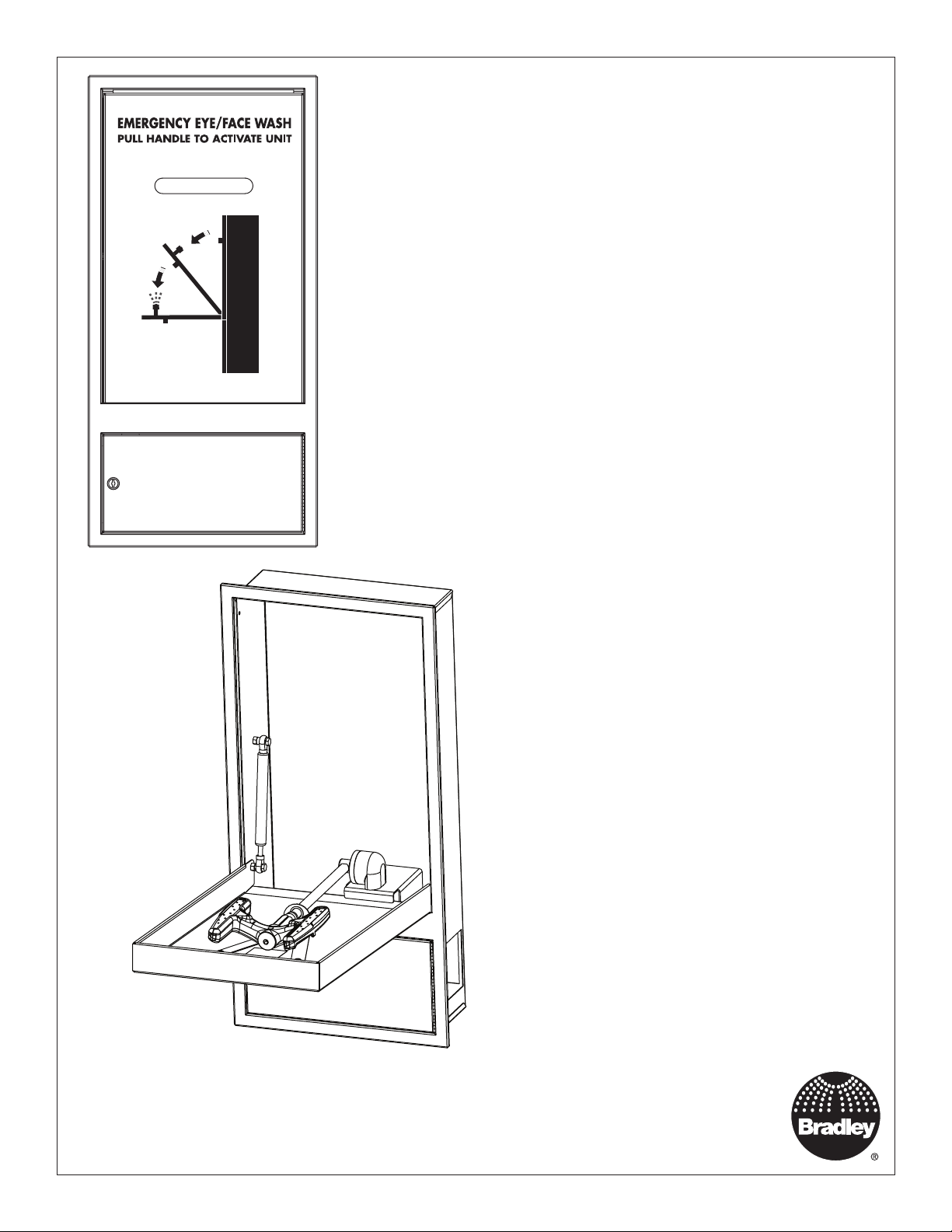

Bradley S19294 Series, S19294JB, S19294JBT, S19294HB, S19294HBT Installation Manual

Installation

S19294JB

Barrier-Free Cabinet-Concealed Swing-Down

Eye/Face Wash with Tailpiece

Douche oculaire/faciale rabattable sans barrière,

dissimulée dans armoire avecc pièce de

raccordement

Lavador de ojos/rostro oscilante de gabinete

empotrado de fácil acceso con tubo de

aspiración

S19294JBT

Barrier-Free Cabinet-Concealed Swing-Down

Eye/Face Wash with P-trap

Douche oculaire/faciale rabattable sans barrière,

dissimulée dans armoire avec siphon en P

Lavador de ojos/rostro oscilante de gabinete

empotrado de fácil acceso con sifón en P

Table of Contents

Pre-Installation Information ...................... 2

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation ...................................4

Assembly of Components ..................... 5–6

Parts List .................................... 6

215-1745 Rev. C; ECN 15-05-042

© 2017 Bradley

Page 1 of 16 12/7/2017

Table des matières

Information avant installation..................... 7

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation ...................................9

Assemblage des composantes ............... 10–11

Liste des pièces ............................. 11

Contenido

Information previa a la instalación ............... 12

Dimensiones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Instalación ..................................14

Armado de los componentes ................ 15–16

Lista de piezas .............................. 16

P.O. Box 309

Menomonee Falls, WI 53052 USA

800 BRADLEY (800 272 3539)

+1 262 251 6000

bradleycorp.com

S19294JB, S19294JBT Installation

WARNING

Flush the water supply lines before beginning installation and after installation is complete. Test

the unit for leaks and adequate water flow. Main water supply to the eyewash should be “ON” at all

times. Provisions shall be made to prevent unauthorized shutoff.

CAUTION

Emergency equipment must be supplied with tepid water (60°F to 100°F/15.6°C to 37.8°C). Any

prolonged exposure to near freezing water affects the body's ability to maintain body temperature,

increasing the risk of hypothermia.

NOTICE

Before installing this product, ensure that there are adequate clearances around the product and

activation of the product does not interfere with other products or obstructions.

Avoid cleaners containing organic solvents, alcohols and hydrocarbons. Rinse with water after

cleaning.

IMPORTANT

The installation and location of all safety drench showers, eye and eye/face washes must comply

with the requirements of ANSI/ISEA Z358.1.

Read this installation manual completely to ensure proper installation, then file it with the owner or

maintenance department. Compliance and conformity to drain requirements and other local codes

and ordinances is the responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for before discarding any

packaging material. If any parts are missing, do not begin installation until you obtain the missing

parts.

The ANSI/ISEA Z358.1 standard requires an uninterrupted supply of flushing fluid. Bradley plumbed

emergency fixtures require a minimum of 30 PSI (0.21MPa) flowing pressure.

Self-closing spring-loaded valves are not UL classified to ANSI/ISEA Z358.1.

Weekly activation must be conducted on all plumbed emergency equipment to ensure a suitable

flushing fluid supply is present and any sediment build-up in the supply line is cleared. Emergency

equipment should be inspected monthly to address any maintenance issues ensuring the

equipment is in good operating condition and that there are no signs of wear.

Workers who may come in contact with potentially hazardous materials should be trained regarding

the placement and proper operation of emergency equipment per ANSI/ISEA Z358.1.

For questions regarding the operation or installation of this product, visit www.bradleycorp.com or

call 800-BRADLEY (272.3539).

Product warranties and parts information may also be found under ”Products” on our web site at

bradleycorp.com.

Supplies Required:

• Piping to ½" NPT water supply inlet on unit

• Bolts for cabinet mounting

• Pipe sealant

• Sign-mounting hardware

2

Local codes may require the installation of a backflow prevention valve

to complete proper installation. Compliance with local codes is the

responsibility of the installer. Valve must be tested annually to verify that

it is functioning properly. Backflow prevention valves are not included

with the fixture and may be supplied by the contractor or purchased from

Bradley Corporation.

12/7/2017 Bradley • 215-1745 Rev. C; ECN 15-05-042

Installation S19294JB, S19294JBT

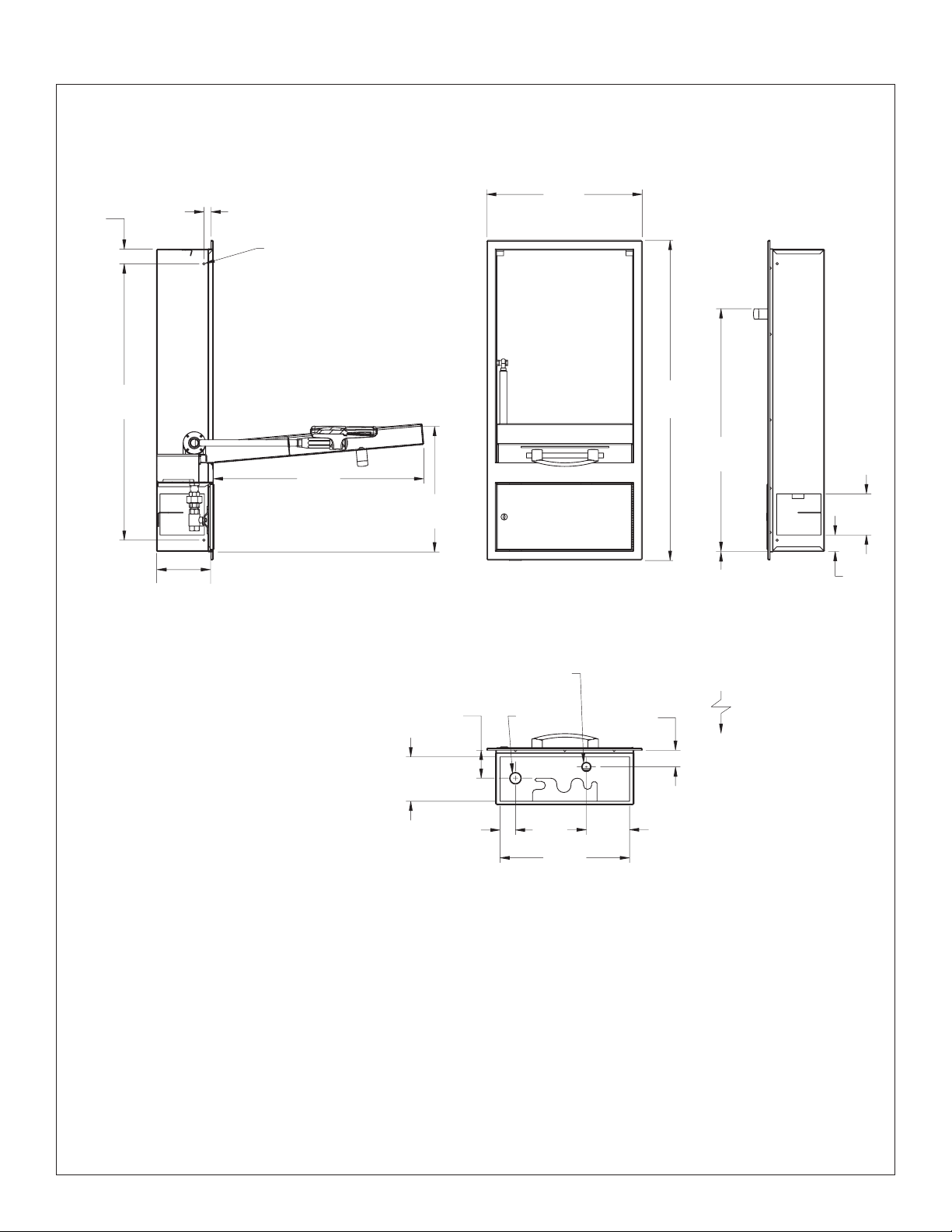

Dimensions

16³⁄₈"

1⁹⁄₁₆"

(40mm)

¾"

(19mm)

Ø ¼" mtg.

hole (qty. 4)

(417mm)

29¹⁄₈"

(740mm)

5¹³⁄₁₆"

(148mm)

"ON"

position

22³⁄₁₆"

(564mm)

12⁷⁄₈"

(327mm)

4¹¹⁄₁₆"

(119mm)

2¹⁵⁄₁₆"

(75mm)

(41mm)

1⁵⁄₈"

½" NPT

Supply

Drain

(348mm)

13¹¹⁄₁₆"

33¹¹⁄₁₆"

(856mm)

25⁵⁄₈"

(651mm)

20¹⁄₈"–32¹⁄₈" (511mm–816mm) to

floor for ANSI compliance

20¹⁄₈"–23¹⁄₈" (511mm–587mm) to

floor for "barrier free" compliance

Bradley recommends mounting

at 20¹⁄₈" to accommodate the

maximum number of users

1¾"

(44mm)

4⁹⁄₁₆"

(116mm)

4⁵⁄₁₆"

(110mm)

1¾"

(44mm)

Bradley • 215-1745 Rev. C; ECN 15-05-042 12/7/2017

3

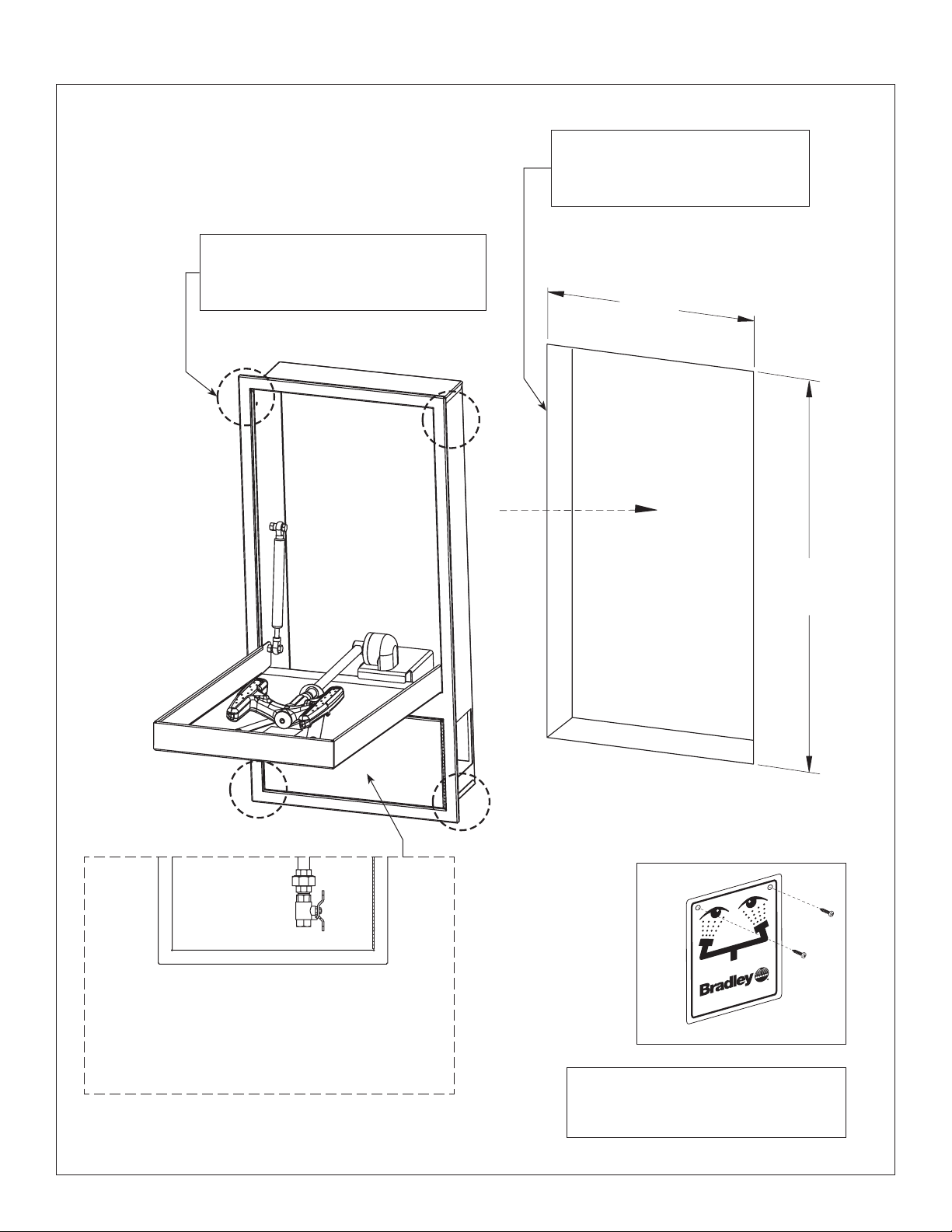

S19294JB, S19294JBT Installation

Installation

Rough in the wall opening and

A

the ½" NPT water supply.

Mount the unit in the wall opening

B

with four bolts (supplied by installer).

14½"

(368mm)

C

With the cabinet door open, connect the water supply.

Tailpiece: Connect the non-flanged end to the drain

pipe and the other end to the 1¼" waste.

P-trap: Connect to the drain pipe and adjust for side

or rear drain according to your application. Connect

the other end to the 1¼" waste.

D

To

Wall

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

114-051

Slowly open the water supply lines

to relieve air and pressurize the

E

valve. Test the unit for leaks and

adequate flow.

32¼"

(819mm)

4

12/7/2017 Bradley • 215-1745 Rev. C; ECN 15-05-042

Installation S19294JB, S19294JBT

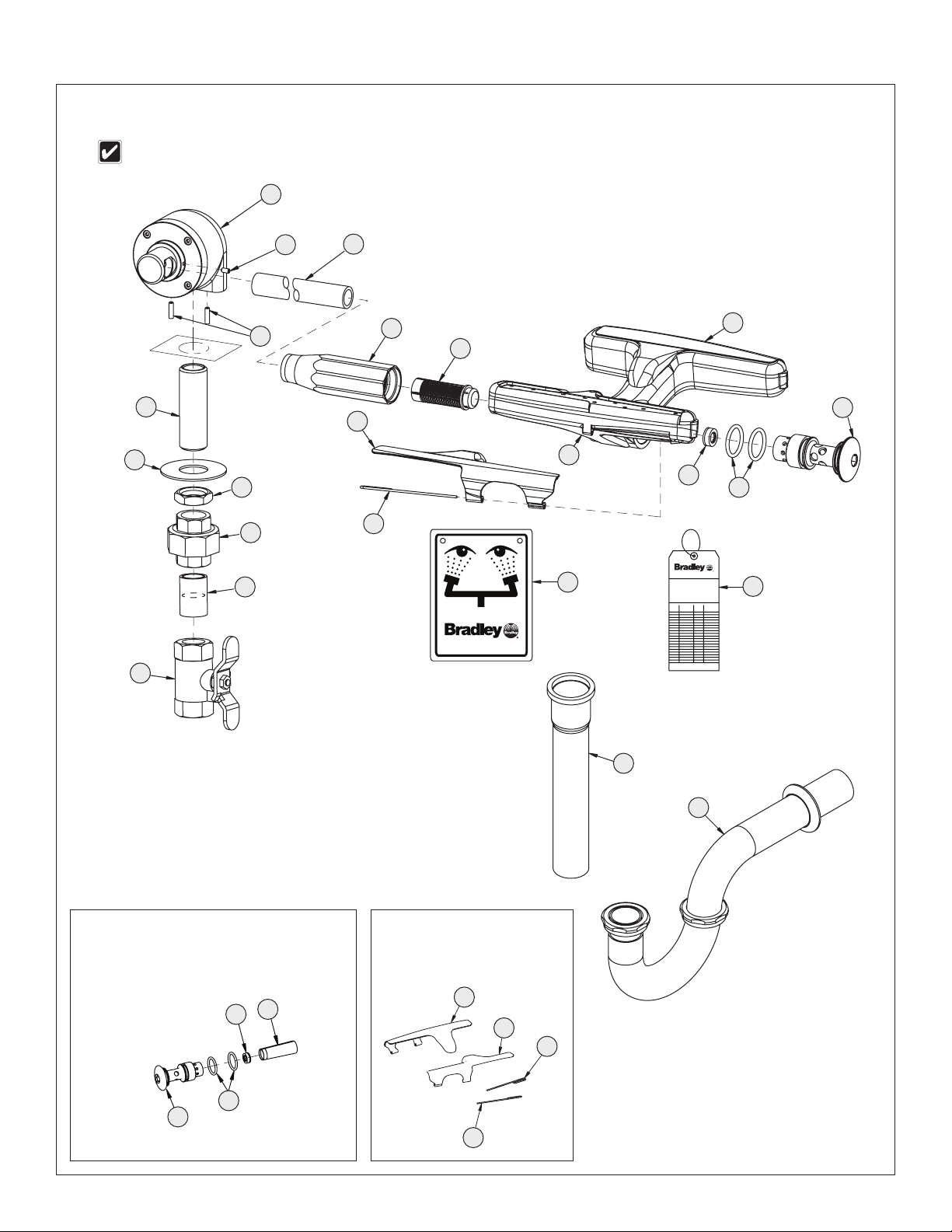

Assembly of Components — S19294JB and S19294JBT

Shown in the "ON" position.

1

2

13

14

19

20

24b

28

25

22

15

16

29

24a

31

bradleycorp.com

21

27

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

34

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Datum

Unterschrift

Date

Signe

Date Signed

Date

Date

26

R

35

Signed

Signed

32

33

Prepack S65-339 includes items 26, 27, 28

Prepack S88-068 includes items 25, 26, 27, 28

28

27

Eye/Face Wash Cover

Prepack S45-2676 includes

items 22, 24a and 24b

24b

24a

22

26

25

22

Bradley • 215-1745 Rev. C; ECN 15-05-042 12/7/2017

Tailpiece

or

P-trap

33

5

Loading...

Loading...