Page 1

Installation

S19390 Series

Gravity Fed Safety Shower

General Area

Table of Contents

Safety Information ...............................2

Dimensions .................................. 3-4

Shipping and Handling Instructions..................5

Gravity Fed Safety Shower Preconstruction Guide ......6

Storage and Preservation Guide ....................7

Secure Frame to Concrete Pad .....................7

Prepare Enclosure...............................8

Electrical Connections ............................9

Filling Water Tank ..............................10

Signaling System Maintenance ....................11

Energizing the Unit .............................11

Test the Signaling System ........................11

Start-Up Check List .............................12

Weekly Inspection Checklist ......................13

Troubleshooting ................................14

Read the instructions in this manual before

beginning installation. Save these instructions

and refer to them for inspection, maintenance

and troubleshooting information.

For questions regarding the operation, installation or maintenance of this product, visit bradleycorp.com

or call 800.BRADLEY (800.272.3539).

Product warranties and parts information may also be found under ”Products” on our web site at bradleycorp.com.

P.O. Box 309

+1 262 251 6000

bradleycorp.com

215-1871 Rev. A; ECN 17-05-055

© 2018 Bradley

Page 1 of 14 2/13/2018

Menomonee Falls, WI 53052 USA

800 BRADLEY (800 272 3539)

Page 2

S19390 Series Installation

Safety Information

To reduce the risk of serious injury or death:

Installation

The installation and location of all safety drench showers, eye and eye/face washes must comply with the

requirements of ANSI/ISEA Z358.1.

Before installation make sure that this equipment will meet the requirements of potential hazardous contaminants in

your location.

Workers who may come in contact with potentially hazardous materials should be trained regarding the placement

and proper operation of emergency equipment per ANSI/ISEA Z358.1.

Installation of this system must be completed by a qualified plumber and electrician in compliance with all national

and local codes. Compliance and conformity to drain requirements and other local codes and ordinances is the

responsibility of the installer.

This unit is to be used with clean, potable water as defined by ANSI/ISEA Z358.1. Bradley recommends the use of

water preservative with this unit. Water preservative may be purchased from various distributors; please contact your

local distributor. If algae or other containments are allowed into the tank or develop in the tank the shower may not

function properly.

Weekly Inspections

Make sure the shower and face wash fixtures are ready to be used when needed by performing regular checks

and maintenance. Weekly inspections must be conducted on all self-contained safety equipment to make sure a

suitable flushing fluid supply is present, check if fluid needs to be changed or supplemented, and to make sure the

equipment is in good operating condition. See page 13 for additional information.

Water Temperature

ANSI/ISEA Z358.1 requires tepid water. Suitable range is 60°F to 100°F (16°C to 38°C). Personal injury is possible

outside this temperature range. If ambient temperature may drop below 60°F (16°C), install a heater with a

continuous power supply. If model selected does not include tank water heater, the ambient temperature will affect

the tank temperature and must be placed in an appropriate location.

Moving the Tank

Drain the tank completely before moving. Lifting or moving a tank with water may cause damage to the unit or a loss

of stability when in motion.

To avoid product or property damage:

• Unit is designed to be installed indoors or in locations above freezing (32°F (0°C)).

• Make all water and electrical connections at temperatures above freezing (32°F (0°C)).

2

2/13/2018 Bradley • 215-1871 Rev. A; ECN 17-05-055

Page 3

Installation S19390 Series

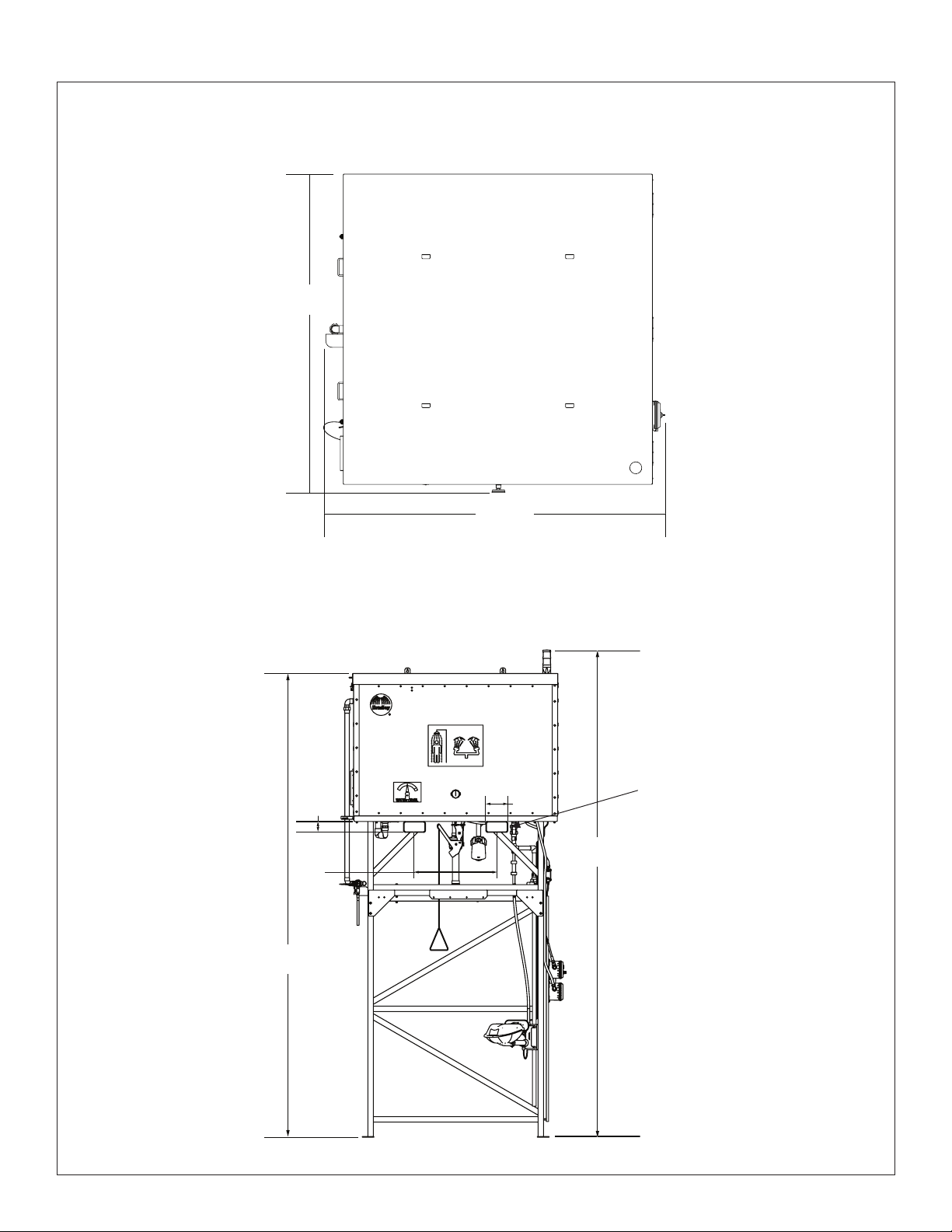

Dimensions

Top View

(mm)

77"

(1956)

82"

(2083)

Front View

3-1/2"

(762)

168-7/8"

(4290)

(89)

30"

7-1/2"

(191)

Fork Truck

Slots

177-3/8"

(4506)

Bradley • 215-1871 Rev. A; ECN 17-05-055 2/13/2018

3

Page 4

S19390 Series Installation

Dimensions

Left Side View Right Side View

Warning

Light

Beacon

Light

Optional

Tank Water

Heater (Inside

Enclosure)

Water Inlet

(mm)

92-3/8"

(2346)

Area Light

with Motion

Sensor Option

See water heater manual

to adjust temperature.

4

2/13/2018 Bradley • 215-1871 Rev. A; ECN 17-05-055

Page 5

Installation S19390 Series

Shipping and Handling Instructions

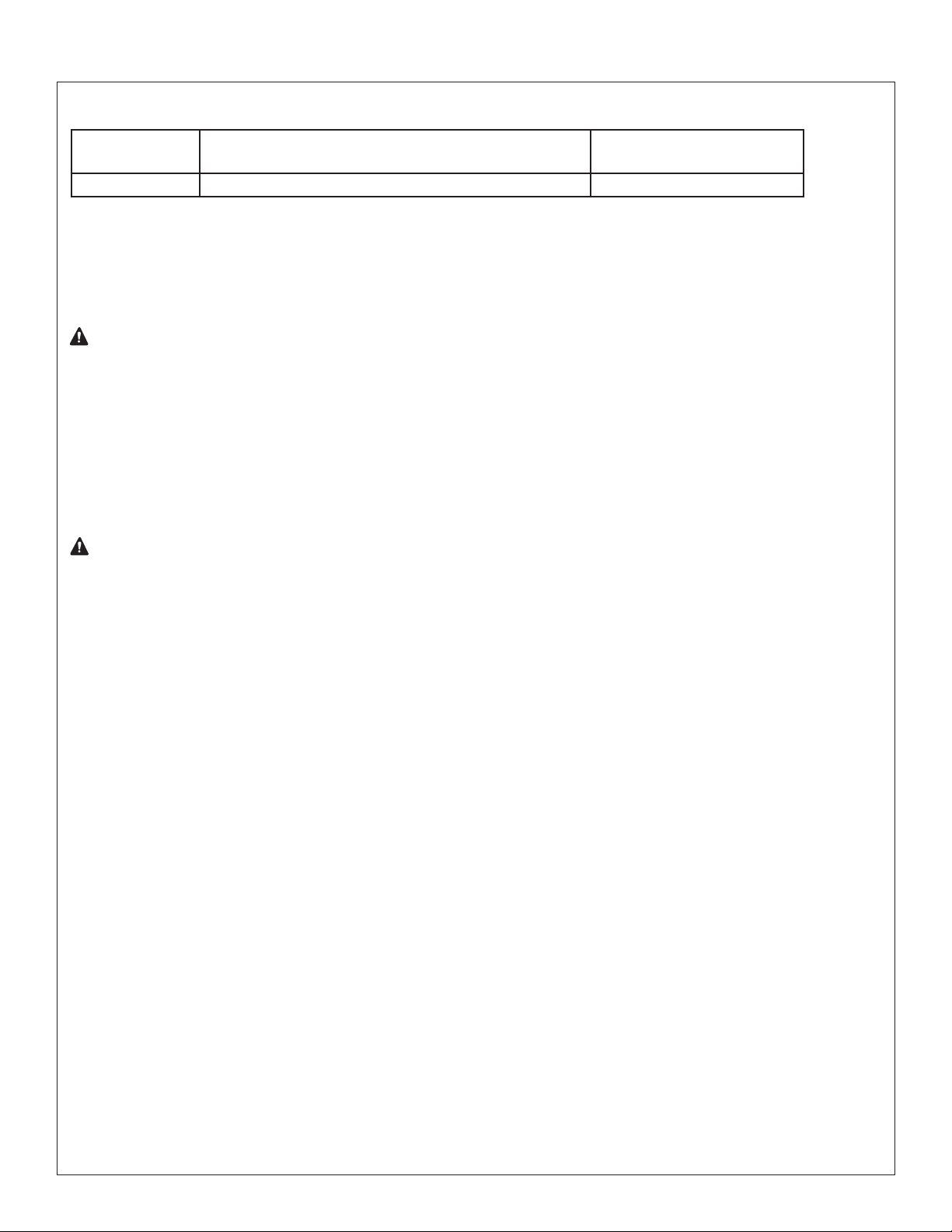

Approximate Total Weight

Base Model No. Description

S19390 Gravity Fed Safety Shower 2200 lbs.*

*Weight will vary depending on options selected.

Transporting the Gravity Fed Safety Shower

Bradley Safety Showers are transported within the continental United States and Canada via commercial truck. Unit

ships in two pieces (steel frame and enclosed water tank). See page 8.

WARNING Always use proper lifting techniques when moving the safety shower. Weight distribution is

unbalanced, and the product may tip over if lifted improperly. Make sure lifting equipment is

properly rated for this load. Overloading could cause serious injury or death from tip over.

Bottom Lift: Locate lifting points at base of tank enclosure or shipping pallet. Notice: Lifting eyelets on top of tank

enclosure are only for lifting the cover. Do not use to lift the entire tank enclosure.

If immediate destination of the unit is storage, refer to the Storage and Preservation Guide.

Each shower will be accompanied by document packaging that includes the installation instructions and electrical

schematics, if applicable. Store safety enclosure documents for reference.

If equipment is relocated, always perform a functional test before returning to service.

(less shipping skids)

WARNING Drain the tank completely before moving. Lifting or moving a tank with water may cause a loss

of stability and tipover.

Storage and Preservation Guide

Keep Bradley Gravity Fed Safety Shower stored in original packaging until installation.

• Store Bradley Safety Shower where temperatures are above 35°F (5°C) at all times.

• Indoor storage is recommended.

• Minimize excessive transportation around a job site to reduce risk of damage.

If the Bradley Safety Shower is stored in an outdoor environment, care should be taken to protect the Safety Shower

from rain or other falling precipitation via tarp or other waterproof material and from runoff and accumulation of

ground water from any source that may exceed 3” depth.

Bradley • 215-1871 Rev. A; ECN 17-05-055 2/13/2018

5

Page 6

S19390 Series Installation

Gravity Fed Safety Shower Preconstruction Guide

Thank you for your business. The purpose of Bradley’s Gravity Fed Safety Shower preconstruction guide is to provide

important pre-installation information to the customer that has determined their product specification needs are met

by a Gravity Fed Safety Shower configuration. For system details refer to Bradley’s Product Technical Data sheets. If

additional information is still required contact the Bradley Corporation Technical Service Department.

Technical Documents Available

• Product Technical Data Sheets

• Storage and Preservation Guide

• Installation Instructions

Recommended Equipment, Materials and Supplies to be provided by Installer

• Concrete slab rated to support a minimum 6000 psi vertical static load. The slab should be sufficiently

anchored to resist upheaval or movement due to environmental causes such as wind loads on the

shower.

• Drain able to accommodate 30 gpm discharge for shower and eye/face wash.

• (8) 1/2” diameter Anti-Corrosion Expansion Anchors (2 per mounting plate)

• Properly rated lifting equipment which exceeds the total weight of the shower unit

• Electrical supply materials (if applicable)

• Plumbing supply materials (if applicable)

Pre-installation Instructions

IMPORTANT: Separate parts from packaging and make sure all parts are accounted for before discarding

any packaging material. If any parts are missing, do not begin installation until you obtain the

missing parts.

• Survey the facility to ensure that the appropriate flushing system is installed per the ANSI/ISEA Z358.1

requirements. Identify a location that is capable of delivering a supply of power which will meet system

electrical requirements (if applicable).

• Review minimum electrical requirements based on the unit and options selected. Refer to wiring

schematic or system rating labels provided with unit.

• Confirm that the installation area is level.

• If concrete is not already present, pour a 6000 psi-rated concrete pad 80” x 72” minimum. The thickness

and foundation for this pad should be designed and constructed to meet the requirements of each site.

• Make allowances to ensure the electrical system is grounded prior to connecting power.

6

2/13/2018 Bradley • 215-1871 Rev. A; ECN 17-05-055

Page 7

Installation S19390 Series

Secure Frame to Concrete Pad

1. Place the frame in position, centering the unit on the concrete pad.

65-1/2"

(1664)

59"

(1499)

50"

(1270)

2. Secure the frame to the concrete using suitable concrete anchoring devices supplied by the installer.

Anchoring devices must be a minimum 6” long and 1/2” diameter, with 2 per corner of the frame.

WARNING Follow anchor manufacturer’s instructions and local requirements to make sure frame is

securely connected to the concrete pad.

Bradley • 215-1871 Rev. A; ECN 17-05-055 2/13/2018

7

Page 8

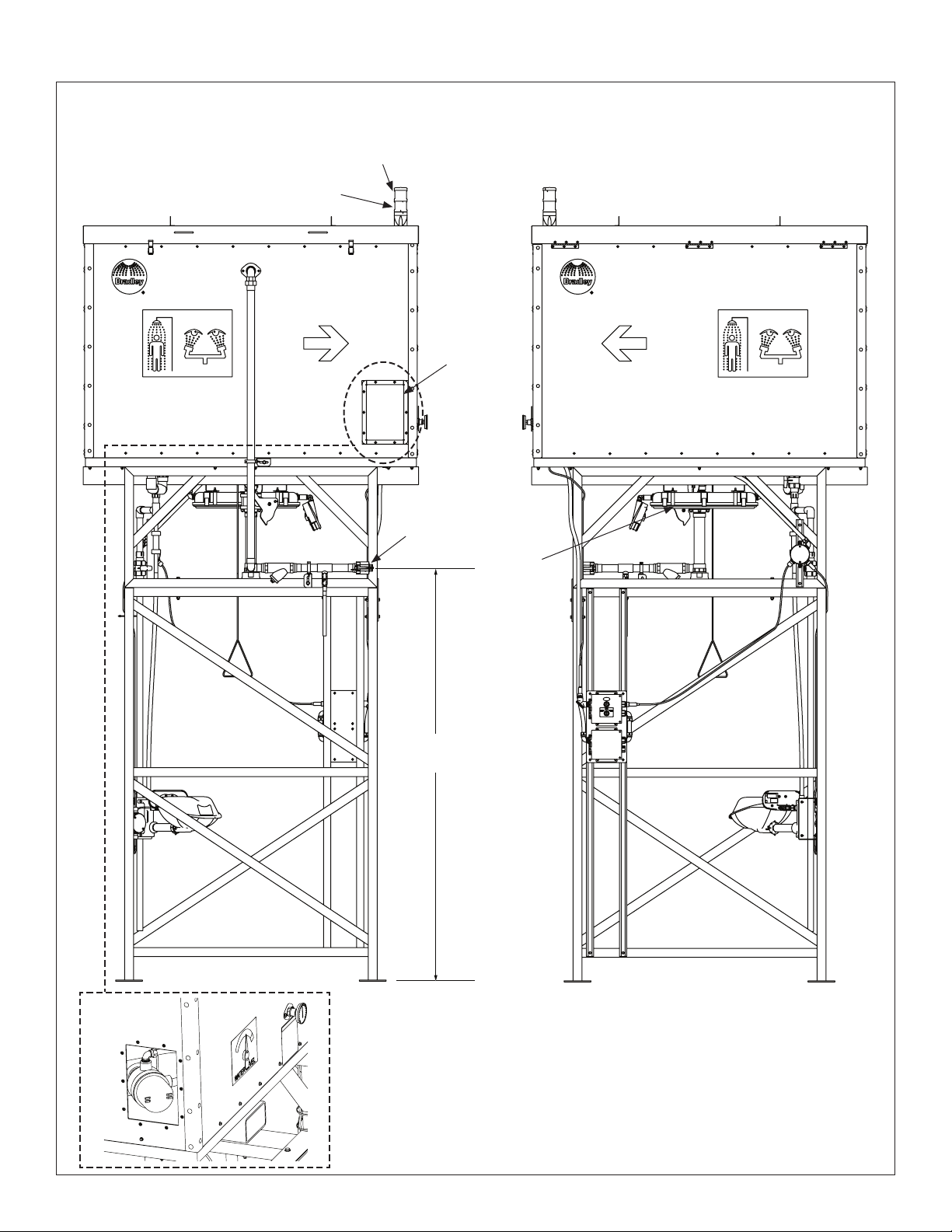

S19390 Series Installation

Prepare Enclosure

3. Use a properly sized fork truck to place the empty tank enclosure onto the frame (secured to the concrete pad in

Secure Frame to Concrete Pad, pg. 7). Locate the tank enclosure on the frame, aligning the two guide pins on

the top of the frame with the corresponding holes in the bottom of the tank enclosure. Notice: The 4 eyelets are

only for lifting off the cover to maintain or repair the water tank or other components in the enclosure.

4. Fasten the two components together with the supplied fasteners(8 sets of 3/8" fasteners). Tighten nut securely.

5. Attach the pipe unions that connect the optional eye/face wash and the tank drain to the corresponding pipe

fittings below the tank.

6. Attach the shower’s pull rod to the lever on the ball valve.

3

4

2

3

6

2

4

5

4

3

8

2/13/2018 Bradley • 215-1871 Rev. A; ECN 17-05-055

Page 9

Installation S19390 Series

Electrical Connections

Some steps apply to optional components. Review and follow if applicable.

WARNING To prevent personal injury or damage to the electrical components, electrical connections

should be made be a qualified electrician. Make sure electrical supply is disconnected

(circuit protection to be provided by installer) and follow all lockout/tagout procedures when

performing any electrical maintenance or installation/connection to the system.

NOTICE:

• It is recommended that installation be completed when ambient temperature is above freezing.

• To avoid damage to the water heater, do not power the water heater unless the tank is filled with water.

1. Verify that the electrical supply is

disconnected.

2. Connect the optional signal system light

4-pin cable to the signal system box.

3. Connect the optional signal system

sensor 3-pin cable to the signal system

box. Connect the 3-pin cable from the face

wash sensor to the junction box.

4. Connect the optional water heater/light

conduit cable to the fuse box.

5. Install incoming power conduit to the

electrical box (installer must provide

suitable disconnect and circuit protection

devices).

6. Refer to the system’s electrical wiring

drawings for proper connections.

Optional Signal

System Light

(4-Pin Cable)

Optional Water

Heater Conduit

Cable

Fuse Box for

Water Heater

and/or Area

Light Options

Optional

Signaling

System

Power Inlet Port,

Optional Signal

System Sensor

(3-Pin Cable)

3/4"

Bradley • 215-1871 Rev. A; ECN 17-05-055 2/13/2018

9

Page 10

S19390 Series Installation

Filling Water Tank

1. Ensure the shower, eye/face wash and drain

valves are in the closed position.

2. At the side of the tank where the water inlet

plumbing is located, verify that the water inlet

drain valve is closed. Remove the 1-1/2” cam

lock plug from the fitting and connect a potable

water source, then fill the tank with water. A

float valve should limit the water allowed into a

full tank, but care should be taken to not overfill

the tank. The water level indicator on the front of

the tank will show the water level.

3. When the tank has been at least partially

filled (approximately 100 gallons or 350 liters

minimum), or when the tank is full, the shower

and eye/face wash should be activated briefly

(10-20 seconds) to flush water through the

fixtures and remove trapped air.

If the water flow pattern from the showerhead or

eye/face wash is not stable or fully shaped, verify

that there are no obstructions. The showerhead

and the eye/face wash head can be removed for

inspection and cleaning.

Water Inlet

Water Inlet

Drain Valve

4. Add water preservative (not included) to the

water tank by opening the tank enclosure cover

and the inner tank lid. Follow the preservative

manufacturer’s instructions for proper use of

their product.

Some water may need to be added to the tank to

achieve full capacity after testing the fixtures.

5. Check for leaks at all connections throughout

the system.

6. With the water supply turned off, open the water

inlet drain valve to empty the water inlet piping,

then disconnect the water supply. Replace the

cam lock plug in the water inlet fitting and lock

the cam levers in the closed position.

10

2/13/2018 Bradley • 215-1871 Rev. A; ECN 17-05-055

Page 11

Installation S19390 Series

Energizing the Unit

1. Verify that all water and electrical connections have been properly made.

WARNING To reduce the risk of electrical shock close all electrical boxes before energizing the unit.

2. Turn on the power at the electrical disconnect switch (supplied by installer).

3. Complete Startup Checklist and the Weekly Visual Inspection Checklist (included in this manual) at this time.

Test the Signaling System

1. Apply power to the alarm branch circuit. The alarm

should remain in the OFF position and the beacon and

area light illuminate (if applicable). The signal light will

not illuminate.

2. Open the eye/face wash valve. The horn should sound

and the signal light flash shortly after water flows from

the system. If there is the optional beacon light, this

beacon light will turn off once the fixture is activated

(the signal light will stay on, flashing). The area light will

always stay on.

Horn

3. If present, use the auto reset on/ off switch to silence

the horn during a water-flow event. Toggling the switch

to silence mode will shut off the horn but allow the

signal light to keep flashing. All units can be silenced by

deactivating the flow.

4. Shut off the eye/face wash flow valve. If applicable, the

signal light should stop flashing and the beacon light

will turn back on.

Discontinuing the flow will automatically reset the silence feature.

5. Repeat steps 1 through 4, this time using the drench shower only.

The alarm signaling system is designed to work properly even if both the eye/face wash and drench shower are used

simultaneously. The alarm will continue to operate so long as either the eye/face wash or drench shower is still in use.

Auto Reset On/Off Switch

Bradley • 215-1871 Rev. A; ECN 17-05-055 2/13/2018

11

Page 12

S19390 Series Installation

S19390 Gravity Fed Safety Shower Start-up Checklist

(some items refer to optional components)

System Flush (All Electrical Power off for System Flush)

• System has been flushed using the emergency fixture.

• Water is clear and free of any contamination, particles or discoloration.

• Check all system fittings for water leaks.

Bradley drench shower and eye/face wash activation checklist

• The horn and warning lights have been activated when the shower and/or eye/face wash are running.

• The alarm silences and the warning light continues to flash when the horn silence button is depressed.

• All system fittings have been checked for water leaks.

• The water temperature at the drench shower and eye/face wash is tepid (per ANSI/ISEA Z358.1). If cold water is initially added to the tank, allow up to 20 hours

for the water heater to warm the water.

• The proper spray pattern is maintained for the drench shower and eye/face wash for the duration of the test.

Bradley drench shower and eye/face wash deactivation checklist

• After the shower and eye/face wash are all turned off, the warning light is turned off and the system is reset when the horn silence button is depressed for the

second time.

Verify other enclosure system checks

•

The interior light is always on, if present, or turns on with motion, if motion sensor is present. (See motion sensor manual for adjustment to motion sensor timer).

• The control panel is not damaged (no cracks, voids, holes or other functional or structural issues).

Complete OKInspector

Initials

• The certification and serial number labels are present.

System Start-up and Test Checklist Completion & Approval

System Serial Number:

Inspection Date:

Inspector Signature:

S19390 Gravity Fed Safety Shower

12

2/13/2018 Bradley • 215-1871 Rev. A; ECN 17-05-055

Page 13

Installation S19390 Series

Weekly Inspection Checklist

Survey the facility to ensure that the appropriate flushing system is installed per the ANSI/ISEA Z358.1 requirement.

Safety Data sheets can help determine what flushing system is appropriate for your hazards.

S19390 Gravity Fed Safety Shower

Weekly Inspection Checklist

Inspect water tank.

• Verify tank is full.

• Tank water should be changed per preservative manufacturer's instructions.

Visually inspect lights.

• Power disconnect switch is in the "ON" position (if applicable).

• Beacon light is "steady on." If this light is blinking, troubleshooting may be needed to determine what is out of normal limits (if applicable).

Inspect all eye/face wash and drench shower systems to ensure they are compliant and operational in case of an emergency.

• Replace any broken or missing parts immediately.

• Remove any obstructions or trip hazards

• Ensure the system is on the same plane as the hazard and within the minimum distance to the hazard.

• Evaluate if the equipment needs to be protected against freezing.

• Inspect the tank's water temperature to ensure it is tepid per ANSI/ISEA Z358.1.

Document inspection on the unit's inspection tag and in any centrally-controlled documentation log.

Complete OKInspector

Initials

S19390 Gravity Fed Safety Shower

Monthly Inspection Checklist

Activate all eye/face wash and drench shower systems to ensure they are compliant and operational in case of an emergency.

• Use a Bradley drench shower tester with a bucket to contain the water released from the drench shower. Measure the water released from the shower to ensure it

complies with the 20 gpm ANSI minimum flow requirements.

• Activate the shower and eye/face wash (if present) whenever the water tank is filled, or monthly, to verify normal water flow and spray pattern.

• Turn OFF all water fixtures (shower and eye/face wash). Press the silence button to reset the system.

Complete OKInspector

Initials

Signaling System Maintenance

The Bradley Emergency Signaling System is designed to be virtually maintenance free. An occasional damp cloth wiping

of the clear dust cover is all that is needed to ensure maximum visual attention-getting ability.

Bradley • 215-1871 Rev. A; ECN 17-05-055 2/13/2018

13

Page 14

S19390 Series Installation

Troubleshooting

Should damage occur to the unit, it is recommended to contact the factory for repair instructions. Cleaning should be

conducted using rinse down water, DO NOT USE STEAM TO CLEAN.

Problem Cause Solution

Low water flow at drench

shower and/or eye/face wash

Difficulty filling the water tank. Wye strainer is plugged with

Water thermometer is not

reading true temperature.

Water level gage is not

reading the true water level.

Water tank interior is dirty. Cover of tank enclosure is not

Cover of tank enclosure is

very heavy to open.

The signal light and horn (if

applicable) does not operate

when water flows.

Debris in system. Disassemble the showerhead, clean and reassemble. Unscrew the

Empty water tank. Fill the tank with clean, potable water.

sediment or algae.

Component failure. Drain the tank of water and replace the thermometer.

Exterior arrow is loose on

shaft.

Interior cable mechanism is

loose, broken or jammed.

Water float inside the water

tank contains water and does

not float.

latched securely.

One or both gas springs has

failed. (Storage temperature

inside the tank enclosure

must be above -13°F.)

No power to the signal station. Check that the circuit breaker or fuse is supplying power to the

Component function. Check the two 3 Amp 24VDC fuses on the printed circuit board in

eye/face wash heads from the yoke, clean and reassemble. If still

clogged, replace the heads.

Remove the strainer screen, clean and replace.

Verify tank is full of water and fasten the arrow to the shaft so that it

points to the "full" mark.

Inspect and adjust the cable mechanism by opening the cover of the

tank enclosure or by opening the water heater access panel on the

side of the tank enclosure.

Replace the water float.

Inspect the two cover latches for proper movement and that the

hook is adjusted and tightened to make the latch toggle closed while

holding the cover snugly.

Open the cover so that there is no weight on the gas springs and

prop open the cover with a suitably strong and secure object.

Replace the gas spring(s). Carefully apply the cover weight and

verify that it is properly balanced by the gas springs.

signal station

the signal system enclosure.

Check the limit switches on the shower and the eye/face wash.

No input power. Check that there is 24VDC being supplied from the power supply

mounted on the printed circuit board in the signal system enclosure.

Installation error Check all electrical connections, including power supply at the quick-

connect cable, from the signal system to the switch.

Horn sounds and signal light

does not light.

Beacon light does not operate.

(This light should turn off

when the signal light turns on

and back on when the signal

light turns off.)

Area light does not operate. No power to the fuse panel. Check the incoming power.

14

Component function. Check light connections and filament in the light.

Fixture in use. Make sure that the switch contacts are open (horn and/or signal light

are not ON).

Power disconnected in error. Check that the circuit breaker or fuse is supplying power to the

signal station.

Component function. Check the 3 Amp 24VDC fuses on the print circuit board in the

signal station enclosure.

No input power. Check that there is 24VDC being supplied from the power supply

mounted on the print circuit board in the signal station enclosure.

Component failure. Check light connections and LED module in the light.

Component failure. Check the 1/2 amp fuses in the fuse panel. If one or more fuses are

blown, open and carefully check the circuit for shorts or electrical

faults.

Component failure. Check the LED for functionality and replace if necessary.

2/13/2018 Bradley • 215-1871 Rev. A; ECN 17-05-055

Loading...

Loading...