Page 1

Parts & Service Guide

Multi-Fount Washfountains

Terreon

®

Models

215-1447 Rev. F; EN 07-005A

©2008 Bradley Corporation

Page 1 of 34 1/30/2008

P.O. Box 309, Menomonee Falls, WI 53052-0309

TEL. 1-800-Bradley FAX 262-251-5817

http://www.bradleycorp.com

Page 2

Terreon®Multi-Fount Washfountains Parts and Service Guide

2 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

Table of Contents

Washfountain Identification Page #

Identification Chart and Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Terreon®Multi-Fount Washfountains

Infrared (IR) — Sprayhead (24V plug-in transformer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Infrared (IR) — Valves (24V plug-in transformer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Infrared (IR)— Solenoid Valve Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Air Metering Valve (AST4) — Pushbutton and Sprayhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

Air Metering Valve (AST4) — Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Air Metering Valve (AST4) — Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Metering Air Valve Maintenance and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-13

AST4 & IR Supply and Mixing Valve — Floor and Wall Mounted . . . . . . . . . . . . . . . . . . . . . . . . .14

Battery Infrared (BIR3) — Sprayhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Battery Infrared (BIR3) — Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-17

Troubleshooting (BIR3) Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

TouchTime

®

(TT) — Sprayhead (24V plug-in transformer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-21

TouchTime

®

(TT) Solenoid Valve Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Mixing Valve — Vernatherm

®

— Thermostatic S01-520 Valve . . . . . . . . . . . . . . . . . . . . . . . . . .23-24

Cleaning the Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23-24

Soap System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25-27

Drain Spud and Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Floor Pedestal — Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Wall Mount Pedestal — Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Sprayhead Cover Attaching Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Sprayhead Covers — Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31-32

Pedestal Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Terreon Care and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Bowl Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Part numbers are subject to change without formal notice.

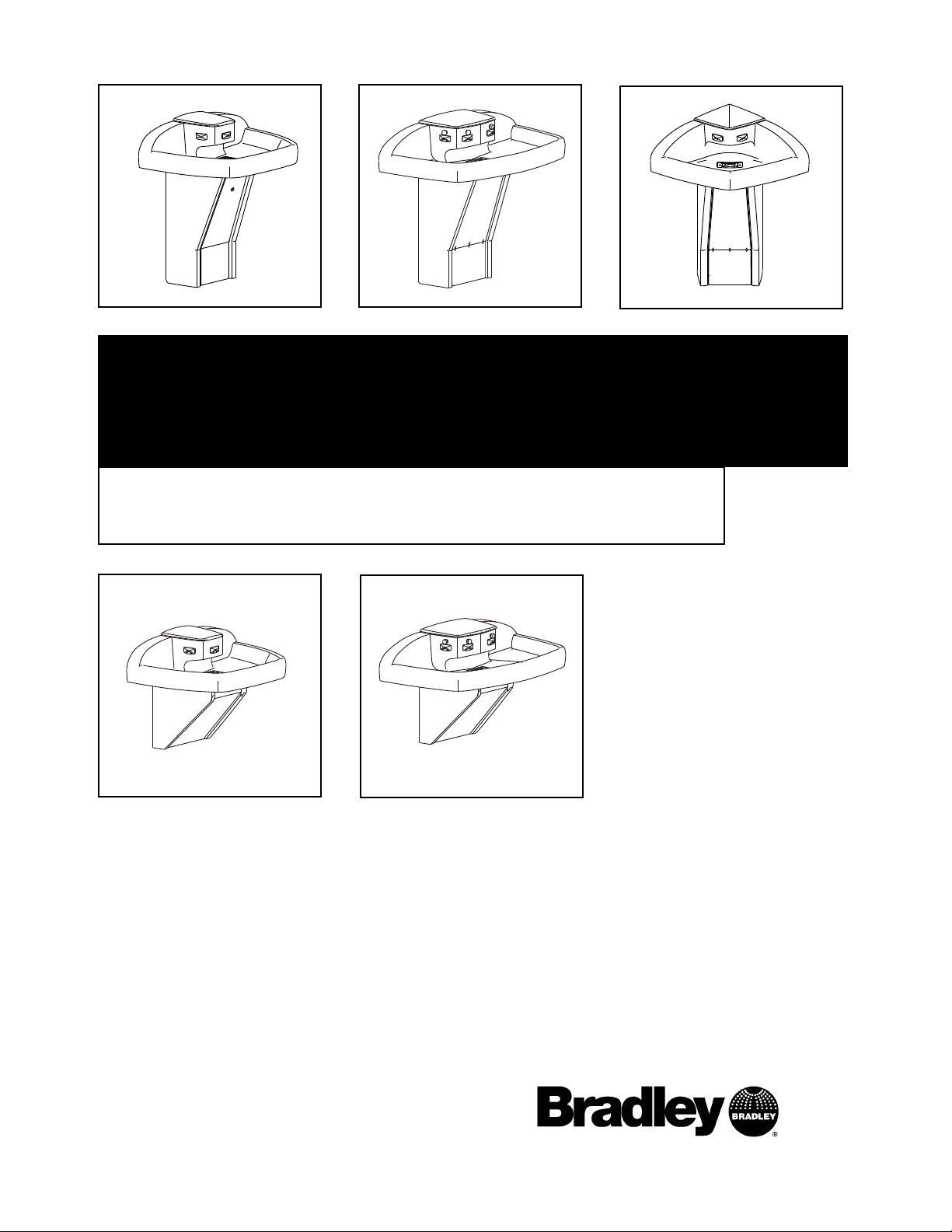

Page 3

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 3

•

Unique, Repairable, Solid Surface Material

• Highly Vandal Resistant

• Saves Water, Energy, and Space

• Available with Air Metering, Infrared or Battery

Operated Infrared and TouchTime

®

Control

Models Available:

MF2922 Terreon Corner-Fount

MF2933 Terreon Tri-Fount

MF2939 Terreon Tri-Fount Wall Hung

MF2944 Terreon Quadra-Fount

MF2949 Terreon Quadra-Fount Wall Hung

Terreon®Multi-Fount Washfountains

MF2922

Air Valve

Shown (AST)

MF2933

Air Valve

Shown (AST)

MF2939

Air Valve

Shown (AST)

MF2944

Infrared Shown (IR)

MF2949

Infrared Shown (IR)

1/30/2008

Page 4

Terreon®Multi-Fount Washfountains Parts and Service Guide

4 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

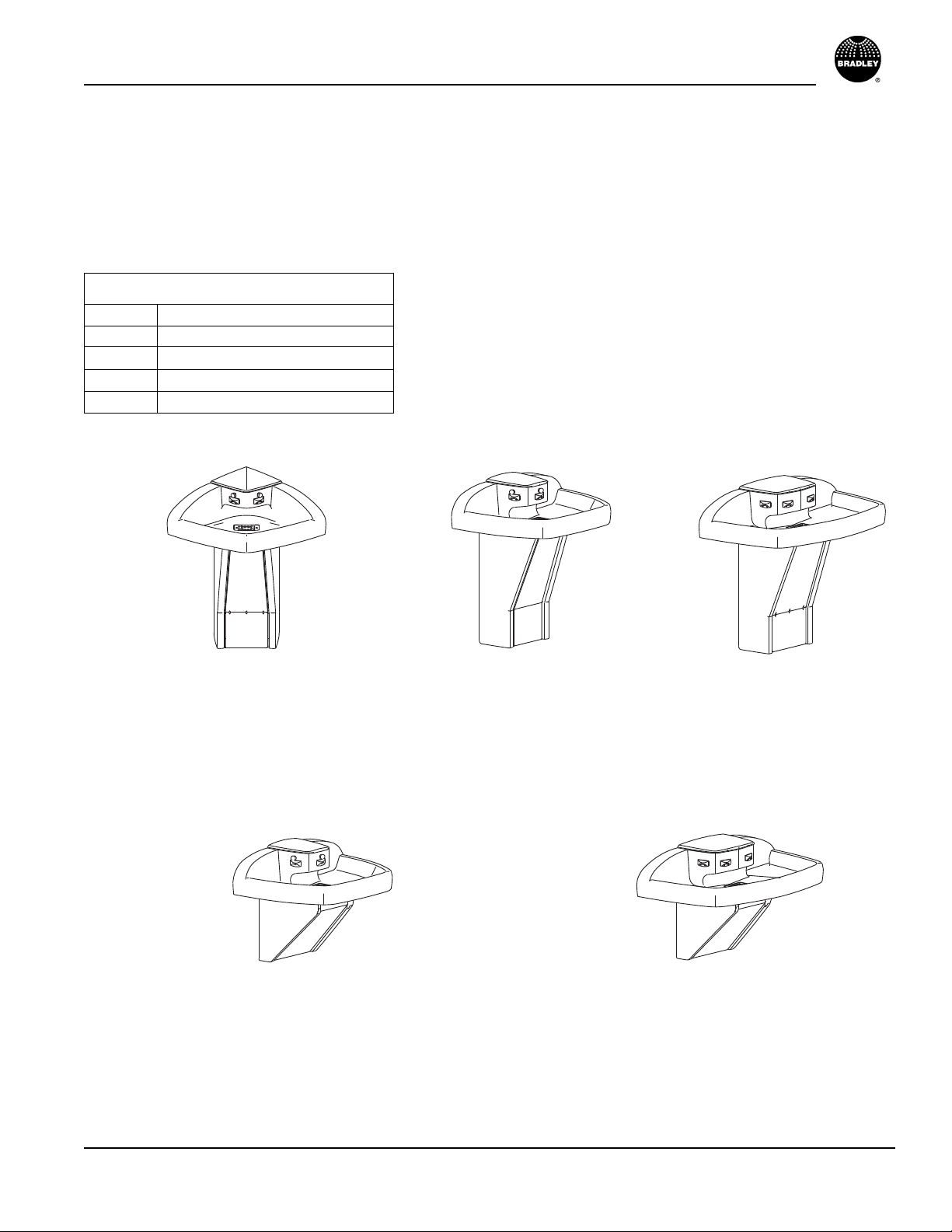

Infrared (IR) — Sprayhead (24V Plug-in Transformer)

Corner Tri Quad

Item Part No. Description Qty Qty Qty

1 269-1608 Sensor - Adaptive 2 3 4

* P10-569 Hook and Loop Fastener Strip (sensor mounting) 2 3 4

2 269-1190 Window 4 6 8

3 115-131 Sprayhead 2 3 4

4 176-119 Threaded Rod 4 6 8

5 140-748 Backplate 2 3 4

6 161-026 Nut 4 6 8

7 142-002BS Lockwasher 4 6 8

8 269-871 Fitting Straight (front sprayhead) — 1 2

9 269-628 Fitting Swivel 90° (side sprayheads) 2 2 2

10 R68-600011-R Tubing 1/4", Red (Specify Length in feet) — — —

10 R68-600011-G Tubing 1/4", Green (Specify Length in feet) — — —

10 R68-600011-B Tubing 1/4", Black (Specify Length in feet) — — —

10 R68-600011-Y Tubing 1/4", Yellow (Specify Length in feet) — — —

Parts List — Infrared Sensor and Sprayhead Assembly

* Not Illustrated.

1

10

1

2

3

4

5

6

7

8

9

Page 5

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 5

1/30/2008

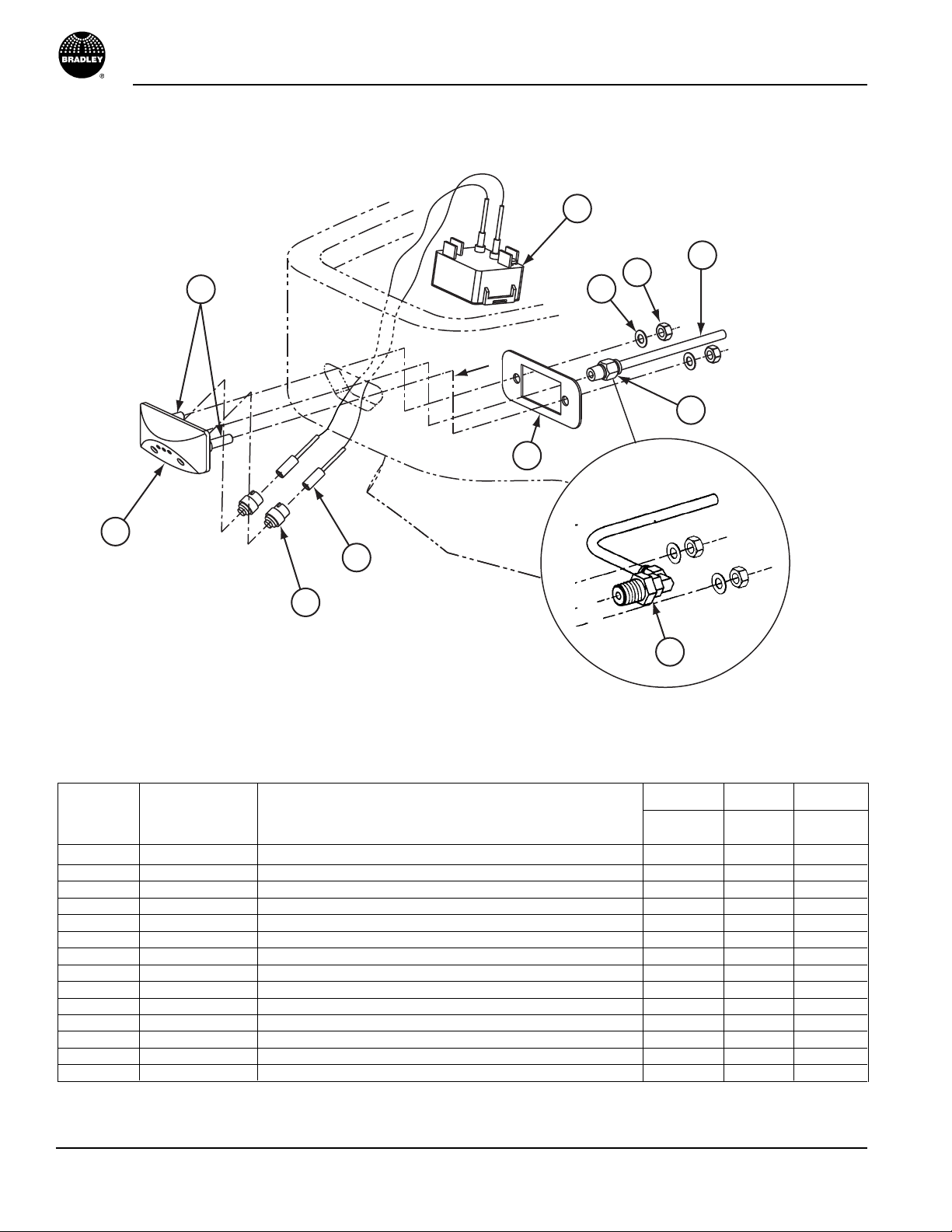

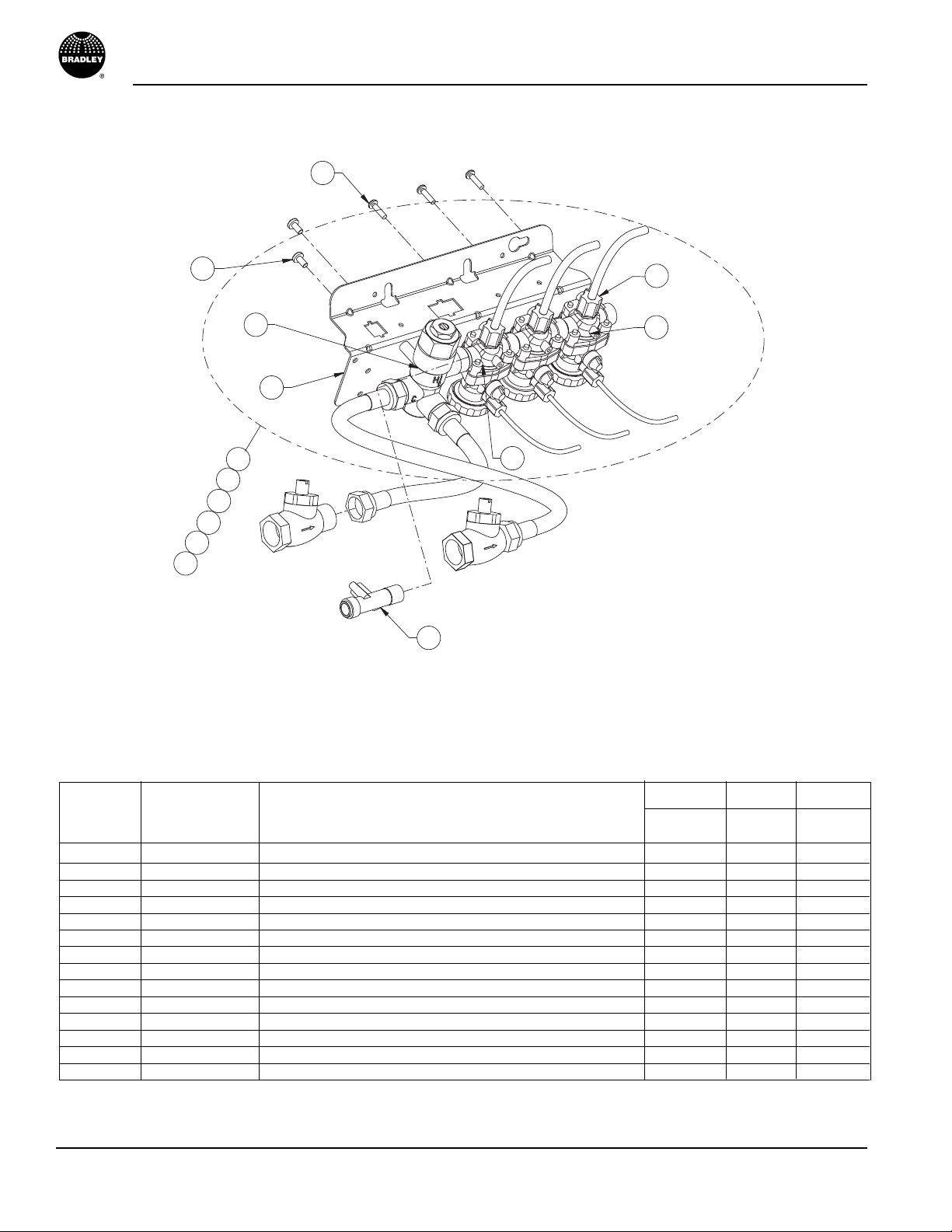

Infrared (IR) — Valves (24V Plug-in Transformer)

Parts List — Solenoid Assembly and Valve Parts

Corner Tri Quad

Item Part No. Description Qty Qty Qty

1 S45-2084 IR TMA Dual Valve Assembly (includes 7-13) 1 — —

2 S45-2085 IR TL Dual Valve Assembly (includes 8-14) 1 — —

3 S45-2090 IR TMA Tri Valve Assembly (includes 7-13) — 1 —

4 S45-2091 IR TL Tri Valve Assembly (includes 8-14) — 1 —

5 S45-2162 IR TMA Quad Valve Assembly (includes 7-13) — — 1

6 S45-2163 IR TL Quad Valve Assembly (includes 8-14) — — 1

7 S01-520 Vernatherm Valve, 4 GP 1 1 1

8 140-928 Bracket, Ganged Valve 1 1 1

9 P18-054 Screw 10-24 x 3/8 PN 2 2 2

10 S07-068A Solenoid Valve, 24 VAC, through 1 2 3

11 S07-068 Solenoid Valve, 24 VAC, closed 1 1 1

12 110-231 Compression Nut, 1/4" 2 3 4

13 160-447 Screw 8-16 x 5/8 PN 2 3 4

14 S39-685 Adapter, Valve Inlet 1 1 1

15 S83-152 Transformer 1 1 1

13

9

8

1

4

2

5

3

6

7

10

Black Supply Tube

(From Sprayhead)

Green Supply Tube

(From Sprayhead)

12

11

Red Spade Terminal

Green Spade Terminal

Black Spade Terminal

White Jumper Terminals

Red Supply Tube

(From Sprayhead)

15

Tri-Fount Shown

14

Page 6

Terreon®Multi-Fount Washfountains Parts and Service Guide

6 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

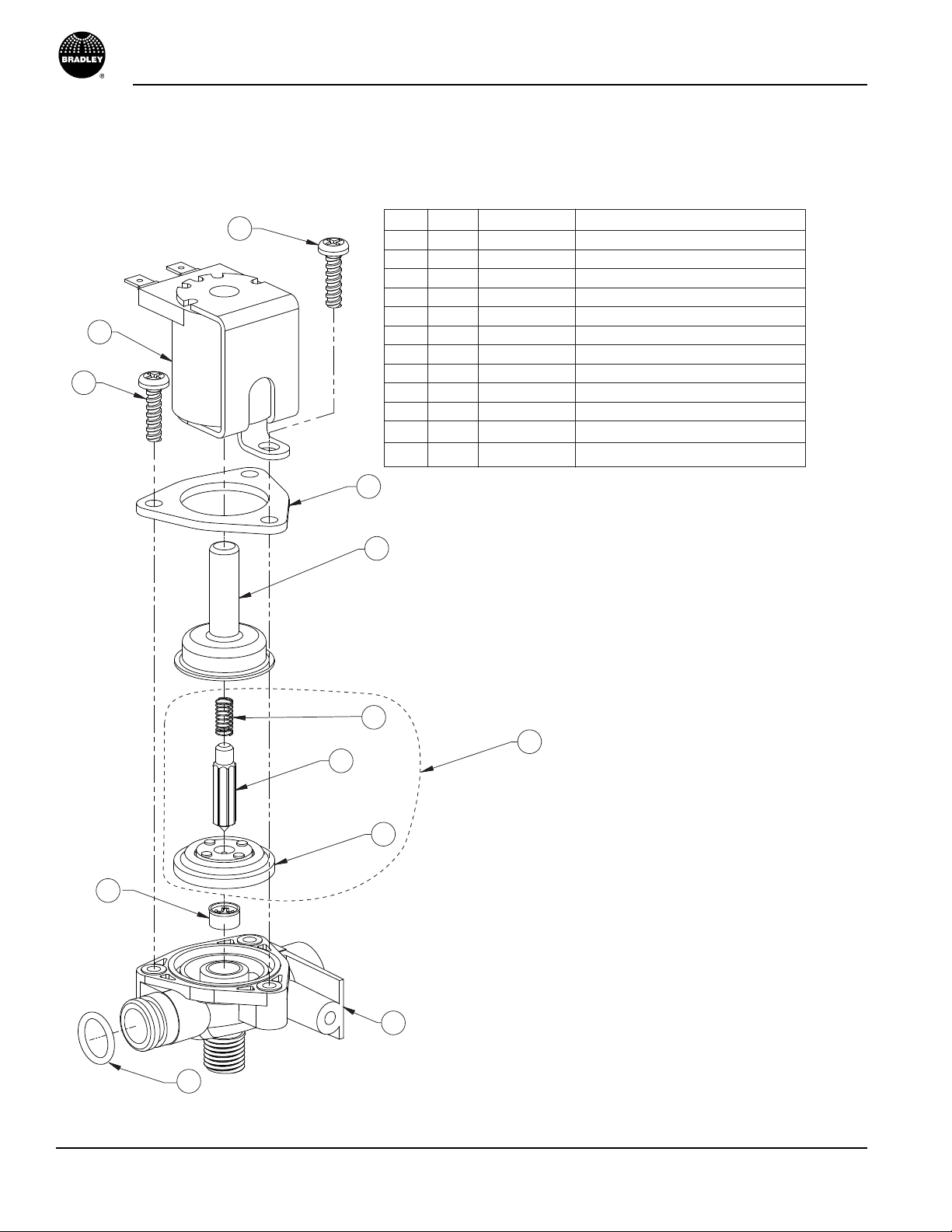

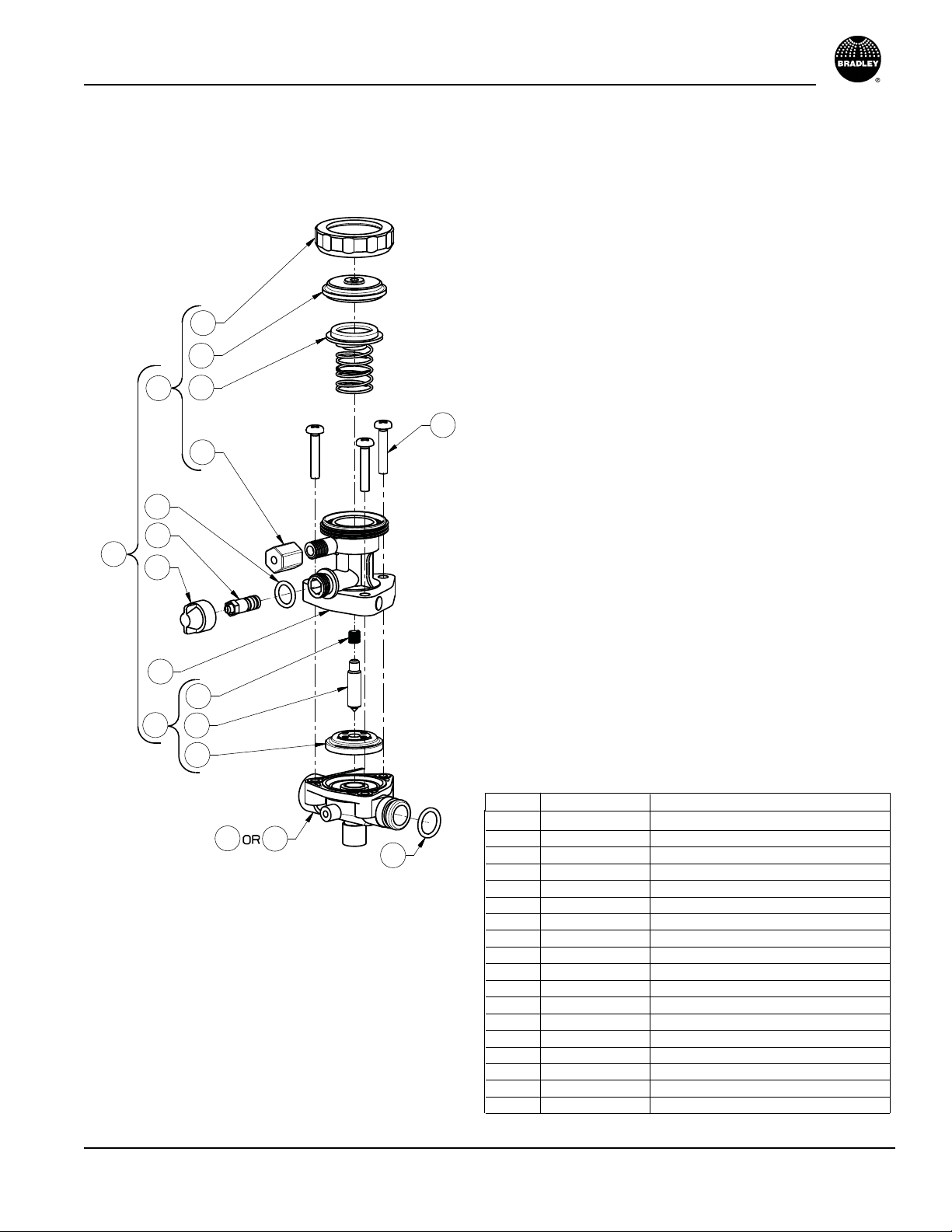

Infrared Valve (IR) — Assembly —

Solenoid Valve S07-068 (closed body) and S07-068A (thru body)

8

7

8

1 1 118-307 VALVE BODY, 1/4" CLOSED

1 1 118-307A VALVE BODY, 1/4" THRU

2 1 269-983 DIAPHRAGM

3 1 269-577 ARMATURE

4 1 269-578 SPRING

5 1 269-1729 ARMATURE HOUSING

6 1 269-1730 CLAMP, ARMATURE HOUSING

7 1 269-579 COIL, SOLENOID VALVE

8 3 160-447 SCREW, #8 X 5/8

9 1 125-165 O-RING, #2-013

10 1 125-160 FLOW RESTRICTOR, .5 GPM

11 1 S65-113 REPAIR KIT

6

5

DESCRIPTIONQTY. PART NO.REF.

10

4

11

3

2

1

9

Page 7

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 7

1/30/2008

Infrared (IR) — Solenoid Valve Troubleshooting

CAUTION: Turn off water supplies to unit before troubleshooting.

Problem: An individual operating station fails to shut off and drips.

Cause: There is debris trapped between the diaphragm and the valve seat.

Solution: Remove debris between diaphragm and the valve seat.

1. Remove the three #8 Phillips-head screws that hold the solenoid valve assembly together. Be

careful not to lose the armature or spring (see previous page).

2. Remove the diaphragm. Remove any particles that have been trapped between the diaphragm

and the valve seat. Rinse off the diaphragm and inspect for damage. Make sure the center orifice

and both small side orifices are open.

3. Reassemble in reverse order, being careful not to overtighten the Phillips-head screws or you

may crack the plastic valve body. Tighten until the armature plate makes contact with the plastic

body.

4. Reconnect the wiring per diagram.

Problem: An individual operating station fails to turn on.

Cause: A failed coil for the valve or loose electrical connection to the terminal.

Solution: Test the station to determine cause.

1. Disconnect the wires from the coil of an adjacent valve. Disconnect the wires from the problem

valve and reconnect to the adjacent valve.

2. Turn on electrical and water supplies to the unit. Place hands in front of sensor for the problem

station; the adjacent station should turn on.

If the adjacent station turns on and cycles normally, replace the coil on the problem valve.

If the adjacent valve fails to turn on, inspect the wires from the sensor cable and do the following:

• make sure there are no breaks and that the fully insulated disconnect terminals are firmly

crimped in place;

• turn off the electrical and water supplies;

• reconnect to the adjacent valve and turn on the water supplies to the unit;

• place hands in front of sensor. If the station still fails to turn on, replace the sensor.

Page 8

Terreon®Multi-Fount Washfountains Parts and Service Guide

8 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

Air Metering Valve (AST4) — Pushbutton and Sprayhead

3

2

1

4

12

27

17

*

*

15

*

11

*

10

*

9

7

14

†

6

*

13

22

23

5

16

14

26

24

21

26

18

19

20

25

Page 9

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 9

1/30/2008

Corner Tri Quad

Item Part No. Description Qty Qty Qty

1 S08-340 Pushbutton Assy. (Includes Items 2 thru 4) 2 3 4

2 128-090 Pushbutton only 2 3 4

3 179-104 Guide for pushbutton 2 3 4

4 147-034 Shoulder Screw for pushbutton 2 3 4

5 182-110 Spacer 2 3 4

6 140-743 Bracket 2 3 4

7 110-115 Nut 2 3 4

- S65-168 Actuator Assy. (Includes items 9 thru 14) 2 1 2

- S65-168A Actuator Assy. (Includes itmes 9 thru 15) — 2 2

9* 119-227A Piston 2 3 4

10* 125-099 U-Cup 2 3 4

11* 135-065 Spring 2 3 4

12* 118-279 Actuator Body 2 3 4

13* 198-010 Duckbill Check 2 3 4

14 169-890 Tube Connector 1/8" straight 2 3 4

15† 269-1186 Fitting Adj J — 2 2

16 160-165 Screw 4 6 8

17 R68-600008-R Tubing 1/8" OD, Red (specify length in feet) — — —

17 R68-600008-G Tubing 1/8" OD, Green (specify length in feet) — — —

17 R68-600008-B Tubing 1/8" OD, Black (specify length in feet) — — —

17 R68-600008-Y Tubing 1/8" OD, Yellow (specify length in feet) — — —

18 115-131 Sprayhead 2 3 4

19 176-119 Threaded Rod 4 6 8

20 269-1190 Window Hole Plug 4 6 8

21 140-748 Backplate 2 3 4

22 161-026 Nut 4 6 8

23 142-002BS Lockwasher 4 6 8

24 269-871 Fitting Straight (front sprayhead) — 1 2

25 269-628 Fitting Swivel 90° (side sprayheads) 2 2 2

26 R68-600011-R Tubing 1/4" ID, Red (specify Length in feet) — — —

26 R68-600011-G Tubing 1/4" ID, Green (specify Length in feet) — — —

26 R68-600011-B Tubing 1/4" ID, Black (specify Length in feet) — — —

26 R68-600011-Y Tubing 1/4" ID, Yellow (specify Length in feet) — — —

27 130-023 Spanner Wrench 1 1 1

Parts List

* Repair Kit S65-168 (incl. parts 9, 10, 11, 12, 13)

*, † Repair Kit S65-168A (incl. parts 9, 10, 11, 12, 13, 15)

Page 10

Terreon®Multi-Fount Washfountains Parts and Service Guide

10 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

Air Metering Valve (AST4) — Assembly

Corner Tri Quad

Item Part No. Description Qty Qty Qty

1 S08-452TMA TMA Dual Valve Assembly (includes 7-13 ) 1 — —

2 S08-452TL TL Dual Valve Assembly (includes 8-14 ) 1 — —

3 S08-453TMA TMA Tri Valve Assembly (includes 7-13 ) — 1 —

4 S08-453TL TL Tri Valve Assembly (includes 8-14 ) — 1 —

5 S08-454TMA TMA Quad Valve Assmbly (includes 7-13 ) — — 1

6 S08-454TL TL Quad Valve Assmbly (includes 8-14 ) — — 1

7 S01-520 Vernatherm Valve, 4 GP 1 1 1

8 140-928 Bracket, Ganged Valve 1 1 1

9 P18-054 Screw 10-24 x 3/8 PN 2 2 2

10 S07-078A AST4 Valve, through 1 2 3

11 S07-078 AST4 Valve, closed 1 1 1

12 110-231 Compression Nut, 1/4" 2 3 4

13 160-447 Screw 8-16 x 5/8 PN 2 3 4

14 S39-685 Adapter, Valve Inlet 1 1 1

Parts List — Air Metering Valve Assembly

13

9

7

8

1

2

3

4

5

6

10

12

11

Tri-Fount Shown

14

Page 11

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 11

1/30/2008

AST4 Valve Repair Kits

1 125-165 O-Ring

2 118-307A Valve Body-Manifolded

3 118-307 Valve Body-Closed

4 269-983 Diaphragm

5 269-577 Armature, Valve

6 269-578 Spring, Valve

7 118-309 Cover, AST4 Valve

8 107-538 Cover, AST4 Valve Timer

9 S27-305 Timer, ASM, AST4 V alve

10 125-001BY O-Ring

11 110-234 Compression Nut, 1/8”

12 S39-591 Magnet/Diaphragm Assy

13 107-535 Cover, AST4 Valve

14 110-233 Clamp Nut, AST4 Valve

15 160-449 Screw 8-16 x 7/8”

16 S65-261 Repair Kit-AST4Valve

17 S65-262 Repair Kit-AST4 Valve-Upper

18 S65-260 Repair Kit-AST4 Valve-Complete

ITEM PART NO. DESCRIPTION

14

13

12

16

15

11

18

17

10

9

8

7

6

5

4

2

3

1

Page 12

Terreon®Multi-Fount Washfountains Parts and Service Guide

12 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

Metering Air Valve Maintenance

Adjust Air Valve Meter Time

NOTE: The air valve timer is located next to the tube connector

on the air valve body. The timer is capped with a filter to prevent

dirt build-up on the timer. The air valve timing can be adjusting

from 5–60 seconds.

1. Remove filter cap and use a screwdriver to tighten or

loosen the timer (see illustration at right). Turning the

timer clockwise increases the time; turning the timer counterclockwise decreases the time.

2. Continue to adjust until the timer is set at desired length.

3. Replace filter cap over the timer.

Tube Connection Leaks

1. Push in the orange manual release button while pulling the

tube out (see illustration at right) to disconnect the tube at

the connector. No tools are needed.

2. To correct a leak, press tubing firmly into the connector

and make sure it is seated.

3. If leak persists, remove tubing from the fitting, and trim

the tubing end square with a razor-sharp knife. If leak continues, replace the fitting or contact your Bradley representative for assistance.

WATER TUBE CONNECTOR

AIR VALVE

FILTER CAP

AIR TUBE

CONNECTOR

Page 13

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 13

1/30/2008

Metering Air Valve Troubleshooting

Problem: Valve will not shut off.

Cause: Timing mechanism is clogged.

Solution: Clean and inspect timing mechanism:

1. If compressed air is available, blow water and debris from timer cover of timing mechanism.

2. Turn adjusting screw out all the way. Clean and inspect screw and valve body.

3. Turn adjusting screw in to desired cycle time.

Problem: Valve will not turn on.

Cause: Water is not being supplied to unit.

Solution: Open all stops on mixing valve.

Cause: Water pressure is over 80 PSI.

Solution: Install a pressure reducing valve.

Cause: Failed diaphragm/magnet assembly.

Solution: Unscrew the valve clamp nut on valve. Remove valve cover. Gently press the the

diaphragm. The valve should activate. If not, replace the diaphragm/magnet assembly.

Problem: Timing can not be adjusted for more than 5 seconds.

Cause: There is an air leak

Solution: Check the valve assembly:

1. Check all tubing and fittings for proper assembly.

2. Tighten cap and nut on 1/8" tubing.

Problem: Pushbutton does not work properly.

Cause: Air volume may not be sufficient to operate valve.

Solution: Check for leaks and lubricate U-cup:

1. Check all fittings for air leaks.

2. Disassemble pushbutton and lubricate U-cup seal (see pushbutton assembly diagram on page 8).

Problem: Water is dripping from the streamformers.

Cause: Debris has accumulated on valve seat or orifices.

Solution: Clean and inspect valve seat.

1. Remove screws and disassemble metering valve.

2. Clean valve seat and inspect for deep gouges or scratches. Replace valve body if necessary.

3. Remove any debris clogging off-center hole in rubber diaphragm.

Page 14

Terreon®Multi-Fount Washfountains Parts and Service Guide

14 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

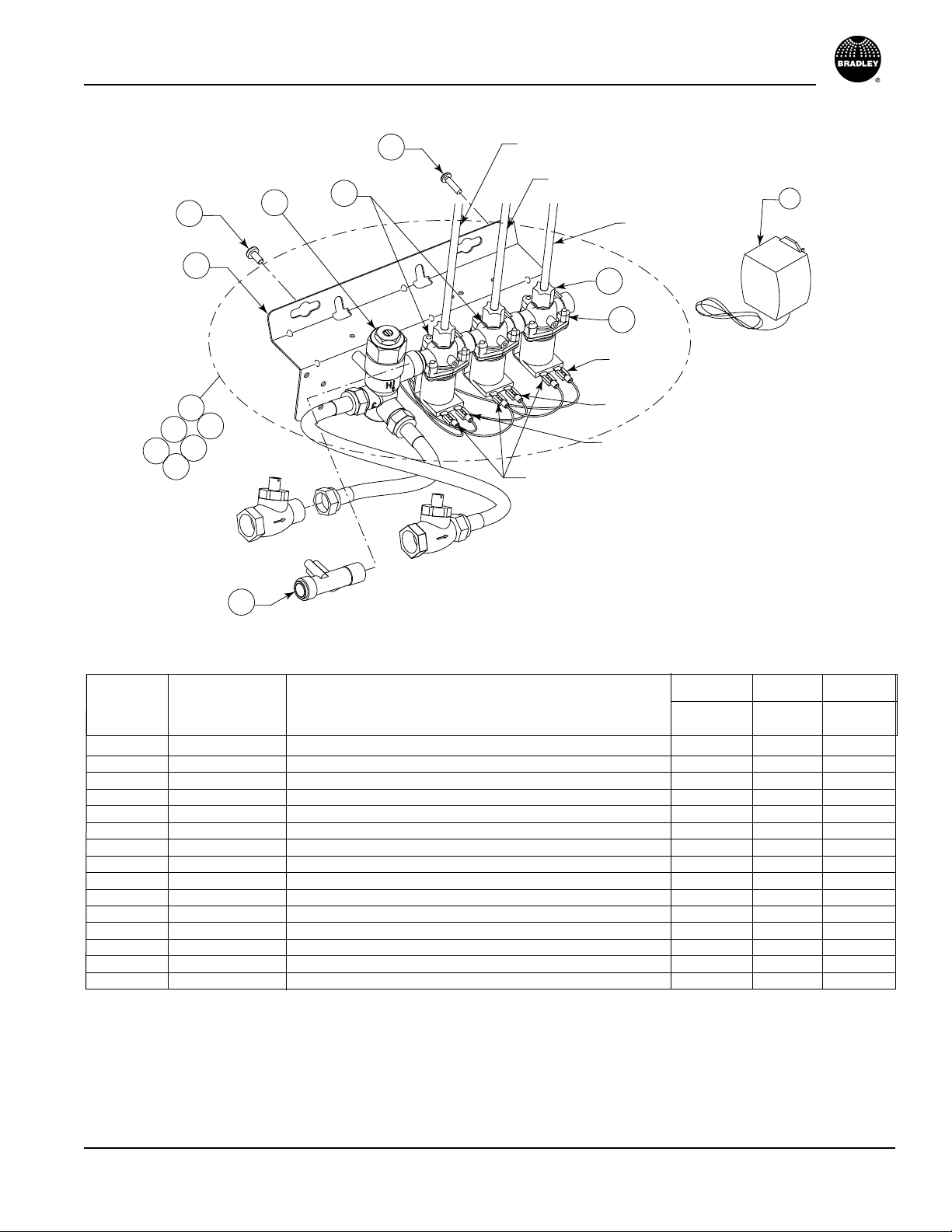

AST4 & IR Supply and Mixing Valve — Floor and Wall Mounted

t

Floor Mount

Wall Mount

Corner Tri Quad

Item Part No. Description Qty Qty Qty

*1 269-1735 Flex Hose ½" NPT x 24" (Supply to TMV) 2 2 2

*2 S27-102 Check Stop 2 2 2

3 160-169 Screw 2 2 2

Parts List — Supply

* Use Qty 1 for TL option, all models.

3

Air Valve Assembly

Vernatherm™ TMV

Hot Supply

Inlet

2

Cold Supply Inle

1

Tri-Fount Shown

Hot Supply Inlet

3

Cold Supply Inlet

2

Air Valve Assembly

Vernatherm™ TMV

1

Quadra-Fount Shown

Page 15

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 15

1/30/2008

Battery Infrared (BIR3) — Sprayhead

Corner Tri Quad

Item Part No. Description Qty Qty Qty

1 251-019A Sensor Eye Leads 2 3 4

2 269-1190 Window 4 6 8

3 115-131 Sprayhead 2 3 4

4 176-119 Threaded Rod 4 6 8

5 140-748 Backplate 2 3 4

6 161-026 Nut 4 6 8

7 142-002BS Lockwasher 4 6 8

8 269-871 Fitting Straight (front sprayhead) — 1 2

9 269-628 Fitting Swivel 90° (side sprayheads) 2 2 2

10 R68-60001-R Tubing 1/4", Red (Specify Length in feet) — — —

10 R68-60001-G Tubing 1/4", Green (Specify Length in feet) — — —

10 R68-60001-B Tubing 1/4", Black (Specify Length in feet) — — —

10 R68-60001-Y Tubing 1/4", Yellow (Specify Length in feet) — — —

Parts List — Battery Infrared Sensor and Sprayhead

4

5

3

10

6

7

8

1

2

9

Page 16

Terreon®Multi-Fount Washfountains Parts and Service Guide

16 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

Battery Infrared Valve (BIR3) — Assembly

Corner Tri Quad

Item Part No. Description Qty Qty Qty

1 S08-432TMA TMA Dual Valve Assembly (includes 7-13 ) 1 — —

2 S08-432TL TL Dual Valve Assembly (includes 8-14 ) 1 — —

3 S08-433TMA TMA Tri Valve Assembly (includes 7-13 ) — 1 —

4 S08-433TL TL Tri Valve Assembly (includes 8-14 ) — 1 —

5 S08-434TMA TMA Quad Valve Assembly (includes 7-13 ) — — 1

6 S08-434TL TL Quad Valve Assembly (includes 8-14 ) — — 1

7 S01-520 Vernatherm Valve, 4 GP 1 1 1

8 140-928 Bracket, Ganged Valve 1 1 1

9 P18-054 Screw 10-24 x 3/8 PN 2 2 2

10 S07-083 BIR3 Valve, through (includes 15-17) 1 2 3

11 S07-083A BIR3 Valve, closed (includes 15-17) 1 1 1

12 110-231 Compression Nut, 1/4" 2 3 4

13 160-447 Screw 8-16 x 5/8 PN 2 3 4

14 S39-685 Adapter, Valve Inlet 1 1 1

16 S83-178 Circuit Board 2 3 4

17 160-451 Screw #6-19 x 3/4 2 3 4

18 S83-177 Battery Holder 2 3 4

19 261-010 Lithium Battery, Type DL223A or Equivalent 2 3 4

20 S45-2083 Battery Prepack (includes 18,19) 2 3 4

Parts List — Air Metering Valve Assembly

13

1

2

3

4

5

6

Tri-Fount Shown

9

8

7

10

14

1819

12

11

16

17

Page 17

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 17

1/30/2008

Battery Infrared Valve (BIR3) — Assembly —

Solenoid Valve S07-073 (closed body) and S07-073A (thru body)

VALVE ASSEMBLY

CLOSED BODY

(S07-073)

THRU BODY

(S07-073A)

SOLENOID VALVE W/CIRCUIT BOARD

CLOSED BODY

(S07-083)

THRU BODY

(S07-083A)

CIRCUIT BOARD

(S83-178)

PAN-HEAD SCREW

6-19 x 3/4"

(160-451)

1

2

3

4

5

6

7

8

9

8

DESCRIPTIONQTY. PART NO.REF.

1 1 118-307 VALVE BODY, 1/4" CLOSED

2 1 269-983 DIAPHRAGM

3 1 192-017 ARMATURE

4 1 135-093 SPRING

5 1 269-1729 ARMATURE HOUSING

6 1 269-1730 CLAMP, ARMATURE HOUSING

7 1 269-1731 COIL, SOLENOID VALVE

8 3 160-447 SCREW, #8 X 5/8

9 1 125-165 O-RING, #2-013

1 1 118-307A VALVE BODY, 1/4" THRU

10

10 1 125-160 FLOW RESTRICTOR, .5 GPM

Parts not sold separately. Hand Tuned.

Page 18

Terreon®Multi-Fount Washfountains Parts and Service Guide

18 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

Troubleshooting BIR3 Components

CAUTION: Turn off water supplies to unit before troubleshooting.

Problem: An individual operating station drips and fails to shut off.

Cause: There is debris trapped between the diaphragm and the valve seat.

Solution: Remove debris between diaphragm and the valve seat.

Disconnect the plug from the battery to the circuit board of the problem valve. Remove the three #8 Phillips-head

screws that hold the solenoid valve assembly together. Be careful not to lose the armature or spring (see previous

page). Remove the diaphragm. Remove any particles that are trapped between the diaphragm and the valve seat.

Rinse off the diaphragm and inspect for damage. Make sure the center orifice and both small side orifices are open.

Reassemble in reverse order, being careful not to overtighten the Phillips-head screws or you may crack the plastic

valve body. Tighten until the armature plate makes contact with the plastic body. Reconnect the battery plug per diagram. Turn on water supplies to the unit.

Problem: An individual operating station fails to turn on or off.

Cause: Excessive line pressure.

Solution: Install Pressure Reducing Valve.

Check the static line pressure. If the pressure exceeds 80 psi, install a pressure reducer valve at the street main.

Excessive line pressure (over 60 psi) will shorten the life of any valve.

Problem: An individual operating station fails to turn on or off.

Cause: A dead or faulty battery.

Solution: Test the station to determine cause and replace battery if

required.

Disconnect the plug from the battery to the circuit board of the problem valve.

Disconnect the plug from the battery to the circuit board of an adjacent valve.

Connect the battery plug from the adjacent working valve to the problem valve.

Wait for ten seconds. Activate the problem station’s sensor ten times. The station

should turn on. If the station turns on, and cycles normally, replace the battery.

Cause: Faulty sensor eyes.

Solution: Test station to determine cause; replace sensor eyes if required.

Disconnect the sensor cable from the circuit board of the problem valve.

Disconnect the sensor cable from the circuit board of an adjacent working valve.

Connect the sensor cable from the adjacent working valve to the problem valve.

Activate the problem station’s sensor. The station should turn on. If the station turns

on and cycles normally, replace the sensor eyes.

Cause: Faulty solenoid valve.

Solution: Test station to determine cause; replace solenoid valve if required.

Remove the screw, circuit board and standoff from the problem valve. Remove the

battery holder. With a good working battery, briefly contact the solenoid valve

directly with the battery as shown in the Open Valve figure. The contact should

cause the valve to open. With the battery holder removed, briefly contact the solenoid valve with the battery in the position shown in the Closed Valve Figure. This

should cause the valve to close. If the valve does not operate when directly contacted with a good battery, and the solenoid valve has already been cleaned as outlined

at the beginning of this troubleshooting section, replace the solenoid valve.

If problems persist:

Pass your hand in front of the problem station, while at the same time looking to see if the indicator light on the circuit board flashes (the indicator light is located near the hole in the circuit board where the standoff is mounted). If

it does not flash, and the battery and sensor eyes have already been tested as outlined above, the problem may be

with the circuit board. Make a note of the numbers printed on the circuit board, then contact your Bradley representative for assistance.

OPEN VALVE

CLOSED VALVE

Page 19

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 19

1/30/2008

TouchTime®(TT) — Sprayhead (24V Plug-in Transformer)

Corner Tri Quad

Item Part No. Description Qty Qty Qty

1 S83-139B Switch Touchtime 2 3 4

2 269-1190 Window 4 6 8

3 115-131 Sprayhead 2 3 4

4 176-119 Threaded Rod 4 6 8

5 140-748 Backplate 2 3 4

6 161-026 Nut 4 6 8

7 142-002BS Lockwasher 4 6 8

8 269-871 Fitting Straight (front sprayhead) — 1 2

9 269-628 Fitting Swivel 90° (side sprayheads) 2 2 2

10 R68-600011-R Tubing 1/4", Red (Specify Length in feet) — — —

10 R68-600011-G Tubing 1/4", Green (Specify Length in feet) — — —

10 R68-600011-B Tubing 1/4", Black (Specify Length in feet) — — —

10 R68-600011-Y Tubing 1/4", Yellow (Specify Length in feet) — — —

11 182-115 Spacer 2 3 4

12 110-115 Nut, 1/2-14 2 3 4

13 130-023 Spanner Wrench 1 1 1

Parts List — TouchTime (Switch and Sprayhead)

11

1

3

4

2

12

6

7

5

13

10

8

9

Page 20

Terreon®Multi-Fount Washfountains Parts and Service Guide

20 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

TouchTime®Metering Valve (TT) — Assembly

Corner Tri Quad

Item Part No. Description Qty Qty Qty

1 S45-2088 TT TMA Dual Valve Assembly (Transformer not included) 1 — —

2 S45-2089 TT TL Dual Valve Assembly (Transformer not included) 1 — —

3 S45-2094 TT TMA Tri Valve Assembly (Transformer not included) — 1 —

4 S45-2095 TT TL Tri Valve Assembly (Transformer not included) — 1 —

5 S45-2164 TT TMA Quad Valve Assembly (Transformer not included) — — 1

6 S45-2165 TT TL Quad Valve Assembly (Transformer not included) — — 1

7 S01-520 Vernatherm Valve, 4 GP 1 1 1

8 140-928 Bracket, Ganged Valve 1 1 1

9 P18-054 Screw 10-24 x 3/8 PN 2 2 2

10 S07-068A Solenoid Valve, 24 VAC, through 1 2 3

11 S07-068 Solenoid Valve, 24 VAC, closed 1 1 1

12 110-231 Compression Nut, 1/4" 2 3 4

13 160-447 Screw 8-16 x 5/8 PN 2 3 4

14 S39-685 Adapter, Valve Inlet 1 1 1

15 S83-134 Transformer 1 1 1

Parts List — TouchTime Metering Valve Assembly

1

Tri-Fount Shown

Black Supply Tube

(From Sprayhead)

9

3

2

4

Green Wires

6

5

7

Supply Inlet

8

14

13

10

Left

Button

Center

Button

Green Supply Tube

(From Sprayhead)

Red Supply Tube

(From Sprayhead)

12

11

Gray Wires

Right

Button

15

Terminal Block

Brown Wires

Black Wires

Page 21

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 21

1/30/2008

TouchTime Valve (TT) — Assembly —

Solenoid Valve S07-068 (closed body) and S07-068A (thru body)

8

7

8

1 1 118-307 VALVE BODY, 1/4" CLOSED

1 1 118-307A VALVE BODY, 1/4" THRU

2 1 269-983 DIAPHRAGM

3 1 269-577 ARMATURE

4 1 269-578 SPRING

5 1 269-1729 ARMATURE HOUSING

6 1 269-1730 CLAMP, ARMATURE HOUSING

7 1 269-579 COIL, SOLENOID VALVE

8 3 160-447 SCREW, #8 X 5/8

9 1 125-165 O-RING, #2-013

10 1 125-160 FLOW RESTRICTOR, .5 GPM

11 1 S65-113 REPAIR KIT

6

5

DESCRIPTIONQTY. PART NO.REF.

10

4

11

3

2

1

9

Page 22

Terreon®Multi-Fount Washfountains Parts and Service Guide

22 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

TouchTime (TT) Solenoid Valve Troubleshooting

CAUTION: Turn off water supplies to unit before troubleshooting.

Problem: An individual operating station fails to shut off and drips.

Cause: There is debris trapped between the diaphragm and the valve seat.

Solution: Remove debris between diaphragm and the valve seat.

1. Remove the three #8 Phillips-head screws that hold the solenoid valve assembly together. Be

careful not to lose the armature or spring (see previous page).

2. Remove the diaphragm. Remove any particles that have been trapped between the diaphragm

and the valve seat. Rinse off the diaphragm and inspect for damage. Make sure the center orifice

and both small side orifices are open.

3. Reassemble in reverse order, being careful not to overtighten the Phillips-head screws or you

may crack the plastic valve body. Tighten until the armature plate makes contact with the plastic

body.

4. Reconnect the wiring per diagram.

Problem: An individual operating station fails to turn on.

Cause: A failed coil for the valve or loose electrical connection to the terminal.

Solution: Test the station to determine cause.

1. Disconnect the wires from the coil of an adjacent valve. Disconnect the wires from the problem

valve and reconnect to the adjacent valve.

2. Turn on electrical and water supplies to the unit. Depress the Touch Time pushbutton of the

problem station, the adjacent station should turn on.

If the adjacent station turns on and cycles normally, replace the coil on the problem valve.

If the adjacent valve fails to turn on, inspect the wires from the sensor cable and do the following:

• make sure there are no breaks and that the fully insulated disconnect terminals are firmly

crimped in place;

• turn off the electrical and water supplies;

• reconnect to the adjacent valve and turn on the water supplies to the unit;

• depress the Touch Time pushbutton. If the station still fails to turn on, replace the sensor.

Page 23

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 23

1/30/2008

Thermostatic Mixing Valve Troubleshooting

NOTE: Before attempting to troubleshoot the valve or disassemble the components, check for the following conditions:

• If stop/check valves are used, make sure that they are fully open.

• Make sure that the hot and cold inlet pipes are connected properly, and that there are no crossconnections or leaking stop/check valves.

• Check the hot water heater output to make sure that it is at least 20° F above the set temperature.

Be sure to close the appropriate shut-off valves prior to disassembly of the valve and reopen the

valves after inspection and repair is complete.

Problem: Limited water flow

Cause: Dirt and debris have built up in the valve or strainer.

1. Remove and clean strainer (see Figures on next page). If strainer needs to be replaced, order

Bradley part no. 173-028.

2. Check the piston for smooth movement.

To check the valve's piston for free and smooth movement, follow the procedures outlined below:

1. Remove the valve's cap and thermostat (see next Page).

2. Push down on the piston with your finger (the piston should move freely). If the movement is

not as it should be, the piston needs to be cleaned. Follow the method outlined below for cleaning the piston and valve body:

• Remove the thermostat.

• Lift the piston out with a needle-nose pliers and remove the spring.

• Any cleaner suitable for brass and stainless steel may be used (if cleaning with suitable cleaner

is not sufficient to remove debris, a 400-grit sandpaper may be used to polish and hone the piston and valve body).

• Snap spring into piston (will detent) and reassemble into the valve body. Retest the piston.

3. If, after a thorough cleaning, the piston does not move freely, the piston must be replaced.

Contact your Bradley representative and ask for Repair Kit (part number S65-259).

Problem: External leaks in the system

Cause: O-rings have been damaged.

Solution: Replace O-rings where necessary. For replacement of the O-rings, contact your

Bradley representative and ask for Repair Kit (part number S65-259).

Problem: Improper water temperature or temperature fluctuation

Cause: Thermostat is slowly failing or not working at all.

Solution: Check the thermostat for proper operation.

1. At room temperature (80° F or less) remove cap and thermostat.

2. Place thermostat into container with 115° F water. The pushrod should pop out of the

thermostat approximately 1/10".

3. If thermostat pushrod does not pop out, the thermostat must be replaced. Contact your Bradley

representative and ask for Repair Kit (part number S65-259).

Cause: Valve temperature is not properly set.

Solution: Adjust the temperature. Using a blade screwdriver, turn the adjustment stem counterclock-

wise to increase the temperature or clockwise to decrease the temperature.

Page 24

Terreon®Multi-Fount Washfountains Parts and Service Guide

24 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

Strainer

173-028

Tempered Line Adapter Assembly (S39-685) Option

Thermostat51

7 1 O-Ring

8 1 O-Ring

Item Qty Description

Repair Kit S65-259

9

6

5

4

3

2

1

7

8

Strainer

(173-028)

Valve Body

Spring

Thermostat

Piston

Stem

O-Ring

O-Ring

Cap

Nut 3/8-24 Hex Jam

10

Seal Cup

11

Vernatherm™ Thermostatic Mixing Valve (S01-524)

Page 25

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 25

1/30/2008

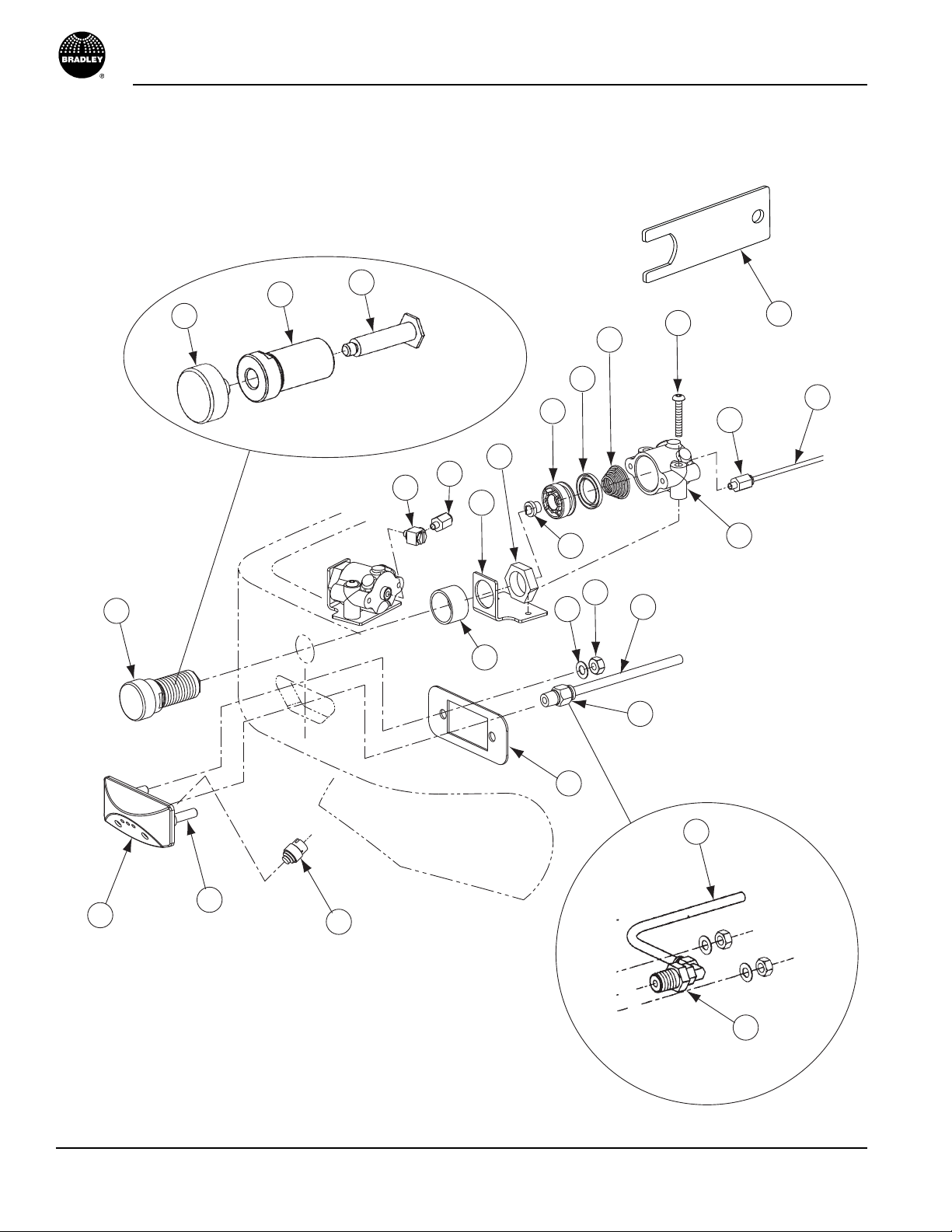

Soap System

Parts List — Soap Valve S09-083

S09-083 1 Soap Valve Complete

1 S64-096 1 Plunger Assy.

2 110-227A 1 Collar

3 160-239 1 Set Screw

4 125-168 1 O-Ring

5 198-013 2 Seat Assy.

6 135-097 1 Spring

7 144-068M 1 Cylinder

8 R68-800002 1 Tube 3/8" ID (Specify length in feet)

Item Part No. Qty Description

2

4

1

5

7

5

8

6

3

Page 26

Terreon®Multi-Fount Washfountains Parts and Service Guide

26 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

Soap System ....Continued

Parts List — Soap System

23

17

16

18

11

10

14

15

8

7

6

5

12

4

3

13

2

12

21

9

22

1

19

20

ITEM PART NO DESCRIPTION

1 240-001 SOAP TANK 1

2 169-989 HOSE 5/8 ID *

3 146-040 HOSE CLAMP

4 169-916 MALE FITTING 1

5 110-093 NUT 1

6 142-002CJ WASHER 1

7 153-174 FILLER 1

8 136-011 SOAP FILLER CAP 1

9

R68-600021

10 136-049 SOAP TANK CAP 1

11 269-1832 BULKHEAD FITTING 1

12 R68-800002 TUBE SUPPLY 1/2 *

13 269-1833 TEE 1

14 110-115 NUT 2

15 142-002CB WASHER 2

16 S52-109 SOAP VALVE BODY ASSY 2

17 S09-083 SOAP VALVE 2

18 130-142 SOAP FILLER CAP WRENCH 1

19

161-026 NUT

142-002AV WASHER

20

21 269-1834 FERRULE

22 R68-600012 TUBE

23 S50-409 COMPLETE SOAP SYSTEM (incl. items 1-22) 1

TUBE VENT 3/16 *

* SPECIFY LENGTH IN FEET

QTY

1

2

2

1

*

Page 27

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 27

1/30/2008

SOAP RECOMMENDATIONS

Quality soap dispensers require good quality soap and periodic maintenance to properly operate. Bradley soap

dispensers will provide dependable, consistent operation over the long term when soap with reasonable viscosity and pH levels are used and when a minimal amount of periodic maintenance is performed on the valves.

Soap thickness is determined by a measurement called viscosity. Soap viscosity should be between 100 cps

(centerpoise) and 2500 cps for all Bradley soap dispensers. Thinner soaps are perceived by the users as being

"watered down" so users tend to take more than they need, resulting in waste. Thick soaps flow slower and

inhibit the "flushing" action of the valves, which allows the soap to congeal in the valve and cause clogs.

The pH (acid) level of the soap should be in the range of 6.5 to 8.5. More acidic soaps (pH levels lower than

6.5) will corrode metal parts (even stainless steel!!) and degrade rubber and plastic components. They will also

cause skin irritation. Most inexpensive soaps (typically the pink lotion type) fall into this acidic category and

will eventually cause valve failure and metal corrosion. Base soaps (pH levels higher than 8.5) will cause

swelling or degradation of rubber and plastic parts and skin irritation.

Generally, any quality soap meeting the viscosity and pH guidelines above will work well with Bradley soap

dispensers. PCMX or Isapropanol based antibacterial soaps (within viscosity and pH limits) will also work

with Bradley dispensers. Soaps satisfying these basic guidelines will provide consistent flow and reduce clogs.

Most soap dispenser problems are caused by soap that is too thick or corrosive, or by a lack of maintenance.

Many soaps come in concentrate form which must be diluted with water. Often, the soap is improperly diluted

or used straight out of the bottle, which causes clogging and valve failure. If proper soap is being used, valves

that have never been cleaned are usually the source of dispensing problems. Bradley has entered into an agreement with Champion Brand Products to provide additional customer service for purchasers of our dispensers

regarding soap issues. They are very helpful and can get to the bottom of almost any soap dispenser related

problem. They also sell an excellent "Bradley approved" soap. Please see Soap Instruction Sheet 215-1286

for details about soap valve cleaning or how to contact Champion. With proper maintenance and soap, Bradley

dispensers will provide long term, trouble free operation.

SOAP

DISPENSER MAINTENANCE INSTRUCTIONS

Multi-Fount Washfountains

Bradley soap dispensers will provide dependable, consistent operation over the long term when the proper

soap is used and when a minimal amount of periodic maintenance is performed on the valves. Valves must be

maintained (cleaned) to function properly.

To ensure proper operation of your soap dispenser, follow these instructions:

• Once per month, remove the cap from the soap tank and insert the draw tube (below the cap) into hot water

and soak it for 30 minutes.

• Push valve at least 20 times while it is soaking.

• Flush soap reservoir with hot water while valve is soaking.

In cases of extreme clogging, the valve should be disassembled and the parts should be soaked in hot water or

cleaning solution to restore proper functioning. Soap dispensers that will not be used for extended periods of

time (schools during summer break, etc.) should be drained, cleaned and left empty until put back into service.

Soap left on the outside of dispensers can cause discoloration and corrosion of the reservoir (even on stainless

steel units). All soap should be wiped or scrubbed off daily, then the outside of the dispenser should be rinsed

with clear water and dried with a soft cloth.

Soap System ....Continued

Page 28

Terreon®Multi-Fount Washfountains Parts and Service Guide

28 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

Drain Spud and Strainer

1 173-023 1 Dome Strainer

2 160-132 2 Screw 10-24 x 1/2" (for strainer)

3 112-029 1 Drain Spud (includes washer & nut)

Item Part No. Qty Description

Parts List

1

3

Spud Washer (part of Item 3)

Spud Locknut (part of Item 3)

2

Washfountain Bowl

Note:

The rubber washer that comes

with this kit is used for certain

applications.

Discard this washer for

this application as it is not

used on Washfountains.

Page 29

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 29

1/30/2008

Floor Pedestal — Assembly

6

5

8

9

7

5

4

2

1

1

4

5

3

4

Corner Tri Quad

Item Part No. Description Qty Qty Qty

1 186-1589 Mounting Panel 2 2 —

1 186-1590 Mounting Panel — — 2

** 2 S04-056 Upper Bracket Assembly 1 1 —

** 2 S04-057 Upper Bracket Assembly — — 1

3 140-1011 Lower Bracket 1 1 —

3 140-1012 Lower Bracket — — 1

4 160-389 Screw ¼-20 x 1/2 8 8 8

5 142-002BJ Washer 4 4 4

6 146-055 Clip 1 1 1

7 S04-100 Access Panel — Standard Height 1 1 —

7 S04-095 Access Panel — Juvenile Height 1 1 —

7 S04-101 Access Panel — Standard Height — — 1

7 S04-096 Access Panel — Juvenile Height — — 1

* 8 132-031 Washer 1 1 1

* 9 147-019 Screw 1 1 1

Parts List — Floor Pedestal

* Access panel (Item 7) part numbers include the screw and washer.

** Upper Bracket Assembly includes Item 6.

Page 30

Terreon®Multi-Fount Washfountains Parts and Service Guide

30 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

1/30/2008

Wall Mount Pedestal — Assembly

Corner Tri Quad

Item Part No. Description Qty Qty Qty

1 S17-237 Pedestal Assy — 1 —

1 S17-280 Pedestal Assy — — 1

*2 160-169 Screw ¼-20 — 6 6

*3 P10-311 Screw 10-32 — 1 1

*4 146-055 Clip — 1 1

5 S04-102 Access Panel — Standard Height — 1 —

5 S04-107 Access Panel — Standard Height — — 1

**6 147-019 Screw — 1 1

**7 132-031 Washer — 1 1

Parts List — Wall Mount Pedestal

* Pedestal Assy (Item 1) part numbers include the screws and clip

** Access panel (Item 5) part numbers include the screw and washer

7

6

2

1

5

4

3

Page 31

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 31

1/30/2008

Arctic Chip S04-106AD Lannonstone S04-106S

Bluesky S04-106AL London Gray S04-106AP

Charcoal S04-106K Mountain Top S04-106AN

Cobblestone S04-106T Mystic Moss S04-106AG

Coffee Bean S04-106AJ Organic Taupe S04-106AR

Cornfield S04-106AK Peppered White S04-106E

Empire Gray S04-106 Riverstone S04-106AF

Graphite S04-106P Stardust S04-106AH

Hillside S04-106AM Summer Sage S04-106AE

Jade S04-106N White Sand S04-106W

Color Covers Color Cover

Part Numbers — MF2922 Corner-Fount

Sprayhead Cover Attaching Hardware

4

2

4

3

2

5

Corner Tri Quad

Item Part No. Description Qty Qty Qty

1 159-367 Anchor Bar — 1 —

2 330-144 Threaded Rod ¼-20 x 11" 2 2 2

3 161-076 Wing Nut ¼-20 2 2 2

4 113-907 Guide Tube 2 — —

5 113-966 Support Tube 1 — —

6 159-377 Anchor Bar — — 1

Parts List — Sprayhead Cover Attaching Hardware

2

3

1

2

3

6

Sprayhead Covers — Replacement Parts

Corner-Fount

Tri-Fount

Quadra-Fount

Contact Bradley for bowl part numbers.

Page 32

Terreo n®Multi-Fount Washfountains Parts and Service Guide

Sprayhead Cover — Replacement Parts ....Continued

Part Numbers — MF2933, MF2939

Tri-Fount

Color Covers Color Cover

Arctic Chip S04-104AD Lannonstone S04-104S

Bluesky S04-104AL London Gray S04-104AP

Charcoal S04-104K Mountain Top S04-104AN

Cobblestone S04-104T Mystic Moss S04-104AG

Coffee Bean S04-104AJ Organic Taupe S04-104AR

Cornfield S04-104AK Peppered White S04-104E

Empire Gray S04-104 Riverstone S04-104AF

Graphite S04-104P Stardust S04-104AH

Hillside S04-104AM Summer Sage S04-104AE

Jade S04-104N White Sand S04-104W

Part Numbers — MF2944, MF2949

Quadra-Fount

Color Covers Color Cover

Arctic Chip S04-105AD Lannonstone S04-105S

Bluesky S04-105AL London Gray S04-105AP

Charcoal S04-105K Mountain Top S04-105AN

Cobblestone S04-105T Mystic Moss S04-105AG

Coffee Bean S04-105AJ Organic Taupe S04-105AR

Cornfield S04-105AK Peppered White S04-105E

Empire Gray S04-105 Riverstone S04-105AF

Graphite S04-105P Stardust S04-105AH

Hillside S04-105AM Summer Sage S04-105AE

Jade S04-105N White Sand S04-105W

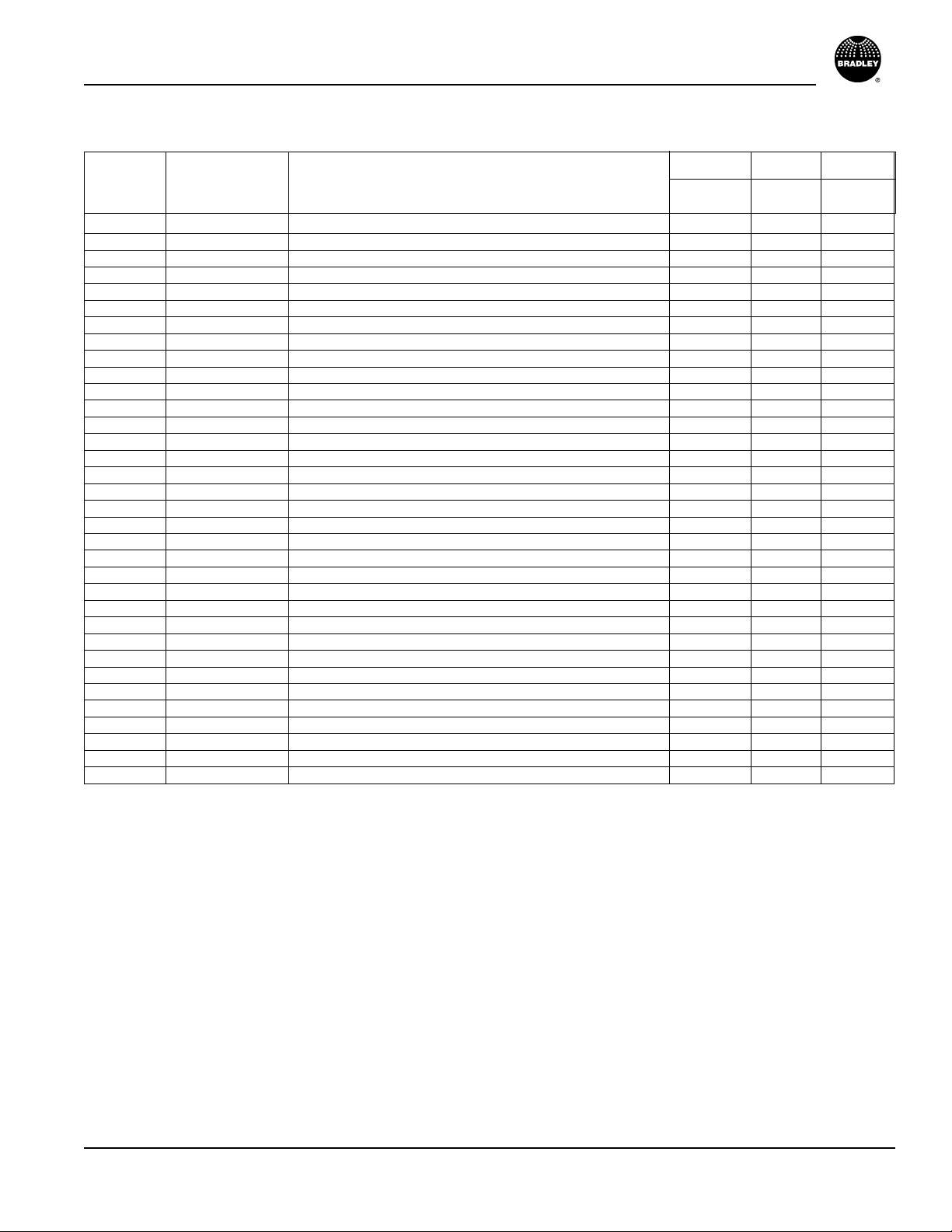

Pedestal Panels

Panel Part Numbers

Wall Wall Juvenile Juvenile Standard Standard

Mounted Mounted Hight Height Height Height

Color Left Panel Right Panel Left Panel Right Panel Left Panel Right Panel

Left Panels

Shown

Arctic Chip S15-123AD S15-124AD S15-121AD S15-122AD S15-119AD S15-120AD

Bluesky S15-123AL S15-124AL S15-121AL S15-122AL S15-119AL S15-120AL

Charcoal S15-123K S15-124K S15-121K S15-122K S15-119K S15-120K

Cobblestone S15-123T S15-124T S15-121T S15-122T S15-119T S15-120T

Coffee Bean S15-123AJ S15-124AJ S15-121AJ S15-122AJ S15-119AJ S15-120AJ

Cornfield S15-123AK S15-124AK S15-121AK S15-122AK S15-119AJ S15-120AK

Empire Gray S15-123 S15-124 S15-121 S15-122 S15-119 S15-120

Graphite S15-123P S15-124P S15-121P S15-122P S15-119P S15-120P

Hillside S15-123AM S15-124AM S15-121AM S15-122AM S15-119AM S15-120AM

Jade S15-123N S15-124N S15-121N S15-122N S15-119N S15-120N

Lannonstone S15-123S S15-124S S15-121S S15-122S S15-119S S15-120S

London Gray S15-123AP S15-124AP S15-121AP S15-122AP S15-119AP S15-120AP

Mountaintop S15-123AN S15-124AN S15-121AN S15-122AN S15-119AN S15-120AN

Mystic Moss S15-123AG S15-124AG S15-121AG S15-122AG S15-119AG S15-120AG

Organic Taupe S15-123AR S15-124AR S15-121AR S15-122AR S15-119AR S15-120AR

Peppered White S15-123E S15-124E S15-121E S15-122E S15-119E S15-120E

Riverstone S15-123AF S15-124AF S15-121AF S15-122AF S15-119AF S15-120AF

Stardust S15-123AH S15-124AH S15-121AH S15-122AH S15-119AH S15-120AH

Summer Sage S15-123AE S15-124AE S15-121AE S15-122AE S15-119AE S15-120AE

White Sand S15-123W S15-124W S15-121W S15-122W S15-119W S15-120W

S15-123

S15-121

S15-119

1/30/2008

noitaroproC yeldarB23 • 215-1447 Rev. F; EN 07-005A

Page 33

Parts and Service Guide Terreon

®

Multi-Fount Washfountains

Bradley Corporation • 215-1447 Rev. F; EN 07-005A 33

1/30/2008

Terreon®Care and Maintenance

Material Description

Constructed of Terreon®, a NAHB Certified densified solid

surface material composed of polyester resin. Terreon®is

resistant to chemicals, stains, burns and impact. Surface damage can be easily repaired with everyday cleansers or fine grit

abrasives.

Routine Cleaning

Clean daily or as often as conditions require using a standard

commercial or household cleaner such as Formula 409®or

Windex®.

Stubborn Stains

Remove tough stains with Ajax®, Comet®, or Soft-Scrub®and

a green Scotch-Brite®pad or lightly sand in a circular motion

with 240 grit wet/dry sandpaper. The finish can be renewed

with a maroon Scotch-Brite pad.

Special Situations for Material

Scratches

Remove scratches with a green Scotch-Brite®pad. The finish can then be renewed with a maroon Scotch-Brite®pad.

Hard Water Deposits

Remove hard water deposits with a mild solution of vinegar and water. Always rinse the unit thoroughly after

cleaning.

Restoring the Surface

Use Hope's®Solid Surface cleaner and polish to refresh and

protect the Terreon Solid Surface material.

Bradley recommends additional care and maintenance for the

darker colored Terreon, for complete instructions on this

additional maintenance see Bradley document #1505.

DO NOT USE STRONG ACID OR ALKALINE

CHEMICALS AND CLEANSERS TO CLEAN

TERREON. IF THESES CHEMICALS COME IN

CONTACT WITH THE TERREON SURFACE WIPE

THEM OFF IMMEDIATELY AND RINSE WITH

SOAPY WATER.

AVOID CONTACT WITH HARSH CHEMICALS

SUCH AS PAINT REMOVER, BLEACH, ACETONE,

ETC. . .

AVOID CONTACT WITH HOT PANS AND

OBJECTS.

Repair Kits

Terreon®repair kits are available, contact your Bradley representative or distributor for part numbers and pricing.

NOTE: Repair kits are made to order and have a shelf

life of 30 days.

Brand Names

Use of brand names is intended only to indicate a type of

cleaner. This does not constitute an endorsement, or does

the omission of any brand name cleaner imply it’s inadequacy. Many products named are regional in distribution, and

can be found in local supermarkets, department and hardware stores, or through your cleaning service.

It is emphasized that all products should be used in

strict accordance with package instructions.

Tip

When cleaning units equipped with infrared

(electronic eye) activation, it is helpful to turn off

the power to the unit or cover the windows to

prevent accidental activation. After the window is

covered, the water will run for approximately 30

seconds and then shut off.

Page 34

Bowl — Assembly

1

2

6

3

4

5

Corner Tri Quad

Item Part No. Description Qty Qty Qty

1 160-301 Bolt 2 2 2

2 142-002CG Washer 2 2 2

3 140-260 Bracket 2 2 2

4 200-015 Plate 2 2 2

5 142-002CH Lockwasher 2 2 2

6 161-065 Nut 2 2 2

Parts List — Bowl Assembly

34 Bradley Corporation • 215-1447 Rev. F; EN 07-005A

Terreon®Multi-Fount Washfountains Parts and Service Guide

Loading...

Loading...