Page 1

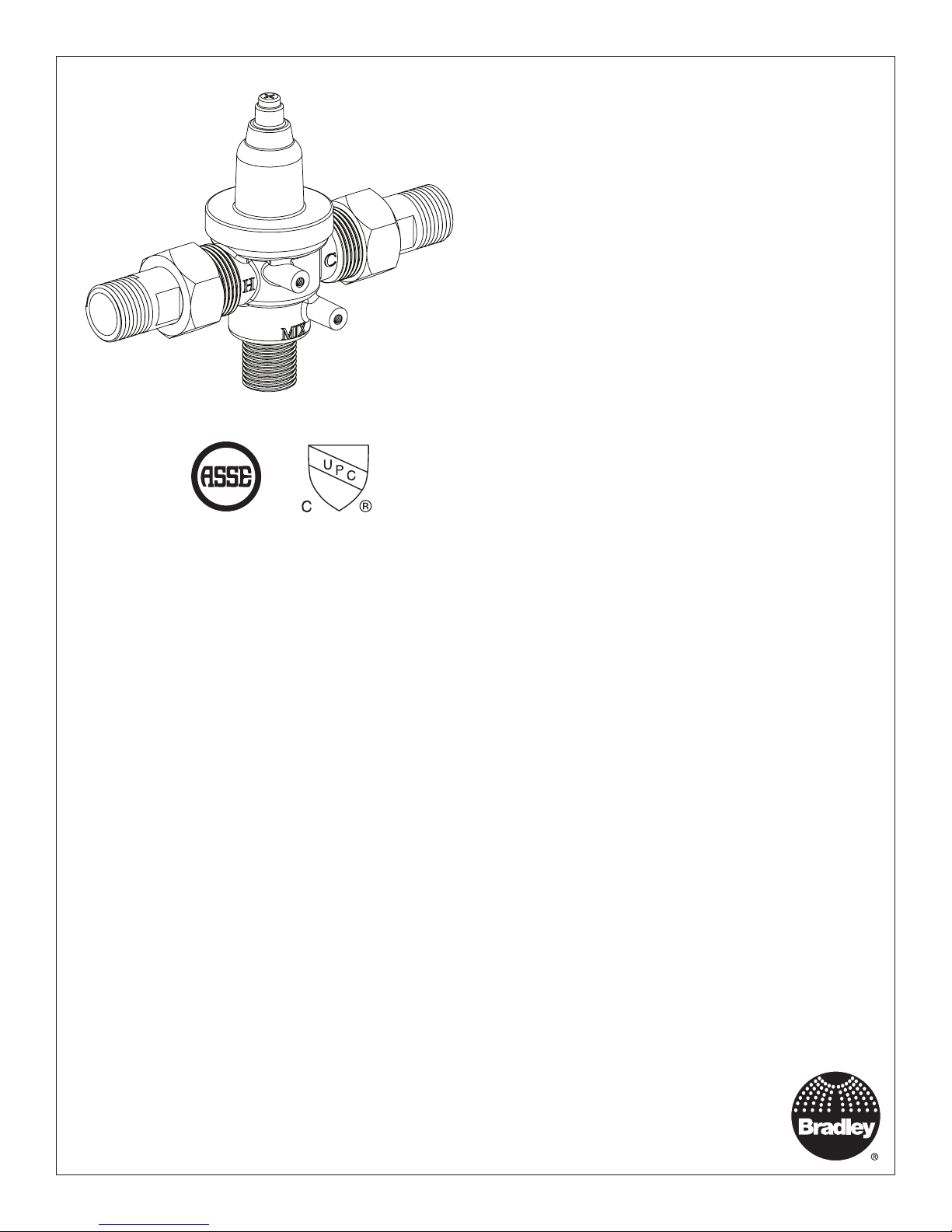

ASSE 1070 & cUPC certified

®

Inlet Connections: 1/2" NPT

Outlet Connection: 1/2" NPT

Temperature Range: 95 – 125°F

Maximum Pressure: 125 PSIG

Inlet Temperature, Hot: 120 – 180°F

Inlet Temperature, Cold: 33 – 80°F

Minimum Temperature Differential (from valve set point): 10°F

Installation

S59-4007

Navigator® Thermostatic Mixing

Valve for Sinks/Faucets

Pre-Installation Information ........................2

Supplies and Tools Required.......................2

Installation .....................................3

Troubleshooting .................................4

Parts List ......................................4

215-1852 Rev. C; ECN 18-09-011

© 2018 Bradley

Page 1 of 4 2/1/2018

Menomonee Falls, WI 53052 USA

P.O. Box 309

800 BRADLEY (800 272 3539)

+1 262 251 6000

bradleycorp.com

Page 2

S59-4007 Installation

WARNING

Failure to comply with proper installation and maintenance instructions could contribute to the valve failure

resulting in severe bodily injury including scalding, chilling, and/or death depending upon system water

pressure changes and/or supply water temperature changes.

Use this Thermostatic Mixing Valve in accordance with ASSE standard 1070. This valve does not provide

protection from pipe freezing.

Output temperature of the valve must be checked and adjusted at initial installation and on a quarterly basis.

Make sure that all water supply lines have been flushed and then completely turned off before beginning

installation. Debris in supply lines can cause valves to malfunction.

NOTICE

Regular checking and cleaning of the valve’s internal components is necessary for maximum life and proper

product function. Periodic inspection and yearly maintenance by a licensed contractor is required. Corrosive

water conditions, and/or unauthorized adjustments or repairs could render the valve ineffective for its

intended service. Frequency of cleaning and inspection depends upon local water conditions.

IMPORTANT

Read this entire installation manual to ensure proper installation. When finished with the installation, file

this manual with the owner or maintenance department. Compliance and conformity to local codes and

ordinances is the responsibility of the installer.

Consult local building and plumbing codes prior to installation. Should these codes differ from the

information in the Manual, follow the local codes. Inquire with governing authorities for additional local

requirements.

Separate parts from packaging and make sure all parts are accounted for before discarding packaging

material. If any parts are missing, do not begin installation until you obtain the missing parts.

Product warranties may be found under “Products” on our web site at bradleycorp.com.

Supplies Required

• Shut-off on the outlet if tempered water is

supplied to a remote location

• Shut-off on the inlets/supplies

• (2) #10 fasteners (and wall anchors, if

necessary) for wall bracket

Tools Required

• Adjustable Wrench

• Needle-Nose Pliers

• Phillips-Head Screwdriver

2 2/1/2018 Bradley • 215-1852 Rev. C; ECN 18-09-011

Page 3

Installation S59-4007

Assemble the Valve

1

Install check valves into valve assembly

A

as shown in the Parts List.

Observe direction of arrow on check

valve when assembling.

Slide tailpiece nuts over tailpieces.

B

Connect Supply Lines

2

Thread hot and cold supplies to

tailpieces. Thread mix outlet line to the

A

valve body outlet.

NOTICE! If tailpieces need to be soldered to

the hot and cold supplies, detach the

tailpieces from valve assembly or the

valve may be damaged.

Pressurize the thermostatic mixing

B

valve and check for pipe leaks.

Insert fiber washers between tailpieces

and hot and cold inlets on the valve

C

assembly. Tighten tailpiece nuts onto

valve body.

Hot

Mix

(to Faucet)

Cold

Adjust Temperature with Water Running

3

This valve is NOT factory preset. Upon installation, the temperature of this valve must be checked and adjusted

to ensure delivery of a safe water temperature. Water in excess of 110°F (43°C) may cause scalding.

Loosen cap screw about

1/4" (4-6 turns) and lift up

A

cover (do not remove)

H

Using cover, turn cartridge gently

until desired water temperature is

reached. Do not turn past stops as

B

this may damage unit. Push cover

down and tighten screw.

Test Unit

4

Shut the hot water inlet off by closing hot water inlet valve. While the hot water supply is turned off, check to make

sure the cold water flow is reduced. If the cold water is reduced properly, reopen the hot water supply.

Shut the cold water inlet off by closing the cold water inlet valve. While the cold water supply is off, check to make

sure that the hot water flow has shut down.

DO NOT SKIP THIS STEP!!!

C

Bradley • 215-1852 Rev. C; ECN 18-09-011 2/1/2018 3

Page 4

S59-4007 Installation

Thermostatic Mixing Valve Troubleshooting

Before attempting to troubleshoot the valve or disassemble the components, check for the following conditions:

• If stop valves are used, make sure that they are fully open.

• Make sure that the hot and cold inlet pipes are connected properly, and that there are no crossconnections or leaking stop valves.

• Check the hot water heater output to make sure that it is at least 10° F above the set temperature.

Be sure to close the appropriate shut-off valves prior to disassembly of the valve and reopen the valves after

inspection and repair is complete.

Problem Cause Solution

External leaks. Damaged cartridge or O-rings. Replace cartridge with part number 269-1927

Improper water temperature

or temperature fluctuation.

Hot water supply is not 10° above desired set

point.

Valve temperature is not properly set. Adjust the temperature as shown on page 3 step 2.

Increase hot water supply temperature

Limited water flow. Dirt and debris have built up in the valve or

strainer.

Parts List

Item Part No. Description Qty

1 118-333 Valve Body 1

5

4

3

2 269-1927 Thermostatic Cartridge 1

3 107-646 Hex Cap 1

4 107-582A Cover, Lead Free Valve 1

5 160-463 Screw, M4X8 PN 1

6 198-012 Check Valve, 16mm 2

7 124-001AF Rubber Washer 2

8 129-007 Tailpiece, Unplated 2

9 110-005 Nut, 1-1/16-14 Hex 2

10 S45-2976 Mounting Bracket Kit (Optional) 1

1. Check to make sure both hot and cold supplies are

connected to the Navigator mixing valve and that they

have water flow.

2. Remove cover and U-clip. Remove the cartridge

and clean the strainer. It is not required to grease

cartridge, however if desired, use silicone grease only.

Do not use grease on check valves.

10

4 2/1/2018 Bradley • 215-1852 Rev. C; ECN 18-09-011

2

6

1

7

8

9

Loading...

Loading...