Bradley S19314TT, S19314UU, S19314SC, S19314DCBF, S19314F User Manual

...

Installation

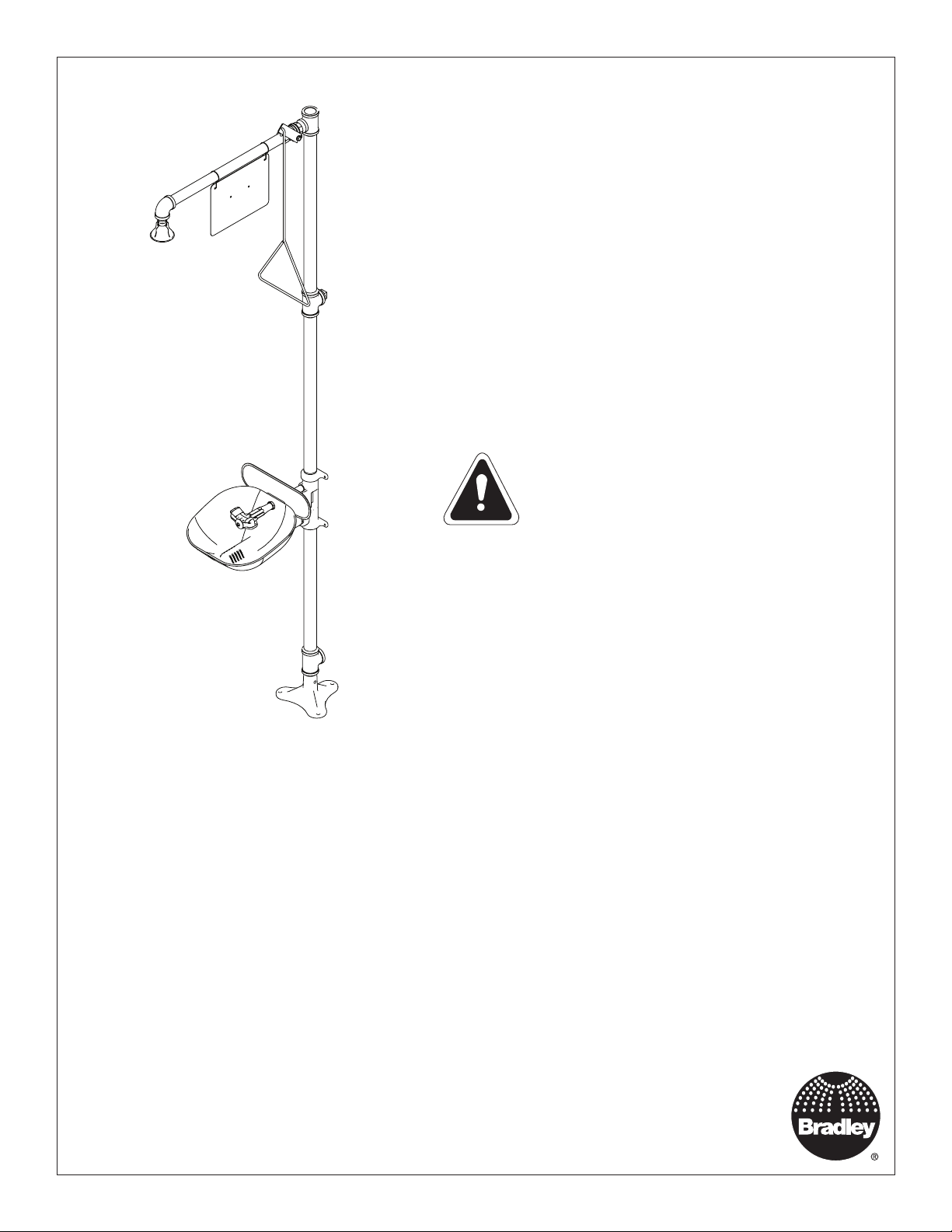

S19314 Series

Halo™ Combination Drench Shower

and Eyewash or Eye/Face Wash

Read the instructions in this manual before

beginning installation. Save these instructions

and refer to them for inspection, maintenance

and troubleshooting information.

Lire les instructions du présent manuel avant

de commencer l’installation. Sauvegarder

ces instructions et s’y reporter pour obtenir

des renseignements relatifs à l’inspection, à

l’entretien et au dépannage.

Lea las instrucciones de este manual

antes de comenzar la instalación. Guarde

estas instrucciones y consúltelas para

obtener información sobre la inspección, el

mantenimiento y la solución de problemas.

For questions regarding the operation, installation or maintenance of this product, visit bradleycorp.com

or call 800.BRADLEY (800.272.3539).

Product warranties and parts information may also be found under “Resources” on our website at bradleycorp.com.

Pour toute question concernant le fonctionnement ou l’installation de ce produit, consulter le site

www.bradleycorp.com ou appeler le 1-800-BRADLEY.

Les garanties de produits figurent sous la rubrique « Resources » (Ressources) sur notre site Internet à www.bradleycorp.com.

Para consultas sobre la operación o instalación de este producto, visite www.bradleycorp.com o llame al

1-800-BRADLEY.

Las garantías del producto se pueden encontrar en “Resources” (Recursos) de nuestro sitio Web, www.bradleycorp.com.

P.O. Box 309

+1 262 251 6000

bradleycorp.com

215-1684 Rev. V; ECO 19-05-002A

© 2019 Bradley

Page 1 of 59 4/17/2019

Menomonee Falls, WI 53052 USA

800 BRADLEY (800 272 3539)

S19314 Installation

Table of Contents

Table of Contents..........................................................................2

Pre-Installation Information ................................................................ 3-4

Halo Pre-Configured Models ................................................................5-7

Halo Configurator..........................................................................8

Dimensions .............................................................................. 9

Installation Instructions ................................................................. 10–11

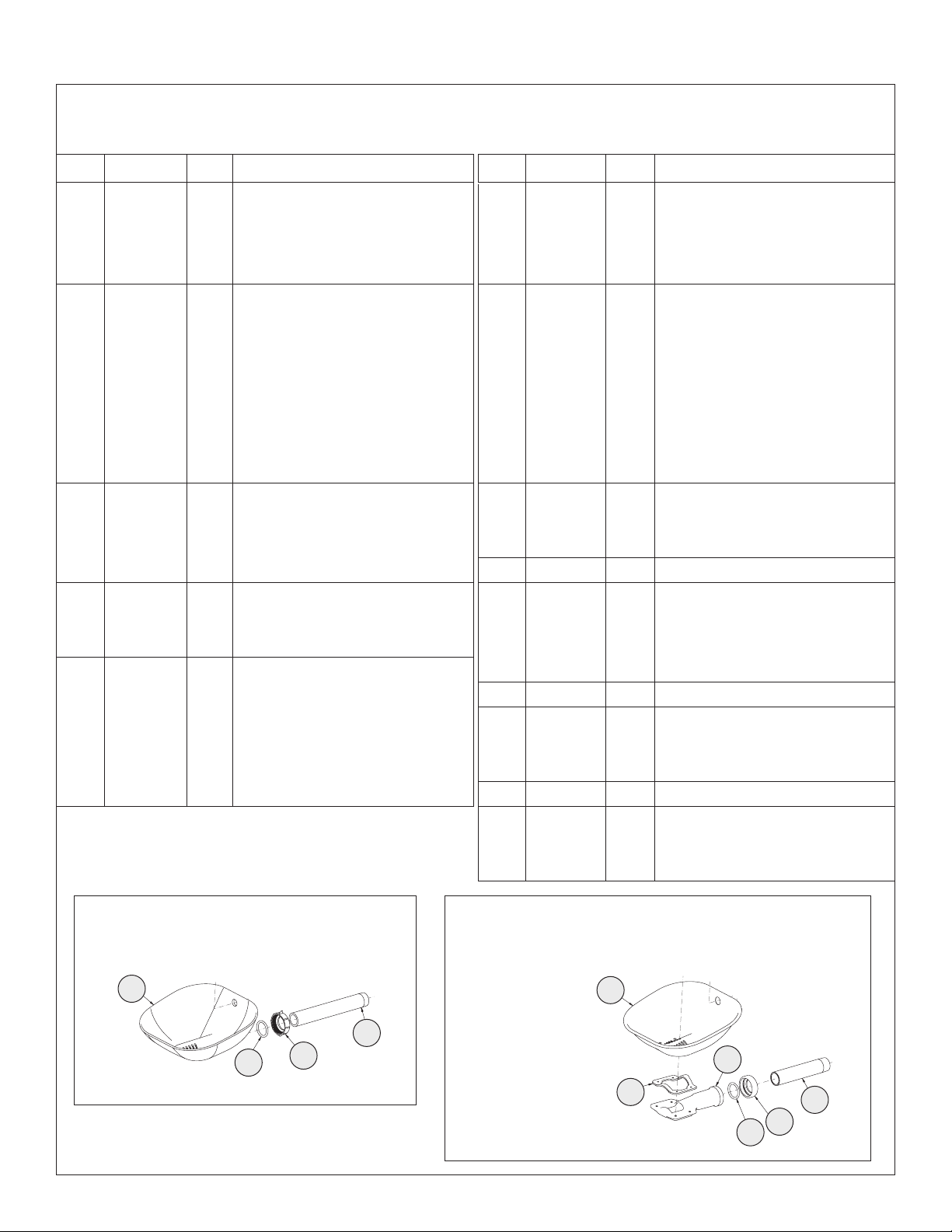

Service Parts — Bowl and Hub ........................................................... 12–13

Service Parts — Eyewash, Eye/Face Wash and Bowl Covers ................................... 14–16

Service Parts — Base and Drain............................................................. 17

Service Parts — Drench Shower.......................................................... 18–20

Service Parts — Optional Accessories ........................................................21

Avant l’installation ..................................................................... 22-23

Modèles préconfigurés Halo ..............................................................24-26

Configuration du produit ...................................................................27

Dimensions ............................................................................. 28

Instructions d'installation ................................................................ 29–31

Pièces de remplacement — Récepteur et moyeu............................................. 32–33

Pièces de remplacement — Douche oculaire, Douche oculaire/faciale et couvercle anti-poussières ..... 34–35

Pièces de remplacement — Bride et drain ..................................................... 36

Pièces de remplacement — Douche d'urgence .............................................. 37–39

Pièces de remplacement — Accessoires en option ..............................................40

Información previa a la instalación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41-42

Modelos preconfigurados Halo ............................................................43-45

Configuración del producto .................................................................46

Dimensiones ............................................................................ 47

Instrucciones de instalación. ............................................................. 48–49

Piezas de repuesto — Receptor y buje..................................................... 50–51

Piezas de repuesto — Lavaojos, lavaojos/rostro y cubierta contrapolvo ........................... 52–54

Piezas de repuesto — Base y drenaje ........................................................ 55

Piezas de repuesto — Ducha de aspersión ................................................. 56–58

Piezas de repuesto — Accesorios opcionales ..................................................59

2

4/17/2019 Bradley • 215-1684 Rev. V; ECO 19-05-002A

Installation S19314

Safety Information

To ensure proper operation:

Installation

This fixture has been designed and 3rd party tested to meet ANSI/ISEA Z358.1. The system must be tested

periodically to be sure it is functioning properly to meet the standard. Please refer to the ANSI/ISEA Z358.1 standard

on testing requirements.

The installation, maintenance and location of all safety drench showers, eye and eye/face washes must comply with

the requirements of ANSI/ISEA Z358.1. Workers who may come in contact with potentially hazardous materials

should be trained regarding the location and proper operation of emergency equipment per ANSI/ISEA Z358.1.

ANSI/ISEA Z358.1 requires this unit to be used with a clean, potable, uninterrupted supply of tepid water. Bradley

plumbed emergency fixtures require a minimum of 30 psi flowing pressure in order to function as designed and meet

the ANSI/ISEA Z358.1 standard.

Self-closing spring-loaded valves are not UL classified to ANSI/ISEA Z358.1.

Before installation make sure that this equipment will meet the requirements of the potential hazardous contaminants

in your location.

Installation of this system must be completed by a qualified plumber in compliance with all national and local codes.

Compliance and conformity to drain requirements and other local codes and ordinances is the responsibility of the

installer.

Weekly Inspections

To ensure all emergency shower and eye/face wash fixtures are ready to be used when needed, regular checks and

maintenance must be conducted. Weekly inspections must be conducted on all safety equipment to make sure a

suitable flushing fluid supply is present and to make sure the equipment is in good operating condition.

Water Temperature

ANSI/ISEA Z358.1 requires tepid water. Suitable range is 60°F to 100°F (16°C to 38°C). Personal injury is possible

outside this temperature range.

Bradley • 215-1684 Rev. V; ECO 19-05-002A 4/17/2019

3

S19314 Installation

Supplies Required:

• (3) 3⁄8" floor anchors and bolts

• Teflon tape and pipe sealant

• 30 PSI (2.0 bar) min/90 PSI (6.1 bar) max flow pressure

• 125 PSI (8.6 bar) max static pressure

• Piping to 1¼" NPT (BSPP) water supply inlet (30–90 psi [2.0-6.1 bar])

• Piping to 1¼" NPT drain outlet on unit (if included with unit)

• Adequate supply pipe supports

• Provisions to dispose of shower waste water (minimum 30 gallons [115 liters]) should be made (minimum 4" [102mm] drain.

• OPTIONAL: sign-mounting hardware

Local codes may require the installation of a backflow prevention valve to complete proper installation. Valve must be

tested annually to verify that it is functioning properly. Backflow prevention valves are not included with the fixture and may

be supplied by the contractor or purchased from Bradley Corporation.

4

4/17/2019 Bradley • 215-1684 Rev. V; ECO 19-05-002A

Installation S19314

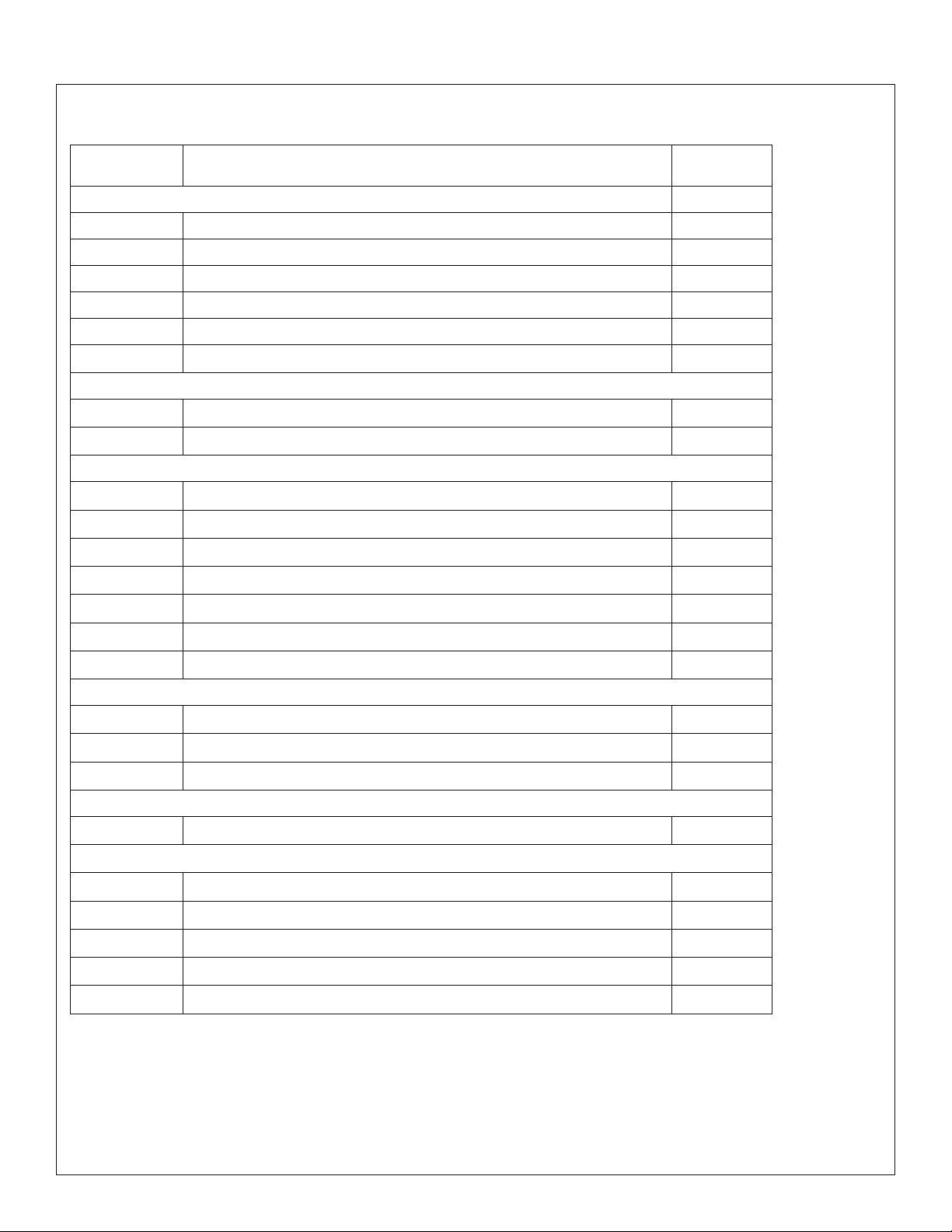

Halo Pre-Configured Models

Halo Model

Number

Eyewashes

S19314EW

S19314P

S19314SB

S19314LL

S19314F

S19314UU

Halo Eyewash, plastic showerhead & bowl

Halo Eyewash, plastic showerhead & bowl w/ hose spray

Halo Eyewash, plastic showerhead, stainless steel bowl

Halo Eyewash, plastic showerhead, stainless steel bowl, hand/foot activated

Halo Eyewash, plastic showerhead w/ stainless steel shroud & bowl

Halo Eyewash, plastic showerhead w/ stainless steel shroud & bowl, hand/foot operated eyewash

Eyewashes with Dust Cover

S19314PDC

S19314DC

Halo Eyewash, plastic showerhead & bowl w/ dust cover

Halo Eyewash, plastic showerhead, stainless steel bowl & hinged dust cover

Eye-Face Washes

S19314FW

S19314SBFW

S19314AC

S19314TT

S19314SPR

Halo Eye/face wash, plastic showerhead & bowl

Halo Eye/face wash, plastic showerhead, stainless steel bowl

Halo Eye/face wash, plastic showerhead, stainless steel bowl, hand/foot operated eyewash

Halo Eye/face wash, plastic showerhead w/ stainless steel shroud & bowl

Halo Eye/face wash, stainless steel showerhead & bowl, hand/foot operated eyewash

Description

UL certified to

ANSI/ISEA

X

X

X

X

X

X

X

X

X

X

X

X

X

S19314BFPB

S19314BF

Halo Eye/face wash, barrier-free, plastic showerhead & bowl

Halo Eye/face wash, barrier-free, plastic showerhead, stainless steel bowl

Eye-Face Washes with Dust Covers

S19314PDCFW

S19314DCFW

S19314DCBF

Halo Eye/face wash, plastic showerhead & bowl w/ dust cover

Halo Eye/face wash, plastic showerhead, stainless steel bowl & hinged dust cover

Halo Eye/face wash, barrier-free, plastic showerhead, stainless steel bowl w/ dust cove

Eye-Face Washes without Eyewash Bowl

S19314GG

Halo Eye/face wash, plastic showerhead, no bowl

All Stainless Steel Eye-Face Wash

S19314BFSS

S19314FSS

S19314SC

S19314SS

S19314SS16

Halo stainless steel eye/face wash and showerhead, barrier free

Halo stainless steel eye/face wash and showerhead

Halo stainless steel eye/face wash, bowl, cover and showerhead

Halo stainless steel eye/face wash and showerhead with foot activation

Halo 316 stainless steel eye/face wash and showerhead with foot activation

X

X

X

X

X

X

X

X

X

X

X

Bradley • 215-1684 Rev. V; ECO 19-05-002A 4/17/2019

5

S19314 Installation

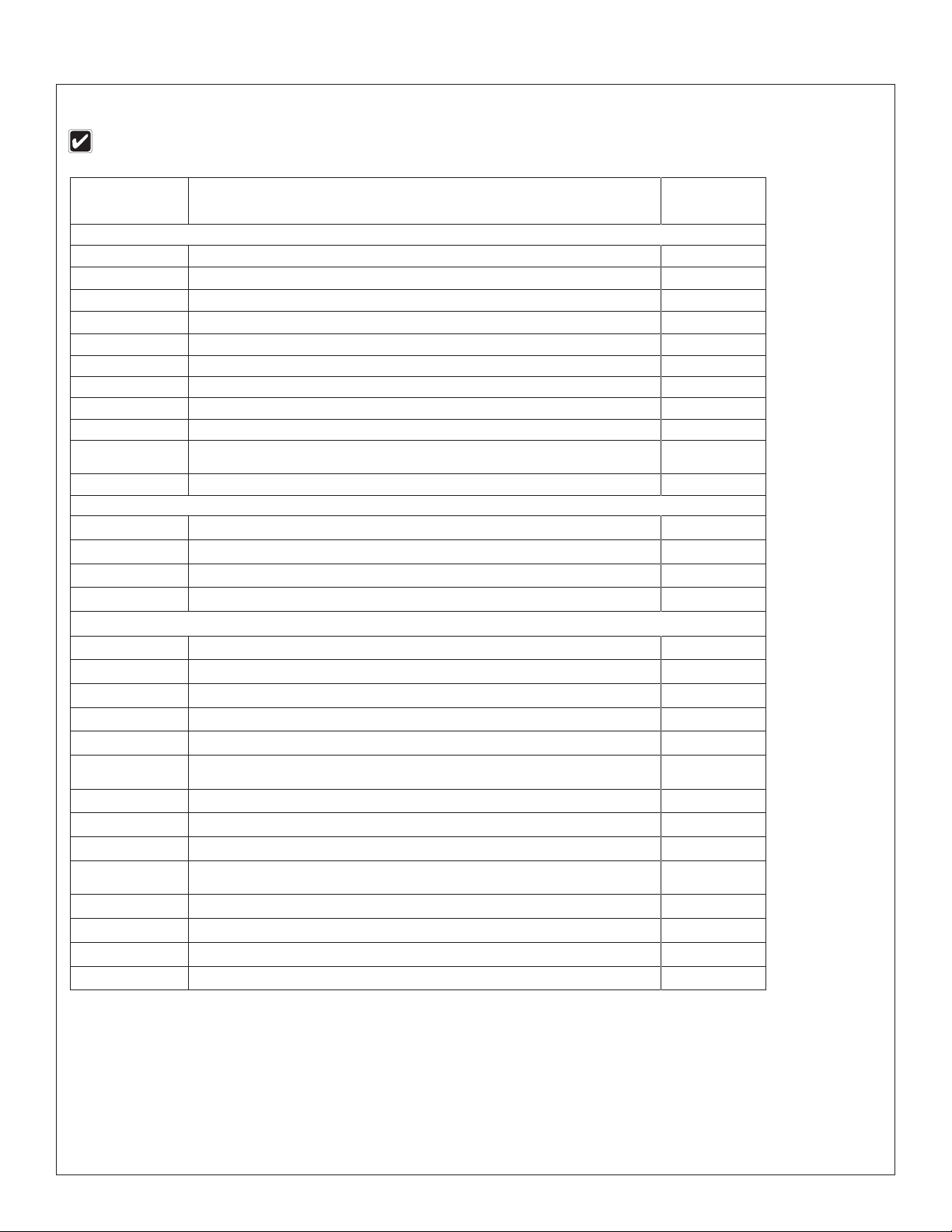

Halo Pre-Configured Models

All models with AS4775, AS/NZS 4020 Certification include BSPP threading.

Halo Model Number Description

Eyewashes

S19314EWZ

S19314EWZS

S19314SBZ

S19314SBZS

S19314LLZ

S19314LLZS

S19314FZ

S19314FZS

S19314UUZ

S19314UUZS

S19314PZ

Eyewashes with Dust Cover

S19314PDCZ

S19314PDCZS

S19314DCZ

S19314DCZS

Eye-Face Washes

S19314FWZ

S19314FWZS

S19314SBFWZ

S19314SBFWZS

S19314ACZ

S19314ACZS

S19314TTZ

S19314TTZS

S19314SPRZ

S19314SPRZS

S19314BFPBZ

S19314BFPBZS

S19314BFZ

S19314BFZS

Halo Eyewash, plastic showerhead & bowl

Halo Eyewash, plastic showerhead & bowl, stainless steel piping X

Halo Eyewash, plastic showerhead, stainless steel bowl

Halo Eyewash, plastic showerhead, stainless steel bowl, stainless steel piping X

Halo Eyewash, plastic showerhead, stainless steel bowl, hand/foot activated

Halo Eyewash, plastic showerhead, stainless steel bowl, hand/foot activated, stainless steel piping

Halo Eyewash, plastic showerhead w/ stainless steel shroud & bowl

Halo Eyewash, plastic showerhead w/ stainless steel shroud & bowl, stainless steel piping X

Halo Eyewash, plastic showerhead w/ stainless steel shroud & bowl, hand/foot operated eyewash

Halo Eyewash, plastic showerhead w/ stainless steel shroud & bowl, hand/foot operated

eyewash, stainless steel piping

Halo Eyewash, plastic showerhead & bowl w/hose spray

Halo Eyewash, plastic showerhead & bowl w/ dust cover

Halo Eyewash, plastic showerhead & bowl w/ dust cover, stainless steel piping X

Halo Eyewash, plastic showerhead, stainless steel bowl & hinged dust cover

Halo Eyewash, plastic showerhead, stainless steel bowl & hinged dust cover, stainless steel piping

Halo Eye/face wash, plastic showerhead & bowl

Halo Eye/face wash, plastic showerhead & bowl, stainless steel piping X

Halo Eye/face wash, plastic showerhead, stainless steel bowl

Halo Eye/face wash, plastic showerhead, stainless steel bowl, stainless steel piping X

Halo Eye/face wash, plastic showerhead, stainless steel bowl, hand/foot operated eyewash

Halo Eye/face wash, plastic showerhead, stainless steel bowl, hand/foot operated eyewash,

stainless steel piping

Halo Eye/face wash, plastic showerhead w/ stainless steel shroud & bowl

Halo Eye/face wash, plastic showerhead w/ stainless steel shroud & bowl, stainless steel piping

Halo Eye/face wash, stainless steel showerhead & bowl, hand/foot operated eyewash

Halo Eye/face wash, stainless steel showerhead & bowl, hand/foot operated eyewash,

stainless steel piping

Halo Eye/face wash, barrier-free, plastic showerhead & bowl

Halo Eye/face wash, barrier-free, plastic showerhead & bowl, stainless steel piping X

Halo Eye/face wash, barrier-free, plastic showerhead, stainless steel bowl

Halo Eye/face wash, barrier-free, plastic showerhead, stainless steel bowl, stainless steel piping

IAPMO Oceana

certified to

AS4775 & AS4020

X

X

X

X

X

X

X

6

4/17/2019 Bradley • 215-1684 Rev. V; ECO 19-05-002A

Installation S19314

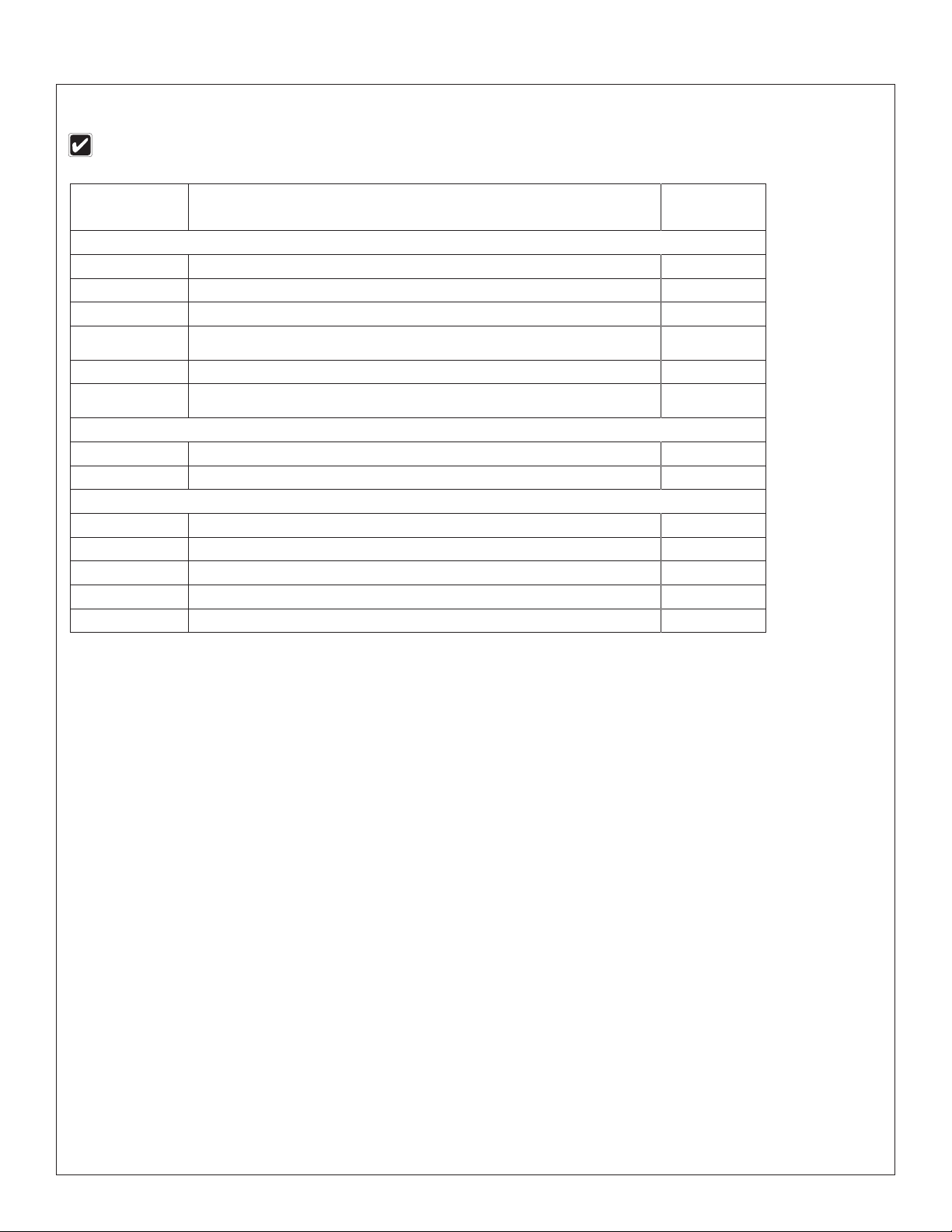

Halo Pre-Configured Models

All models with AS4775, AS/NZS 4020 Certification include BSPP threading.

Halo Model Number Description

Eye-Face Washes with Dust Cover

S19314PDCFWZ

S19314PDCFWZS

S19314DCFWZ

S19314DCFWZS

S19314DCBFZ

S19314DCBFZS

Eye-Face Washes without Eyewash Bowl

S19314GGZ

S19314GGZS

All Stainless Steel Eye/Face Wash

S19314BFSSZ

S19314FSSZ

S19314SCZ

S19314SSZ

S19314SS16Z

Halo Eye/face wash, plastic showerhead & bowl w/ hinged dust cover

Halo Eye/face wash, plastic showerhead & bowl w/ hinged dust cover, stainless steel piping X

Halo Eye/face wash, plastic showerhead, stainless steel bowl & hinged dust cover

Halo Eye/face wash, plastic showerhead, stainless steel bowl & hinged dust cover, stainless

steel piping

Halo Eye/face wash, barrier-free, plastic showerhead, stainless steel bowl w/ hinged dust cover

Halo Eye/face wash, barrier-free, plastic showerhead, stainless steel bowl w/ hinged dust

cover, stainless steel piping

Halo Eye/face wash, plastic showerhead, no bowl

Halo Eye/face wash, plastic showerhead, no bowl, stainless steel piping

Halo stainless steel eye/face wash & showerhead, barrier free X

Halo stainless steel eye/face wash & showerhead

Halo stainless steel eye/face wash, bowl, cover & showerhead

Halo stainless steel eye/face wash and showerhead with hand/foot activation

Halo 316 stainless steel eye/face wash and showerhead with hand/foot activation

IAPMO Oceana

certified to

AS4775 & AS4020

X

X

X

X

X

X

X

Bradley • 215-1684 Rev. V; ECO 19-05-002A 4/17/2019

7

S19314 Installation

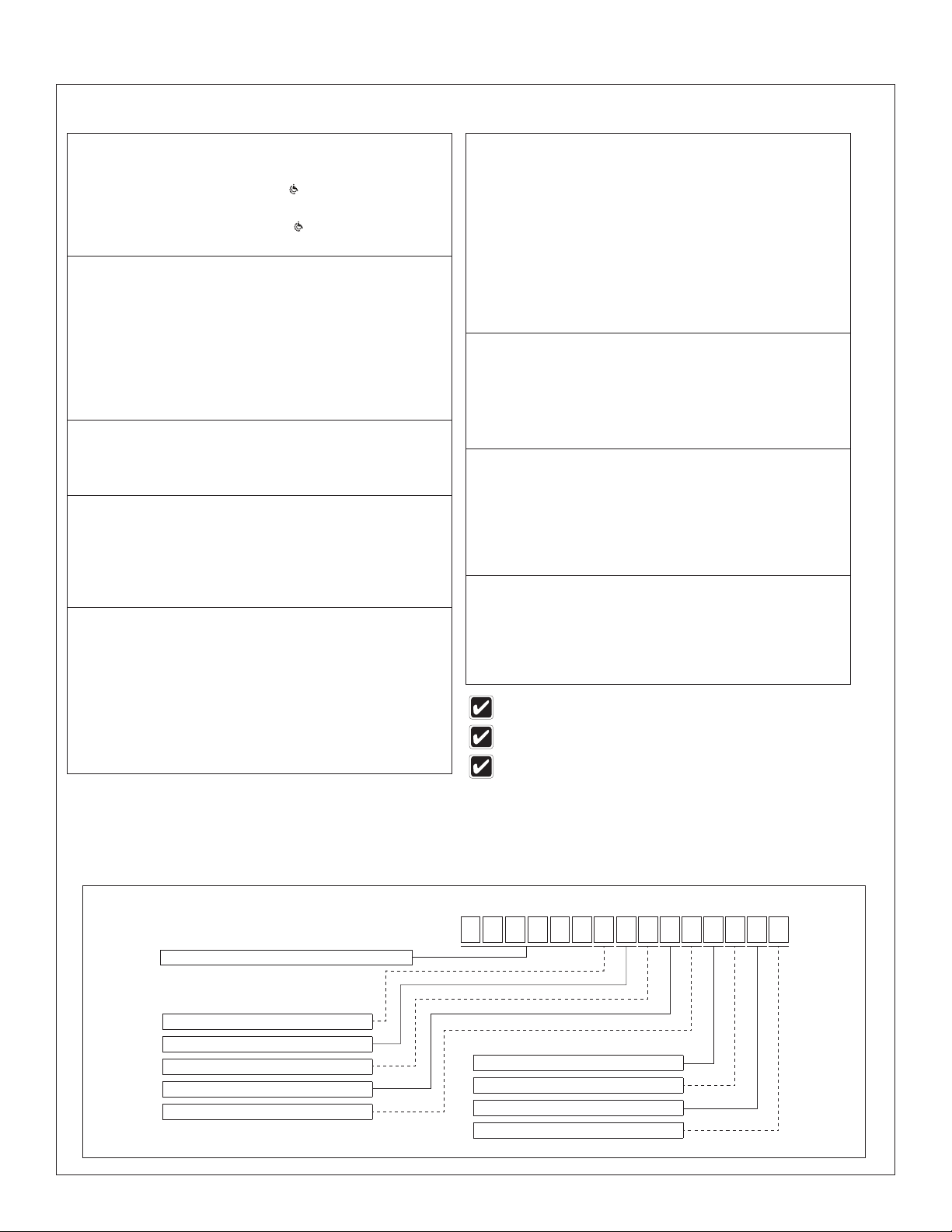

Halo Configurator

Standard Selections (Must select one from each category)

Configuration

¨A

¨B

¨C

¨0

Pipe Material

¨A

¨B

¨C

¨D

¨F

¨G

¨H

¨J

Ball Valve

¨1

¨2

¨3

Showerhead

¨A

¨B

¨C

¨D

¨E

Eyewash – Eye/Face Wash

¨A

¨B

¨D

¨E

¨F

¨G

¨H

¨J

* Not available with barrier-free configurations.

** Self-closing valves are not ANSI/ISEA Z358.1 compliant.

‡

Not available in the U.S.

† Must select stainless steel pipe and ball valve when stainless

steel eye/face wash is required.

6" Drain Height, B

24" Drain Height

24" Drain Height, B

6" Drain Height, Standard

NPT, Yellow BradTect Galvanized Steel

NPT, All 304 Stainless Steel

NPT, All 316 Stainless Steel *

NPT, Chrome-Plated

BSPP, Yellow BradTect Galvanized Steel ‡

BSPP, All 304 Stainless Steel ‡

BSPP, All 316 Stainless Steel‡

BSPP, Chrome-Plated ‡

Stay-Open Shower and Eyewash, Chrome-Plated Brass

Stay-Open Shower and Eyewash, 316 SS

Self-Closing Shower and Stay-Open Eyewash, Chrome-Plated Brass **

Plastic Showerhead

Plastic Showerhead with Plastic Shroud

Plastic Showerhead with Stainless Steel Shroud

304 SS High Performance Showerhead

316 SS High Performance Showerhead

Halo Eyewash

Halo Eye/Face Wash

Halo Eyewash, 304 SS Yoke

Halo Eye/Face Wash, 304 SS Yoke

304 SS Halo Eye/Face Wash, 304 SS Yoke†

Halo Eyewash, 316 SS Yoke

Halo Eye/Face Wash, 316 SS Yoke

316 SS Halo Eye/Face Wash, 316 SS Yoke†

arrier Free

arrier Free

Bowl and Dust Cover

¨A

¨B

¨D

¨E

¨F

¨G

¨H

¨J

¨0

Activation

¨A

¨B

¨C

¨D

¨E

Drench Hose and Backflow Prevention

¨A

¨B

¨C

¨D

¨0

¨Z

Freeze and Scald Protection

¨N

¨P

¨R

¨0

¨Z

Plastic Bowl, No Dust Cover

Plastic Bowl, Plastic Dust Cover

304 SS, No Dust Cover

304 SS, 304 SS Dust Cover

304 SS, Plastic Dust Cover

316 SS, No Dust Cover

316 SS, 316 SS Dust Cover

316 SS, Plastic Dust Cover

No Bowl or Dust Cover

300 SS Handle

316 SS Handle

300 SS Handle, 300 SS Foot Pedal

300 SS Handle, 316 SS Foot Pedal *

316 SS Handle with 316 SS Foot Pedal *

Drench Hose Kit with Vacuum Breaker

Drench Hose Kit with N9 Backflow Preventer

Drench Hose Kit with 9D Backflow Preventer

Drench Hose Kit without Backflow Preventer

No Drench Hose and No Backflow Prevention

Drench Hose Ready

Anti-Freeze Valve

Anti-Scald Valve

Anti-Freeze and Anti-Scald Valves

No Anti-Freeze Valve and No Anti-Scald Valve

Anti-Freeze and Anti-Scald Valve Ready

NPT = National Pipe Thread

BSPP = British Standard Pipe Parallel Threads

All selections made through the configurator are only

UL certified to ANSI/ISEA Z358.1

3

How to Specify Model and Configurations

for Bradley Halo Products:

Model No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .S19314

1. Configuration

2. Pipe Material

3.

Ball Valve

4.

Showerhead

5. Eyewash – Eye/Face Wash

8

4/17/2019 Bradley • 215-1684 Rev. V; ECO 19-05-002A

S

6. Bowl and Dust Cover

7. Activation

8. Drench Hose and Backflow Prevention

9. Freeze and Scald Protection

3 1 4

9

1

421

5 6

7 8 9

Installation S19314

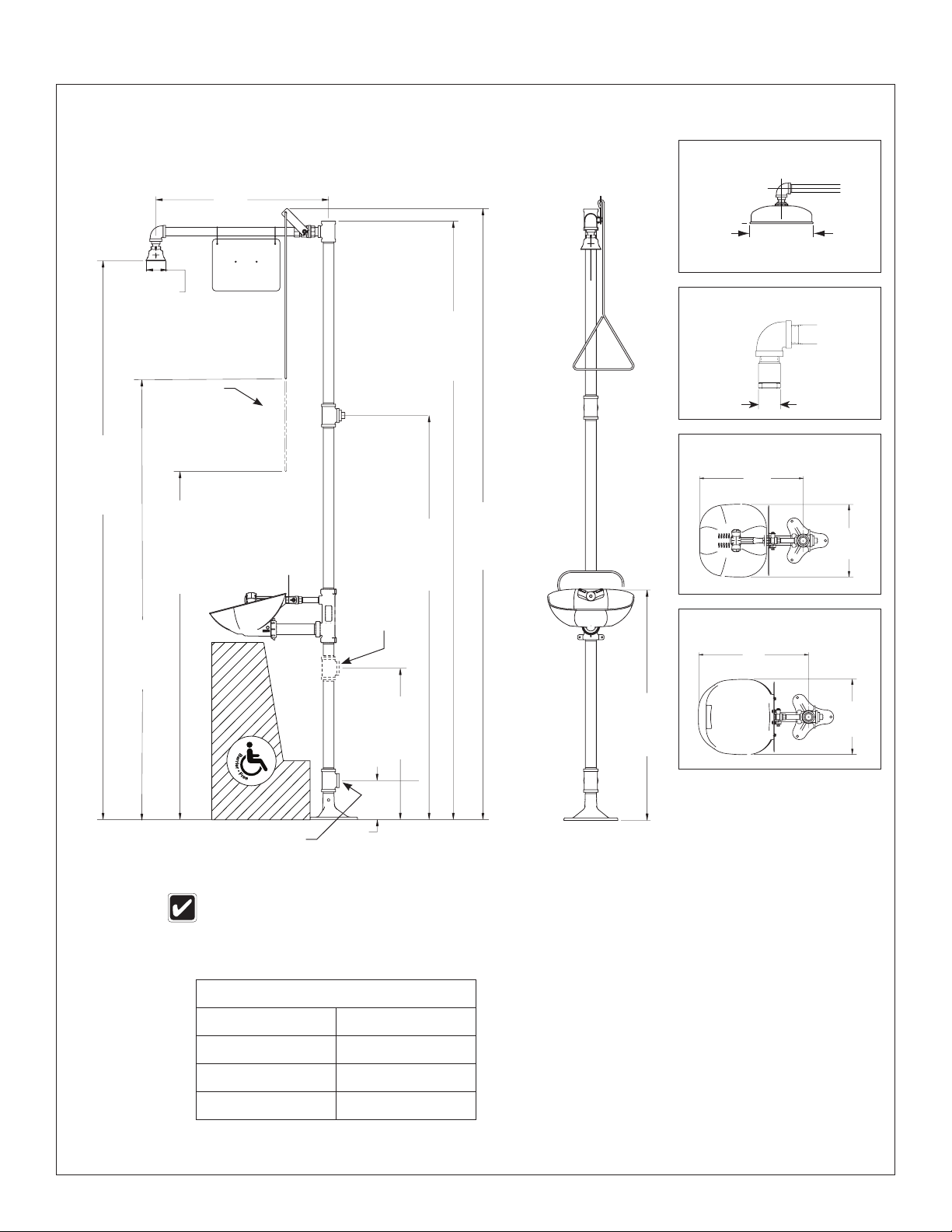

Dimensions

S19314 shown with Plastic Bowl and Plastic Showerhead

2613⁄16"

(681mm)

Ø 3.1"

(78.7mm)

Optional

barrier free

pull rod

861⁄8"

(2188mm)

to bottom

of base

47"

(1193mm)

to bottom

of base for

barrier free

option

677⁄8"

(1724mm)

to bottom

of base

Optional

drain

outlet

923⁄16"

(2342mm)

to bottom

of base

62¼"

(1581mm)

to bottom

of base

941⁄8"

(2391mm)

to bottom

of base

Plastic Showerhead with Plastic

or Stainless Steel Shroud

Plastic Ø 10" (254mm)

Stainless Steel Ø 10¾" (273mm)

Type 304 and 316 Stainless Steel

Showerheads

1½"

(38mm)

Eyewash Bowl

18½"

(470mm)

13"

(330mm)

Dust Cover

19¾"

(502mm)

34¾"

(883mm)

to bottom

of base

Standard

drain

outlet

24½"

(622mm)

to Bottom

of Base

6"

(152mm)

All dimensions assume standard thread engagement. Variations in manufacturing allow for +/- 1⁄8"

(3mm) per threaded joint. To find the tolerance of a dimension, add the number of thread joints

across the length of the dimension and multiply it by 1⁄8" (3mm).

Water Flow Rate

Showerhead 20–26 gpm

Eyewash 4–5¼ gpm

Eye/Face Wash 4–5¼ gpm

Body Wash 2–8 gpm

13¼"

(337mm)

Bradley • 215-1684 Rev. V; ECO 19-05-002A 4/17/2019

9

S19314 Installation

1

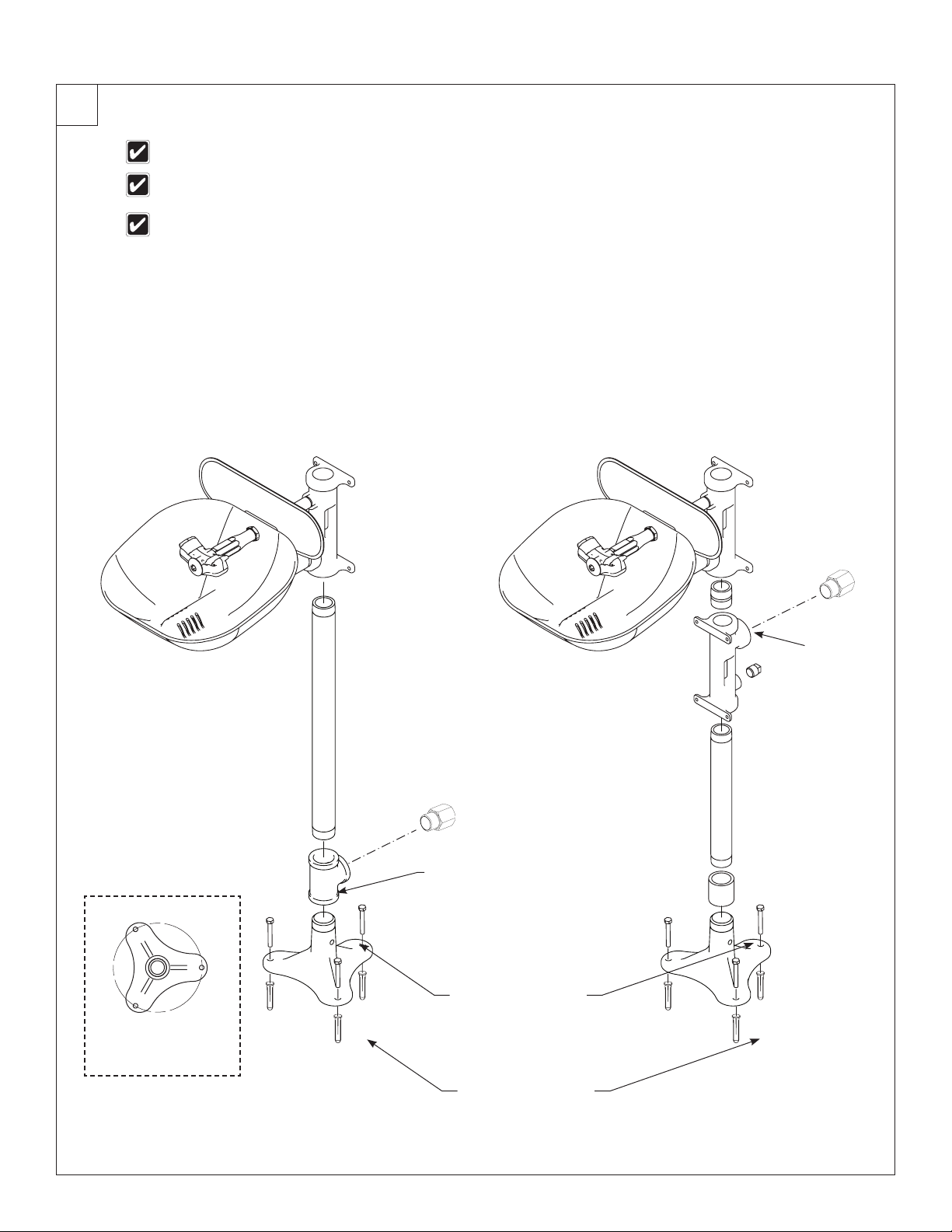

Assembly — Connect Base and Eyewash

Standard eyewash unit is shown. Other units are similar.

Connect components before securing the base to the floor. When connecting

components, use the rubber grip pad (provided) around pipes to prevent marring.

Apply pipe sealant (supplied by installer) to all male-threaded pipe joints, making

sure not to get any excess over the edge of the pipes.

Halo unit with standard

drain option

20½"

(521mm)

pipe length

BSPP-NPT

1-1/4" Adapter

if supplied

with provided

option

Halo unit with 24"

drain option

BSPP-NPT

1-1/4" Adapter

if supplied

with provided

option

1¼" NPT

drain outlet

12¾"

(324mm)

pipe length

(3) Ø 3⁄8" (10mm) holes on

Ø 8" (203mm) bolt circle

10

1¼" NPT

drain outlet

For optional foot pedal

installation, the base

must be positioned

so that the hole in the

base is perpendicular

to the user.

³⁄₈" bolts and anchors

supplied by installer.

4/17/2019 Bradley • 215-1684 Rev. V; ECO 19-05-002A

Installation S19314

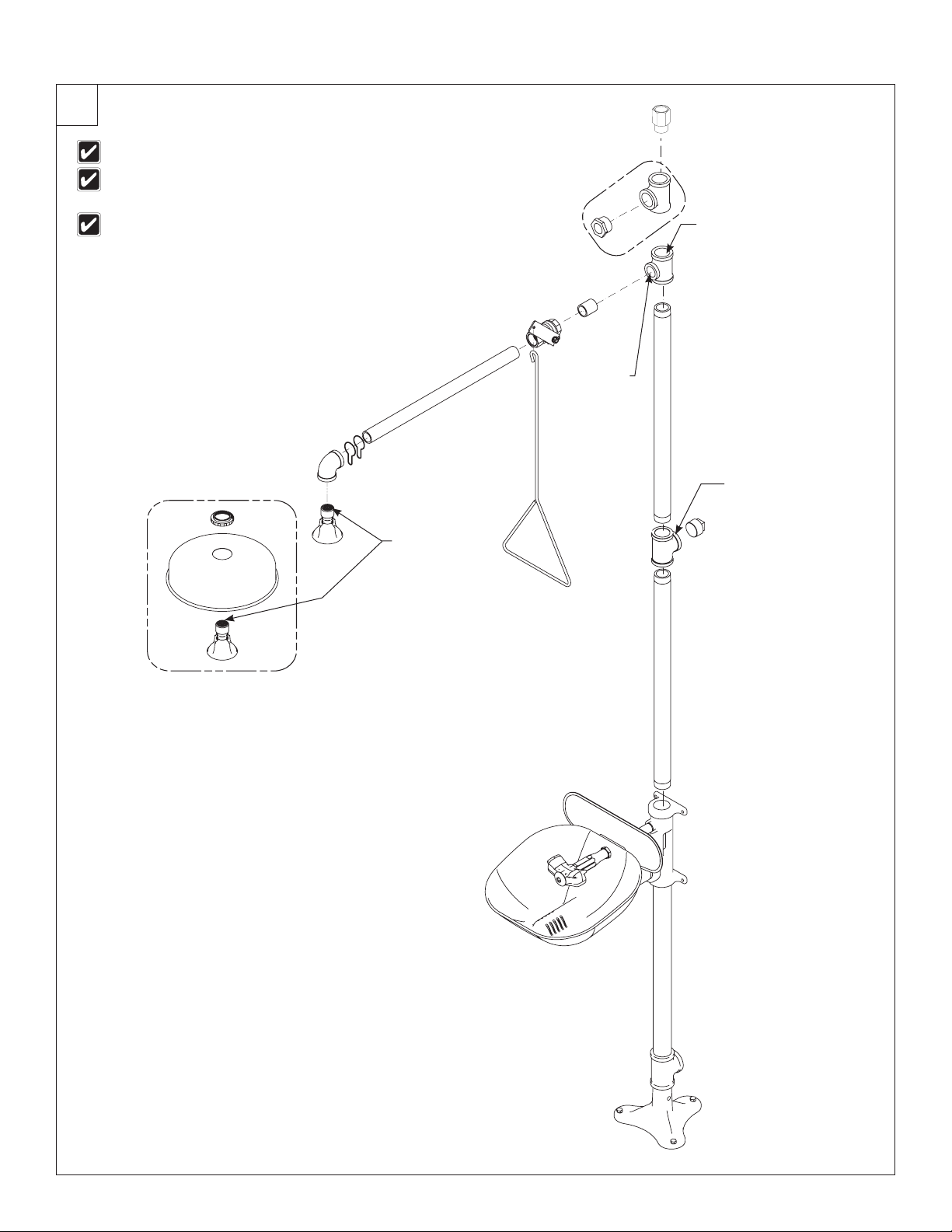

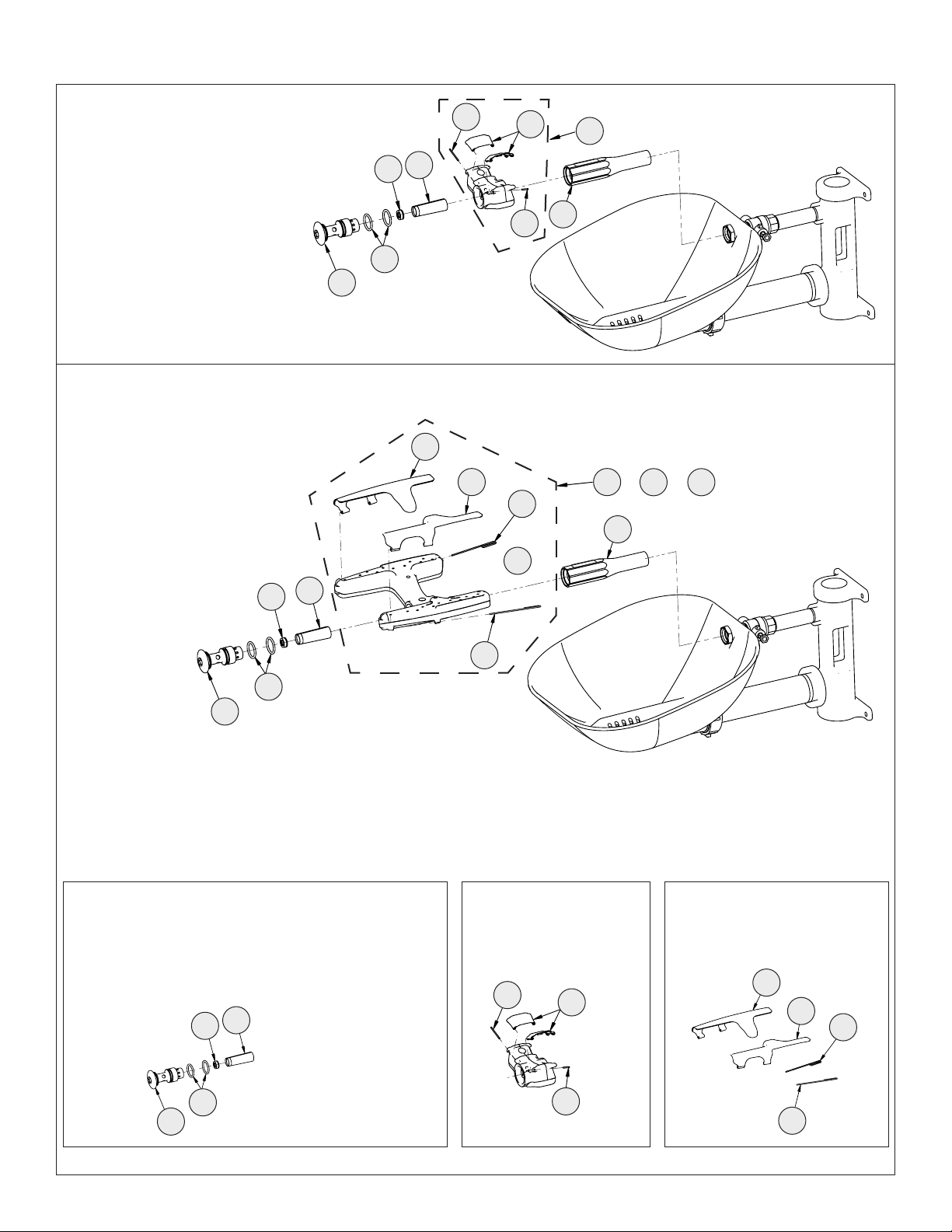

2

Assembly — Connect Drench Shower Components

Standard eyewash unit is shown. Other units are similar.

Apply pipe sealant (supplied by installer) to all male-threaded pipe

joints, making sure not to get any excess over the edge of the pipes.

BSPP = British Standard Pipe Parallel Thread (not available in the

U.S.)

Showerhead with

stainless steel

shroud option

Use teflon

tape only.

Stainless

steel tee with

reducer

1" outlet

for shower

BSPP-NPT

1-1/4" Adapter

if supplied

with provided

option

1¼" NPT below supply inlet

26" (660mm)

pipe length

Alternate 1¼" NPT below

supply inlet

If this tee is used as the

supply inlet, use the plug

on the top supply inlet

and use BSPP adapter

here if supplied with

provided option.

26" (660mm)

pipe length

Bradley • 215-1684 Rev. V; ECO 19-05-002A 4/17/2019

11

S19314 Installation

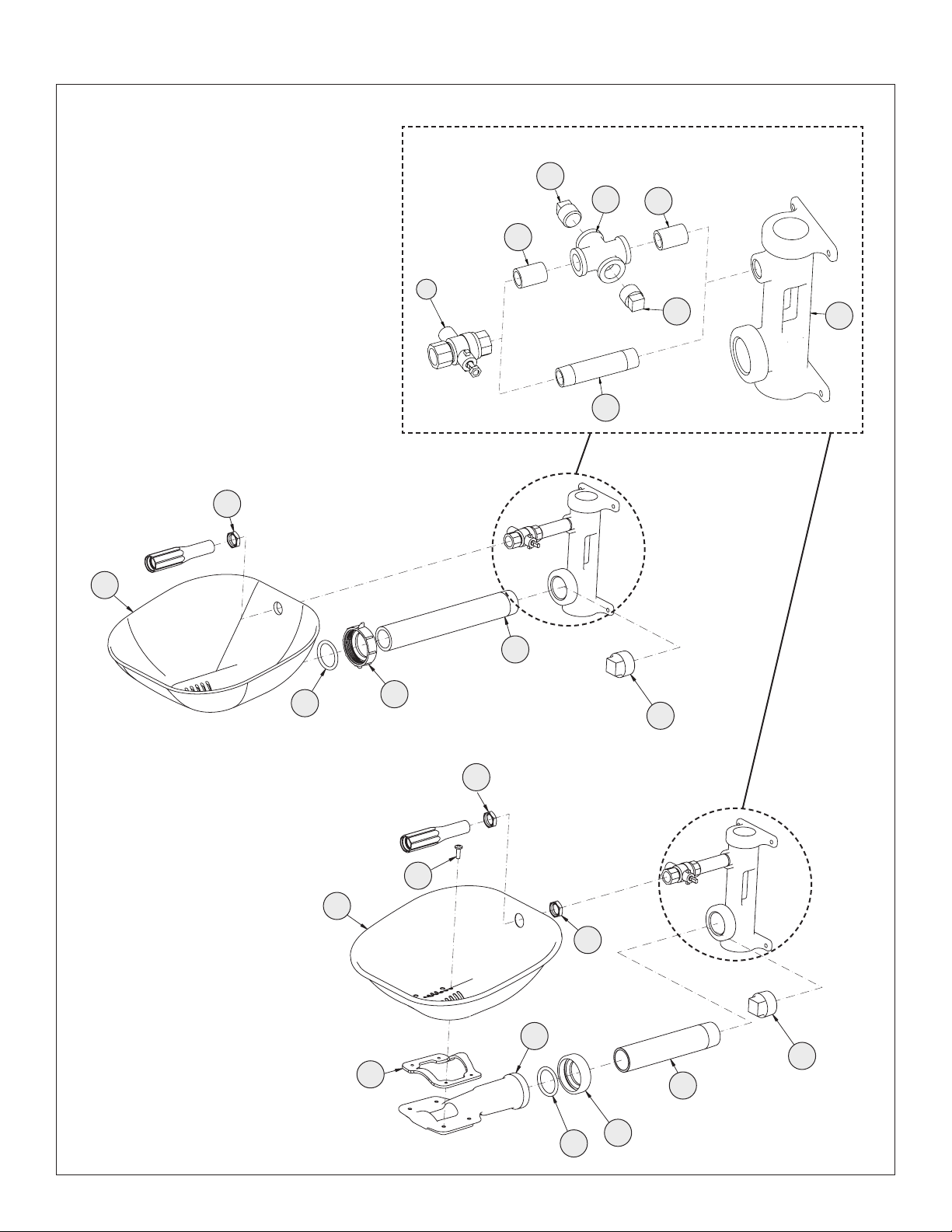

Service Parts — Bowl and Hub

Cross (Item #3) is for use with freeze/scald

valves and drench hose accessories only.

4

3

2b

5

2a

Hub with Plastic Bowl

2b

4

1

15a

17

12

Hub with Stainless Steel Bowl

15b

10a

11a

10c

17

16

17

12

13

10c

14

11b

12

10b

4/17/2019 Bradley • 215-1684 Rev. V; ECO 19-05-002A

Installation S19314

Service Parts List — Bowl and Hub

Item Part No. Qty Description

1 111-092 1 Hub

1 111-093 1 Hub stainless steel

1 111-095 1 Hub stainless steel 316

1 111-094 1 Hub stainless steel polish

2a 113-006LQ 1 Pipe ½" x 3½"

2a 113-965 1 Pipe ½" x 3½" stainless steel

2a 113-1211 1 Pipe ½" x 3½" stainless steel 316

2a 113-596 1 Pipe ½" x 3½" chrome

2b 113-006LG 2 Pipe ½" x close

2b 113-867 2 Pipe ½" x close stainless steel

2b 113-1210 2 Pipe ½" x close stainless steel 316

2b 113-006aw 2 Pipe ½" x close chrome

3 169-1090 1 Cross ½"

3 169-1091 1 Cross ½" stainless steel

3 169-1098 1 Cross ½" stainless steel 316

3 169-1097 1 Cross ½" chrome

4 300-0393 2 Plug ½" chrome

4 153-230 2 Plug ½" stainless steel

4 153-460 2 Plug ½” stainless steel 316

5 S27-327 1 Ball valve ½" with nut

5 S27-328 1 Ball valve ½" ss 316 with nut

5 S27-329 1 Ball valve ½" frost proof with nut

5 S27-330 1 Ball valve ½" ss 316 frost proof with nut

5.1 110-215 1 Nut

5.1 110-248 1 Nut stainless steel 316

Item Part No. Qty Description

10a 113-1202 1 Pipe 1¼" x 11" thd. one end

10a 113-1203 1 Pipe 1¼" x 11" thd. one end stn. steel

10a 113-1138 1 Pipe 1¼" x 11" thd. one end chrome

10a 113-1139 1 Pipe 1¼" x 11" thd. one end stn. steel 316

10b 113-1204 1 Pipe 1¼" x 7" thd. one end

10b 113-1205 1 Pipe 1¼" x 7" thd. one end stainless steel

10b 113-1206 1 Pipe 1¼" x 7" thd. one end chrome

10b 113-1212 1 Pipe 1¼" x 7" thd. one end stn. steel 316

10c 169-724 1 Plug 1¼" painted galvanized

10c 269-251 1 Plug 1¼" chrome

10c 269-238 1 Plug 1¼" stainless steel

10c 269-1402 1 Plug 1¼" stainless steel 316

11a 110-239 1 Nut plastic, slip joint

11b 110-240 1 Nut, stainless steel slip joint

11b 110-242 1 Nut, stainless steel 316 slip joint

12 125-176 1 O-ring

13 111-099 1 Bowl mount aluminum

13 111-100 1 Bowl mount aluminum painted

13 111-101 1 Bowl mount stainless steel

13 111-102 1 Bowl mount stainless steel 316

14 124-082 1 Bowl gasket

15a 187-320 1 Bowl plastic

15b S90-393 1 Bowl stainless steel (includes Item 14)

15b S90-394 1 Bowl stn. steel 316 (includes Item 14)

16 160-467 4 Screw

17 110-115a as req’d. Nut ½" NPSM chrome brass

17 110-238 as req’d. Nut ½" NPSM stainless steel

17 110-241 as req’d. Nut ½" NPSM stainless steel 316

S90-395 Plastic Prepack includes items 10a, 11a, 12, 15a

15a

10a

12

11a

300 Series SS Prepack S90-391 includes items 10b, 11b, 12, 13, 14, 15b

316 Series SS Prepack S90-392 includes items 10b, 11b, 12, 13, 14, 15b

15b

Bradley • 215-1684 Rev. V; ECO 19-05-002A 4/17/2019

13

14

12

10b

11b

13

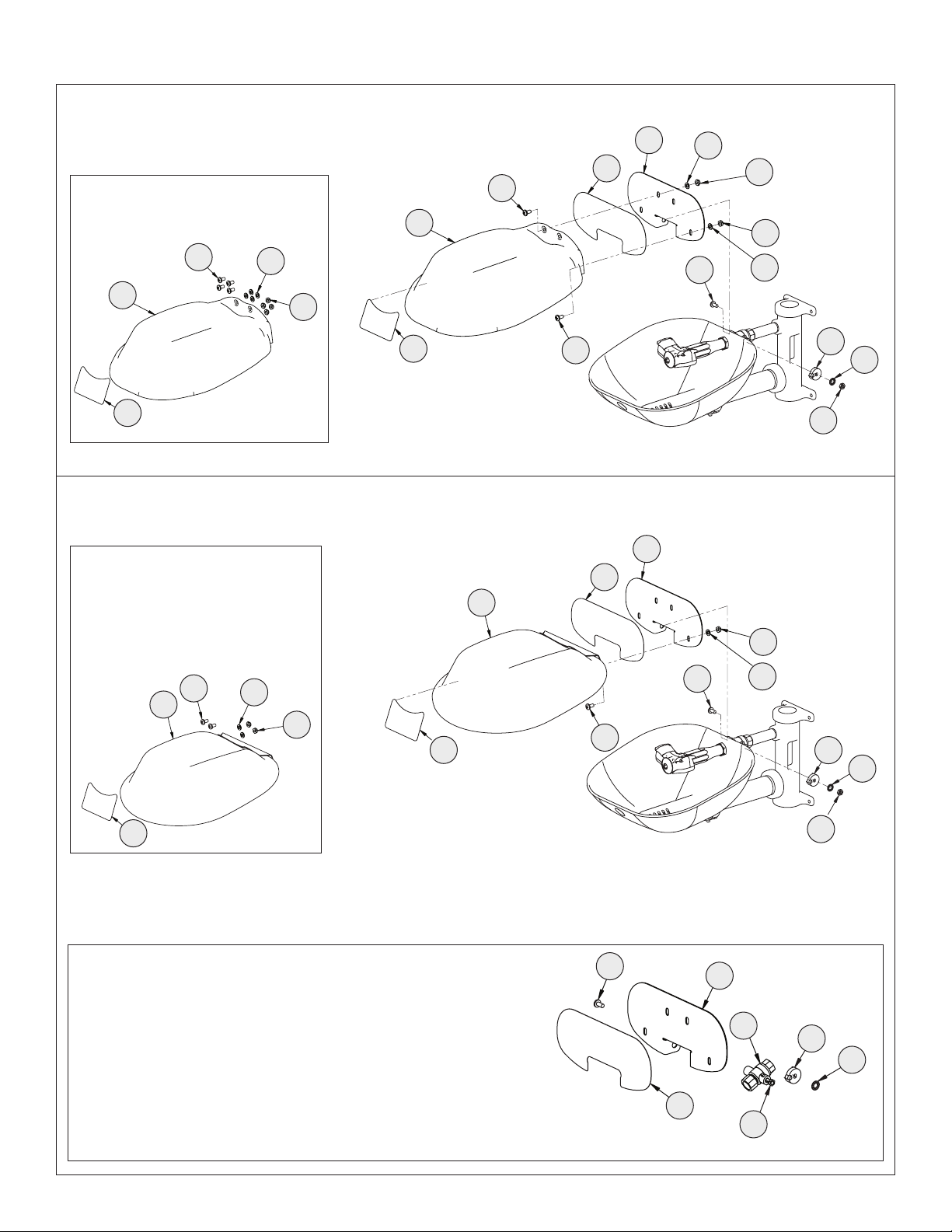

S19314 Installation

Service Parts — Eyewash

25

Service Parts — Eye/Face Wash

22

28

27

26

24b

24a

23

22

22

21a

20

or or

21b

21f 21j

20

28

27

26

25

Prepack S65-339 includes items 26, 27, 28

Prepack S88-068 includes items 25, 26, 27, 28

Prepack S88-069 includes items 25, 26, 27, 28 (300 series ss)

Prepack S88-070 includes items 25, 26, 27, 28 (316 ss)

28

27

21b

22

Eyewash Cover Prepack

S45-2675 includes items

22 and 23

22

23

Eye/Face Wash Cover Prepack

S45-2676 includes items 22,

24a and 24b

24b

24a

22

14

26

25

22

22

4/17/2019 Bradley • 215-1684 Rev. V; ECO 19-05-002A

Installation S19314

Service Parts — Plastic Bowl Cover

Plastic Bowl Cover Prepack S90-390

includes items 35a, 36, 39, 42, 43

39

35a

36

42

43

35a

36

Service Parts — Stainless Steel Bowl Cover

Stainless Steel Bowl Cover Prepack

S90-388 includes items 35b, 36, 39,

42, 43

Stainless Steel (316) Bowl Cover

Prepack S90-389 includes items 35b,

36, 39, 42, 43

35b

40

41

39

39

40

41

42

43

43

39

42

44

45

5.1

43

39

35b

36

42

43

36

Handle Prepacks include items 39, 40, 41, 44, 45, 5, 5.1

Prepack S08-390 (for units with brass ball valve)

Prepack S08-391 (for units with stainless steel ball valve)

Prepack S08-392 (for units with brass frost-proof ball valve)

Prepack S08-393 (for units with stainless steel frost-proof ball valve)

Prepack S08-394 (for units with 316 stainless steel ball valve and handle)

Prepack S08-395 (for units with 316 stainless steel frost-proof ball valve

and handle)

39

39

39

41

42

44

45

5.1

40

5

44

45

5.1

Bradley • 215-1684 Rev. V; ECO 19-05-002A 4/17/2019

15

S19314 Installation

Service Parts List — Eyewash, Eye/Face Wash and Bowl Covers

Item Part No. Qty Description

20

20

20

21a

171-001

171-002

171-003

S05-190

1

Body

1

Body stainless steel

1

Body stainless steel 316

1

Sprayhead ass’y. eyewash

(includes)

22

23

21b

in service kit

in service kit

S05-192

Pivot pin

2

Flip cover eyewash

2

1

Sprayhead ass’y. eye/face wash

(includes)

22

24a

24b

21f

in service kit

in service kit

in service kit

S05-204

Pivot pin

2

Flip cover right

1

Flip cover left

1

1

Sprayhead stainless steel 304

ass'y. eye/face (includes)

22

24a

24b

21j

in service kit

in service kit

in service kit

S05-205

Pivot pin

2

Flip cover right

1

Flip cover left

1

1

Sprayhead stainless steel 316

ass'y. eye/face (includes)

22

24a

24b

25

25

25

in service kit

in service kit

in service kit

115-158

115-159

115-164

Pivot pin

2

Flip cover right

1

Flip cover left

1

1

Cap

1

Cap stainless steel

1

Cap stainless steel 316

Item Part No. Qty Description

26 125-157 2 O-ring

27 125-175 1 Flow control

28 S65-340 1 Screen (incl. 3 per pack)

35a

35b

35b

in service kit

in service kit

in service kit

1

Bowl cover plastic

1

Bowl cover stainless steel

1

Bowl cover stainless steel 316

36 114-097 1 Bowl cover decal

3939160-389

160-469

4040S08-385

as req'd.

as req'd.

Screw ¼-20 x ½" stn. steel

Screw ¼-20 x ½" stn. steel 316

11Handle ss (incl. items 41, 44,

45, 5.1)

S08-388

Handle ss 316 (incl. items 41,

44, 45, 5.1)

41 114-096 1 Decal

42 142-002AV

4343161-060

161-062

as req'd.

as req'd.

as req'd.

Bowl cover washer

Nut stainless steel

Nut stainless steel 316

44 153-372R 1 Adapter ball valve

44

153372R316

1 Adapter ball valve stainless steel

316

45 142-002DA 1 Lockwasher

16

4/17/2019 Bradley • 215-1684 Rev. V; ECO 19-05-002A

Installation S19314

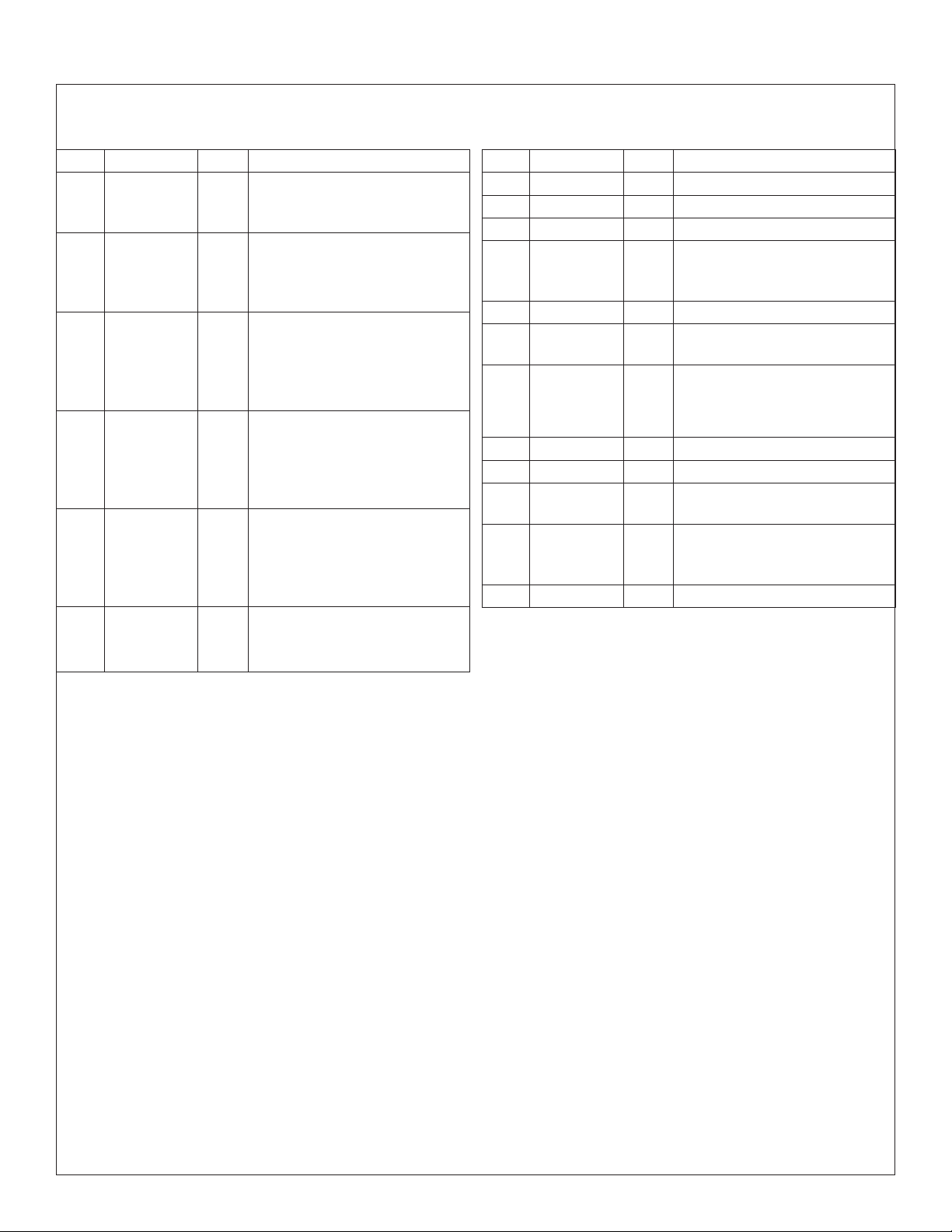

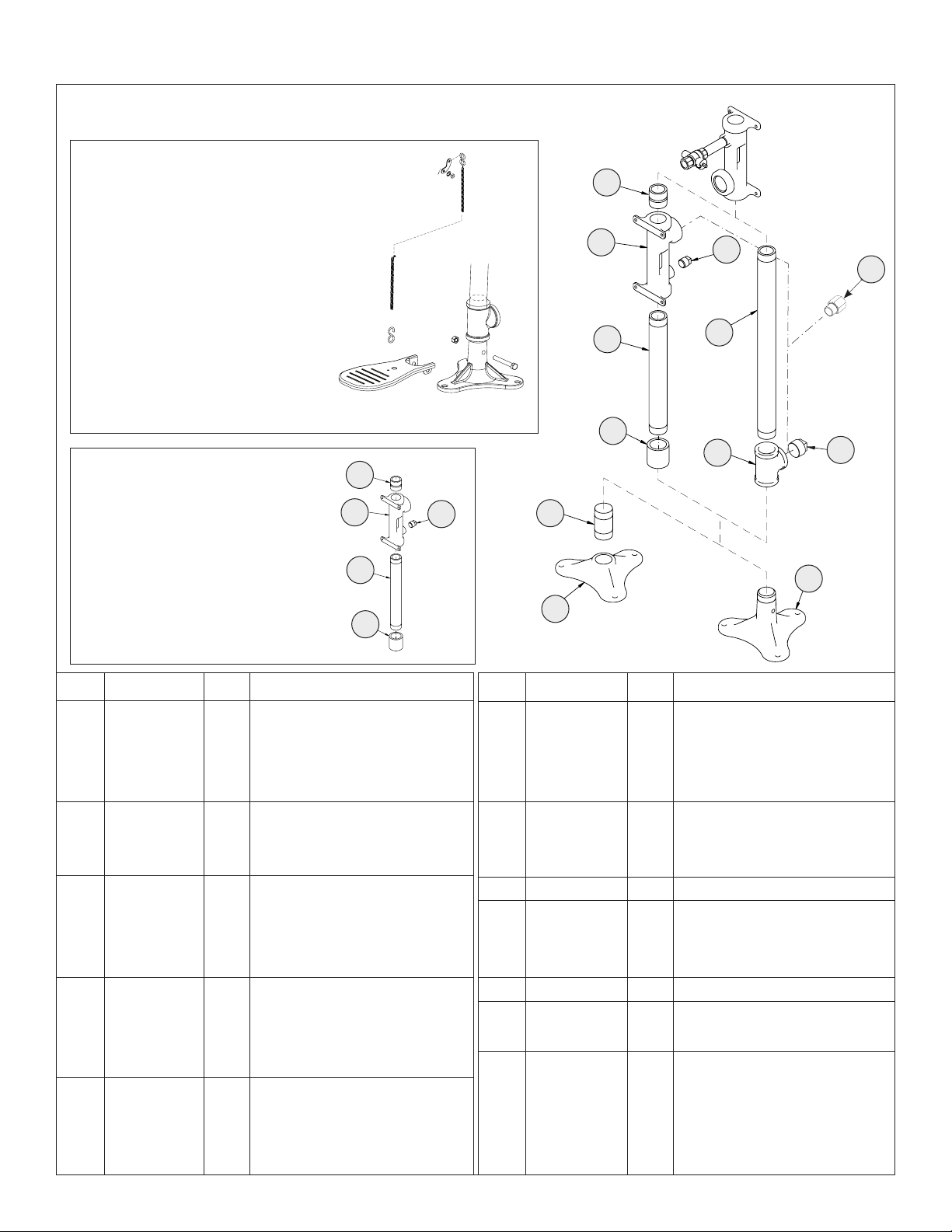

Service Parts and Parts List — Base and Drain

Foot Pedal kits

S45-572 (standard foot pedal kit)

S45-1314SS (stainless steel foot pedal kit)

S45-1314SS16 (316 stainless steel foot pedal kit)

303

1

4

321

Base and Drain Kits for 24" Drains include

items 1, 4, 301b, 302b, 303

S29-098 (standard)

S29-099 (stainless steel)

303

1

4

S29-100 (316 stainless steel)

S29-101 (chrome)

301b

302b

Item Part No. Qty. Description

1 111-092 1 Hub

1 111-093 1 Hub stainless steel

1 111-095 1 Hub stainless steel 316

1 111-094 1 Hub stainless steel polish

4 300-0393 2 Plug ½" chrome

4 153-230 2 Plug ½" stainless steel

4 153-460 2 Plug ½" stainless steel 316

301a 113-1197 1 Pipe 1¼" x 20½"

301a 113-1198 1 Pipe 1¼" x 20½" chrome

301a 113-541 1 Pipe 1¼" x 20½" stainless steel

301a 113-1213 1 Pipe 1¼" x 20½" stainless steel 316

301b 113-1217 1 Pipe 1¼" x 12¾"

301b 113-1218 1 Pipe 1¼" x 12¾" chrome

301b 113-1219 1 Pipe 1¼" x 12¾" stainless steel

301b 113-1220 1 Pipe 1¼" x 12¾" stainless steel 316

302a 169-727 1 Tee 1¼" painted galvanized

302a 269-237 1 Tee 1¼" stainless steel

302a 269-1398 1 Tee 1¼" stainless steel 316

302a 269-253 1 Tee 1¼" chrome

301b

301a

Supplied

with BSPP

Thread

options only

302b

302a

304

305b

326

305a

Item Part No. Qty. Description

302b 169-853 1 Coupling 1¼" galvanized

302b 269-257 1 Coupling 1¼" chrome

302b 269-1048 1 Coupling 1¼" stainless steel

302b 269-2016 1 Coupling 1¼" stainless steel 316

303 113-006NA 1 Pipe 1¼" x close painted galvanized

303 113-865 1 Pipe 1¼" x close stainless steel

303 113-1223 1 Pipe 1¼" x close stainless steel 316

304 S06-189 1 Plug chrome solid

305a 131-059 1 Base painted

305a 131-062 1 Base stainless steel

305a 131-079 1 Base stainless steel 316

305b 131-044 1 Base chrome

321 169-1117 1 BSPP-NPT 1-1/4" 303SS

321 169-1118 1 BSPP-NPT 1-1/4" 316SS

326 169-724 1 Plug 1¼" painted galvanized

326 269-251 1 Plug 1¼" chrome

326 269-238 1 Plug 1¼" stainless steel

326 269-1402 1 Plug 1¼" stainless steel 316

Bradley • 215-1684 Rev. V; ECO 19-05-002A 4/17/2019

17

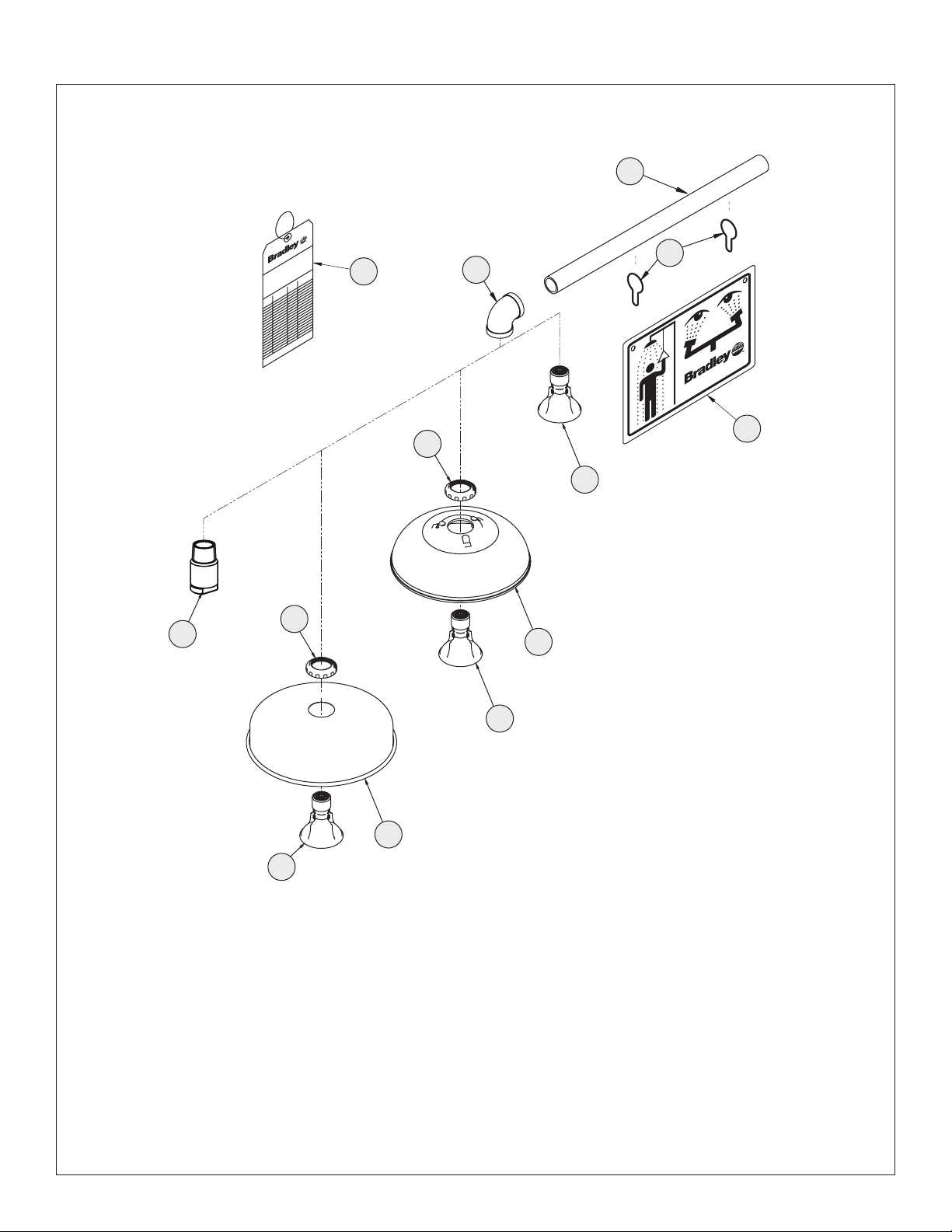

S19314 Installation

Service Parts — Drench Shower

330

360b

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Date Signed

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

Date

durch Unterschrift. Jegliche Störung sofort melden.

Date

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

Signed

un rapport immédiatement.

Unterschrift

Signe

Date

Datum

Date

362

R

343

Signed

Signed

341

331

http://www.bradleycorp.com

TEL: 1-800-BRADLEY FAX: (262-251-5817)

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

114-052

342

362

360a

361b

360a

360a

361a

18

4/17/2019 Bradley • 215-1684 Rev. V; ECO 19-05-002A

Loading...

Loading...