Page 1

Commercial Electric

Water Heaters

9kW – 900kW Input Models

CHP-I&S-01

INSTALLATION AND SERVICE MANUAL

1

If the information in this

manual is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or loss of life

.

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of

this or any other appliance.

USE THIS APPLIANCE IF ANY

PART HAS BEEN UNDER WATER. THE

POSSIBLE DAMAGE TO A FLOODED

APPLIANCE CAN BE EXTENSIVE AND

PRESENT NUMEROUS SAFETY HAZARDS.

ANY APPLIANCE THAT HAS BEEN UNDER

WATER MUST BE REPLACED.

Installation and service must be performed by

Qualified Service Personnel Only

.

Factory warranty (shipped with unit) does not

apply to units improperly installed or improperly

operated.

Experience has shown that improper installation

or system design, rather than faulty equipment, is

the cause of most operating problems.

Excessive water hardness causing a lime/scale

build-up in the heater and/or on the immersion

heating elements is not the fault of the equipment

and is not covered under the manufacturer’s

warranty. (See Water Treatment and Water

Chemistry)

Do not energize electrical system before heater

is completely filled with water.

Damage caused

to the immersion heating elements by dry fire is

not covered under the manufacturer’s warranty.

Follow start up procedure in the manual.

Water heater corrosion and component failure

caused by air-borne chemical vapors is not

covered under the manufacturer’s warranty.

Corrosion damage caused by current leakage due

to improper grounding of electrical systems or

electronic components to the storage tank and

related piping is not covered by the

manufacturer’s warranty. Under no circumstance

will the manufacturer be liable for consequential

damages resulting from the installation or use of

this equipment. Correct installation procedure

and local codes must be adhered to.

This manual supplies information for the

installation, operation and servicing of the

appliance. It is strongly recommended that this

manual be reviewed completely before

proceeding with an installation. Upon receiving

equipment, check for signs of shipping damage.

Pay particular attention to parts accompanying

the water heater, which may show signs of being

hit or otherwise being mishandled. Verify total

number of pieces shown on packing slip with

those actually received. In case there is damage

or a shortage, immediately notify carrier.

CHECKING EQUIPMENT

WARNING:

NOTE: Retain this manual for future reference.

WARNING:

Improper Installation, Adjustment,

Alteration, Service or Maintenance

can cause injury or property damage. Refer

to this manual. For assistance or additional

information consult a qualified installer,

service agency or the electric utility.

SPECIAL INSTRUCTIONS

TO OWNER

WARRANTY

DO NOT

Page 2

2

CONTENTS

Star

t-Up Procedure

Filling the Water Heater . . . . . . . . .22

Start-Up Checks . . . . . . . . . . . . . . .23

Shutdown Procedure . . . . . . . . . . . .24

Maintenance

T&P Relief Valve . . . . . . . . . . . . . .24

Water Chemistry . . . . . . . . . . . . . . .25

Flushing the Tank . . . . . . . . . . . . . .25

Sediment Removal . . . . . . . . . . . . .25

Scale Removal - Elements . . . . . . .25

T

rouble Shooting

Not Enough Hot Water . . . . . . . . . .27

Water Is Too Hot . . . . . . . . . . . . . .27

Water Heater Sounds . . . . . . . . . . .27

Leakage . . . . . . . . . . . . . . . . . . . . .27

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety Warnings . . . . . . . . . . . . . . . .1

Checking the Equipment . . . . . . . . . .1

Codes . . . . . . . . . . . . . . . . . . . . . . . .4

Installation Requirements

Location . . . . . . . . . . . . . . . . . . . . . .4

Drain Pan Requirements . . . . . . . . . .5

Clearances . . . . . . . . . . . . . . . . . . . .6

Mounting . . . . . . . . . . . . . . . . . . . . .7

Water Connections . . . . . . . . . . . . . .7

Tank Construction . . . . . . . . . . . . . .8

Relief Valve . . . . . . . . . . . . . . . . . . .8

Thermal Expansion . . . . . . . . . . . . .8

Cathodic Protection . . . . . . . . . . . . .9

Electrical Ser

vice

Electrical Connection . . . . . . . . . . .9

Wire Sizing . . . . . . . . . . . . . . . . . . .9

Fusing . . . . . . . . . . . . . . . . . . . . . .9

Electrical Connection . . . . . . . . . . . .9

Jacket Assembly . . . . . . . . . . . . . . .10

Standard and Optional Controls . . .10

Components and Contr

ols

Terminal Block . . . . . . . . . . . . . . . .11

Fuses and Fuse Blocks . . . . . . . . . .12

Contactors . . . . . . . . . . . . . . . . . . .12

Transformer . . . . . . . . . . . . . . . . . .12

Immersion Thermostat . . . . . . . . . .13

Temperature Regulation . . . . . . . . .13

Risk of Scald Warnings . . . . . . . . .14

Temperature Control Sequencer . . .14

Display . . . . . . . . . . . . . . . . . . . . . .16

Temperature Adjustment . . . . . . . . .17

Error Messages . . . . . . . . . . . . . . . .18

Temperature Limit Control . . . . . . .18

Immersion Heating Elements . . . . .19

Safety Door Lock . . . . . . . . . . . . . .19

Low Water Cut-Off . . . . . . . . . . . . .20

Low Water Pressure Switch . . . . . .20

High Water Pressure Switch . . . . . .20

Manual Limiting Switches . . . . . . .20

Time Clock . . . . . . . . . . . . . . . . . . .21

Pilot Lights . . . . . . . . . . . . . . . . . . .21

Alarm Bell . . . . . . . . . . . . . . . . . . .21

Page 3

3

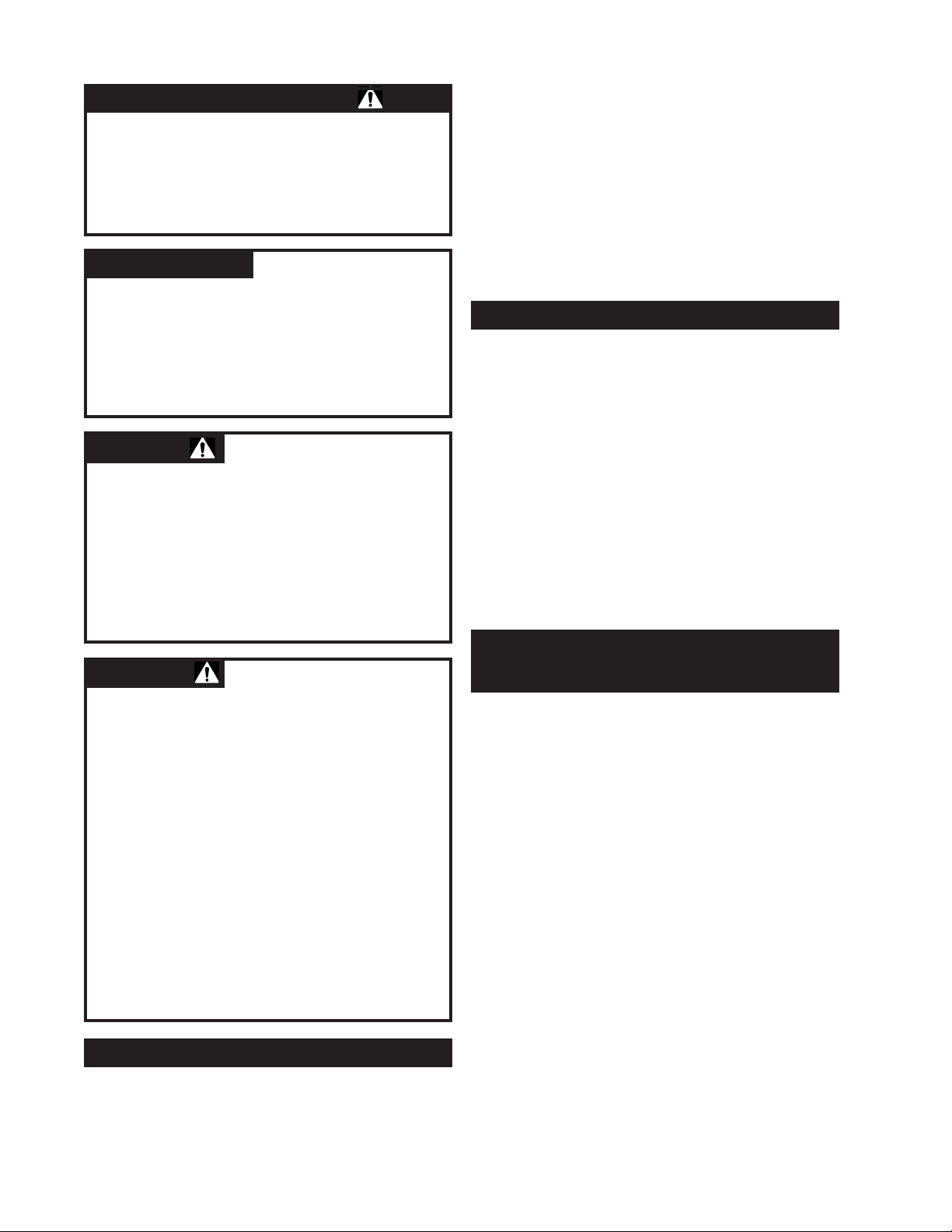

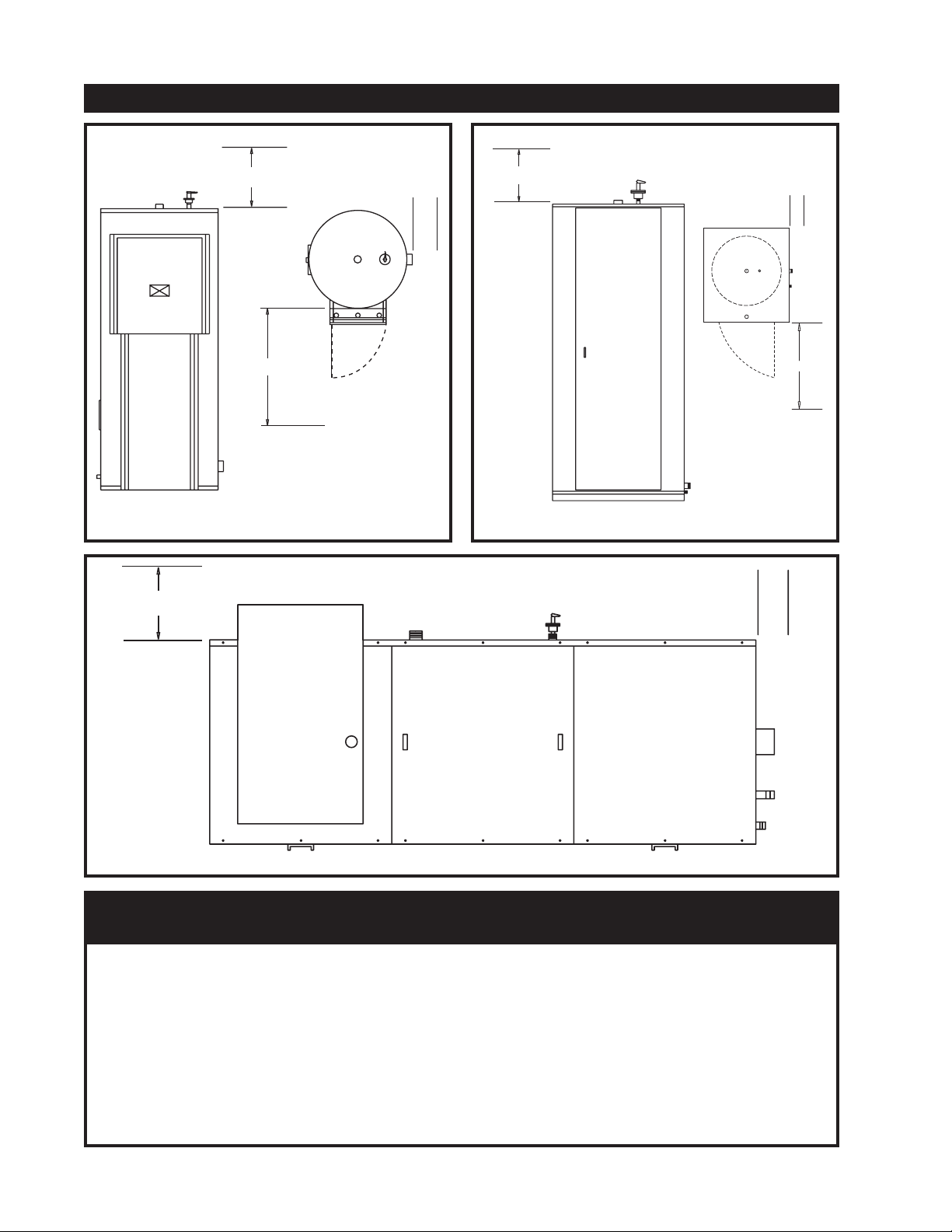

FIG. 2 Front View Vertical Square Models

FIG. 1 Front View Vertical Round Models

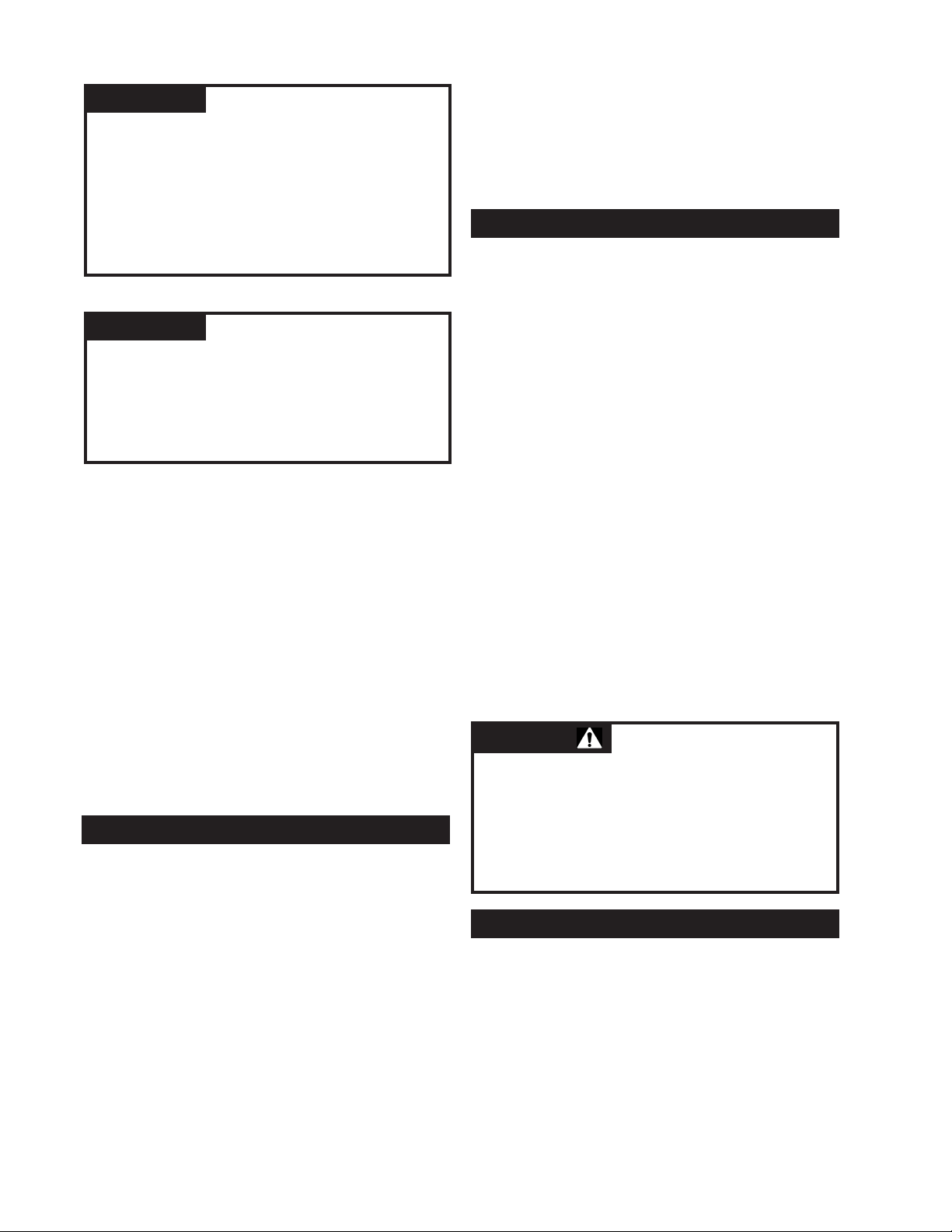

FIG. 3 Front View Horizontal Models

Page 4

To minimize the possibility

of serious personal injury, fire or damage to

your appliance, never violate the following

safety rules.

1. Always keep the area around your

appliance free of combustible

materials, gasoline, and other

flammable liquids and vapors.

2. Never cover your appliance, lean

anything against it, store trash or

debris near it, stand on it or in any

way block the access to your

appliance.

Be sure to turn off power

when working on or near the electrical

system of the water heater. Never touch

electrical components with wet hands or

when standing in water. When replacing

fuses, always use the correct size for the

circuit. Do not test electrical system before

the water heater is completely filled with

water. Follow the start-up procedure.

Consult and follow

local Electrical Codes, Building and Fire

Regulations and other Safety Codes that

apply to this installation. Consult local

codes officials and electric utility company

to authorize and inspect all field installed

electrical connections.

The equipment shall be installed in accordance

with those installation regulations in force in the

local area where the installation is to be made.

These shall be carefully followed in all cases.

Authorities having jurisdiction shall be consulted

before installations are made. In the absence of

such requirements, the installation shall conform

to the latest edition of the National Electrical

Code, NFPA 70. When the appliance is installed

in Canada, it must conform to the CAE C22.1,

Canadian Electrical Code, Part 1 and/or local

Electrical Codes.

This complete appliance is design certified and

Listed by Underwriters Laboratories as a

commercial storage electric water heater. This

water heater bears the UL certification for the

United States as tested under the Standard for

Electric Booster and Commercial Storage Tank

Water Heaters, UL1453 and C-UL in Canada as

tested under the Standard for Construction and Test

of Electric Storage Tank Water Heaters,

CAN/CSA-C22.2 No. 110-M90. All water heater

storage tanks conform to the latest edition of the

ASME Boiler and Pressure Vessel Code, Section IV.

1. Locate the appliance so that if water

connections should leak, water damage

will not occur. When such locations

cannot be avoided, it is recommended that

a suitable drain pan, adequately drained,

be installed under the unit. Under no

circumstances is the manufacturer to be

held responsible for water damage in

connection with this unit, or any of its

components.

2. Insure that the appliance is located near

an acceptable drain so that the vessel can

be properly drained when performing

service or maintenance. The drain must

also provide adequate drainage in the

event of leakage the tank or related

piping. The drain must prevent water

damage to the adjacent area and lower

floors of the structure.

4

INSTALLATION PROCEDURE

LOCATION OF UNIT

OWNER WARNING

IMPORTANT:

CAUTION:

WARNING:

CODES

APPROVALS

The information contained in this manual

is intended for use by qualified professional

installers, service technicians or the electric

utility. Consult your local expert for

proper installation or service procedures.

Page 5

3. The appliance must be installed so that

the electrical components are protected

from water (dripping, spraying, etc.)

during appliance operation and service

(replacing of fuses, elements, etc.)

4. Appliances located in a garage or parking

structure shall be installed so that the

jacket and all piping shall be located or

protected so that it is not subject to

physical damage by a moving vehicle.

5. The appliance must be installed on a level

floor. Shim the base as necessary if

leveling is required.

6. The floor on which the appliance is

installed must be capable of supporting

the total weight of the water heater when

completely filled with water.

Combustible floor locations may be used.

Maintain required clearances from

combustible surfaces.

7. The appliance must not be installed on

carpet.

8. The appliance must be installed indoors

where it is protected from exposure to

wind, rain and weather.

9. Locate the appliance as close as possible

to the point of major hot water usage, the

water piping and branch electrical circuit

wiring.

10. Insulate water piping to control heat loss

and possible condensation.

11. The appliance must be located in an area

that is not subject to freezing. The

ambient temperature of the space where

the appliance is installed must not go

below 32° F (0° C) or above 104° F (40° C).

The lower pan of the horizontal water heater

jacket or vertical square water heater jacket is

specially constructed to function as a drain pan.

A water discharge opening is located in either end

of the pan. The discharge opening(s) used must

be piped to a suitable floor drain. If only one

discharge opening in the jacket pan is piped to a

floor drain, the unused opening must be plugged.

This jacket pan provides an extra margin of

protection against water damage on vertical

square or horizontally constructed models.

5

Drain Pan on Horizontal Models

and Vertical Square Models

1250 Gallons and Larger

CAUTION:

This water heater, as well as all water

heaters will eventually leak. Installation of

the water heater should be accomplished in

such a manner that if the tank, piping or

any connections should leak, the flow of

water will not cause damage to the

structure. For this reason, it is not

advisable to install the water heater in an

attic or upper floor. When such locations

can not be avoided, a suitable drain pan

must be installed under the water heater.

Drain pans may be fabricated or

purchased from your plumbing wholesaler.

The drain pan must be piped to an

adequate drain. Under no circumstances is

the manufacturer to be held liable for any

water damage in connection with this

water heater.

Page 6

Right Side - 6" (15cm) (24" (0.61m) for high kW vertical square models with an

additional control panel on right side)

Rear - 0"

Left Side - 0"

Front - 36" (0.91m) for service access to controls and heating elements

Top - 12" (30cm) for service access to electrical service, water connections and piping

Water Pipes - 1" (25.4mm)

6

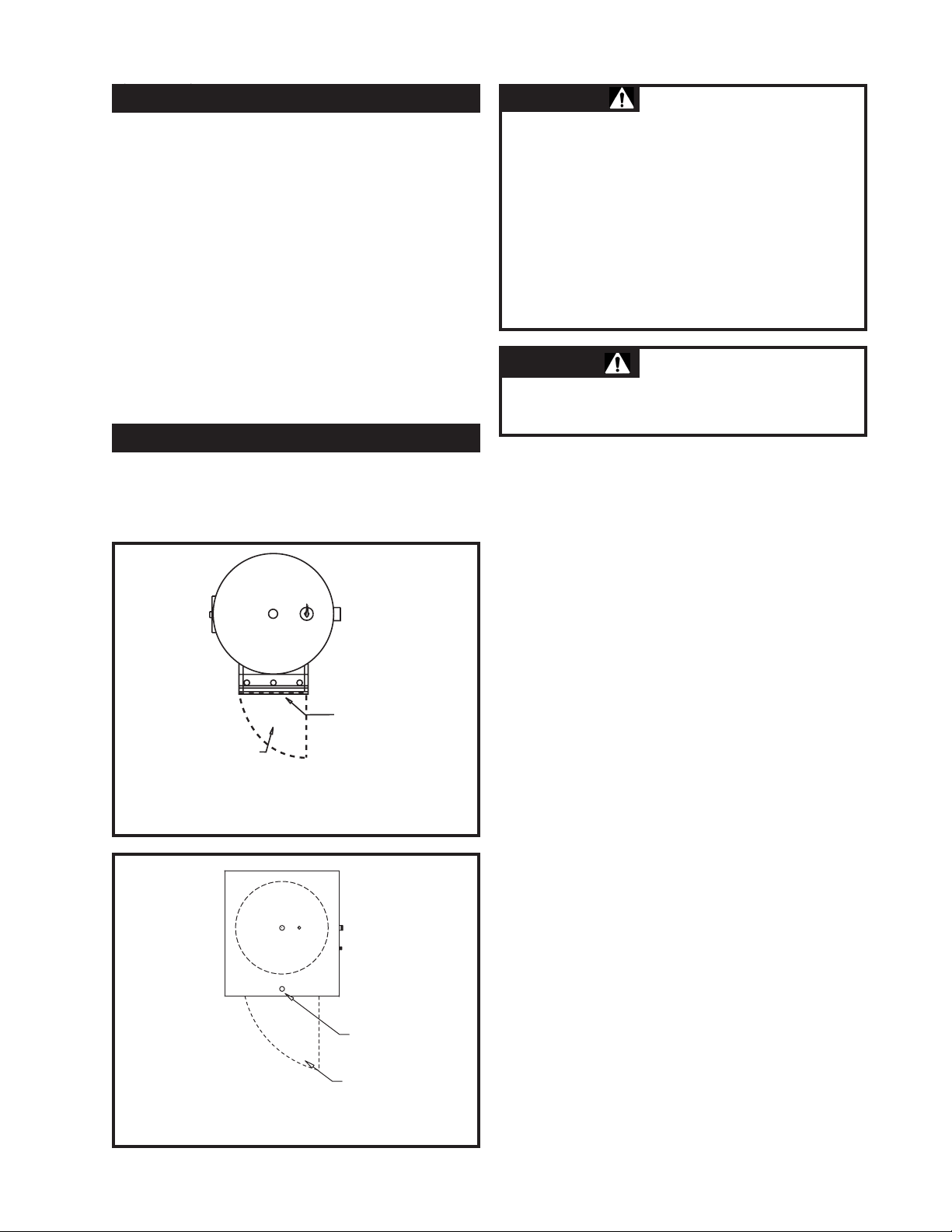

FIG. 5 Clearances from Combustible Construction

12"

36"

6"

FIG. 4 Clearances from Combustible Construction

CLEARANCES FROM COMBUSTIBLE CONSTRUCTION

6"

12"

FIG. 6 Clearances from Combustible Construction

TABLE A

CLEARANCES FROM COMBUSTIBLE CONSTRUCTION

12"

6"

36"

Page 7

7

Maintain minimum specified clearances for

adequate operation. All installations must allow

sufficient space for servicing the electrical

components, water pipe connections, piping and

other auxiliary equipment, as well as the appliance.

Multiple appliances may be installed in a modular

water heater installation. Multiple appliances

may be installed side by side with minimum

clearance between the sides of adjacent

appliances because no service access is required

from the sides on most models. Note that high

kW input vertical square water heaters may have

an additional control access panel located on the

right side of the jacket requiring an additional

service access from the right side.

The water heater should be mounted to the floor

following applicable architectural and local code

requirements or accepted standards for the specific

site and model purchased. In areas prone to seismic

activity, it is recommended that the water heater be

mounted to the floor according to recommended

procedures for the site. In some geographic areas,

additional strapping or braces may be required,

consult local codes for specific requirements.

Proper mounting will help to make the water heater

less susceptible to seismic damage.

WATER CONNECTIONS

HANDHOLE

CLEANOUT

DRAIN

HOT WATER

OUTLET

TEMPERATURE & PRESSURE

RELIEF VALVE

COLD WATER

INLET

FIG. 7 Water Connections- Vertical Round Models

TEMPERATURE & PRESSURE

RELIEF VALVE

HOT WATER

OUTLET

DRAIN PAN

CONNECTION

COLD WATER

INLET

FIG. 8 Water Connections- Vertical Square Models

MOUNTING

WATER CONNECTIONS

TEMPERATURE & PRESSURE

RELIEF VALVE

HOT WATER

OUTLET

COLD WATER

INLET

MANWAY (OPTIONAL)

DRAIN

FIG. 9 Water Connections- Horizontal Models

Page 8

Before making any

connections to the cold water inlet or hot

water outlet, insure that all piping is clean and

free of material or scale. This can usually be

accomplished by “blowing out the pipe.” Any

foreign material or scale entering the water

heater can adversely affect operation and

performance.

Inlet and Outlet Connections

For ease of service, install unions on the cold

water inlet and hot water outlet of the water

heater. The cold water inlet connection is located

on the lower right side of the water heater. A

manual shutoff valve should be installed

upstream on the cold water source as an isolation

device. The hot water outlet connection is located

on the top center of the water heater. A manual

shutoff valve should be installed downstream on

the hot water outlet source as an isolation device

in case the water heater must be disconnected

from the system.

This appliance uses a glass lined steel tank to

store the heated water for use. The storage tank

is constructed in accordance with the ASME

Boiler and Pressure Vessel Code requirements,

stamped and registered with the National Board

of Boiler and Pressure Vessel Inspectors. The

tank is furnished with threaded connections for

cold water inlet, hot water outlet, a relief valve

and a drain connection. The storage tank has a

hand hole for ease of inspection, cleanout and

service. An optional manhole may be specified

for greater ease of inspection. The interior of the

storage tank is glass lined and fired to 1600˚F

(871˚C) to insure a molecular fusing of glass and

steel to protect the steel base metal against

corrosion . A magnesium anode(s) is standard to

help prevent dissipation of the tank material by

electrolytic action.

This water heater is supplied with a temperature

and pressure relief valve(s) sized in accordance

with ASME Boiler and Pressure Vessel Code,

Section IV. Some water heaters may be supplied

with an optional pressure only relief valve. The

relief valve(s) is installed in the vertical position

and mounted in the tapping provided in the

storage tank. No valve is to be placed between

the relief valve and the water heater. To prevent

water damage, the discharge from the relief valve

must be piped to a suitable floor drain for

disposal when relief occurs. No reducing

couplings or other restrictions shall be installed in

the discharge line. The discharge line shall allow

complete drainage of the valve and line. Relief

valves should be manually operated at least once

a year. A relief valve that fails to completely

reseat and continues to discharge water must be

immediately replaced with a new, properly sized,

temperature and pressure relief valve.

A relief valve that discharges periodically may be

due to thermal expansion in a closed system. A

water heater installed in a closed system, such as

one with a backflow preventer or check valve

installed in the cold water supply, shall be

provided with means to control expansion.

Contact the water supplier or local plumbing

inspector on how to correct this situation.

DO NOT plug or cap the relief valve.

8

STORAGE TANK

NOTE:

When using copper tubing,

solder tubing to an adapter before attaching

to the threaded nipple connection provided

on the water heater. Soldering directly to the

threaded connection may harm a lining in the

nipple or damage the tank lining.

NOTE:

RELIEF VALVE

Avoid contact with hot

discharge water. Insure that no one is in

front of or around the relief valve discharge

line. Make sure that the extremely hot

water manually discharged from the relief

valve will not cause bodily injury or

property damage.

CAUTION:

THERMAL EXPANSION OF WATER

Page 9

discharge!

Hydrogen gas can be produced in a hot water

system that has not been used for a long period of

time (generally two weeks or more). Hydrogen

gas is extremely flammable. To prevent the

possibility of injury under these conditions, we

recommend the hot water faucet be open for

several minutes at a sink close to the water heater

before you use any electrical appliance which is

connected to the hot water system. If hydrogen is

present, there will be an unusual sound such as air

escaping through the pipe as the hot water begins

to flow. There should be no smoking or open

flames near the faucet at the time it is open.

All installation procedures involving electric

power connection should only be performed by a

trained, certified electrician.

9

HINGED DOOR TO

ELECTRIC CONTROL

COMPARTMENT

ELECTRIC ACCESS

FIG. 11 Electric Power Connections –

Electrical Control Panel – Square Models

HINGED DOOR

TO ELECTRICAL

COMPARTMENT

ELECTRIC

ACCESS

FIG. 10 Electric Power Connections –

Electrical Control Panel – Round Models

The appliance, when installed, must be

electrically grounded in accordance with the

requirements of the authority having

jurisdiction or in the absence of such

requirements, with the latest edition of the

National Electrical Code, NFPA No. 70.

When the appliance is installed in Canada, it

must conform to the CAE C22.1, Canadian

Electrical Code, Part 1 and/or local Electrical Codes.

1. Use copper conductors only. All wiring

between the appliance and field installed devices

shall be made with copper wire suitable for at

least 75° C (167° F) temperature rating. If the

wiring from an old water heater installation was

aluminum, replace the old wire with copper wire.

2. The factory internal wiring is attached to a

terminal block inside the unit. The branch

circuit is connected to the terminal block

through an opening provided on the top of the

water heater electrical access panel.

3. Line voltage wire exterior to the appliance

must be enclosed in approved conduit or

approved metal clad cable.

4. To avoid serious damage,

DO NOT energize

the appliance until the system is full of

water

. Ensure that all air is removed from the

storage tank and piping before beginning

CATHODIC PROTECTION

ELECTRICAL CONNECTIONS

WATER HEATER IS

EQUIPPED FOR OPERATION ON ONE

VOLTAGE ONLY.

Check the rating plate on

the front of the control panel access for the

correct voltage and phase.

DO NOT use this

water heater with any other voltage other than

the voltage specified on the rating plate.

Failure to use the correct voltage can cause

problems that can result in death, serious

bodily injury or property damage.

DO NOT CONNECT THE

WATER HEATER TO AN IMPROPER

SOURCE OF ELECTRICITY!

CAUTION:

WARNING:

Page 10

initial operation. Operation of a water heater

without a completely filled tank may result in

serious damage to the appliance and heating

element burn out.

5. The water heater should be connected with a

separate grounded branch circuit with over

current protection and disconnect switch. The

water heater should be grounded in accordance

with national and local codes. A ground

terminal is provided for ground connection only.

6. Provide the appliance with proper overload

protection in the branch circuit. It is suggested

that the electrician size the branch circuit at 125

percent of the heater ampere rating and further

increase wire size as necessary to compensate

for voltage drop in long runs. Branch circuit

voltage drop should not exceed 3% at the heater.

7. Voltage applied to the heater should not vary

more than +5% to -10% of the model and

rating plate marking for satisfactory operation.

8. A wiring diagram is provided with the water

heater for the electricians use.

Outer Jacket – The outer jacket assembly is

constructed from steel, galvanized on both sides.

The galvanized surface is specially prepared and

phosphate coated to allow application of a

multiple coat enamel paint process. This coating

process insures a long life from the jacket

assembly.

Your commercial electric water heater is

equipped with the following as standard

equipment.

• Low watt density immersion heating

elements with an incoloy sheath.

• Internal fusing of all elements in a

maximum of 48 amp increments provides

additional safety. Fuse cartridges are

related at 1,000,000 amps interrupting

capacity.

• A galvanized steel outer jacket and

electrical control panel are provided.

• Channel iron skid base.

• Electrical control panel is provided with a

hinged door and key lock.

• A glass lined steel tank constructed to

ASME specifications and provided with

magnesium anode(s).

• ASME rated temperature and pressure relief

valve provided by factory to insure safe

heater operation.

• Terminal block connections are installed by

the factory for safe easy wiring connection.

• Manual reset high water temperature limit

control.

• Immersion thermostat (one per 54kW of

input as standard).

• 180˚F (82.2˚C) temperature operation is possible

to provide water for sanitizing applications.

• Insulated to meet the latest edition of

ASHRAE 90.1 energy efficiency

standards.

• 3 year limited warranty provides protection

against failure of tanks due to defects in

material and workmanship in commercial

application.

• Underwriter’s Laboratories, Inc. listing for

all models as a commercial electric water

heater.

10

JACKET ASSEMBLY

Never turn on the electric

power or attempt to use this electric water

heater unless it is completely full of water.

Water must flow from the hot water faucet

before turning electrical power “ON.”

Operation of a water heater without a

completely filled tank may result in serious

damage to the appliance and heating

element burn out

CAUTION:

STANDARD EQUIPMENT

Page 11

The following items are available as extra cost

options.

• Electronic low water cut-off prevents

energizing of the heater when it is not filled

with water.

• Pilot lights – Monitor on-off cycle of

contactors.

• Manual limiting switches with indicating

lights to permit heater kW input to be

manually limited as desired.

• Temperature and pressure gauges are

available installed flush with the jacket to

monitor heater performance.

• Electronic step controller modulates power

in-put and balances load to demand.

• Safety door interlock prevents opening of

access door while heater is energized.

• Shunt trip disconnect provides power

disconnect upon a control sensed

malfunction.

• Alarm bell provides an audible alarm to

warn of various control failures.

• Time clock to control off-on cycles of the

heater as programmed by the owner or

electric utility requirements.

• Low water pressure switch.

• High water pressure switch.

A main power terminal block is provided for field

connection of the branch power supply to the

electric water heater. All internal power circuits

to the immersion heating elements are connected

to the load side of the main terminal block. The

line side of the terminal block has individual lug

type connections properly sized for the

recommended copper field wire size.

11

OPTIONAL EQUIPMENT

COMPONENTS AND CONTROLS

POWER CIRCUIT FUSE BLOCK

IMMERSION

THERMOSTAT

CONTACTOR

(IF EQUIPPED)

LOW WATER

CUTOFF

(IF EQUIPPED)

CONTROL

CIRCUIT

FUSE BLOCK

CONTROL

CIRCUIT

FUSE BLOCK

TRANSFORMER

TERMINAL BLOCK

GROUND LUG

FIG. 12 Electrical Panel Component Location

Drawing

TERMINAL BLOCK

LOAD

LINE

FIG. 13 Main Power Terminal Block

Page 12

Each internal power circuit is fused for safety.

Each power circuit to an immersion element is

fused at a maximum of 48 amps. Power circuits

may be fused at lower current levels as needed to

balance current on three phase units. The power

circuit fuses are held by a spring loaded fuse

block rated for the voltage specified to operate

the water heater.

The control circuit is also fused on both the

primary and secondary sides of the control circuit

transformer.

The power to the immersion electric heating

elements is switched by a definite purpose

magnetic contactor. The contactor is supplied

with 120 VAC from the control circuit when the

immersion thermostat senses a drop in stored

water temperature below the desired set point. A

magnetic coil in the contactor is energized to

complete the electrical circuit supplying power to

the immersion heating elements. When the

thermostat is satisfied, the contactor coil is deenergized and power to the heating elements is

turned off.

CONTROL CIRCUIT TRANSFORMER

A transformer is used to reduce the line voltage to

120 VAC for internal control operation. The

transformer is fused on both the primary and

secondary side. The common side of the

secondary control circuit is grounded. The VA

rating of the control circuit transformer is based

on the load of the various components in the

water heater control circuit.

12

FIG. 14 Fuse Block with Power Circuit Fuses

FUSE AND FLUE BLOCKS

FIG. 15 Magnetic Contactor

CONTACTORS

CONTROL CIRCUIT TRANSFORMER

HAZARD OF ELECTRICAL SHOCK –

Before opening the electrical access panel

to adjust the thermostat or servicing the

water heater, make sure the electrical

supply to the water heater is turned “OFF”.

Failure to do this could result in death,

serious bodily injury or property damage.

WARNING:

FIG. 16 Control Circuit Transformer

Page 13

This water heater uses an immersion

thermostat(s) to activate magnetic contactors

allowing current to flow to the immersion heating

elements. The standard control system uses one

immersion thermostat for each 54kW of electric

heating power in a water heater. As an option,

additional immersion thermostats may be

provided to add additional steps of thermostatic

control. The sensing bulb for each immersion

thermostat is immersed in the stored water in the

tank to provide quick, accurate response to

changes in water temperature, The thermostat

sensing bulb is located in the tank just above the

elements it is controlling. The immersion

thermostat set point is adjustable by rotating a

knob on the control. Turning the knob counter

clockwise decreases the temperature set point and

turning the knob clockwise increases the set

point. The temperature setting shown at the top

of the knob is the selected set point. The

immersion thermostat has a fixed 6°F (3.3°C)

differential.

Set temperature control to the lowest setting

which satisfies the hot water requirements of the

system. Lower water temperatures help minimize

scale formation on the heating elements. See

thermostat information below. For sequencer

specifications, consult controller literature.

This water heater has an adjustable thermostat to

control water temperature. The thermostat is

factory pre-set at approximately 125˚ F (51.7° C)

or less. Households with small children or

invalids may require a 120˚ F (48.9° C) or lower

temperature setting to reduce risk of scald injury.

Some states may require a lower temperature

setting. Check with your local codes or electric

utility for local requirements governing the

temperature setting. Remember, no water heating

system will provide exact temperatures at all

times. Allow a few days of operation at the

setting to determine the correct temperature

setting consistent with your needs.

13

WATER TEMPERATURE SETTINGS

TEMPERATURE REGULATION

IMMERSION THERMOSTAT(S)

FIG. 17 Immersion Thermostat with Adjustment Knob

HAZARD OF ELECTRICAL SHOCK –

Before opening the electrical access panel

to adjust the thermostat make sure the

electrical supply to the water heater is

turned “OFF”.

WARNING:

Full power is present whenever the cabinet

door is opened, even with the pilot

switch(es) turned off.

DANGER:

Hotter water increases the

risk of scald injury. Setting the temperature

selector dial higher provides hotter water,

which increases the risk of scald injury.

CAUTION:

(1) This water heater, when set at the lower

temperature setting, is not capable of

producing hot water of sufficient temperature

for sanitizing purposes.

(2) Higher stored water temperature increases

the ability of the heater to supply desired

quantities of hot water, however remember:

NOTE:

Page 14

The maximum temperature

setpoint that should be set for the

Immersion Thermostats or programmed

into the Electronic Temperature Control

Sequencer is 190° F ( 88° C)

Always close the electrical control panel door

after making a temperature adjustment. Turn on

electricity.

1. Turn “OFF” the electrical power to the water

heater. If the power disconnect point is out of

sight, lock it in the open (“OFF”) position

and tag to prevent unexpected application

of power.

2. Open the water heater’s electrical access panel.

3. Adjust each immersion thermostat to the

desired temperature setting by turning the

adjusting knob. Each thermostat will be

factory pre-set to approximately 125° F

(51.7° C) or less as shipped.

4. Close the water heater’s electrical access panel.

5. Turn “ON” the electrical power to the

water heater.

ELECTRONIC TEMPERATURE

CONTROL SEQUENCER

14

CAUTION:

TEMPERATURE ADJUSTMENT

DANGER

HOT!

BURN

• Water temperature over 125˚F can

cause severe burns instantly or

death from scalds.

• Children, disabled and elderly are

at highest risk of being scalded.

• See instruction manual before

setting temperature at heating

appliance.

• If this appliance is used to produce

water that could scald if too hot,

such as domestic hot water use,

adjust the outlet control (limit) or

use temperature limiting valves to

obtain a maximum water temperature

of 125˚F. SEE MANUAL.

FIG. 18

WARNING: SHOULD OVERHEATING

OCCUR OR THE TEMPERATURE

CONTROLS FAIL TO SHUT OFF, TURN OFF

OR DISCONNECT THE ELECTRICAL

SUPPLY AT THE MAIN POWER

DISCONNECT EXTERNAL TO THE

APPLIANCE.

WARNING:

• Water temperature over 125˚ F (51.7°C)

can cause severe burns instantly or death

from scalding.

• Children, disabled and elderly are at

highest risk of being scalded.

• See instruction manual before setting

temperature at heating appliance.

• Feel water before bathing or showering.

• If this appliance is used to produce water

that could scald if too hot, such as

domestic hot water use, adjust the outlet

control (limit) or use temperature

limiting valves to obtain a maximum

water temperature of 125˚ F (51.7° C).

ELECTRONIC TEMPERATURE

CONTROL SEQUENCER

DANGER:

FIG. 19 Electronic Temperature Control

with Digital Display

Page 15

The water heater uses an optional adjustable

electronic temperature control to provide staged

ON/OFF control of the electric heating elements.

Operation is based on temperature input from an

immersion temperature sensor. The sensor is a

positive coefficient platinum thermistor. The

sensor is placed in a well located above the

heating elements it is controlling. A liquid crystal

display is provided to indicate sensed temperature

and operating parameters. The temperature

control may operate in as many as four stages of

control. For more stages of operation, multiple

electronic temperature control sequencers are

installed and wired to operate in series.

Set Point Adjustment Range: Max setting

220° F (105° C).

Temperature Accuracy: +/- 1° F.

Display Resolution: 1° F via Liquid Crystal

Display (LCD). Sensor: Thermistor 4.8 ohms/° F.

Operating Humidity: 5 - 95% RH

Noncondensing.

Operating Ambient Temperature: -30° to 125° F.

Access to the control is achieved by opening the

hinges control panel door covering the electrical

components. Four programming keys are

provided to program set point and differential

values for each stage and to control the display.

The four keys are

Select, Up arrow, Down arrow

and

Enter.

Select Key - Sequentially prompts the user as to

what parameter is being displayed: set point,

differential, stage energized, operation mode

(heat), indication of assigned stage (1,2,3). Once

the last parameter value has been viewed,

pressing the

Select key will display the control

values again from the beginning of the display

loop.

Up and Down Arrow Keys - Allow the displayed

parameter to be increased or decreased. After

pressing the Select key, a control value can be

changed by using the

Arrow keys. Control

values will be increased or decreased by 1° F for

each time the Arrow keys are depressed.

Enter Key - Places the new value into the

memory of the microprocessor.

15

125

1 2 3 4

FIG. 20 Electronic Temperature Control

Digital Display and Programming Keys

SPECIFICATIONS

A control value or

operation will not be entered in the memory of

the microprocessor until the

Enter key is

pressed.

Control values and operation selection will

remain in the device memory even after power

is removed.

Select and Enter Keys simultaneously

pressed - Changes operation mode of the

control from heat to cool mode. DO NOT

CHANGE THIS SETTING.

This control

must always be in the “HEAT” position for

proper operation of the water heater.

When all stages have been programmed the

display will revert back to sensed temperature

and load energized status.

IMPORTANT:

Page 16

Once power is applied to the temperature

controller the display will countdown from 210

until the display reads zero. All outputs are

de-energized at this time. This countdown

process will repeat each time main power is

interrupted. To avoid viewing this entire

countdown, press the

Select key. The display will

now show normal readings: load (sensed)

temperature and stages energized. At any time

during the programming procedure, the display

will revert back to showing the sensed

temperature and stage status indication 60

seconds after the last programming key is pushed.

Each stage on the controller has its own

independent set point and differential which are

determined by the programming keys. Each

stage of heating is de-energized as the sensed

temperature reaches the programmed set point.

Each available stage of heating is energized as the

sensed temperature reaches the set point minus

the differential.

EXAMPLE:

Using stage one of the control as an example, the

corresponding load would be energized and

de-energized at the following temperatures based

on the programmed settings.

Settings

Set point: 160oF

Differential: 8oF

Output Energized

Stage One: Energized at 152oF

Output De-energized

Stage One: De-energized at 160oF

Each available stage of operation must be

programmed with a set point and a differential. If

two stages are programmed with the same set

point and differential the control will sequence

both stages on and off with only a slight delay

between switching of the stages. The control is

normally programmed with a few degrees

difference between the set point of each stage to

sequence individual stages on as required by

demand. This will allow input to be balanced to

system demand. The exact settings will be

determined by your system hot water

requirements.

Based on your system requirements, determine

the set point and switching differential for each

stage of operation and enter into the worksheet

below.

Pro

gramming W

orksheet

Stage 1:

Set Point 1 ___________ Off at ___________

Differential 1 ________ On at __________

Stage 2:

Set Point 2 ___________ Off at ___________

Differential 2 ________ On at __________

Stage 3:

Set Point 3 ___________ Off at __________

Differential 3 ________ On at _________

Stage 4:

Set Point 4 ___________ Off at __________

Differential 4 ________ On at _________

These values will be programmed into the

temperature controller.

16

DISPLAY

SETUP OF THE TEMPERATURE

CONTROLLER

Page 17

Stag

e Set Point Differential

1 125˚ F 2˚ F

2 123˚ F 2˚ F

3 121˚ F 2˚ F

4 120˚ F 2˚ F

Re-program the set points and differentials to

meet your system hot water requirements.

The operating control uses a Liquid Crystal

Display for interactive prompting during

programming and display of sensed and assigned

set point and differential values. Programming is

accomplished through the use of the four

programming keys.

1. Turn “OFF” the electrical power to the water

heater. If the power disconnect point is out of

sight, lock it in the open (“OFF”) position and

tag to prevent unexpected application

of power.

2. Open the water heater’s electrical access panel.

3. Verify that the unit is properly applied and the

model number on the rating plate correctly

identifies the unit.

4. Turn the electrical power switch to the “ON”

position. The control will begin counting

down from 210. This countdown sequence

will last for approximately 3-1/2 minutes.

5. To override this time delay, press

Select.

6. Press Select to display the current stage

set point.

7. Press

Up Arrow key to increase or Down

Arrow

key to decrease to the desired

set point.

8. Press

Enter to enter the displayed value

into memory.

9. Press

Select to display the current stage

switching differential.

10. Press

Up Arrow key to increase or Down

Arrow key to decrease to the desired

switching differential.

11. Press

Enter to enter the displayed value

into memory.

12. Repeat steps 6 through 11 to program each

additional stage.

13. Press

Select, Select, Select, Select (4 times)

to return to stage 1 parameters. Scroll

through the programming loop a second

time to confirm that the appropriate values

have been entered into memory by

pressing Select.

14. Press

Select after viewing the switching

differential for the final stage to display

stored water temperature.

15. Close the water heater’s electrical

access panel.

16. The temperature control is now ready

for operation.

17

When power is initially

applied to a new water heater, the control

points will be pre-programmed. The

factory final quality test sets the unit for

test firing. The preset values are as follows:

NOTE:

PROGRAMMING

TEMPERATURE ADJUSTMENT

HAZARD OF ELECTRICAL SHOCK –

Full power is present whenever the cabinet

door is open and the main power

disconnect is in the “ON” position, even

with the pilot switch(es) turned off.

WARNING:

Page 18

FIG. 21 High Water Temperature Limit Control

- Fixed Setting

ERROR MESSAGES DISPLAYED BY THE

ELECTRONIC TEMPERATURE CONTROL

There are seven error messages that can be

displayed in response to software or hardware

problems with the boiler’s internal electronic

temperature control. The error codes that may be

seen flashing on the display are:

SF - Sensor Failure

The display flashing SF indicates an

out-of-range or defective sensor. Make sure

sensors are properly installed, wired and

connected to the control. Correct sensor

installation or replace sensor.

EF- EEPROM Failure

The values read form the EEPROM are not

the same as the values written into the

EEPROM. This error cannot be field

repaired. Replace the water heater’s

electronic temperature control.

CF - Calibration Failure

The calibration resistor reading was not

within the range of the Analog to Digital

converter. This error cannot be field repaired.

Replace the water heater’s electronic

temperature control.

OF - Stray Interrupt Failure

An unused interrupt occurred. This error

cannot be field repaired. Replace the water

heater’s electronic temperature control.

CE - Configuration Error

The device hardware was configured to a

nonexistent device. This error cannot be field

repaired. Replace the water heater’s electronic

temperature control.

OE - ROM Error

The internal ROM of the microprocessor in

the boiler’s electronic temperature control is

defective. This error cannot be field repaired.

Replace the water heater’s electronic

temperature control.

AE - RAM Error

The internal RAM of the microprocessor in

the boiler’s electronic temperature control is

defective. This error cannot be field repaired.

Replace the water heater’s electronic

temperature control.

The unit is equipped with a fixed setting, manual

reset high water temperature limit control. The

water heater temperature limit control has a fixed

limit setting of 195° F (90.6° C). If water

temperature exceeds the limit set point, the limit

will break the control circuit and shut down the

unit. The limit control can only be reset after the

water temperature has cooled below the set point

of the limit. The high water temperature limit

control is mounted on the surface of the tank,

above the heating element installed at the highest

point in the tank. The high limit control is reset

by pushing the red reset button on the control.

Operation of the limit control usually indicates a

major problem with the thermostat, contactors or

heating elements.

Do not continue to push the

18

HIGH WATER TEMPERATURE

LIMIT CONTROL

The control values

programmed into memory will not be lost

because of a power failure.

NOTE:

Page 19

The high limit control will not

reset until the water temperature has

dropped below the set point of the high limit.

reset multiple times.

The source of the problem

must be found and corrected to insure proper

operation. The limit control is covered with an

insulation blanket which must be removed to

push the red reset button. The blanket of

insulation must be replaced before the power is

turned on and the water heater is returned to

service.

The heating input to this commercial electric

water heater is provide by low watt density

immersion heating elements. The heating

elements are constructed from an incoloy sheath

with a tin plate on the exterior surface. Three

element blades are mounted on a single hex-head

screw-in mounting flange. The element flange

mounts into a 1 1/2” NPT threaded connection

welded to the storage tank. The hex-head screwin mounting flange seals to the tank with an “O”

ring gasket at the base of the threaded portion of

the flange. The tank flange has a matching recess

for the “O” ring gasket to insure a proper water

tight seal. . The “O” ring element gasket must be

replaced with a new gasket when an element is

removed for inspection, cleaning or replacement.

The optional safety door interlock is an

electrically operated locking pawl that is

energized when main power to the water heater is

turned “ON.” The interlock is mounted to the

inside of the electrical control panel door and

extends behind a locking flange when energized.

Main power may be turned off and the electrical

access door may be opened for service.

With the door open, main power may be

energized if required to service or troubleshoot

the operation of selected components.

19

SAFETY DOOR INTERLOCK (Optional)

FIG. 22 Immersion Heating Element

NOTE:

IMMERSION HEATING ELEMENT

HAZARD OF ELECTRICAL SHOCK –

Before opening the access panel to remove or

service the immersion heating elements,

make sure the electrical supply to the water

heater is turned “OFF”. Failure to do this

could result in death, serious bodily injury

or property damage.

WARNING:

Disconnect the main power

to the heater before opening the element

access panel to reset the high limit control.

CAUTION:

FIG. 23 Safety Door Interlock

HAZARD OF ELECTRICAL SHOCK –

Full power is present whenever the cabinet

door is opened and main power is turned

“ON”, even with the pilot switch(es) turned off.

DANGER:

Page 20

This water heater may be equipped with an

optional electronic low water cut-off installed at

the factory. This low water cut-off device uses a

water level sensing probe located above the

heating element installed in the highest point in

the storage tank. If the internal water level drops

below this point, the low water cut-off will shut

down operation of the heating elements. An

electronic type low water cut-off is available as a

factory supplied option on all models. The

optional electronic low water cut-off has an LED

located on the main circuit board. This LED will

be illuminated and the control circuit will be

completed between the common and normally

open contacts on the circuit board when the

sensing probe is below the water level in the

storage tank. An optional manual reset function

and test button is available on the electronic low

water cut-off. The operation of a low water cutoff should be inspected every six months.

A low water pressure switch is available as an

option on this water heater. A water pressure

switch is used to monitor the water pressure in the

water heater storage tank. If the water pressure

drops below an adjustable set point, the control

circuit is opened and operation of the water

heater is shut down. The low water pressure

switch may be specified with either a auto-reset

function or a manual reset function on low water

pressure.

A high water pressure switch is available as an

option on this water heater. A water pressure

switch is used to monitor the water pressure in the

water heater storage tank. If the water pressure

rises above an adjustable set point, the control

circuit is opened and operation of the water

heater is shut down. The low water pressure

switch may be specified with either a auto-reset

function or a manual reset function on high water

pressure.

As an option, a switch or multiple switches may be

provided to interrupt the 120 VAC control circuit

feed to the contactor coil or coils from the

immersion heating thermostat(s). This switch may

be used to manually turn off a portion of the heating

element input. This feature may be used to reduce

20

Control Board

Probe

LED

FIG. 24 Electronic Low Water Cut-off Control

LOW WATER PRESSURE SWITCH

(Optional)

FIG. 25 Low Water Pressure Switch

LOW WATER CUTOFF (Optional)

HIGH WATER PRESSURE SWITCH

(Optional)

FIG. 26 High Water Pressure Switch

MANUAL LIMITING SWITCHES (Optional)

Page 21

electrical input of the water heater in the summer

months when ground water temperatures are

warmer and full electrical input from the

immersion heating elements is not required. The

water heater may be restored to full input by

moving the switches to the “ON” position.

The water heater may be provided with an

optional time clock. The time clock will allow

the water heater to be turned on and off with a

pre-set schedule. The time clock may be

specified with a 24 hour scheduling period or

with a 7 day scheduling period. By the

adjustment of the setpoints on the time clock, the

water heater may be turned off when hot water is

not needed or in periods when the building may

not be occupied. The time clock allows the water

heater to automatically cycle on in advance of the

time when hot water may be needed. This will

insure that hot water is always available yet save

energy when there are scheduled periods when

there will be no requirement for hot water. This

feature is especially useful for schools and

building that are occupied on a fixed schedule.

As an additional feature, time clocks may be

furnished with a spring wound carry-over

function to insure that a switching schedule is

maintained in periods where there may be power

interruptions. The time clock works by making

and breaking the 120 VAC control circuit to the

contactor coils to shut down operation of the

heating elements in the desired time periods.

The water heater may be provided with optional

pilot lights to provide an external indicator for

each contactor or stage of heating elements that is

energized. Each pilot light is wired in parallel

with the 120 VAC control circuit feed to the

contactor coil(s). The pilot will be turned on as

the contactor coil(s) is energized by the

temperature controls.

Shunt trip disconnect provides a power

disconnect upon a control sensed malfunction via

a circuit breaker installed in the main power

supply to the water heater. The circuit breaker is

shipped as a separate item that must be field

installed. The water heater 120 VAC control

circuit provides a feed to the circuit breaker that

will shut down main power on either a low water

level condition (if equipped) or high water

temperature. Once the water heater is installed

and all power is connected, the toggle switch that

arms the shunt trip must be placed in the on

position to provide the shunt trip function on the

desired control sensed malfunction.

21

FIG. 27 Time Clock

TIME CLOCK (Optional)

PILOT LIGHTS (Optional)

SHUNT TRIP DISCONNECT (Optional)

ALARM BELL (Optional)

FIG. 28 Alarm Bell

Page 22

The cold water supply must be

left in the open position when the water

heater is in use.

An alarm bell with silencing switch is available as

an option on this water heater. The alarm bell can

be used to provide an audible indication of a

control sensed malfunction. The user must

specify the safety function or multiple safety

functions that the alarm bell will sound on when

the water heater is ordered from the factory. The

alarm bell typically is used to indicate a low water

condition or a high water temperature condition.

The alarm is furnished with a silencing switch to

turn off the audible alarm while trouble shooting

a control sensed malfunction that is indicated by

an audible alarm. Once the control sensed

malfunction is corrected, the silencing switch

must be returned to the “ON” position to

re-establish the audible alarm function.

Never operate the heating elements without

being certain the water heater is filled with

water and a temperature and pressure relief

valve is installed in the relief valve opening on

top of the heater.

The pilot switch(es) (if equipped) mounted on the

control cabinet permit the heater to be turned on and off

without having to operate the electrical disconnect

switch. The pilot switch interrupts only the 120 VAC

control circuit in the water heater. Full power is still

present at the terminal block, fuses and contactors.

A relief valve that discharges periodically may be

due to thermal expansion in a closed system.

Many water systems are equipped with pressure

reducing valves, check valves or back flow

preventers which may cause the water system to

be closed. As water is heated it will expand in

volume due to thermal expansion. The system

must make allowance for this expansion. If an

expansion tank is not provided in the system,

water pressure may increase to the point where

the water heater’s temperature and pressure relief

valve opens to relieve the excess pressure. The

temperature and pressure relief valve is not

intended for the constant relief of thermal

expansion. This is an unacceptable condition and

must be corrected.

Do not plug or cap the relief

valve discharge!

A properly sized expansion

tank is typically installed in the potable water

system to relieve the pressure built up by thermal

expansion of heated water. Consult your local

plumbing contractor and plumbing wholesaler for

assistance in properly selecting an expansion tank

for your system.

As the water heater operates, there may be noises

generated by the expansion and contraction of the

metal parts of the water heater and related piping.

These noises may occur during periods of heat up

or cool down. They do not represent harmful or

dangerous conditions.

1. Insure that the electrical power to the water

heater is in the “OFF” position. If the power

disconnect point is out of sight, lock it in the

open (“OFF”) position and tag to prevent

unexpected application of power.

2. Close the water heater drain valve(s).

3. Open a nearby hot water faucet to allow the

air in the system to escape as the tank fills.

4. Fully open the cold water inlet valve to the

water heater to begin filling the heater and piping.

5. Check the nearby hot water faucet to verify

that air is exiting the tank as it fills with water.

Allow water to run until a constant flow is

obtained at the faucet. This will insure that all

air is purged from the system.

22

START-UP PROCEDURE

Full power is present whenever the cabinet

door is opened, even with the pilot

switch(es) turned off.

DANGER:

THERMAL EXPANSION OF WATER

FILLING THE WATER HEATER

NOTE:

Page 23

6. While the tank is filling, open the electrical

control panel and set the thermostat(s) to the

desired water temperature. If equipped with

multiple thermostats, all individual

thermostats may be adjusted to the same

temperature set point or they may be set a 2°F

to 4°F (1˚C to 2˚C) apart to step the elements

on in stages.

7. Insure that any pilot switches or manual

limiting switches are placed in the

“ON” position.

8. When a constant flow is obtained at the

faucet, it may be turned off. The temperature

and pressure relief valve should be manually

opened to insure that there is no captive air in

the storage tank. A constant stream of water

must flow from the manually opened relief

valve. Release the handle on the relief valve

and allow it to close after water flow is observed.

9. Carefully check the tank, pipe and fittings for

any sign of a water leak. Immediately repair

as needed. Open the access door to the

immersion heating elements and check for

leaks at the element mounting flanges. If any

leak is detected, tighten the screw–in element.

10. Insure that the electrical access panel (field

wiring compartment) is closed and the

heating element access panel is in place

before proceeding.

11. After assuring that the tank is completely

filled with water and no leaks are detected,

you are now ready to start operation of the

water heater.

12. Turn on the electric power at the main

disconnect point. The contactors should be

energized as the elements start to heat the

water in the tank.

23

START-UP

13. As the water heater starts heating, check the

contactors for “buzzing” or “chattering”

during operation. If noise is detected, turn off

main power, open the control panel and clean

the contact points of the magnetic

contactor(s). Remove any dust, dirt or foreign

matter that may have found its way into the

contactor or other electrical components in

the control panel during shipping, installation

or service.

14. Close the electrical control panel and turn on

main power.

15. The water heater is now ready for normal

operation.

The following checks should be made by the

installer when the water heater is placed into

operation for the first time.

1. Allow the water heater to heat for

approximately thirty minutes after following

the filling and start up procedures.

2. Turn off the main electrical power to the

water heater

. If the power disconnect point

is out of sight, lock it in the open (“OFF”)

position and tag to prevent unexpected

application of power.

3. Open the electrical control panel door and

feel each wire connection and fuse clip for

excessive temperature. If any connection is

found to be excessively hot, check the

tightness of the connection. Check all factory

internal wiring connections and the field

made main power connections for tightness.

INITIAL START-UP CHECKS

The power supply must

remain off until the water heater and all

related piping are completely filled with water

to insure that there will not be a possible

problem with heating element burn out.

CAUTION:

HAZARD OF ELECTRICAL SHOCK –

Before opening the access panel to perform

service on any electrical component, make

sure the electrical supply to the water

heater is turned “OFF”. Failure to do this

could result in death, serious bodily injury

or property damage.

WARNING:

Page 24

4. Close and lock the electrical control panel door.

5. Turn on the main electrical power to the

water heater.

6. Temperature control and contactor operation

should be checked by allowing the water

heater to come up to temperature and shut off

automatically.

7. The water heater is now ready continuous

normal operation.

Draining the Water Heater

1. Turn off the main electrical power to the

water heater. If the power disconnect point is

out of sight, lock it in the open (“OFF”)

position and tag to prevent unexpected

application of power.

2. Turn the valve in the water heater’s cold water

supply to the closed or “OFF” position.

3. Turn the valve in the water heater’s hot water

outlet to the closed or “OFF” position.

4. Manually open the temperature and pressure

relief valve to remove any pressure from the

storage tank.

5. Allow the system to cool and then open the

drain valve to empty the storage tank. It will

be necessary to manually hold the

temperature and pressure relief valve in the

open position to break the vacuum in the tank

and allow it to vent and drain. Insure that the

water heater drain is routed to a properly sized

floor drain to allow the water to be removed

from the tank. If a floor drain is not available,

a hose may be attached to the water heater

drain to take the water outdoors.

6. The water heater is now shut down and ready

for service or maintenance.

7. Follow the filling and start up procedure to

place the water heater back into service.

Listed below are items that must be checked to

insure safe reliable operations. Verify proper

operation after servicing.

The temperature and pressure relief valve(s)

should be manually operated at least once a year.

A relief valve that fails to completely reseat after

manual operation and continues to discharge

water must be immediately replaced with a new,

properly sized, temperature and pressure relief

valve.

The relief valve(s) should be installed in the

vertical position and mounted in the tapping

provided in the storage tank. No valve should be

placed between the relief valve, and the water

heater. To prevent water damage, the discharge

from the relief valve must be piped to a suitable

floor drain for disposal when relief occurs. No

reducing couplings or other restrictions shall be

installed in the discharge line. The discharge line

shall allow complete drainage of the valve and

line. The discharge line from the relief valve

24

SHUTDOWN PROCEDURE

Any water discharged from

the manually opened relief valve may be hot

and cause a scald injury.

CAUTION:

MAINTENANCE

WARNING:

HAZARD OF ELECTRICAL SHOCK –

Before opening the access panel to perform

service on any electrical component, make

sure the electrical supply to the water

heater is turned “OFF”. Failure to do this

could result in death, serious bodily injury

or property damage.

Label all wires prior to

disconnection when servicing controls.

Wiring errors can cause improper and

dangerous operation.

CAUTION:

TEMPERATURE AND PRESSURE

RELIEF VALVE OPERATION

Page 25

should be metallic pipe or a high temperature

plastic pipe (CPVC, etc.) to insure that hot water

flow will not damage the discharge piping from

the relief valve.

In hard water areas, water treatment should be

used to reduce the introduction of minerals to the

system. Minerals in the water can collect in the

storage tank and on the immersion heating

elements causing noise on operation. Excessive

build up of minerals on the surface of the heating

elements can reduce the service life of the

elements and lead to a non-warrantable failure.

Proper operation of this electric water heater is

based on heating potable water with a hardness of

5 to 25 grains per gallon and a total dissolved

solids not exceeding 350 PPM. Consult the

manufacturer when heating potable water

exceeding these specifications. Heating of high

hardness and/or high total dissolved solids water

may require frequent cleaning of the storage tank

and heating elements to achieve proper operation.

The higher the level of dissolved solids or water

hardness, the faster the dissolved minerals in the

water will precipitate out and form scale deposits

on the heating elements and in the storage tank.

The level of scale formation is also accelerated

as stored water temperature increases. Water with

a hardness of less than 5 grains per gallon will

usually have a low pH which can be aggressive

and corrosive causing non-warrantable damage to

the storage tank, heating elements and associated

piping. Corrosion due to water chemistry

generally shows up first in the hot water system

because heated water increases the rate of

corrosive chemical reactions.

25

Water heater maintenance includes periodic tank

flushing, cleaning and removal of lime scale from

the heating elements. Where used, the water

heating system circulating pump should be oiled.

1. Turn off main power at the electrical

disconnect switch.

2. Open the drain valve. Allow water to flow

until it runs clean.

3. Close the drain valve when finished flushing.

4. Turn on the electrical disconnect switch

(after filling).

Water born impurities consist of dissolved

minerals which precipitate out of the heated water

and fine particles of soil and sand which settle out

and form a layer of sediment on the bottom of the

tank. In time, if not removed, the level of

sediment might reach the heating elements.

For convenience, sediment removal and element

lime scale removal should be performed at the

same time as follows:

Sediment and Lime Scale Removal

Sediment and lime scale accumulation on the

heating elements is a normal condition

common to all immersion type elements. Factors

which affect the amount of this formation are:

1. Amount of hot water used. As the volume

of water increases, more scale results.

2. Water temperature. As the temperature of the

water is increased, more scale is deposited on

the elements.

3. Characteristics of water supply. Regardless

of water treatment, the elements should be

examined regularly.

Avoid contact with hot

discharge water. Insure that no one is in

front of or around the relief valve

discharge line. Make sure that the

extremely hot water manually discharged

from the relief valve will not cause bodily

injury or property damage.

CAUTION:

WATER CHEMISTRY

FLUSHING THE STORAGE TANK

SEDIMENT REMOVAL

Page 26

All gaskets on disassembled

clean-out openings must be

replaced with new gaskets on re-assembly.

Gaskets are available from your distributor.

Scale accumulation in the bottom of the storage

tank may be removed by turning off main power

and draining the tank. Once all water is removed,

the hand hole access can be removed. This will

allow large accumulations of scale to be cleaned

from the bottom of the tank.

Water scale accumulations on the immersion

heating element reduce the ability of the elements

to heat water and may cause noise to occur during

operation. It is recommended that a heating

element be removed at least once a year for

examination. If it is scaled, all of the elements

should be removed and cleaned. The element

gasket must be replaced when the element is

removed for cleaning.

Small accumulations of lime scale may be

removed with a stiff bristle brush. Severe

accumulations of lime scale should be removed

by dissolving the accumulation in a commercial

delimer. Do not use muratic or hydrochloric acid

base deliming solutions to remove lime scale

from the elements.

Do not pour delimer into

tank. Deliming solutions may damage the

glass lined interior of the tank

1. Drain the heater following “SHUTDOWN

PROCEDURE” instructions.

2. On some high kW input models it is necessary

to remove a side panel to gain access to the

exposed ends of the elements which are not

accessible through the front element access door.

3. Disconnect the wires attached to the element

terminals. Try not to disturb the wiring

unnecessarily and reconnection will be easier.

4. Loosen the screw-in element flange with a

socket and breaker bar. Do not use an impact

gun (air or electric) to remove the element

flanges from the tank. Mark the location of

each element in the tank openings so they may

be returned to their original position.

5. Remove the elements from the opening with a

twisting, pulling action if the elements are

scaled beyond the size of the tank flange

openings. Brush loose scale from elements.

6. Place scaled ends of heating elements into a

delimer solution and allow scale to dissolve.

Do not permit delimer or water to contact

heating element electrical terminals.

7. Flush clean ends of elements with water when

deliming or cleaning is completed.

8. Clean remaining gasket recess on each

screw-in element flange. Do not reuse

element gaskets.

9. Install a new gasket on each element. Install

element into the tank opening where it was

originally installed. Tighten the flange with

the socket and breaker bar used to remove

the element.

10. Attach wires to element terminals from which

they were removed.

11. Follow “FILLING THE WATER HEATER”

instructions to restore hot water service.

Check for water leaks around elements and

proper operation when heater is filled.

26

NOTE:

Keep all delimers away from anode rods to

prevent the formation of flammable and

explosive gas.

DANGER:

Page 27

27

TROUBLE SHOOTING

Checklist

Before calling for service, check the following

points to see if the cause of trouble can be

identified and corrected. Reviewing this checklist

may eliminate the need of a service call and

quickly restore hot water service.

Not enough or no hot water

1. Ensure that the electrical disconnect switch

serving the water heater is in the “ON”

position. The pilot switch(es) on the cabinet

should also be in the on position. In some

areas, water heater electrical service may be

limited by the power company. If the heater

operates on a controlled circuit, heater

recovery may be affected.

2. Check the fuses. The electrical disconnect

switch usually contains fuses. The water

heater has fuses located behind the cabinet

front door. When replacing internal fuses in

the water heater control panel, insure that the

same type and size of fuse is used.

3. If the water was excessively hot and is now

cold, the manual reset high limit may

have operated.

To reset, turn off electricity and push the reset

button. The high limit is located above the

upper most heating element in the storage tank.

On some high input models additional hi

limits may be located behind the side access

panel. Repeat operation of the high

temperature cut-off should be investigated by

your mechanical contractor or by a qualified

technician. A contactor or thermostat may be

malfunctioning.

4. The capacity of the heater may have been

exceeded by a large demand for hot water.

Large demands require a recovery period to

restore water temperature.

5. Cold incoming water temperature will

lengthen the time required to heat water to the

desired temperature. If the heater was

installed in the summer when incoming water

temperature was warm, colder ground water

in the winter months can create the effect of

less hot water.

6. Look for wasted hot water and leaking or

open hot water faucets.

7. Sediment or lime scale may be affecting water

heater operation. Refer to “Maintenance”

for details.

Water is too hot

Refer to “Temperature Regulation” and reset the

thermostat setpoint to a lower temperature that

will meet requirements for hot water

Water heater makes sounds

1. Sediment or lime scale accumulation on the

elements causes sizzling and hissing noises,

when the heater is operating. If this occurs,

the tank bottom and elements should be

cleaned. Refer to “MAINTENANCE”

for details.

2. Some of the electrical components of the

water make sounds which are normal.

Contactors will “click” or snap as the heater

starts and stops. Transformers and contactors

often hum.

Water leakage is suspected

1. Check to see if the drain valve is

tightly closed.

2. The apparent leakage may be condensation

which forms on cool surfaces of the heater

and piping.

3. If the outlet of the relief valve if leaking, it

may represent:

a. Excessive water pressure.

b. Excessive water temperature.

c. Faulty relief valve.

Page 28