Bradley Express SS Series, Express SS-2N, Express SS-IR, Express SS-STD, Express SS-2N-WH Installation Manual

...

Installation

SS-2N/IR/STD

SS-2N/IR-WH

SS-2N/IR/STD/LSD-2

SS-2N/IR-WH/LSD-2

Express® Lavatory System SS-Series

Express Lavatory Systems are ADA and TAS compliant

U.S. Pat. Nos. 5,611,093, D447,224

Other Patents Pending

Table of Contents

Pre-Installation Information .........................2

Components .......................................3

Supplies Required .................................4

Dimensions..................................... 4–5

Rough-Ins .........................................6

Installation .................................... 7–10

Sensor Assembly and Solenoid Valve Access ........11

Solenoid Valve Troubleshooting .....................12

Navigator

Stop Valve Troubleshooting ........................14

Cleaning and Maintenance for Terreon

Soap Dispenser Maintenance ......................15

®

Mixing Valve Troubleshooting ............13

®

.............14

215-1497 Rev. G; ECM 11-08-011

© 2011 Bradley Corporation

Page 1 of 15 10/19/11

P.O. Box 309, Menomonee Falls, WI USA 53052-0309

PHONE 800.BRADLEY (800.272.3539) FAX 262.251.5817

bradleycorp.com

SS-2N/IR/STD, SS-2N/IR/WH Installation

IMPORTANT!

Installation

Read this entire installation manual to ensure proper installation. When fi nished with the

installation, fi le this manual with the owner or maintenance department. Compliance and

conformity to local codes and ordinances is the responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for before discarding any

Packing List

•

•

packaging material. If any parts are missing, do not begin installation until you obtain the missing

•

S

I

H

T

E

ID

S

P

•

U

parts.

Make sure that all water supply lines have been fl ushed and then completely turned off before

beginning installation. Debris in supply lines can cause valves to malfunction.

Turn OFF electrical power to the electrical outlets, then unplug all electrical units prior to

installation. Electrical power MUST remain off until unit and optional water heater have been

plumbed. After installation is complete, turn on the water supply fi rst, then turn on the electrical

power.

Hardware supplied by installer must be appropriate for wall construction. Wall anchors must have

a minimum pull-out rating of 1,000 lbs. Follow appropriate dimensions for standard or juvenile

height based on confi guration and required rim height. Overtightening fasteners can damage the

Terreon® material. Use caution when tightening bowl and sprayhead fasteners.

Product warranties may be found in the “Products” section on our Web site at bradleycorp.com.

2 10/19/11 Bradley Corporation • 215-1497 Rev. G; ECM 11-08-011

Installation SS-2N/IR/STD, SS-2N/IR/WH

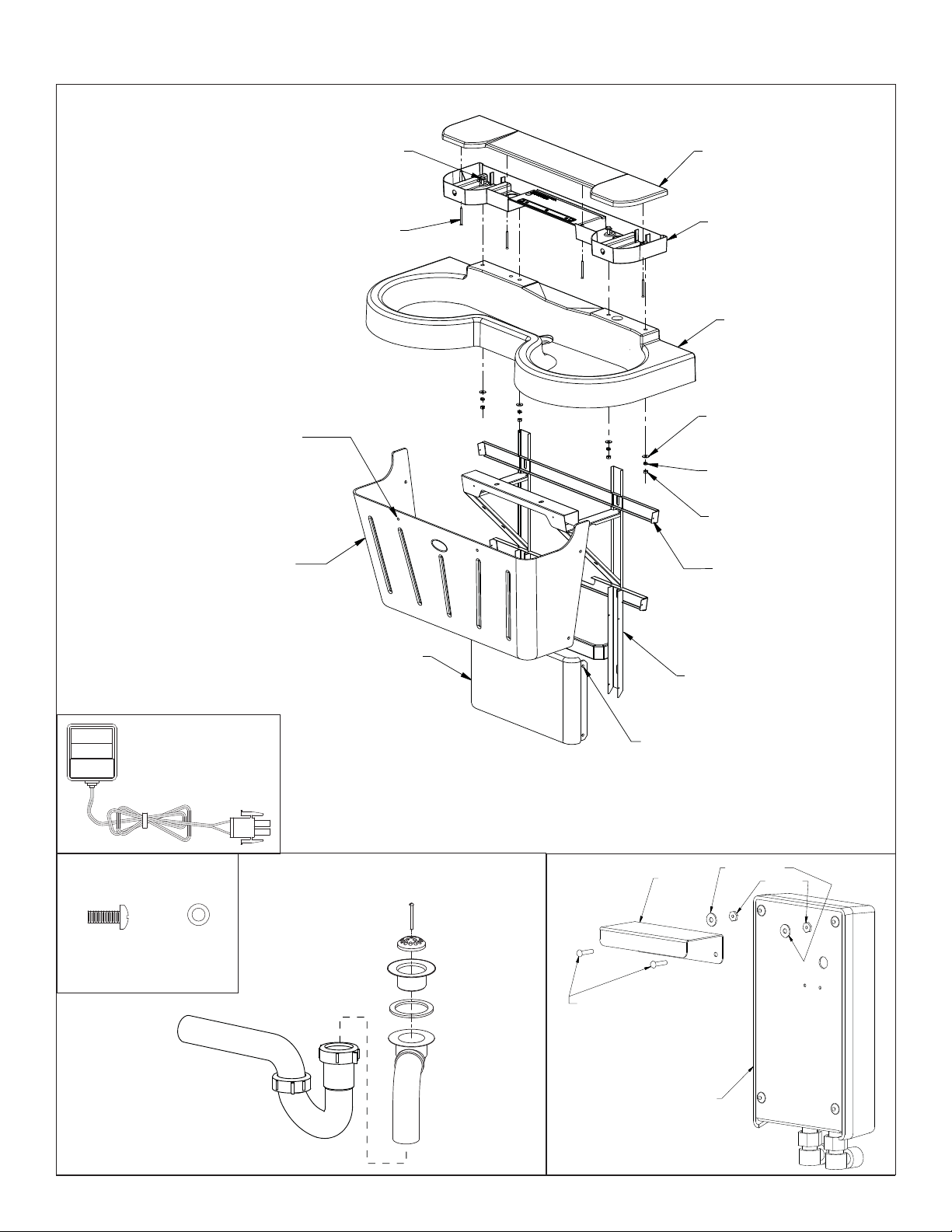

Components

PA NE L

FASTENERS

(160-450)

WASHERS

(142-002CA)

(6) PLACES

ACCESS PANEL

GRAY (186-1455)

PUTTY (186-1455A)

COAL (186-1455B)

BOLT 5/16-18

160-371

SCREW 10-24

160-386

SPRAYHEAD COVER

(PART NUMBER VARIES WITH

COLOR OF UNIT. CONTACT

YOUR LOCAL BRADLEY REP.

FOR ASSISTANCE).

SPRAYHEAD BODY

(PART NUMBER VARIES WITH

COLOR OF UNIT. CONTACT

YOUR LOCAL BRADLEY REP.

FOR ASSISTANCE).

BOWL

(PART NUMBER VARIES

WITH COLOR OF UNIT.

CONTACT YOUR LOCAL

BRADLEY REP. FOR

ASSISTANCE).

WASHER

142-002BJ

LOCKWASHER

142-002BK

NUT 5/16-18

161-036

MAIN FRAME

S17-325

CLASS II PLUG-IN

TRANSFORMER

BOWL MOUNTING

HARDWARE

1/4"-20 x 1/2"

PAN HEAD

SCREW (qty. 2)

(160-389)

P-TRAP (POLYPROPYLENE)

(CHROME-PLATED BRASS)

(142-002DB)

(269-1697)

OPTIONAL P-TRAP

(S29-094)

110/24 VAC

S83-152

1/4"-20

WASHER

(qty. 2)

SCUFF BASE PANEL

GRAY (185-034)

PUTTY (185-034A)

COAL (185-034B)

DRAIN

ASSEMBLY

#8-32 SCREW

(160-319)

DRAIN PLUG

(P16-072)

STRAINER

(P16-075)

1/8" RUBBER

WASHER

(125-001DP)

TAILPIECE

(129-056)

SCUFF PANEL FASTENERS (160-450)

WASHERS (142-002CA)

(4) PLACES

#8-32 x 3/4"

ROUND HEAD

MACHINE SCREW

(160-276)

OPTIONAL WATER HEATER

EX95TMLB, 240/208 volts

EX100TMLB, 277 volts

SCUFF FRAME S17-326

USED WITH STANDARD

HEIGHT FRAME ONLY

BRACKET

(140-950)

(269-1767)

(269-1768)

#8 WASHER

#8 NUT

Bradley Corporation • 215-1497 Rev. G; ECM 11-08-011 10/19/11 3

SS-2N/IR/STD, SS-2N/IR/WH Installation

Supplies Required:

• (6) ³⁄₈" wall anchors, bolts and 1" min. O.D. washers to mount main frame and bowl to wall (minimum pull-out rating of 1,000 lbs.)

• STD. HEIGHT ONLY: (2) ³⁄₈" wall anchors, bolts and 1" min. O.D. washers to mount scuff base to wall

• ½" nominal copper tubing for hot and cold supplies and 1½" NPT drain piping

• 110 volt GFCI protected electrical outlet for 1110/24 VAC plug-in transformer (supplied)

• OPTIONAL: 240/208-volt or 277-volt electrical box for electric tankless water heater

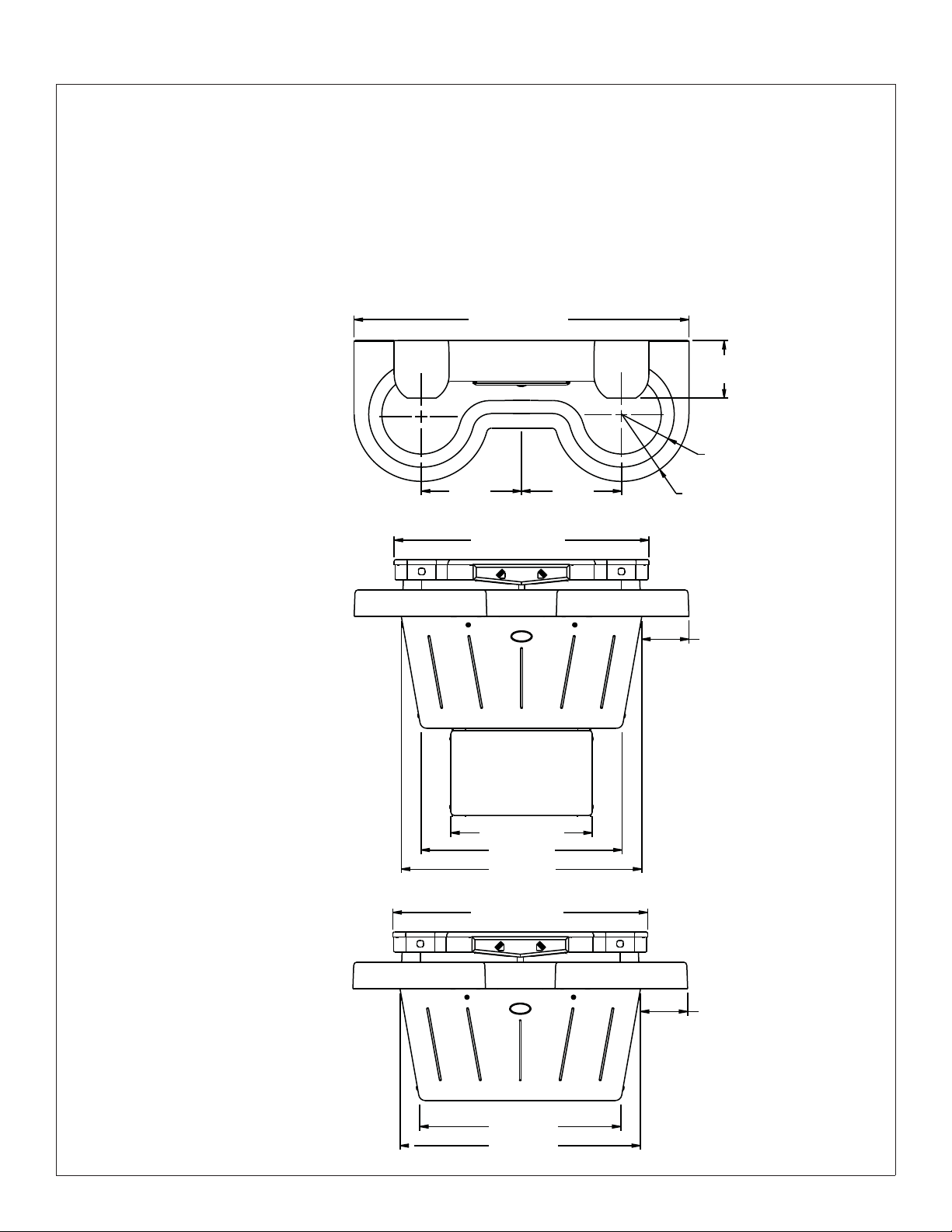

Dimensions - Front and Top Views

50" (1270mm)

Top View

85⁄8

" (219mm)

8" (203mm) Radius

Front View

Standard Frame

Front View

Wall-Hung Frame

15"

(381mm)

38¼" (972mm)

21¼" (540mm)

30" (762mm)

36" (914mm)

38¼" (972mm)

15"

(381mm)

10" (254mm) Radius

7" (178mm)

7" (178mm)

30" (762mm)

36" (914mm)

4 10/19/11 Bradley Corporation • 215-1497 Rev. G; ECM 11-08-011

Installation SS-2N/IR/STD, SS-2N/IR/WH

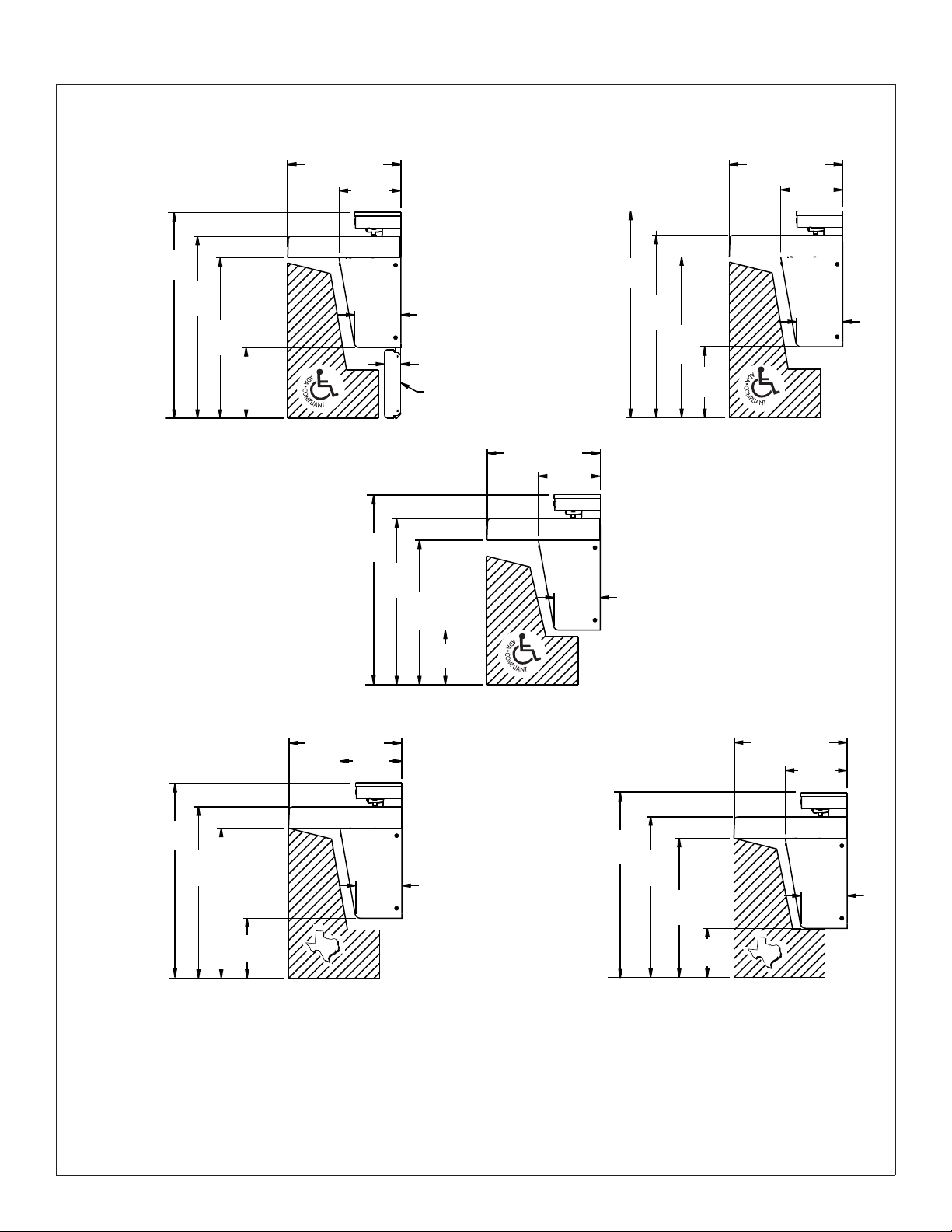

Dimensions - Side Views

Standard

Height

38½"

(978mm)

34"

(864mm)

30"

(762mm)

13¼"

(311mm)

Wall Hung Mounted

at Juvenile Height

Ages: 6 through 12

211⁄8" (537mm)

11½"

(292mm)

(219mm)

(902mm)

8

35½"

5

⁄8"

31"

(787mm)

3" (76mm)

Standard Height Only

27"

(686mm)

Scuff Base on

Wall Hung Mounted

at Standard Height

(978mm)

1

21

⁄8" (537mm)

11½"

(292mm)

5

⁄8"

8

(219mm)

38½"

34"

(864mm)

30"

(762mm)

13¼"

(311mm)

1

⁄8" (537mm)

21

11½"

(292mm)

8

(219mm)

5

⁄8"

Wall Hung Mounted

at TAS Height

Grades: 6

through

8 or 9

36½"

(927mm)

32"

(813mm)

(711mm)

28"

11¼"

(286mm)

211⁄8" (537mm)

11½"

(292mm)

(219mm)

TAS

85⁄8"

10¼"

(260mm)

Wall Hung Mounted

at TAS Height

Grades: Pre-K

through 5 or 6

34½"

(876mm)

30"

(762mm)

26"

(660mm)

9¼"

(235mm)

211⁄8" (537mm)

(292mm)

TAS

11½"

85⁄8"

(219mm)

Bradley Corporation • 215-1497 Rev. G; ECM 11-08-011 10/19/11 5

Loading...

Loading...