Page 1

"Highest in Subcontractor Satisfaction among Water Heater/Boiler Manufacturers"

SUGGESTED

BURNER

Residential Combi2

™

Energy Saver Oil-Powered Water Heater

Combi2™ Oil-Powered Model Features:

■ Dual Purpose Heating—Provides domestic potable hot water and hydronic

Photo is of

C-DW1-70L6OF

heating in one energy saving system.

■ Heat Exchanger—Double wall 1

Two pipes guarantee that the potable water will stay separate from the

hydronic fluid. A positive leak path between the inner and outer pipes is

used to indicate leaks of either the domestic side of the coil or the hydronic

side of the coil.

■ Low Heat Exchanger Head Loss—Up to 10 GPM flow, with less than 5 ft.

of head loss. Greatly reduces the required pump size for heat exchange.

■ High Recovery Rates—Oil heats water 3 to 4 times faster than other

methods. This model is designed to assure a constant supply of hot water

provided the draw-off rate is within the recovery capacity of the unit.

■ Vitraglas

®

Lining—Bradford White water heater tanks are protected from

the corrosive effects of hot water by an exclusive ceramic porcelain-like

coating. The Bradford White high silica Vitraglas

interior surface for our hot water tanks.

■ Factory Installed Hydrojet

sediment reducing device helps prevent sediment build up in tank.

Increases first hour delivery of hot water while minimizing temperature build

up in tank.

■ Oil-Powered Burner—Beckett Burner with dual aquastat wired 120 Volt

1-stage with a firing rate of 0.85 GPH (Shipped with heater in a separate

box).

■ New Beckett Burners are Compatible with Biofuel—Up to B5

(5% Biofuel) can be used with water heater, provided the Biofuel meets

ASTM D6751.

■ Thermostatic Mixing Valve—Supplied with unit to help prevent injury due

to scalding.

■ Space Heating Connections—3/4" NPT female tappings on the front of

the water heater for easy pipe connections.

■ 1" Non-CFC Foam Insulation—Covers the sides and top of tank to save

energy by retarding loss of heat. Also increases jacket rigidity.

ater Connections—

■ W

3/4" NPT factor

extend water heater life and eases installation.

■ Two Protective Aluminum Anode Rods—Provide added protection

against corrosion for long trouble-free service.

■ Flue Baffle—Designed to maximize the amount of heat absorbed in the

lower por

tion of tank. Reduces air movement in the heater during standby

periods to retard heat loss up the flue.

■ Steel T

■ T&P Relief Valve—Installed.

■ Brass Drain Valve.

■ Design Cer

ank—

Heavy gauge steel automatically for

tified by CSA Inter

1

⁄2" O.D. glass coated (Vitraglas®) steel coil.

®

lining provides a tough

®

Total Performance System—Cold water inlet

y installed tr

ue dielectric fittings

med, r

national (formerly AGA/CGA)

olled and welded.

.

ear Limited W

oprietar

y study r

arranties / 2-Y

esults are based on experiences and perceptions of subcontractors surveyed in May through July 2006. Your

ear Limited T

6-Y

For mor

For products installed in USA, Canada and Puerto Rico. Some states do not allow limitations on warranties. See complete

copy of the warranty included with the heater.

Bradford White received the highest numerical score among water heater/boiler manufacturers in the proprietary J.D. Power and Associates/ McGraw-Hill Construction 2006 HVAC and Water Heater/Boiler Subcontractor Satisfaction StudySM.

Study based on 882 r

experiences may vary. Visit jdpower.com

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S. PATENTS: 5,954,492; 5,761,379; 5,943,984; 5,081,696; 5,988,117; 6,142,216; 5,199,385; 5,574,822; 5,372,185; 5,485,879; 5,277,171;

(B1)5,341,770; 5,660,165; 5,596,952; 5,682,666; 4,904,428; 5,023,031; 5,000,893; 4,669,448; 4,829,983; 4,808,356; 5,115,767; 5,092,519; 5,052,346; 4,416,222; 4,628,184; 4,861,968; 4,672,919; Re. 34,534;

7,270,087 B2. OTHER U.S. AND FOREIGN P

Vitraglas®and Hydrojet®are registered trademarks of Bradford White®Corporation.

esponses measuring 3 water heater/boiler manufactur

TENT APPLICA

A

TIONS PENDING. CURRENT CANADIAN P

ank and Heat Exchanger W

e information on warranty, please visit www.bradfordwhite.com

ers and measur

es opinions of subcontractors. Pr

ATENTS: 1,272,914; 1,280,043; 1,289,832; 2,045,862; 2,112,515; 2,108,186; 2,107,012; 2,092,105; 2,409,271.

arranty on Component P

arts.

544-B-1207-A

Page 2

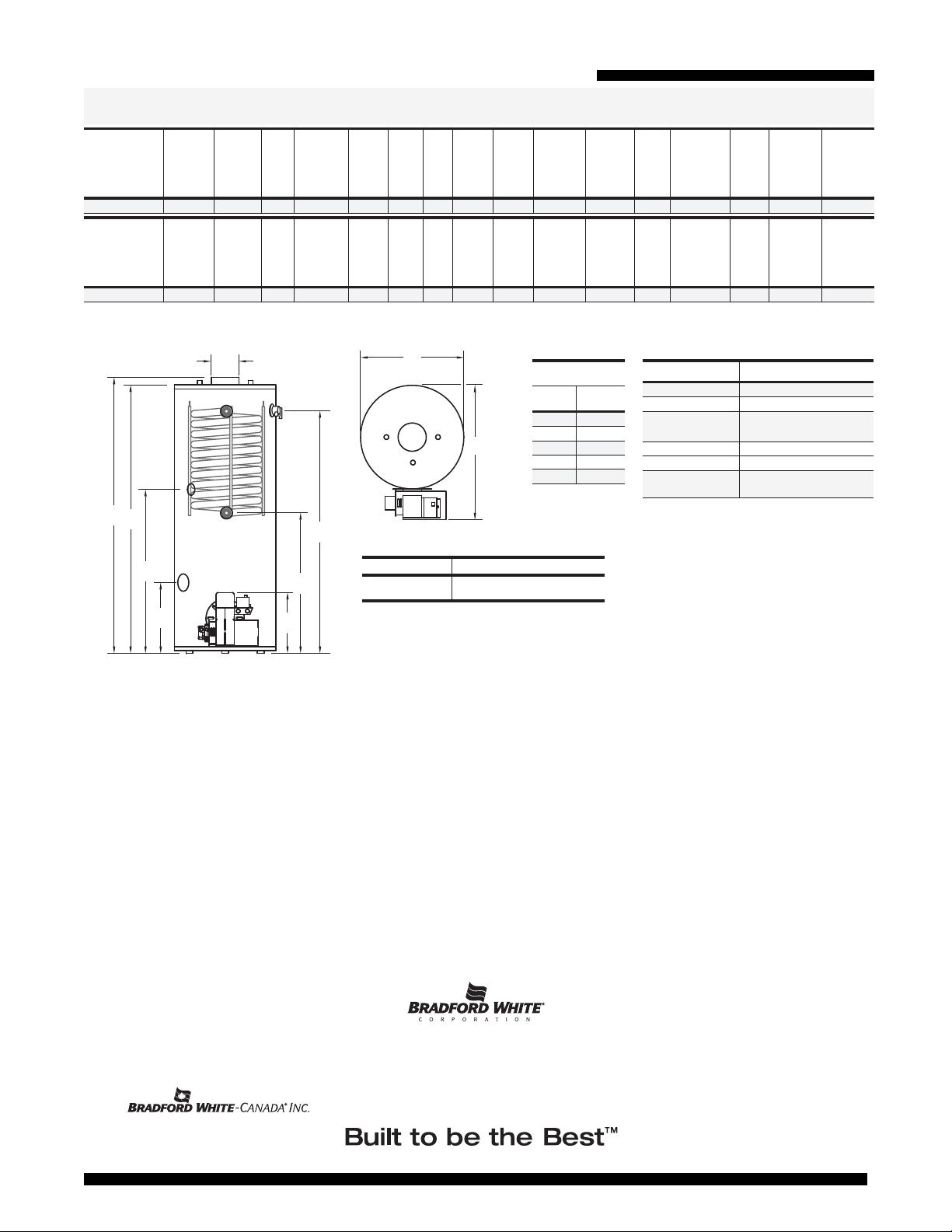

Model

Number

C

apacity

Combi2™Energy Saver Model

H

Floor

to Top

o

f Unit

in.

A

pprox.

Shipping

Weight

lbs.†

G

Floor to

Exchanger

I

nlet

in.

A

Floor to

Flue

C

onn.

in.

F

Floor to

Exchanger

O

utlet

in.

C

Vent

Size

in.

B

Jacket

Dia.

in.

Gal.

U.S.

B

TU/Hr.

Input

GPH

F

iring

Rate

k

W Input

GPH

F

iring

R

ate

GPH

U.S.

R

ecovery

90°F Rise*

M

odel

N

umber

Capacity

Liters

A

F

loor to

Flue

C

onn.

mm.

Hour

Liters/

Recovery

5

0°C Rise*

Meet or exceed ASHRAE 90.1b (current standard)

7

8% Recovery Efficiency

68 57

Gal.

Imp.

119,000 0.85 24 6 299127

GPH

Imp.

119

C

-DW1-70L6OF

L

Floor to

Control

T

hermostat

in.

J

Floor to C/L

Combustion

C

hamber

Sight Hole

in.

H

F

loor

to Top

o

f Unit

mm.

A

pprox.

S

hipping

Weight

kg.†

G

F

loor to

Exchanger

I

nlet

mm.

F

F

loor to

Exchanger

O

utlet

mm.

C

V

ent

Size

mm.

B

J

acket

Dia.

mm.

L

F

loor to

Control

T

hermostat

mm.

J

F

loor to C/L

Combustion

C

hamber

S

ight Hole

mm.

C-DW1-70L6OF

2

59 34.8

1695 610 152 1407 845 1626 860337

D

Floor to

T&P

in.

D

F

loor to

T&P

mm.

194 1370.85 537

57

3

/8663/4 351/4 64 337/8131/4573/8

K

Depth

in.

K

D

epth

mm.

829

32

1

/2

E

Floor to

Top of

B

urner

in.

E

F

loor to

Top of

B

urner

mm.

267

10

1

/2

Residential Oil-Powered Water Heater System

C

-DW1-70L6OF

Input

Water Heating❂

F

irst Hour Rating

Space Heating

C

A

A

FUE

%

Max. Heating

C

apacity✦

119,000 BTU/Hr.

1

45

Imp. Gal.

55,000

B

TU/Hr.

6

59

Liters/Hr.

16.1 kW

1

74

Gal.

78

34.8 kW

C

K

A

H

E

D & F

G

L

J

B

H

eat Exchanger

Head Loss

G

PM

2

5

8

1

0

12

F

t. of

Hd. Loss

t

race

0.4

2.3

4

.6

6.9

Part Number Description

228-44392-05

Beckett Burner with dual Aquastat

@0.85 GPH, 120 V, 1-stage

*Based on manufacturers rated recovery efficiency.

†Shipping weights do not include burner and controls.

❂ Based on ANSI Z21.10.1 and 10.3 and

DOE Test Methods.

✦ Based on ANSI/ASHRAE 124 Standard.

Actual values may vary based on circulator

flow rate, number of zones, water and

space heating demands. Numbers subject

to change.

Meets NAECA Requirements

General

This oil powered water heater is certified at 300 PSI test pressure (2068 kPa) and 150 PSI working pressure (1034 kPa). All potable water and heat

exchanger connections are 3⁄4" NPT (19mm). The potable water connections are on 11" (203mm) centers.

All models design certified by CSA International (formerly AGA/CGA).

Dimensions and specifications subject to change without notice in accordance with our policy of continuous product improvement.

Suitable for Water (Potable) Heating and Space Heating

Toxic chemicals, such as those used for boiler treatment, shall NEVER be introduced into the potable water side. The potable side of this unit may NEVER

be connected to any existing heating system or component(s) previously used with a non-potable water heating appliance. The heat exchanger side of the

unit may be used in space heating applications.

Sales 800-523-2931 ●Fax 215-641-1670 / Technical Support 800-334-3393 ●Fax 269-795-1089 ●Warranty 800-531-2111 ●Fax 269-795-1089

544-B-1207-A

For U.S. and Canada field ser

vice, contact your pr

International:

Telephone 215-641-9400 ●Telefax 215-641-9750 / www.bradfordwhite.com

Sales / T

echnical Suppor

©2007, Bradford White Corporation. All rights reserved.

, PA

Ambler

ofessional installer or local Bradfor

t

866-690-0961 / 905-238-0100 ●Fax 905-238-0105 / www

d White sales representative.

.bradfor

dwhite.com

Printed in U.S.A.

Loading...

Loading...