Page 1

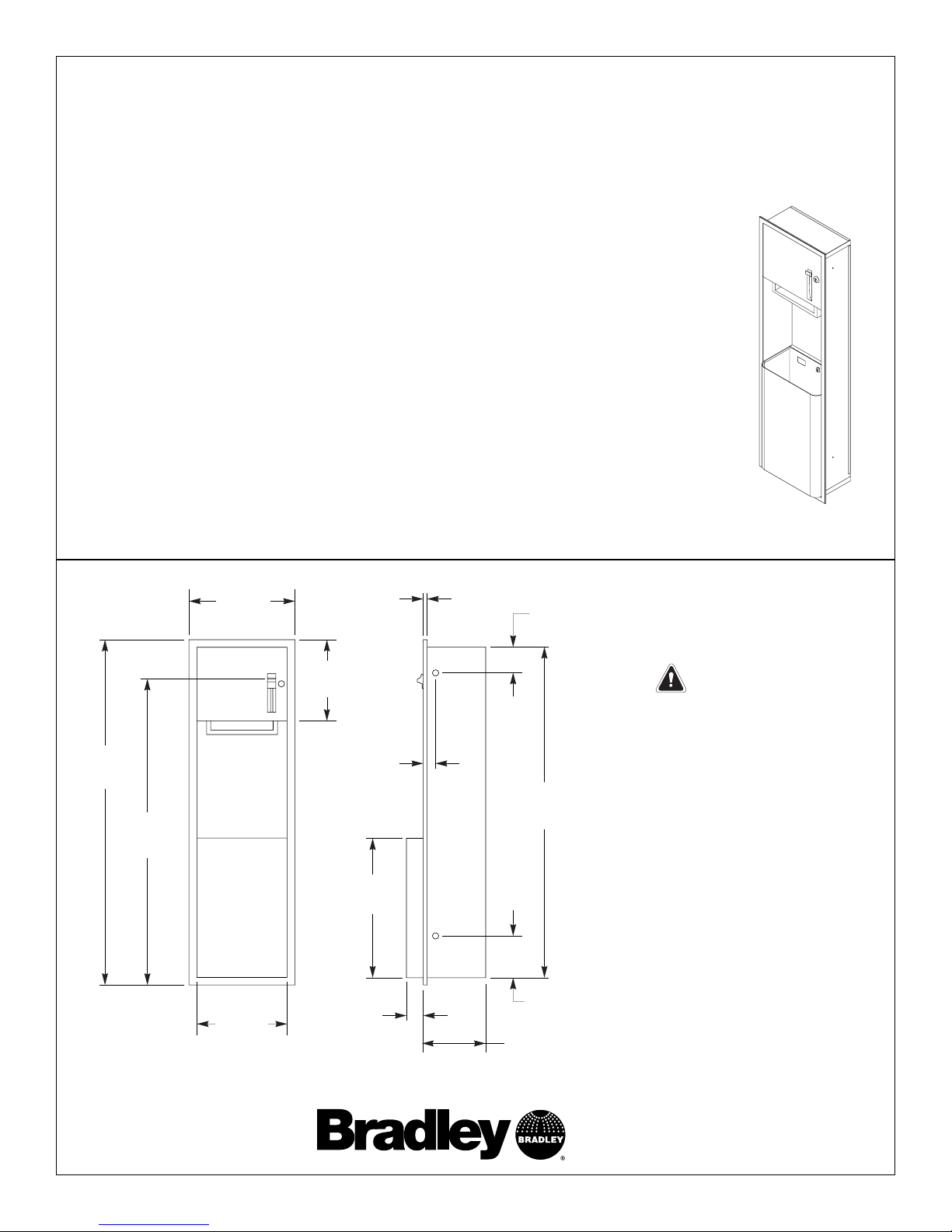

Installation

Semi-Recess and Recess-Mounted Towel/Waste Unit

NOTE: For surface-mounted unit, refer to the instructions on page 2.

NOTE: Coordinate installation with architect and contractor to avoid protrusion

from opposite wall, pipes vent, conduits, electrical wiring etc. in wall. Grounding

is recommended for plaster wall installation. If installing where unit projects

above top of wainscot, provide aluminum channel or other filler to prevent gap

from finished wall and flange of unit. For block walls, use metal expansion shields

(not provided).

1. Provide the wall opening per the dimensions shown in Figure 1.

2. Position the unit into the opening, unlock the door and remove the waste can.

NOTE: Shims may be required to prevent distortion when positioning the unit into

the wall opening. Place shims at the mounting holes between the outside of the

unit and the wall before securing the towel/waste unit.

3. Secure the unit to wall through the concealed mounting holes provided with

the four #10 screws supplied.

15-1/8"

(384mm)

54-1/8"

(1375mm)

17-1/8"

(435mm)

56"

(1423mm)

10-1/2"

(267mm)

50-1/2"

(1283mm)

7"

(178mm)

12"

(305mm)

1/4"

(6mm)

2-5/16"

(59mm)

4-1/8"

(105mm)

3"

(76mm)

23"

(584mm)

Figure 1

IMPORTANT

For ADA Accessibility compliance

• the unit should be installed so

that the top of the wall opening

is 73" (1854mm) maximum

above the finished floor (AFF)

if additional clear-floor sidereach access is provided, OR

67" (1701mm) maximum AFF if

only clear-floor forward-reach

access is provided.

• the unit cannot be located

where it will protrude into

walks, halls, corridors,

passageways or aisles.

P.O. Box 309, Menomonee Falls, WI 53052-0309

Phone: 1-800-BRADLEY Fax: (262) 251-5817

http:\\www.bradleycorp.com

227 Towel Dispenser/Waste Unit

P20-164; EN 05-1512

© 2005 Bradley Corporation

Page 1 of 6 3/9/05

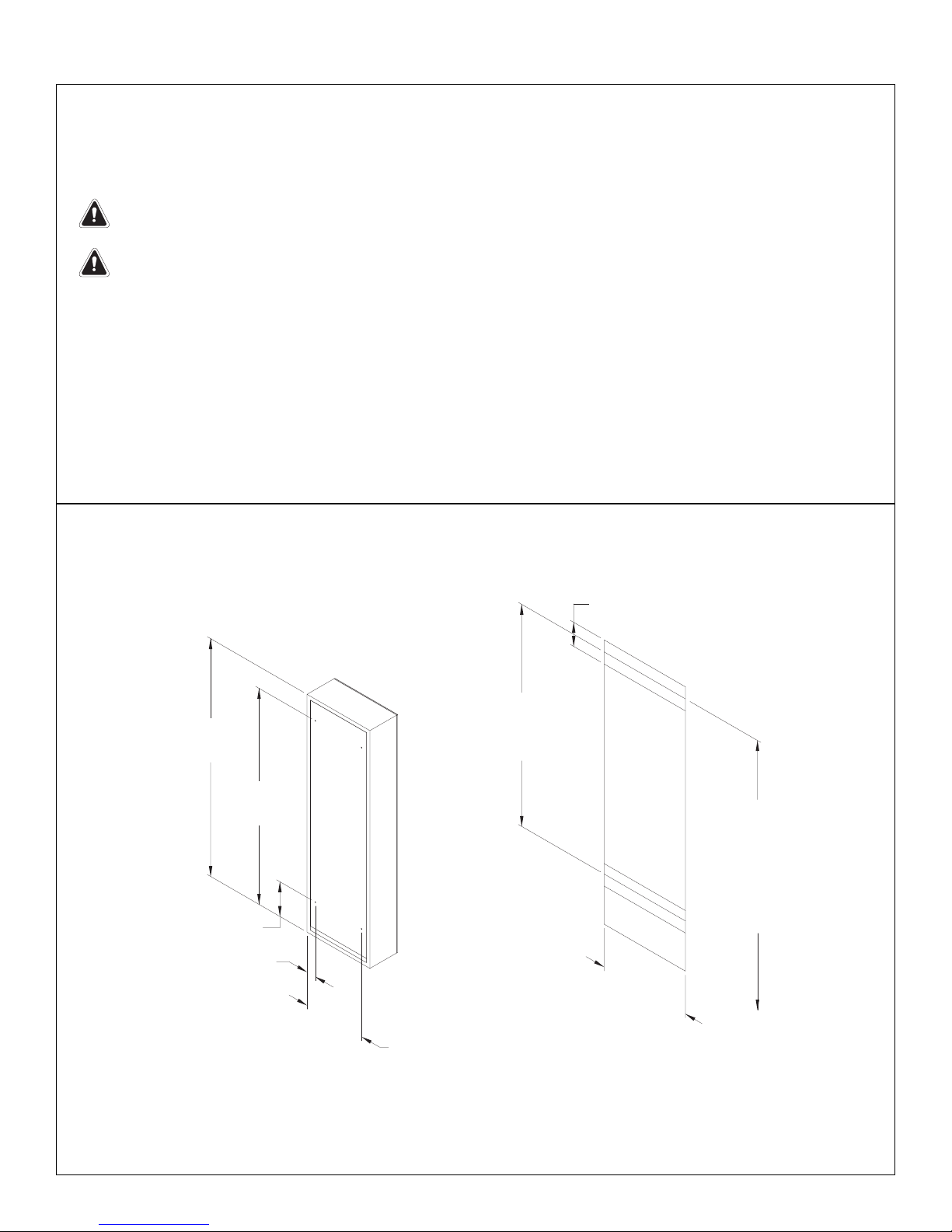

Page 2

Installation 227

2

Installation

Surface-Mounted Towel/Waste Unit

NOTE: For semi-recess and recess-mounted unit, refer to the instructions on page 1.

IMPORTANT: Adequate in-wall backing must be provided by installer to fully support the

weight of the unit. Always check local codes and ordinances prior to installation.

IMPORTANT: Concealed mounting holes in back of the unit must be provided by installer

prior to installation. Refer to Figure 2 for suggested mounting hole locations.

1. Plaster or dry wall construction: Provide in-wall backing (suitable for use with #10 x 1"

screws) at the mounting slot locations shown in Figure 2 below.

Other wall surfaces: Provide fiber plugs or expansion shields (suitable for use with #8 x 1-1/4"

sheet-metal screws supplied by installer), OR provide 1/8" toggle bolts or expansion bolts. If

installing where unit projects above top of wainscot, provide aluminum channel or other filler to

prevent gap from finished wall to back of unit. For block walls, use metal expansion shields

(provided by installer).

2. Unlock the door and remove the waste can. Secure the unit to the wall through the concealed

mounting holes (provided by installer) with the hardware appropriate for your wall construction.

Bradley Corporation • P20-164; EN 05-1512 3/9/05

17-1/8"

(435mm)

56"

(1423mm)

42-1/2"

(1080mm)

CENTERLINE

OF BACKING

4" TYP

(102mm)

51"

(1295mm)*

8-1/2"

(216mm)*

14-13/16"

(376mm)*

2-1/4"

(57mm)*

CENTERLINE

OF BACKING

TO FLOOR

5'-0" MIN

(1524mm)

TO

6'-3" MAX

(1905mm)

* Suggested mounting hole

locations for installer

Figure 2

Page 3

Installation

Distributeur d'essuie-mains/Vide-déchets semi-encastré et encastré

REMARQUE : Pour l'unité montée en surface, se reporter aux instructions en page 4.

REMARQUE : Coordonner l'installation avec l'architecte ou l'entrepreneur pour éviter

toute saillie du mur opposé, des évents de tuyaux, conduits, câblage électrique, etc. dans

le mur. Une mise à la terre est recommandée pour toute installation dans un mur en

plâtre. Si une fois installée, l'unité doit surplomber le dessus du lambris, fournir une

moulure en aluminium ou toute autre garniture pour empêcher tout espace entre le mur

fini et la bride de l'unité. Pour les murs en blocs, utiliser des coquilles d'expansion

métalliques (non fournies).

1. Prévoir une ouverture murale conformément aux dimensions illustrées à la Figure 1.

2. Positionner l'unité dans l'ouverture, déverrouiller la porte et retirer la poubelle.

REMARQUE : Des cales sont peut-être nécessaires pour empêcher toute déformation lors

du positionnement de l'unité dans l'ouverture murale. Placer les cales au niveau des trous

de fixation entre l'extérieur de l'unité et le mur avant de fixer le distributeur d'essuiemains/vide-déchets.

3. Fixer l'unité au mur dans les trous de fixation dissimulés fournis à l'aide des quatre

vis n° 10 fournies.

15-1/8"

(384mm)

54-1/8"

(1375mm)

17-1/8"

(435mm)

56"

(1423mm)

10-1/2"

(267mm)

50-1/2"

(1283mm)

7"

(178mm)

12"

(305mm)

1/4"

(6mm)

2-5/16"

(59mm)

4-1/8"

(105mm)

3"

(76mm)

23"

(584mm)

Figure 1

IMPORTANT

Conformité d'accès facile ADA

(Americans with Disabilities Act)

• l'unité doit être installée de

manière à ce que le haut de

l'ouverture murale se trouve à

1 854 mm (73") maximum audessus du sol fini si un accès

supplémentaire latéral sol

dégagé est fourni OU à 1 701

mm (67") maximum au-dessus

du sol fini si seul un accès par

l'avant sol dégagé est fourni.

• l'unité ne peut être située dans

des endroits où elle fera saillie

dans les allées, les halls, les

corridors, les passages ou les

couloirs.

P.O. Box 309, Menomonee Falls, WI 53052-0309

Phone: 1-800-BRADLEY Fax: (262) 251-5817

http:\\www.bradleycorp.com

227 Distributeur

d'essuie-mains/Vide-déchets

P20-164; EN 05-1512

© 2005 Bradley Corporation

Page 3 of 6 3/9/05

Page 4

Installation 227

4

Installation

Distributeur d'essuie-mains/Vide-déchets monté en surface

REMARQUE : Pour l'unité semi-encastrée et encastrée, se reporter aux instructions en page 3.

IMPORTANT : Un support adéquat dans le mur doit être fourni par l'installateur pour

soutenir entièrement le poids de l'unité. Toujours vérifier les codes locaux et arrêtés

municipaux avant toute installation.

IMPORTANT : Des trous de fixation dissimulés dans le dos de l'unité doivent être fournis

par l'installateur avant toute installation. Se reporter à la Figure 2 pour voir les

emplacements suggérés des trous de fixation.

1. Construction murs en plâtre ou cloisons sèches : Prévoir un support dans le mur (convenant pour

l'emploi de vis n° 10 x 1") au niveau des emplacements de fentes de montage illustrés à la Figure 2 cidessous.

Autres surfaces murales : prévoir

des chevilles en fibre ou des coquilles d'expansion (convenant

pour l'emploi de vis à tôle n° 8 x 1-1/4" fournies par l'installateur) OU prévoir des boulons à ailettes ou

des boulons à coquilles d'expansion de 1/8". Si une fois installée, l'unité doit surplomber le dessus du

lambris, fournir une moulure en aluminium ou toute autre garniture pour empêcher tout espace entre le mur

fini et le dos de l'unité. Pour les murs en blocs, utiliser des coquilles d'expansion métalliques (fournies par

l'installateur).

2. Déverrouiller la porte et retirer la poubelle. Fixer l'unité au mur dans les trous de fixation dissimulés

(fournis par l'installateur) avec la visserie appropriée à la construction murale.

Bradley Corporation • P20-164; EN 05-1512 3/9/05

17-1/8"

(435mm)

56"

(1423mm)

42-1/2"

(1080mm)

CENTERLINE

OF BACKING

4" TYP

(102mm)

51"

(1295mm)*

8-1/2"

(216mm)*

14-13/16"

(376mm)*

2-1/4"

(57mm)*

CENTERLINE

OF BACKING

TO FLOOR

5'-0" MIN

(1524mm)

TO

6'-3" MAX

(1905mm)

* Suggested mounting hole

locations for installer

Figure 2

* Les emplacements suggérés des

trous de fixation (pour l'installateur)

42-1/2"

(1080mm)

axe de

support

axe de

support

du sol

5'-0"

(1524mm)

du

6'-3"

(1905mm)

Page 5

Instalación

Unidad para toallas/desechos semiempotrada y empotrada

NOTA: Para la unidad montada superficialmente, consulte las instrucciones de la página 6.

NOTA: Coordine la instalación en el muro con un arquitecto o con un contratista a fin de

evitar que la unidad sobresalga del muro opuesto, de la ventilación de las tuberías,

conductos, cableado eléctrico, etc. Se recomienda aplicar una capa de imprimación para

las instalaciones en muros de yeso. Si se realiza la instalación en sitios en que la unidad

se proyecta por sobre la parte superior del friso de madera, disponga un perfil de

aluminio en U o algún otro relleno que evite la aparición de una brecha entre el muro

terminado y el reborde de la unidad. Para los muros en bloques, utilice escudos

ensanchadores de metal (no incluidos).

1. Disponga la abertura del muro de acuerdo con las dimensiones que aparecen en la

Figura 1.

2. Ubique la unidad en la abertura, abra la puerta y saque el basurero.

NOTA: Es posible que se necesiten cuñas que eviten la distorsión al momento de ubicar la

unidad en la abertura del muro. Coloque las cuñas en los orificios de montaje entre la

parte exterior de la unidad y el muro antes de fijar la unidad para toallas/desechos.

3. Fije la unidad al muro a través de los orificios de montaje ocultos que se

proporcionan junto con cuatro tornillos Nº 10.

15-1/8"

(384mm)

54-1/8"

(1375mm)

17-1/8"

(435mm)

56"

(1423mm)

10-1/2"

(267mm)

50-1/2"

(1283mm)

7"

(178mm)

12"

(305mm)

1/4"

(6mm)

2-5/16"

(59mm)

4-1/8"

(105mm)

3"

(76mm)

23"

(584mm)

Figura 1

IMPORTANTE

Para cumplir con las normas de

ADA relacionadas con la

accesibilidad

• la unidad se debe instalar de

modo que la parte superior de

la abertura del muro esté a un

máximo de 1854 mm (73 pulg.)

por sobre el piso acabado

(AFF, por sus siglas en inglés)

si se dispone un acceso con

alcance lateral en el piso

despejado, O a un máximo de

1701 mm (67 pulg.) por sobre el

piso acabado si sólo se

dispone un acceso con alcance

hacia delante en el piso

despejado.

• la unidad no puede ubicarse en

lugares en que sobresalga

hacia pasillos, salones,

corredores, pasadizos ni

galerías.

P.O. Box 309, Menomonee Falls, WI 53052-0309

Phone: 1-800-BRADLEY Fax: (262) 251-5817

http:\\www.bradleycorp.com

227 Dispensador de toallas/recipiente

para desechos

P20-164; EN 05-1512

© 2005 Bradley Corporation

Page 5 of 6 3/9/05

Page 6

Installation 227

6

Instalación

Unidad para toallas/desechos montada superficialmente

NOTA: Para la unidad semiempotrada y empotrada, consulte las instrucciones de la página 1.

IMPORTANTE: El instalador debe disponer refuerzos en el interior del muro a fin de que soporte

completamente el peso de la unidad. Revise siempre los códigos y ordenanzas locales antes de

una instalación.

IMPORTANTE: El instalador debe proporcionar orificios de montaje ocultos en la parte posterior

de la unidad antes de la instalación. Consulte la Figura 2 para conocer las sugerencias de

ubicaciones para los orificios de montaje.

1. Muros secos y de yeso: Disponga refuerzos en el interior del muro (que sirva para tornillos Nº 10 x 1

pulg.) en los lugares en que irán las ranuras de montaje que aparecen en la Figura 2 a continuación.

Otros tipos de pared: Disponga tapones de fibra o escudos ensanchadores (que sirvan para tornillos Nº 8

x 1-1/4 pulg. para lámina metálica, que proporciona el instalador), O disponga pernos acodillados o de

expansión de 1/8". Si se realiza la instalación en sitios en que la unidad se proyecta por sobre la parte

superior del friso de madera, disponga un perfil de aluminio en U o algún otro relleno que evite la

aparición de una brecha entre el muro terminado y la parte posterior de la unidad. Para los muros en

bloques, utilice escudos ensanchadores de metal (proporcionados por el instalador).

2. Abra la puerta y saque el basurero. Fije la unidad al muro a través de los orificios de montaje ocultos (que

proporciona el instalador), con el equipo adecuado para la construcción de su muro.

Bradley Corporation • P20-164; EN 05-1512 3/6/05

17-1/8"

(435mm)

56"

(1423mm)

42-1/2"

(1080mm)

CENTERLINE

OF BACKING

4" TYP

(102mm)

51"

(1295mm)*

8-1/2"

(216mm)*

14-13/16"

(376mm)*

2-1/4"

(57mm)*

CENTERLINE

OF BACKING

TO FLOOR

5'-0" MIN

(1524mm)

TO

6'-3" MAX

(1905mm)

* Suggested mounting hole

locations for installer

Figura 2

* Las sugerencias de ubicaciones

para los orificios de montaje (para

el instalador)

42-1/2"

(1080mm)

linea central

del apoyo

linea central

del apoyo

au suelo

5'-0"

(1524mm)

au

6'-3"

(1905mm)

Loading...

Loading...