Page 1

S19-270C eyewash

douche oculaire

lavador de ojos

Installation

S19-270C, S19-270E,

S19274C, S19274E

Swing-Activated Eyewash and Eye/Face

Wash

Douche oculaire et oculaire/faciale

activée par bras mobile

Lavador de ojos y de ojos/rostro

activado por brazo oscilante

S19-270E eye/face wash

douche oculaire/faciale

lavador de ojos/rostro

S19274C Halo™ eyewash

douche oculaire

lavador de ojos

S19274E Halo™ eye/face wash

douche oculaire/faciale

lavador de ojos/rostro

215-1326 Rev. V; ECN 15-05-042

© 2017 Bradley

Page 1 of 35 10/5/2017

Menomonee Falls, WI 53052 USA

P.O. Box 309

800 BRADLEY (800 272 3539)

+1 262 251 6000

bradleycorp.com

Page 2

S19-270C, S19-270E, S19274C, S19274E Installation

Table of Contents

Pre-Installation Information .................................................................. 3

S19-270C, S19274C Dimensions .............................................................4

S19-270E, S19274E Dimensions .............................................................5

Installation .............................................................................6–7

Installation Left-Hand Units ................................................................8–9

S19-270C Assembly of Components and Parts List .............................................. 10

S19274C Assembly of Components and Parts List .............................................. 11

S19-270E Assembly of Components and Parts List .............................................. 12

S19274E Assembly of Components and Parts List............................................... 13

Table des matières

Avant l’installation ........................................................................ 14

S19-270C, S19274C Dimensions ............................................................15

S19-270E, S19274E Dimensions ............................................................16

Installation ........................................................................... 17–18

Installation Gaucher.................................................................... 19–20

S19-270C Assemblage des composantes et liste des pièces....................................... 21

S19274C Assemblage des composantes et liste des pièces ....................................... 22

S19-270E Assemblage des composantes et liste des pièces....................................... 23

S19274E Assemblage des composantes et liste des pièces ....................................... 24

Contenido

Información previa a la instalación ........................................................... 25

S19-270C, S19274C Dimensiones ...........................................................26

S19-270E, S19274E Dimensiones ...........................................................27

Instalación ........................................................................... 28–29

Instalación de Mano Izquierda............................................................ 30–31

S19-270C Armado de los componentes y lista de piezas ......................................... 32

S19274C Armado de los componentes y lista de piezas .......................................... 33

S19-270E Armado de los componentes y lista de piezas.......................................... 34

S19274E Armado de los componentes y lista de piezas .......................................... 35

2

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Page 3

Installation S19-270C, S19-270E, S19274C, S19274E

WARNING

The installation and location of all Safety drench showers, eye and eye/face washes must comply

with the requirements of ANSI Z358.1.

Emergency equipment must be supplied with tepid water (60-100°F/ 15.6-37.8°C). Any prolonged

exposure to near freezing water affects the body’s ability to maintain body temperature, increasing

the risk of hypothermia.

Flush the water supply lines before beginning installation and after installation is complete. Test

the unit for leaks and adequate water flow. Main water supply to the eyewash should be “ON” at all

times. Provisions shall be made to prevent unauthorized shutoff.

The ANSI Z358.1 standard requires an uninterrupted supply of flushing fluid. Bradley plumbed

emergency fixtures require a minimum of 30 PSI (0.21 MPa) flowing pressure. Flushing fluid should

be tepid per ANSI Z358.1.

Weekly activation must be conducted on all plumbed emergency equipment to ensure a suitable

flushing fluid supply is present and any sediment build-up in the supply line is cleared. Emergency

Equipment should be inspected monthly to address any maintenance issues ensuring the

equipment is in good operating condition and that there are no signs of wear.

Workers who may come in contact with potentially hazardous materials should be trained regarding

the placement and proper operation of emergency equipment per ANSI Z358.1.

NOTICE

Before installing this product ensure that there are adequate clearances around the product and

activation of the product does not interfere with other products or obstructions

For classic eye/face wash units, avoid cleaners containing organic solvents, alcohols, and

hydrocarbons. Rinse with water after cleaning.

IMPORTANT

Read this installation manual completely to ensure proper installation, then file it with the owner

or maintenance department. Compliance and conformity to drain requirements and other local

codes/ordinances is the responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for before discarding

any packaging material. If any parts are missing, do not begin installation until you obtain the

missing parts.

For questions regarding the operation or installation of this product, visit bradleycorp.com or

call 800.BRADLEY (800.272.3539).

Product warranties may also be found under ”Products” on our web site at bradleycorp.com.

Supplies Required:

• Piping to ½" NPT water supply inlet on unit

• Pipe sealant

• Inlet strainer (recommended)

• Sign-mounting hardware

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

Local codes may require the installation of a backflow prevention

valve to complete proper installation. Compliance with local codes

is the responsibility of the installer. Valve must be tested annually

to verify that it is functioning properly. Backflow prevention valves

are not included with the fixture and may be supplied by the

contractor or purchased from Bradley Corporation.

3

Page 4

S19-270C, S19-270E, S19274C, S19274E Installation

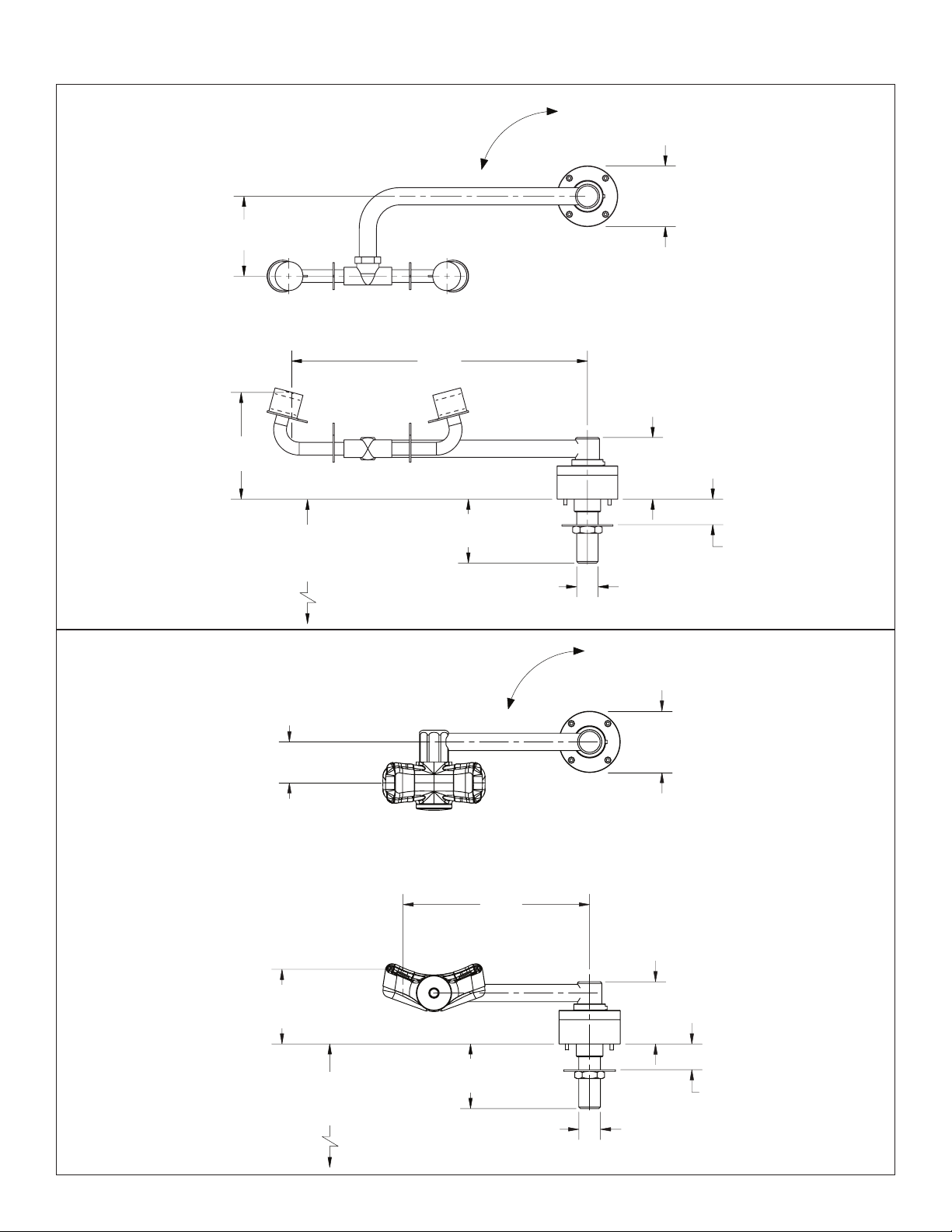

Dimensions — S19-270C

3¹⁄₈"

(79mm)

4¹⁄₈"

(105mm)

28-7/8" to 40-7/8"

(733 mm to 1038 mm)

to finished floor

11⁵⁄₈"

(295mm)

On

2½"

(64mm)

Off

Ø 2³⁄₈"

(60mm)

2³⁄₈"

(60mm)

1³⁄₈"

(35mm)

Max.

Ø ⁷⁄₈"

Dimensions — S19274C

1⁵⁄₈"

(41mm)

2⁷⁄₈"

(73mm)

30-1/8" to 42-1/8"

(765 mm to 1070 mm)

to finished floor

(181mm)

2½"

(64mm)

7¼"

On

Off

Ø 2³⁄₈"

(60mm)

2³⁄₈"

(60mm)

Ø ⁷⁄₈"

Ø 1¹⁄₈"

1³⁄₈"

(35mm)

Max.

4

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Page 5

Installation S19-270C, S19-270E, S19274C, S19274E

Dimensions — S19-270E

3¹⁄₈"

(79mm)

5¾"

(146mm)

27-1/4" to 39-1/4"

(692 mm to 997 mm)

to finished floor

11³⁄₈"

(289mm)

On

2½"

(64mm)

Off

(60mm)

Ø ⁷⁄₈"

Ø 2³⁄₈"

(60mm)

2³⁄₈"

1³⁄₈"

(35mm)

Max.

Dimensions — S19274E

1⁵⁄₈"

(41mm)

3³⁄₈"

(86mm)

29-5/8" to 41-5/8"

(752 mm to 1057 mm)

to finished floor

On

11"

(279mm)

2½"

(64mm)

Off

(60mm)

Ø ⁷⁄₈"

Ø 2³⁄₈"

(60mm)

2³⁄₈"

1³⁄₈"

(35mm)

Max.

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

5

Page 6

S19-270C, S19-270E, S19274C, S19274E Installation

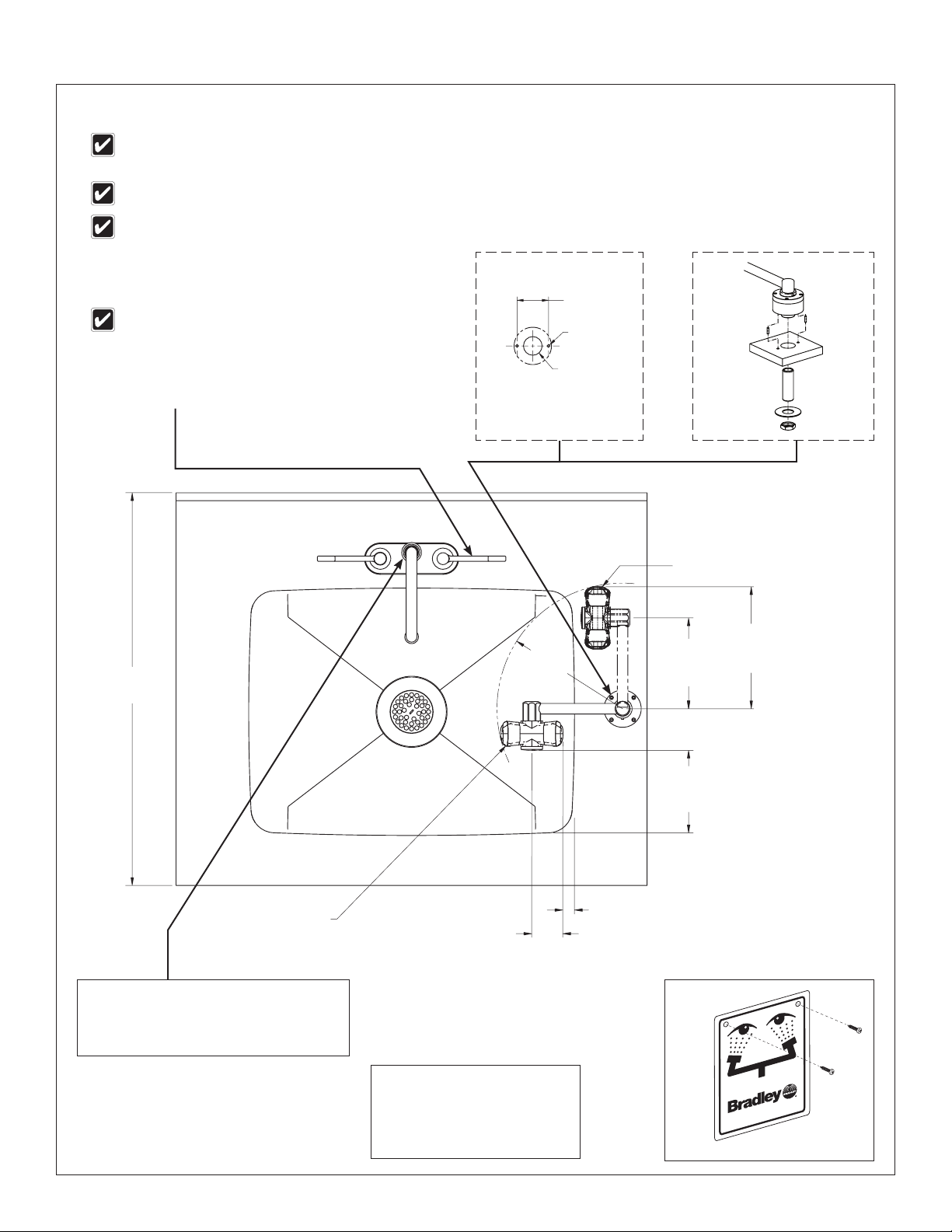

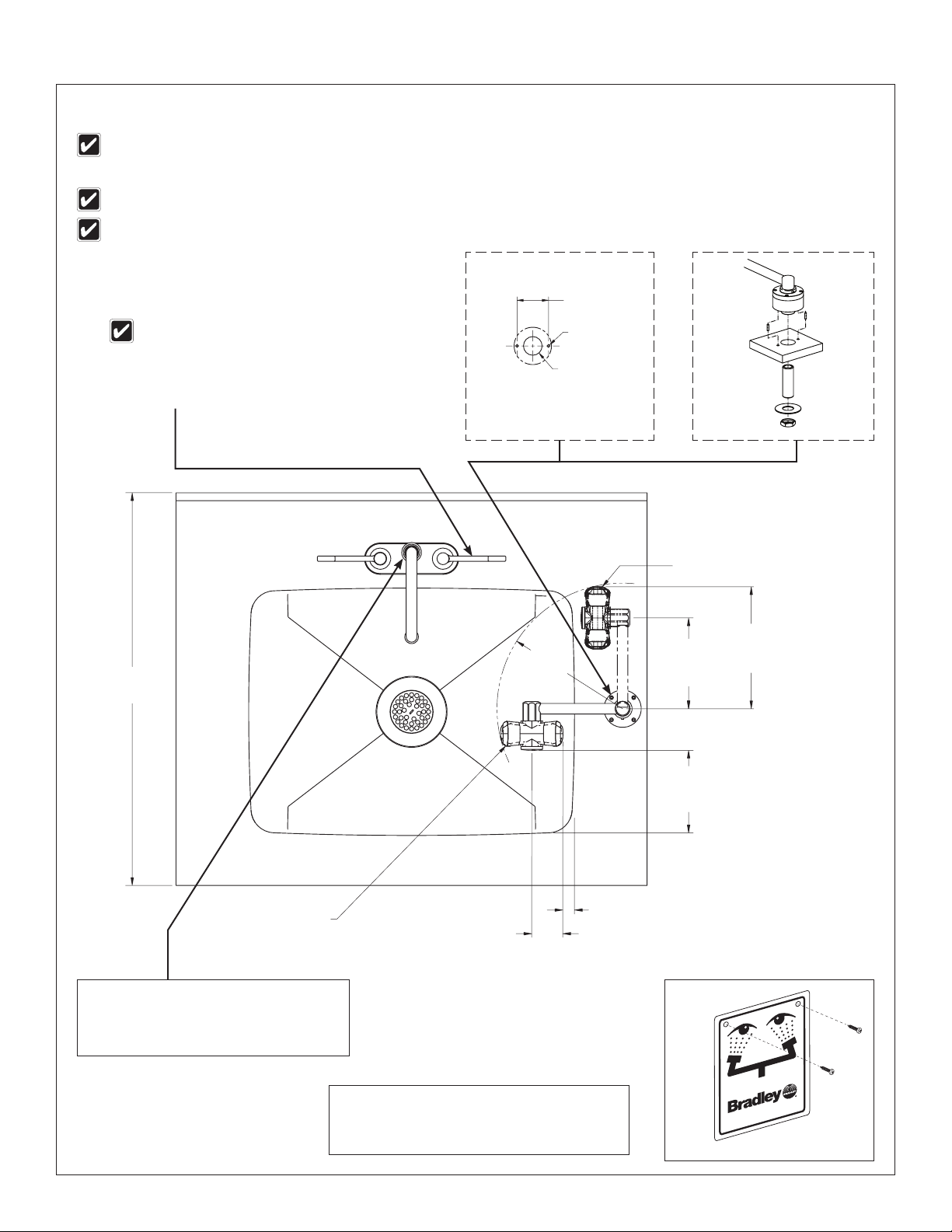

Installation — Eyewash

Halo eyewash right-hand unit is shown on a sample 25" deck. Other units are similar. For classic eyewash installation,

refer to the dimensions on page 4 to determine optimal mounting position. Refer to page 8 for left-hand units.

Minimum dimensions necessary to contain splashing from Halo units are shown.

Apply pipe sealant (supplied by installer) to all male-threaded pipe joints. The top of the eyewash heads should be

positioned a minimum of 33" and a maximum of 45" from the floor and 6" from the nearest obstruction.

Proper faucet shank/handle

clearance and recommended

minimum splash containment

dimensions must be considered

when selecting the desired

location for mounting.

25"

(635mm)

A

2"

(51mm)

Ø ³⁄₁₆"

Ø 1¹⁄₈"

Deck Mounting Pattern

(drill (3) holes as shown)

8"

(203mm)

Radius

B

"OFF" Position

5¾"

(146mm)

Ref.

2⁵⁄₈" (67mm)

Ref.

Deck

7¾"

(197mm)

Ref.

5¼"

(133mm)

Min.

"ON" Position

Connect the water supply using

piping (supplied by installer) with

C

½" NPT female threaded end.

(51mm)

Slowly open the water

supply lines to relieve air

and pressurize the valve.

E

Test the unit for leaks

2"

Ref.

¾" (19mm)

Min.

D

To

Wall

114-051

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

and adequate flow.

6

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Page 7

Installation S19-270C, S19-270E, S19274C, S19274E

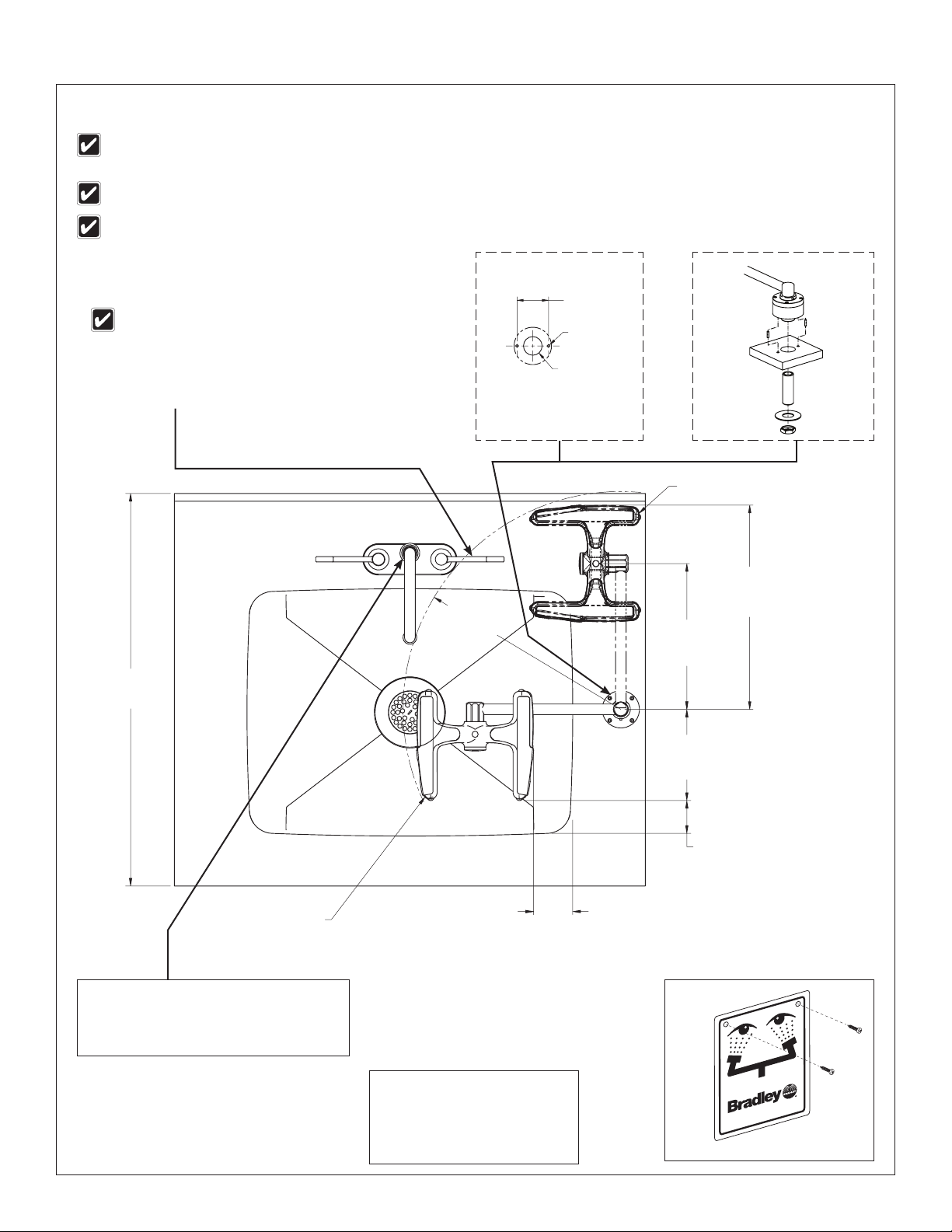

Installation — Eye/Face Wash

Halo eye/face wash right-hand unit is shown on a sample 25" deck. Other units are similar. For classic eye/face wash

installation, refer to the dimensions on page 5 to determine optimal mounting position. Refer to page 8 for left-hand units.

Minimum dimensions necessary to contain splashing from Halo units are shown.

Apply pipe sealant (supplied by installer) to all male-threaded pipe joints. The top of the eyewash heads should be positioned

a minimum of 33" (838mm) and a maximum of 45" (1143mm) from the floor and 6" (152mm) from the nearest obstruction.

Proper faucet shank/handle

clearance and recommended

minimum splash containment

dimensions must be considered

when selecting the desired

location for mounting.

25"

(635mm)

13⁷⁄₈"

(352mm)

Radius

A

2"

(51mm)

Ø ³⁄₁₆"

Ø 1¹⁄₈"

Deck Mounting Pattern

Drill (3) holes as shown.

B

Deck

"OFF" Position

13"

(330mm)

Ref.

9¼"

(235mm)

Ref.

"ON" Position

2½"

(64mm)

Min.

Connect the water supply using

piping (supplied by installer) with

C

½" NPT female threaded end.

Slowly open the water

supply lines to relieve air

and pressurize the valve.

E

Test the unit for leaks

and adequate flow.

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

5¾"

(146mm)

Ref.

2¹⁄₈"

(54mm)

Min.

D

To

Wall

114-051

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

7

Page 8

S19-270C, S19-270E, S19274C, S19274E Installation

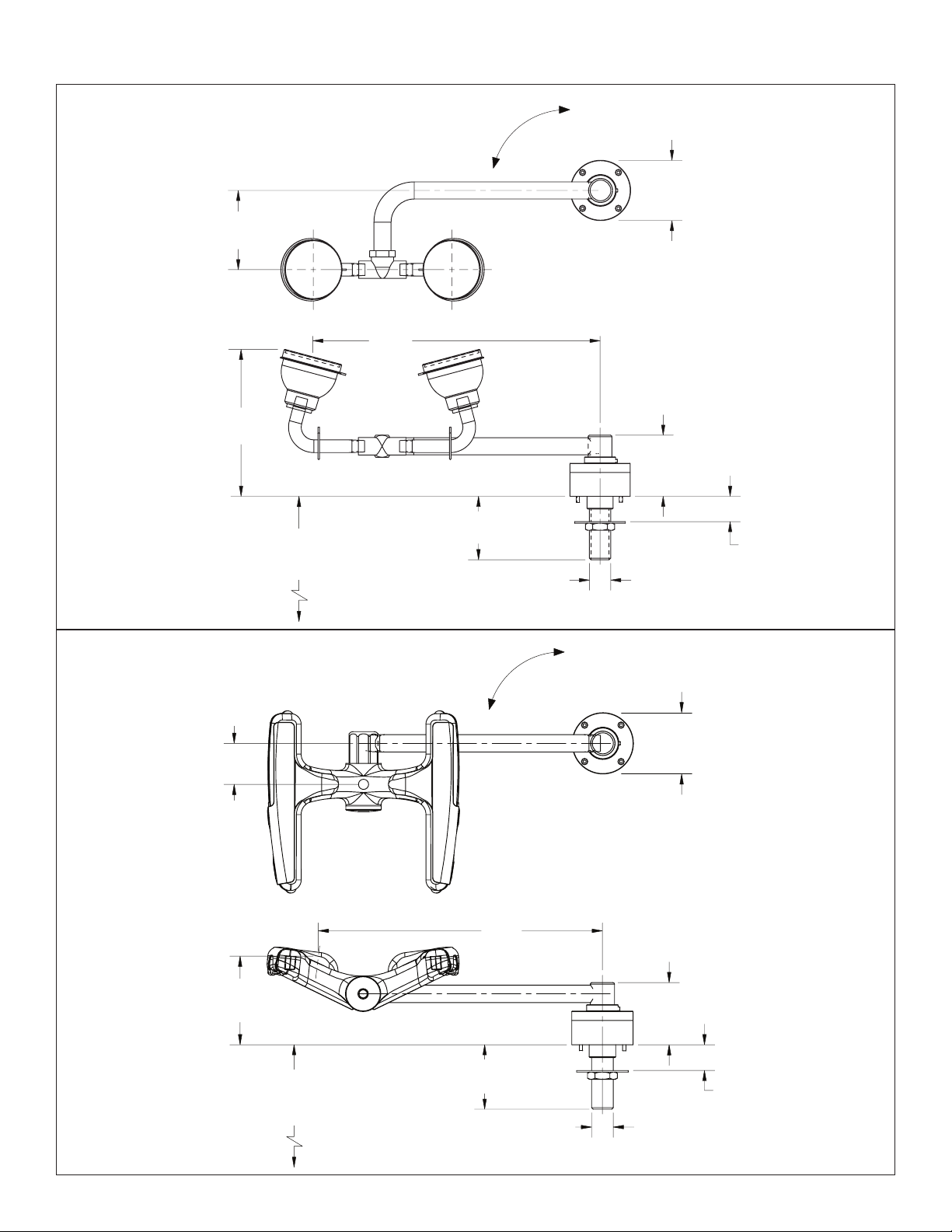

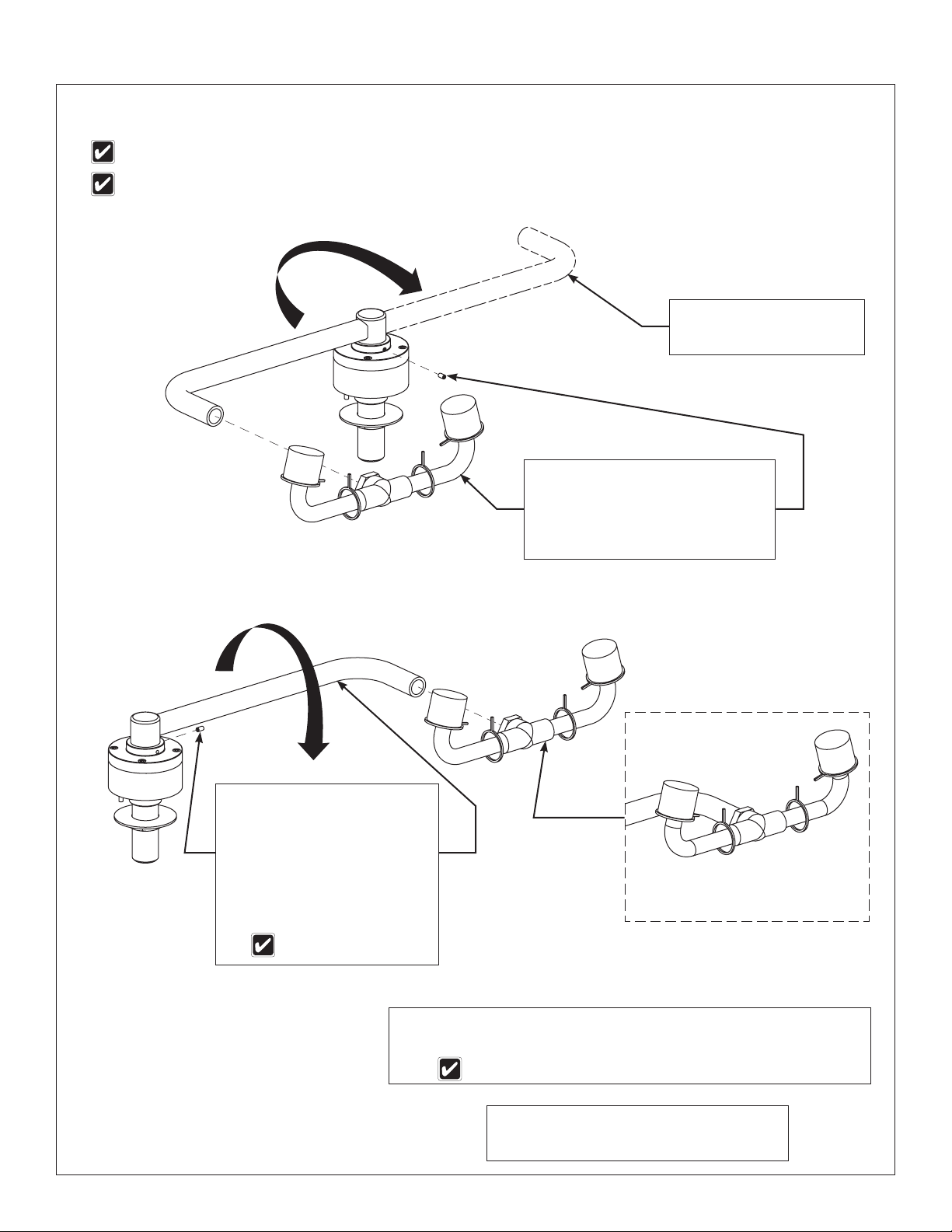

Installation — Left-Hand Units (Classic)

Classic eyewash unit is shown. Classic eye/face wash unit is similar.

Apply pipe sealant (supplied by installer) to all male-threaded pipe joints.

Rotate the bent arm

B

180° around the valve.

Remove the sprayhead from the

bent arm. Remove the set screw

from the valve assembly with an

A

Allen key (1/16"(1.5mm)). Set

the two items aside.

Rotate the bent arm 180°

around the valve. Using

low strength thread locker,

reinstall the set screw

C

into the valve in the new

location shown until it

bottoms out, then back off

½ turn.

Arm must swing freely.

D

Reattach the sprayhead to the

bent arm, resealing as necessary.

Mount the unit onto the deck. Refer to the instructions on page 6 for

eyewash units or page 7 for eye/face wash units.

E

The left-hand unit must be installed on the left side of the deck.

Slowly open the water supply lines to

relieve air and pressurize the valve. Test

F

the unit for leaks and adequate flow.

8

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Page 9

Installation S19-270C, S19-270E, S19274C, S19274E

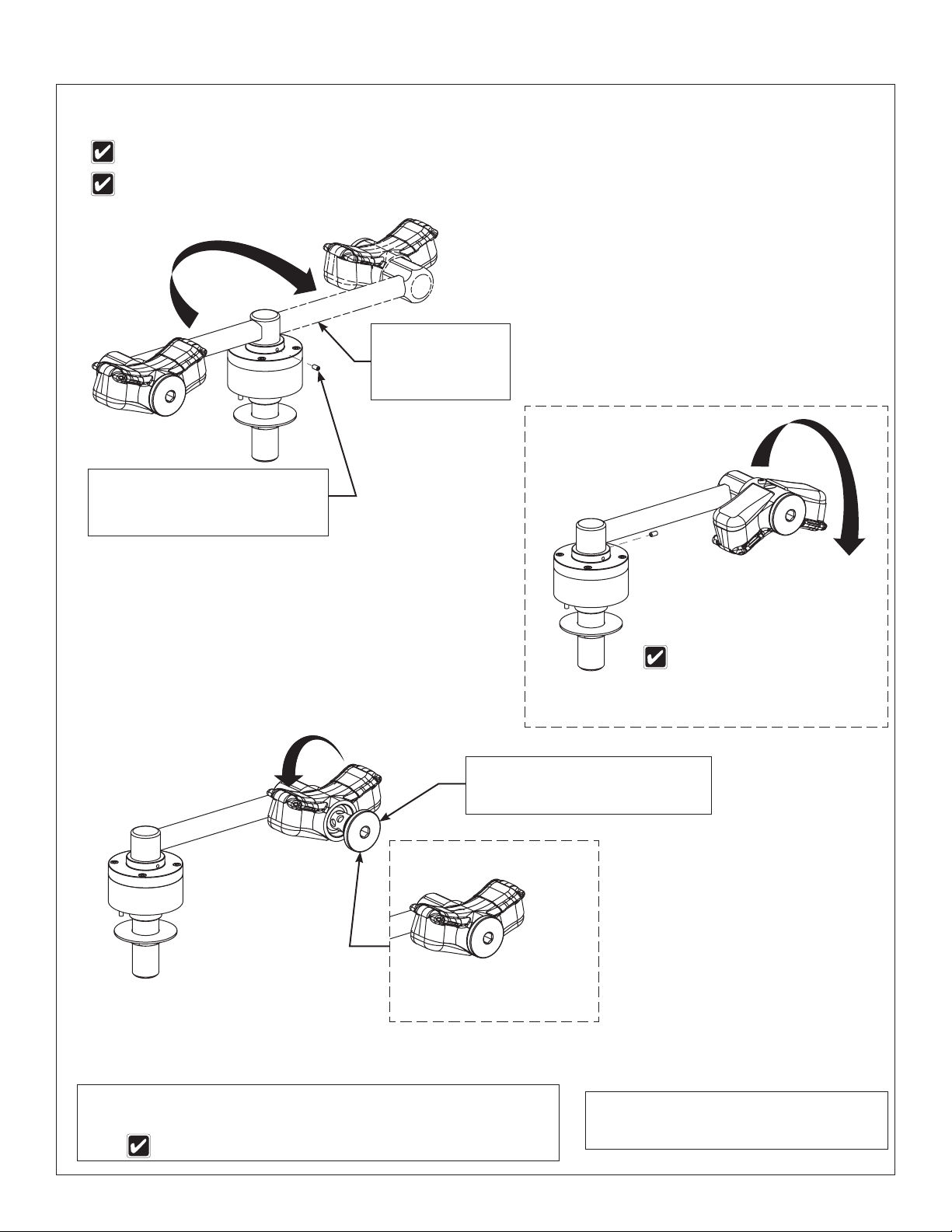

Installation — Left-Hand Units (Halo)

Halo eyewash unit is shown. Halo eye/face wash unit is similar.

Apply pipe sealant (supplied by installer) to all male-threaded pipe joints.

Rotate the

arm 180°

B

around the

valve.

C

Remove the set screw from

the valve assembly with an

A

Allen key (1/16"(1.5mm)) and

set aside.

D

E

Tighten cap assembly,

ensuring head is level.

Using low strength thread locker,

reinstall the set screw into the valve

in the new location shown until it

bottoms out, then back off ½ turn.

Arm must swing freely.

Rotate the head and body 180°

around the arm.

Loosen the cap assembly with

an Allen key (5/16"(8mm)) and

rotate the sprayhead 180°.

Mount the unit onto the deck. Refer to the instructions on page 6 for

eyewash units or page 7 for eye/face wash units.

F

The left-hand unit must be installed on the left side of the deck.

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

G

Slowly open the water supply lines to

relieve air and pressurize the valve. Test

the unit for leaks and adequate flow.

9

Page 10

S19-270C, S19-270E, S19274C, S19274E Installation

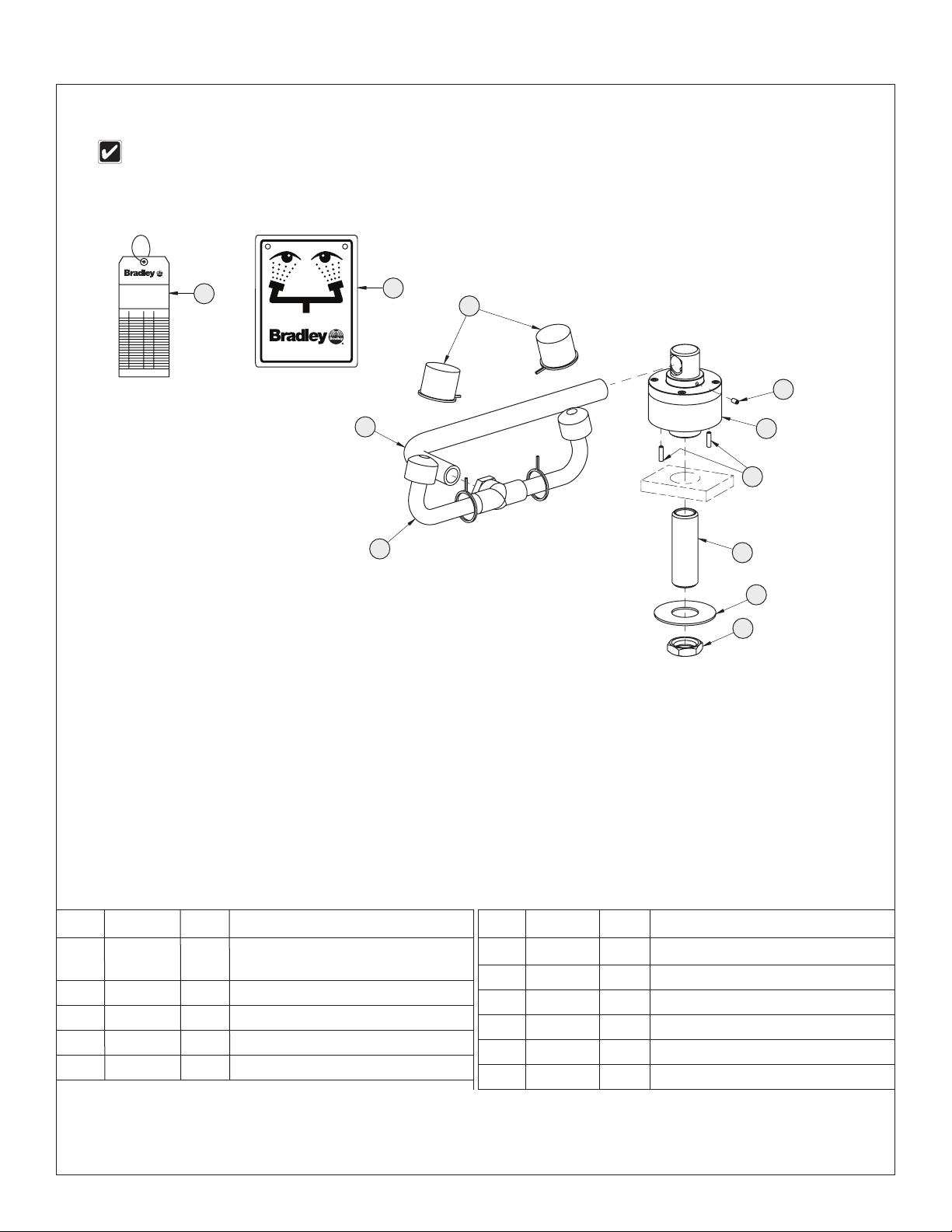

Assembly of Components and Parts List — S19-270C

Right-hand swivel version is shown in the "ON" position.

R

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Date

Signe

Date

31

Signed

Signed

bradleycorp.com

114-051

30

23

2

19

Deck

21

1

13

14

15

16

Item Part No. Qty Description

1 N/A 1 Valve not available for service; must

replace complete fixture.

2 160-473 2 Screw, Set

13 160-474 2 Screw, Set

14 113-514 1 Shank, ½" x 2½"

15 142-002CB 1 Washer, Flat ⁷⁄₈" x 2"

10

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Item Part No. Qty Description

16 110-115 1 Nut, Brass ½"-14 NPSM

19 113-1032 1 Pipe, Bent Plated

21 S05-092 1 Eyewash Yoke 90°

23 107-371 2 Tethered Dust Cover

30 114-051 1 Safety Sign

31 204-421 1 Emergency Inspection Tag

Page 11

Installation S19-270C, S19-270E, S19274C, S19274E

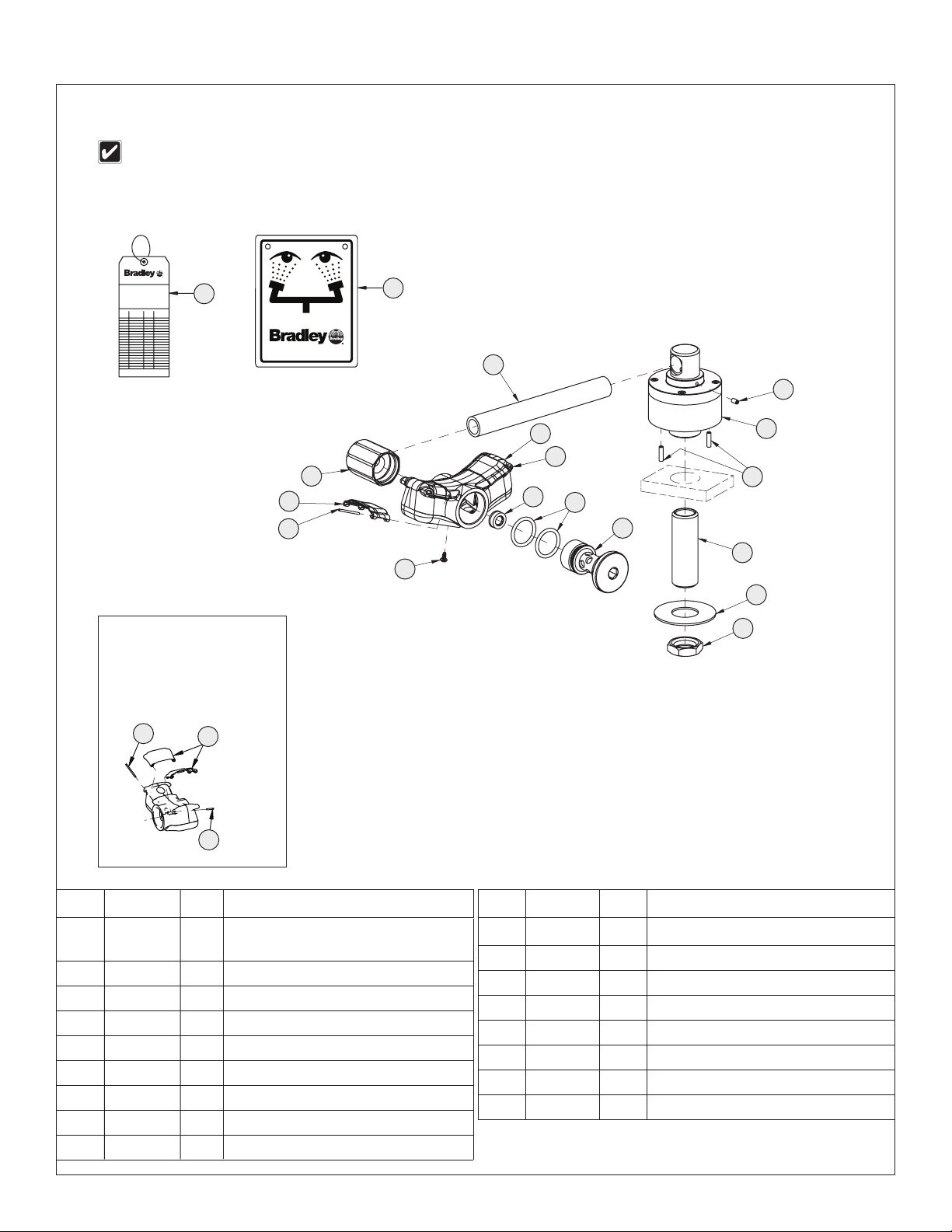

Assembly of Components and Parts List — S19274C

Right-hand swivel version is shown in the "ON" position.

R

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Date

Signe

Date

31

Signed

Signed

bradleycorp.com

114-051

30

19

2

Eyewash Cover Prepack

S45-2675 includes items

22 and 23

22

23

22

23

1

21

20

23

27

22

Deck

26

25

13

14

29

15

16

Item Part No. Qty Description

1 N/A 1 Valve not available for service; must

replace complete fixture.

2 160-473 2 Screw, Set

13 160-474 2 Screw, Set

14 113-514 1 Shank, ½" x 2½"

15 142-002CB 1 Washer, Flat ⁷⁄₈" x 2"

16 110-115 1 Nut, Brass ½"-14 NPSM

19 113-1236 1 Pipe, ³⁄₈" x 5½" Chrome Red Brass

Item Part No. Qty Description

22 in service kit 2 Pivot Pin

23 in service kit 2 Flip Cover, Eyewash

25 115-169 1 Cap, Short

26 125-157 2 O-Ring

27 125-175 1 Flow Control

29 160-500 1 Screw, Weep

30 114-051 1 Safety Sign

31 204-421 1 Emergency Inspection Tag

20 171-005 1 Body, Mount, Short ³⁄₈" NPT

21 S05-190 1 Sprayhead Ass'y Eyewash (includes)

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

11

Page 12

S19-270C, S19-270E, S19274C, S19274E Installation

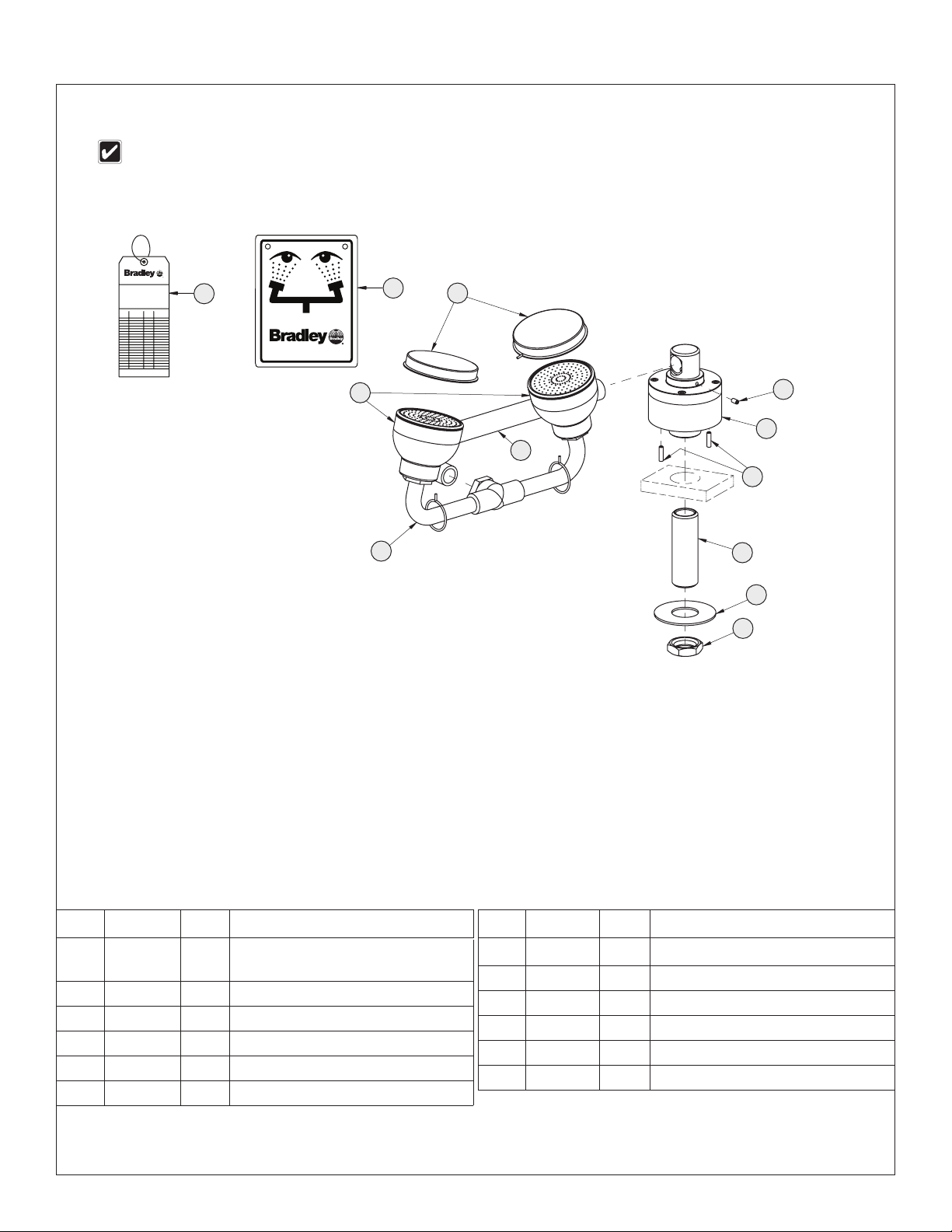

Assembly of Components and Parts List — S19-270E

Right-hand swivel version is shown in the "ON" position.

R

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date Signed

Signed

Date

Unterschrift

Date

Datum

Signe

Date

Date

31

Signed

Signed

bradleycorp.com

114-051

30

23

21a

2

1

19

Deck

21

13

14

15

16

Item Part No. Qty Description

1 N/A 1 Valve not available for service; must

replace complete fixture.

2 160-473 2 Screw, Set

13 160-474 2 Screw, Set

14 113-514 1 Shank, ½" x 2½"

15 142-002CB 1 Washer, Flat ⁷⁄₈" x 2"

16 110-115 1 Nut, Brass ½"-14 NPSM

12

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Item Part No. Qty Description

19 113-1032 1 Pipe, Bent Plated

21 S05-206 1 Eye/Face Wash Assembly

21A S45-2453 1 Service Kit EFW - Black Sprayheads

23 S53-063 2 Tethered Dust Cover

30 114-051 1 Safety Sign

31 204-421 1 Emergency Inspection Tag

Page 13

Installation S19-270C, S19-270E, S19274C, S19274E

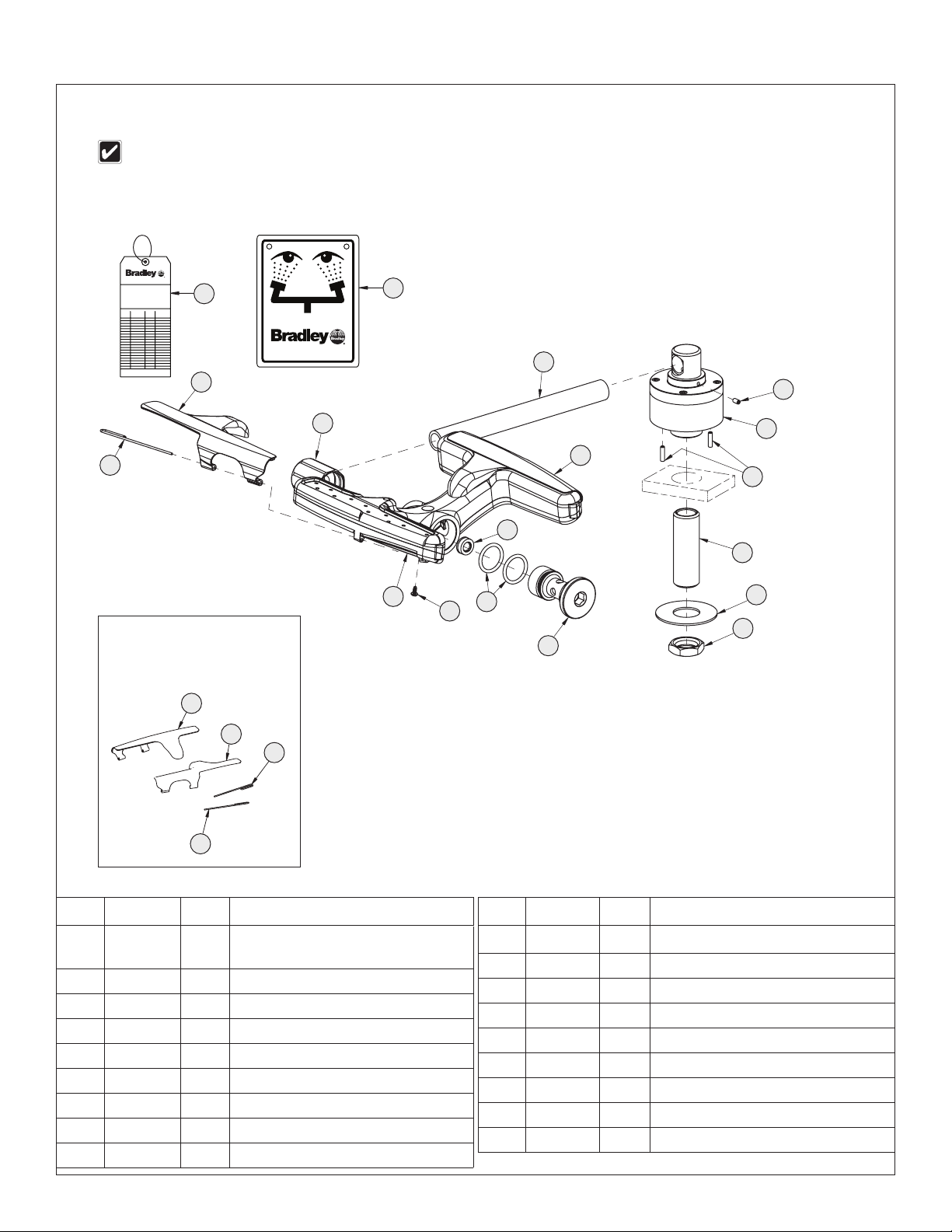

Assembly of Components and Parts List — S19274E

Right-hand swivel version is shown in the "ON" position.

R

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Date

Signe

Date

31

Signed

Signed

bradleycorp.com

114-051

24a

30

19

2

22

Eye/Face Wash Cover

Prepack S45-2676 includes

items 22, 24a and 24b

24b

24a

22

20

1

24b

Deck

13

27

14

21

26

29

15

16

25

22

Item Part No. Qty Description

1 N/A 1 Valve not available for service; must

replace complete fixture.

2 160-473 2 Screw, Set

13 160-474 2 Screw, Set

14 113-514 1 Shank, ½" x 2½"

15 142-002CB 1 Washer, Flat ⁷⁄₈" x 2"

16 110-115 1 Nut, Brass ½"-14 NPSM

19 113-1075 1 Pipe, ³⁄₈" x 9" Chrome Red Brass

20 171-005 1 Body, Mount, Short ³⁄₈" NPT

Item Part No. Qty Description

22 in service kit 2 Pivot Pin

24a in service kit 1 Flip Cover, Right

24b in service kit 1 Flip Cover, Left

25 115-169 1 Cap, Short

26 125-157 2 O-Ring

27 125-175 1 Flow Control

29 160-500 1 Screw, Weep

30 114-051 1 Safety Sign

31 204-421 1 Emergency Inspection Tag

21 S05-192 1 Sprayhead Ass'y Eye/Face Wash (incl.)

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

13

Page 14

S19-270C, S19-270E, S19274C, S19274E Installation

AVERTISSEMENT

L’installation et l’emplacement de toutes les douches d’urgence, oculaires et oculaires-faciales

doivent être conformes aux exigences d’ANSI Z358.1.

Le matériel d’urgence doit être alimenté en eau tiède (15,6 °C à 37,8 °C/60 °F à 100 °F). Toute

exposition prolongée à de l’eau proche de la température de congélation peut altérer la capacité

de l’organisme à maintenir la température corporelle, ce qui accroît le risque d’hypothermie.

Rincez la conduite d’alimentation avant et apres l’installation. Assurez-vous que le débit d’eau est

adéquat et qu’il n’y a pas de fuites. L’alimentation principale en eau doit être toujours OUVERTE.

On devra prévoir des dispositions pour empêcher tout arrêt non autorisé.

La norme ANSI Z358.1 prévoit une alimentation ininterrompue du liquide de rinçage. Les appareils

d’urgence Bradley raccordés au réseau nécessitent une pression d’écoulement d’au moins 30 PSI

(0,21 MPa). Selon ANSI Z358.1, le liquide de rinçage doit être tiède.

Une activation hebdomadaire doit être effectuée sur tout le matériel d’urgence à tuyauterie

d’alimentation pour vérifier que l’arrivée de liquide de rinçage est suffisante et éliminer tout dépôt

de sédiment de la conduite d’alimentation. Le matériel d’urgence doit être contrôlé chaque mois

pour régler tout problème d’entretien éventuel et s’assurer que le matériel est en bon état de

marche et ne présente aucun signe d’usure.

Les ouvriers susceptibles d’entrer en contact avec des matières potentiellement dangereuses

doivent recevoir une formation sur la mise en place et le bon fonctionnement du matériel

d’urgence conformément à la norme ANSI Z358.1.

AVIS

Avant d’installer ce produit, vérifier qu’il y a des dégagements suffisants autour du produit et que

l’activation du produit n’est pas entravée par d’autres produits ou obstructions.

Pour les classiques unités de douche oculaire/faciale, eviter les nettoyants qui contiennent des

solvants organiques, de l’alcool et de l’hydrocarbure. Rincer avec de l’eau après le nettoyage.

IMPORTANT

Lire ce manuel d’installation dans son intégralité pour garantir une installation appropriée.

Une fois celle-ci terminée, classer ce manuel auprès du service à la clientèle ou d’entretien.

L’installateur est responsable de la conformité de l’installation aux codes pour des drain et

codes et règlements en vigueur.

Assurez-vous que toutes les pièces sont incluses dans l’emballage et qu’il n’en manque aucune

avant de jeter l’emballage. Ne commencez pas l’assemblage avant de recevoir les pièces

manquantes.

Pour toute question concernant le fonctionnement ou l’installation de ce produit, consulter le

site www.bradleycorp.com ou appeler le 800-BRADLEY (800-272-3539).

Les garanties de produits figurent sous la rubrique « Produits » sur notre site Internet à www.

bradleycorp.com.

Equipements nécessaires :

• Amener la tuyauterie à l'entrée ½" NPT

d'approvisionnement en eau de la douche oculaire

• Produit d’étanchéité pour tuyau

• Filtre d'entrée (recommandé)

• Quincaillerie pour l'installation de l'enseigne

14

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Les codes locaux peuvent exiger l’ installation d’une soupape de

prévention d’écoulement de retour pour réaliser une installation

appropriée. L’installateur est responsable de la conformité

aux codes locaux. La soupape doit être testée une fois par an

pour vérifier qu’elle fonctionne correctement. Les soupapes de

prévention d’écoulement de retour ne sont pas fournies avec

l’appareil et peuvent être fournies par l’entrepreneur ou achetées

auprès de Bradley Corporation.

Page 15

Installation S19-270C, S19-270E, S19274C, S19274E

Dimensions — S19-270C

3¹⁄₈"

(79mm)

4¹⁄₈"

(105mm)

28-7/8" to 40-7/8"

(733 mm to 1038 mm)

au plancher fini

11⁵⁄₈"

(295mm)

(64mm)

Off

On

Ø 2³⁄₈"

(60mm)

2³⁄₈"

(60mm)

2½"

1³⁄₈"

(35mm)

Max.

Ø ⁷⁄₈"

Dimensions — S19274C

1⁵⁄₈"

(41mm)

2⁷⁄₈"

(73mm)

30-1/8" to 42-1/8"

(765 mm to 1070 mm)

au plancher fini

(181mm)

2½"

(64mm)

On

7¼"

Off

Ø 2³⁄₈"

(60mm)

2³⁄₈"

(60mm)

1³⁄₈"

(35mm)

Max.

Ø ⁷⁄₈"

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

15

Page 16

S19-270C, S19-270E, S19274C, S19274E Installation

Dimensions — S19-270E

3¹⁄₈"

(79mm)

5¾"

(146mm)

27-1/4" to 39-1/4"

(692 mm to 997 mm)

au plancher fini

11³⁄₈"

(289mm)

On

2½"

(64mm)

Off

Ø 2³⁄₈"

(60mm)

2³⁄₈"

(60mm)

Ø ⁷⁄₈"

1³⁄₈"

(35mm)

Max.

Dimensions — S19274E

1⁵⁄₈"

(41mm)

3³⁄₈"

(86mm)

29-5/8" to 41-5/8"

(752 mm to 1057 mm)

au plancher fini

On

11"

(279mm)

2½"

(64mm)

Off

(60mm)

Ø ⁷⁄₈"

Ø 2³⁄₈"

(60mm)

2³⁄₈"

1³⁄₈"

(35mm)

Max.

16

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Page 17

Installation S19-270C, S19-270E, S19274C, S19274E

Installation — Douche Oculaire

La douche oculaire Halo droite est montrée sur un exemple de comptoir de 25" (635 mm). Les autres unités sont similaires. Pour l’installation

d’une douche oculaire classique, voir les dimensions à la page 15 pour déterminer la position optimale de montage. Consulter les

pages19–20 pour un montage gaucher.

Les dimensions minimales nécessaires pour contenir les éclaboussures des unités Halo sont indiquées.

Mettez du produit d’étanchéité (non fourni) sur tous les filetages mâles. Le dessus des érogateurs de la douche oculaire doit être situé à une

taille minimum de 83cm (33 po) et à une hauteur maximum de 115 cm (45 po) du plancher et de 15 cm (6 po) de l'obstruction la plus proche.

Le dégagement pour les poignées et le tube

montant du robinet et les dimensions

minimales pour contenir les éclaboussures

doivent être pris en compte lors du choix de

l’emplacement de pose.

25"

(635mm)

A

2"

(51mm)

Ø ³⁄₁₆"

Ø 1¹⁄₈"

Dessin de montage (comptoir)

Percez (3) trous

8"

(203mm)

Rayon

B

Comptoir

Montré dans la position de "ÉTEINT"

7¾"

5¾"

(146mm)

Ref.

2⁵⁄₈" (67mm)

Ref.

(197mm)

Ref.

Montré dans la position

de "Ouverte"

2"

(51mm)

Ref.

¾" (19mm)

Min.

Un boyau flexible fileté femelle ½"

NPT (fourni par l'installateur) peut

C

également être utilisé.

Ouvrir les arrivées d’eau lentement

pour libérer l’air et mettre le robinet

E

sous pression. Vérifier s'il y a des

fuites et si le débit d'eau est adéquat.

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

5¼"

(133mm)

Min.

D

sur le

mur

114-051

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

17

Page 18

S19-270C, S19-270E, S19274C, S19274E Installation

Installation — Douche Oculaire/Faciale

La douche oculaire/faciale Halo droite est montrée sur un exemple de comptoir de 25". Les autres unités sont similaires. Pour l’installation

d’une douche oculaire/faciale classique, voir les dimensions à la page 15 pour déterminer la position optimale de montage. Consulter les

pages 19–20 pour un montage gaucher.

Les dimensions minimales nécessaires pour contenir les éclaboussures des unités Halo sont indiquées.

Mettez du produit d’étanchéité (non fourni) sur tous les filetages mâles. Le dessus des érogateurs de la douche oculaire doit être situé à une

taille minimum de 83cm (33 po) et à une hauteur maximum de 115 cm (45 po) du plancher et de 15 cm (6 po) de l'obstruction la plus proche.

Le dégagement pour les poignées et le tube

montant du robinet et les dimensions

minimales pour contenir les éclaboussures

doivent être pris en compte lors du choix de

l’emplacement de pose.

25"

(635mm)

A

2"

(51mm)

Ø 1¹⁄₈"

Dessin de montage (comptoir)

Percez (3) trous

13⁷⁄₈"

(352mm)

Rayon

B

Ø ³⁄₁₆"

Comptoir

Montré dans la position de "ÉTEINT"

13"

(330mm)

Ref.

9¼"

(235mm)

Ref.

18

Montré dans la position

de "Ouverte"

Un boyau flexible fileté femelle ½"

NPT (fourni par l'installateur) peut

C

également être utilisé.

5¾"

(146mm)

Ref.

2¹⁄₈"

(54mm)

Min.

2½"

(64mm)

Min.

D

sur le

Ouvrir les arrivées d’eau lentement

pour libérer l’air et mettre le robinet

E

sous pression. Vérifier s'il y a des

fuites et si le débit d'eau est adéquat.

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

mur

114-051

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

Page 19

Installation S19-270C, S19-270E, S19274C, S19274E

Installation — Unités Gaucher (classique)

Douche oculaire classique illustrée. L'unité douche oculaire/faciale classique est similair.

Mettez du produit d’étanchéité (non fourni) sur tous les filetages mâles.

Faire pivoter le bras

coudé de 180° autour

B

du robinet.

Retirer la tête de douche du

bras coudé. Retirer la vis

calante du l’aide d’une clé

A

Allen (1/16"(1.5mm)). Mettre

ces deux articles de côté.

Faire pivoter le bras

coudé de 180° autour du

robinet. En utilisant un

enduit-frein pour filet de

faible résistance, visser

C

la vis calante à fond dans

le robinet puis revenir en

arrière d’un demi-tour.

Le bras doit pivoter

librement.

D

Rattacher la tête de douche

au bras coudé, en refaisant

l’étanchéité au besoin.

Monter l'unité sur le comptoir. Consulter la page 17 pour douche

oculaire ou la page 18 pour douche oculaire/faciale.

E

Le modèle gauche doit être posé sur le côté gauche du comptoir.

Ouvrir les arrivées d’eau lentement

pour libérer l’air et mettre le robinet

F

sous pression. Vérifier s'il y a des

fuites et si le débit d'eau est adéquat.

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

19

Page 20

S19-270C, S19-270E, S19274C, S19274E Installation

Installation — Unités Gaucher (Halo)

Douche oculaire Halo illustrée. L'unité douche oculaire/faciale Halo est similaire.

Mettez du produit d’étanchéité (non fourni) sur tous les filetages mâles.

Faire pivoter

le bras de

B

180° autour

du robinet.

C

Retirer la vis calante du

robinet à l’aide d’une clé

A

Allen (1/16"(1.5mm)) et la

mettre de côté.

Desserrer le capuchon à l’aide d’une

clé Allen (5/16"(8mm)) et faire pivoter

D

le tête de douche de 180°.

E

Serrer le capuchon en

s’assurant que la tête est

de niveau.

En utilisant un enduit-frein pour filet

de faible résistance, visser la vis

calante à fond dans le robinet au

nouvel emplacement représenté puis

revenir en arrière d’un demi-tour.

Le bras doit pivoter librement.

Faire pivoter le bec et le corps de

180° autour du bras.

20

Monter l'unité sur le comptoir. Consulter la page 17 pour douche

oculaire ou la page 18 pour douche oculaire/faciale.

F

Le modèle gauche doit être posé sur le côté gauche du comptoir.

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Ouvrir les arrivées d’eau lentement

pour libérer l’air et mettre le robinet

G

sous pression. Vérifier s'il y a des

fuites et si le débit d'eau est adéquat.

Page 21

Installation S19-270C, S19-270E, S19274C, S19274E

Assemblage des composantes et liste des pièces — S19-270C

La version pivotante à droite est montrée en position « Ouverte ».

R

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Date

Signe

Date

31

Signed

Signed

bradleycorp.com

114-051

30

23

2

19

Comptoir

21

1

13

14

15

16

Piéce Réf. Qté Description

1 N/A 1 Le robinet n’est pas disponible en tant que

pièce de rechange; l’appareil complet doit

être changé.

2 160-473 2 Vis de reglage

13 160-474 2 Vis de reglage

14 113-514 1 Tige ½" x 2½"

15 142-002CB 1 Rondelle ⁷⁄₈" x 2"

Piéce Réf. Qté Description

16 110-115 1 Écrou ½"-14 NPSM

19 113-1032 1 Tuyau Courbe (Plaque)

21 S05-092 1 Douche oculaire 90°

23 107-371 2 Cache-poussière ancré

30 114-051 1 Enseigne de sécurité

31 204-421 1 Etiquette d’inspection

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

21

Page 22

S19-270C, S19-270E, S19274C, S19274E Installation

Assemblage des composantes et liste des pièces — S19274C

La version pivotante à droite est montrée en position « Ouverte ».

R

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Date

Signe

Date

31

Signed

Signed

bradleycorp.com

114-051

30

19

2

Paquet couvertures à

bascule (douche oculaire)

S45-2675 comprend les

éléments 22 et 23

22

23

22

23

1

21

20

23

27

22

Comptoir

26

25

13

14

29

15

16

Piéce Réf. Qté Description

1 N/A 1 Le robinet n’est pas disponible

en tant que pièce de rechange;

l’appareil complet doit être changé.

2 160-473 2 Vis de reglage

13 160-474 2 Vis de reglage

14 113-514 1 Tige ½" x 2½"

15 142-002CB 1

16 110-115 1 Écrou ½"-14 NPSM

19 113-1236 1

20 171-005 1

21 S05-190 1 Douche oculaire (comprend)

22

Rondelle ⁷⁄₈" x 2"

Tuyau ³⁄₈" x 5½" laiton chromé rouge

Corps ³⁄₈" NPT court

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Piéce Réf. Qté Description

22 dans la trousse

d’entretien

23 dans la trousse

d’entretien

25 115-169 1 Bouchon corto

26 125-157 2 Bague

27 125-175 1 Contrôle du débit

29 160-500 1 Vis, purge

30 114-051 1 Enseigne de sécurité

31 204-421 1 Etiquette d’inspection

2 Axe de pivotement (kit de

remplacement)

2 Couverture à bascule (kit de

remplacement)

Page 23

Installation S19-270C, S19-270E, S19274C, S19274E

Assemblage des composantes et liste des pièces — S19-270E

La version pivotante à droite est montrée en position « Ouverte ».

R

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date Signed

Signed

Date

Unterschrift

Date

Datum

Signe

Date

Date

31

Signed

Signed

bradleycorp.com

114-051

30

23

21a

2

1

19

Comptoir

21

13

14

15

16

Piéce Réf. Qté Description

1 N/A 1 Le robinet n’est pas disponible en tant que

pièce de rechange; l’appareil complet doit

être changé.

2 160-473 2 Vis de reglage

13 160-474 2 Vis de reglage

14 113-514 1 Tige ½" x 2½"

15 142-002CB 1 Rondelle ⁷⁄₈" x 2"

Piéce Réf. Qté Description

19 113-1032 1 Tuyau Courbe (Plaque)

21 S05-206 1 Douche oculaire/faciale

21A S45-2453 1 Trousse d’entretien EFW - Diffuseurs noirs

23 S53-063 2 Cache-poussière ancré

30 114-051 1 Enseigne de sécurité

31 204-421 1 Etiquette d’inspection

16 110-115 1 Écrou ½"-14 NPSM

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

23

Page 24

S19-270C, S19-270E, S19274C, S19274E Installation

Assemblage des composantes et liste des pièces — S19274E

La version pivotante à droite est montrée en position « Ouverte ».

R

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Date

Signe

Date

31

Signed

Signed

bradleycorp.com

114-051

24a

30

19

2

22

Paquet couvertures à

bascule (douche oculaire/

faciale) S45-2676 comprend

les éléments 22, 24a et 24b

24b

24a

22

20

1

24b

Comptoir

13

27

14

21

26

29

15

16

25

22

Piéce Réf. Qté Description

1 N/A 1 Le robinet n’est pas disponible

en tant que pièce de rechange;

l’appareil complet doit être changé.

2 160-473 2 Vis de reglage

13 160-474 2 Vis de reglage

14 113-514 1 Tige ½" x 2½"

15 142-002CB 1

16 110-115 1 Écrou ½"-14 NPSM

19 113-1075 1

20 171-005 1

21 S05-192 1 Douche oculaire/faciale (comprend)

24

Rondelle ⁷⁄₈" x 2"

Tuyau ³⁄₈" x 9" laiton chromé rouge

Corps ³⁄₈" NPT court

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Piéce Réf. Qté Description

22 dans la trousse

d’entretien

24a dans la trousse

d’entretien

24b dans la trousse

d’entretien

25 115-169 1 Bouchon corto

26 125-157 2 Bague

27 125-175 1 Contrôle du débit

29 160-500 1 Vis, purge

30 114-051 1 Enseigne de sécurité

31 204-421 1 Etiquette d’inspection

2 Axe de pivotement (kit de

remplacement)

1 Couverture à bascule (kit de

remplacement)

1 Couverture à bascule (kit de

remplacement)

Page 25

Installation S19-270C, S19-270E, S19274C, S19274E

ADVERTENCIA

La instalación y ubicación de todas las duchas, lavaojos y lavaojos/lavacara de seguridad deben

cumplir con los requisitos de ANSI Z358.1.

Los equipos de emergencia deben contar con agua tibia (entre 15,6 °C y 37,8 °C). Cualquier

exposición prolongada a aguas bajo cero afecta la capacidad del cuerpo para mantener su

temperatura, lo que incrementa el riesgo de hipotermia.

Aclarar el conducto del suministro de agua antes y después de la instalación. Verificar que no haya

fugas y que el flujo de agua sea adecuado. El suministro principal de agua a la unidad debe estar

siempre en posición “ON” (abierto). Se deben tomar medidas a fin de evitar el corte no autorizado

del suministro.

La norma ANSI Z358.1 exige un suministro ininterrumpido de líquido de limpieza. Los equipos de

emergencia con tuberías de Bradley requieren una presión de flujo mínima de 0,21 MPa (30 PSI). El

líquido de limpieza debe estar tibio en conformidad con la norma ANSI Z358.1.

Se deben llevar a cabo activaciones semanales de todos los equipos de emergencia conectados

a la plomería para garantizar que hay un suministro de líquido de limpieza adecuado presente

y liberar la tubería de suministro de cualquier acumulación de sedimento. Los equipos de

emergencia se deben inspeccionar mensualmente para solucionar cualquier problema de

mantenimiento; esto garantizará que los equipos están en buenas condiciones de funcionamiento

y que no hay señales de desgaste.

Los trabajadores que puedan tener contacto con materiales potencialmente peligrosos deben

recibir capacitación sobre la ubicación y operación adecuada de los equipos de emergencia en

conformidad con la norma ANSI Z358.1.

AVISO

Antes de instalar este producto, asegúrese de que haya espacio adecuado alrededor del producto y

de que su activación no interfiera con otros productos u obstrucciones.

Para unidades clásicas de lavado de ojos/rostro, evite los limpiadores que contengan solventes

orgánicos, alcoholes e hidrocarburos. Enjuague con agua después de limpiar.

IMPORTANTE

Lea en su totalidad este manual de instalación para garantizar una instalación adecuada.

Una vez que termine la instalación, entregue este manual al propietario o al Departamento de

Mantenimiento. Es responsabilidad de quien instale el equipo cumplir con los códigos para

desagüe y otra códigos y ordenanzas locales.

Separar todas las piezas del material de embalaje y asegurarse que todas las piezas estén

incluídas antes de desechar cualquier material de embalaje. Si faltase alguna pieza, no intentar

instalar la unidad combinada Bradley hasta obtener las piezas faltantes.

Para consultas sobre la operación o instalación de este producto, visite www.bradleycorp.com o

llame al 800.BRADLEY (800.272.3539).

Las garantías del producto se pueden encontrar e n “Productos” o en nuestro sitio Web, www.

bradleycorp.com.

Materiales necesarios:

• Proporcione la tubería a la toma de ½" NPT del

suministro de agua del lavador de ojos

• Sellador de tubería

• Filtro de la entrada (recomendado)

• Tornillería para montar el aviso de seguridad

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

Los códigos locales pueden exigir la instalación de una válvula de

prevención de contraflujo para completar la instalación correcta.

La conformidad con los códigos locales es de responsabilidad del

instalador. La válvula se debe probar anualmente para verificar que

funcione de manera correcta. Las válvulas de prevención de contraflujo

no se incluyen con el accesorio y las puede proporcionar el contratista

o las puede comprar en Bradley Corporation.

25

Page 26

S19-270C, S19-270E, S19274C, S19274E Installation

Dimensiones — S19-270C

3¹⁄₈"

(79mm)

4¹⁄₈"

(105mm)

28-7/8" to 40-7/8"

(733 mm to 1038 mm)

al suelo terminado

11⁵⁄₈"

(295mm)

(64mm)

2½"

On

Off

Ø 2³⁄₈"

(60mm)

2³⁄₈"

(60mm)

1³⁄₈"

(35mm)

Max.

Ø ⁷⁄₈"

Dimensiones — S19274C

1⁵⁄₈"

(41mm)

2⁷⁄₈"

(73mm)

30-1/8" to 42-1/8"

(765 mm to 1070 mm)

al suelo terminado

(181mm)

2½"

(64mm)

7¼"

On

Off

Ø 2³⁄₈"

(60mm)

2³⁄₈"

(60mm)

Ø ⁷⁄₈"

1³⁄₈"

(35mm)

Max.

26

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Page 27

Installation S19-270C, S19-270E, S19274C, S19274E

Dimensiones — S19-270E

3¹⁄₈"

(79mm)

5¾"

(146mm)

27-1/4" to 39-1/4"

(692 mm to 997 mm)

al suelo terminado

11³⁄₈"

(289mm)

On

2½"

(64mm)

Off

Ø ⁷⁄₈"

Ø 2³⁄₈"

(60mm)

2³⁄₈"

(60mm)

1³⁄₈"

(35mm)

Max.

Dimensiones — S19274E

1⁵⁄₈"

(41mm)

3³⁄₈"

(86mm)

29-5/8" to 41-5/8"

(752 mm to 1057 mm)

al suelo terminado

On

11"

(279mm)

2½"

(64mm)

Off

(60mm)

Ø ⁷⁄₈"

Ø 2³⁄₈"

(60mm)

2³⁄₈"

1³⁄₈"

(35mm)

Max.

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

27

Page 28

S19-270C, S19-270E, S19274C, S19274E Installation

Instalación — Lavador de ojos

Se observa la unidad de lavado ocular Halo del lado derecho en una cubierta de muestra de 25" . Las otras unidades son similares. Para la

instalación del lavaojos clásico, consulte las dimensiones en la página 26 para determinar la posición óptima de montaje Consulte la páginas

30–31 para el montaje de la izquierda.

Se muestran las dimensiones mínimas necesarias para contener las salpicaduras de las unidades Halo.

Aplicar sellador de tubería o cinta (suministrados por el instalador) a las juntas de tubería de rosca macho. La parte superior de los rociadores

del lavador de ojos debe colocarse a una altura máxima de 33 pulgadas (83 cm) y a una altura mínimo de 45 pulg. (115 cm) del piso y 6 pulg.

(15 cm) de la obstrucción más cercana.

Se debe considerar el espacio

adecuado entre la caña y la manilla

de la llave y las dimensiones mínimas

para la contención de salpicaduras

cuando se seleccione la ubicación

deseada para el montaje.

25"

(635mm)

A

2"

(51mm)

Ø ³⁄₁₆"

Ø 1¹⁄₈"

Patrón de montaje (mostrador)

Perforar (3) orificios

8"

(203mm)

Radio

B

Pared

Mostrado en la posición

de "APAGADA"

7¾"

5¾"

(146mm)

Ref.

2⁵⁄₈" (67mm)

Ref.

(197mm)

Ref.

28

Mostrado en la posición

de "CONECTADO"

Se puede usar también una manguera flexible

(provista por el instalador) con terminación de

C

rosca hembra de ½" (12,8 mm) NPT.

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

2"

(51mm)

Ref.

Abra lentamente las tuberías de

suministro de agua para liberar el

aire y presurizar la válvula. Revise si

E

existen fugas y verifique si el flujo de

agua es adecuado.

¾" (19mm)

Min.

5¼"

(133mm)

Min.

D

a la

pared

114-051

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

Page 29

Installation S19-270C, S19-270E, S19274C, S19274E

Instalación — Lavador de ojos y rostro

Se observa la unidad de lavado ocular y facial Halo del lado derecho en una cubierta de muestra de 25". Las otras unidades son similares.

Para la instalación de lavado ocular y facial clásico, consulte las dimensiones en la página 27 para determinar la posición óptima de montaje.

Consulte la páginas 30–31 para el montaje de la izquierda.

Se muestran las dimensiones mínimas necesarias para contener las salpicaduras de las unidades Halo.

Aplicar sellador de tubería o cinta (suministrados por el instalador) a las juntas de tubería de rosca macho. La parte superior de los rociadores

del lavador de ojos debe colocarse a una altura máxima de 33 pulgadas (83 cm) y a una altura mínimo de 45 pulg. (115 cm) del piso y 6 pulg.

(15 cm) de la obstrucción más cercana.

Se debe considerar el espacio

adecuado entre la caña y la manilla

de la llave y las dimensiones mínimas

para la contención de salpicaduras

cuando se seleccione la ubicación

deseada para el montaje.

25"

(635mm)

A

2"

(51mm)

Ø ³⁄₁₆"

Ø 1¹⁄₈"

Patrón de montaje (mostrador)

Perforar (3) orificios

13⁷⁄₈"

(352mm)

Radio

B

Pared

Mostrado en la posición

de "APAGADA"

13"

(330mm)

Ref.

9¼"

(235mm)

Ref.

Mostrado en la posición

de "CONECTADO"

2½"

(64mm)

Min.

Se puede usar también una manguera flexible

(provista por el instalador) con terminación de

C

rosca hembra de ½" (12,8 mm) NPT.

Abra lentamente las tuberías de

suministro de agua para liberar el

aire y presurizar la válvula. Revise si

E

existen fugas y verifique si el flujo de

agua es adecuado.

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

5¾"

(146mm)

Ref.

2¹⁄₈"

(54mm)

Min.

D

a la

pared

114-051

P.O. BOX 309, MENOMONEE FALLS, WI 53052-0309 USA

TEL: 1-800-BRADLEY FAX: (262-251-5817)

http://www.bradleycorp.com

29

Page 30

S19-270C, S19-270E, S19274C, S19274E Installation

Instalación — Unidades izquierda (clásico)

Se muestra una unidad lavador de ojos clásico. La unidad lavador de ojos/rostro clásico son similares.

Aplicar sellador de tubería a todas las juntas de tubería de rosca macho.

Gire el brazo doblado

en 180º alrededor de

B

la válvula.

Retire la boquilla rociadora

del brazo doblado. Retire el

tornillo de ajuste del conjunto

A

de válvula con la llave Allen

(1/16"(1.5mm)). Deje ambos

elementos a un lado.

Gire el brazo doblado

en 180º alrededor de la

válvula. Con un cierre de

roscas de baja resistencia,

C

enrosque el tornillo de

fijación en la nueva

ubicación en la válvula

hasta que salga el extremo

inferior, luego devuélvalo ½

vuelta.

El brazo debe oscilar

libremente.

D

Vuelva a conectar la boquilla

rociadora en el brazo doblado; selle

nuevamente si es necesario.

Monte la unidad sobre el mostrador. Consulte la página 28 para el

lavador de ojos o la página 29 para el lavador de ojos/rostro.

E

La unidad de lado izquierdo se debe instalar en el lado

izquierdo de la cubierta.

Abra lentamente las tuberías de suministro de agua para

liberar el aire y presurizar la válvula. Revise si existen

F

fugas y verifique si el flujo de agua es adecuado.

30

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Page 31

Installation S19-270C, S19-270E, S19274C, S19274E

Instalación — Unidades izquierda (Halo)

Se muestra una unidad lavador de ojos Halo. La unidad lavador de ojos/rostro Halo son similares.

Aplicar sellador de tubería a todas las juntas de tubería de rosca macho.

Gire el brazo

en 180º

B

alrededor de

la válvula.

C

Retire el tornillo de ajuste del

conjunto de válvula con la llave

A

Allen (1/16"(1.5mm)) y déjelo a

un lado.

Suelte el conjunto de de la tapa

con la llave Allen (5/16"(8mm)) y

D

gire la boquilla rociadora en 180º.

E

Apriete el conjunto de la

tapa y asegúrese de que el

cabezal esté nivelado.

Con un cierre de roscas de baja

resistencia, enrosque el tornillo de

fijación en la nueva ubicación en la

válvula hasta que salga el extremo

inferior, luego devuélvalo ½ vuelta.

El brazo debe oscilar

libremente.

Gire el cabezal y el cuerpo en 180º

alrededor del brazo.

Monte la unidad sobre el mostrador. Consulte la página 28 para el

lavador de ojos o la página 29 para el lavador de ojos/rostro.

F

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

La unidad de lado izquierdo se debe instalar en el lado

izquierdo de la cubierta.

G

Abra lentamente las tuberías de

suministro de agua para liberar el aire y

presurizar la válvula. Revise si existen

fugas y verifique si el flujo de agua es

adecuado.

31

Page 32

S19-270C, S19-270E, S19274C, S19274E Installation

Armado de los componentes y lista de piezas — S19-270C

La versión que oscila hacia la derecha se muestra en la posición abierta.

R

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Date

Signe

Date

31

Signed

Signed

bradleycorp.com

114-051

30

23

2

19

Mostrador

21

1

13

14

15

16

Art. Pieza N° Ctd. Descripción

1 N/A 1 Válvula no disponible para servicio;

se debe reemplazar el accesorio por

completo.

2 160-473 2 Tornillo prisionero

13 160-474 2 Tornillo prisionero

14 113-514 1 Varilla tornillante ½" x 2½"

15 142-002CB 1 Arandela ⁷⁄₈" x 2"

32

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Art. Pieza N° Ctd. Descripción

16 110-115 1 Tuerca ½"-14 NPSM

19 113-1032 1 Tubo Acodado (Niquelado)

21 S05-092 1 Lavador de ojos 90°

23 107-371 2 Cubierta contrapolvo

30 114-051 1 Aviso de seguridad

31 204-421 1 Etiqueta de inspección

Page 33

Installation S19-270C, S19-270E, S19274C, S19274E

Armado de los componentes y lista de piezas — S19274C

La versión que oscila hacia la derecha se muestra en la posición abierta.

R

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Date

Signe

Date

31

Signed

Signed

bradleycorp.com

114-051

30

19

2

Paquete tapa protectora

lavaojos S45-2675 incluye

art. 22 and 23

22

23

22

23

1

21

20

23

27

22

Mostrador

26

25

13

14

29

15

16

Art. Pieza N° Ctd. Descripción

1 N/A 1 Válvula no disponible para servicio;

se debe reemplazar el accesorio

por completo.ccesorio por completo.

2 160-473 2 Tornillo prisionero

13 160-474 2 Tornillo prisionero

14 113-514 1 Varilla tornillante ½" x 2½"

15 142-002CB 1

16 110-115 1 Tuerca ½"-14 NPSM

19 113-1236 1

20 171-005 1

Arandela ⁷⁄₈" x 2"

Tubo ³⁄₈" x 5½" cromado latón rojo

Cuerpo ³⁄₈" NPT corto

Art. Pieza N° Ctd. Descripción

22 En el kit de

mantenimiento

23 En el kit de

mantenimiento

25 115-169 1 Tapa corto

26 125-157 2 Arosello

27 125-175 1 Control del flujo

29 160-500 1 Tornillo, Drenaje

30 114-051 1 Aviso de seguridad

31 204-421 1 Etiqueta de inspección

21 S05-190 1 Lavador de ojos (incluye)

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

2 Pasador de pivote (juego de

repuesto)

2 Tapa protectora (juego de repuesto)

33

Page 34

S19-270C, S19-270E, S19274C, S19274E Installation

Armado de los componentes y lista de piezas — S19-270E

La versión que oscila hacia la derecha se muestra en la posición abierta.

R

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date Signed

Signed

Date

Unterschrift

Date

Datum

Signe

Date

Date

31

Signed

Signed

bradleycorp.com

114-051

30

23

21a

2

1

19

Mostrador

21

13

14

15

16

Art. Pieza N° Ctd. Descripción

1 N/A 1 Válvula no disponible para servicio;

se debe reemplazar el accesorio por

completo.

2 160-473 2 Tornillo prisionero

13 160-474 2 Tornillo prisionero

14 113-514 1 Varilla tornillante ½" x 2½"

15 142-002CB 1 Arandela ⁷⁄₈" x 2"

16 110-115 1 Tuerca ½"-14 NPSM

34

10/5/2017 Bradley • 215-1326 Rev. V; ECN 15-05-042

Art. Pieza N° Ctd. Descripción

19 113-1032 1 Tubo Acodado (Niquelado)

21 S05-206 1 Lavado de ojos y rostro

21A S45-2453 1 Kit de mantenimiento para lavado de ojos y

rostro: Boquillas rociadoras negras

23 S53-063 2 Cubierta contrapolvo con ligaduras

30 114-051 1 Aviso de seguridad

31 204-421 1 Etiqueta de inspección

Page 35

Installation S19-270C, S19-270E, S19274C, S19274E

Armado de los componentes y lista de piezas — S19274E

La versión que oscila hacia la derecha se muestra en la posición abierta.

R

P.O. Box 309, Menomonee Falls, WI 53051

TEST THIS UNIT EACH WEEK

DIESES GERÄT 1ST WÖCHENTLICH ZU PRÜFEN.

ESSAI HEBDOMADAIRE

Test-operate valve(s) each week and sign below.

Report any malfunctions immediately.

Ventil(e) wöchentlich im Testbetrieb prüfen, bestätigt

durch Unterschrift. Jegliche Störung sofort melden.

Test le fonctionnement des valves chaque semaine et

signe en bas. S'il y à quelque chose qui ne va pas fait

un rapport immédiatement.

Date

Signed

Date Signed

Datum

Unterschrift

Date

Date

Signe

Date

31

Signed

Signed

bradleycorp.com

114-051

24a

30

19

2

22

Paquete tapa protectora

lavaojos/rostro S45-2676

incluye art. 22, 24a y 24b

24b

24a

22

20

1

24b

Mostrador

13

27

14

21

26

29

15

16

25

22

Art. Pieza N° Ctd. Descripción

1 N/A 1 Válvula no disponible para servicio;

se debe reemplazar el accesorio

por completo.

2 160-473 2 Tornillo prisionero

13 160-474 2 Tornillo prisionero

14 113-514 1 Varilla tornillante ½" x 2½"

15 142-002CB 1

16 110-115 1 Tuerca ½"-14 NPSM

19 113-1075 1

20 171-005 1

21 S05-192 1 Lavador de ojos y rostro (incluye)

Arandela ⁷⁄₈" x 2"

Tubo ³⁄₈" x 9" cromado latón rojo

Cuerpo ³⁄₈" NPT corto

Art. Pieza N° Ctd. Descripción

22 En el kit de

mantenimiento

24a En el kit de

mantenimiento

24b En el kit de

mantenimient

25 115-169 1 Tapa corto

26 125-157 2 Arosello

27 125-175 1 Control del flujo

29 160-500 1 Tornillo, Drenaje

30 114-051 1 Aviso de seguridad

31 204-421 1 Etiqueta de inspección

Bradley • 215-1326 Rev. V; ECN 15-05-042 10/5/2017

2 Pasador de pivote (juego de

repuesto)

1 Tapa protectora (juego de repuesto)

1 Tapa protectora (juego de repuesto)

35

Loading...

Loading...