operación o instalación de este producto, visite www.bradleycorp.

com o llame al 800.BRADLEY (800.272.3539).

Las garantías del producto se pueden encontrar e n “Información del producto” o en nuestro

sitio Web, www.bradleycorp.com.

8

7/29/2014 Bradley • 215-1691 Rev. D; ECN 14-05-013

Page 9

Installation S1944011CBC, S1944011CBD

Instalación

¡AVISO! Evite los limpiadores que contengan solventes

orgánicos, alcoholes e hidrocarburos.

Enjuague con agua después de limpiar.

Materiales necesarios:

• Sellador de tubería

• Suministro de agua NPT de ½" (30–90 psi)

• (2) tornillos de ¼-20 (se recomiendan tornillos de

acero inoxidable) y anclas

• UPC, IPC y las reglamentaciones locales de

plomería exigen la instalación de un dispositivo

antiretorno

Los códigos locales pueden exigir la instalación de una

válvula de prevención de contraflujo para completar la

instalación correcta. La conformidad con los códigos

locales es de responsabilidad del instalador. La válvula

se debe probar anualmente para verificar que funcione

de manera correcta. Las válvulas de prevención de

contraflujo no se incluyen con el accesorio y las puede

proporcionar el contratista o las puede comprar en

Bradley Corporation.

Pared

Paso 1: Montar el soporte a la pared

1. Enfoscar tubería de suministro NPT de ½" NPT de la

pared en que se desea colocar la manguera.

2. Usar la brida del soporte como plantilla para marcar la

ubicación de ancla y tornillo.

3. Montar el soporte a la pared usando dos tornillos ¼-20

y anclajes (suministrados por el instalador).

Paso 2: Connect the hose assembly

Aplicar sellador de tubería (suministrada por el

instalador) a todas las juntas de tubería de rosca

macho.

1. Conecte el extremo rígido de la manguera al codo de

1/2" NPT.

2. Conectar el codo NPT de ½" NPT suministrado a la

tubería de suministro NPT de ½" NPT de la pared.

3. Instale el cuerpo de la válvula en el extremo giratorio de

la manguera.

4. Abra la línea de suministro de agua. Compruebe que no

haya fugas y que el flujo de agua sea el adecuado.

9"

(229mm)

7-1/2"

(191mm)

5-1/2"

(140mm)

6-3/4"

(171mm)

Bradley • 215-1691 Rev. D; ECN 14-05-013 7/29/2014

9

Page 10

S1944011CBC, S1944011CBD Installation

Armado de los componentes y lista de piezas

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Date

Signe

Date

1.2

1.3

1.1

1.4

1

2

7

R

5

Signed

Signed

3

Extremo

giratorio

El flujo de agua: 2.2–2.7 galones (8.3–10.2 litros) por minuto.

Art. Pieza N° Cant. Descripción

1 S39-817 1 Conjunto de Rociador

1.1 S27-332 1 Válvula

1.2 S45-2453 1 Kit de mantenimiento para

lavado de ojos y cara: Boquillas

rociadoras negras

1.3 S53-063 1 Cubiertas contra el polvo

1.4 128-182 1 Manija

2 S70-175 1 Soporte pared

4

6

Extremo

rígido

Art. Pieza N° Cant. Descripción

3 169-078 1

4 269-053 1 Manguera 12' (S1944011CBC)

269-054 1 Manguera 25' (S1944011CBD)

5 113-1225 1 Tubo

6 169-639 1 Codo NPT de ½"

7 204-421 1 Etiqueta de Inspeccion

Acoplamiento Reductor, ½" x ³⁄₈"

10

7/29/2014 Bradley • 215-1691 Rev. D; ECN 14-05-013

Loading...

Loading...