Page 1

215-180 Rev. K; EN 00-569

Page 1 of 2

P.O. Box 309, Menomonee Falls, WI 53052-0309

TEL. 1-800-BRADLEY FAX 262-251-5817

http://www.bradleycorp.com

Adjustment Instructions and Parts List for the HFP V alve

Model No. S90-252 HFP

Model No. E90-252HFP

HFP Valve Adjustment Instructions

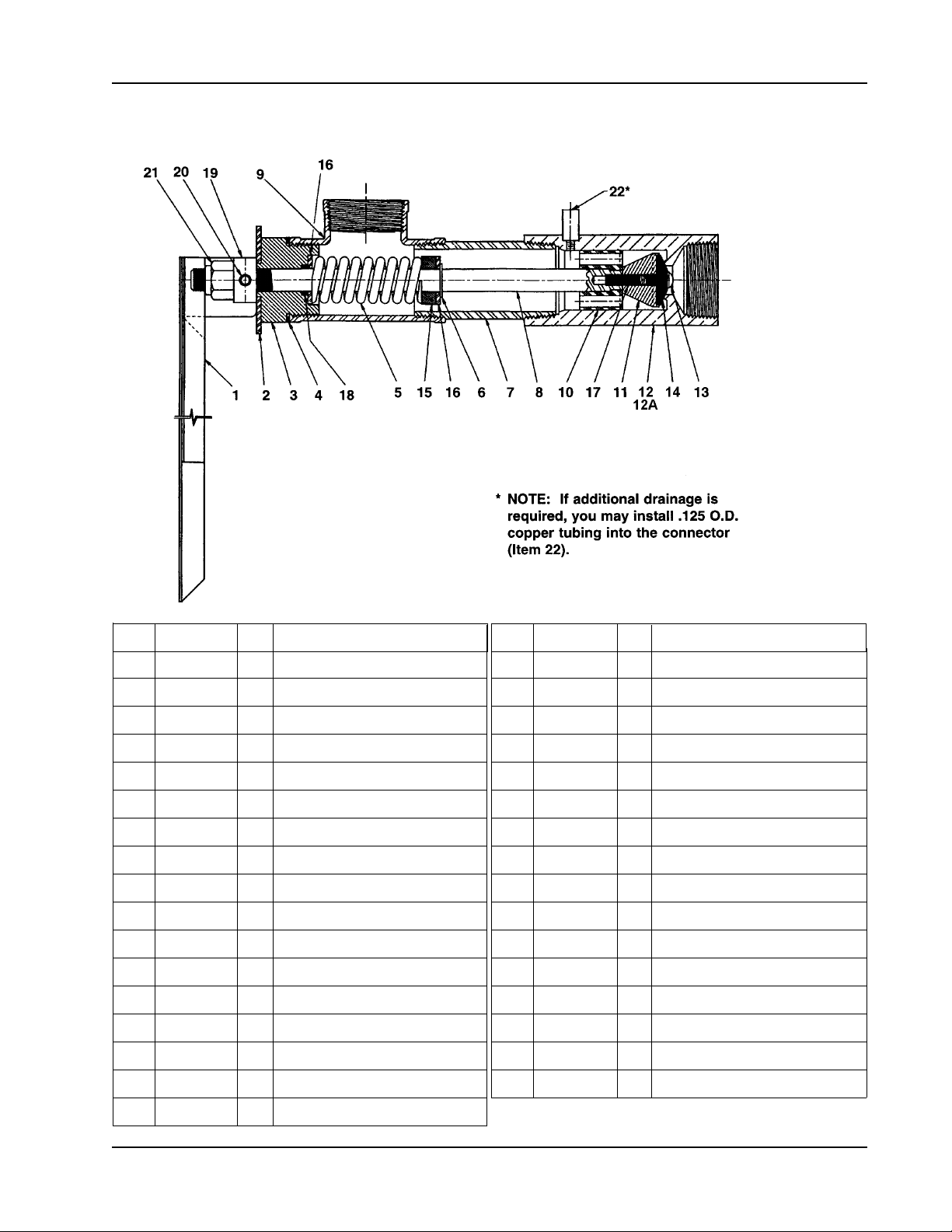

NOTE: Refer to the illustration and parts list on page 2.

1. Turn off the water supply to the HFP valve.

2. Insert a 3/16” hex wrench into the broached/hex end of the lifting stem (Item 8).

3. Holding the lifting stem (Item 8) in place, back off the stop nut (Item 21).

4. Back off the bar nut (Item 19) by turning the handle assembly (Item 1).

5. Tighten the bonnet nut (Item 3).

6. Run the bar nut (Item 19) down by turning the handle assembly (Item 1) until the bar nut

sits on the stainless steel washer (Item 2). Then back off the bar nut approximately 1/4"

turn until the handle assembly returns to its original position.

7. Tighten the stop nut (Item 21) down on the bar nut (Item 19).

8. Open the water supply line to the unit. Test for leaks and adequate water flow.

Troubleshooting Instructions for Valve Leakage

NOTE: Through normal daily usage the valve may begin to leak. If leakage occurs, follow the

procedure outlined below (refer to the illustration and parts list on page 2):

1. Turn off the water supply to the HFP valve.

2. Loosen the bonnet nut (Item 3) only. DO NOT loosen the stop nut (Item 21) or the bar

nut (Item 19).

3. Remove the bonnet nut (Item 3) and handle assembly (Item 1) to expose the lifting stem

(Item 8).

4. Check the condition of the faucet washer (Item 14) at the end of the lifting stem (Item 8).

If the faucet washer is scored or worn, replace it with a new one.

5. If the faucet washer (Item 14) is undamaged, or after replacing the faucet washer, reinsert the lifting stem (Item 8) into the casing pipe (Item 7). Care must be taken to make

sure the guide (Item 10) does not get hung up as the lifting stem is lowered.

6. Hand tighten the bonnet nut (Item 3).

7. Open the water supply line to the unit. Test for leaks and adequate water flow.

Page 2

Bradley Corporation • 215-180 Rev. K; EN 00-569

2

HFP Valve Parts Breakdown

1 S08-040 1 HANDLE ASSY.

2 142-002BB 1 STN. STL. WASHER

3 110-108 1 BONNET NUT

4 124-001BS 1 GASKET

5 135-001AP 1 SPRING

6 132-012 1 RETAINING RING

7 113-772 1 CASING PIPE (18" BURY DEPTH)

7 113-773 1 CASING PIPE (3' BURY DEPTH)

7 113-774 1 CASING PIPE (4' BURY DEPTH)

7 113-775 1 CASING PIPE (5' BURY DEPTH)

7 113-776 1 CASING PIPE (6' BURY DEPTH)

7 113-987 1 CASING PIPE (3' EUROPE)

8 120-022K 1 LIFTING STEM (18" BURY DEPTH)

8 120-022D 1 LIFTING STEM (3' BURY DEPTH)

8 120-022E 1 LIFTING STEM (4' BURY DEPTH)

8 120-022F 1 LIFTING STEM (5' BURY DEPTH)

8 120-022G 1 LIFTING STEM (6' BURY DEPTH)

8 120-022L 1 LIFTING STEM (3' EUROPE)

9 169-727A 1 TEE

10 145-072 1 GUIDE

11 132-011 1 RETAINER

12 118-246 1 VALVE BODYASSY.

12A 118-246B 1 VALVE BODY ASSY. EUROPE

13 160-138 1 MACHINE SCREW

14 169-920 1 FAUCET WASHER

15 182-061 1 SPACER

16 142-002CC 3 WASHER

17 160-251 1 SCREW STUD

18 125-001CD 1 O-RING

19 110-109 1 BAR NUT

20 165-038 2 ROLL PIN

21 161-061 1 STOP NUT

22 169-890 1 CONNECTOR

Item Part No. Qty Description Item Part No. Qty Description

Bradley Adjustment Instructions for the HFP Valve

Installation Instructions Model Nos. S90-252HFP, E90-252HFP

Loading...

Loading...