Page 1

Solar Water Heater With Electric Backup

Solar Saver® Heaters

SERVICE

MANUAL

Troubleshooting Guide

and Instructions for Service

(To be performed ONLY by

qualified service providers)

Models Covered

by This Manual:

S-SW2-60R6DS

S-SW2-75R6DS

S-SW2-115R6DS

Manual 238-47297-00A

Save this manual for future reference

Page 2

Table of Contents

Page Service Procedure

Introduction ………………………………………………………………………. 2

Tools……………………………………………………………………………… 2

General Information ……………………………………………………………… 3 - - -

Sequence of Operation …………………………………………………………… 5 - - -

Troubleshooting ……………………………………………………………….…. 6 - - -

Line Voltage and High Limit (ECO) Testing…………………………………..… 8 RE-I

Heating Element Testing ……………................................................................... 9 RE-II

Thermostat Testing ……........................................................................................ 10 RE-III

Thermostat Removal and Replacement …………………………………………. 12 RE-IV

Heating Element Removal and Replacement ……………………………………. 13 RE-V

Dip Tube and Anode Inspection and Replacement ……………………………… 14 RE-VI

Generic Parts List ………………………………………………………………... 15 - - -

Page 2

This service manual is designed to aid service and maintenance professionals on the function, proper diagnosis and repair of

Bradford White solar water heaters with electric backup. Required service for system components beyond the solar water

heater should be directed to the system installer or directly to the system component manufacturer. System components

include such items as the solar controller, solar collector and circulator.

The text and illustrations in this manual provide step by step instructions to facilitate proper operation and troubleshooting

procedures. Contact the Bradford White Technical Support Group immediately for Bradford White supplied equipment if

diagnosis can not be made using the methods described in this service manual. Contact the solar component manufacturer for

assistance regarding other equipment.

Introduction

Solar Water Heater With

Electric Backup

Tools

- Multi Meter. - Phillips Head Screwdriver.

- 1-½ Deep Well Socket (element removal). - Thermometer.

- ¼" Nut Driver. - Drain Hose.

- Various Hand Tools: Pipe Wrench, Channel Locks, Pliers (common & needle nose), Wire Cutters, Wire Strippers,

Flashlight.

2

Page 3

G

ENERAL INFORMATION

240 VOLT

Ungrounded

Ungrounded

Grounding

BLACK

RED

GREEN

240 120

120

Service Wire Configuration

Single Phase Amps = Watts Example 4500W/240V = 18.75A

Volts

Watts = Amps x Volts Example 18.75A x 240V = 4500W

Ohms = Volts Example (240V) / 4500W = 12.8 Ohms

Watts

2

2

Commonly Used Formulas

Page 3

Wattage Limitation at 240 Volts

Solar Water Heater with Double Electric Element Backup Series (Non-Simultaneous operation)

Maximum

Wattage

Element

Upper/Lower

5,500

5,500/5,500

3

Page 4

G

ENERAL INFORMATION

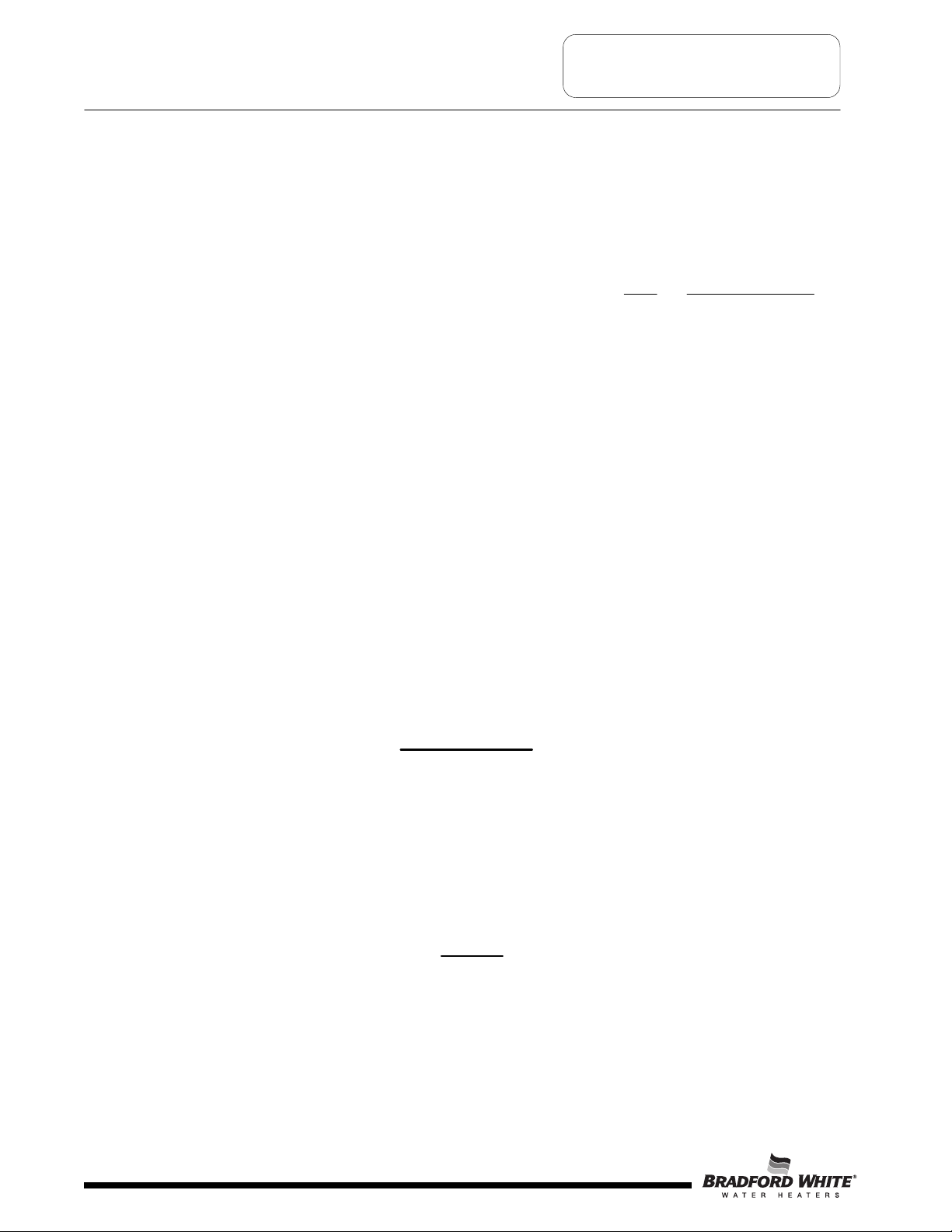

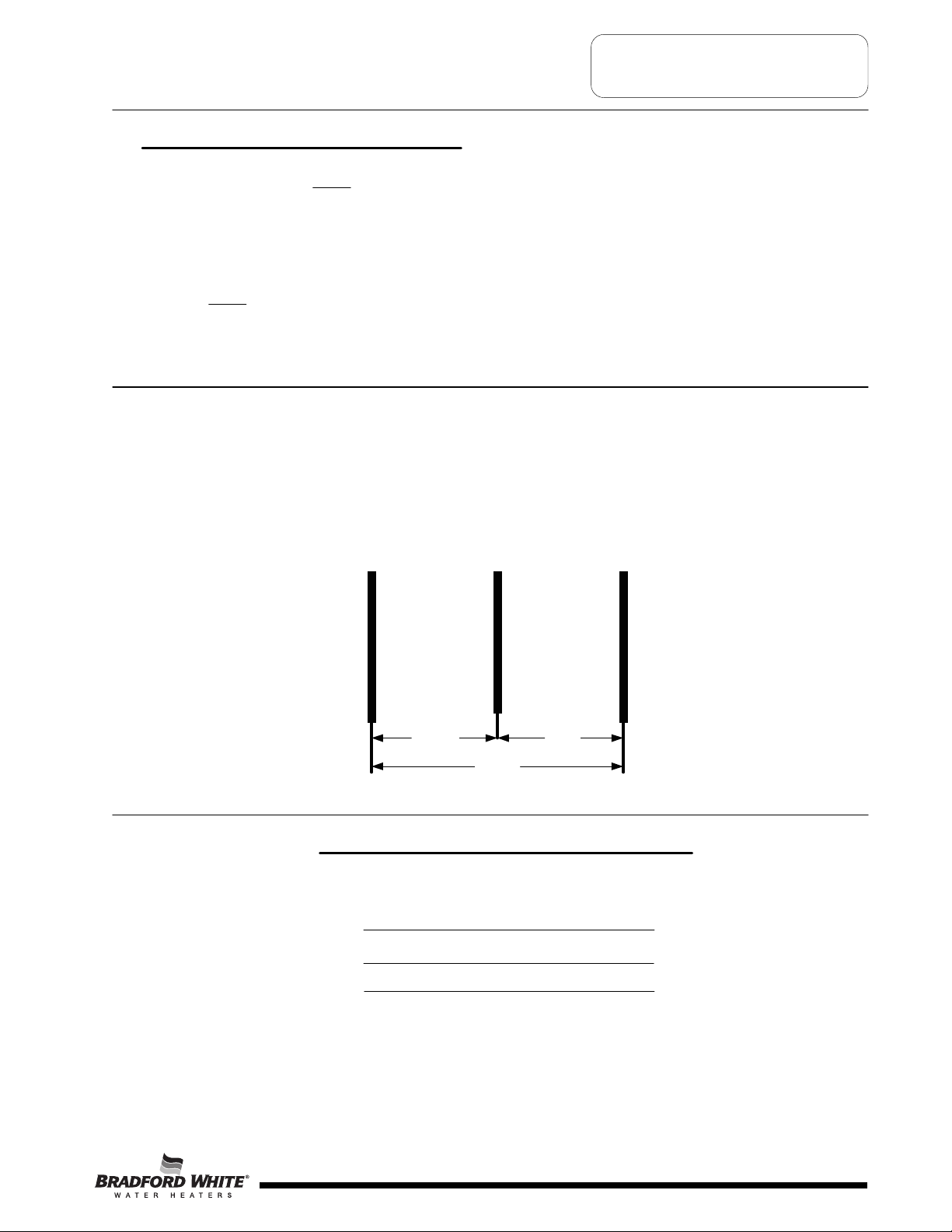

Upper thermostat

Surface Mount

With

ECO (high limit)

89T Series

Manual

ECO (high limit)

Reset button

Temperature

control Dial

Lower thermostat

Surface Mount

59T Series

Surface Mounted Thermostats

Surface mounted thermostats are mounted into a bracket which holds the thermostat against the side of the tank.

Surface mounted thermostats respond to tank surface temperatures to sense a call for heat, set point temperature

settings and high limit (ECO) activation. It is important that the entire back surface of the thermostat is in full contact or

flush with the tank. Improperly mounted thermostat will lead to improper heater operation.

1-½ Hex

Screw-in Flange

Terminal Block

Screw

Terminal Block

Zinc Incoloy Sheath

Element Rating Ink Stamped

on side of Terminal Block.

Direct Immersion “Screw-in” Type Heating Element

Page 4

4

Page 5

Non-Simultaneous Operation

Non-Simul taneous Mode: Allows only one heating element to operate at a time. For example, when the tank is cold,

the upper element is energized first, heating the top of the tank. Only when the upper thermostat is satisfied, the upper

element is de-energized and power is directed to the lower thermostat, energizing the lower element and heating the

b

ottom portion of the tank until the lower thermostat is satisfied. As hot water is drawn off the tank, it is replaced with

cold water delivered through the dip tube to the bottom of the tank. When the tank cools at the lower thermostat level,

the thermostat will call for heat energizing the lower element. If enough hot water is drawn from the tank, the top portion

of the tank cools and the upper thermostat will call for heat, de-energizing the lower element and allowing only the top

element to energize until the upper thermostat is satisfied.

The lower thermostat in the solar water heater is located above the internal heat exchanger. This design allows the heat

exchanger to be in cooler water during short draws, providing more heat transfer from the solar heating system.

S

EQUENCE OF OPERATION

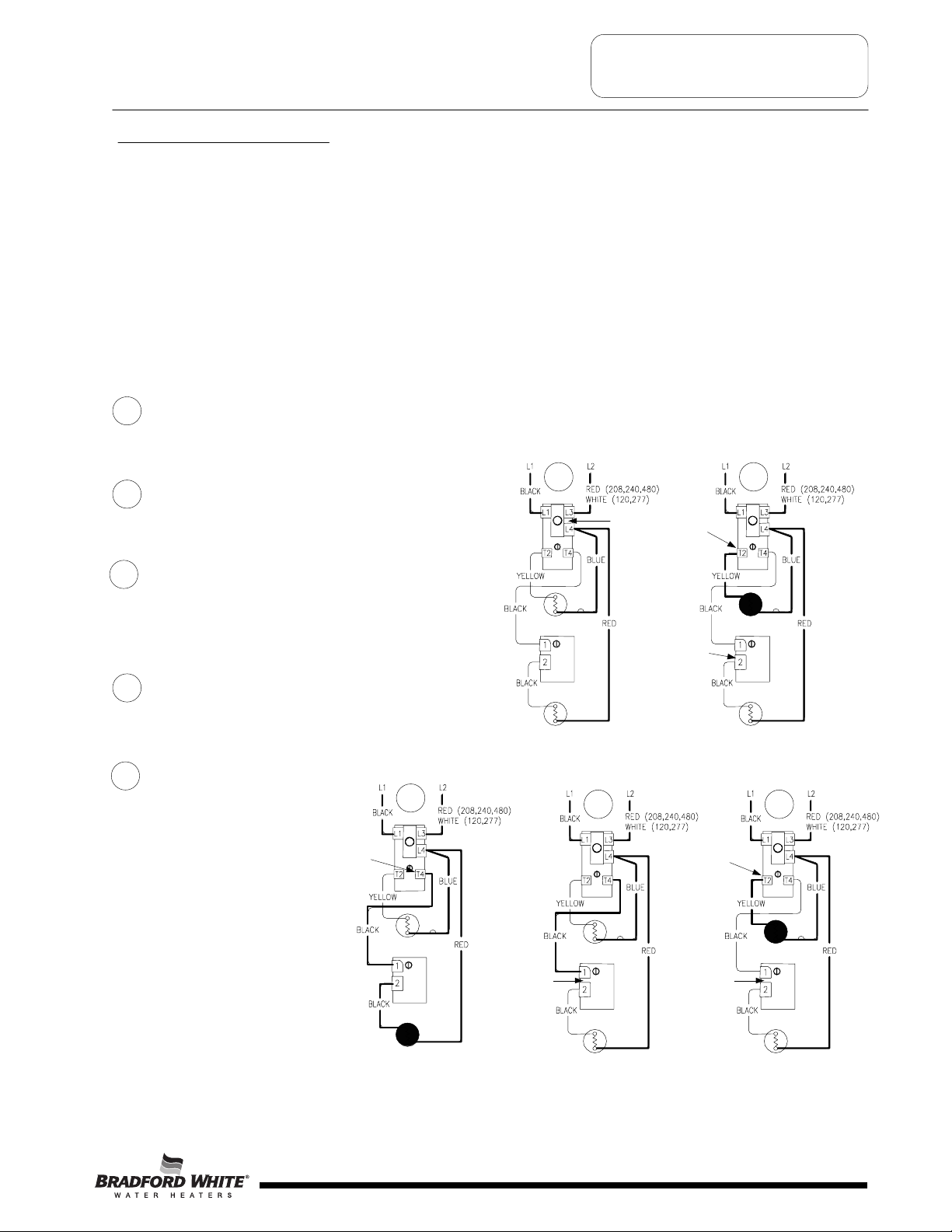

Sequence of Operation- Double Element, Non-Simultaneous Operation, Single Phase.

Line voltage is applied across terminals

L1 & L3 of the upper thermostat. ECO is

closed, so there is voltage at terminal L4

and to one side of the upper and lower

elements.

Tank is cold. Therefore, the thermostats are closed

at terminals T2 & 2 (calling for heat). The circuit is

complete through the upper thermostat only,

allowing current to flow through the upper element.

1

2

1 2

ECO

C

losed

Therm ostat closed

at terminal T2

When the upper thermostat is satisfied, it opens at

terminal T2, interrupting current flow through the

upper element. Terminal T4 closes, allowing voltage

to pass to terminal 1 of the lower thermostat. This

completes the circuit through the lower thermostat

and allows current flow through the lower element.

3

3

Thermostat closed

at terminal T4

4

Thermostat open

between terminals

1 and 2

Upper

T’stat

Upper

Element

Upper

T’stat

Upper

Element

Lower

T’stat

Lower

Element

Lower

T’stat

Lower

Element

When the lower thermostat is satisfied, it opens at

terminal 2, interrupting current flow through the

lower element. The system is now in stand-by mode

waiting for the next call for heat

4

The lower thermostat/element

combination will generally

cycle on and off more often

then the upper. In some cases,

such as a cold tank or in high

demand periods, the

upper thermostat will

call for heat (opening at

terminal T4 and closing at

terminal T2) prior to the lower

thermostat being satisfied. This

will interrupt current flow

through the lower thermostat

and element and allow current

to flow through the upper

element only. When the upper

thermostat is satisfied, it

resumes operation as

described in sequence #3

above.

5

5

Thermostat closed

between terminals

1 and 2

Upper

T’stat

Upper

Element

Lower

T’stat

Lower

Element

Upper

T’stat

Upper

Element

Lower

T’stat

Lower

Element

Upper

T’stat

Upper

Element

Lower

T’stat

Lower

Element

Thermostat closed

at terminal 2

Therm ostat closed

at terminal T2

Page 5

Solar water heaters with double electric element backup are designed to operate using a single operating mode detailed

as follows:

5

Page 6

T

ROUBLESHOOTING

Most common cause for improper electric backup operation can be linked to heating element failure.

When troubleshooting an electric backup solar water heater with the incidence of “No Hot Water” or “Insufficient Amount

of Hot Water”, it’s always a good idea to check the heating elements first following the procedure on page 9.

Common Heating Element Failures Are:

1. Dry Firing. Element may be partially submerged in water or most likely, completely exposed with no water in

the tank. In some cases sediment or lime build up around an element can eventually cause an air pocket, and

within seconds, result in a dry-fired element. At this point the element becomes inoperative. When element

replacement is required, be sure the tank is full of water prior to energizing the water heater.

2. Grounded Element. An element with a short circuit to ground will in most cases cause the circuit breaker in

the service panel to open or shut off. In some cases there may not be enough current draw for the circuit

breaker to open. This will allow the heating element to be in continuous operation resulting in over-heated

water, limited only by the ECO (Energy Cut Off) located in the thermostat. Repeated actuation of the ECO

reset button on the thermostat usually is the result of a grounded element.

3. Sediment build up. Slow hot water recovery can usually be traced back to sediment or lime build up around

the heating element. Sediment build up can also over time cause a dry-fired element.

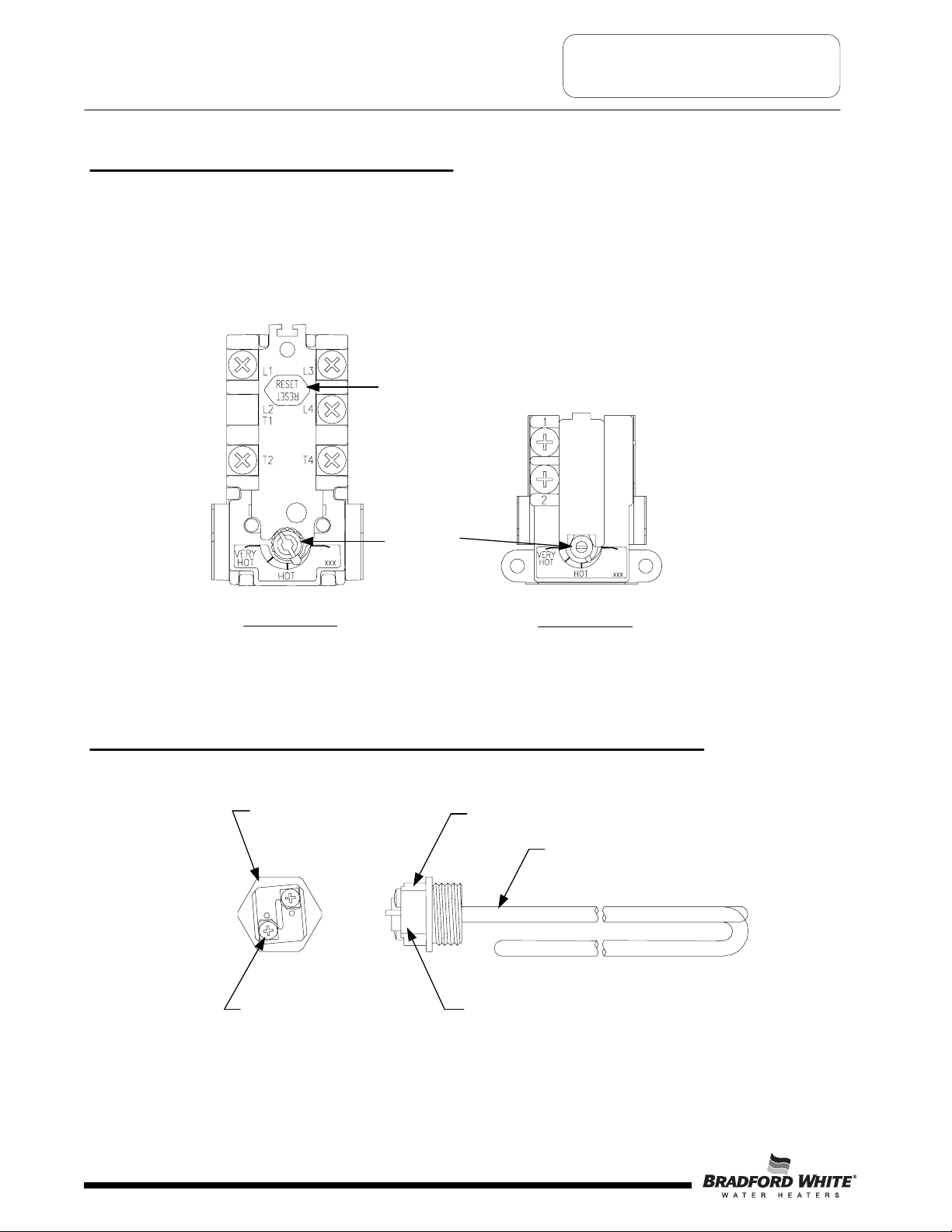

Illustration 1, below shows a common “Screw-In” type heating element identifying certain features commonly referred

to throughout this manual.

1-½ Hex

Screw-in Flange

Terminal Block

Screw

Terminal Block

Zinc Plated Incoloy Sheath

Element Rating Ink Stamped

on side of Terminal Block.

Illustration 1

Typical Direct Immersion “Screw-In”

Type Heating Element

Page 6

0642

4500W 240V

RC02404524

NOTICE

This Service Manual is for servicing the solar water heater. If other components of an

installed system requires service, those questions should be directed to the installer or

the specific component manufacturer.

6

Page 7

SYMPTOM PROBABLE CAUSE

CORRECTIVE ACTION

No Hot Water

1. No Power to heater.

2. Loose wire connections.

3

. Inoperative upper heating element.

4. Inoperative upper thermostat.

5

. Open ECO.

6. Inoperative solar controller or

connect ion.

7. Inoperative circulator in solar heating

system.

1. Inoperative lower heating element.

2. Ther mostats set to low.

3. Inoperative thermostat s.

4. Loose wire connection.

5. Sediment or lime build up on elements.

6. High demand period.

7. Undersized heater.

8. Very cold inlet water to h eater.

9. Plumbing connections reversed.

10. Damaged dip tube.

11. Improper solar collector application.

Not Enough Hot

Water

Slow Hot Water

Recovery

1. Sediment or lime build up on elements.

2. Loose wire connections.

3. Inoperative thermostat s.

4. Derated heating element installed.

Over Heated

Water or

Continues

Operation

1. Ther mostat not in contact with tank.

2. Grounded heating elements.

3. Ther mostat set to high.

4. Inoperative thermostat s.

5. Inoperative ECO.

6. Undersized water heater.

7. Incorrectly adjusted mixing device.

8. Improperly programmed solar controller.

1. Check fuse s or circuit brea kers in service panel.

2. Check all wire connections.

3

. Check heating elements. Replac e as needed.

4. Check therm ostats operation. Replace as

needed.

5. Check ECO. Reset or rep lace t hermostats as

needed.

6. Check for pr oper solar controller operation.

7. Check for proper circulator operation.

1. Check heating elements, replace as needed.

2. Incr ease thermostat setting.

3. Check thermostats, replace as needed.

4. Check all wire connection.

5. Remove heating elements and check for lime

build up .

6. Reduce demand.

7. Replace with larger heater.

8. Temper water to heater.

9. Correct plumbing connec tions.

10. Check dip tube, replace as needed.

11. Review solar collector calculations and

orientation.

1. Remove heating elements and check for

lime build up.

2. Check all wire connections.

3. Check thermostats, replace as needed.

4. Check te rminal block of element for proper

voltage and wattag e rating.

1. Position thermostat flush with tank surface.

2. Check heating elements. Replac e as needed.

3. Adjust thermostats to d esired setting.

4. Check thermostats, replace as needed.

5. Check ECO, replace thermostat as needed.

6. Replace with larger heater.

7. Adjust mixing device.

8. Refer to solar controller instructions.

SERVICE

PROCEDURE

3. See Service Procedure

RE-II, Page 9.

4

. See Service Procedure

RE-III, Page 10.

5. See Service Procedure

RE-I, Page 8.

6. Refer to Controller

manufacturer

7. Refe r to circulator

manufacturer

1. See Service Procedure

RE-II, Page 9.

3. See Service Procedure

RE-III, Page 10.

5. See Service Procedure

RE-V, Page 13.

10. See Service Procedure

RE-VI, Page 14.

11. Refer to solar collector

manufacturer.

1. See Service Procedure

RE-V, Page 13.

3. See Service Procedure

RE-III, Page 10.

1. See Service Procedure

RE-IV, Page 12.

2. See Service Procedure

RE-II, Page 9.

4. See Service Procedure

RE-III, Page 10.

5. See Service Procedure

RE-I, Page 8.

7. Refer to included mixing

device instructions.

Page 7

Noisy (singing or

hissing) Elements

1. Lime formation on elements. 1. Remove and clean heating elements.

Replace as needed.

1. See Service Procedure

RE-V, Page 13.

T

ROUBLESHOOTING

Quick Step Plan to Hot Water

1. TURN OFF power to water heater and solar controller.

Check all wire connections to insure they are tight and

corrosion free.

2. Turn power “ON” and determine that service voltage is

present and the high limit (ECO) has not actuated

(see procedure on page 8).

3. Check for inoperative heating element (see procedure on page 9).

4. Check for proper thermostat operation (see procedures beginning on page 10). NOTE: Thermostat testing procedures

assume items 2 and 3 above are in working order.

WARNING

High voltage exposure. Use caution when

making voltage checks to avoid personal injury.

NOTICE

This Service Manual is for servicing the solar water heater.

If other components of an installed system requires

service, those questions should be directed to the installer

or the specific component manufacturer.

7

Page 8

SERVICE PROCEDURE RE-I

L

ine Voltage & High Limit (ECO)

Testing

WARNING

High voltage exposure. Use caution when

making voltage checks to avoid personal injury.

Line Voltage Testing

Illustration 2 Illustration 3

1. Turn “OFF” power to water heater.

2. Remove access cover(s) from front of water

heater. Remove insulation and plastic cover

from thermostat.

3. Set multi-meter to volts AC.

4. Turn power “ON” to water heater.

5. Check voltage across terminals L1 & L3

of upper thermostat (see illustration 2).

A) Rated voltage IS present, power to the water

heater is okay.

B) Rated voltage NOT present, Check circuit breaker

at service panel.

ECO reset

button

1. Check voltage across terminals L1 & L4 upper thermostat (see illustration 3).

A) Rated Voltage IS present, ECO is okay.

B) Rated voltage NOT present, proceed to step 2.

2. Turn power “OFF” to water heater and firmly press ECO reset button on thermostat. Turn power “ON” and recheck

voltage across terminals L1 & L4 of upper thermostat

(see illustration 3).

A) Rated voltage IS present, the ECO has previously opened indicating the water in the tank, at

some point did overheat, check the following:

1. Thermostat must be in full contact with tank.

2. Be sure heating elements are not shorted to ground (see page 9).

3. Proper thermostat operation (see procedures beginning on page 10).

B) Rated voltage NOT present, water in tank may be over heated.

1. If water is hot, turn “OFF” power to water heater and flow water through tank to cool below set point

of upper thermostat. Recheck voltage per step 1.

2. If water is cool, Replace upper thermostat.

Page 8

High Limit (ECO) Testing

8

Page 9

SERVICE PROCEDURE RE-II

Heating Element Testing

Step 1. TURN OFF POWER TO WATER HEATER.

Step 2. Remove access covers from front of water

heater. Remove insulation and plastic cover

from thermostat.

Step 3. Disconnect wires from heating element.

Step 4. Set multi-meter to “ohms” setting.

Step 5. Touch probes of multi-meter to screw

terminals of heating element

(see illustration 4).

Step 6. Reading should be 12.8 ohms (±6%) for a 240

volt, 4500 watt element:

A reading outside the range using the formula

above (±6%), indicates a bad element and the

element must be replaced.

Testing For Open Or Burned Out Element.

WARNING

High voltage exposure. Be sure power is turned

OFF to water heater prior to performing this

procedure.

Testing For Heating Element Short Circuit To

Ground.

Step 1. TURN OFF POWER TO WATER HEATER.

Step 2. Remove access covers from front of water

heater. Remove insulation and plastic cover

from thermostat.

Step 3. Disconnect wires from heating element.

Step 4. Set multi-meter to “ohms” setting.

Step 5. Touch one probe of multi-meter to either screw

terminal of heating element and the other on

the element flange (see illustration 5). There

should be no reading on the ohm meter. Any

reading indicates a grounded element and the

element must be replaced. Repeat this step for

the other screw terminal.

Ohms = Volts

2

Watts

Element Screw Terminals

Meter Probe

Element Screw Terminal

Element Flange

M

eter Probe

Illustration 4

Illustr ation 5

Page 9

9

Page 10

W

ARNING

High voltage exposure. Use caution to avoid

personal injury during this procedure.

Double Element, Non-Simultaneous, Single Phase

Operation.

Water In Tank Is Cold With Power ON.

1. This procedure assumes line voltage, ECO and

elements are in working order.

2. Turn power “ON” to water heater.

3. Set multi-meter to “Volts AC”.

4. Check across terminals L4 and T2 of

upper thermostat (see illustration 6).

A) Rated voltage NOT present,

Recheck ECO. If ECO is okay,

replace thermostat.

B) Rated voltage IS present,

proceed to next step.

5. Check across element terminals

(see illustration 7).

A) Rated voltage NOT present,

check wire connections from

thermostat to element.

B) Rated voltage IS present,

Repeat element testing

see page 9.

Illustr ation 6

Tank Does Not Deliver Enough Hot Water.

1. This procedure assumes line voltage, ECO and

elements are in working order.

2. Turn power “ON” to water heater and set multi-meter to “Volts AC”.

3. Adjust temperature setting of upper thermostat to the highest setting.

Water temperature in tank must be below thermostat setting for this test.

4. See illustration 6 above, check voltage across terminals L4 and T2 of upper

thermostat.

A) Rated voltage IS present, okay, upper thermostat is

calling for heat. Go to step 5 below.

B) Rated voltage NOT present, replace upper thermostat.

5. Adjust temperature setting of upper thermostat to the minimum setting.

Water temperature in tank must be above thermostat setting for this test.

6. Check voltage across terminals L4 and T4 of upper thermostat

(see illustration 8).

A) Rated voltage NOT present, replace upper thermostat.

B) Rated voltage IS present, thermostat is okay. Go to step 7 on next page.

Illustration 7

Illustration 8

Page 10

SERVICE PROCEDURE RE-III

Thermostat Testing

10

Page 11

Double Element, Non-Simultaneous, Single Phase

Operation (continued).

Not Enough Hot Water (continued).

7. Check voltage across terminal L4 of upper

thermostat and terminal 1 of lower thermostat

(see illustration 9).

A) Rated voltage NOT present,

- check wire connection between thermostats.

B) Rated voltage IS present, okay, go to step 8.

8. Adjust lower thermostat to highest setting. Water temperature in

tank must be below the lower thermostat setting for this test.

9. Check voltage across terminal L4 of upper

thermostat and terminal 2 of lower thermostat (see illustration 10).

A) Rated voltage NOT present, replace lower thermostat.

B) Rated voltage IS present, thermostat is ok.

W

ARNING

High voltage exposure. Use caution to avoid

personal injury during this procedure.

Illustration 9

Illustration 10

WARNING

Be sure thermostats are reset to their original

temperature settings as found prior to

thermostat testing

Page 11

SERVICE PROCEDURE RE-III

Thermostat Testing

Water Temperature In Tank Is Above Thermostat Setting.

1. This procedure assumes line voltage, ECO and elements are in working

order.

2. Adjust upper and lower thermostats to the lowest setting.

3. Turn power “ON” to water heater and set multi-meter to “Volts AC”.

4. Check across terminals L4 and T2 of upper thermostat

(see illustration 6 on page 10).

A) Rated voltage IS present, replace upper thermostat.

B) Rated voltage NOT present, upper thermostat is okay. Go to step

5 below.

C) Lower than rated voltage IS present, recheck for grounded upper

element (see page 9).

5. Check across terminals L4 and 2 of lower thermostat (see illustration 10).

A) Rated voltage IS present, replace lower thermostat.

B) Rated voltage NOT present, lower thermostat is okay.

C) Lower than rated voltage IS present, recheck for grounded lower

element (see page 9).

11

Page 12

SERVICE PROCEDURE RE-IV

Thermostat Removal and Replacement

Front View

Thermostat Mounting

Thermostat Removal

1. Turn power “OFF” To water heater.

2

. Remove access cover and insulation.

3. Remove plastic thermostat protector from thermostat.

4. Disconnect wires from thermostat terminals. It may be necessary to label wires for proper re-connection to

new thermostat.

5. Note thermostat temperature setting for proper setting of new thermostat.

6. Slide thermostat upwards and out of mounting bracket.

W

ARNING

High voltage exposure. Be sure power is

“OFF” when performing this procedure.

Thermostat Replacement

1. Use a stiff brush to remove any debris or loose scale from tank surface where new thermostat will be installed.

2. Slide new thermostat down into thermostat bracket until it snaps into place. IMPORTANT! Thermostat must set

completely flat or flush to tank surface. An improperly installed thermostat will cause improper water heater

operation.

3. Refer to the wire diagram located on the inside of the access cover and re-connect wires to the thermostat. Be

sure wire connections are snug and corrosion free. Do not over tighten, doing so may damage thermostat.

4. Set thermostat to the original thermostat setting found on the old thermostat.

5. Re-install plastic thermostat protector.

6. Re-install insulation and access cover.

7. Restore power to water heater and verify proper heater operation.

Thermostat

Thermostat

mounting

bracket

Side View

Proper Thermostat

Mounting

Tank Surf ace

Side View

Improper Thermostat

Mounting

Proper Thermostat mounting

flush with tank surface

Improper Thermostat mounting.

Thermostat not flush with tank surface

Page 12

12

Page 13

SERVICE PROCEDURE RE-V

H

eating Element Removal

and Replacement

Heating Element Removal

1

. Turn power “OFF” To water heater.

2

. Turn off cold water supply to heater. Connect hose to drain

spigot of water heater and route to an open drain. Open

a nearby hot water faucet to vent heater for draining. Open

drain spigot of water heater and allow heater to drain

to a point below the elements.

3. Close drain spigot and remove hose.

4. Remove access cover and insulation.

5. Remove plastic thermostat protector from thermostat.

6. Disconnect wires from element terminals.

7. Remove element from tank using 1-½ deep well socket or appropriate wrench. Unscrew element counter-clockwise to

remove from tank.

8. Be sure to remove old element gasket from the tank. It is not recommended to be re-used.

W

ARNING

High voltage exposure. Be sure power is

“OFF” when performing this procedure.

Heating Element Replacement

1. Check element terminal block for proper electrical rating. NOTE: Some elements have dual ratings, be sure to check

all surfaces of the element terminal block (see illustration below).

2. Apply new element gasket to the new element. Be sure gasket is seated flat against element flange without rolls or

gaps (see illustration below).

3. Clean any debris from element fitting on tank. Lubricate element threads as needed with thread lubricant.

4. Thread new element clockwise into tank. Tighten element using 1-½ deep well socket or appropriate wrench. Do not

over tighten, over tightening may damage element gasket.

5. Reconnect wires to element, be sure wires are snug and corrosion free. Do not over tighten, doing so may damage

terminal block.

6. Resume water supply to heater, be sure tank is full of water and check for leaks.

7. Re-install plastic thermostat protector.

8. Re-install insulation and access cover.

9. To resume operation, BE SURE TANK IS FULL OF WATER and restore power to water heater. Verify proper heater

operation.

WARNING

Heater components and stored water may be

HOT when performing the following steps in

this procedure. Take necessary precaution to

prevent personal injury.

0642

4500W 240V

RC02404524

Date Code

Element Rating.

Example : (4500 Watt, 240 Volt)

Manufacturer Id entification

Element Flange

Element Gasket Seated Flat Against

Element Flange Without Rolls or Gaps

Page 13

Terminal

Block

13

Page 14

Page 14

S

tep 1. Turn power “OFF” to water heater.

Step 2. Turn off cold water supply to heater. Connect hose to drain spigot of water heater and route to an open drain.

Open a nearby hot water faucet to vent heater for draining. Open drain spigot of water heater and allow

heater to drain to a point below the inlet connection nipple.

Step 3. Close drain spigot and remove hose.

Step 4. Disconnect inlet nipple from plumbing system.

Step 5. With an appropriate wrench, remove inlet nipple/dip tube from the water heater. Use caution not to damage

nipple threads.

Step 6. Visually inspect inlet nipple/dip tube. Inlet nipple/dip tube should be free of cracks and any blockage.

Hydro-jets located near the bottom of the dip tube should be open and free of any blockage.

Anti-siphon hole located approximately 6" from the bottom of nipple, should be free of any blockage.

Any damage such as cracks, restriction due to deformation or unintentional holes are not field repairable

and the inlet nipple/dip tube must be replaced.

Step 7. Upon completion of inspection or subsequent replacement, reinstall inlet nipple/dip tube into heater. Connect

nipple to plumbing system, close spigot and remove drain hose, resume water supply and refill heater with

water.

Step 8. To resume operation, BE SURE TANK IS FULL OF WATER and turn power “ON” to water heater.

Dip Tube Inspection and Replacement

WARNING

Heater components and stored water may be HOT when performing the following steps in

this procedure. Take necessary precaution to prevent personal injury.

SERVICE PROCEDURE RE-VI

D

ip Tube and Anode Inspection and

Replacement

Anode Inspection and Replacement

Step 1. Turn power “OFF” to water heater.

Step 2. Turn off cold water supply to heater. Connect hose to drain spigot of water heater and route to an open drain.

Open a nearby hot water faucet to vent heater for draining. Open drain spigot of water heater and allow

heater to drain to a point below the outlet connection nipple.

Step 3. Close drain spigot and remove hose.

Step 4. Disconnect outlet nipple from plumbing system.

Step 5. With an appropriate wrench, remove outlet nipple/anode from the water heater. Use caution not to damage

nipple threads.

Step 6. Visually inspect outlet nipple/anode. Outlet nipple/anode should show signs of depletion, this is normal.

If depletion is ½ of the original anode diameter (original diameter approximately ¾”), replacement is

recommended. If any of the steel core of the anode is exposed, replacement is recommended.

Step 7. Upon completion of inspection or subsequent replacement, reinstall outlet nipple/anode into heater. Connect

nipple to plumbing system, close spigot and remove drain hose, resume water supply and refill heater with

water.

Step 8. To resume operation, BE SURE HEATER IS FULL OF WATER and turn power “ON” to water heater.

14

Page 15

Page 15

G

eneric Parts List

1. Integrated Mixing Device

2. Hex Head Anode

3. Junction Box Cover

4. Cover Conduit/Ground

5. ¾" Plug

6. Hot Water Outlet/Anode

7. Cold Water Inlet Dip Tube

8. Access Cover

9. Thermostat Protector (Large)

10. Heating Element

11. Thermostat Mounting Bracket

12. Thermostat w/High Limit (89T33)

13. Element Gasket

14. T&P Relief Valve

15. Lower Thermostat Protector (Small)

16. Thermostat (59T)

17. Brass Drain Valve

18. Kit Dairy Barn Leg

15

Page 16

Email

parts@bradfordwhite.com

techserv@bradfordwhite.com

www.bradfordwhite.com

Loading...

Loading...