Page 1

MAGNUM Series

Commercial Electric Booster

Installation and Operating Manual

I&W #07.05.228.00

Do not operate this equipment unless you have

read and understood the contents of this manual!

Failureto follow the instructionscontained in this

manual may result in serious injury or death. This

manual contains important safety information

concerning the maintenance, use, and operation

of this product. If you’re unable to understand the

contents of this manual, please bring it to the

attention of your supervisor. Keep this manual in

a safe location for future reference.

No opere este equipo al menos que haya leído y

comprendido el contenido de este manual!

Cualquier falla en el seguimiento de las

instrucciones contenidas en este manual puede

resultar en un serio lesión o muerte. Este manual

contieneimportante información sobre seguridad

concerniente al mantenimiento, uso y operación

de este producto. Si usted no puede entender el

contenido de este manual por favor pregunte a

su supervisor. Almacenar este manual en una

localización segura para la referencia futura.

Page 2

CONTENTS

NOTICE

CAUTION

WARNING

Important Owner Information ...............................................i

Introduction............................................................................i

Important Safety Information...............................................1

Model Description.................................................................3

Magnum Series Commercial Electric Booster .................3

Specifications........................................................................3

Dimensions......................................................................3

Circuit Breaker and Fused Disconnect Switch Sizes.......4

Capacity...........................................................................5

Installation.............................................................................6

General............................................................................6

Temperature/Pressure Relief Valves ...............................8

Pressure Reducing Valve ................................................8

Temperature/Pressure Gauges .......................................8

Blended Phosphate Water

Treatment System (optional).........................................8

Plumbing Connections.....................................................9

Electrical — All Sizes and Voltages ...............................11

IMPORTANT OWNER INFORMATION

Record the model number, serial number, voltage, and

purchase date of the unit in the spaces below (specification

label located on the unit). Please have this information available

when calling Bradford White for service assistance.

Model No. ____________________________________

Serial No. ____________________________________

Operation.............................................................................12

General..........................................................................12

Maintenance........................................................................13

General..........................................................................13

Thermostat Adjustment..................................................13

Temperature/Pressure Relief Valve ...............................13

High Temperature Limit Safety Switch...........................14

Blended Phosphate Water

Treatment System (optional).......................................14

Troubleshooting Guide ......................................................14

Accessories.........................................................................17

Wiring Diagrams .................................................................18

Limited Warranty.................................................................24

Business Hours: 8:00

Telephone: 800.334.3393 — Technical Service

Additional information can be found by visiting our web site at

www.bradfordwhite.com.

AM to 7:00 PM EST

800.538.2020 — Service Parts

800.531.2111 — Warranty Service

Voltage ______________________________________

Date of Purchase ______________________________

INTRODUCTION

The Bradford White Magnum Series Commercial Electric

Booster water heater is designed for use with commercial

dishwashers to boost the temperature of the regularly available

hot water, usually 110°–150°F (43°–66°C) up to 180°F (82°C).

Water at 180°F (82°C) can be used as sanitizing rinse water in

commercial dishwashers in accordance with Health Codes,

NSF Standard #5 and plumbing codes.

Bradford White Commercial Electric Booster water heaters are

ready for electrical and plumbing service connections, with a

pre-set ambient compensated immersion thermostat and a high

temperature limit switch. The service area is accessible from

the front of the unit, permitting easy installation.

Bradford White Commercial Electric Booster water heaters are

products of extensive research and field testing. The materials

used were selected for maximum durability, attractive

appearance, and optimum performance. Every unit is inspected

and tested thoroughly prior to shipment.

This manual provides the installation, safety, and operating

instructions for Bradford White Commercial Electric Booster

water heaters. Bradford White recommends all installation,

operating, and safety instructions appearing in this manual be

read prior to installation or operation of the unit.

Safety information that appears in this manual is identified by

the following signal word panels:

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

i

Form No. EBOOSTERBWM-1009

Page 3

IMPORTANT SAFETY INFORMATION

WARNING

WARNING

Read the following important safety information before using this equipment to avoid serious injury or death

and to avoid damage to equipment or property.

ELECTRIC SHOCK HAZARD:

• This unit must be installed by qualified, trained

installers. Installation must conform to all local

electrical and plumbing codes. Check with your local

plumbing and electrical inspectors for proper

procedures and codes.

• Turn power OFF at disconnect switch/circuit breaker

and allow unit to cool before performing any

maintenance or cleaning.

• Consult a licensed electrical contractor for proper

electrical installation conforming to local electrical

codes and the National Electrical Code (N.E.C.).

• Unit is not weatherproof. Locate unit indoors where

ambient air temperature is a minimum of 70°F (21°C).

• Do not place aftermarket covers on or over booster

water heater. Doing so can cause temperature and

moisture build-up resulting in premature failure and

electrical shock.

• This unit must be serviced by qualified personnel only.

Service by unqualified personnel may lead to electric

shock or burn.

• Use only Genuine Bradford White Replacement Parts

whenserviceisrequired.Failuretouse GenuineBradford

WhiteReplacementPartswillvoidallwarrantiesand may

subject operators of the equipment to hazardous

electrical voltage, resulting in electrical shock or burn.

GenuineBradfordWhiteReplacementPartsarespecified

to operate safely in the environments in which they are

used.Some aftermarket or genericreplacement parts do

nothavethecharacteristicsthatwillallowthemtooperate

safely in BradfordWhite equipment.

EXPLOSION HAZARD: Do not store or use gasoline or

other flammable vapors or liquids in the vicinity of this or

any other appliance.

Bradford White has always endorsed the use of safety

equipment when using an booster water heater or storagetype water heater. Bradford White booster water heaters

are shipped with a temperature/pressure relief valve at no

extra charge. This valve must be installed into the marked

opening provided in the tank. Valves supplied with this

booster water heater are designed for high temperature

commercial operation. Do not substitute these valves with

valves designed for domestic water heaters.

Temperature/pressure protective equipment should not be

less than a combination temperature/pressure relief valve

certified by a nationally recognized testing laboratory that

maintains periodic inspection of the production of this

equipment and meets the requirements for Relief Valves

and Automatic Shutoff Devices for Hot Water Supply

Systems, ANSI Z21.22-1979. The temperature/pressure

relief valve must be marked with a minimum set pressure

not to exceed the marked hydrostatic test pressure of the

booster heater as noted on the unit specifications.

Do not connect an expansion tank of any type to booster

water heater lines.

FOR INSTALLING COMBINATION TEMPERATURE/

PRESSURE RELIEF VALVES IN ACCORDANCE WITH

AMERICAN NATIONAL STD. Z21.22-1979. Combination

temperature/pressure relief valves with extension

thermostats must be installed so that the temperaturesensing element is immersed in the water within the top 6"

(152 mm) of the tank. They must be installed either in the

hot outlet service line or directly in a tank tapping.

Combination temperature/pressure relief valves that do

not have extension elements must be mounted directly in

a tank tapping located within the top 6" (152 mm) of the

tank, and shall be adequately insulated and located so as

to assure isolation from the flue gas heat or other ambient

conditions that are not indicative of stored water

temperature. TO AVOID WATER DAMAGE OR SCALDING

DUE TO VALVE OPERATION, DRAIN PIPE MUST BE

CONNECTED TO VALVE OUTLET AND RUN TO A SAFE

PLACE OF DISPOSAL. Discharge line must be as short as

possible and be the same size as the valve discharge

connection throughout its entire length. Drain line must

pitch downward from the valve and must terminate

between 1-1/2" (38 mm) and 6" (152 mm) above the floor

drain where any discharge will be clearly visible. The drain

line shall terminate plain, not threaded, with material

serviceable for temperatures up to 250°F (121°C) or

greater. Excessive length, over 30' (9144 mm), or use of

more than four elbows can cause a restriction and reduce

the discharge capacity of the valve. No shut-off valve shall

be installed between the relief valve and tank, or in the

drain line. Valve lever must be tripped periodically to

assure that waterways are clear.This device is designated

for emergency safety relief and shall not be used as an

operating control. The valves are set to relieve at 150 psi

(1034 kPa) or when water temperature reaches 210°F

(99°C). Read tag on valve for additional information.

Inspect combination temperature/pressure relief valve at

least once every two to four years, depending on local

water conditions. Contact a licensed plumber or qualified

service technician for inspection. Replace valve, if

necessary. DO NOT attempt to self-inspect valve.

Use only plumbing material suitable for a minimum water

temperature of 200°F (93°C). Materials used must meet

National Sanitation Foundation (NSF) specifications and

all local plumbing codes and regulations.

Install booster water heater in horizontal position with

base parallel to the floor and inlet connection at the lowest

point. If installing with legs, mount on floor. If installing

with slide brackets, mount under dish table. DO NOT

mount on walls or in ceiling. Unit must be accessible for

service. Improper installation could create an unsafe

condition.

Valves supplied with this booster water heater are

designed for high temperature commercial operation. Do

not substitute these valves with valves designed for

domestic water heaters.

Form No. EBOOSTERBWM-1009

1

Page 4

IMPORTANT SAFETY INFORMATION

WARNING

CAUTION

CAUTION

NOTICE

Read the following important safety information before using this equipment to avoid serious injury or death

and to avoid damage to equipment or property.

Units are equipped with a high temperature limit safety

switch that will shut off power if the unit overheats.

Contact an Authorized Service Agent if high temperature

limit safety switch cannot be reset or continues to trip.

Install booster water heater as close as possible to the

commercial dish machine. Employ recirculation if

distance between booster and commercial dish machine

exceeds National Sanitation Foundation (NSF)

specifications of five (5) linear feet (1524 mm).

Make sure the dish table is strong enough to support the

weight of the booster heater and water when installing

with slide mounting brackets.

Follow standard welding safety and operational

procedures when attaching sliderails to bottom of dish

table.

This product contains fiberglass, a product known to the

state of California to cause cancer, birth defects or other

reproductive harm.

It is essential to recognize that even though a booster

water heater may be installed properly and approved

initially, there always exists the possibility that unknowing

individuals might alter or change the installation in a

manner that would render it unsafe. Therefore, it is

important that all safety programs provide some

mechanism to assure that these installations are

inspected periodically.

This unit has no “user-serviceable” parts. If service is

required on this unit, contact an Authorized Service Agent

or the Bradford White Service Department.

BURN HAZARD:

• Water in unit is very hot. Wear protective gloves and

proper attire when operating to avoid injury.

• Some exterior surfaces on unit will get hot. Avoid

unnecessary contact with unit.

• Valves supplied with this booster water heater are

designed for high temperature commercial operation.

Do not substitute these valves with valves designed for

domestic water heaters.

Do not use anti-siphon or check valves on incoming water

line.

Do not connect booster water heater directly to a boiler or

furnace coil or any other uncontrolled temperature

source. The booster heater thermostat could be damaged

causing unit to overheat.

Do not connect booster water heater to domestic

(consumer) dishwashers or other domestic utilized

equipment. Hot water from booster heater may damage

domestic equipment resulting in a hazardous condition.

Do not store any materials or items on or against the

housing of the booster water heater.

Bradford White requires that two temperature/pressure

gauges be installed to assure proper operation. Install one

in the supply line before the pressure reducing valve and

one in the outlet line as close to the booster water heater

as possible. This provides a visual check of the water

temperature and pressure before and after the water

heater.

If water supply pressure to the booster water heater inlet

is over 20 psi (138 kPa) during flow, install a commercialgrade pressure reducing valve with built-in bypass for

proper operation of dish machine rinse nozzles.

NOTE: The pressure reducing valve must be the type

equipped with a high pressure bypass, like the valve

supplied with this booster water heater.

DO NOT turn on power to the booster water heater until

tank has been filled with water and all air has been vented

through dish machine rinse nozzle. The heating elements

will burn out in seconds if operated when they are not

immersed in water.

ALWAYS drain booster water heater with power to the unit

off or element burnout could occur.

Use dielectric couplings when connecting dissimilar

metals, such as galvanized to copper. This will prevent

electrolysis or premature plumbing damage.

DO NOT turn or adjust inlet water connection on Magnum

Series booster water heaters. Doing so will change the

internal water flow.

Do not back out or loosen any pipe fittings. Doing so may

cause leaks.

Do not lay unit on the side with the control panel. Damage

to the unit could occur.

Incoming water in excess of 3 grains of hardness per

gallon (GPG) (0.75 grains of hardness per liter [GPL]) must

be treated and softened before being supplied to booster

heater(s). Water containing over 3 GPG (0.75 GPL) will

decrease efficiency, increase energy use, and reduce the

operating life of the unit through increased lime build-up.

Product failure caused by liming or sediment buildup is

not covered under warranty.

Do not use deionized or reverse osmosis (R.O.) treated

water in booster water heaters. Damage to booster heater

may occur.

Connect electric booster water heater to the same power

supply as indicated on the specification decal only.

Connecting unit to an incorrect power supply voids the

product warranty and will damage the equipment.

2

Form No. EBOOSTERBWM-1009

Page 5

MagnumSeries CommercialElectric Booster

The Magnum Series Commercial Electric Booster water heater

includes a booster heater with low-water cut-off system,

temperature/pressure relief valve, pressure reducing valve with

built-in high pressure bypass, two temperature/pressure gauges

and a high temperature limit safety switch.

Magnum Series models feature a Castone

limited warranty, an ON/OFF switch, an indicator light and either

6" (152 mm) legs or slide mounting brackets for mounting under

a dish table. Magnum Series units have a capacity of 6 gallons

(23 liters) and provide up to 573 gph (2169 lph) of sanitizing

rinse water based on a 40°F (22°C) temperature rise.

®

tank with a 5 year

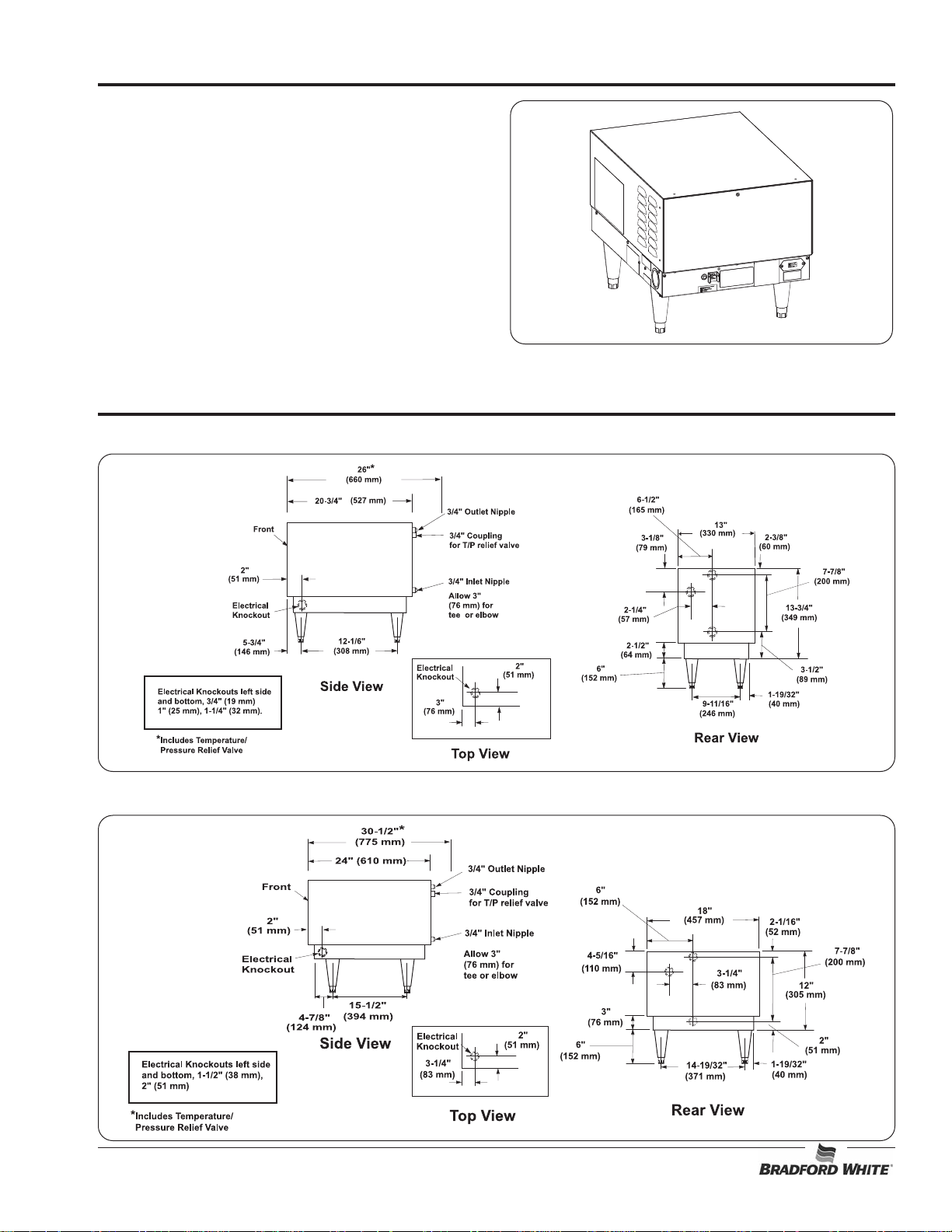

Dimensions — Magnum Series 6 to 18 kW

MODEL DESCRIPTION

Figure 1. Magnum Series Commercial Electric Booster

SPECIFICATIONS

Dimensions — Magnum Series 24 to 57 kW

Form No. EBOOSTERBWM-1009

3

Page 6

SPECIFICATIONS

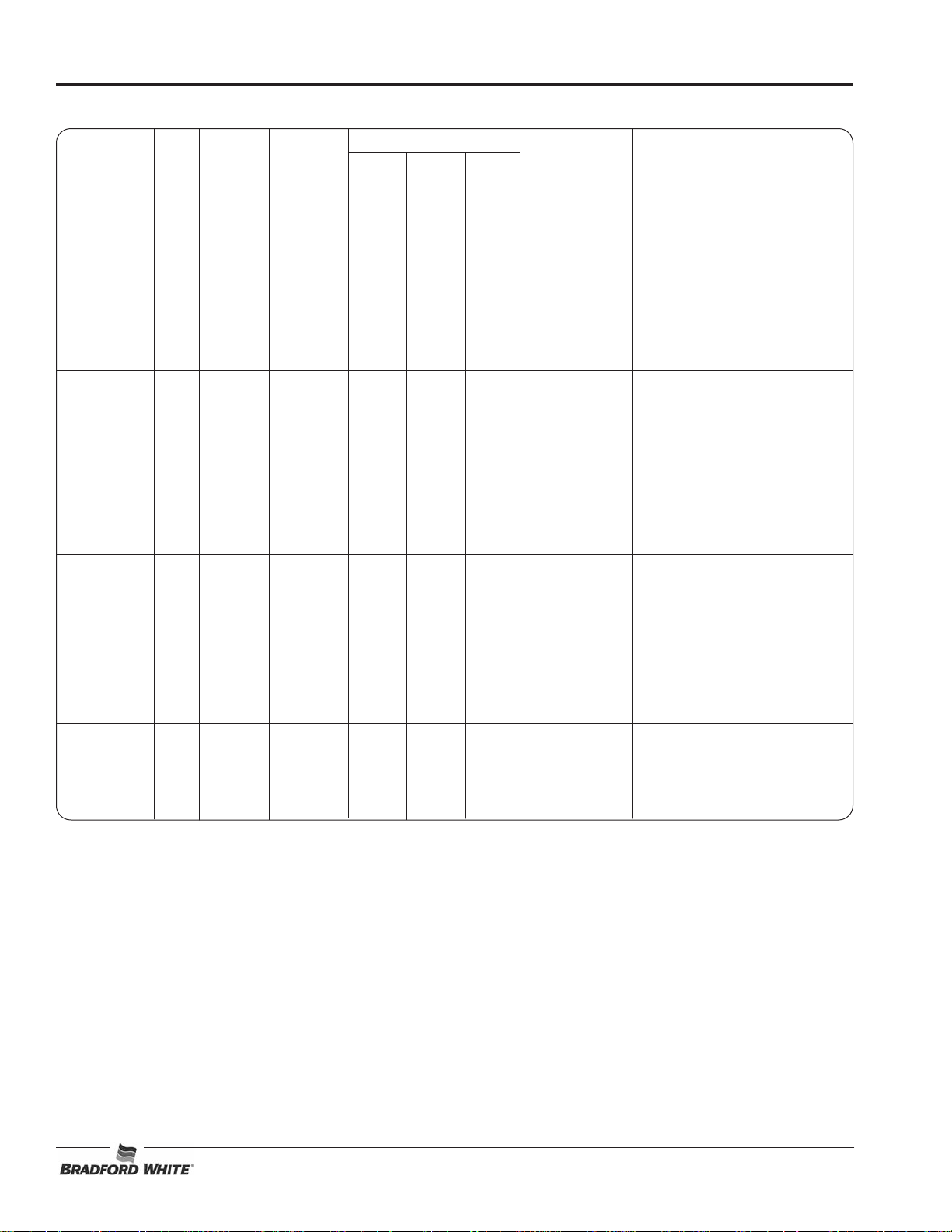

Circuit Breaker and Fused Disconnect Switch Sizes — 6 to 30 kW

Model kW Volts Phase Amp Draw Breaker or Copper Conduit

L1 L2 L3 Fuse Size Wire Size Size

LI663CFC 6 208 1 29 29 - 40 8 1/2" (13 mm)

LI663CFD 6 208 3 14 25 14 40 8 1/2" (13 mm)

LI663CFE 6 240 1 25 25 - 40 8 1/2" (13 mm)

LI663CFF 6 240 3 13 22 13 30 10 1/2" (13 mm)

LI663CFM 6 480 3611 6 15 14 1/2" (13 mm)

LI693CFC 9 208 1 43 43 - 60 6 1/2" (13 mm)

LI693CFD 9 208 3 22 38 22 50 8 1/2" (13 mm)

LI693CFE 9 240 1 38 38 - 50 8 1/2" (13 mm)

LI693CFF 9 240 3 19 33 19 50 8 1/2" (13 mm)

LI693CFM 9 480 3916 9 20 12 1/2" (13 mm)

LI6123CFC 12 208 1 58 58 - 90 3 1" (25 mm)

LI6123CFD 12 208 3 33 33 33 50 8 1/2" (13 mm)

LI6123CFE 12 240 1 50 50 - 70 6 1/2" (13 mm)

LI6123CFF 12 240 3 29 29 29 40 8 1/2" (13 mm)

LI6123CFM 12 480 3 14.5 14.5 14.5 20 12 1/2" (13 mm)

LI6153CFC 15 208 1 72 72 - 90 3 1" (25 mm)

LI6153CFD 15 208 3 41.7 41.7 41.7 60 6 3/4" (19 mm)

LI6153CFE 15 240 1 62.5 62.5 - 90 3 1" (25 mm)

LI6153CFF 15 240 3 36.1 36.1 36.1 50 8 1/2" (13 mm)

LI6153CFM 15 480 3 18.1 18.1 18.1 30 10 1/2" (13 mm)

LI6183CFC 18 208 1 86.5 86.5 - 125 1 1-1/4" (32 mm)

LI6183CFE 18 240 1 75 75 - 100 3 1" (25 mm)

LI6183CFF 18 240 3 43.4 43.4 43.4 60 6 3/4" (19 mm)

LI6183CFM 18 480 3 21.7 21.7 21.7 30 10 1/2" (13 mm)

LI6243CFC 24 208 1 115.4 115.4 - 150 1/0 1-1/4" (32 mm)

LI6243CFD 24 208 3 66.7 66.7 66.7 90 3 1" (25 mm)

LI6243CFE 24 240 1 100 100 - 125 1 1-1/4" (32 mm)

LI6243CFF 24 240 3 57.8 57.8 57.8 90 3 1-1/4" (32 mm)

LI6243CFM 24 480 3 29.9 29.9 29.9 40 8 1/2" (13 mm)

LI6303CFC 30 208 1 144 144 - 200 3/0 1-1/2" (38 mm)

LI6303CFD 30 208 3 83.3 83.3 83.3 125 1 1-1/4" (32 mm)

LI6303CFE 30 240 1 125 125 - 175 2/0 1-1/2" (38 mm)

LI6303CFF 30 240 3 72.3 72.3 72.3 100 3 1" (25 mm)

LI6303CFM 30 480 3 36 36 36 50 8 1/2" (13 mm)

Wire size is based on THHN wire for branch circuit protection at .91 derate factor. Circuit breakers and fused disconnects are to

be mounted remote and wired by contractor. Sizes are based on the 2002 NEC table 310-16. Conduit size based on conductors

plus ground wire sizing per Table C1 from Appendix C.

Only 6 and 9 kW models can be field converted to single- or three-phase (open delta on 3-phase). Check wiring diagram supplied

with the unit when converting the phase of a unit. Larger branch circuit required than for balanced 3-phase of equal kW. Balanced

3-phase available, consult factory.

NOTE: 250 kcmil maximum wire size for terminal block.

WARNING! Consult a licensed electrical contractor for proper electrical installation conforming to local electrical codes

and the National Electrical Code (N.E.C.).

4

Form No. EBOOSTERBWM-1009

Page 7

SPECIFICATIONS

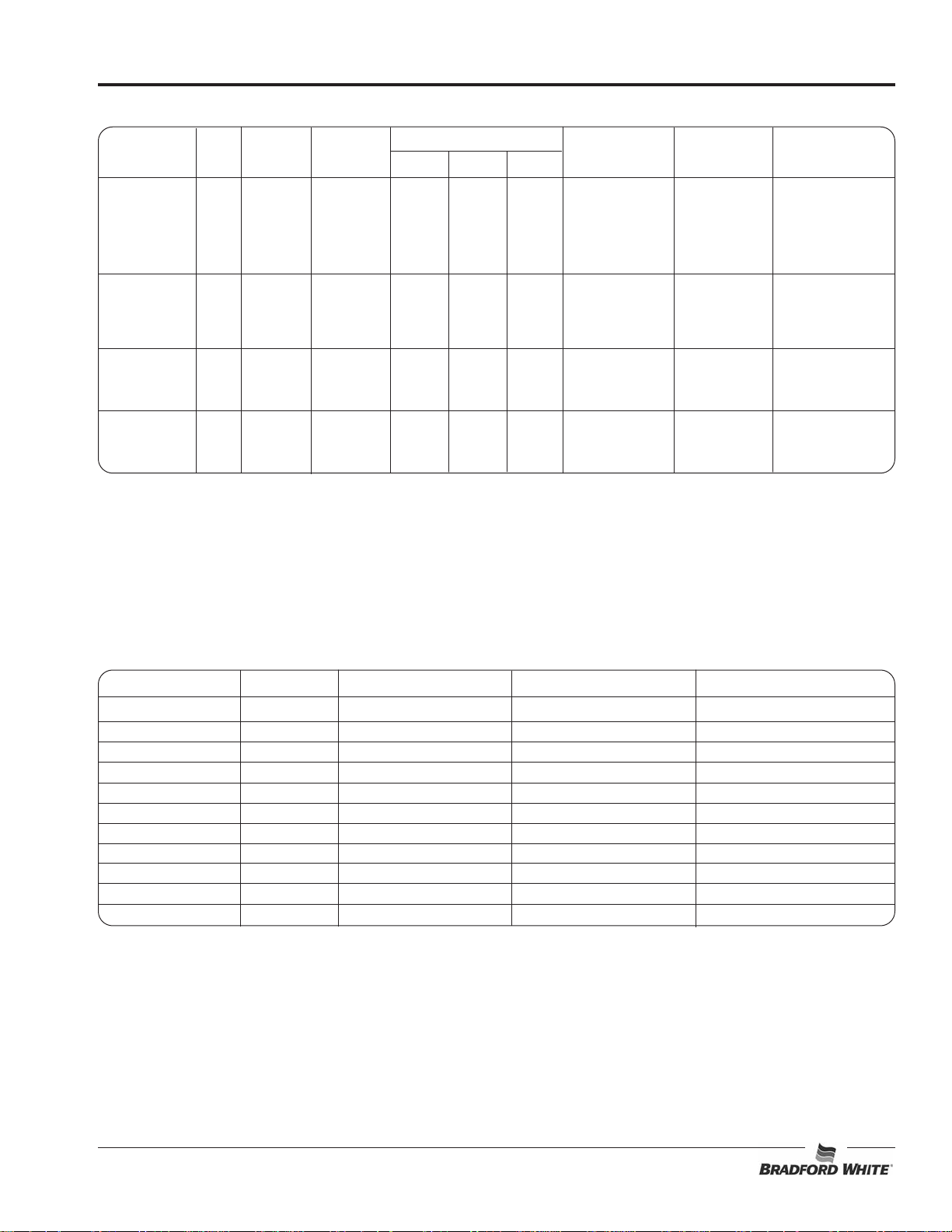

Circuit Breaker and Fused Disconnect Switch Sizes — 36 to 57 kW

Model kW Volts Phase Amp Draw Breaker or Copper Conduit

L1 L2 L3 Fuse Size Wire Size Size

LI6363CFC 36 208 1 173 173 - 225 4/0 1-1/2" (38 mm)

LI6363CFD 36 208 3 100 100 100 125 1 1-1/4" (32 mm)

LI6363CFE 36 240 1 150 150 - 200 3/0 1-1/2" (38 mm)

LI6363CFF 36 240 3 86.7 86.7 86.7 125 1 1-1/4" (32 mm)

LI6363CFM 36 480 3 43.3 43.3 43.3 60 6 3/4" (19 mm)

LI6453CFD 45 208 3 125 125 125 175 2/0 1-1/2" (38 mm)

LI6453CFE 45 240 1 188 188 - 250 250 kcmil 2" (51 mm)

LI6453CFF 45 240 3 108 108 108 150 1/0 1-1/4" (32 mm)

LI6453CFM 45 480 3 54 54 54 70 4 1" (25 mm)

LI6543CFD 54 208 3 150 150 150 200 3/0 2" (51 mm)

LI6543CFF 54 240 3 130 130 130 175 2/0 1-1/2" (38 mm)

LI6543CFM 54 480 3 65 65 65 90 3 1" (25 mm)

LI6573CFD 57 208 3 158.4 158.4 158.4 200 3/0 2" (51 mm)

LI6573CFF 57 240 3 137.3 137.3 137.3 175 2/0 1-1/2" (38 mm)

LI6573CFM 57 480 3 68.6 68.6 68.6 90 3 1" (25 mm)

Wire size is based on THHN wire for branch circuit protection at .91 derate factor. Circuit breakers and fused disconnects are to

be mounted remote and wired by contractor. Sizes are based on the 2002 NEC table 310-16. Conduit size based on conductors

plus ground wire sizing per Table C1 from Appendix C.

NOTE: 250 kcmil maximum wire size for terminal block.

WARNING! Consult a licensed electrical contractor for proper electrical installation conforming to local electrical codes

and the National Electrical Code (N.E.C.).

Capacity

Model kW 40°F (22°C) Rise 70°F (39°C) Rise Shipping Weight

LI663XXX Models 6 60 gph (227 lph) 34 gph (129 lph) 118 lbs. (54 kg)

LI693XXX Models 9 90 gph (341 lph) 52 gph (197 lph) 118 lbs. (54 kg)

LI6123XXX Models 12 120 gph (454 lph) 69 gph (261 lph) 120 lbs. (54 kg)

LI6153XXX Models 15 151 gph (572 lph) 86 gph (326 lph) 120 lbs. (54 kg)

LI6183XXX Models 18 181 gph (685 lph) 103 gph (390 lph) 120 lbs. (54 kg)

LI6243XXX Models 24 241 gph (912 lph) 138 gph (522 lph) 142 lbs. (64 kg)

LI6303XXX Models 30 301 gph (1139 lph) 172 gph (651 lph) 142 lbs. (64 kg)

LI6363XXX Models 36 361 gph (1367 lph) 206 gph (780 lph) 142 lbs. (64 kg)

LI6453XXX Models 45 452 gph (1711 lph) 258 gph (977 lph) 142 lbs. (64 kg)

LI6543XXX Models 54 542 gph (2052 lph) 310 gph (1174 lph) 142 lbs. (64 kg)

LI6573XXX Models 57 573 gph (2169 lph) 326 gph (1234 lph) 142 lbs. (64 kg)

NOTE: Storage capacity is 6 gallons (23 liters).

Form No. EBOOSTERBWM-1009

5

Page 8

INSTALLATION

NOTICE

WARNING

WARNING

Models 24–58 kW

20-1/4″

(514 mm)

Weld slide rail

to bottom of

dish table.

Models 6–18 kW

15-1/4″

(387 mm)

Fasten slide brackets

to booster water heater

sides.

General

For the most effective operation, install the booster water heater

as close as possible to the commercial dish machine. The

location must have a solid foundation or strong table/counter

construction along with being clean and dry. Adequate front

clearance is required to allow for accessibility to the control

compartment. Location must have adequate clearance to allow

for inspection, testing, or replacement of temperature/pressure

relief valve.

ELECTRIC SHOCK HAZARD:

• This unit must be installed by qualified, trained

installers. Installation must conform to all local

electrical and plumbing codes. Check with your local

plumbing and electrical inspectors for proper

procedures and codes.

• Consult a licensed electrical contractor for proper

electrical installation conforming to local electrical

codes and the National Electrical Code (N.E.C.).

• Unit is not weatherproof. Locate unit indoors where

ambient air temperature is a minimum of 70°F (21°C).

• Do not place aftermarket covers on or over booster

water heater. Doing so can cause temperature and

moisture build-up resulting in premature failure and

electrical shock.

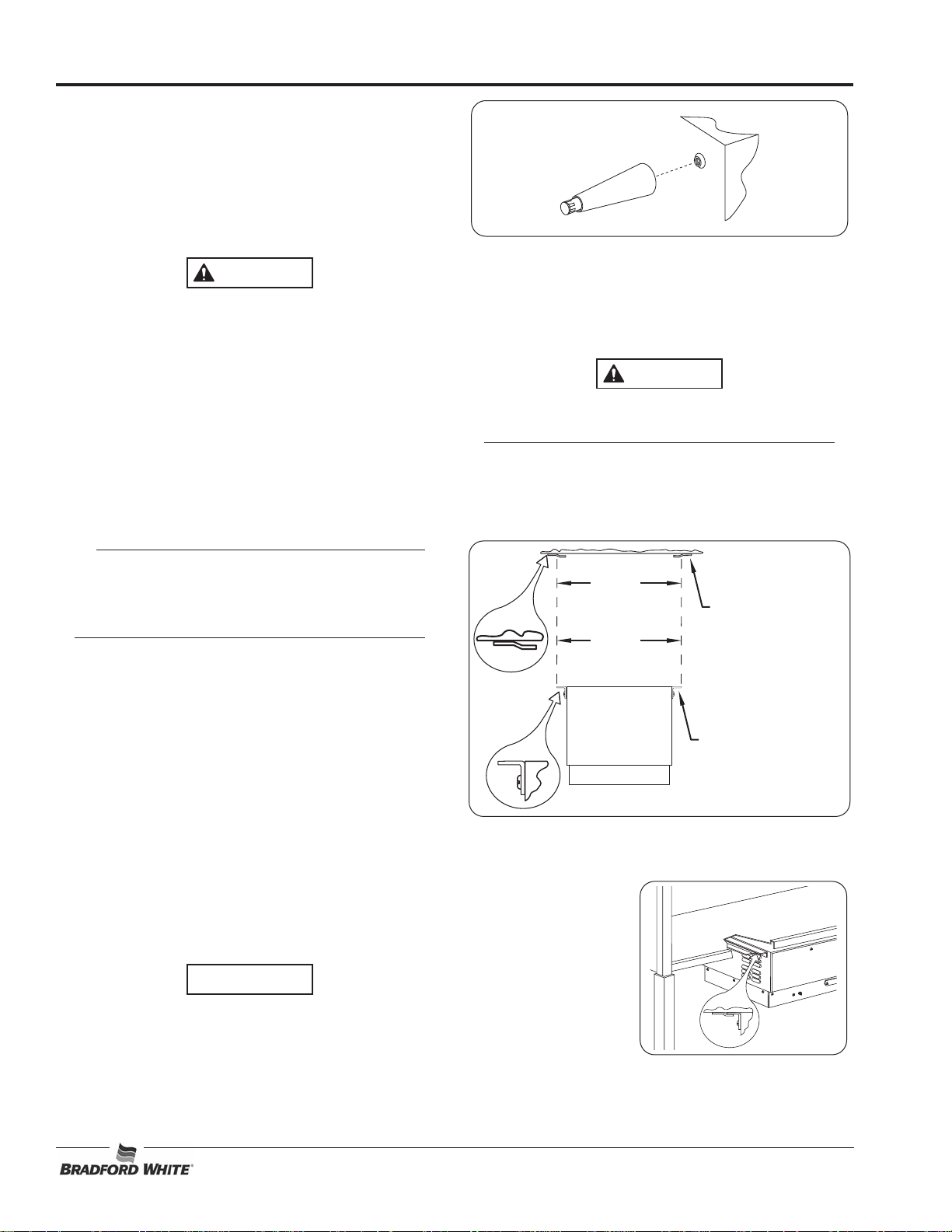

Figure 2. Installing the Legs

NOTE: If unit is not level, use an adjustable open-end wrench

to adjust the foot of each leg until unit is level. Each leg

is adjustable from 6″ (152 mm) to 7″ (178 mm).

5. If installing the unit with mounting brackets, use the

following procedure:

Make sure the dish table is strong enough to support the

weight of the booster heater and water when installing

with slide mounting brackets.

Follow standard welding safety and operational

procedures when attaching sliderails to bottom of dish

table.

• Space slide rails as shown below, and weld the rails to

the bottom of the dish table.

Install booster water heater as close as possible to the

commercial dishwasher. Employ recirculation if distance

between booster and commercial dishwasher exceeds

National Sanitation Foundation (NSF) specifications of

five (5) linear feet (1524 mm).

Install booster water heater in horizontal position with

base parallel to the floor and inlet connection at the lowest

point. If installing with legs, mount on floor. If installing

with slide brackets, mount under dish table. DO NOT

mount on walls or in ceiling. Unit must be accessible for

service. Improper installation could create an unsafe

condition.

Booster Heaters are shipped with most components preassembled. Care should be taken when unpacking shipping

carton to avoid damage to unit and components enclosed.

Components are shipped with the heater unit (see Figure 4).

1. Remove the unit from the carton.

2. Remove the information packet.

3. Remove tape and protective packaging from all surfaces

of unit.

4. If the unit is equipped with legs, carefully lay the unit on its

side and install the four legs as shown in Figure 2.

Do not lay unit on the side with the control panel. Damage

to the unit could occur.

Figure 3. Attaching the Slide Rails to the Dish Table

• Using the Bradford White slide brackets as a template,

drill 1/8″ (3 mm) holes into the sides of the heater jacket.

• Attach slide brackets

to the sides of the

booster water heater

with 3/4 x 8 sheet

metal screws

supplied.

• Slide the booster

water heater onto

slide rails under dish

table.

6

Form No. EBOOSTERBWM-1009

Page 9

INSTALLATION

Legs

Plastic Leg

Stainless Steel Leg

Mounting Brackets with Hardware

A set of mounting brackets or a set of legs are supplied with

each booster water heater.

Pressure Reducing Valve

One pressure reducing valve with built-in bypass supplied

with all booster water heaters.

Shock Absorber

An optional

heaters.

shock absorber is available for all booster water

Temperature/Pressure Gauge

Two temperature/pressure gauges are supplied with all

booster water heaters.

Temperature/Pressure Relief Valve

One temperature/pressure relief valve supplied with all

booster heaters.

Blended Phosphate Water Treatment System

An optional

available for all booster water heaters.

blended phosphate water treatment system is

Back Pressure Relief Valve

An optional

booster water heaters.

back pressure relief valve is available for all

Figure 4. Components Shipped with the Magnum Series Commercial Electric Booster

Form No. EBOOSTERBWM-1009

7

Page 10

INSTALLATION

CAUTION

WARNING

CAUTION

CAUTION

Temperature/Pressure Relief Valves

For protection against excessive pressures and temperatures in

the booster heater, install temperature/pressure protective

equipment required by local codes. The temperature/pressure

relief valve supplied with this booster water heater is

constructed with brass working parts and heat resistant silicone

seat discs.

Temperature/pressure protective equipment should not be

less than a combination temperature/pressure relief valve

certified by a nationally recognized testing laboratory that

maintains periodic inspection of the production of this

equipment and meets the requirements for Relief Valves

and Automatic Shutoff Devices for Hot Water Supply

Systems, ANSI Z21.22-1979. The temperature/pressure

relief valve must be marked with a minimum set pressure

not to exceed the marked hydrostatic test pressure of the

booster heater as noted on the unit specifications.

FOR INSTALLING COMBINATION TEMPERATURE/

PRESSURE RELIEF VALVES IN ACCORDANCE WITH

AMERICAN NATIONAL STD. Z21.22-1979. Combination

temperature/pressure relief valves with extension

thermostats must be installed so that the temperaturesensing element is immersed in the water within the top 6"

(152 mm) of the tank. They must be installed either in the

hot outlet service line or directly in a tank tapping.

Combination temperature/pressure relief valves that do

not have extension elements must be mounted directly in

a tank tapping located within the top 6" (152 mm) of the

tank, and shall be adequately insulated and located so as

to assure isolation from the flue gas heat or other ambient

conditions that are not indicative of stored water

temperature. TO AVOID WATER DAMAGE OR SCALDING

DUE TO VALVE OPERATION, DRAIN PIPE MUST BE

CONNECTED TO VALVE OUTLET AND RUN TO A SAFE

PLACE OF DISPOSAL. Discharge line must be as short as

possible and be the same size as the valve discharge

connection throughout its entire length. Drain line must

pitch downward from the valve and must terminate

between 1-1/2" (38 mm) and 6" (152 mm) above the floor

drain where any discharge will be clearly visible. The drain

line shall terminate plain, not threaded, with material

serviceable for temperatures up to 250°F (121°C) or

greater. Excessive length, over 30' (9144 mm), or use of

more than four elbows can cause a restriction and reduce

the discharge capacity of the valve. No shut-off valve shall

be installed between the relief valve and tank, or in the

drain line. Valve lever must be tripped periodically to

assure that waterways are clear.This device is designated

for emergency safety relief and shall not be used as an

operating control. The valves are set to relieve at 150 psi

(1034 kPa) or when water temperature reaches 210°F

(99°C). Read tag on valve for additional information.

Pressure Reducing Valve

If water supply pressure to the booster water heater inlet

is over 20 psi (138 kPa) during flow, install a commercialgrade pressure reducing valve with built-in bypass for

proper operation of dish machine rinse nozzles.

NOTE: The pressure reducing valve must be the type

equipped with a high pressure bypass like the valve

supplied with this booster water heater.

Proper operation of the commercial dish machine rinse nozzles

requires that available water pressure at the rinse nozzle be

between 15 and 25 psi (103 and 172 kPa) when the nozzle is

operated. 20 psi (138 kPa) is recommended. If water pressure

available to the booster water heater inlet is over 20 psi

(138 kPa), a pressure reducing valve must be installed in the hot

water supply line to the booster water heater and adjusted to

deliver 20 psi (138 kPa) flow pressure.

The valve supplied with the unit has a built-in high pressure

bypass that prevents excessive pressure build-up as the

booster heats up. Final adjustment is required at the time of

installation.

Temperature/Pressure Gauges

Bradford White requires that two temperature/pressure

gauges be installed to assure proper operation. Install one

in the supply line before the pressure reducing valve and

one in the outlet line as close to the booster water heater

as possible. This provides a visual check of the water

temperature and pressure before and after the water

heater.

NOTE: If a check valve is installed and cannot be removed

install a back pressure relief valve set at 125 psi (862

kPa) on the incoming line between the pressure

reducing valve and the inlet to the booster water

heater. Discharge must be to open site drain (see

Figure 7).

Blended Phosphate Water Treatment

System (optional)

Bradford White recommends that the Blended Phosphate Water

Treatment System be installed with unions on the incoming 3/4"

water supply line after the pressure reducing valve and before

the booster water heater.

Cartridges supplied have a usage rating of 100,000 gallons

(378,541 liters) of water. To assure proper operation the

cartridges must be replaced when expired.

NOTE: Product failure caused by liming or sediment buildup is

not covered under warranty.

BURN HAZARD: Valves supplied with this booster water

heater are designed for high temperature commercial

operation. Do not substitute these valves with valves

designed for domestic water heaters.

Do not use an anti-siphon or check valves on incoming

water line.

8

Form No. EBOOSTERBWM-1009

Page 11

INSTALLATION

NOTICE

CAUTION

WARNING

Plumbing Connections

Use the following procedures to connect the inlet and outlet

water lines as well as inspect the system once the plumbing

connections are complete.

Do not connect an expansion tank of any type to booster

water heater lines.

Use only plumbing material suitable for a minimum water

temperature of 200°F (93°C). Materials used must meet

National Sanitation Foundation (NSF) specifications and

all local plumbing codes and regulations.

Do not connect booster water heater directly to a boiler or

furnace coil or any other uncontrolled temperature

source. The booster heater thermostat could be damaged

causing unit to overheat.

Do not connect booster water heater to domestic

(consumer) dish machines or other domestic utilized

equipment. Hot water from booster heater may damage

domestic equipment resulting in a hazardous condition.

Use dielectric couplings when connecting dissimilar

metals, such as galvanized to copper. This will prevent

electrolysis or premature plumbing damage.

DO NOT turn or adjust inlet water connection on Magnum

Series booster water heaters. Doing so will change the

internal water flow.

Do not back out or loosen any pipe fittings. Doing so may

cause leaks.

Do not lay unit on the side with the control panel. Damage

to the unit could occur.

Incoming water in excess of 3 grains of hardness per

gallon (GPG) (0.75 grains of hardness per liter [GPL]) must

be treated and softened before being supplied to booster

heater(s). Water containing over 3 GPG (0.75 GPL) will

decrease efficiency, increase energy use, and reduce the

operating life of the unit through increased lime build-up.

Product failure caused by liming or sediment buildup is

not covered under warranty.

Do not use deionized or reverse osmosis (R.O.) treated

water in booster water heaters. Damage to booster heater

may occur.

NOTE: Product failure caused by liming or sediment buildup is

not covered under warranty.

Inlet

(Refer to Figure 5, 6, or 7)

1. Connect the booster water heater inlet to a hot water

supply line from the regular water heater. Water

temperature from the regular water heater should be 110°

or 140°F (43° or 60°C) and should not exceed 160°F

(71°C).Minimum temperature differential between inlet and

outlet should never be less than 20°F (11°C).

NOTE: The red mark on the inlet and outlet water pipes of

Magnum Series units must remain in the top most

position.

2. Provide the inlet line with a shut-off valve, (a full opening

gate or ball type), one temperature/pressure gauge, and

the pressure reducing valve. Set pressure reducing valve

at 20 psi (138 kPa) flow pressure.

NOTE: A 3/4" union and a drain valve are required

for easy servicing.

NOTE: Be sure water flows through the pressure reducing

valve in the proper direction. Check directional arrow.

Valve will reduce pressure only during flow conditions.

NOTE: An optional back pressure relief valve is available for

installation on the water inlet line when local plumbing

codes require a check valve.

3. Install a temperature/pressure gauge in both the inlet and

outlet lines. Install the temperature sensing bulb in the

water stream. The gauge must be mounted upright (see

Figures 8 and 9).

NOTE: Tighten gauge during installation by only turning the

1/2" brass nut. DO NOT turn the face of the gauge.

Turning the face will cause inaccurate measurements.

Form No. EBOOSTERBWM-1009

9

Page 12

INSTALLATION

Temperature/Pressure Gauge

Temperature/Pressure Relief Valve

150 psi (1034 kPa)/210°F (99°C)

3/4″ Union*

Pressure Reducing Valve w/Bypass.

Maximum 20 psi (138 kPa)

flow pressure.

Temperature/Pressure

Gauge

Outlet to

dish

machine

Shock Absorber †

Drain Valve*

3/4″ Union*

Floor Drain

Outlet

Inlet

Discharge from T/P relief valve.

Air gap must comply with plumbing code.

Blended Phosphate Water

Treatment System †

† Optional accessory * Not supplied with booster water heater

3/4″ Gate or

Ball Valve*

Water inlet

from regular

water heater

Temperature/Pressure Gauge

Temperature/Pressure Relief Valve

150 psi (1034 kPa)/210°F (99°C)

3/4″ Union*

Pressure Reducing Valve w/Bypass.

Maximum 20 psi (138 kPa)

flow pressure.

Temperature/Pressure

Gauge

Outlet to

dish

machine

Shock Absorber †

Drain Valve*

3/4″ Union*

Floor Drain

Outlet

Inlet

Discharge from T/P relief valve.

Air gap must comply with plumbing code.

Blended Phosphate Water

Treatment System †

† Optional accessory * Not supplied with booster water heater

3/4″ Gate or

Ball Valve*

Water inlet

from regular

water heater

Temperature/Pressure Gauge

Temperature/Pressure Relief Valve

150 psi (1034 kPa)/210°F (99°C)

3/4″ Union*

Pressure Reducing Valve w/Bypass.

Maximum 20 psi (138 kPa)

flow pressure.

Temperature/Pressure

Gauge

Outlet to

dish

machine

Back Pressure

Relief Valve

Shock Absorber †

Drain Valve*

3/4″ Union*

Floor Drain

Floor Drain

Outlet

Inlet

Discharge from T/P relief valve.

Air gap must comply with plumbing code.

Discharge from back pressure

relief valve. Air gap must

comply with plumbing code.

Blended Phosphate

Water Treatment

System †

† Optional accessory * Not supplied with booster water heater

3/4″ Gate or

Ball Valve*

Water inlet

from regular

water heater

Figure 5. Plumbing Connections - Magnum Series 6-18 kW

Figure 6. Plumbing Connections - Magnum Series 24-57 kW

Figure 7. Booster Water Heater with Optional Back Pressure Relief Valve

10

Form No. EBOOSTERBWM-1009

Page 13

Knockout

Locations

NOTICE

WARNING

CAUTION

Outlet

Temperature/

Pressure Gauge

w/1/2″ pipe thread

1/2″ Copper

Female Fitting

Adapter

Temperature

Sensing

Element

Bottom of sensor

centered in

copper pipe.

3/4″ Nominal

Copper Pipe

3/4″ Copper Tee

Temperature/Pressure

Gauge

3/4″ Nominal

Copper Pipe

1/2″ pipe thread

1/2″ Copper Female

Fitting Adapter

Temperature

Sensing

Element

1. Using a 3/4″ union and piping, connect the booster water

heater outlet to the commercial dish machine sanitizing

rinse pipe connection.

NOTE: The red mark on the inlet and outlet water pipes of

Magnum Series units must remain in the top most

position.

NOTE: Make sure the connection is made to the final rinse

and not to the wash tank.

2. Install a temperature/pressure gauge in the outlet line. The

temperature sensing element must be in the water stream

and the gauge must be mounted upright. Water

temperature at the outlet should be 185°–190°F

(85°–88°C).

INSTALLATION

DO NOT turn on power to the booster water heater until

tank has been filled with water and all air has been vented

through dish machine rinse nozzle. The heating elements

will burn out in seconds if operated when they are not

immersed in water.

Electrical — All Sizes and Voltages

General

Bradford White Electric Booster Water Heaters are available for

operation on standard power systems. Check the identification

decal for the proper power supply.

ELECTRIC SHOCK HAZARD:

• Turn power OFF at disconnect switch/circuit breaker

and allow unit to cool before performing any

maintenance or cleaning.

• Consult a licensed electrical contractor for proper

electrical installation conforming to local electrical

codes and the National Electrical Code (N.E.C.).

Figure 8. Recommended Temperature/Pressure Gauge Installation

Figure 9. Alternate Temperature/Pressure Gauge Installation

NOTE: Bradford White recommends installing an optional

Plumbing Installation Inspection

1. Close drain pipe shut-off valve and fill booster water heater

2. Check all pipe connections for leaks.

3. Make sure the temperature/pressurerelief valve discharge

4. Vent air from the booster tank before turning on the unit by

Form No. EBOOSTERBWM-1009

shock absorber in the outlet line as close as possible

to the commercial dish machine solenoid rinse valve.

The shock absorber softens the water hammer caused

by automatic dish machine valves.

with water.

is not blocked.

opening the temperature/pressure relief valve as well as

running the dish machine through several cycles.

Connect electric booster water heater to the same power

supply as indicated on the specification decal only. Units

connected to an incorrect power supply voids the product

warranty and will damage the equipment.

All internal electrical connections have been made at the

factory. See the “Circuit Breaker and Fused Disconnect Switch

Sizes” charts in the SPECIFICATIONS section for supply wire

size, fuse, breaker, and conduit recommendations. Consult local

codes for verification and compliance.

Electrical Connections

1. Remove the front jacket cover screws. Ease the cover

forward and upward. The control box is under the front

hinged jacket cover.

2. Locate the heater terminal or fuse block(s) inside the unit.

NOTE: See the “Circuit Breaker and Fused Disconnect Switch

Sizes” charts for proper connections and wire size.

3. Bring power leads from a

properly sized disconnect

switch or circuit breaker

through the knockout provided

on the unit, and connect to the

terminal or fuse block(s). USE

COPPER WIRE ONLY.

TIGHTEN CONNECTIONS

PROPERLY TO A MINIMUM

OF 40 INCH POUNDS.

NOTE: Due to the rigors

of transportation all

connections should be

checked for tightness before booster water heater is

put into operation.

4. A grounding lug is provided near the supply terminals. An

equipment grounding conductor must be properly

connected to it.

5. Replace and secure the front jacket cover.

11

Page 14

OPERATION

WARNING

CAUTION

Power ON/OFF

Switch

Indicator Light

NOTICE

WARNING

General

Use the following procedures to operate the Magnum Series

Commercial Electric Booster water heater.

Read all safety messages in the Important Safety

Information section before operating this equipment.

DO NOT turn on power to the booster water heater until

tank has been filled with water and all air has been vented

through dish machine rinse nozzle. The heating elements

will burn out in seconds if operated when they are not

immersed in water.

Startup

1. Close the drain pipe shut-off valve.

2. Open the shut-off valve to primary water supply. The water

temperature at the inlet should be 110° to 140°F (43° to

60°C) and should not exceed 160°F (71°C)

NOTE: Minimum temperature differential between inlet and

outlet should never be less than 20°F (11°C).

3. When the booster tank is filled with water, vent all air from

the tank before turning on the unit. To vent the booster tank:

• Open the temperature/pressure relief valve.

• Run the dish machine through several cycles to vent air

through the rinse nozzles.

4. Check all plumbing connections for leaks.

5. Check the temperature/pressure relief valve discharge

opening to be sure it is not blocked and no scale or other

foreign matter has reduced the size of the opening.

BURN HAZARD:

• Water in unit is very hot. Wear protective gloves and

proper attire when operating to avoid injury.

• Some exterior surfaces on unit will get hot. Avoid

unnecessary contact with unit.

6. Turn on the electrical supply to the booster heater.

7. Move the Power ON/OFF switch to the ON position. The

indicator light will turn on.

.

8. When the booster water heater has had sufficient heating

time, operate the rinse cycle and check the water

temperature and pressure readings on the gauges.

Water temperature at the booster outlet should be

185°–190°F (85°–88°C) and flow pressure should be 20

psi (138 kPa) maximum.

NOTE: Outlet water temperatures can be adjusted

for low-temperature dish machine applications. See

the Maintenance section for thermostat adjustment

procedure.

Units are equipped with a high temperature limit safety

switch that will shut off power if the unit overheats.

Contact an Authorized Service Agent if high temperature

limit safety switch cannot be reset or continues to trip.

Shutdown

Under normal and regular operation, Bradford White

recommends that the unit be turned on at all times.

If the booster water heater will not be used for an extended

period of time or will be exposed to freezing conditions it should

be drained to prevent damage to the unit.

1. Move the Power ON/OFF switch to the OFF position.

2. Disconnect power supply to the booster water heater.

3. Close the inlet water supply line shut-off valve to the

booster water heater.

ALWAYS drain booster water heater with power to the unit

off or element burnout could occur.

4. Open the drain shut-off valve and drain all water from the

booster water heater tank.

Figure 10. Control Panel

12

Form No. EBOOSTERBWM-1009

Page 15

General

Access Cover

High Temperature

Limit Safety Switch

Thermostat

WARNING

Temperature/Pressure

Relief Valve Lever

(Closed Position)

Discharge

Line

WARNING

Outer

Adjustment

Screw

Inner

Adjustment

Screw

Bradford White Magnum Series Commercial Electric Booster

water heaters are designed for maximum durability and

performance, with minimum maintenance.

ELECTRIC SHOCK HAZARD:

• Turn power OFF at disconnect switch/circuit breaker

and allow unit to cool before performing any

maintenance or cleaning.

• This unit must be serviced by qualified personnel only.

Service by unqualified personnel may lead to electric

shock or burn.

• Use only Genuine Bradford White Replacement Parts

whenserviceisrequired.Failuretouse GenuineBradford

WhiteReplacementPartswillvoidallwarrantiesandmay

subject operators of the equipment to hazardous

electrical voltage, resulting in electrical shock or burn.

GenuineBradfordWhiteReplacementPartsare specified

to operate safely in the environments in which they are

used.Some aftermarket or generic replacement parts do

not have the characteristics that will allow them to

operate safelyinBradfordWhite equipment.

This unit has no “user-serviceable” parts. If service is

required on this unit, contact an Authorized Service Agent

or the Bradford White Service Department.

Thermostat Adjustment

The thermostat is factory calibrated to produce temperatures of

185°–190°F (85°–88°C). If adjustment or recalibration is

required use the following procedure.

NOTE: Low temperature dish machines require the thermostat

1. Remove the access cover.

2. Adjust the thermostat in the desired direction.

• To lower the temperature setpoint, turn the outer

• To raise the temperature setpoint, turn the outer

Form No. EBOOSTERBWM-1009

to be adjusted to 140°–150°F (60°–66°C).

Figure 11. Access Cover for Thermostat and

High Temperature Limit Safety Switch

adjustment screw counterclockwise.

adjustment screw clockwise.

MAINTENANCE

Figure 12. Thermostat Adjustment

NOTE: 1/6 turn of the outer screw equals 12°F (6.7°C).

If recalibration is necessary, with the outer screw at high stop

turn inner adjustment screw clockwise to raise the set point.

NOTE: 1/6 turn of the inner

Temperature/Pressure Relief Valve

The temperature/pressure relief valve lever must be operated at

least once a year to ensure that waterways are clear. Certain

naturally occurring mineral deposits may adhere to the valve,

blocking waterways and rendering it inoperative. When the lever

is operated, hot water will discharge from the attached discharge

line if waterways are clear. In addition to annual operation of the

valve lever, the condition of the temperature/pressure relief valve

must be inspected every two to four years by a licensed plumber

or qualified service technician.

Inspect combination temperature/pressure relief valve at

least once every two to four years, depending on local

water conditions. Contact a licensed plumber or qualified

service technician for inspection. Replace valve, if

necessary. DO NOT attempt to self-inspect valve.

BURN HAZARD: Water in unit is very hot. Wear protective

gloves and proper attire when operating to avoid injury.

Use the following procedure to test the temperature/pressure

relief valve.

1. Make sure a properly installed

discharge line is connected to

the relief valve. The discharge

line must direct the flow of hot

water from the valve to a

proper place of disposal.

2. Pull up slightly on therelief valve

lever. The lever is connected to

a strong spring, so it will take

some force to move the lever.

• If water flows freely from the

discharge line, the valve is

clear and operating properly.

Release the lever down into the closed position (vertical).

• If water does not flow freely from the discharge line, the

valve is obstructed and must be replaced immediately.

Release the lever, turn off the booster water heater, and

contact a trained, licensed plumber to replace the valve.

NOTE: If dripping or discharge occurs when the relief valve

lever is in the closed position (vertical), turn off the

booster water heater and contact a licensed plumber

immediately. Discharge may indicate that an unsafe

temperature or pressure condition exists.

13

screw equals 8°F (4.4°C).

Page 16

MAINTENANCE

WARNING

Red Reset Button

High Temperature Limit Safety Switch

Bradford White Commercial Electric Booster water heaters are

equipped with a manually reset high temperature limit safety

switch. If the temperature of the water in the heater exceeds

210°F (99°C) the safety switch will shut off the power. The

switch must be reset manually by pushing the red button.

Use the following procedure if the high temperature limit safety

switch needs to be reset.

1. Remove the access cover (see Figure 11).

2. Push the red reset button on the high temperature limit

safety switch.

Figure 13. High Temperature Limit Safety Switch

3. If tripping repeats, call an Authorized Service Agent.

Blended Phosphate Treatment System

(optional)

The Blended Phosphate Water Treatment System dispenses a

small amount of polyphosphate into the water before the water

enters the booster water heater. The mineral molecules in the

water, which have a positive charge, are attracted to the

negative charge of the polyphosphate. The mineral molecules

are unable to join together, so scale is unable to form. Use the

following procedure to replace a blended phosphate cartridge.

1. Shut off electrical power to the booster water heater.

2. Shut off the inlet water supply and open drain shut-off valve

to remove water in piping.

3. Loosen canister using wrench attached.

4. Remove canister and discard depleted cartridge.

5. Using a clean damp cloth, wipe interior of canister clean.

NOTE: Make sure the o-ring seal is placed properly in canister.

6. Reverse procedure to reinstall.

TROUBLESHOOTING GUIDE

General

ELECTRIC SHOCK HAZARD:

• Turn power OFF at disconnect switch/circuit breaker

and allow unit to cool before performing any

maintenance or cleaning.

• This unit must be serviced by qualified personnel only.

Service by unqualified personnel may lead to electric

shock or burn.

IMPORTANT! Many times when a booster water heater does

not appear to be functioning properly, the fault is not with the

booster water heater itself but with factors outside the heater.

Before proceeding with the troubleshooting charts, perform the

following steps first.

1. Check the temperature of the water feeding into the

booster tank. It must be 110° to 140°F (43° to 60°C)

depending on the heating capability of the unit. The inlet

water supply must be in sufficient quantity to hold its

temperature throughout the dishwashing operation.

2. If incoming water exceeds 20 psi (138 kPa), a pressure

reducing valve must be installed.

3. If the wash tank of the dish machine is filled through the

booster water heater, this will use up all of the 180°F (82°C)

water in storage. Sufficient time must be allowed to reheat

the water in storage before starting the dishwasher.

4. Booster water heater voltage must be correct for the

voltage available. Check nameplate on the booster water

heater for full information.

5. Water pressure at the inlet to the booster water heater must

be adequate for proper operation of the rinse cycle of the

dish machine, not to exceed 20 psi (138 kPa). Check with

dish machine manufacturer for specific details.

6. The breakers or fuses MUST be sized properly.

7. Be sure that the temperature/pressure relief valve is one

supplied by Bradford White and is installed properly.

8. A check valve should not be installed ahead of the booster.

NOTE: If a check valve is installed and cannot be removed,

install a back pressure relief valve set at 125 psi

(862 kPa) on the incoming line between the pressure

reducing valve and the inlet to the booster water

heater. Discharge must be to open site drain.

9. Primary water heater temperature should not exceed 160°F

(71°C).

14

Form No. EBOOSTERBWM-1009

Page 17

TROUBLESHOOTING GUIDE

Symptom Probable Cause Corrective Action

Water reaches 180°F (82°C) but

does not last through the entire

dishwasher operation.

The booster heater does not heat

at all or only delivers water at

120°–150°F (49°–66°C).

Low incoming water temperature. Incoming water temperature must be adequate

Incoming water temperature drops.

Flow pressure is too high. Higher pressure uses an excessive quantity of hot

Booster water heater may be

undersized.

Incorrect voltage.

Unit may have been energized

without water (dry fired).

Fuses may be blown or circuit

breaker tripped.

Over-current fuses may be blown. Contact Authorized Service Agent or Bradford

for booster size. Increase incoming water

temperature.

Primary water supply is not adequate to provide

correct temperature in sufficient quantities.

Increase supply of primary hot water.

water. Adjust flow pressure to 20 psi (138 kPa).

Booster water heater must be sized properly for

incoming water temperature and rinse

requirements of the dish machine.

Check voltage on heater serial plate and make

sure supplied voltage matches. A 240 V booster

water heater operating on 208 V reduces wattage

to 76% of the normal output.

This will cause the elements to burn out quickly.

Replace the element(s).

Check for proper fuse sizing. Replace fuses.

Check/reset circuit breaker.

White for assistance.

Temperature setting out of

calibration or inoperable.

Contactors do not pull in. Contact Authorized Service Agent or Bradford

High limit switch may be tripped or

defective.

Transformer not working properly. Contact Authorized Service Agent or Bradford

Low water cutoff inoperable,

contacts do not close.

Temperature setting should be maximum

of 190°F (88°C).

White for assistance.

Reset switch. If switch continues to trip or cannot

be reset contact an Authorized Service Agent.

White for assistance.

Contact Authorized Service Agent or Bradford

White for assistance.

Form No. EBOOSTERBWM-1009

15

Page 18

TROUBLESHOOTING GUIDE

Symptom Probable Cause Corrective Action

Water at dish machine is not at the

proper temperature.

Heating elements burn out.

Relief valve dribbles.

Gauge(s) not working properly. Check temperature of water with a thermometer

Thermostat set too low.

Booster heater has more than 5

linear feet (1524 mm) of water pipe

to the dishwasher, causing the water

to cool off inside the pipe.

Tank inadvertently drained leaving

elements in a dry condition.

Lime buildup in tank causing

elements to split and burn out.

No pressure reducing valve installed

or incorrect valve installed causing

pressure build-up inside booster

tank.

Bypass in pressure reducing valve

may be blocked.

Check valve or anti-siphon valve

installed in the feed line.

to be certain gauges are working correctly. If not,

replace gauge(s).

Adjust or recalibrate. If thermostat will not

recalibrate properly, replace it.

If located farther than 5 linear feet (1524 mm),

pipes should be wrapped in insulation, and/or a

recirculating system installed.

Make sure tank is full of water at all times.

Contact Authorized Service Agent or Bradford

White for assistance.

Clean or delime tanks periodically. A water

softener or blended phosphate treatment system

may be required.

A pressure reducing valve with high pressure

bypass must be installed in the incoming water

line to allow water to expand back into the feed

line.

Clean bypass or replace with new valve

with built in bypass.

Remove check valve or anti-siphon valve to allow

for water expansion or install a back pressure

relief valve on the incoming water line.

Relief valve opens.

High temperature limit trips.

Chattering contactor or low water

cutoff circuit board.

Unit is overheating. Thermostat may be set too high or is sticking.

Contactor may be sticking in closed

position not allowing unit to cycle off.

Temperature limit set too low. If booster water heater is not overheating,

Thermostat set too high. Adjust or recalibrate to proper temperature.

Incoming water temperature too high

causing nuisance tripping of high

temperature limit switch.

Loose connections or wire

connection has insulation under

crimp.

Low voltage. Contact Authorized Service Agent or Bradford

Probe may be fouled. Contact Authorized Service Agent or Bradford

Contactor(s) may be bad. Contact Authorized Service Agent or Bradford

Recalibrate or replace the thermostat.

Contact Authorized Service Agent or Bradford

White for assistance.

Contact Authorized Service Agent or Bradford

White for assistance.

Incoming water temperature should not be higher

than 160°F (71°C).

Contact Authorized Service Agent or Bradford

White for assistance.

White for assistance.

White for assistance.

White for assistance.

16

Form No. EBOOSTERBWM-1009

Page 19

ACCESSORIES

NOTICE

Stainless Steel Adjustable Legs

1. Carefully place the unit on its side.

Do not lay unit on the side with the control panel. Damage

to the unit could occur.

2. Thread the adjustable legs into the existing leg holes on

the bottom of the unit.

3. After all legs are secure, return the unit to the upright

position.

NOTE: If unit is not level, use an adjustable open-end wrench

to adjust the foot of each leg until unit is level. Each leg

is adjustable from 6″ (152 mm) to 7″ (178 mm).

Figure 14. Optional Stainless Steel Adjustable Legs

Floor Mounting Hardware

Stainless steel adjustable legs with deck mounting flange are

available for securing the booster heater to the floor.

Shock Absorber

The shock absorber installed between the booster and the

commercial dish machine reduces water hammer induced by

rapidly operating valves. The water hammer can cause damage

to the equipment.

Blended Phosphate Water Treatment

System

The Blended Phosphate Water Treatment System is installed

before the booster water heater and reduces mineral scale

build-up by introducing a measured amount of polyphosphate

into the water.

Bradford White recommends that the Blended Phosphate Water

Treatment System be installed with unions on the incoming 3/4"

water supply line after the pressure reducing valve and before

the booster water heater.

Cartridges supplied have a usage rating of 100,000 gallons

(378,541 liters) of water. To assure proper operation the

cartridges must be replaced when expired.

NOTE: Product failure caused by liming or sediment buildup is

not covered under warranty.

Form No. EBOOSTERBWM-1009

17

Page 20

WIRING DIAGRAMS

10-01-454

10-01-448

6 – 9 kW Wiring Diagram, All Voltages, Single- or Three-Phase

12 – 18 kW Wiring Diagram, All Voltages, Three-Phase

18

Form No. EBOOSTERBWM-1009

Page 21

10-01-452

12 – 15 kW Wiring Diagram, 208 and 240 V, Single-Phase

10-01-447

WIRING DIAGRAMS

18 kW Wiring Diagram, 208 and 240 V, Single-Phase

Form No. EBOOSTERBWM-1009

19

Page 22

WIRING DIAGRAMS

10-01-432

10-01-433

24 – 30 kW Wiring Diagram, 240 V, Single-Phase

24 – 36 kW Wiring Diagram, 208 and 240 V, Three-Phase

20

Form No. EBOOSTERBWM-1009

Page 23

10-01-435

24 – 36 kW Wiring Diagram, 480 V, Three-Phase

10-01-436

WIRING DIAGRAMS

36 kW Wiring Diagram, 240 V, Single-Phase

Form No. EBOOSTERBWM-1009

21

Page 24

WIRING DIAGRAMS

10-01-434

10-01-437

36 – 57 kW Wiring Diagram, 208 and 240 V, Three-Phase

45 – 57 kW Wiring Diagram, 480 V, Three-Phase

22

Form No. EBOOSTERBWM-1009

Page 25

LIMITED COMMERCIAL WATER HEATER WARRANTY

WHAT DOES THIS LIMITED WARRANTY COVER?

This limited warranty covers both the tank and component parts

for leakage or other malfunction caused by defects in materials

and/or workmanship. It extends to the first buyer and to any

subsequent owner(s) as long as the water heater remains

installed at its original place of installation.

WHAT DOES THIS LIMITED WARRANTY NOT COVER?†

1. This limited warranty does not cover leakage or other

malfunction caused by:

a) Defective installation, and specifically, any installation

which is made:

i) in violation of applicable state or local plumbing,

housing or building codes, or

ii) without a certified American Gas Association, ASME,

or comparable combination temperature and pressure

relief valve, or

iii) contrary to the written instructions furnished with the

unit.

b) Adverse local conditions, and specifically, sediment or

lime precipitate in the tank or corrosive elements in the

atmosphere.

c) Misuse, and specifically, operations, and maintenance

contrary to the written instructions furnished with the

unit, removal of anode(s), disconnection, alteration or

addition of nonapproved components or apparatus,

operation with fuels or at settings other than those set

forth on the rating plate, or accidental or other exterior

damage.

2. This warranty also does not cover:

a) Production of noise, taste, odors, discoloration or rusty

water.

b) Incidental property damage, loss of use, inconvenience

or other incidental or consequential costs.

c) Costs associated with the replacement and/or repair of

the unit, including:

i) any freight, shipping or delivery charges

ii) any removal, installation or re-installation charges

iii) any material, and/or permits required for installation,

re-installation or repair

iv) charges to return the defective water heater and/or

component part to the manufacturer.

WHAT IS THE PERIOD OF COVERAGE?

This limited warranty runs from date of installation (or without

proof of installation, from three [3] months after the date of

manufacture) for one (1) year on Parts, PLUS four (4) additional

years on the tank only.

WHAT IS THE DURATION OF THE IMPLIED WARRANTY?

ANY IMPLIED WARRANTIES, INCLUDING THE WARRANTY

OF MERCHANTABILITY IMPOSED ON THE SALE OF THE

WATER HEATER UNDER THE LAWS OF THE STATE OF

SALE ARE LIMITED IN DURATION TO ONE YEAR FROM

DATE OF ORIGINAL INSTALLATION.

HOW DOES STATE LAW RELATE TO THE WARRANTY?

Some states do not allow:

1. Limitations on how long an implied warranty lasts.

2. Limitations on incidental or consequential damages.

So the above limitations or exclusions may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

WHAT WILL WE DO TO CORRECT PROBLEMS?

If a defect occurs within the warranty period, we will:

1. Provide a replacement water heater of our manufacture,

(or at our option) repair any unit which develops a leak in

the tank within the tank warranty period. If government

regulations require the replacement water heater to have

features not found in the defective water heater, you will

be required to pay the difference in price represented by

those government required features.

2. Provide a replacement part (or at our option repair) any part

which fails to function within the parts warranty period. To

obtain a replacement, you must forward the defective part

to us. If government regulations require the replacement

part to have features not found in the defective part, you

will be required to pay the difference in price represented

by those government required features.

We do reserve the right to verify any claims of defect by

inspection.

WHAT WILL WE NOT DO?

We will not:

1. Repair or replace any water heater, or part, subject to

conditions outlined in “What Does This Limited Warranty

Not Cover?”

2. Reimburse any costs associated with repair and/or

replacement.

3. Replace and/or repair any water heater without complete

model/serial number.

HOW DO YOU GET WARRANTY ASSISTANCE?

Upon discovering a defect or problem, you should:

1. Contact either the installer or dealer, or

2. Contact us--

BRADFORD WHITE CORPORATION

WARRANTY SUPPORT GROUP

200 LAFAYETTE STREET

MIDDLEVILLE, MI 49333

(800) 531-2111

CALIFORNIA RESIDENTS CALL 1-800-538-2020

Please have model number and serial number ready.

Continued...

† Restrictions are not applicable to implied warranties in California. See “Special State Provisions” on next page.

Form No. EBOOSTERBWM-1009

23

Page 26

LIMITED COMMERCIAL WATER HEATER WARRANTY (CONTINUED)

WHAT SHOULD YOU DO TO KEEP THE WARRANTY IN

EFFECT?

To facilitate warranty assistance, you should:

1. Follow all instructions enclosed with the product.

2. Retain all bills of sale or receipts for proof of installation,

etc.

3. Contact your installer, dealer or our Warranty Department

as soon as any problem or defect is noticed.

4. When necessary, allow us, or our chosen representative,

to inspect the unit.

5. For your reference, fill in the Model and Serial Number

found on the units Rating Plate:

Model Number ____________________________________

Serial Number ____________________________________

Date of Installation ________________________________

SPECIAL STATE PROVISIONS

For water heaters installed in California or Oregon,

Paragraphs 2(c) (i) (iv) of the paragraph “WHAT DOES

THIS WARRANTY NOT COVER?” does not apply.

All other terms and conditions of this warranty apply as

stated.

PLEASE RETAIN THIS WARRANTY IN A SAFE LOCATION FOR FUTURE REFERENCE.

24

Form No. EBOOSTERBWM-1009

Page 27

NOTES

Form No. EBOOSTERBWM-1009

25

Page 28

Ambler, PA 19002

Technical Service 800.334.3393

Service Parts 800.538.2020

Warranty Service 800.531.2111

www.bradfordwhite.com

Printed in U.S.A. October 2009 Part No. 07.04.474.00 Form No. EBOOSTERBWM-1009

Loading...

Loading...