Bradley 832-039 Datasheet

TECHNICAL DATA SHEET

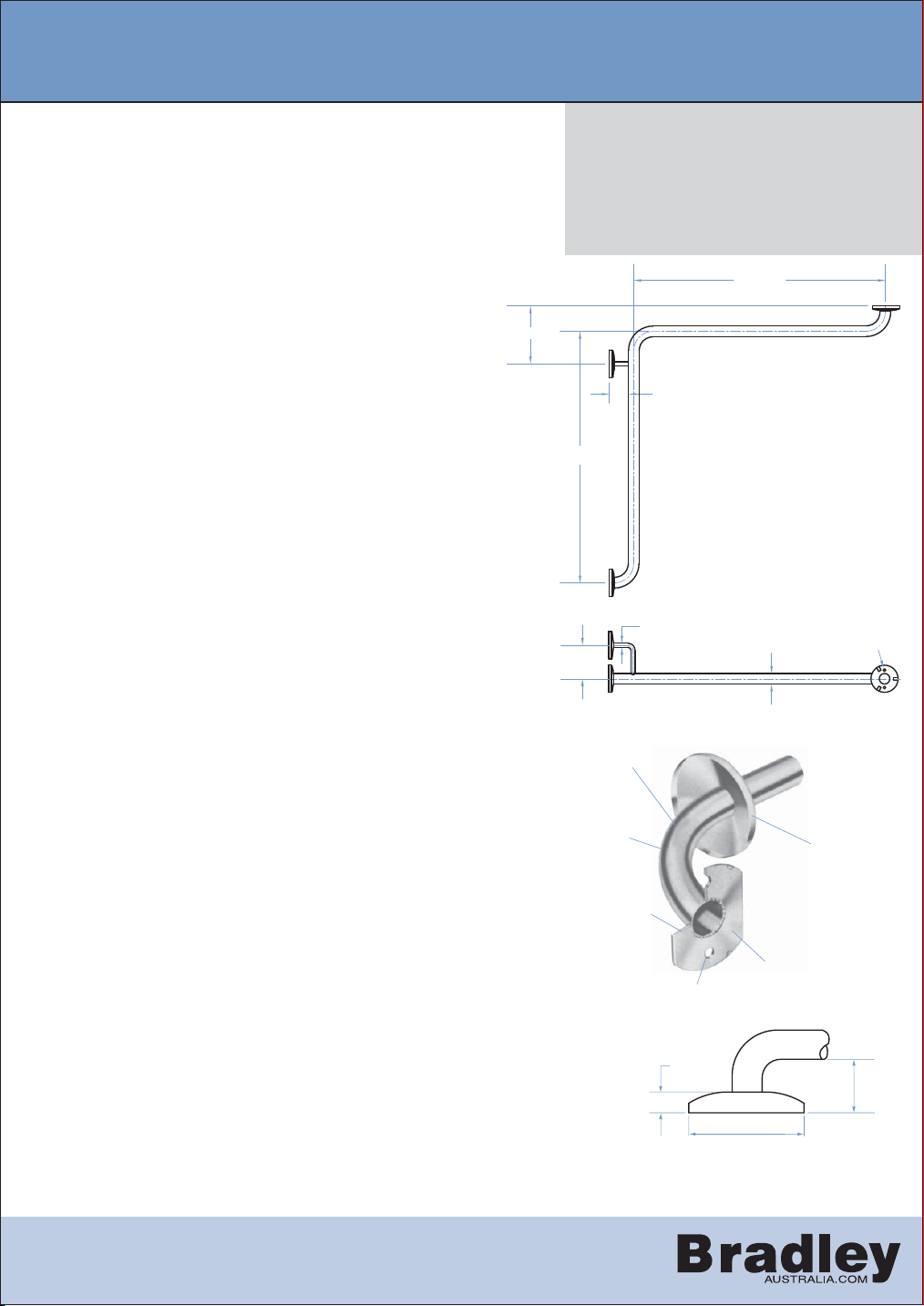

SURFACE MOUNTED GRAB BAR

GRAB BAR AND RAILS 832-039-3030

- 32mm diameter with concealed fixing

- Standard - 750mm + 750mm W

- Complies with AS1428.1

GRAB BAR AND RAILS 832-039-3636

- 32mm diameter with concealed fixing

- Standard - 900mm + 900mm W

- Complies with AS1428.1

For special sizes of all grab bar rails nominate: Horizontal (A) =

(all dimensions centre to centre) Horizontal (B) =

Vertical (C) =

CONSTRUCTION:

FLANGES: Fabricated of type 304 (18-8), 80mm dia. 13 gauge

stainless steel.

ESCUTCHEONS: Fabricated of type 304 (18-8), 22 gauge stainless

steel. One-piece drawn construction with exposed surfaces in

architectural satin finish. Snap over flanges to conceal

mounting screws.

TUBING: Fabricated of type 304 (18-8), 32mm (1-1/4") O.D.

18 gauge stainless steel, seamless construction with exposed surfaces

in architectural satin finish. Bent ends of tubing pass through the

flanges and are heliarc welded into a single structural unit for

maximum strength. Intermediate supports are contour cut and

joined by heliarc welding to form an integral part of the grab bar.

All welds ground and polished to blend. Mandrel bending process

maintains uniform bar diameter.

STRENGTH:

When properly mounted, all Bradley heavy duty grab bar systems

meet or exceed the requirements of Australian Standard AS1428.1(2,3),

of ANSI Standard A117.1, the ADA and ABA Accessibility Guidelines for

Buildings and Facilities (ADAAG) and the Uniform Federal Accessibility

Standard (UFAS).

INSTALLATION:

Secure to wall where adequate in-wall backing exists. Use bar as

template to locate mounting holes. Drill holes and set anchors as

appropriate. Mount grab rail and secure mounting screws. Snap

escutcheons into place.

GUIDE SPECIFICATION:

Grab bar shall be fabricated of type 304 satin finish stainless steel

with concealed mounting flanges in sizes and configurations as indicated.

173mm

MODEL 832-039-3030

Options:

832-039-3636 - 900mm x 900mm

-2 Peened (Safety Grip)

-4 Mirror Polished

-6 Powdercoat

750mm

57mm

750mm

Ø12mm

100mm

Polished (No. 4) satin finish

will not scratch hands

or catch dirt

Mandrel bending

process maintains

uniform

bar diameter

Bar heliarc welded

to flange to form

a single structural

unit for maximum

strength

Mounting holes

16mm

Ø32mm

Escutcheon snaps over flange

to conceal mounting screws

Flange of 13 gauge type 304

83mm

CONCEALED

*50-60mm wall clearance required

under most building design codes

Ø9mm

18 gauge type 304

stainless steel

Flange escutcheon

stainless steel

*57mm

TOLL FREE 1300 364 561

The manufacturer reserves the right to make changes in design and material

without formal notice and without incurring obligation.

Loading...

Loading...