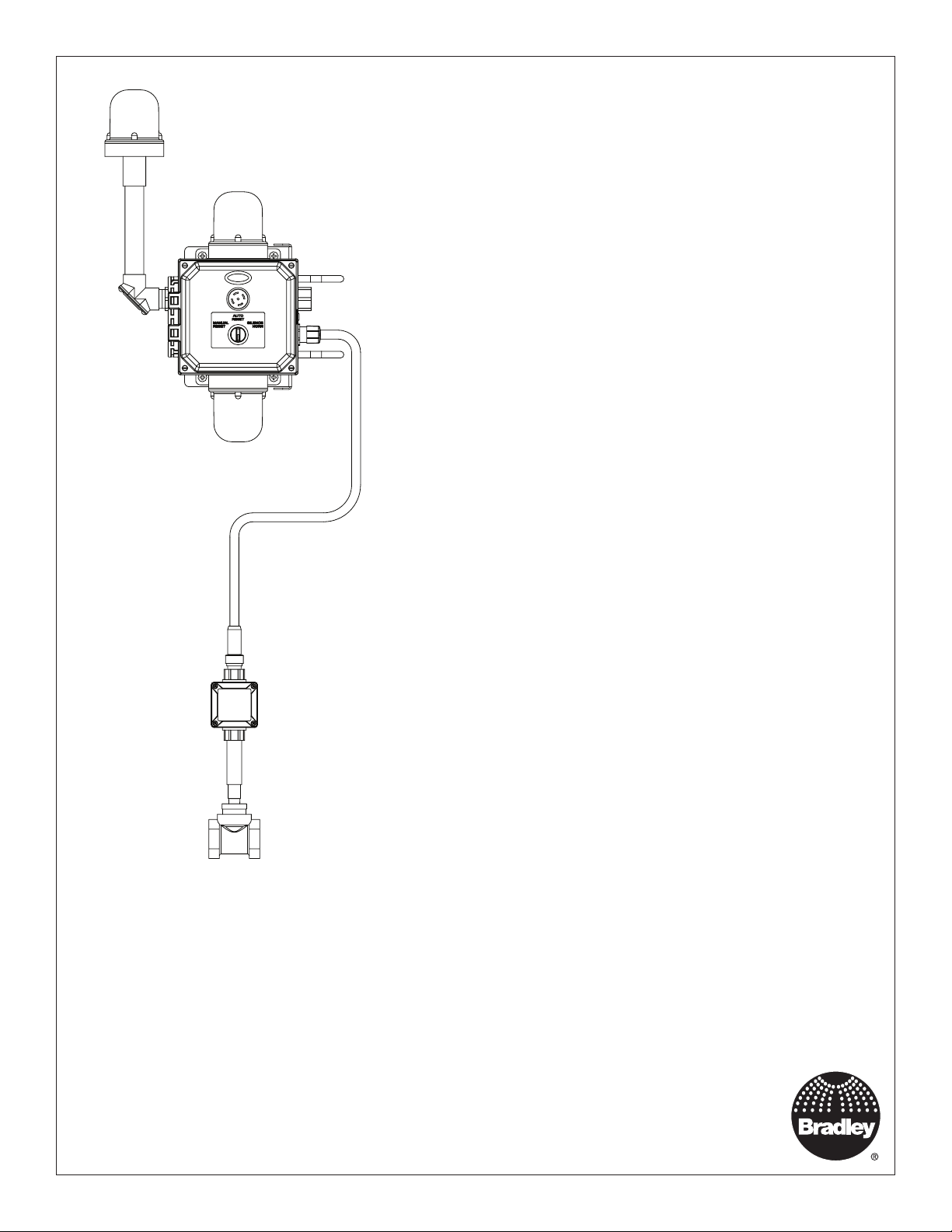

Bradley S19-323, S19-324DGW, S19-324 Wiring Diagram

Installation

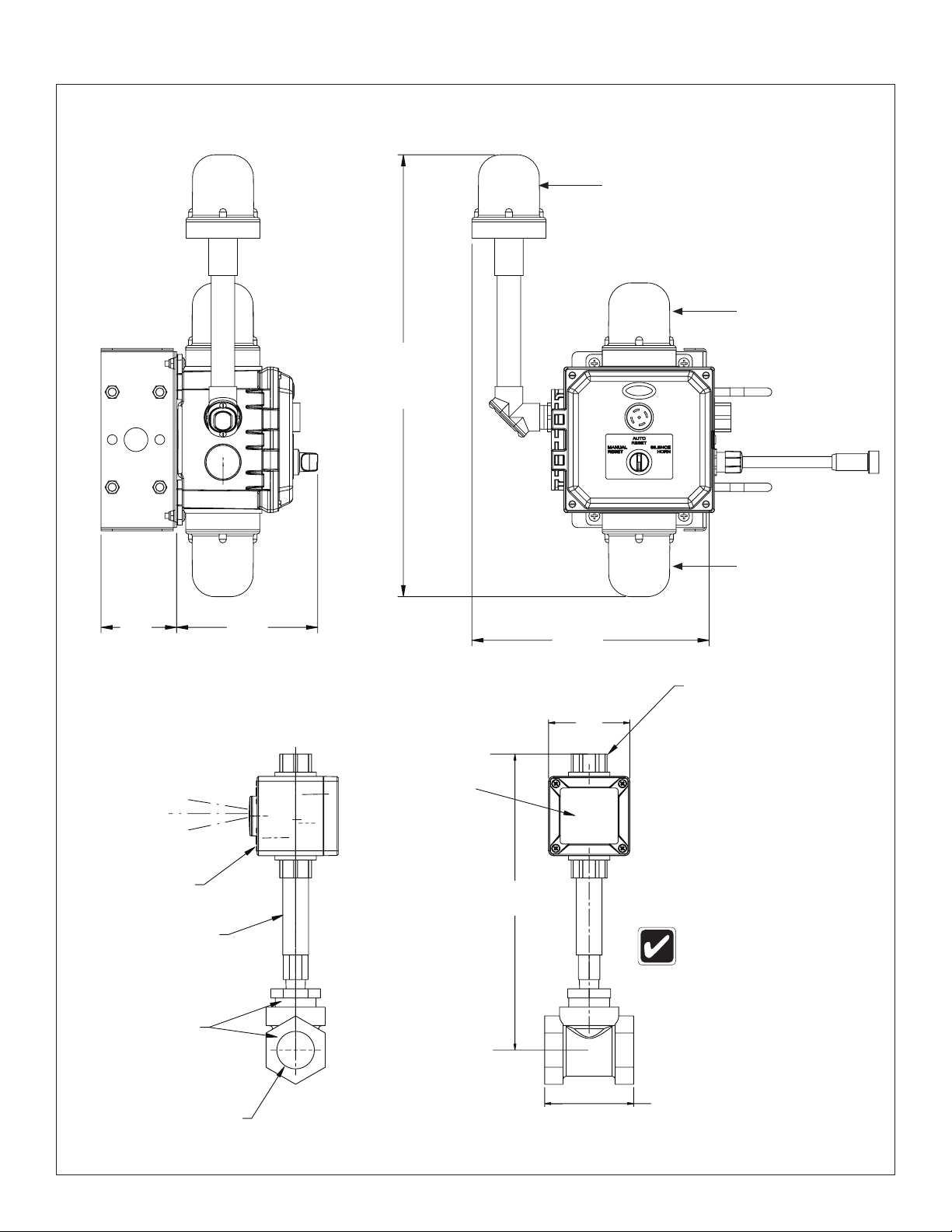

S19-323

NEMA 3R

S19-324

NEMA 4X

Emergency Signaling System

Table of Contents

Pre-Installation Information ..........................2-3

Components......................................4-5

Install Flow Switch and Mount Assembly ................ 6

Connect Signaling Assembly to Flow Switch.............. 7

Complete Electrical Supply Connections................. 7

Test the Signaling System ............................ 8

Maintenance ...................................... 8

Remote Sensing Option.............................. 8

Servicing of Lights .................................. 9

Troubleshooting ................................... 10

Service Parts ...................................11-12

Wiring Diagram ................................... 13

Schematic ....................................... 14

S19-324DGW shown

215-1846 Rev. C; ECN 17-05-068

© 2017 Bradley

Page 1 of 14 11/21/2017

Menomonee Falls, WI 53052 USA

P.O. Box 309

800 BRADLEY (800 272 3539)

+1 262 251 6000

bradleycorp.com

S19-323, S19-324 Installation

WARNING

Power supplied to the unit should be between 90-264VAC, 50-60 Hz, 15 amp branch circuit with a

dedicated circuit breaker or fuse and should not supply power to any other device. Compliance

and conformity to local codes and ordinances is the responsibility of the installer.

Do not use this safety equipment in a location that does not match its hazardous location rating.

Verify the appropriate ratings prior to installation.

When making electrical connections be sure to follow all lockout–tagout safety procedures.

Flush the water supply lines before beginning installation and after installation is complete. Test

the unit for leaks and adequate water flow. Main water supply should be “ON” at all times unless

system is being serviced. Provisions shall be made to prevent unauthorized shutoff.

CAUTION

Supply the unit with clean, potable water.

NOTICE

Before installing this product, ensure that there are adequate clearances around the product and

activation of the product does not interfere with other products or obstructions.

It is recommended that all water supply and electrical connections be made at temperatures above

freezing. Failure to do so may result in major product and/or property damage.

Constant power supply to safety equipment is necessary for it to function.

Avoid cleaners containing organic solvents, alcohols and hydrocarbons. Rinse with potable water

after cleaning.

2

11/21/2017 Bradley • 215-1846 Rev. C; ECN 17-05-068

Installation S19-323, S19-324

IMPORTANT

The installation and location of all safety drench showers, eye and eye/face washes must comply

with the requirements of ANSI/ISEA Z358.1.

Read this installation manual completely to ensure proper installation, then file it with the owner

or maintenance department. Compliance and conformity to local codes and ordinances is the

responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for before discarding any

packaging material. If any parts are missing, do not begin installation until you obtain the missing

parts.

Installation and maintenance of this system must be completed by a qualified plumber and

electrician according to the information contained in this installation manual and in compliance

with all national and local codes.

The ANSI/ISEA Z358.1 standard requires an uninterrupted supply of flushing fluid. Bradley

plumbed emergency fixtures require a minimum of 30 PSI (0.21MPa) flowing pressure.

Weekly activation must be conducted on all plumbed emergency equipment to ensure a suitable

flushing fluid supply is present and any sediment build up in the supply line is cleared. Inspect

safety equipment monthly to address any maintenance issues ensuring the equipment is in good

operating condition and that there are no signs of wear.

Perform functional test upon relocation of safety equipment.

Workers who may come in contact with potentially hazardous materials should be trained

regarding the placement and proper operation of emergency equipment per ANSI/ISEA Z358.1.

For questions regarding the operation or installation of this product, visit www.bradleycorp.com or

call 800-BRADLEY (272.3539).

Product warranties and parts information may also be found under ”Products” on our web site at

bradleycorp.com.

Supplies Required

• Teflon tape or pipe sealant

• Black, white and green AWG 18 minimum (14 AWG maximum) wire to connect signaling system to electric

power supply

• 3/4" hubs and fittings for electrical wiring (all customer supplied hubs and fittings must match the electrical

rating of the enclosures)

Bradley • 215-1846 Rev. C; ECN 17-05-068 11/21/2017

3

S19-323, S19-324 Installation

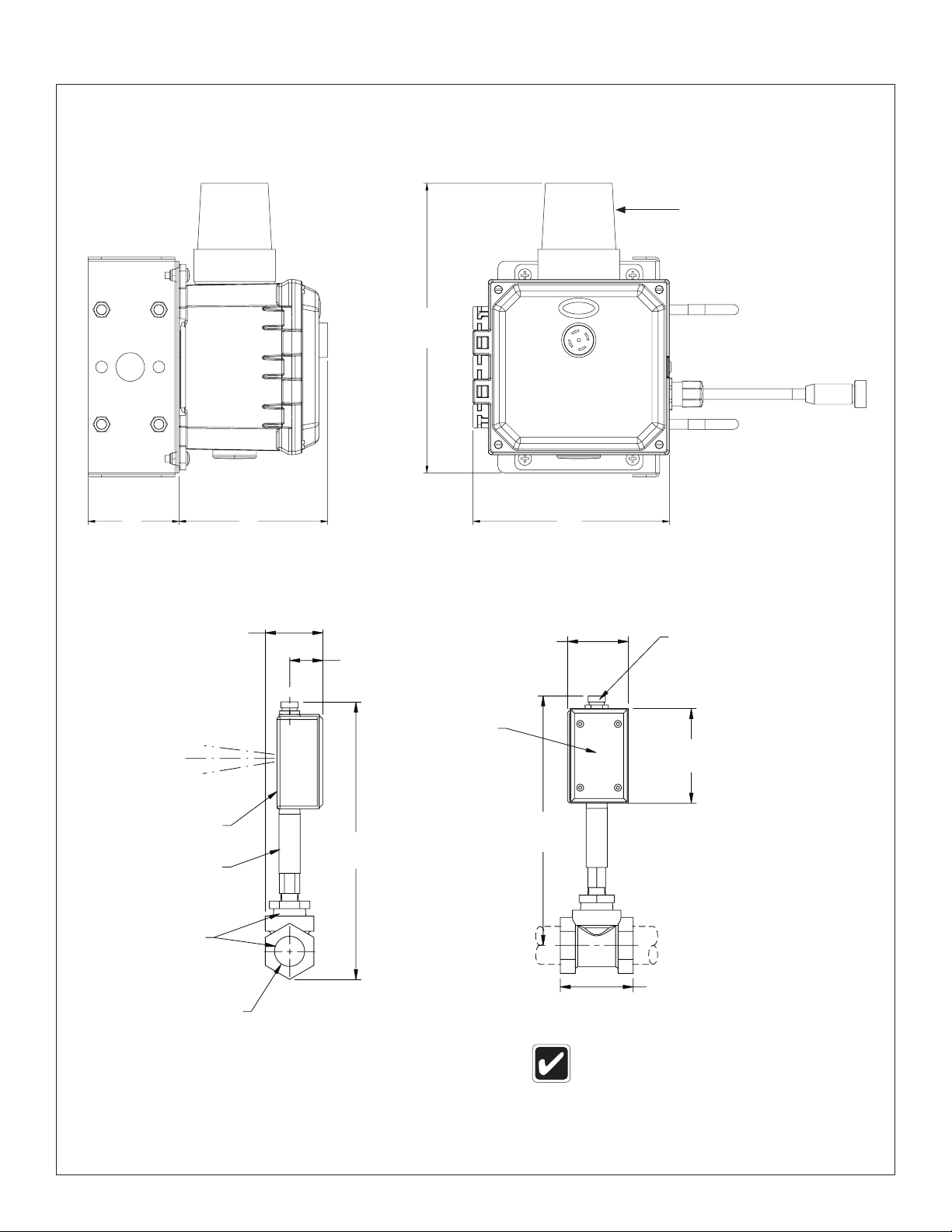

S19-323 Components

Signal Light

Type-3R Shown

(Standard)

10-3/4"

(273mm)

3-3/8"

(86mm)

Sensing

Blue

Black

¾" NPT Hub,

Plugged

Brass

Adapter

and Tee

1/2" (eyewash)

or 1-1/4" (drench

shower) NPT Inlet

and Outlet

2-7/8"

(73mm)

Remote

Red

Brass

Sensor

Body

5-1/2"

(140mm)

1-5/8"

(41mm)

13-13/16"

(351mm)

NEMA 3R

Junction Box

and Cover

3" (76mm)

12-3/8"

(315mm)

7-5/16"

(185mm)

Electrical Quick

Disconnect Male

4-11/16"

(119mm)

2-3/8" (60mm) for

eyewash or

3-9/16" (91mm) for

drench shower

System is prewired. Installer connects

ONLY ground black and white wires.

4

11/21/2017 Bradley • 215-1846 Rev. C; ECN 17-05-068

Installation S19-323, S19-324

S19-324 Components

Beacon Light

Type-4X Shown

(Optional)

Signal Light

Type-4X Shown

(Standard)

19-3/4"

(501mm)

3-3/8"

(86mm)

Remote

Sensing

Red

Blue

Black

¾" NPT Hub,

Plugged

Brass

Sensor

Body

6-5/16"

(160mm)

Area Light

Type-4X Shown

(Optional)

10-9/16"

(269mm)

Electrical Quick

Disconnect Male

3-5/16"

(84mm)

NEMA 4X

Junction Box

and Cover

12-1/16"

(306mm)

System is prewired. Installer

connects ONLY ground black

and white wires.

Brass

Adapter

and Tee

1/2" (eyewash)

or 1¼" (drench

shower) NPT Inlet

and Outlet

Bradley • 215-1846 Rev. C; ECN 17-05-068 11/21/2017

2-3/8" (60mm) for

eyewash or

3-9/16" (91mm) for

drench shower

5

Loading...

Loading...