Page 1

Installation

COMBI5500

17" Chase-Mounted Five-Sided

Stainless Steel Combination Unit

Table of Contents

Supplies Required ...........................2

Rough-In Information ...................... 2, 3

Installation Instructions .......................3

Cleaning Instructions ......................... 4

Bradley Security Fixtures are tamper resistant. All mounting hardware

Installation

THIS

SIDE

UP

215-329 Rev. K EN 08-703

© 2008 Bradley Corporation

Page 1 of 4 9/30/08

provided is essential for properly anchoring the unit. Bradley cannot

assume any responsibility for any improperly installed units. Read this

entire installation manual to ensure proper installation. When fi nished

with the installation, fi le this manual with the owner or maintenance

department. Compliance and conformity to local codes and ordinances is

Packing List

the responsibility of the installer.

•

•

•

•

Separate parts from packaging and make sure all parts are accounted for

before discarding packaging material. If any parts are missing, do not begin

installation until you obtain the missing parts.

Make sure that all water supply lines have been fl ushed and then completely

turned off before beginning installation. Debris in supply lines can cause

valves to malfunction.

Product warranties may be found under “Products” on our web site at

bradleycorp.com.

IMPORTANT!

P.O. Box 309, Menomonee Falls, WI 53052-0309

Phone: 1-800-BRADLEY Fax: 262-253-4161

www.bradleycorp.com

Page 2

COMBI5500 Installation

Supplies Required:

• 1" NPT supply piping to flush valve

• Toilet/Lav waste connections

• For optional air valve manifold: 1/2" NPT supply piping. Refer to Bradley Installation Manual (215-1158) provided with assembly.

• For optional self-closing valve: 1/2" NPT supply piping. Refer to Bradley Installation Manual (215-581) provided with assembly.

• For optional TouchTime

®

solenoid valve: 1/8" NPT supply piping; wire nuts sized for 22 AWG to connect to 24 VAC power source.

Refer to Bradley Installation Manual (215-1378) provided with assembly.

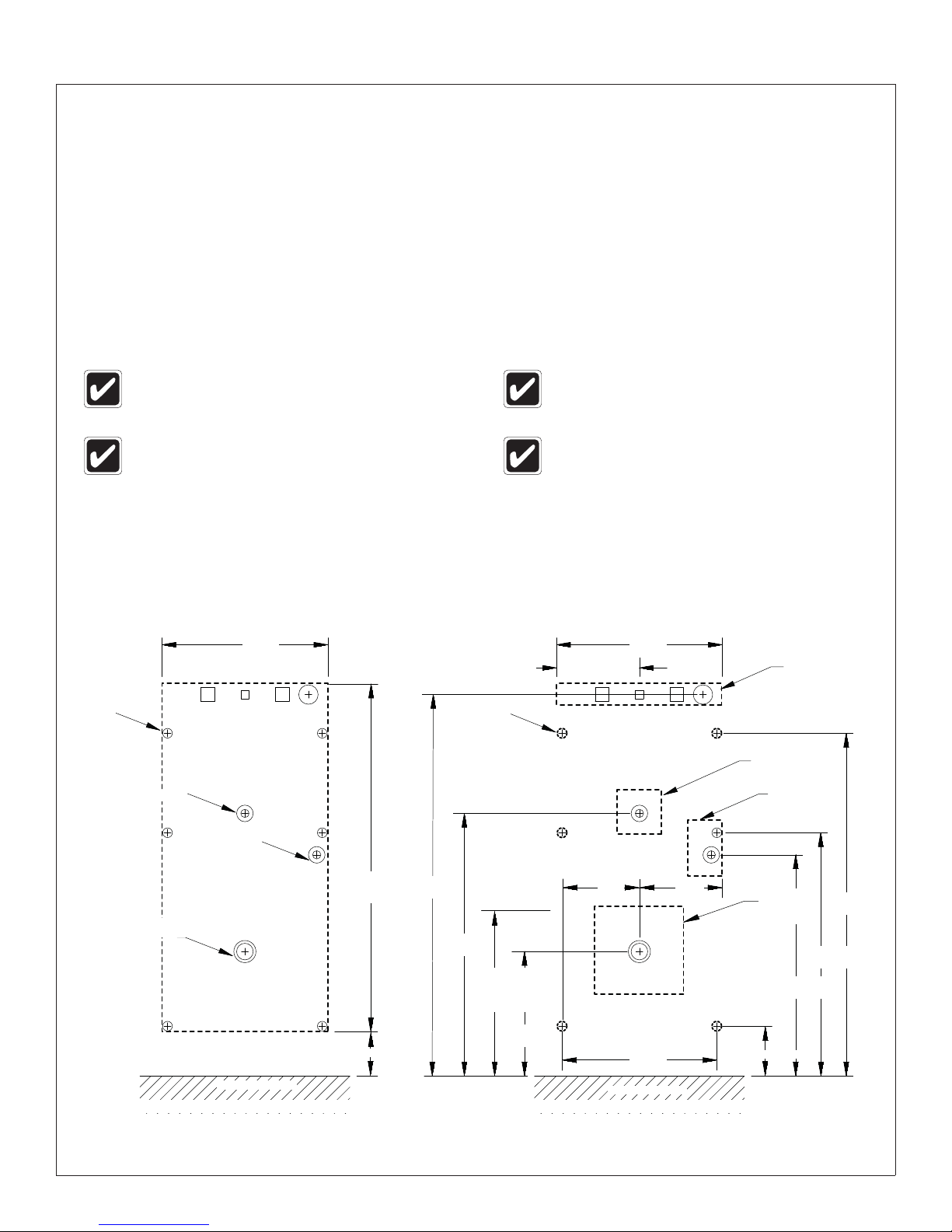

Roughing-In Supplies, Drain, and Waste Outlet

Threaded

Studs (6)

All views are from the fi xture side

(right-hand unit shown).

Rough-in 1-1/4" or 1-1/2" NPT (size dependent

on options ordered) lavatory waste outlet at the

dimensions shown below. Use single or multiple

openings, depending on site requirements.

15"

(381)

Lav Waste

7/8" (22)

Dia. Holes [5]

7-1/2"

(190)

Top of integral seat is to be mounted 15" ( 381 mm)

above fi nished fl oor.

On fl oor outlet waste units, centerline of

waste is 4-1/4" (108mm) from wall.

(mm)

15"

(381)

2" X 15" (51 x 381)

Valve Mounting Hole

4" (102)

Square Hole

3" x 5"

(76 x 127)

Hole

Flush Valve

Supply

Toilet

Waste

Finished Floor

Single Opening in Wall* Multiple Openings in Wall

*Recommended when using optional wall sleeve

2 9/30/08 Bradley Corporation • 215-329 Rev. K; EN 08-703

31-1/2"

(800)

4" (102)

34-1/2"

(876)

23-3/4"

(603)

15" (381)

Top of

Integral

Seat

11-1/4"

(286)

7"

(178)

Finished Floor

14"

(356)

7-3/4"

(197)

8" (203)

Square

Hole

4-1/2" (190)

20"

(508)

22"

(538)

31"

(787)

Page 3

Installation COMBI5500

Five-Sided Unit Dimensions

3-1/2"

(89)

12-1/4"

(311)

18"

(457)

COMBI55000 Series

(Center Confi guration)

17"

(432)

14"

(356)

4-1/4"

(108)

Floor

Waste

Option

Top View

23-3/8"

(721)

3-1/2"

(89)

18"

(457)

14"

(356)

COMBI55000 Series

(Angle Confi guration)

23-1/2"

(597)

12-1/4"

(311)

16-1/2"

(418)

4-1/4"

(108)

Floor

Waste

Option

17"

(432)

19-11/16"

(500)

32-1/2"

(826)

3-1/8" (79)

Wall-Mounted

Units Only

Install Unit

1

B

C

15"

(381)

Insert six 1/2"-13 threaded studs (supplied by

installer) into the back of the unit and screw in

A

approximately 1/2".

Connect the flush valve supply pipe, lav waste,

and toilet waste (supplied by installer) to the

couplings located on the back of the fixture.

Sliding studs and pipes through the wall openings,

position the fixture in place (top of integral toilet seat

is 15" above finished floor). Mount Valve Asembly.

Secure the fixture to the wall using anchor

brackets, washers, and nuts provided.

D

All fasteners must be securely

tightened to approximately 30 ft./lbs.

Side View

32-1/2"

(826)

15"

(381)

3-1/8" (79)

Wall-Mounted

Units Only

Mounting

Channel

(140-558)

Valve

Mounting

Plate

(159-292)

1/2" -13 Threaded Stud

0" - 4" Wall (109-039)

4" - 8" Wall (109-040)

8" - 12" Wall (109-048)

When fi nished, turn on the water supplies and check for

leaks and adequate water fl ow. Activate lavatory pushbuttons

and fl ush valve several times to purge air from the lines.

Bradley Corporation • 215-329 Rev. K; EN 08-703 9/30/08 3

Nut

(110-119)

Washer

(140-002AM)

Page 4

COMBI5500 Installation

Cleaning Stainless Steel

Material Description: Stainless steel is extremely durable, and maintenance is simple and inexpensive. Proper care, particularly

under corrosive conditions, is essential. Always start with the simplest solution and work your way toward the more complicated.

Routine Cleaning: Daily or as often as needed use a solution of warm water and soap, detergent, or ammonia. Apply the cleaning

solution per the manufactures instructions and always use a soft cloth or sponge to avoid damaging the fi nish.

Stubborn Stains: To remove stains from stainless steel use a stainless steel cleaner and polish such as Ball® stainless steel

cleaner or a soft abrasive. Always follow the manufactures instructions and apply in the same direction as the polish lines.

Never use ordinary steel wool or steel brushes on stainless steel. Always use stainless steel wool or stainless

steel brushes.

Special Situations for Stainless Steel Material

Fingerprints and Smears: To remove fi ngerprints or smears use a high quality stainless steel cleaner and polish in accordance

with the manufactures instructions. Many of these products leave a protective coating the helps prevent future smears and

fi ngerprints.

Grease and Oil: Grease and Oil : To remove grease and oil use a quality commercial detergent or caustic cleaner. Apply in

accordance to the manufactures instructions and in the direction of the polish lines.

Precautions: Precautions: Avoid prolonged contact with chlorides (bleaches, salts), bromides (sanitizing agents), thiocyanates

(pesticides, photography chemicals, and some foods), and iodides on stainless steel equipment, especially if acid conditions

exist.

Do not permit salty solutions to evaporate and dry on stainless steel.

The appearance of rust streaks on stainless steel leads to the belief that the stainless steel is rusting. Look for the actual source

of the rust in some iron or steel particles which may be touching, but not actually a part of the stainless steel structure.

Strongly acidic or caustic cleaners may attack the steel causing a reddish fi lm to appear. The use of these

cleaners should be avoided.

Brand Names

Use of brand names is intended only to indicate a type of cleaner. This does not constitute an endorsement, nor does the omission

of any brand name cleaner imply inadequacy. Many products named are regional in distribution, and can be found in local

supermarkets, department and hardware stores, or through your cleaning service. It is emphasized that all products should be used

in strict accordance with package instructions.

4 9/30/08 Bradley Corporation • 215-329 Rev. K; EN 08-703

Loading...

Loading...