Page 1

ACCESSORY MODULE

Including Protection, Performance, and Inlet Shut-off Valve Packages

This manual must be used in

conjunction with the Installation and

Operation Manual for the water heater.

Tech. Service..........................(800) 334-3393

Service Parts ..........................(800) 538-2020

Warranty Department .............(800) 531-2111

Ambler, PA 19002

www.bradfordwhite.com

- Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of the water heater or any

other appliance

- What to do if you smell gas:

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor phone. Follow

the gas supplier instructions.

• If you cannot reach your gas

supplier, call the fire department.

- For your family comfort, safety and

convenience, it is recommended these

packages be installed and serviced by

a plumbing professional.

- Read and understand the water heater

manual before installing or operating

the Accessory Module and its

associated packages.

INSTALLATION & OPERATION MANUAL

With Troubleshooting Guide

PLACE THESE INSTRUCTIONS ADJACENT TO WATER HEATER AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE

238-47878-00B 04/10

Page 2

Important Information

CONGRATULATIONS!

You have just purchased one of the finest water heater accessories on the market today!

This Installation and Operation Manual will explain in detail how to install and operate your

new Accessory Module, as well as the packages that can be connected to the Accessory

Module. We strongly recommend you contact a plumbing professional for the installation of

this new control.

We require that you carefully read this manual and your water heater manual and refer to

them when questions arise. If you have any specific questions concerning your warranty,

please consult the plumbing professional from whom your Accessory Module was

purchased. For your records, we recommend that you write the installation date for these

accessories in the back of this manual.

This manual should be kept with the Accessory Module.

NOTICE

The Accessory Module and its associated packages are for use only with Bradford White water

heaters equipped with compatible Honeywell gas controls.

The Accessory Module is always required in order to use the Protection, Performance, and/or

the Inlet Shut-off Valve Packages.

The Protection Package is required in order to use the Inlet Shut-off Valve Package.

For easier installation, the Integrated Mixing Device and Inlet Shut-off Valve should be installed

first.

Accessory Module:

The Accessory Module is an electronic component that allows the water heater gas control to be

connected to the Protection, Performance, and Inlet Shut-off Valve Packages.

Accessory Module:

Contains:

Features:

o Accessory Module

o Plug-in transformer

o Transformer wire harness

o (2) gas control harnesses (only

o Wire holders

o Wire ties

o Installation & Operation Manual

o Screws

(1) used per water heater)

o Multi-color LED used to display status and diagnostics

o Audible alarm to sound in the event a fault occurs

o Easily mounts to the water heater or can be remote mounted

o One Accessory Module fits all diameter water heaters

o Durable construction

-2-

Page 3

Important Information

Protection Package (sold separately):

Contains:

Features:

Performance Package (sold separately):

Contains:

Setback Control Features:

Integrated Mixing Device Features:

Inlet Shut-off Valve (sold separately):

Contains:

Features:

o Leak sensor (2 piece)

o Dam

o Leak sensor wire harness

o Senses a collection of water near the water heater

o Sounds the alarm to alert homeowners when a water heater leak is detected and

verified

o Alarm is re-settable and can be temporarily silenced

o Durable construction

o Easy installation – all wiring is provided

o Can be used without the need for a water heater drain pan

o Includes dam, which corrals the water in order for the leak to be detected

o Setback Control

o Setback Control Junction Box

Assembly

o Setback Control wire harness

o Wire ties

o Screws

o 7 day / 4 period programming

o Conserves energy

o Hot water capacity indicator (provides an estimate of available hot water)

o Battery back-up stores programming during a power outage

o Can be programmed to comply with Sabbath requirements

o Similar interface to furnace / air conditioning thermostats

o Precision control of water temperature

o Push to turn handle

o Thermo-strip to indicate approximate outlet water temperature

o Port to draw off tank temperature water

o Port to return recirculation water into the mixing valve

o Port on cold water tee to draw off water for use without installing a saddle valve

o Allows water in the tank to be stored at higher temperatures while controlling the hot

water outlet temperature at a safe and comfortable level

o Precision control of water temperature

o Inlet shut-off valve with

integrated wire harness

o Shuts off water supply to the water heater in the event a water heater tank leak is

detected

o Solid brass construction

o Robust design

o Easy wiring with integral wire harness

o Mounts directly to the water heater inlet

o Can be used on both 3/4” and 1” NPT inlet fittings

o Wire holders

o Wire ties

o Screws

o Integrated Mixing Device (IMD)

Mixing valve

Cold water tee

(2) flexible connectors (only

(1) used per water heater)

Thermo-strip

o (2) 3/4” to 1” NPT bushing

o Wire ties

-3-

Page 4

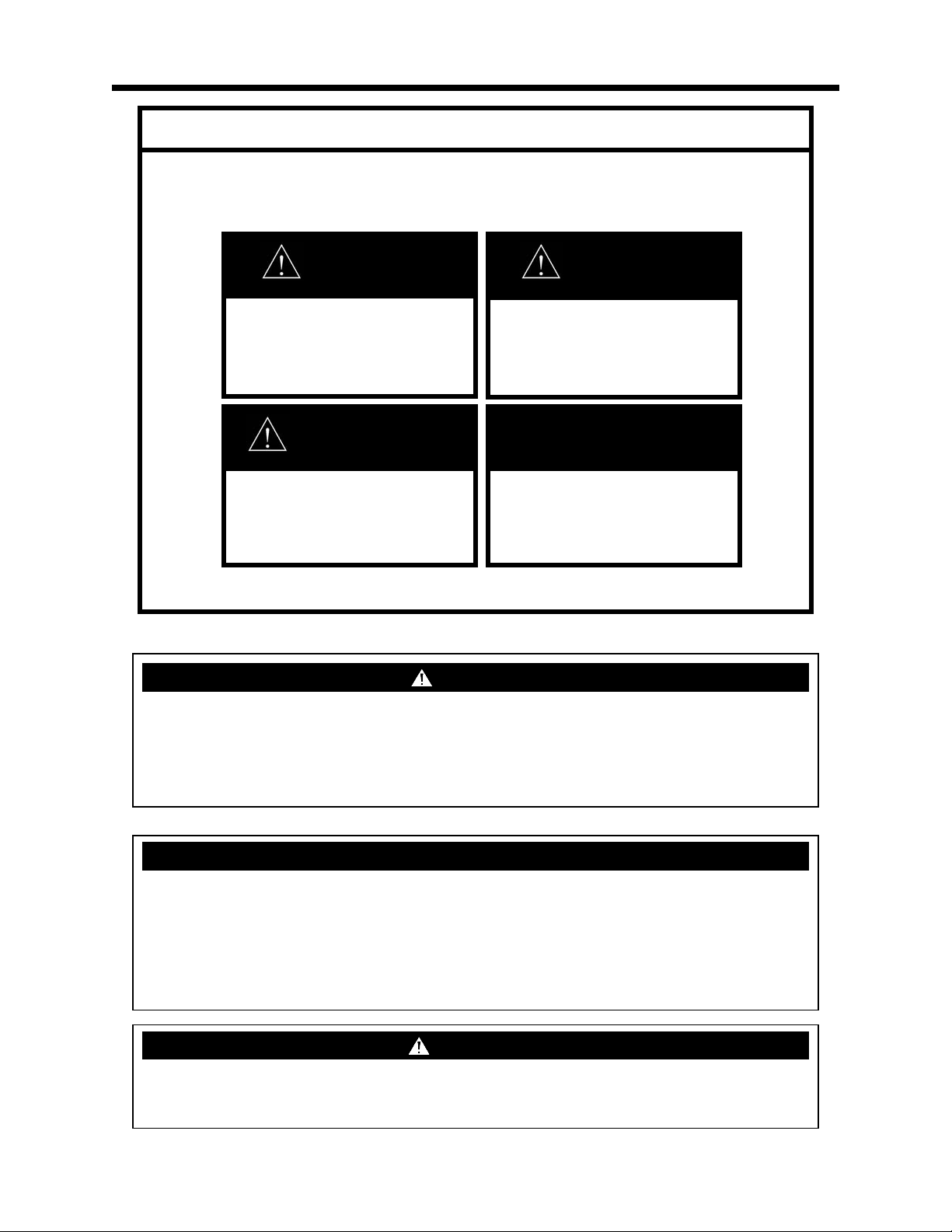

Important Information

The following terms are used throughout this manual to bring attention to the

presence of hazards at various risk levels, or to important information concerning

product life.

DANGER

Indicates an imminently hazardous

situation, which, if not avoided, will result

in death, serious injury or substantial

property damage.

READ CAREFULLY

CAUTION

Indicates potentially hazardous situation,

which, if not avoided, may result in

moderate or minor injury or property

damage.

WARNING

Indicates a potentially hazardous

situation, which, if not avoided, could

result in death, serious injury or

substantial property damage.

NOTICE

Indicates special instructions on

installation, operation or maintenance,

which are important but not related to

personal injury hazards.

DANGER

Hotter water increases the risk of scald injury. Scalding may occur within five (5) seconds at a

temperature setting of 140°F (60

°

C). To protect against hot water injury, install an ASSE

approved mixing valve in the water system. This valve will reduce point of discharge

temperature by mixing cold and hot water in branch water lines. A licensed plumbing

professional or local plumbing authority should be consulted.

NOTICE

The water heater is equipped with an energy cut out device to prevent overheating. Should

overheating occur or the gas supply fails to shut off, turn off the manual gas control valve to the

water heater and call a qualified service technician.

Whenever the water heater is filled with cold water, condensate will form on the cool tank

surface and drops of water will fall on the hot burner and combustion chamber surfaces

producing a “sizzling” noise. Condensation is normal and does not indicate a leak. It will

disappear when the tank becomes heated.

CAUTION

The water heater, when set at a lower temperature setting, is not capable of producing hot water

of sufficient temperature for sanitizing purposes.

-4-

Page 5

Important Information

NOTICE

The lower the temperature setting, the greater the energy efficiency, both to heat the water and

to maintain the storage temperature during standby periods. Lower water temperatures also

extend tank life. Remember, no water heating system will provide exact temperatures at all

times. Allow a few days of operation at this setting to determine the correct temperature setting

consistent with the requirements for the installation.

WARNING

Do not operate the water heater or Accessory Module without the Accessory Module cover in

place. Do not operate the water heater or Setback Control without the Setback Control Junction

Box Assembly cover in place.

Do not operate water heater, Accessory Module, and Setback Control with jumpered or absent

controls or safety devices.

Turn off or disconnect the electrical power supply to the water heater and its accessories before

servicing. Label all wires prior to disconnection when servicing controls. Wiring errors can

cause improper and dangerous operation. Verify proper operation after servicin g.

All electrical wiring must be installed and grounded in accordance with local codes, or in the

absence of local codes, the National Electrical Code, ANSI/NFPA 70 and/or CSA C22 Electrical

Code.

Do not use wire holders to the right of the water heater gas valve. The screws used for the wire

holders can damage the water heater internal components.

For energy efficient operation of your water heater, the suggested initial water temperature setting is

120˚F (49˚C). During the winter season, or any cold period, you may desire a higher water temperature

setting to adjust for the colder incoming water. This adjustment, however, may cause additional

condensation to form on the cooler tank surface. This does not mean the tank is leaking. During summer

months, the warmer incoming water temperatures will benefit the performance of your water heater and

reduce the amount of condensation developed.

Condensation does not mean your tank is leaking. Over 40% of reported tank leaks on installation are

proven to be condensation. To avoid unnecessary expense and inconvenience, make sure the tank is

leaking before calling a service technician.

Water temperature over 125°F

can cause se vere burn s

instantly or death from scalds.

Children, disa bled and elde r ly

are at highes t risk of being

scalded.

Review this instruction manual

before setting temperature

at wat er heater.

Feel water bef ore bathing or

showering.

Tem perat ure limi ting va lves

are available.

-5-

Page 6

Table of Contents

Tools Required............................................................................................ 7

Package Components................................................................................. 8

Accessory Module........................................................................... 8

Protection Package ......................................................................... 9

Performance Package..................................................................... 10

Inlet Valve Shut-off Package........................................................... 11

Wiring Diagram ........................................................................................... 12

Accessory Module Installation..................................................................... 13

Setback Control Installation ........................................................................ 27

Integrated Mixing Device - IMD................................................................... 39

Leak Sensor Installation.............................................................................. 40

Page

Inlet Shut-off Valve Installation.................................................................... 49

Remote Mounting the Setback Control ....................................................... 56

Start-up Procedure...................................................................................... 67

Diagnostic Codes........................................................................................ 73

Notes........................................................................................................... 74

Warranty...................................................................................................... 75

-6-

Page 7

Tools Required

Slotted Screwdriver

Philips Screwdriver

1/8” Drill bit

Drill

Needle nose pliers

Pipe dope

Adjustable wrench

Caulk gun

RTV sealant (silicone)

Pipe cutter

Propane torch

Solder

Flux

Wire Cutters

Wire Strippers

Fine Point Marker

-7-

Page 8

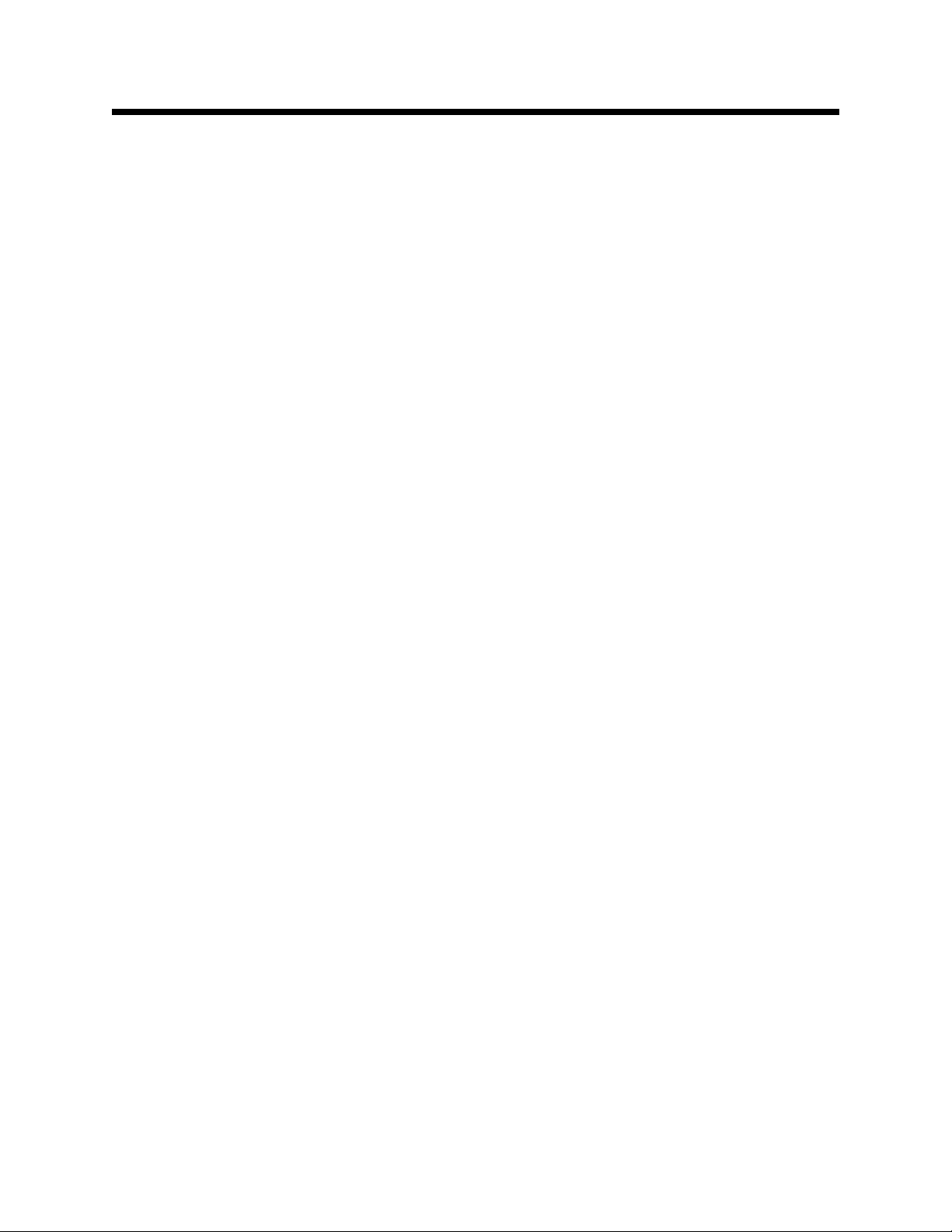

Package Components Accessory Module

Table 1

Description Quantity

1A Plug-in Transformer 1

2A WV4460 Wire Harness 1

3A Transformer Wire Harness 1

4A WV8840 Wire Harness 1

5A Wire Holders 4

6A Installation & Operation Manual 1

7A Wiring Diagram Label 1

8A Diagnostic Label 1

9A Wire Ties 4

10A Screws 9

11A Accessory Module 1

Accessory Module

FOR USE WITH THE FOLLOWING GAS VALVES:

222-47463-01

222-47466-02

222-47463-02

222-46402-01

222-47464-01

222-46402-02

222-47464-02

222-46990-01

222-47465-01

222-46990-02

222-47465-02

222-46991-01

222-47466-01

222-46991-02

ACCESSORY MODULE

R1 C1 LK C2 NO NC D/1 R/2 C/3 A1 A2

BK

BK BL BKBR R WBK BK Y

W

R

*WHEN CONNECTING LEAK SENSOR, REMOVE RESISTOR

BETWEEN C1 & LK.

**WHEN CONNECTING ANODE DEPLETION SENSOR, REMOVE RESISTOR

BETWEEN A1 & A2.

SEE INSTALLATION AND OPERATION MANUAL FOR MORE INFORMATION.

FOR USE WITH THE FOLLOWING GAS VALVES:

222-45613-01

222-45614-01

222-45613-02

222-45614-02

ACCESSORY MODULE

R1 C1 LK C2 NO NC D/1 R/2 C/3 A1 A2

BK

BK BL BKBR R WBK BK Y

W

R

*WHEN CONNECTING LEAK SENSOR, REMOVE RESISTOR

BETWEEN C1 & LK.

**WHEN CONNECTING ANODE DEPLETION SENSOR, REMOVE RESISTOR

BETWEEN A1 & A2.

SEE INSTALLATION AND OPERATION MANUAL FOR MORE INFORMATION.

ACCESSORY MODULE DIAGNOSTIC CODES

ACCESSORY MODULE STATUS LED STATUS

COLOR PATTERN

LED on continuously. Power on (no fault).

GREEN

One flash and three second pause. Leak alarm fault. W ater shut-off valve open.

RED

Two flashes and three second pause. Leak alarm fault. Water shut-off valve closed.

RED

Three flashes and three second pause. Anode depletion alarm or not connected.

AMBER

Four flashes and three second pause. Leak sensor malf unction.

BK

W

R

D

R

R

BK

C

W

238-47880-00A

AMBER

Five flashes and three second pause. Gas valve missing/not connected.

AMBER

RED LED strobe (quick flashes). Hardware error.

See Installation and Operation Instruction Manual f or probable causes

associated with each control status code.

238-47879-00A

NOTICE

The WV4460 wire harness must be used w ith gas con tro ls with in term ittent p ilots. T he WV884 0

wire harness must be used with gas controls with standing pilots.

-8-

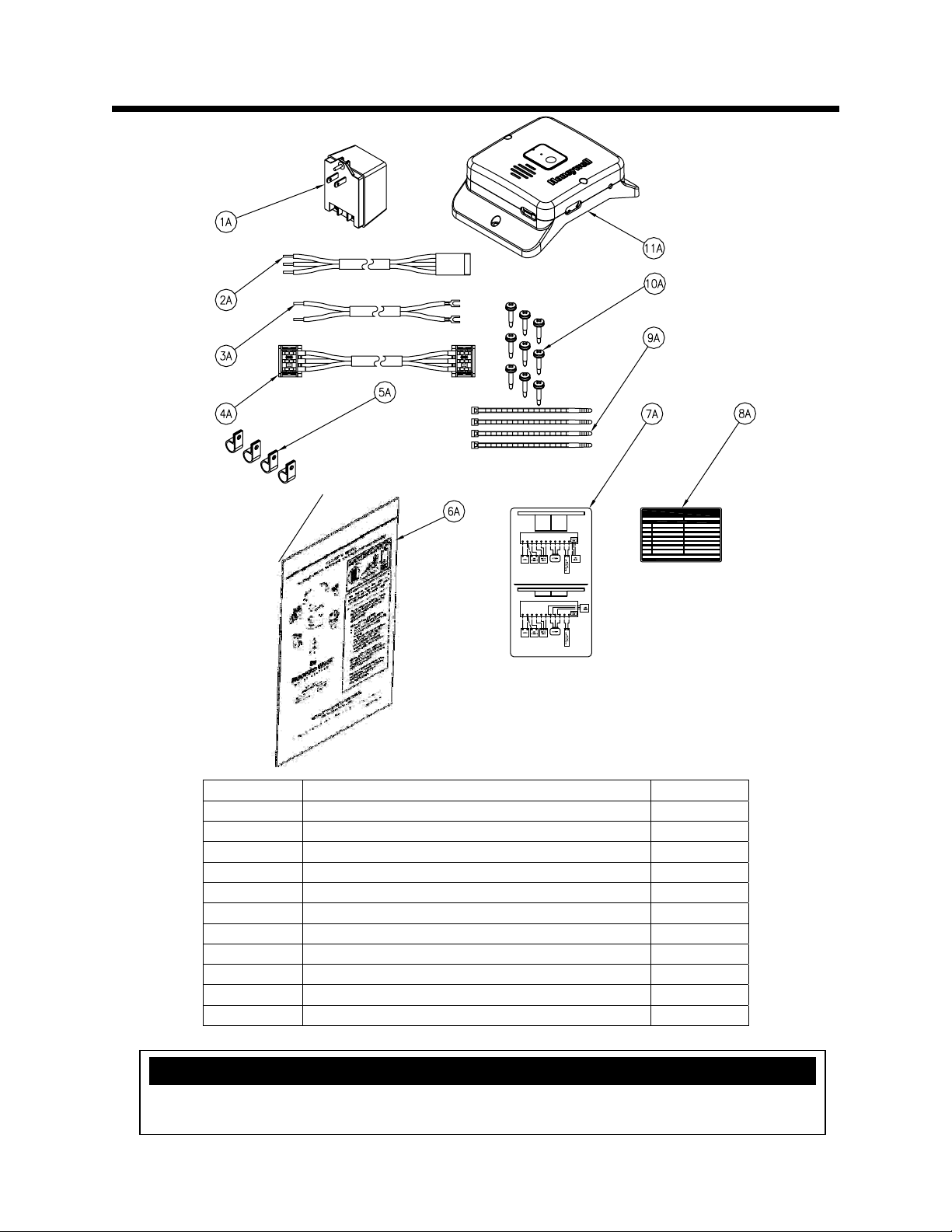

Page 9

Package Components Protection Package

Table 2

Description Quantity

1B Leak Sensor Bracket 1

2B Leak Sensor Housing 1

3B Dam 1

4B Screws 6

5B Leak Sensor Wire Harness 1

6B Wire Holders 4

7B Wire Ties 4

Protection Package

-9-

Page 10

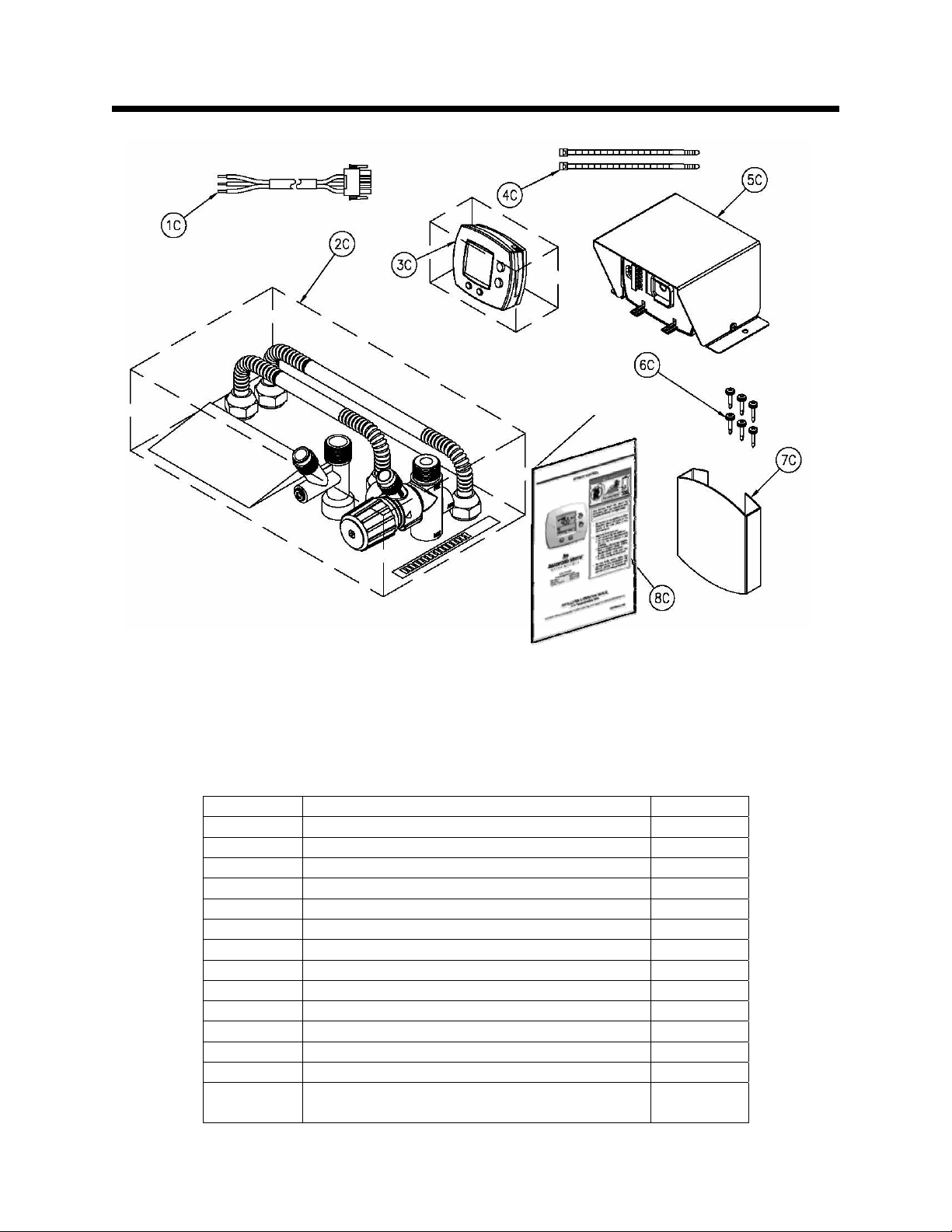

Package Components Performance Package

Table 3

Description Quantity

1C Setback Control Wire Harness 1

2C Integrated Mixing Device, IMD 1

- Cold Water Tee

- Mixing Valve

- 8” Flexible Connector

- 11” Flexible Connector

- Instruction & Operation Manual

- Thermo-strip

3C Setback Control (batteries included) 1

4C Wire Ties 2

5C Setback Control Junction Box Assembly 1

6C Screws 6

7C Setback Cover Plate 1

8C

Setback Control Instruction & Operation

Manual

Performance Package

1

-10-

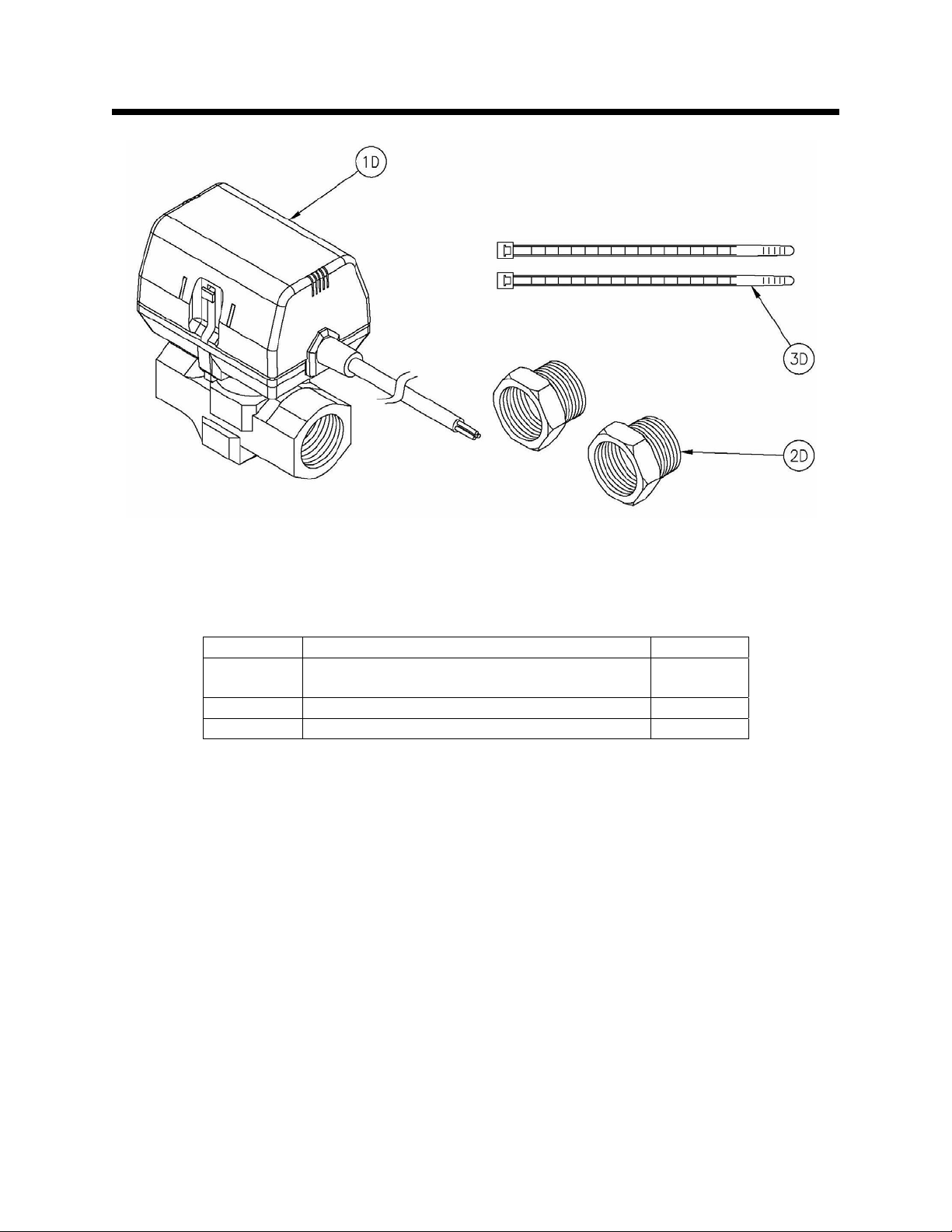

Page 11

Package Components Inlet Shut-off Valve Package

Table 4

Description Quantity

1D Inlet Shut-off Valve with Integrated Wire

Harness

2D ¾” x 1” NPT Brass Bushings 2

3D Wire Ties 4

Inlet Shut-off Valve

1

-11-

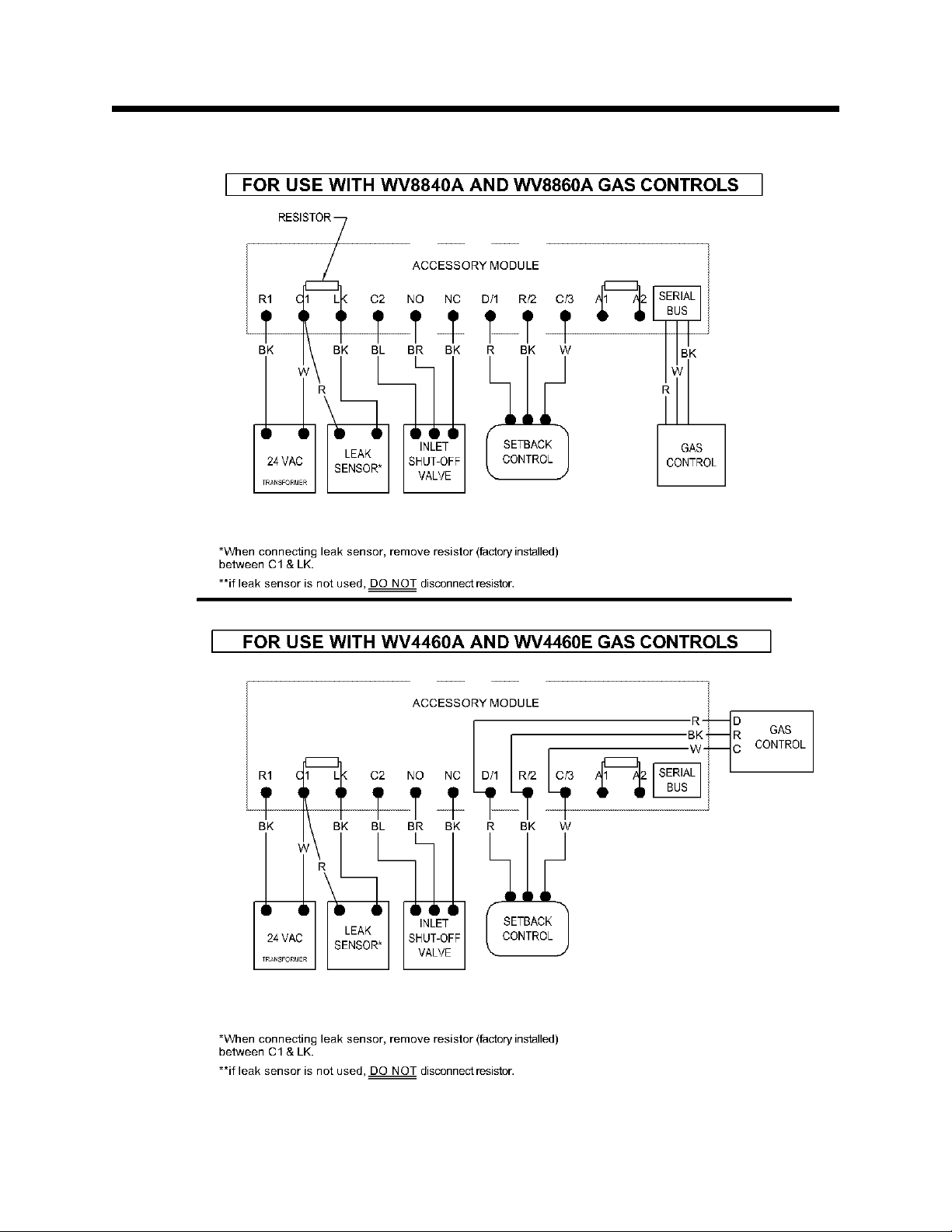

Page 12

Wiring Diagram

-12-

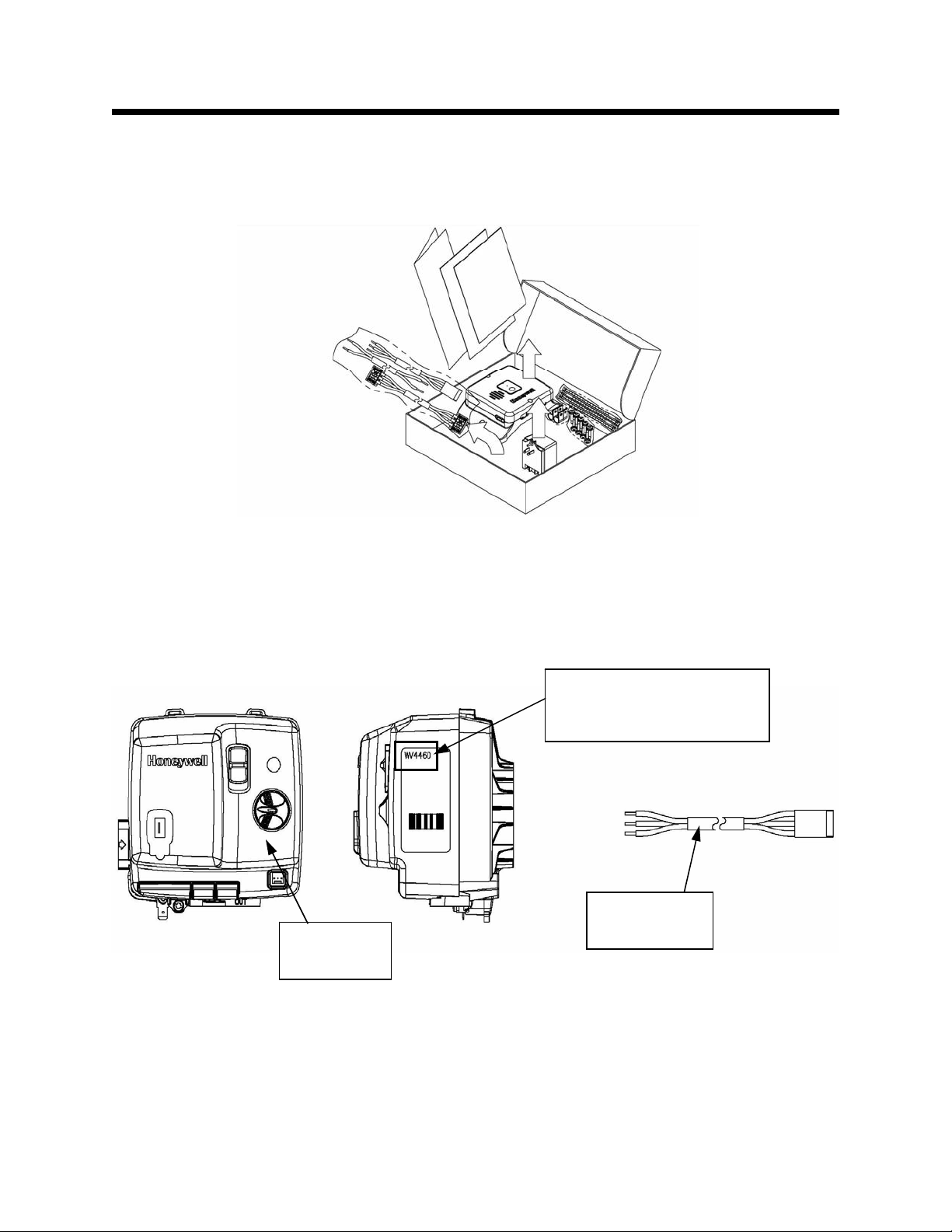

Page 13

Accessory Module Installation

In the following section, the instructions detail how to install the Accessory Module. Properly

locating and mounting the Accessory Module is required.

Unpack the Accessory Module

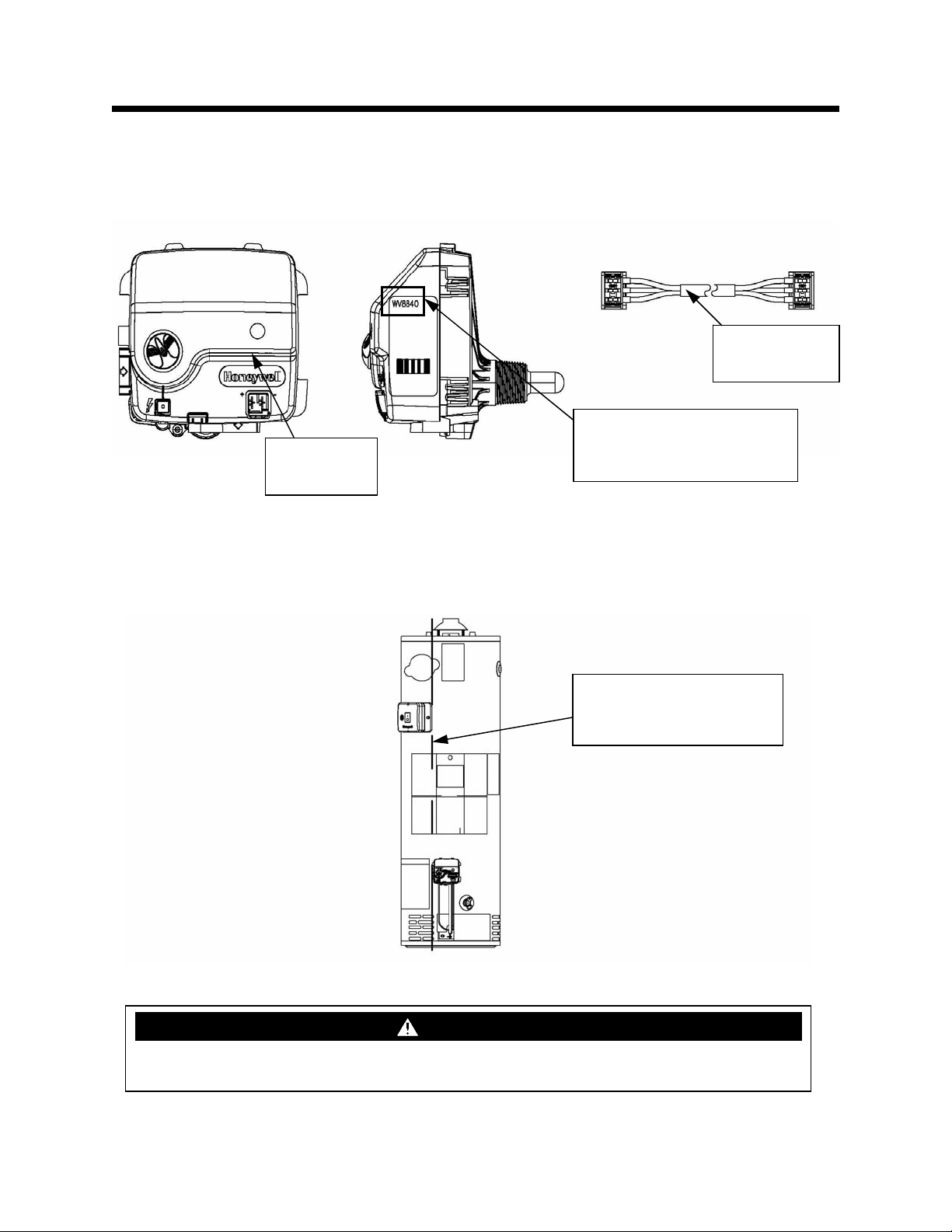

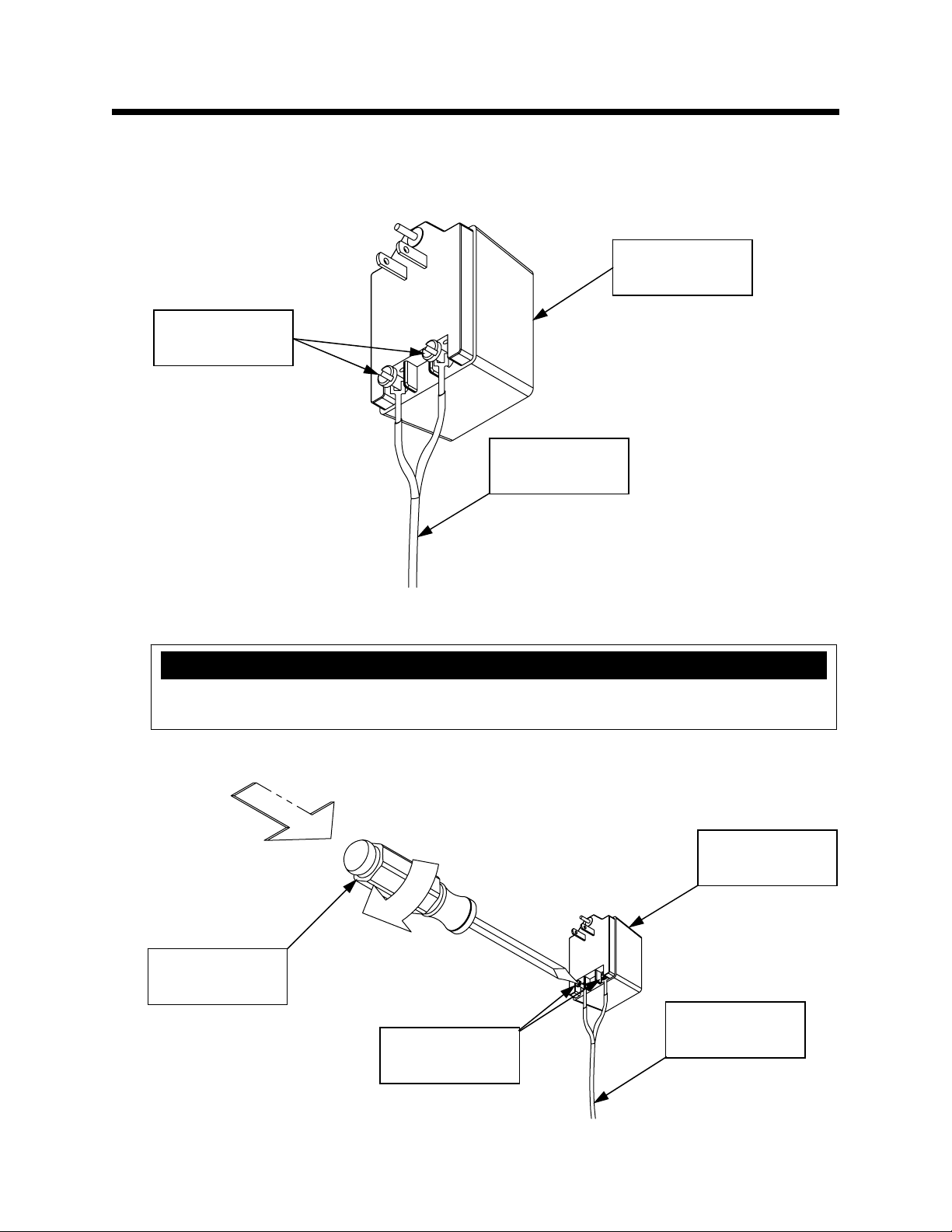

Step 1: Remove the Accessory Module and its components from their packaging, as shown in Figure 1.

Determine the Gas Control Wire Harness

Step 2: If the gas control uses an intermittent pilot, the WV4460 wire harness must be used. The

WV4460 gas control and wire harness are shown in Figure 2. Discard the WV8840 wire harness.

Otherwise, proceed to Step 3.

WV4460

Gas Control

Figure 1

Determine gas control

number using label on side

of control

WV4460 Wire

Harness

Figure 2

-13-

Page 14

Accessory Module Installation

Determine the Gas Control Wire Harness – cont’d

Step 3: If the gas control uses a standing pilot, the WV8840 wire harness must be used. The WV8840

gas control and wire harness are shown in Figure 3. Discard the WV4460 wire harness.

Locate the Accessory Module

Step 4: The Accessory Module must be mounted to the left of the water heater gas control. Hold the

Accessory Module to the water heater jacket as high as possible and practical. Do not cover any safety

or warning labels on the water heater. This is shown in Figure 4.

WV8840

Gas Control

Figure 3

Figure 4

Determine gas control

number using label on side

of control

Accessory Module must

be mounted to the left of

this line

WV8840 Wire

Harness

WARNING

Failure to properly locate the Accessory Module may cause damage to the water heater wiring

harness.

-14-

Page 15

Accessory Module Installation

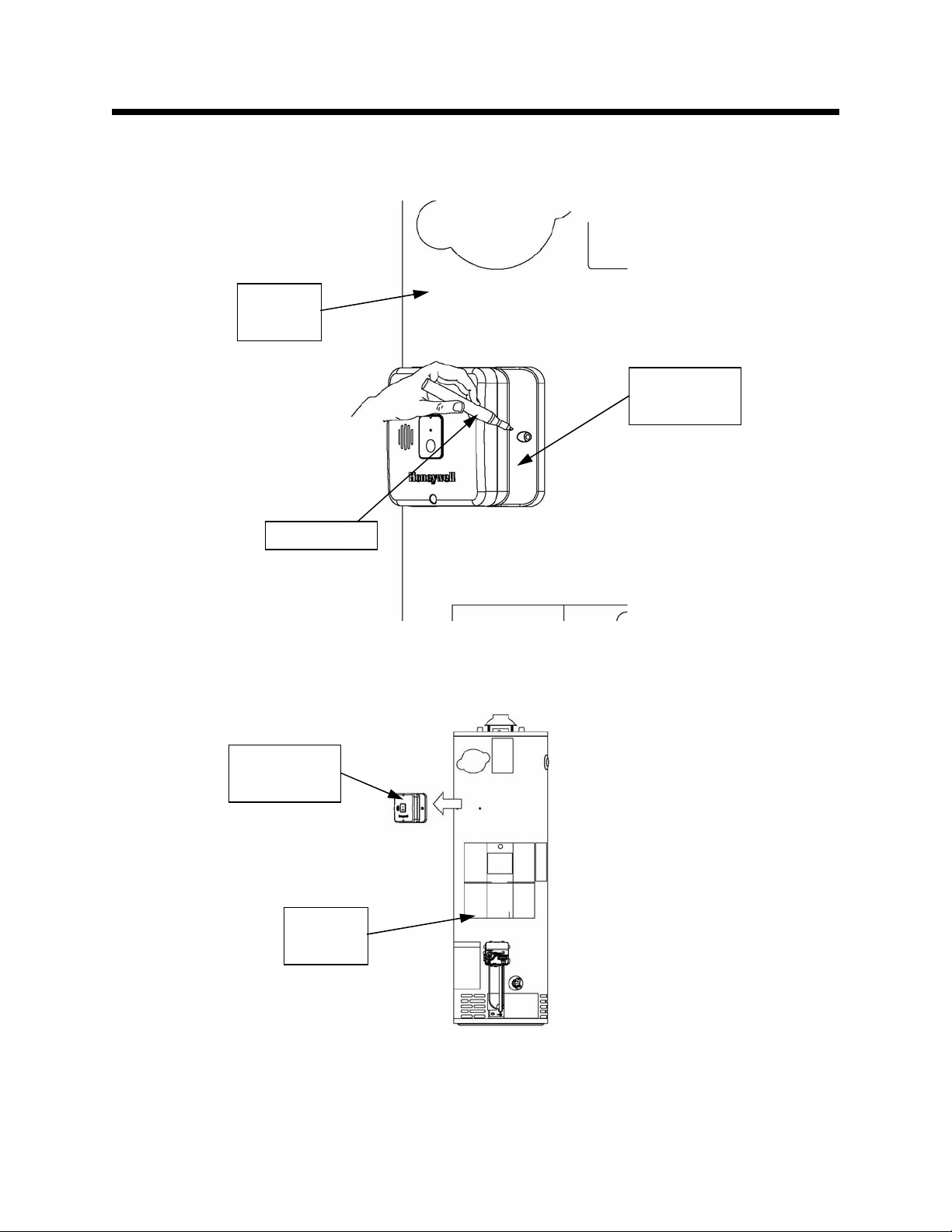

Mark the Location of the Accessory Module

Step 5: Using a marker, mark the location of the Accessory Module screw holes. This is shown in

Figure 5.

Water

Heater

Accessory

Module

Marker

Figure 5

Set the Accessory Module Aside

Step 6: Remove the Accessory Module from the water heater jacket, as shown in Figure 6.

Accessory

Module

Water

Heater

Figure 6

-15-

Page 16

Accessory Module Installation

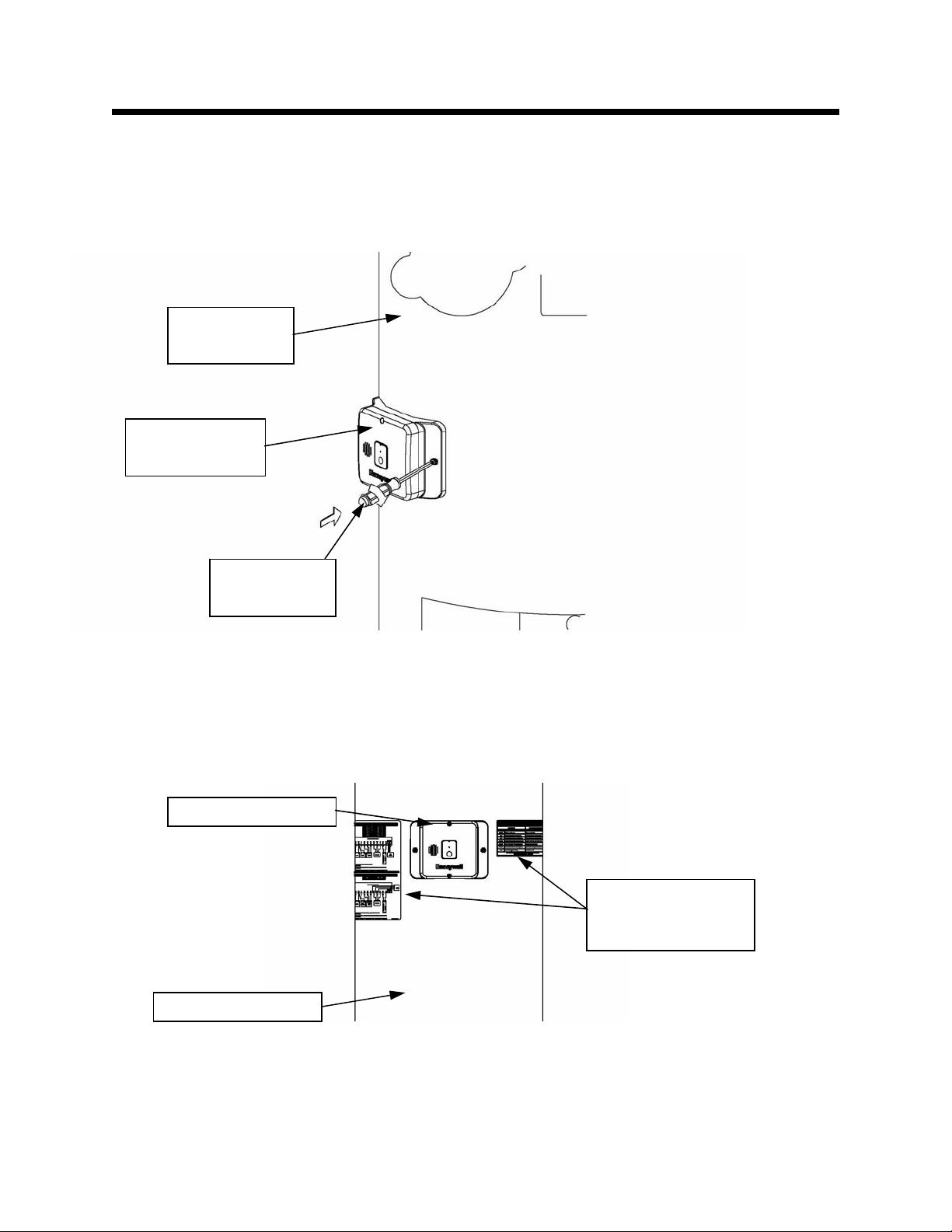

Drill the Accessory Module Screw Holes

Step 7: Using a 1/8” drill bit and drill, drill the (2) screw holes that were marked in Step 5. This is shown

in Figure 7.

Position the Accessory Module

Step 8: Put the Accessory Module up against the water heater jacket and position it to the pre-drilled

holes. This is shown in Figure 8.

Accessory

Module

Water

Heater

Marked drill

locations

Drill

Figure 7

Pre-drilled

holes

Water

Heater

Figure 8

-16-

Page 17

Accessory Module Installation

A

Mounting the Accessory Module

Step 9: Using (2) of the included Philips head screws, screw the Accessory Module to the water heater

jacket, as shown in Figure 9.

Apply the Necessary Labels

Step 10: Apply both the wiring diagram and diagnostic labels. These labels should be applied to the

water heater jacket near the Accessory Module. This is shown in Figure 10.

Water Heater

jacket

Accessory

Module

Philips head

screwdriver

Figure 9

ccessory Module

Apply the Wiring

Diagram and

Diagnostic labels

Water Heater

Figure 10

-17-

Page 18

Accessory Module Installation

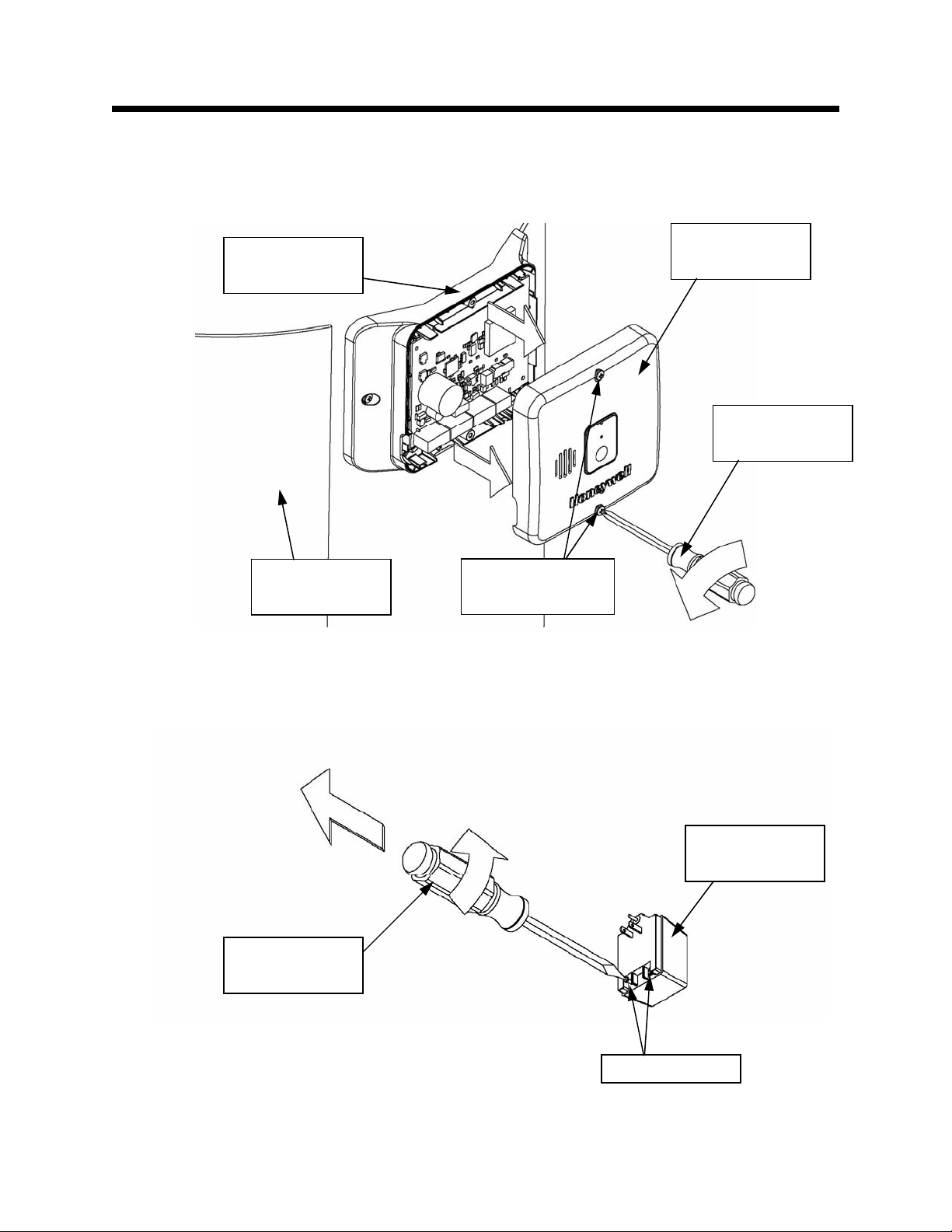

Remove the Accessory Module Cover

Step 11: Using a Philips head screwdriver, loosen both screws on the Accessory Module cover, as

shown in Figure 11. The cover screws are permanently retained and cannot be completely removed.

Retain the cover for later use.

Accessory

Module base

Accessory

Module base

Philips head

screwdriver

Wiring Diagram

label

Prepare the Plug-in Transformer for Assembly

Step 12: Loosen the (2) slotted sc rews on the transfo rmer. These screws are permanently re tained and

cannot be completely removed. This is shown in Figure 12.

Slotted head

screwdriver

Accessory Module

cover screws

Figure 11

Plug-in

Transformer

Figure 12

Slotted screws

-18-

Page 19

Accessory Module Installation

Assemble the Transformer and its Wire Harness

Step 13: Take one end of the transformer wire harness and slide each fork terminal under one of the

screws. This is shown in Figure 13.

Plug-in

Transformer

Transformer

slotted screws

Transformer

wire harness

Figure 13

NOTICE

If the Transformer wire harness is not of sufficient length, move the nearest electrical box to

within reaching distance.

Connect the Transformer and its Wire Harness

Step 14: Tighten both screws on the transformer down, as shown in Figure 14.

Slotted head

screwdriver

Transformer

slotted screws

Plug-in

Transformer

Transformer

wire harness

Figure 14

-19-

Page 20

Accessory Module Installation

Prepare to Connect the Transformer Wire Harness to the Accessory Module

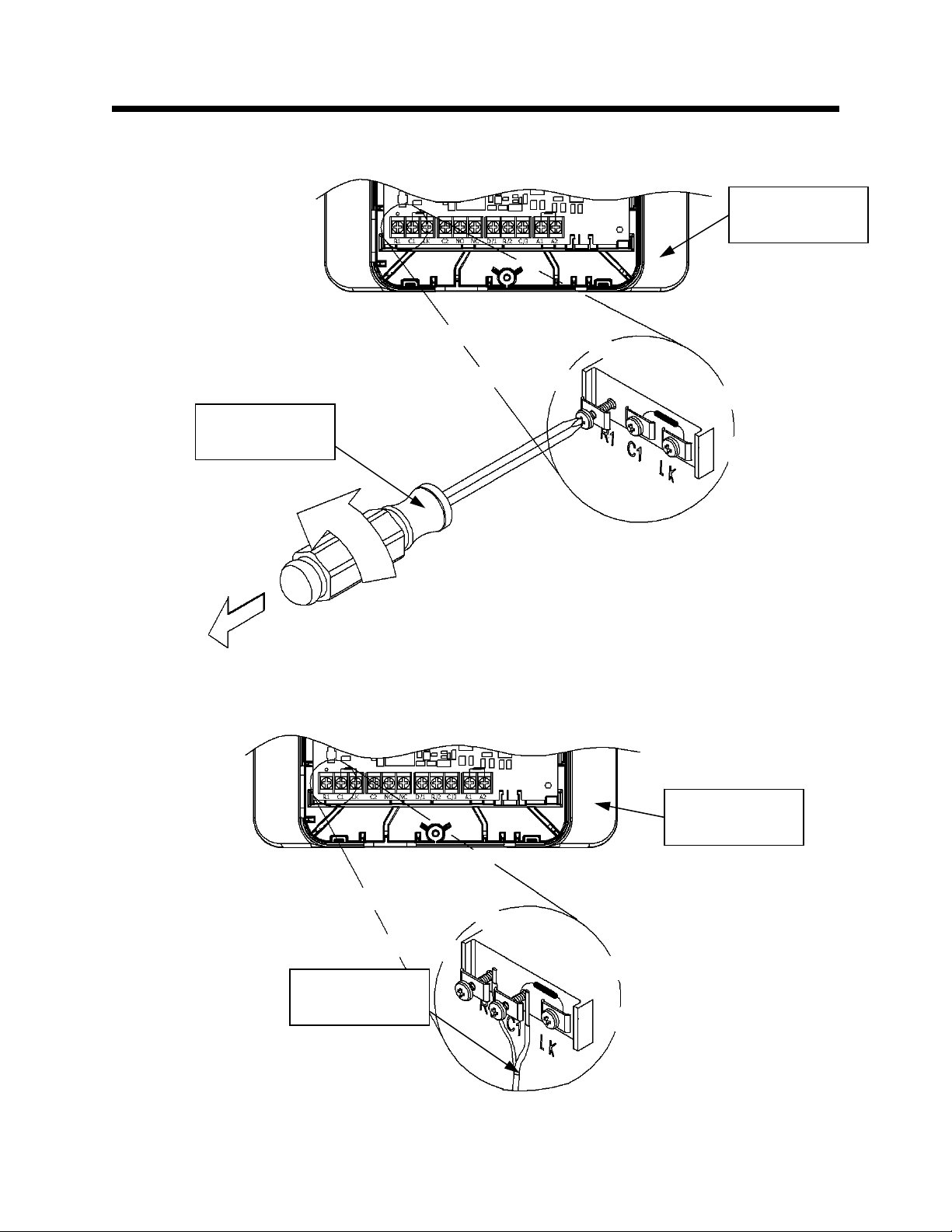

Step 15: Loosen the (2) Philips head screws on the Accessory Module, labeled “R1” and “C1.” This is

shown in Figure 15.

Philips head

screwdriver

Accessory

Module

Figure 15

Insert the Transformer Wire Harness into the Accessory Module

Step 16: Insert each wire stripped end of the Transformer wire harness under the screws labeled “R1”

and “C1.” This is shown in Figure 16.

Transformer

Wire Harness

Accessory

Module

Figure 16

-20-

Page 21

Accessory Module Installation

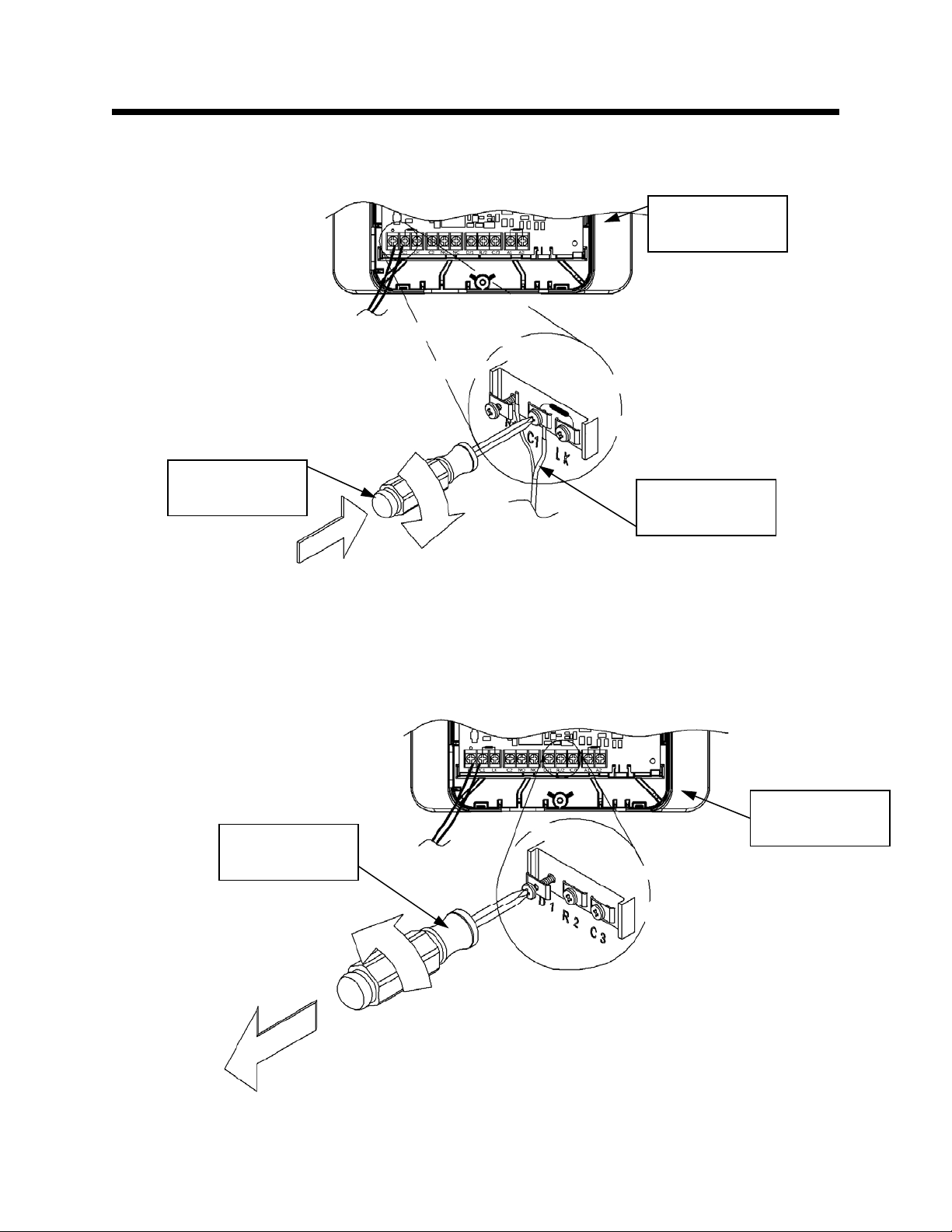

Connect the Transformer Wire Harness and the Accessory Module

Step 17: Tighten both screws, “R1” and “C1,” while holding the Transformer wire harness in place, as

shown in Figure 17.

Accessory

Module

Philips head

screwdriver

Transformer

Wire Harness

Figure 17

Connect Accessory Module to WV4460 Wire Harness

Step 18: If the water heater gas control has an intermittent pilot (WV4460 gas control), loosen the (3)

screws on the Accessory Module labeled “D/1,” “R/2,” and “C/3.” This is shown in Figure 18. If the water

heater has a standing pilot, proceed to Step 25.

Philips head

screwdriver

Accessory

Module

Figure 18

-21-

Page 22

Accessory Module Installation

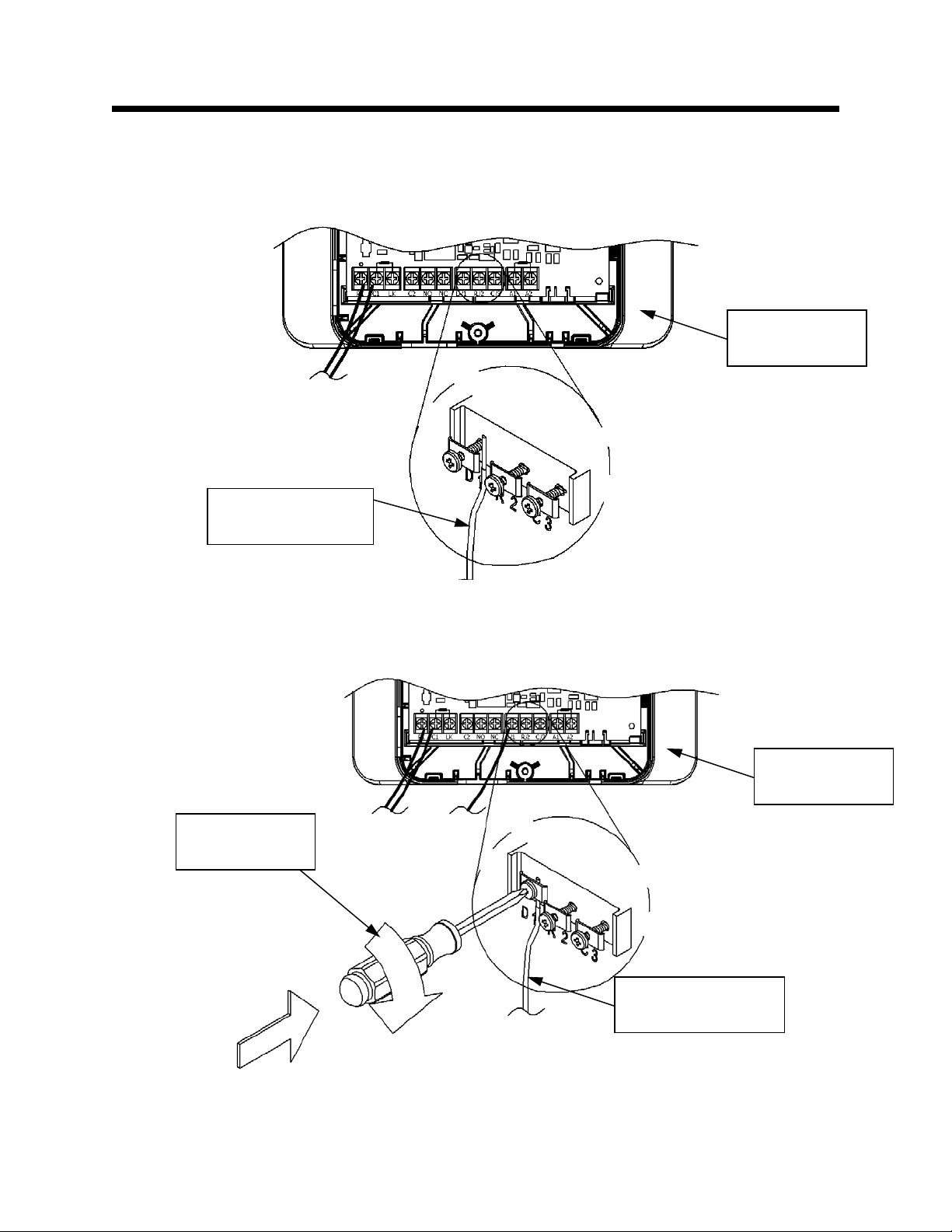

Assemble the WV4460 Wire Harness and Accessory Module

Step 19: Insert the red wire, from the WV4460 wire harness, under the screw labeled “D/1.” This is shown

in Figure 19.

Accessory

Module

WV4460 Wire

Harness Red Wire

Figure 19

Connect the WV4460 Wire Harness and Accessory Module

Step 20: Tighten the screw labeled “D/1,” as shown in Figure 20.

Philips head

screwdriver

Accessory

Module

WV4460 Wire

Harness Red Wire

Figure 20

-22-

Page 23

Accessory Module Installation

Assemble the WV4460 Wire Harness and Accessory Module – cont’d

Step 21: Insert the black wire, from the WV4460 wire harness, under the screw labeled “R/2.” This is

shown in Figure 21.

Accessory

Module

WV4460 Wire

Harness Red Wire

Harness Black Wire

Connect the WV4460 Wire Harness and Accessory Module – cont’d

Step 22: Tighten the screw labeled “R/2,” as shown in Figure 22.

WV4460 Wire

Harness Red Wire

Philips head

screwdriver

Figure 21

WV4460 Wire

Accessory

Module

WV4460 Wire

Harness Black Wire

Figure 22

-23-

Page 24

Accessory Module Installation

Assemble the WV4460 Wire Harness and Accessory Module – cont’d

Step 23: Insert the white wire, from the WV4460 wire harness, under the screw labeled “C/3.” This is

shown in Figure 23.

Accessory

Module

WV4460 Wire

Harness Red Wire

WV4460 Wire

Harness Black Wire

Connect the WV4460 Wire Harness and Accessory Module – cont’d

Step 24: Tighten the screw labeled “C/3,” as shown in Figure 24. Proceed to Step 26 when finished.

WV4460 Wire

Harness Red Wire

Philips head

screwdriver

Figure 23

WV4460 Wire

Harness White Wire

Accessory

Module

WV4460 Wire

Harness White Wire

WV4460 Wire

Figure 24

-24-

Harness Black Wire

Page 25

Accessory Module Installation

Connect the Accessory Module to the WV8840 Wire Harness

Step 25: Insert one end of the WV8840 wire harness over the edge of the Accessory Module circuit board.

This connection point is on the bottom right hand side of the circuit board, and it is shown in Figure 25.

Proceed to Step 27 when finished.

Accessory

Module

WV8840 Wire

Harness

WV8840 Wire

Harness

Figure 25

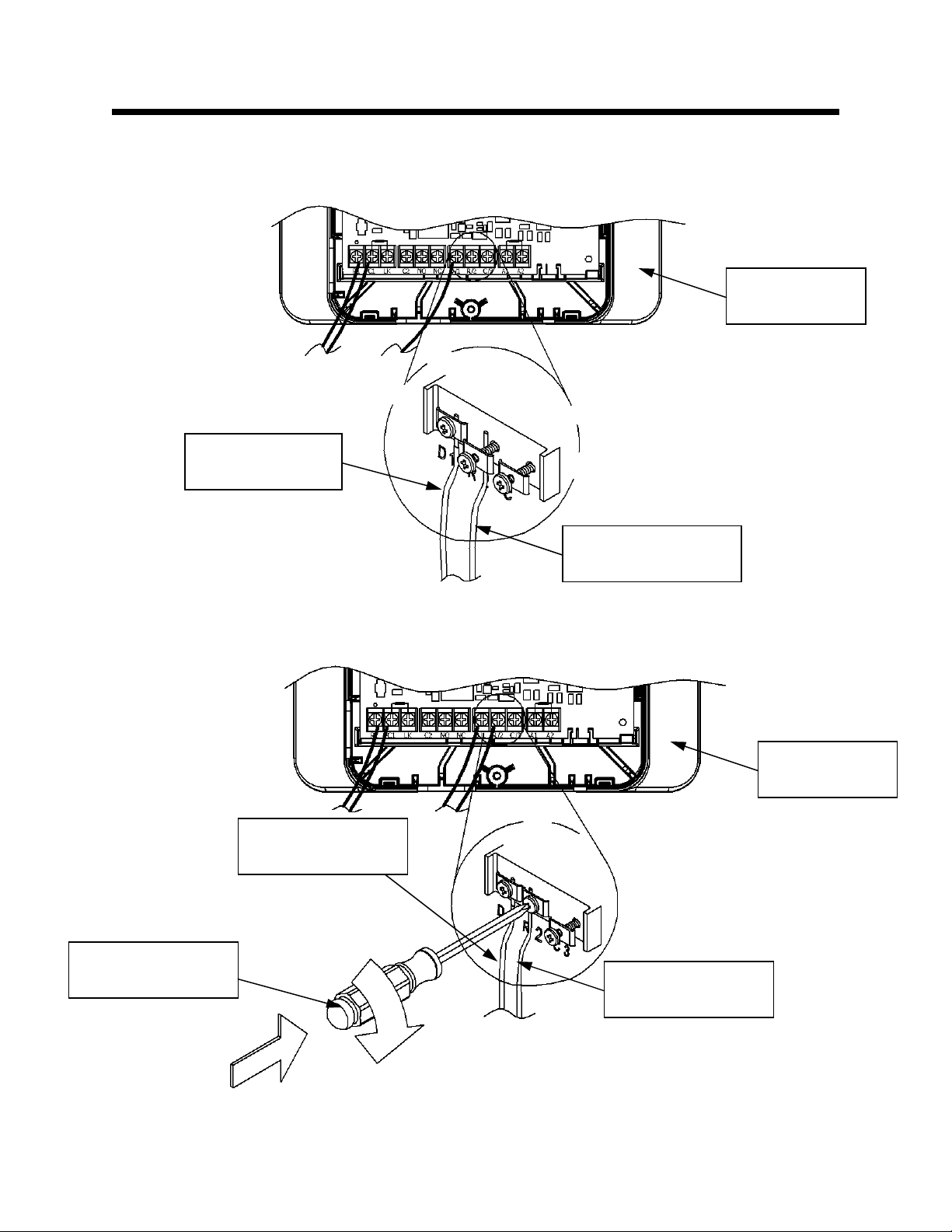

Connect the WV4460 Wire Harness to the WV4460 Gas Control

Step 26: Push the plastic connector on the WV4460 wire harness into the recessed area on the right side

of the WV4460 gas control. This is shown in Figure 26.

WV4460 Gas

Control

Figure 26

-25-

WV4460 Wire

Harness

Page 26

Accessory Module Installation

Connect the WV8840 Wire Harness to the WV8840 Gas Control

Step 27: Push the plastic connector on the WV8840 wire harness into the recessed area on the bottom

side of the WV8840 gas control. This is shown in Figure 27.

WV8840 Wire

Harness

WV8840 Gas

Control

Figure 27

The Accessory Module installation is complete. Proceed to the

installation sections for the other purchased packages.

-26-

Page 27

Setback Control Installation

In the following section, the instructions detail how to install the Setback Control on the water

heater. The Accessory Module must be installed for the Setback Control to work with the water

heater gas control.

Unpack the Setback Control Junction Box Assembly

Step 1: Remove the Setback Control Junction Box Assembly and its components from their packaging.

This is shown in Figure 28.

Unpack the Setback Control

Step 2: Remove the Setback Control and its batteries from their packaging, as shown in Figure 29.

Setback

Control

Figure 28

Supplied AAA

Batteries

Figure 29

-27-

Page 28

Setback Control Installation

Remove the Setback Control Battery Holder

Step 3: Depress the top side of the battery holder and remove it. This is shown in Figure 30.

Battery

Holder

Setback

Control

Install the Setback Control Batteries

Step 4: Install the (2) supplied AAA batteries into the battery holder of the Setback Control, as shown in

Figure 31.

Figure 30

Battery

Holder

(2) Supplied AAA

Batteries

Figure 31

-28-

Page 29

Setback Control Installation

Install the Setback Control Battery Holder

Step 5: Install the Setback Control Battery Holder, just as it was installed prior to Step 3. This is shown in

Figure 32.

Battery

Holder

Setback

Control

Remove the Protective Plate

Step 6: Remove the Setback Control protective plate from the Setback Control by pulling these items

apart. This is shown in Figure 33. Some force may be required to separate these. Discard the protective

plate.

Figure 32

Setback

Control

Figure 33

NOTICE

Do not discard the Protective Plate if the Setback Control is going to be remote mounted.

-29-

Protective

Plate

Page 30

Setback Control Installation

Locate the Setback Control Junction Box Assembly

Step 7: Place the Setback Control Junction Box Assembly on top of the water heater. This assembly must

face the front of the water heater, and it must be located close to the centerline of the water heater. This is

shown in Figure 34. The Setback Control Junction Box Assembly must be located as far from the draft

hood as possible, if installed on an atmospheric water heater.

Move the Setback Control

Junction Box Assembly as

far from the draft hood (or

blower) as possible

Water Heater

Centerline

Figure 34

WARNING

Do not mount the Setback Control Junction Box Assembly close to the draft hood.

Mark the Location of the Setback Control Junction Box Assembly

Step 8: Using a marker, mark the location of both holes in the Setback Control Junction Box Assembly.

This is shown in Figure 35.

Setback Control

Junction Box Assembly

Marker

Figure 35

Top of Water

Heater

-30-

Page 31

Setback Control Installation

Remove the Setback Control Junction Box Assembly

Step 9: Remove the Setback Control Junction Box Assembly from the top of the water heater, as shown in

Figure 36.

Setback Control

Junction Box Assembly

Drill the Setback Control Junction Box Assembly Mounting Holes

Step 10: Using a 1/8” drill bit and drill, drill the (2) screw holes that were marked in Step 8. This is shown

in Figure 37.

Figure 36

Drill

Top of Water

Heater

Marked Drill

Locations

Figure 37

-31-

Top of Water

Heater

Page 32

Setback Control Installation

Position the Setback Control Junction Box Assembly

Step 11: Put the Setback Control Junction Box Assembly back on top of the water heater and position it to

the pre-drilled holes. This is shown in Figure 38.

Setback Control

Junction Box Assembly

Mount the Setback Control Junction Box Assembly

Step 12: Using (2) of the included Philips head screws, screw the Setback Control Junction Box Assembly

to the top of the water heater, as shown in Figure 39.

Setback Control

Junction Box Assembly

Philips head

screwdriver

Figure 38

Figure 39

Top of Water

Heater

Top of Water

Heater

WARNING

Do not mount the Setback Control Junction Box Assembly close to the draft hood. Position this

assembly as close to the front of the water heater as possible.

-32-

Page 33

Setback Control Installation

Install the Setback Control

Step 13: Snap the Setback Control into the backplate on the Setback Control Junction Box Assembly.

Align the Setback Control to the backplate, and press until it is fully seated. This is shown in Figure 40.

Setback Control

Junction Box Assembly

Backplate Already

Installed

Setback

Control

Top of Water

Heater

Connect the Setback Control Wire Harness to the Setback Control Junc tion Box Assembly

Step 14: Take the plastic connector end of the Setback Control wire harness, and connect it to its

connector mate in the back of the Setback Control Junction Box Assembly. This is shown in Figure 41.

Connector

Mate

Figure 40

Setback Control Junction

Box Assembly

Top of Water

Heater

Setback Control

Wire Harness

Figure 41

-33-

Page 34

Setback Control Installation

Connect the Setback Control Wire Harness to the Accessory Module

Step 15: If the water heater gas control has an intermittent pilot (WV4460 gas control), the connection,

“D/1,” is already being used. This same connection point is used to connect the Setback Control. Loosen

the screw “D/1.” This is shown in Figure 42.

Accessory

Module

WV4460 Wire Harness

Red Wire (if installed)

Philips head

screwdriver

Figure 42

Assemble the Setback Control Wire Harness and Accessory Module

Step 16: Insert the red wire, from the Setback Control wire harness, under the screw labeled “D/1.” If the

water heater has a WV4460 gas control, the gas control wire harness red wire must be retained

underneath this screw also. This is shown in Figure 43.

WV8840 Wire

Harness (if installed)

WV4460 Wire Harness

White Wire (if installed)

WV4460 Wire Harness

Black Wire (if installed)

Accessory

Module

WV4460 Wire Harness

Red Wire (if installed)

Setback Control Wire

Harness Red Wire

WV4460 Wire Harness

White Wire (if installed)

Figure 43

-34-

WV4460 Wire Harness

Black Wire (if installed)

WV8840 Wire

Harness (if installed)

Page 35

Setback Control Installation

Connect the Setback Control Wire Harness and Accessory Module

Step 17: Tighten the screw labeled “D/1,” as shown in Figure 44.

Accessory

Module

WV8840 Wire

WV4460 Wire Harness

Red Wire (if installed)

Setback Control Wire

Harness Red Wire

Harness (if installed)

WV4460 Wire Harness

White Wire (if installed)

WV4460 Wire Harness

Philips head

Assemble the Setback Control Wire Harness and Accessory Module – cont’d

Step 18: If the water heater gas control has an intermittent pilot (WV4460 gas control), the connection,

“R/2,” is already being used. This same connection point is used to connect the Setback Control. Loosen

the screw “R/2.” This is shown in Figure 45.

Setback Control Wire

Harness Red Wire

Philips head

screwdriver

screwdriver

Figure 44

Black Wire (if installed)

Accessory

Module

WV8840 Wire

Harness (if installed)

WV4460 Wire Harness

White Wire (if installed)

Figure 45

-35-

WV4460 Wire Harness

Black Wire (if installed)

WV4460 Wire Harness

Red Wire (if installed)

Page 36

Setback Control Installation

Assemble the Setback Control Wire Harness and Accessory Module – cont’d

Step 19: Insert the black wire, from the Setback Control wire harness, under the screw labeled “R/2.” If

the water heater has a WV4460 gas control, the gas control wire harness black wire must be retained

underneath this screw also. This is shown in Figure 46.

Accessory

Module

WV4460 Wire Harness

Red Wire (if installed)

Setback Control Wire

Harness Red Wire

Setback Control Wire

Harness Black Wire

Connect the Setback Control Wire Harness and Accessory Module – cont’d

Step 20: Tighten the screw labeled “R/2,” as shown in Figure 47.

WV4460 Wire Harness

Red Wire (if installed)

Figure 46

Harness (if installed)

WV4460 Wire Harness

White Wire (if installed)

WV4460 Wire Harness

Black Wire (if installed)

WV8840 Wire

Accessory

Module

WV8840 Wire

Harness (if installed)

Setback Control Wire

Harness Red Wire

Philips head

screwdriver

Setback Control Wire

Harness Black Wire

Figure 47

WV4460 Wire Harness

White Wire (if installed)

WV4460 Wire Harness

Black Wire (if installed)

-36-

Page 37

Setback Control Installation

Assemble the Setback Control Wire Harness and Accessory Module – cont’d

Step 21: If the water heater gas control has an intermittent pilot (WV4460 gas control), the connection,

“C/3,” is already being used. This same connection point is used to connect the Setback Control. Loosen

the screw “C/3.” This is shown in Figure 48.

Accessory

Module

WV4460 Wire Harness

Red Wire (if installed)

WV8840 Wire

Harness (if installed)

Setback Control Wire

Harness Red Wire

Philips head

screwdriver

WV4460 Wire Harness

White Wire (if installed)

WV4460 Wire Harness

Black Wire (if installed)

Setback Control Wire

Harness Black Wire

Assemble the Setback Control Wire Harness and Accessory Module – cont’d

Step 22: Insert the white wire, from the Setback Control wire harness, under the screw labeled “C/3.” If

the water heater has a WV4460 gas control, the gas control wire harness white wire must be retained

underneath this screw also. This is shown in Figure 49.

WV4460 Wire Harness

Red Wire (if installed)

Setback Control Wire

Harness Red Wire

Figure 48

Accessory

Module

WV8840 Wire

Harness (if installed)

WV4460 Wire Harness

White Wire (if installed)

Setback Control Wire

Setback Control Wire

Harness Black Wire

Figure 49

-37-

Harness White Wire

WV4460 Wire Harness

Black Wire (if installed)

Page 38

Setback Control Installation

Connect the Setback Control Wire Harness and Accessory Module – cont’d

Step 23: Tighten the screw labeled “C/3,” as shown in Figure 50.

WV4460 Wire Harness

Red Wire (if installed)

Setback Control Wire

Harness Red Wire

Philips head

screwdriver

WV4460 Wire Harness

White Wire (if installed)

Setback Control Wire

Harness White Wire

Accessory

Module

WV8840 Wire

Harness (if installed)

WV4460 Wire Harness

Black Wire (if installed)

Setback Control Wire

Harness Black Wire

Figure 50

The Setback Control installation is complete. Proceed to the

installation sections for the other purchased packages. Or, if finished,

proceed to the Start-up Procedure on page 67.

-38-

Page 39

Integrated Mixing Device - IMD

Refer to the instructions included with Integrated Mixing Device (IMD), on how to install and

operate the IMD. Figure 51 shows the contents included with the integrated mixing device.

Figure 51

CAUTION

The piping diagram supplied with the water heater must be followed.

-39-

Page 40

Leak Sensor Installation

In the following section, the instructions detail how to install the Leak Sensor. The Accessory

Module must be installed for the Leak Sensor to work with the water heater gas control.

The leak sensor can take up to 15 minutes to sense and verify a water heater tank leak.

Unpack the Leak Sensor and its Components

Step 1: Remove the Leak Sensor and its components from their packaging, as shown in Figure 52.

Figure 52

Assemble the Leak Sensor

Step 2: Insert the Leak Sensor bracket into the Leak Sensor housing, as shown in Figure 53.

Leak Sensor

Housing

Leak Sensor

Bracket

Leak Sensor

(assembled)

Figure 53

-40-

Page 41

Leak Sensor Installation

Connect the Leak Sensor and its Wire Harness

Step 3: Connect the Leak Sensor wire harness to the Leak Sensor (specifically the end with the plastic

connector), as shown in Figure 54.

Leak Sensor

Wire Harness

Connector

Figure 54

Prepare the Accessory Module for the Leak Sensor

Step 4: Loosen the screw labeled “C1,” as shown in Figure 55. Ensure that the Transformer wire harness

wire going to this same location remains inserted under this screw.

Philips head

screwdriver

Leak Sensor

Plastic

Accessory

Module

Leak Sensor

Resistor

Transformer

Wire Harness

Figure 55

-41-

Page 42

Leak Sensor Installation

Prepare the Accessory Module for the Leak Sensor – cont’d

Step 5: Loosen the screw labeled “LK,” as shown in Figure 56.

Philips head

screwdriver

Accessory

Module

Leak Sensor

Resistor

Transformer

Wire Harness

Remove the Leak Sensor Resistor

Step 6: Using needle nose pliers, remove the Leak Sensor resistor from the Accessory Module and

discard. This is shown in Figure 57.

Figure 56

Accessory

Module

Leak Sensor

Resistor

Transformer

Wire Harness

Figure 57

-42-

Page 43

Leak Sensor Installation

Assemble the Leak Sensor Wire Harness and the Accessory Module

Step 7: Insert the red wire, from the Leak Sensor wire harness, under the screw labeled “C1.” This is

shown in Figure 58. Ensure that the wire from the Transformer wire harness at this location is retained

under this screw.

Accessory

Module

Transformer

Wire Harness

Leak Sensor Wire

Harness Red Wire

Connect the Leak Sensor Wire Harness and Accessory Module

Step 8: Tighten the screw labeled “C1,” as shown in Figure 59.

Philips head

screwdriver

Figure 58

Accessory

Module

Leak Sensor Wire

Harness Red Wire

Transformer

Wire Harness

Figure 59

-43-

Page 44

Leak Sensor Installation

Assemble the Leak Sensor Wire Harness and the Accessory Module – cont’d

Step 9: Insert the black wire, from the Leak Sensor wire harness, under the screw labeled “LK.” This is

shown in Figure 60.

Accessory

Module

Transformer

Wire Harness

Leak Sensor Wire

Harness Red Wire

Leak Sensor Wire

Harness Black Wire

Connect the Leak Sensor Wire Harness and Accessory Module – cont’d

Step 10: Tighten the screw labeled “LK,” as shown in Figure 61.

Transformer

Wire Harness

Philips head

screwdriver

Figure 60

Leak Sensor Wire

Harness Black Wire

Leak Sensor Wire

Harness Red Wire

Accessory

Module

Figure 61

-44-

Page 45

Leak Sensor Installation

Position the Leak Sensor

Step 11: Position the Leak Sensor up against the water heater jacket, as shown in Figure 62. The Leak

Sensor must be positioned to the left of the water heater gas control. The Leak Sensor must sit flat on the

floor or in the drain pan.

Position the Leak Sensor 3” from the Air Slots or

if not Present, Position it 6” from the Doorway

Air Slots

Mark the Location of the Leak Sensor

Step 12: Using a marker, mark the location of the hole in the Leak Sensor bracket, as shown in Figure 63.

The water heater must be installed on a level floor.

Doorway

Figure 62

Marker

Leak Sensor

Bracket

Figure 63

CAUTION

Leak Sensor

Leak Sensor

Wire Harness

WARNING

The Leak Sensor can be mounted in a water heater drain pan. If the installation does not use a

drain pan, the dam should be used to corral the water heater tank leak to the Leak Sensor.

The bottom of the Leak Sensor must be touching the floor. Failure to do so will result in

inaccurate leak detection.

-45-

Page 46

Leak Sensor Installation

Remove the Leak Sensor

Step 13: Remove the Leak Sensor from the water heater jacket, and set it aside. This is shown in Figure

64.

Leak Sensor

Wire Harness

Leak Sensor

Drill the Leak Sensor Mounting Hole

Step 14: Using a 1/8” drill bit and drill, drill the screw hole that was marked in Step 12. This is shown in

Figure 65.

Marked Drill

Location

Drill

Figure 64

Figure 65

-46-

Page 47

Leak Sensor Installation

Position the Leak Sensor

Step 15: Put the Leak Sensor back in position against the water heater jacket and position to the predrilled hole, as shown in Figure 66.

Water Heater

Jacket

Leak Sensor

Wire Harness

Leak Sensor

Mount the Leak Sensor

Step 16: Using (1) of the included Philips head screws, screw the Leak Sensor to the water heater jacket.

This is shown in Figure 67.

Leak Sensor

Wire Harness

Philips Head

Screw

Philips head

screwdriver

Figure 66

Leak Sensor

Figure 67

-47-

Page 48

Leak Sensor Installation

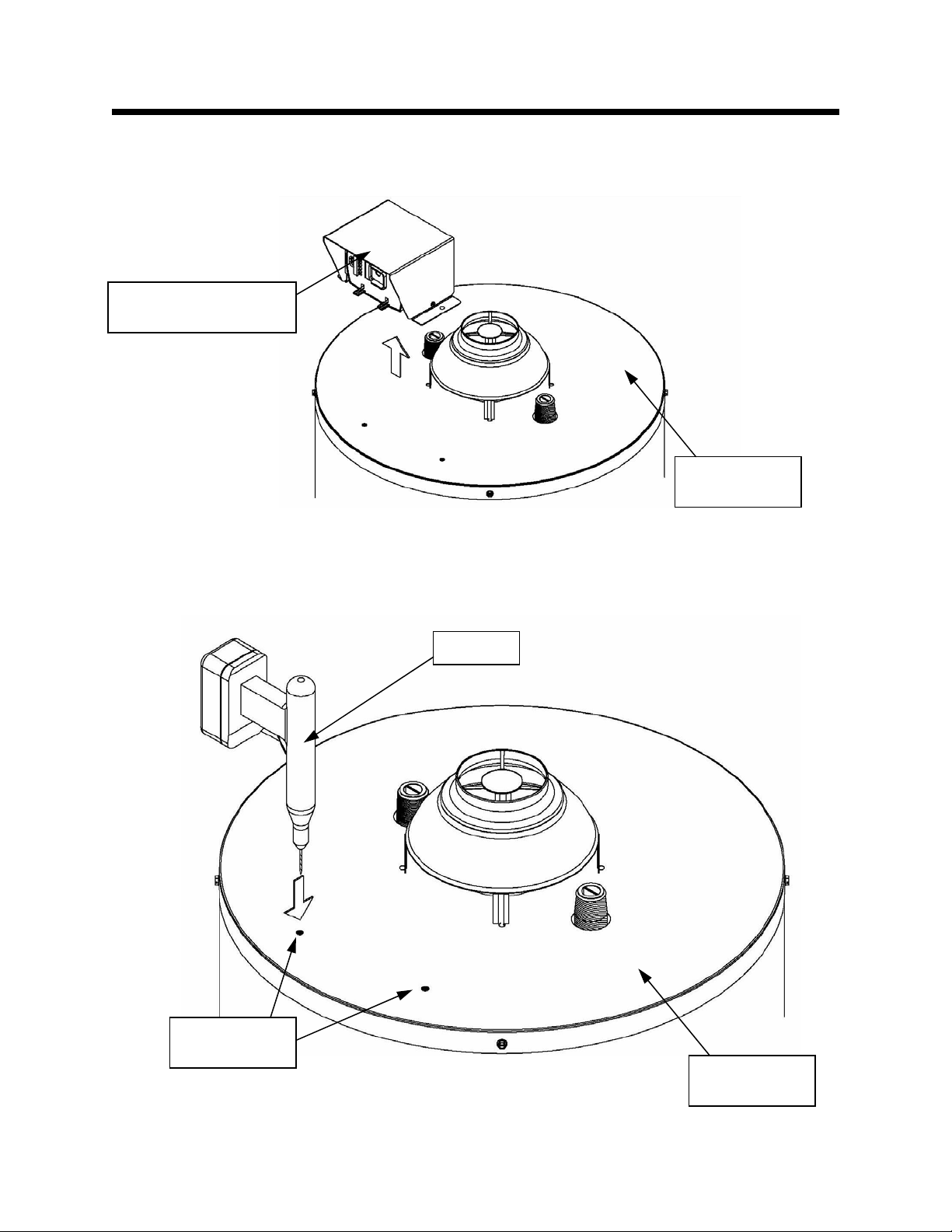

Position the Dam

Step 17: Position the dam around the water heater, so it surrounds the water heater and corrals a water

heater tank leak towards the Leak Sensor. This is shown in Figure 68.

Dam

Leak Sensor

Figure 68

WARNING

The dam must be mounted against the floor or it will not hold any water.

Fill in the Gaps

Step 18: Fill in any gaps between the dam and the floor. This is shown in Figure 69.

Caulk Gun with

RTV Silicone

Figure 69

Fill Gaps

between Floor

and Dam

The Leak Sensor installation is complete. Proceed to the installation

sections for the other purchased packages. Or, if finished, proceed to

the Start-up Procedure on page 67.

-48-

Page 49

Inlet Shut-off Valve Installation

In the following section, the instructions detail how to install the Inlet Shut-off Valve. If installed,

this device will shut off the water supply to the water heater after the Leak Sensor has sensed

and verified a water heater tank leak has occurred. The Accessory Module and Leak Sensor

must be installed for the Inlet Shut-off Valve to work with the water heater gas control.

The inlet shut-off valve can take up to 16 minutes to close, if installed, after a water heater tank

leak is sensed and verified.

Unpack the Inlet Shut-off Valve

Step 1: Remove the Inlet Shut-off Valve and its components from their packaging, as shown in Figure 70.

Prepare the Water Heater for the Installation of the Inlet Shut-off Valve

Step 2: If the water heater is already installed and the water heater is full of water, pressure must be

removed from the water heater tank, and the tank must be at least partially drained.

Figure 70

WARNING

If installed properly, the Inlet Shut-off Valve will prevent continuous flow when a water heater

tank leak is detected and verified. If damage will occur, a drain pan must be installed and piped

to an adequate floor drain.

-49-

Page 50

Inlet Shut-off Valve Installation

Determine if Bushings are Necessary

Step 3: If the water heater uses a 3/4” NPT thread water inlet, the (2) included 3/4” x 1” NPT bushings

must be used. Proceed to Step 4. Otherwise, proceed to Step 6.

Prepare Bushings for Installation

Step 4: Apply pipe dope (suitable for potable water use) to the threads of the bushings, as shown in

Figure 71.

Put Pipe Dope

onto Bushing

Threads

Figure 71

-50-

Page 51

Inlet Shut-off Valve Installation

Install the Bushings

Step 5: Thread the bushings into each end of the Inlet Shut-off Valve, as shown in Figure 72.

Inlet Shut-off

Valve

Bushings

Install the Inlet Shut-off Valve

Step 6: Thread the Inlet Shut-off Valve onto the water heater inlet (cold). Or, if an integrated mixing

device is used, thread the Inlet Shut-off Valve onto the IMD inlet. This is shown in Figure 73.

Figure 72

Inlet Shut-off

Valve

Water Heater

Inlet (cold)

Figure 73

NOTICE

Remove the draft hood and venting to install the Inlet Shut-off Valve, if necessary.

-51-

IMD Inlet (cold)

Page 52

Inlet Shut-off Valve Installation

Connect the Cold Water Supply

Step 7: Pipe the cold water supply piping to the Inlet Shut-off Valve inlet, as shown in Figure 74.

Cold Water

Supply Piping

Inlet Shut-off

Valve

Figure 74

CAUTION

The piping diagram supplied with the water heater must be followed.

Connect the Inlet Shut-off Valve Harness to the Accessory Module

Step 8: Loosen the (3) screws on the Accessory Module labeled “C2,” “NO,” and “NC.” This is shown in

Figure 75.

Philips head

screwdriver

Accessory

Module

Figure 75

-52-

Page 53

Inlet Shut-off Valve Installation

Assemble the Inlet Shut-off Valve Wire Harness and the Accessory Module

Step 9: Insert the blue wire, from the Inlet Shut-off Valve wire harness, under the screw labeled “C2,” as

shown in Figure 76.

Accessory

Module

Inlet Shut-off

Valve Wire

Harness Blue

Wire

Connect the Inlet Shut-off Valve Wire Harness to the Accessory Module

Step 10: Tighten the screw labeled “C2.” This is shown in Figure 77.

Inlet Shut-off

Valve Wire

Harness Blue

Wire

Figure 76

Accessory

Module

Philips head

screwdriver

Figure 77

-53-

Page 54

Inlet Shut-off Valve Installation

Assemble the Inlet Shut-off Valve Wire Harness and the Accessory Module – cont’d

Step 11: Insert the brown wire, from the Inlet Shut-off Valve wire harness, under the screw labeled “NO,”

as shown in Figure 78.

Accessory

Module

Inlet Shut-off Valve

Wire Harness Blue

Wire

Inlet Shut-off Valve

Wire Harness Brown

Wire

Connect the Inlet Shut-off Valve Wire Harness and the Accessory Module – cont’d

Step 12: Tighten the screw labeled “NO.” This is shown in Figure 79.

Inlet Shut-off Valve

Wire Harness Blue

Wire

Philips head

screwdriver

Figure 78

Inlet Shut-off Valve

Wire Harness Brown

Wire

Accessory

Module

Figure 79

-54-

Page 55

Inlet Shut-off Valve Installation

Assemble the Inlet Shut-off Valve Wire Harness and the Accessory Module – cont’d

Step 13: Insert the black wire, from the Inlet Shut-off Valve wire harness, under the screw labeled “NC,” as

shown in Figure 80.

Accessory

Module

Inlet Shut-off Valve

Wire Harness Blue

Wire

Inlet Shut-off Valve

Wire Harness Black

Wire

Connect the Inlet Shut-off Valve Wire Harness to the Accessory Module – cont’d

Step 14: Tighten the screw labeled “NC.” This is shown in Figure 81.

Figure 80

Inlet Shut-off Valve

Wire Harness Brown

Wire

Inlet Shut-off Valve

Wire Harness Blue

Wire

Philips head

screwdriver

Inlet Shut-off Valve

Wire Harness Black

Figure 81

Inlet Shut-off Valve

Wire Harness Brown

Wire

The Inlet Shut-off Valve installation is complete. Proceed to the

installation sections for the other purchased packages. Or, if

finished, proceed to the Start-up Procedure on page 67.

Accessory

Module

Wire

-55-

Page 56

Remote Mounting the Setback Control

In the following section, the instructions detail how to Remote Mount the Setback Control.

Remove the Setback Control from the Backplate

Step 1: Remove the Setback Control from the backplate attached to the Setback Control Junction Box

Assembly. Some force may be required. This is shown in Figure 82.

Setback

Control

Setback Control

Junction Box

Assembly

Backplate (already

installed)

Figure 82

Prepare the Backplate for Wiring

Step 2: Loosen the (3) slotted screws on the backplate attached to the Setback Control Junction Box

Assembly. This is shown in Figure 83.

Slotted head

screwdriver

Slotted head

screws

Setback Control

Junction Box

Assembly

Backplate (already

Figure 83

-56-

installed)

Page 57

Remote Mounting the Setback Control

Mount the Protective Plate

Step 3: Mount the Setback Control Protective Plate in a desired location. Be sure that the Setback

Control will not be direct sunlight, as the display may be difficult to read. This is shown in Figure 84.

Measure Wire for Remote Mounting

Step 4: Measure and cut (3) pieces of 18 AWG wire to a sufficient length to reach from the backplate on

the Setback Control Junction Box Assembly to the Setback Control Protective Plate. This is shown in

Figure 85.

18 AWG

Wire

Drill

Wall

Protective

Plate

Figure 84

Figure 85

-57-

Page 58

Remote Mounting the Setback Control

Label the Wires for Remote Mounting

Step 5: Label the (3) cut wires (A), (B), and (C) respectively. Label both ends of the wires. This is shown

in Figure 86. Masking tape can be used to label the wires.

Prepare the Wires for Installation

Step 6: Strip approximately 1/4” of the wire’s insulation from each end of the three wires. This is shown in

Figure 87.

Approximately 1/4”

Strip

from Each End of

All (3) Wires

Figure 86

Figure 87

Label Each

Wire

-58-

Page 59

Remote Mounting the Setback Control

Install Wire (A) – Backplate

Step 7: Using wire (A), insert one end into the top terminal location on the backplate (located on the

Setback Control Junction Box Assembly). This is shown in Figure 88. Be sure that the wire already

located in this location is not dislodged.

Wire (A)

Wires Already

Installed

Fasten Wire (A) into its Designated Location – Backplate

Step 8: Tighten the slotted screw in the top terminal location on the backplate (located on the Setback

Control Junction Box Assembly). This is shown in Figure 89.

Figure 88

Wire (A)

Backplate

Slotted head

screwdriver

Figure 89

-59-

Junction Box Assembly

Backplate

Setback Control

Page 60

Remote Mounting the Setback Control

Install Wire (B) – Backplate

Step 9: Using wire (B), insert one end into the middle terminal location on the backplate (located on the

Setback Control Junction Box Assembly). This is shown in Figure 90. Be sure that the wire already

located in this location is not dislodged.

Fasten Wire (B) into its Designated Location – Backplate

Step 10: Tighten the slotted screw in the middle terminal location on the backplate (located on the

Setback Control Junction Box Assembly). This is shown in Figure 91.

Wires Already

Installed

Wire (A) Wire (B)

Backplate

Figure 90

Wire (A)

Wire (B)

Setback Control

Junction Box Assembly

Slotted head

screwdriver

Figure 91

Backplate

-60-

Page 61

Remote Mounting the Setback Control

Install Wire (C) – Backplate

Step 11: Using wire (C), insert one end into the bottom terminal location on the backplate (located on

the Setback Control Junction Box Assembly). This is shown in Figure 92. Be sure that the wire already

located in this location is not dislodged.

Wires Already

Fasten Wire (C) into its Designated Location – Backplate

Step 12: Tighten the slotted screw in the bottom terminal location on the backplate (located on the

Setback Control Junction Box Assembly). This is shown in Figure 93.

Installed

Wire (C)

Wire (A) Wire (B)

Backplate

Figure 92

Wire (A)

Wire (B)

Wire (C)

Setback Control

Slotted head

screwdriver

Figure 93

Backplate

-61-

Junction Box Assembly

Page 62

Remote Mounting the Setback Control

Route Wires to Protective Plate

Step 13: Route all three wires to the Setback Control Protective Plate.

Install Wire (A) – Protective Plate

Step 14: Using wire (A), insert one end into the top terminal location on the Protective Plate. This is

shown in Figure 94.

Wire (A)

Figure 94

Protective

Plate

-62-

Page 63

Remote Mounting the Setback Control

Fasten Wire (A) into its Designated Location – Protective Plate

Step 15: Tighten the slotted screw in the top terminal location on the Protective Plate. This is shown in

Figure 95.

Install Wire (B) – Protective Plate

Step 16: Using wire (B), insert one end into the middle terminal location on the Protective Plate. This is

shown in Figure 96.

Wire (A)

Figure 95

Slotted head

screwdriver

Protective

Plate

Wire (A)

Wire (B)

Figure 96

Protective

Plate

-63-

Page 64

Remote Mounting the Setback Control

Fasten Wire (B) into its Designated Location – Protective Plate

Step 17: Tighten the slotted screw in the middle terminal location on the Protective Plate. This is shown in

Figure 97.

Wire (B)

Wire (A)

Figure 97

Slotted head

screwdriver

Protective

Plate

Install Wire (C) – Protective Plate

Step 18: Using wire (C), insert one end into the bottom terminal location on the Protective Plate. This is

shown in Figure 98.

Wire (A)

Wire (B)

Protective

Wire (C)

Plate

Figure 98

-64-

Page 65

Remote Mounting the Setback Control

Fasten Wire (C) into its Designated Location – Protective Plate

Step 19: Tighten the slotted screw in the bottom terminal location on the Protective Plate. This is shown

in Figure 99.

Install Setback Control

Step 20: Snap the Setback Control into the Protective Plate. Align the Setback Control to the Protective

Plate, and press until it is fully seated. This is shown in Figure 100.

Wire (B)

Wire (C)

Wire (A)

Figure 99

Protective

Plate

Slotted head

screwdriver

Setback

Control

Protective

Plate

Figure 100

-65-

Page 66

Remote Mounting the Setback Control

Install Cover Plate

Step 21: Snap the Setback Cover Plate onto the backplate (located on the Setback Control Junction Box

Assembly). This is shown in Figure 101.

Cover Plate

Setback Control

Junction Box

Assembly

Backplate

Figure 101

Remote Mounting the Setback Control is complete. Proceed to the

installation sections for the other purchased packages. Or, if

finished, proceed to the Start-up Procedure on page 67.

-66-

Page 67

Start-up Procedure

In the following section, the instructions detail the Start-up Procedure for the Accessory Module,

once any or all of its packages are completely installed.

Route the Wire Harnesses in the Accessory Module

Step 1: Route all of the wire harnesses out of the openings in the bottom and left side of the Accessory

Module. And, hold them in place. This is shown in Figure 102.

Accessory

Module

Route the Wire

Harnesses

through These

Holes

Re-install Accessory Module Cover

Step 2: With all wire harnesses properly routed, place the Accessory Module cover back onto the

Accessory Module base. This is shown in Figure 103.

Figure 102

Figure 103

Accessory Module

Cover

-67-

Page 68

Start-up Procedure

Fix the Accessory Module Cover in Place

Step 3: Tighten both Accessory Module cover screws, as shown in Figure 104.

Philips head

screwdriver

Accessory

Module

Route the Various Wire Harnesses

Step 4: Route the wire harnesses along the jacket and group them using the included wire ties. This is

shown in Figure 105.

Figure 104

Group the Wire

Harnesses with the

Included Wire Ties

Water Heater

Jacket

Wire Harnesses

Figure 105

-68-

Page 69

Start-up Procedure

Fix the Wire Harnesses

Step 5: Using the included wire holders, fix the wire harnesses to the water heater jacket only to the left of

the water heater gas control, as shown in Figure 106. Wire holders can be used to fix the wire harnesses

to the water heater jacket only to the left of the water heater gas control.

Use Wire Holders

to the Left of this

Line Only

Wire Holders

Wire Harnesses

Route Transformer Wire Harness

Step 6: Route the Transformer wire harness, so it is not in trip contact or touching the floor between the

water heater and dam. This is shown in Figure 107.

Transformer

Transformer Wire

Harness

Figure 106

Figure 107

WARNING

Failure to properly located the Transformer Wire Harness will result in a trip hazard or potential

electrical hazard.

-69-

Page 70

Start-up Procedure

Plug in Transformer

Step 7: Plug in the Transformer that powers the Accessory Module, as well as its components. This is

shown in Figure 108.

Observe Accessory Module Start-up Sequence

Step 8: Watch the LED on the Accessory Module, and observe as it progresses through the Start-up

Sequence. This is shown in Figure 109. If the LED on the Accessory Module goes green at the end of the

Start-up Sequence, proceed to Step 11 on page 72.

Figure 108

Transformer

Observe LED

Accessory

Module

Figure 109

-70-

Page 71

Start-up Procedure

Action Required for Improper Start-up Sequence

Step 9: If the Start-up Sequence results in a red LED strobe, the internal electronics on the Accessory

Module failed. The Accessory Module must be replaced. This is shown in Figure 110.

Faulty Component / Improper Assembly of Components

Step 10: If another LED sequence is showing (other than a red LED strobe), diagnose the sequence using

the Diagnostic Codes table on page 73.

Figure 110

Observe LED

Accessory

Module

-71-

Page 72

Start-up Procedure

Verify Inlet Shut-off Valve Operation (if installed)

Step 11: If the Inlet Shut-off Valve is installed, the valve will open during the Start-up Sequence. Verify

that the valve is open by drawing water from a faucet (specifically hot water). This is shown in Figure 111.

Figure 111

Program the Setback Control (if installed)

Step 12: Refer to the instructions included with the Setback Control on how to program the control.

The Start-up Procedure is complete. The installation of the Accessory

Module and its components is complete.

-72-

Page 73

Diagnostic Codes

LED Status

None No LED. Power not on.

Green LED on continuously. Power on (no fault). n/a

Red

Red

Amber

Amber

Red

One flash and three

second pause.

Two flashes and three

second pause.

Four flashes and three

second pause.

Five flashes and three

second pause.

LED strobe (quick

flashes).

Status Probable Cause

Setback Control not on.

Setback Control is showing

“Conn” error.

Accessory Module

Status

1. No power at outlet.

2. Transformer bad, replace

transformer.

3. Transformer wire harness not

properly connected. Check all wire

connections.

Leak alarm fault.

Inlet Shut-off valve

open.

Leak alarm fault.

Inlet Shut-off valve

closed.

Leak sensor

malfunction.

Gas control missing /

not connected.

Hardware error.

1. No power at Setback Control or outlet.

2. Transformer bad, replace transformer.

3. Transformer wire harness not properly connected.

Check all wire connections.

1. The Setback Control is not connected to the Accessory

Module and/or the water heater gas control (at all).

2. The Setback Control wire harness has some wrong

connections. Replace the wire harness.

Water heater tank leak.

Water heater tank leak.

1. Leak Sensor resistor removed.

2. Leak Sensor improperly

connected to Accessory Module.

1. Wrong gas control wire harness

was used.

2. Accessory Module was not

connected to gas control.

Internal electronics failure, replace

Accessory Module.

Probable Cause

NOTICE

The leak detection alarm can be muted. Press the button on the front of the Accessory Module

to mute this alarm for 1 day.

Perform a cycle of the Test Mode on the Accessory Module on a regular basis. Perform the

cycle by depressing the “Mute” button on the Accessory Module for at least (7) seconds. In the

Test Mode, the Accessory Module will go through the following sequence:

• Inlet Shut-off Valve opened for (10) seconds with continuously shown Amber LED and

the alarm on for the first second

• Inlet Shut-off Valve closed for (10) seconds with continuously shown Red LED with and

Inlet Shut-off Valve installed (or flashing Red LED without Inlet Shut-off Valve).

• Inlet Shut-off Valve opened for (10) seconds with flashing Green LED.

CAUTION

-73-

Page 74

Notes

-74-

Page 75

LIMITED PARTS WARRANTY

WHAT DOES THIS LIMITED WARRANTY COVER?

This limited warranty covers component parts for

malfunction caused by defects in materials and/or

workmanship. It extends to the first buyer and to any

subsequent owner(s) at the original place of installation.

WHAT DOES THIS LIMITED WARRANTY NOT COVER?

h

1. This limited warranty does not cover malfunction

caused by:

a) Excessive use

b) Defective Installation, and specifically, any

installation which is made:

i. in violation of applicable state or local

plumbing, housing or building codes, or

ii. contrary to the written instructions

furnished with the unit.

c) Adverse local conditions, misuse, and

specifically, operation, and maintenance contrary to the

written instructions furnished with the unit, or accidental or

other exterior damage.

2. This warranty also does not cover:

a) Incidental property damage, loss of use,

inconvenience or other incidental or consequential costs.

b) Costs associated with the replacement

and/or repair of the unit, including:

i. any freight, shipping or delivery charges

ii. any removal, installation or re-installation

charges

iii. any material, and/or permits required for

installation, re-installation or repair

iv. charges to return the component part to

the manufacturer.

WHAT IS THE PERIOD OF COVERAGE?

This limited warranty runs for six (6) years from date

of installation when used in a single family housing unit or

three (3) years when used in other than a single family

housing unit. PROOF OF PURCHASE/INSTALLATION IS

REQUIRED FOR ANY WARRANTY CLAIM.

WHAT IS THE DURATION OF THE IMPLIED

WARRANTY?

ANY IMPLIED WARRANTIES, INCLUDING THE

WARRANTY OF MERCHANTABILITY IMPOSED ON THE

SALE OF THE PRODUCT UNDER THE LAWS OF THE

STATE OF SALE ARE LIMITED IN DURATION TO ONE

YEAR FROM DATE OF ORIGINAL INSTALLATION.

HOW DOES STATE LAW RELATE TO THE WARRANTY?

Some states do not allow:

1. Limitations on how long an implied warranty lasts.

2. Limitations on incidental or consequential damages.

So the above limitations or exclusions may not apply to you.

This warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

•Restrictions are not applicable to implied warranties in

California. See “Special State Provisions.”

WHAT WILL WE DO TO CORRECT PROBLEMS?

If a defect occurs within the warranty period, we will:

1. Provide a replacement part (or at our option repair)

any part which fails to function within the parts

warranty period. To obtain a replacement, you must

forward the defective part to us. If government

regulations require the replacement part to have

features not found in the defective part, you will be

required to pay the difference in price represented

by those government required features.

We do reserve the right to verify any claims of defect by

inspection.

WHAT WILL WE NOT DO?

We will not:

1. Repair or replace any part, subject to conditions

outlined in “What Does This Limited Warranty Not

Cover?”

2. Reimburse any costs associated with repair and/or

replacement.

HOW DO YOU GET WARRANTY ASSISTANCE?

Upon discovering a defect or problem, you should:

1. Contact either the installer or dealer, or

2. Contact us:

BRADFORD WHITE CORPORATION

WARRANTY SUPPORT GROUP

200 LAFAYETTE

MIDDLEVILLE, MI 49333

(800) 531-2111

CALIFORNIA RESIDENTS CALL 1-800-538-2020

WHAT SHOULD YOU DO TO KEEP THE WARRANTY

IN EFFECT?

To facilitate warranty assistance, you should:

1. Follow all instructions enclosed with the product.

2. Retain all bills of sale or receipts for proof of

installation, etc. PROOF OF

PURCHASE/INSTALLATION IS REQUIRED FOR

ANY WARRANTY CLAIM.

3. Contact your installer, dealer or our Warranty

Department as soon as any problem or defect is

noticed.

4. When necessary, allow us, or our chosen

representative, to inspect the unit.

SPECIAL STATE PROVISIONS

For water heaters installed in California or Oregon,

paragraphs 2 (b), (i) and (iv) of the paragraph

“WHAT DOES THIS WARRANTY NOT COVER?” do not

apply.

All other terms and conditions of this warranty apply as

stated.

PLEASE RETAIN THIS WARRANTY IN A SAFE

LOCATION FOR FUTURE REFERENCE.

-75-

Page 76

Ambler, PA

For U.S. and Canada field service,

contact your professional installer or

local Bradford White sales representative.

Sales/800-523-2931

Fax/215-641-1670

Parts Fax/215-641-2108

Technical Support/800-334-3393

Fax/269-795-1089

Warranty/800-531-2111

Fax/269-795-1089

International:

Telephone/215-641-9400

Telefax/215-641-9750

Mississauga, ON

Sales/866-690-0961

905-238-0100

Fax/905-238-0105

Technical Support/800-334-3393

Email:

parts@bradfordwhite.com

techserv@bradfordwhite.com

www.bradfordwhite.com

Loading...

Loading...