Bradley CRS Series, Express Crescent CRS-2/IR/LSD, Express Crescent CRS-3/IRS/LSD Installation Manual

Page 1

CRS-3/IR/LSD

Installation

CRS-2/IR, CRS-3/IR

Express® Crescent® Lavatory System

CRS-Series

Complies with Texas

Accessibility Standards (TAS)

for Juvenile Height applications.

Table of Contents

Dimensions ........................................................................ 2

Rough-Ins .......................................................................3-4

Supplies Required .............................................................5

Mount Bowl to Wall ............................................................ 5

Install Drain Spud ..............................................................5

Connect Supply .................................................................6

Electrical and Supply Connections .................................... 6

Adjust the temperature ......................................................7

Install Top Cover ................................................................7

Cleaning and Maintenance ................................................ 8

Solenoid Valve Troubleshooting and Repair Parts .............9

Navigator

®

Valve Troubleshooting and Repair Parts ........ 10

CRS-2/IR/LSD

3-station unit is shown throughout. 2-station

is similar.

For soap system installation, refer to

installation manual 215-1583.

WARNING

Flush all the water supply lines before making con nec tions. Debris in supply lines will cause the valves to

malfunction.

Hardware supplied by installer must be appropriate for wall construction. Wall anchors used must have a

minimum pull-out rating of 1,000 lbs.

IMPORTANT

Read this entire installation manual to ensure proper installation, then file these instructions with the owner

or maintenance department.

Product warranties may be found under “Products” on our web site at www.bradleycorp.com.

215-1330 Rev. N; ECN 16-08-022

© 2016 Bradley

Page 1 of 10 11/3/2016

Menomonee Falls, WI 53052 USA

800 BRADLEY (800 272 3539)

P.O. Box 309

+1 262 251 6000

bradleycorp.com

Page 2

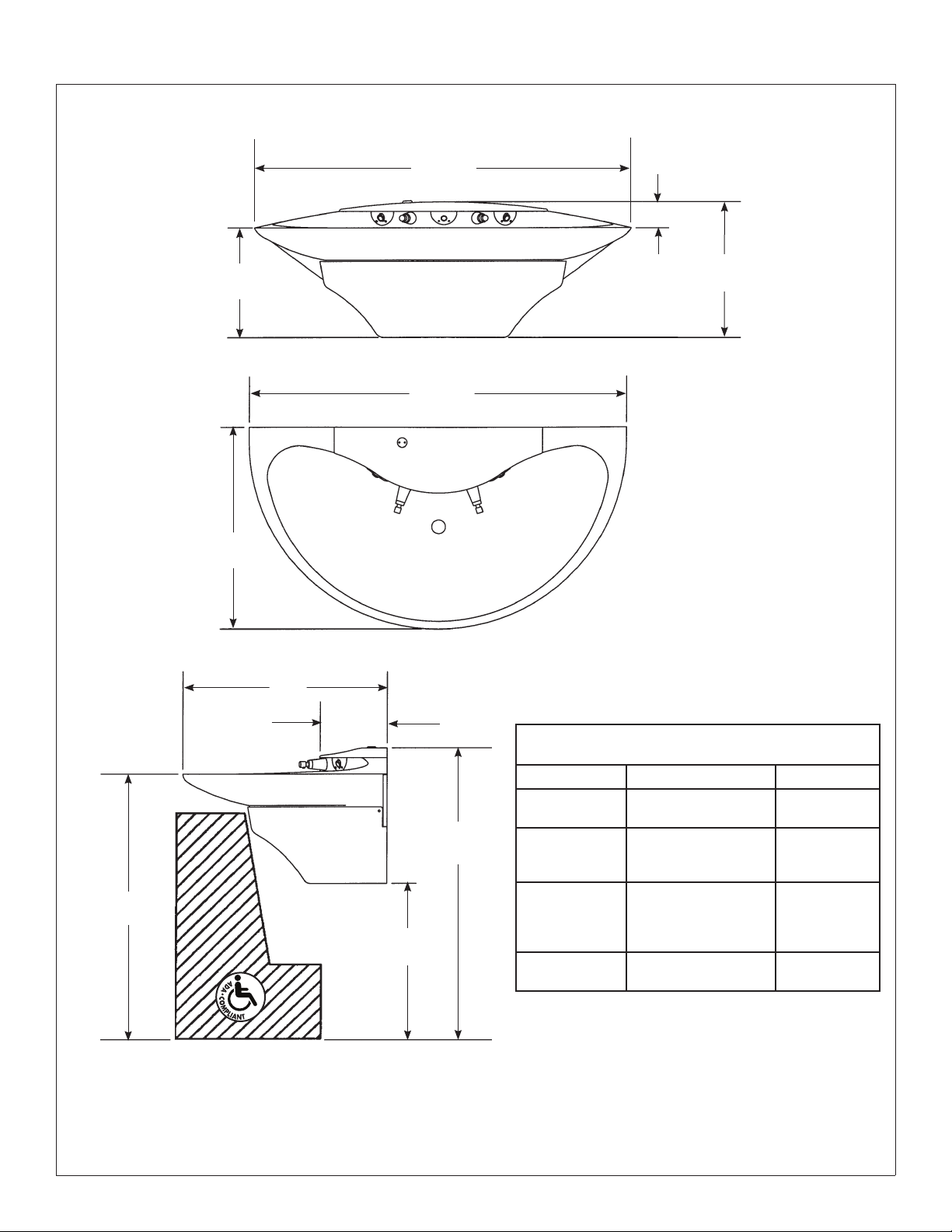

CRS-2/IR, CRS-3/IR Installation

Express® Crescent® Lavatory System Dimensions

14"

(356)

26"

(660)

48"

(1219)

48"

(1219)

33⁄8"

(86)

(mm)

173⁄8"

(441)

*34"

(864)

26"

(660)

8-1/2"

(216)

*20"

(508)

*37-3⁄8"

(949)

*Adjustments to Vertical Dimensions

for Various Rim Heights

Rim Height Application Adjustment

34" Adult Height ADA,

TAS Adult Height

32" TAS Ages 11 thru 14

or 15, Grades 6

thru 8 or 9

30" TAS Ages 4 thru 10 or

11, Grades Pre-K thru

5 or 6 & Proposed

Juvenile Height ADA

24" Preschool (required

by some local codes)

None, as

shown

Subtract 2"

Subtract 4"

Subtract 10"

2 11/3/2016 Bradley • 215-1330 Rev. N; ECN 16-08-022

Page 3

Installation CRS-2/IR, CRS-3/IR

Rough-ins

WARNING Flush all the water supply lines before making connections. Debris in

supply lines will cause valves to malfunction.

Standard Height Mounting

Rim

Height

34"

(864)*

25-5/8"

(651)*

Trap Cover

(Optional)

1/2" NPT Drain

Stub Out 2" (51)

Centerline

of Fixture

(mm)

2"

(51)

6-1/2"

(165)

23-3/4"

(603)*

1/2" Nominal Copper

Tubing Hot and Cold

Supplies Stub Out 2" (51)

Floor

*Adjustments to Vertical Dimensions for Various Rim Heights

Rim Height Application Adjustment

34" Adult Height ADA, TAS Adult Height None, as shown

32" TAS Ages 11 thru 14 or 15, Grades 6 thru 8 or 9 Subtract 2"

30" TAS Ages 4 thru 10 or 11, Grades Pre-K thru 5 or 6 & Proposed Juvenile Height ADA Subtract 4"

24" Preschool (required by some local codes) Subtract 10"

Bradley • 215-1330 Rev. N; ECN 16-08-022 11/3/2016 3

Page 4

CRS-2/IR, CRS-3/IR Installation

Rough-ins cont’d.

Standard Height Mounting

10"

(254)

33-1/2"

(851)

31"

(788)

22-3/4"

(578)*

3-3/4"

(45)

(4) 1/4" Wall

Anchors for

Optional

Soap System

Optional 1/4"

Wall Anchor For

Trap Cover (Use

Trap Cover For

Template)

13-1/2"

(343)

7-11⁄16"

(195)

10"

(254)

(mm)

3⁄8" Wall Anchors (6) Places, Min.

Pull-Out Force 1,000 lbs. Per Anchor.

10"

(254)

13-1/2"

(343)

10-1/2"

(267)

110 Volt GFCI Protected

Electrical Outlet

(Recommended Location)

(Check Local Electrical

Codes Before Roughing In)

C

L

10"

(254)

35"

(889)*

27-1/4"

(692)

Floor

*Adjustments to Vertical Dimensions for Various Rim Heights

Rim Height Application Adjustment

34" Adult Height ADA, TAS Adult Height None, as shown

32" TAS Ages 11 thru 14 or 15, Grades 6 thru 8 or 9 Subtract 2"

30" TAS Ages 4 thru 10 or 11, Grades Pre-K thru 5 or 6 & Proposed Juvenile Height ADA Subtract 4"

24" Preschool (required by some local codes) Subtract 10"

4 11/3/2016 Bradley • 215-1330 Rev. N; ECN 16-08-022

Page 5

Installation CRS-2/IR, CRS-3/IR

Supplies required for installation

• (6) 3/8" wall anchors, bolts and washers to mount bowl to wall (min. pull-out force of 1,000 lbs.)

• 1/2" nominal copper tubing hot and cold or tempered supply piping

• 1-1/2" drain piping and P-Trap (available from Bradley, p/n 269-1697)

• 110 VAC power source for 110/12VDC regulated wall adapter (supplied)

• OPTIONAL TRAP COVER: 1/4" wall anchor, bolt and washer to mount trap cover to wall

• OPTIONAL: Bradley recommends installing an electrical cut-off switch to the unit (this feature prevents accidental

water delivery during regular maintenance and service)

1

Mount Bowl to the wall

WARNING Do not attempt to install the bowl alone. To prevent serious injury,

install the bowl with the assistance of another person and always

use appropriate lifting procedures.

Unpack bowl and cover assembly. Remove

wing nuts on the two threaded rods which

A

retain the cover. Remove the top cover

bracket and lift the cover off and set aside.

With 2 people, move the bowl assembly

to the wall using appropriate lifting

B

procedures, secure the bowl to the wall.

Level the bowl assembly with shims if

necessary and then tighten anchors.

C

Top Cover

Threaded Rod

(330-078)

Top Cover

Bracket

(140-852)

Wing Nut

(161-076)

2

Bradley • 215-1330 Rev. N; ECN 16-08-022 11/3/2016 5

Install Drain Spud

Assemble the P-trap (supplied by installer)

by connecting the 1-1/2" tubular pipe to the

1-1/4" tailpiece and to the 1-1/2" drain pipe

A

stubbed out of the wall

Strainer and

Tailpiece

(269-1584)

P-Trap

(Polyphopylene)

(269-1697)

Drain Assembly

1/4" Rubber

Washer

Fiber

Washer

Nut

Trim to Fit

Page 6

CRS-2/IR, CRS-3/IR Installation

3

Connect Supply

Connect the 1/2" compression female end

A

of the stop valves to the rough-ins.

Connect one end of the supply hoses to the

B

stop valves.

The hose attached to the hot water inlet

of the Navigator® TMV valve must be

connected to the hot water rough-in.

Connect the other end of the supply hoses

C

to the Navigator TMV valve assembly.

Optional Single Tempered Supply: Attach

the stop valve to the 1/2" tempered supply

line. Connect the stop alive to the solenoid

D

valve with the flexible supply hose.

The thermostatic mixing valve requires at least 115° water from the hot water side from

proper operation. As with all lavatories, there will be a delay in obtaining warm water. If the

hot water is too far away from the unit, a circulating pump may be required.

Navigator Mixing Valve

Cold Supply Inlet

Valve Mounting

Bracket

Navigator

Mixing Valve

Hot Supply

Inlet

Hot

Supply

Flexible

Supply

Hose

Cold

Supply

Stop Valve

4

Electrical and Supply Connections

CAUTION The adaptive infrared control must be connected with a 12VDC regulated wall adapter.

Connections to 110VAC will result in damage to the electronics and can cause personal injury.

NOTICE! Connection of leads other than shown may cause permanent damage to the sensor.

Compliance and conformity to local codes and ordinances is the responsibility of the installer.

The solenoid valves have been pre-wired.

Snap each sensor circuit plug into the

associated solenoid circuit plug located on

A

the valve bracket.

Snap the wall adapter barrel plug into the

barrel plug located on the valve bracket

B

wire harness.

Black Supply Tube

(From Sprayhead)

Green Supply Tube

(From Sprayhead)

Red Supply

Tube (From

Sprayhead)

Compression

Nut

(110-231)

Supply Inlet

Navigator Thermostatic

Mixing Valve

6 11/3/2016 Bradley • 215-1330 Rev. N; ECN 16-08-022

Page 7

Installation CRS-2/IR, CRS-3/IR

5

6

Adjust the Temperature

WARNING This valve is NOT factory

preset. Upon installation,

the temperature of this

valve must be checked and

adjusted to ensure delivery

of a safe water temperature.

Water in excess of 110°F

(43°C) may cause scalding.

Install the Optional Soap Dispenser

For Express Crescent Lavatory System units with an optional soap dispenser, see

installation manual 215-1583 for instructions on installing the soap dispenser.

Loosen Cap Screw about 1/4" (4-6

turns) and lift up cover (do not

A

remove).

Using cover, turn cartridge gently until

desired water temperature is reached.

B

Do not turn past stops as this may

damage unit. Push cover down and

tighten screw.

After testing is complete, reinstall

panel to frame.

C

H

C

7

Install the Top Cover

Carefully place the top cover on top of

the lavatory system bowl.

A

Install the threaded rods into the holds

on the bottom of the top cover.

B

Slide the anchor plate onto the threaded

rods and secure anchor plate against

C

bowl using the wing nuts provided.

Optional Soap Dispenser: Install

soap filler assembly in mounting

bracket previously installed. Tighten

D

the optional soap filler cap nut with a

spanner wrench.

Top Cover

Threaded Rod

(330-078)

Top Cover

Bracket

(140-852)

Wing Nut

(161-076)

Bradley • 215-1330 Rev. N; ECN 16-08-022 11/3/2016 7

Page 8

CRS-2/IR, CRS-3/IR Installation

Cleaning and Maintenance for Terreon® (Bowl and Cover)

Material Description: Terreon is an NAHB-certified densified solid surface material composed of polyester resin and is resistant

to chemicals, stains, burns and impact. Surface damage can be easily repaired with everyday cleansers or fine grit abrasives.

Routine Cleaning: Clean daily or as often as conditions require using a standard commercial or household cleaner such as

Formula 409® or Windex®.

®

Stubborn Stains: Remove tough stains with Ajax

circular motion with 240 grit wet/dry sandpaper. The finish can be renewed with a maroon Scotch-Brite pad.

Special Situations for Terreon Material

Scratches: Remove scratches with a green Scotch-Brite pad. The finish can then be renewed with a maroon Scotch-Brite pad,

followed by a white Scotch-Brite pad or 30-micron sandpaper.

Hard Water Deposits: Remove hard water deposits with a mild solution of vinegar and water. Always rinse the unit thoroughly

after cleaning.

Restoring the surface: Use Hope’s® Solid Surface cleaner and polish to refresh and protect the Terreon Solid Surface material.

Bradley recommends additional care and maintenance for the darker colored Terreon. For complete instructions on this additional

maintenance, visit bradleycorp.com.

NOTICE! Do not use strong acid or alkaline chemicals and cleansers to clean Terreon. If these chemicals

come in contact with the surface, wipe them off immediately and rinse with soapy water. Avoid

contact with harsh chemicals such as paint remover, bleach, acetone, etc. Avoid contact with hot

pans and objects.

Repair Kits: Terreon repair kits are available. Contact your Bradley representative or distributor for part numbers and pricing.

Repair kits are made to order and have a shelf life of 30 days.

, Comet®, or Soft-Scrub® and a green Scotch-Brite® pad or lightly sand in a

Terreon® is a unique, cast solid surface material. Aggregate flow and distribution as well as shades of color can

vary from product to product creating natural characteristics.

Cleaning and Maintenance for Stainless Steel

Material Description: Stainless steel is extremely durable, and maintenance is simple and inexpensive. Proper care, particularly

under corrosive conditions, is essential. Always start with the simplest solution and work your way toward the more complicated.

Routine cleaning: Daily or as often as needed use a solution of warm water and soap, detergent, or ammonia. Apply the

cleaning solution per the manufacturer's instructions and always use a soft cloth or sponge to avoid damaging the finish.

Stubborn Stains: To remove stains from stainless steel use a stainless steel cleaner and polish such as Ball® stainless steel

cleaner or a soft abrasive. Always follow the manufacturer's instructions and apply in the same direction as the polish lines.

NOTICE! Never use ordinary steel wool or steel brushes on stainless steel. Always use stainless steel wool

or stainless steel brushes.

Fingerprints and Smears: To remove fingerprints or smears use a high quality stainless steel cleaner and polish in accordance

with the manufacturer's instructions. Many of these products leave a protective coating that helps prevent future smears and

fingerprints.

Grease and Oil: To remove grease and oil use a quality commercial detergent or caustic cleaner. Apply in accordance to the

manufacturer's instructions and in the direction of the polish lines.

Precautions: Avoid prolonged contact with chlorides (bleaches, salts), bromides (sanitizing agents), thiocyanates (pesticides,

photography chemicals, and some foods), and iodides on stainless steel equipment, especially if acid conditions exist.

NOTICE! Do not permit salty solutions to evaporate and dry on stainless steel.

The appearance of rust streaks on stainless steel leads to the belief that the stainless steel is rusting. Look for the actual source

of the rust in some iron or steel particles which may be touching, but not actually a part of the stainless steel structure.

NOTICE! Strongly acidic or caustic cleaners may attack the steel causing a reddish film to appear. The use

of these cleaners should be avoided.

8 11/3/2016 Bradley • 215-1330 Rev. N; ECN 16-08-022

Page 9

Installation CRS-2/IR, CRS-3/IR

Troubleshooting – Solenoid Valve: Part nos. S07-067-DC (closed

body) & S07-067A-DC (thru body)

Turn off water supplies to the unit before troubleshooting.

Item Qty. Part No. Description

1 1 118-334 Valve Body, ¼" Closed

1 1 118-334A Valve Body, ¼" Thru

2 1 S27-352 12VDC Valve Cartridge

3 1 125-165 O-Ring, #2-013

3

2

1

Problem Cause Solution

An individual

operating

station fails

to shut off

and drips.

An individual

operating

station fails

to turn on.

Internal

cartridge

failure.

A failed

cartridge for

the valve or

loose electrical

connection to

the terminal.

Replace S27-352 cartridge.

Test the station to determine the cause.

1. Disconnect the wires from the cartridge of an adjacent valve. Disconnect the wires from the

problem valve and reconnect to the adjacent valve.

2. Turn on electrical and water supplies to the unit. Pass your hand in front of the sensor of the

problem station, and the adjacent station should turn on.

If the adjacent station turns on and cycles normally, replace the cartridge on the problem valve.

If the adjacent valve fails to turn on, inspect the wires from the sensor cable and do the following:

• make sure there are no breaks and that the fully insulated disconnect terminals are firmly

crimped in place;

• turn off the electrical and water supplies;

• reconnect to the adjacent valve and turn on the water supplies to the unit;

• pass your hand in front of the sensor. If the station still fails to turn on, replace the sensor.

Bradley • 215-1330 Rev. N; ECN 16-08-022 11/3/2016 9

Page 10

CRS-2/IR, CRS-3/IR Installation

Thermostatic Mixing Valve Troubleshooting

Before attempting to troubleshoot the valve or disassemble the components, check for the following conditions:

• If stop valves are used, make sure that they are fully open.

• Make sure that the hot and cold inlet pipes are connected properly, and that there are no cross-connections or

leaking stop valves.

• Check the hot water heater output to make sure that it is at least 10° F above the set temperature.

Be sure to close the appropriate shut-off valves prior to disassembly of the valve and reopen the valves after inspection

and repair is complete.

Problem Cause Solution

External leaks. Damaged cartridge or O-rings. Replace cartridge with part number 269-1927

Improper water

Hot water supply is not 10° above desired set point. Increase hot water supply temperature

temperature or

temperature

fluctuation.

Valve temperature is not properly set. Adjust the temperature as shown on page 7, step 5.

Limited water flow. Dirt and debris have built up in the valve or strainer. 1. Check to make sure both hot and cold supplies are

connected to the Navigator mixing valve and that they

have water flow.

2. Remove cover and U-clip. Remove the cartridge and

clean the strainer. It is not required to grease cartridge,

however if desired, use silicone grease only. Do not

use grease on check valves.

1

Parts List

Item Part No. Description

2

3

1 160-463 Cap Screw 1

2 107-582 Cover 1

3 269-1927 Thermostatic Cartridge 1

4 198-014 Check Valve* 2

5 132-051 Retaining Ring* 2

6 118-319 Valve Body 1

7 146-079 U-Clip 1

* Included with Prepack S65-326

Quantity

S59-4000

5

4

Tempered Line Adapter Option

Part no. S39-804

(replaces S59-4000 if tempered

line is used)

Strainer

(173-028)

6

4

5

7

10 11/3/2016 Bradley • 215-1330 Rev. N; ECN 16-08-022

Loading...

Loading...