Bradley Express MG Series, Express MG-3/AST4 Installation Manual

Installation

MG-3/AST4

Express® Lavatory

System - MG Series

with Pushbutton

Air Valve

Table of Contents

Pre-Installation Information ...................2

Dimensions..................................3

Supplies Required ........................... 3

Rough-Ins ...................................4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–8

Components . . . . . . . . . . . . . . . . . . . . . . . . . .9–10

Cleaning and Maintenance . . . . . . . . . . . . .11–12

Check Valve Troubleshooting . . . . . . . . . . . . . . .12

Metering Air Valve Troubleshooting . . . . . . . . . .13

Thermostatic Mixing Valve Troubleshooting . . . .14

A

D

A

•

C

O

M

P

L

T

I

A

N

215-1323 Rev. P; EN 07-814

© 2007 Bradley Corporation

Page 1 of 14 12/10/07

P.O. Box 309, Menomonee Falls, WI 53052-0309

Phone: 1-800-BRADLEY Fax: 262-253-4161

www.bradleycorp.com

MG-3/AST4 Installation

IMPORTANT!

Installation

Read this entire installation manual to ensure proper installation. For optional

soap dispenser, refer to Installation Instructions for Express® Lavatory System

MG-Series document 215-1585. When fi nished with the installation, fi le this manual

with the owner or maintenance department. Compliance and conformity to local

codes and ordinances is the responsibility of the installer.

Packing List

Separate parts from packaging and make sure all parts are accounted for

•

•

•

IS

H

T

E

D

I

S

P

U

before discarding any packaging material. If any parts are missing, do not begin

•

installation until you obtain the missing parts.

Make sure that all water supply lines have been fl ushed and then completely

turned off before beginning installation. Debris in supply lines can cause valves to

malfunction.

Turn OFF electrical power to the electrical outlets, then unplug all electrical

units prior to installation. Electrical power MUST remain off until installation is

completed. After installation is complete, turn on the water supply fi rst, then turn

on the electrical power.

Hardware supplied by installer must be appropriate for wall construction. Wall

anchors used must have a minimum pull-out rating of 1,000 lbs. Overtightening

fasteners can damage the Terreon

®

material. Use caution when tightening bowl and

sprayhead fasteners.

Product warranties may be found under “Product Information” on our web site at

www.bradleycorp.com.

2 12/10/07 Bradley Corporation • 215-1323 Rev. P; EN 07-814

Installation MG-3/AST4

A

D

A

•

C

O

M

P

L

I

A

N

T

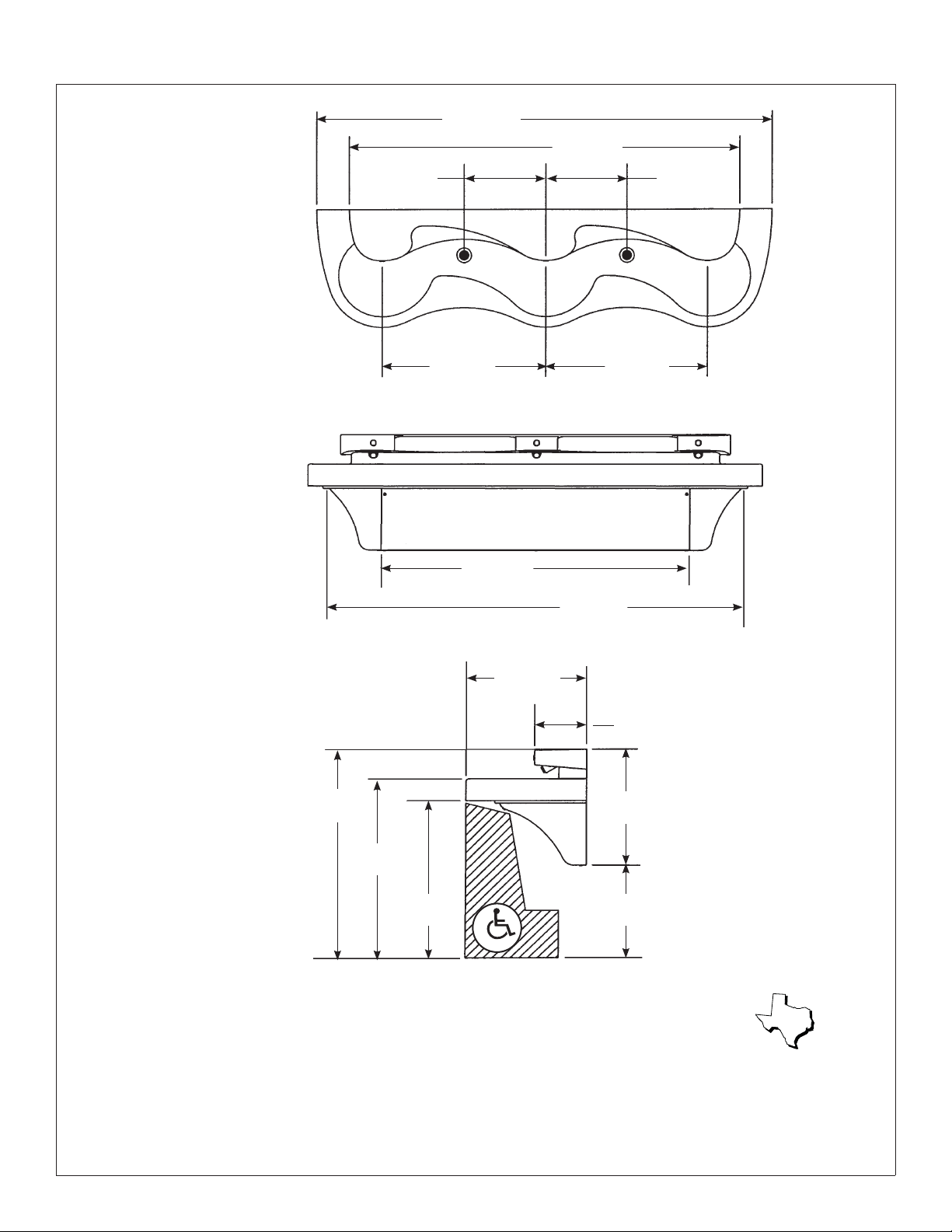

Dimensions

15"

(381mm)

(762mm)

84"

(2134mm)

30"

72"

(1829mm)

15"

(381mm)

30"

(762mm)

57"

(1445mm)

77"

(1956mm

22"

(559mm)

9-1/2"

(241mm)

39"

(991mm)*

21-1/2"

(546mm)

33-1/2"

(851mm)*

29-1/2"

(749mm)*

17-1/2"

(445mm)*

* Subtract 4" from all vertical dimensions for Juvenile Height Mounting.

Subtract 3.5" from all vertical dimensions for TAS Juvenile Height Mounting (grades Pre-K through 5 or 6).

Subtract 1.5" from all vertical dimensions for TAS Juvenile Height Mounting (grades 6 through 8 or 9).

TAS

Supplies Required:

• (8) 3/8" wall anchors, bolts and 1" min. O.D. washers to mount main frame and bowl to wall (minimum pull-out rating of

1,000 lbs.)

• 1/2" NPT hot and cold supply piping and 1-1/2" NPT drain piping

• Optional: 240/208 volt or 277 volt electrical box for optional electrical tankless water heater

Bradley Corporation • 215-1323 Rev. P; EN 07-814 12/10/07 3

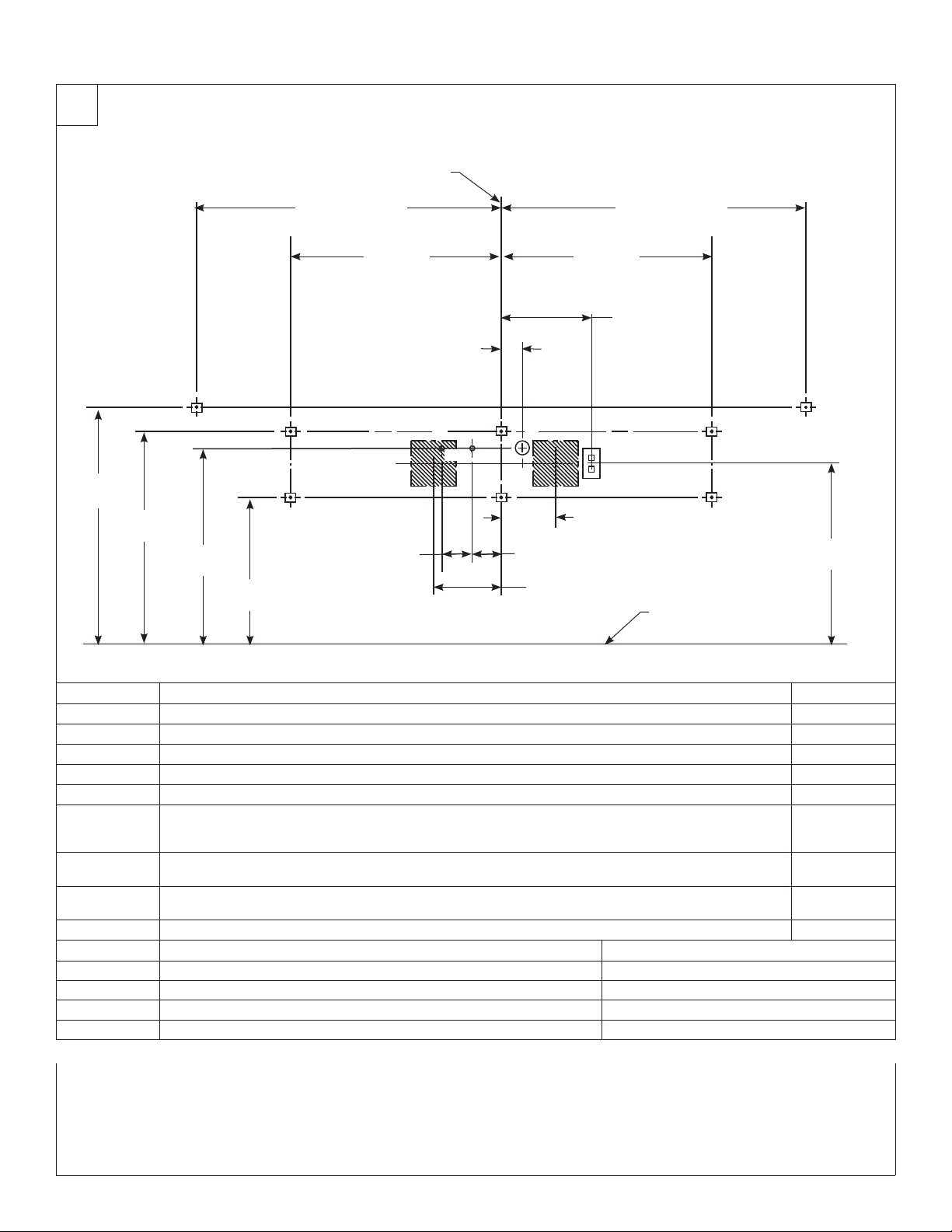

MG-3/AST4 Installation

1

Rough-Ins

CENTERLINE OF FIXTURE

40-1/2" (1029mm) 40-1/2" (1029mm)

APPROX. DIMENSION

APPROX. DIMENSION

31-1/2"

(800mm)*

(718mm)*

28-1/4"

B, E

26"

(660mm)*

19-1/2"

(496mm)*

28"

(711mm)

2-3/4"

(70mm)

C2

C1

A

4"

(102mm)

D

FG

7-1/4"

(184mm)

4"

(102mm)

9"

(229mm)

28"

(711mm)

(305mm)

H

12"

B, E

AAA

AA

(610mm)*

FLOOR

CODE DESCRIPTION QTY.

A

B

C1

C2

D

E

F

G

H

3/8" Wall Anchors with a minimum pull-out force of 1,000 lbs. for Frame

3/8" Wall Anchors with a minimum pull-out force of 1,000 lbs. for Bowl

1/2" NPT Hot Supply, stub out 2" from wall

1/2" NPT Cold or Tempered Supply, stub out 2" from wall

1-1/2" NPT Drain, stub out 2" from wall

On the bowl back, measure the distance between the 3/4" bowl mounting holes. Divide this measurement

in half. Measure and mark this dimension on the wall to the left and the right of the centerline. Install two

3/8" wall anchors with a minimum pull-out rating of 1,000 lbs. (supplied by installer) at locations marked.

Water Heater Option #1: Rough in appropriate electrical supply per local code (recommended location for

240/208V electrical box [6"L x 3"W x 6"H])

Water Heater Option #2: Rough in appropriate electrical supply per local code (recommended location for

240/208V electrical box [6"L x 3"W x 6"H])

110V GFCI Protected Electrical Outlet, I.R. and touch time only

RIM HEIGHT * VERTICAL HEIGHT ADJUSTMENTS FIXTURE STYLE

33-1/2" None Standard Height

29-1/2" Subtract 4" Juvenile Height

32" Subtract 1-1/2" TAS, Grades 6 through 8 or 9

30" Subtract 3-1/2" TAS, Pre-K through 5 or 6

24"

6

2

1

1

1

2

1

1

1

NOTE: The Express® Lavatory System with Pushbutton Air Valve (model MG-3/AST4) must have a rim height no higher

than 34" above finished floor to be compliant with Americans with Disabilities Act (ADA). When mounted at

33-1/2" rim height, the MG-3/AST4 Express® meets ADA, ANSI and UFAS requirements for barrier-free clearances,

reaches and controls. Always check local codes and ordinances for compliance.

4 12/10/07 Bradley Corporation • 215-1323 Rev. P; EN 07-814

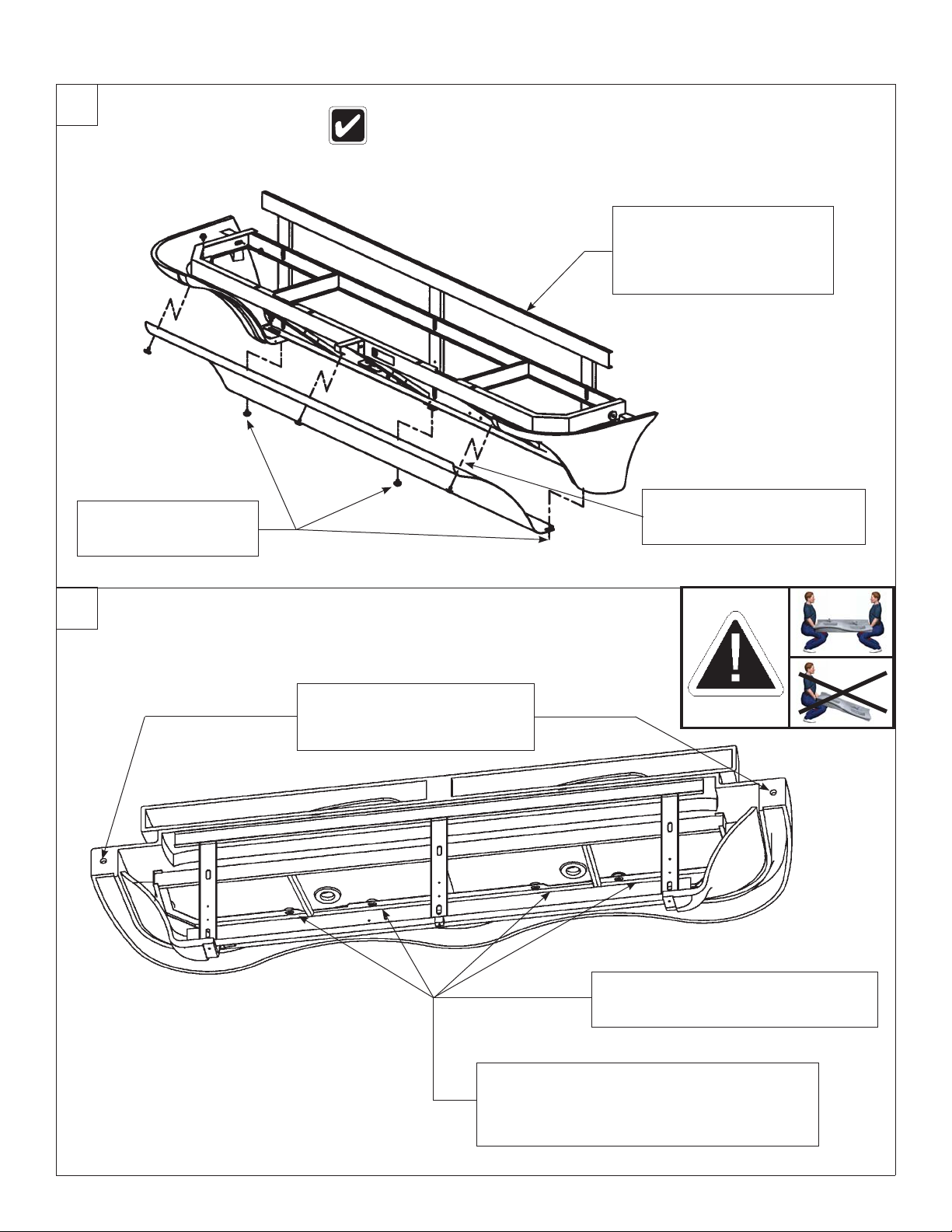

Installation MG-3/AST4

2

Mount the Frame

Anchoring the frame to a wall that is not flat may cause the frame to bend,

making it difficult to reinstall the access panels. If necessary, use shims to

compensate for wall distortion.

Once you have positioned

the frame such that it is level

and flat against the wall or

shimmed, use the 3/8" bolts

C

and washers (6 places) to

mount the frame to the wall.

Loosen, but do not

remove the bottom

A

access panel screws.

3

Install the Bowl

Secure the bowl to the wall

anchors with two 3/8" bolts and

B

washers. Do not overtighten.

Remove the top access panel

screws and washers and

B

remove the access panel.

Attach the bowl to the frame using the

four 1/4-20 x 1/2" pan-head screws and

A

washers. Do not tighten screws.

Tighten the pan-head screws. Do not overtighten.

If necessary, adjust the sprayhead body to fit

closely to the wall by adjusting the sprayhead

C

mounting bolts. Refer to the components

illustration for bolt locations.

Bradley Corporation • 215-1323 Rev. P; EN 07-814 12/10/07 5

MG-3/AST4 Installation

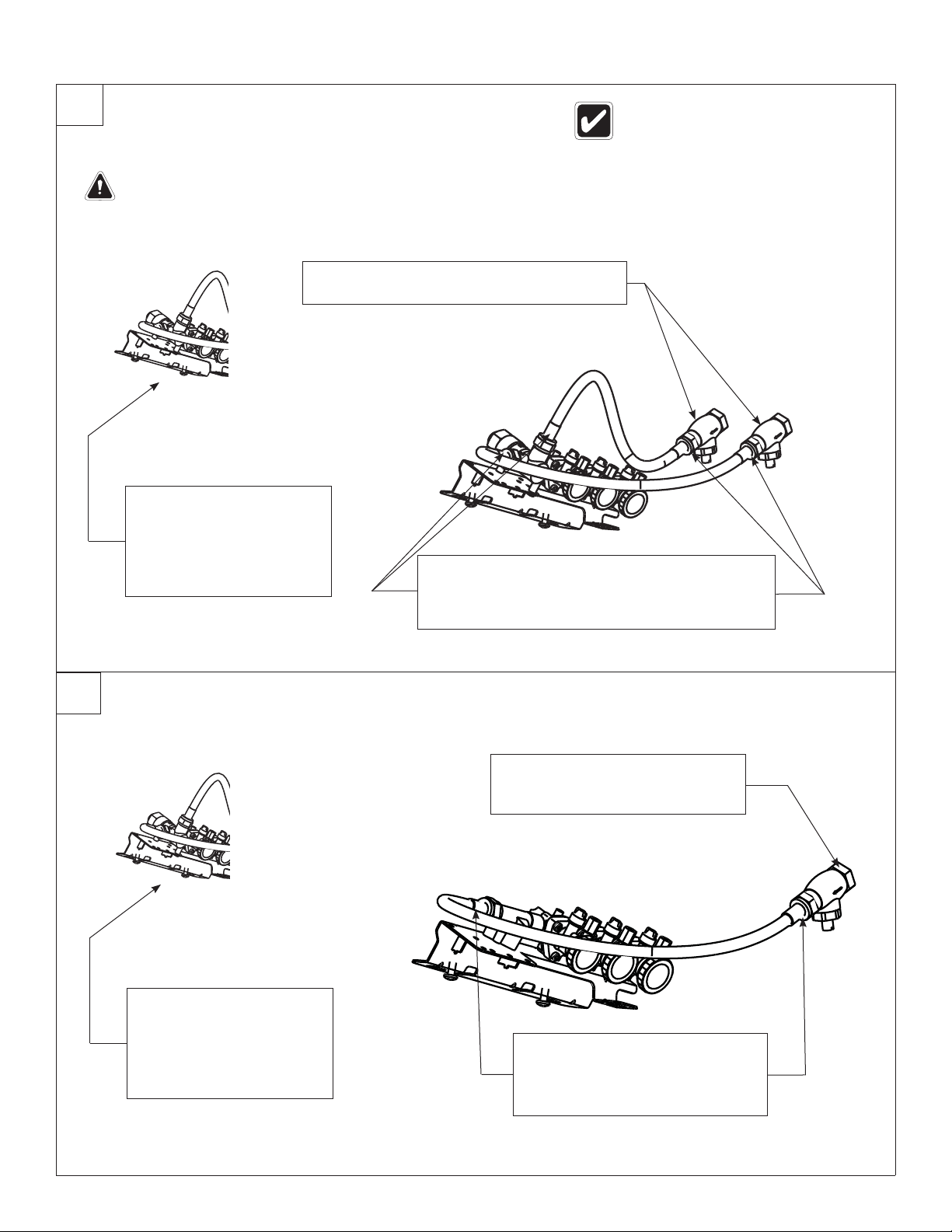

4a

Connect the Supply — Hot and Cold Supply

WARNING:

The Vernatherm™ valve is NOT factory-preset. Upon installation, the valve temperature must be checked and

adjusted to assure delivery of safe water temperature. Water in excess of 110°F (43°C) may cause scalding.

Using a thread sealer, thread the stop/check

B

valves onto the hot and cold wall stub-outs.

Loosen but do not remove

the two mounting screws

holding the valve bracket

to the frame.

A

Slide the valve bracket up

and lift it from the frame.

Connect one end of each hose to the Vernatherm™

valve (one on the hot side, one on the cold side).

C

Connect the other swivel end to the stop/check

valves.

The letter “H” on the Vernatherm™ Mixing

Valve indicates hot water supply inlet.

4b

Connect the Supply — Single Tempered Supply

Loosen but do not remove

the two mounting screws

holding the valve bracket

to the frame.

A

Slide the valve bracket up

and lift it from the frame.

Using a thread sealer, thread

the stop/check valve onto the

B

tempered wall stub-out.

Connect one end of flexible hose

to the tempered line adapter.

C

Connect the other swivel end to

the stop/check valve.

6 12/10/07 Bradley Corporation • 215-1323 Rev. P; EN 07-814

Installation MG-3/AST4

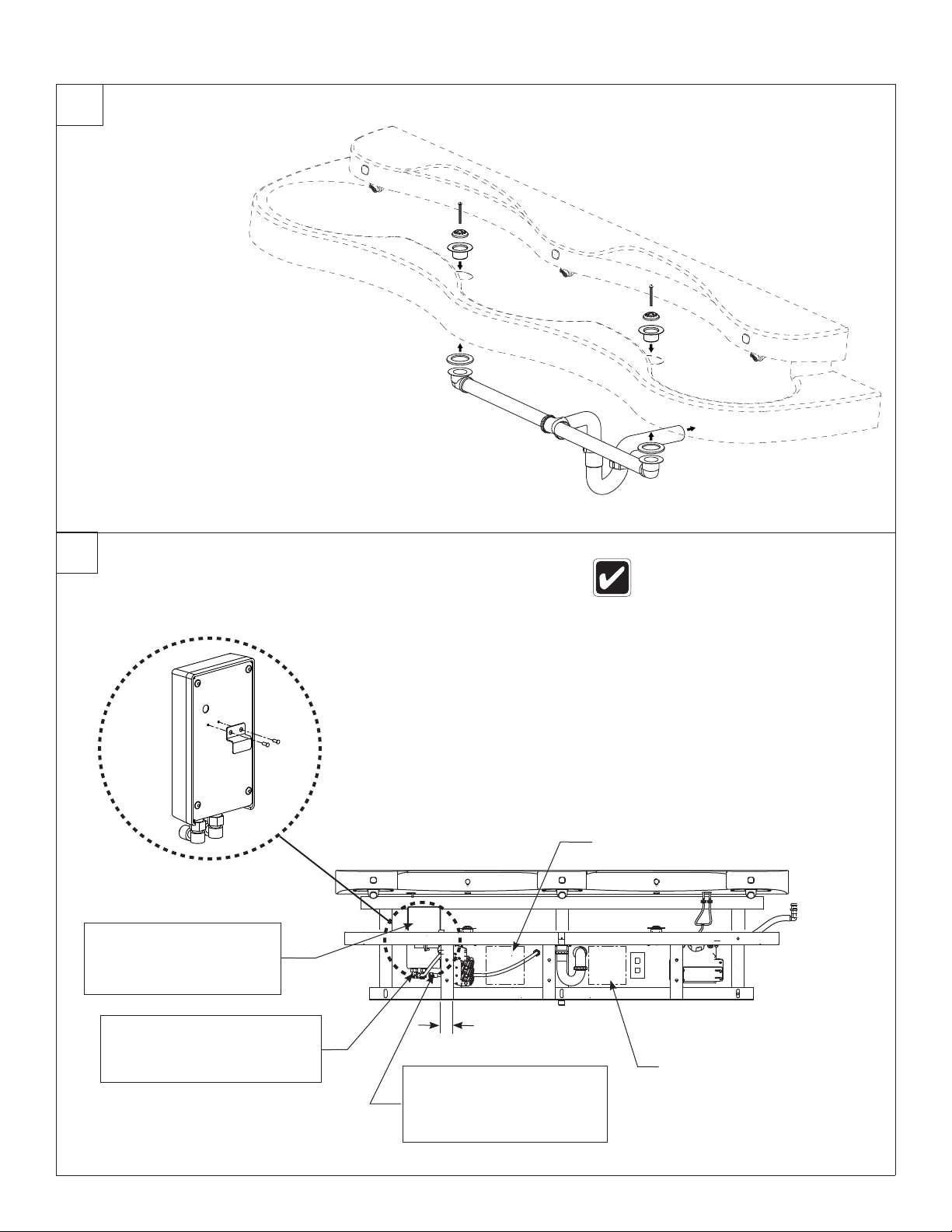

5

6

Install the Drains

Connect Optional Electric Tankless Water Heater

To Drain

Stub-Out

240/208 or 277 voltage is required for

electric tankless water heater. Refer

to the installation manual provided

with the water heater for further

installation information.

Optional Electrical Box location

Hang water heater on

rear frame member to

A

the right of the vertical

frame member.

Connect the 1/2" flexible

hose from the hot water

C

outlet to the supply inlet on

the valve assembly.

B

2" (51mm)

REF. ONLY

Connect the 1/2" flexible

hose from the cold water

supply stub-out to the hot

water heater inlet.

Recommended Electrical

Box location

Bradley Corporation • 215-1323 Rev. P; EN 07-814 12/10/07 7

MG-3/AST4 Installation

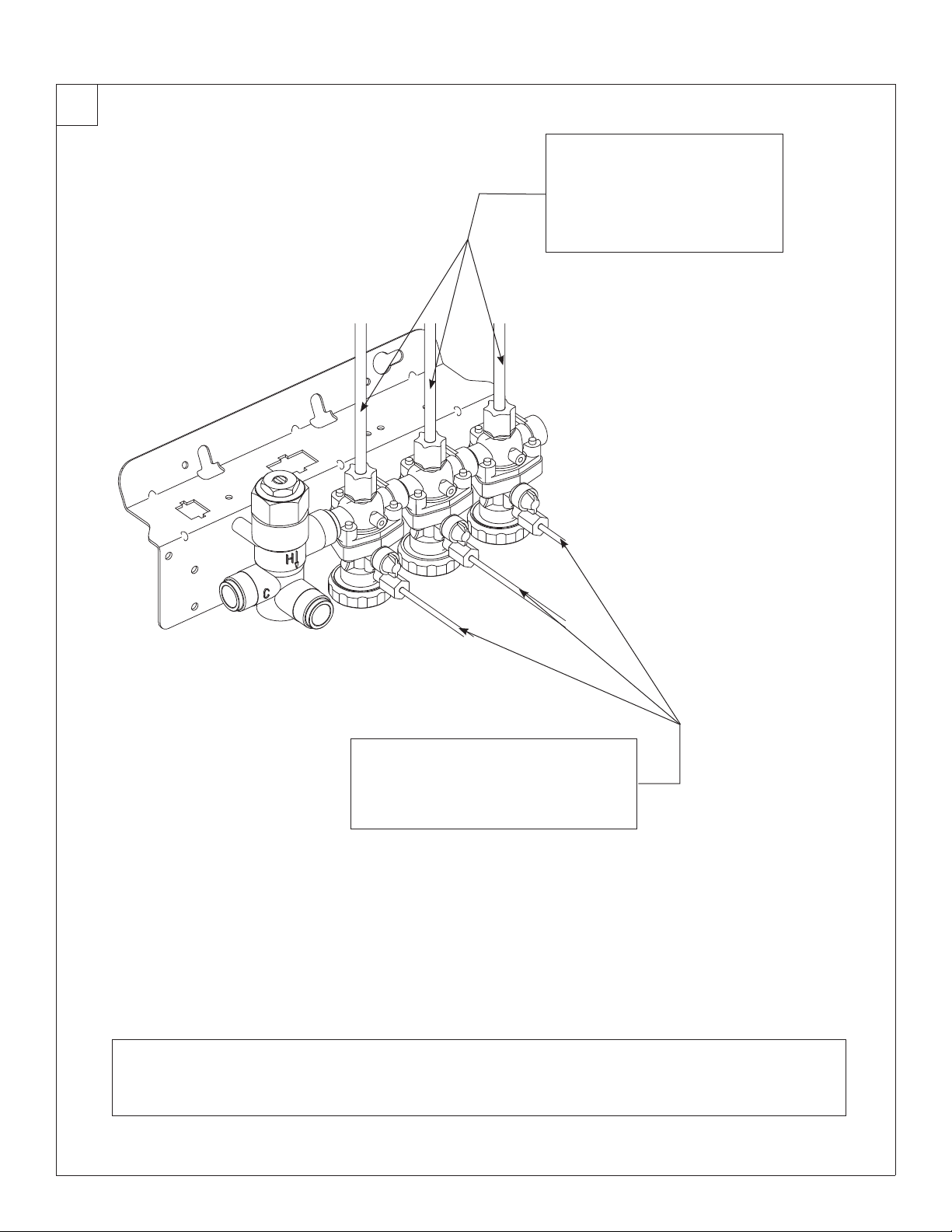

7

Connect Supply Tubing

Loosen the compression nuts.

Push the sprayhead supply

tubes firmly into the tube

connectors until they are fully

A

seated.

Tighten the compression nuts

by hand.

Loosen the compression nuts.

Push the matching color 1/8" tubes

firmly into the tube connectors until

B

they are fully seated.

Tighten the compression nuts by hand.

Reinstall the bracket. Turn on the water supply to the Express® and check for leaks.

Push the operating buttons of each station until all the air is purged from the lines and water is flowing smoothly.

C

Reinstall the ccess panel.

8 12/10/07 Bradley Corporation • 215-1323 Rev. P; EN 07-814

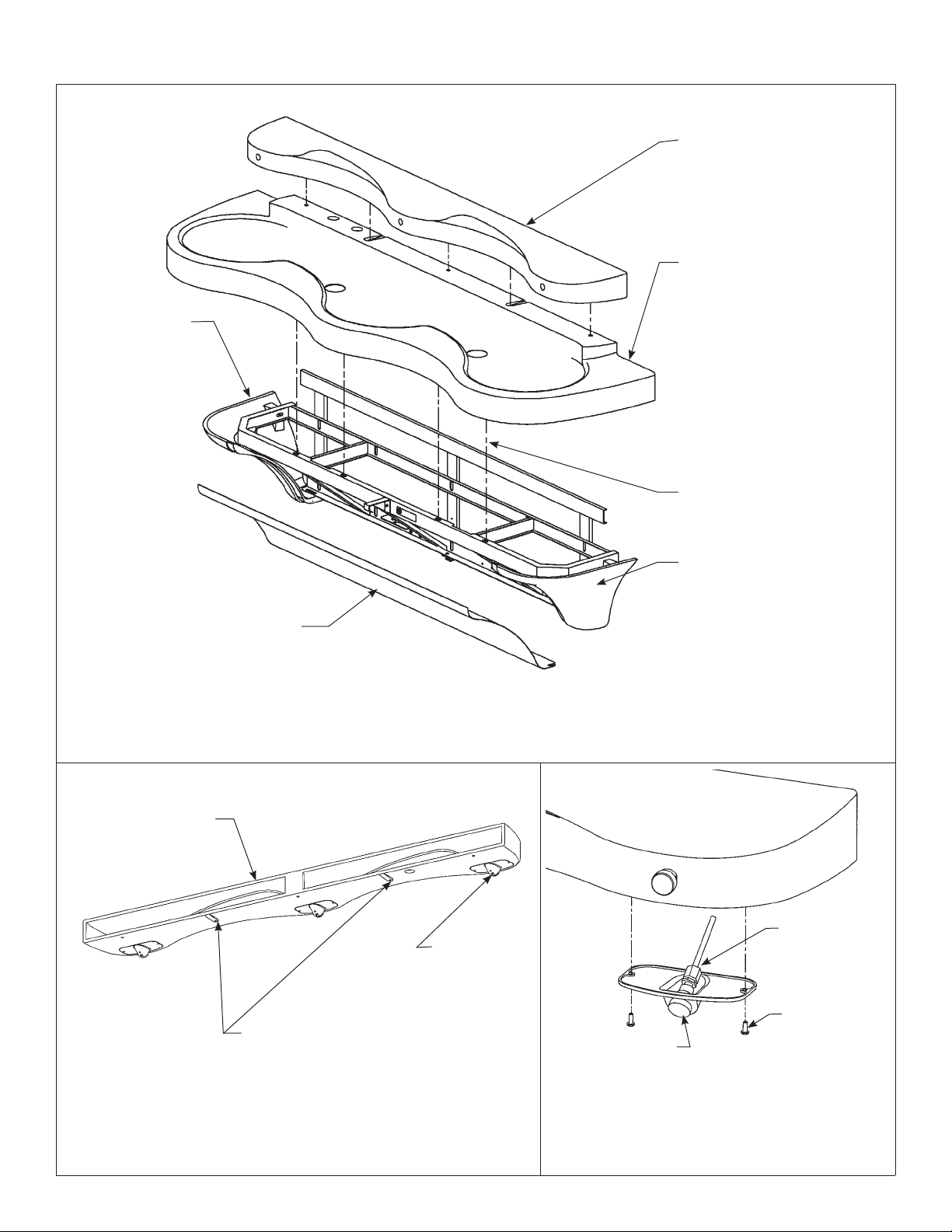

Installation MG-3/AST4

Components

SPRAYHEAD BODY

(PART NUMBER VARIES WITH

COLOR OF UNIT. CONTACT

YOUR LOCAL BRADLEY REP.

FOR ASSISTANCE).

BOWL

(PART NUMBER VARIES WITH

END CAP (LEFT)

(PART NUMBER

VARIES WITH

COLOR OF UNIT.

CONTACT YOUR

LOCAL BRADLEY

REP. FOR

ASSISTANCE).

COLOR OF UNIT. CONTACT

YOUR LOCAL BRADLEY REP.

FOR ASSISTANCE).

SPRAYHEAD

MOUNTING BOLTS (3)

STAINLESS STEEL

ACCESS PANEL

SPRAYHEAD BODY

186-1263.

MOUNTING LOCATION

TO BOWL (5) PLACES

SPRAYHEAD

AERATOR

ASSEMBLY

S05-166

HOUSING-FLOW

CONTROL S05-142

END CAP (RIGHT)

(PART NUMBER VARIES WITH

COLOR OF UNIT. CONTACT

YOUR LOCAL BRADLEY REP.

FOR ASSISTANCE).

CONNECTOR 1/4"

TUBE 145-089

SCREW ALLEN

SOCKET #10-24

160-138

Bradley Corporation • 215-1323 Rev. P; EN 07-814 12/10/07 9

Loading...

Loading...