Page 1

Save this manual for future reference

Manual 238-50629-00A

SERVICE

MANUAL

Troubleshooting Guide

and Instructions for Service

(To be performed ONLY by

qualified service providers)

Models Covered

by This Manual:

U2TW75T*RN

UTW475S76R*N

(*) Denotes Warranty Years

Gas Water Heaters

U TTW 75 Series

®

Page 2

Bradford White

2

U2TW Series

Gas Water Heaters

Table of Contents

Page U2TW Service Procedure

Introduction 4 - - -

How to Use This Manual 5 - - -

Tool Required for Service 5 - - -

Specifications 6 - - -

Control Timings 8 - - -

Sequence of Operation 9 - - -

Troubleshooting 12 - - -

Burner and Inner Door/Gasket Removal, Inspection

Burner Operation Inspection, Cleaning and Replacement 17 II

Pilot Testing, Cleaning and Replacement 19 III

Pressure Switch Testing and Replacement 20 IV

Blower Testing and Replacement 22 V

Blower Temperature Switch Testing and Replacement 24 VI

Gas Control Testing and Replacement 26 VII

Simulated Resistive Device Testing and Replacement 28 VIII

Resettable Thermal Switch Testing and Replacement 29 IX

Safety Circuit Voltage Trace 31 X

115VAC Circuit Trace 32 XI

Dip Tube Inspection and Replacement 33 XII

Anode Inspection and Replacement 34 XIII

Flue Baffle Inspection and Replacement 35 XIV

Glossary of Terms 36 - - -

Replacement and Reinstallation 14 I

Parts List 39 - - -

Page 2

Page 3

WARNING: If the information in these instructions is

3

not followed exactly, a fire or explosion may result

causing property damage, personal injury, or death.

Incorrect operation of this appliance may

CAUTION

create a hazard to life and property and

will nullify the warranty.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable,

combustible, or corrosive vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

x Do not touch any electrical switch; do not use any

phone in your building.

x Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

x If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

WARNING

Water heaters are heat producing appliances. To avoid

damage or injury, do not store materials against the

water heater or vent-air intake system. Use proper care

to avoid unnecessary contac

the water heater and vent-air intake components.

UNDER NO CIRCUMSTANCES MUST FLAMMABLE

MATERIALS, SUCH AS GASOLINE OR PAINT THINNER BE

USED OR STORED IN THE VICINITY OF THIS WATER

HEATER, VENT-AIR INTAKE SYSTEM OR IN ANY

LOCATION FROM WHICH FUMES COULD REACH THE

WATER HEATER OR VENT-AIR INTAKE SYSTEM.

t (especially by children) with

CAUTION

If sweat fittings are to be used DO NOT apply heat to the

nipples on top of the water heater. Sweat the tubing to

the adapter before fitting the adapter to the water

connections. It is imperative that heat is not appli

the nipples containing a plastic liner.

ed to

WARNING

Hydrogen gas can be produced in an operating water

heater that has not had water drawn from the tank for a

long period of time (generally two weeks or more).

Hydrogen gas is extr

possibility of injury under these conditions, we

recommend the hot water faucet to be open for several

minutes at the kitchen sink before you use any electrical

liance which is connected to the hot water system. If

app

hydrogen is present, there will be an unusual sound such

as air escaping through the pipes as hot water begins to

flow. Do not sm

at the time it is open.

emely flammable. To prevent the

oke or have open flame near the faucet

Do not store or use gasoline or other

flammable, combustible, or corrosive

vapors and liquids in the vicinity of this

or any other appliance.

Before proceeding, please inspect the

water heater and its components for

possible damage. DO NOT install any

water heater with damaged components.

If damage is evident then please contact

the supplie

purchased or the manufacturer listed on

the rating plate for replacement parts.

DANGER

IMPORTANT

r where the water heater was

WARNING

DO NOT ATTEMPT TO LIGHT ANY GAS APPLIANCE IF YOU

ARE NOT CERTAIN OF THE FOLLOWING:

x Liquefied petroleum gases/propane gas and natural gas

have an odorant added by the gas supplier that aids in

the detection of the gas.

x Most people recognize this odor as a “sulfur” or “rotten

egg” smell.

x Other conditions, such as “odorant fade” can cause the

odorant to diminish in intensity, or ”fade”, and not be

as readily detectable.

x If you have a diminished sense of smell, or are in any

way unsure of the presence of gas, immediately contact

your gas supplier from a neighbor's telephone.

Gas detectors are available. Contact your gas supplier, or

plumbing professional, for more information.

WARNING

FAILURE TO INSTALL AND MAINTAIN A NEW, LISTED 3/4” X

3/4” TEMPERATURE AND PRESSURE RELIEF VALVE WILL

RELEASE THE MANUFACTURER FROM ANY CLAIM THAT

MIGHT RESULT FROM EXCESSIVE TEMPERATURE AND

PRESSURES.

CAUTION

Turn off or disconnect the electrical power supply to the

water heater before servicing. Label all wires prior to

disconnection when servicing controls. Wiring errors can

cause improper and d

operation after servicing.

angerous operation. Verify proper

Page 3

Page 4

Introduction

4

The newBradford White U2TW & UTW4water heaters are designed toprovidereliable

performance with enhanced standardfeatures.Newdesign features includereliablespark to

pilot ignition system, enhanceddiagnostics, simplified

and additionalvent lengths.Inaddition, the U2TW & UTW4water heaters provideUltra Low

NOx emissions.

SparktoPilot Ignition System-employing thespark to pilot ignition systempromotes

reliableand cons

istent pilotand main burner ignitionstoprovide hot water on demand.

Integrated Immersion Thermostat/Gas Control Valve with LED -was developedfor ease

of troubleshooting by providing simple diagnostic codes to pinpointaninstallation or

component performance issu

e.

Powerful Blower - will eliminate problems with difficult venting situations.

Quieter and Cooler Blower Operation - blower noise issignificantly reducedfor both

interiorand exteriorenvironments. Cooler operation increases blower life by reducing bearing

wear and noise

.

RuggedWiring Connections - receptacletype connections promote error free wiring.

IncreasedVent Lengths - increasedventing performance isachieved while maintaining

Energy Factor &FHSR performance.

servicing, significantly quiet operation

Page 4

The U2TW & UTW4w

ater heaters use a combustion systemwhere flue gases are combined

with dilution airto reducethe flue gas temperature in the blower. The diluted flue gases are

evacuated to theexteriorthrough low temperature vent materials. The gas control ma

intains

water temperature, ignition sequenceand regulates gas flow. A safetycircuit consisting of a

pressure switch and blower temperature switch verifies proper conditionsexist forsafeand

reliable operation. If asituation outside of normaloperating parameters exi

sts, the gas control

diagnostic LED will flash a codetopositively identify anoperationalissue.

This service manualis designed tofacilitate problemdiagnosisand enhance serviceefficiency.

Please read the service manual completely before atte

mpting service on this new series of

power vent models.

Page 5

How to Use This Manual

5

It is intended for this manual to be used by qualified service personnel for the primary purpose of

troubleshooting and repair of the Bradford White U2TW Series water heaters. Understanding the

sequence of operation section of this manual will contribute greatly to troubleshooting the water

heater.

The Honeywell WV4462A Electronic Gas Control will display error codes in the event of abnormal

operation. Error codes are listed in the troubleshooting chart beginning on page 12 of this service

manual. The troubleshooting chart will also indicate the probable cause for the error code and

direct the service professional to a service procedure to properly diagnose the abnormal operation.

In some difficult to diagnose conditions, it may be necessary to isolate the heater from the vent

system to determine the problem.

Contact the Bradford White technical support group immediately if diagnosis cannot be made

using the methods described in this service manual.

Tools Required for Service

Manometer:A liquid “U” tube type or a digital type can be used. This device is used to

measure gas and/or air pressure and vacuum.

Multi-Meter:A digital type is strongly recommended. This device is used to measure

electrical values. The meter you select must have the

measure volts AC, volts DC, Amps, micro-amps and ohms.

Electronic Probes: In some cases, standard multi-meter probes will damage or simply

not be effective to obtain certain voltage and ohm reading. It will be

necessary to have special electronic “pin” type multi-meter probes.

These probes are available at

Thermometer: Used to measure water temperature. An accurate thermometer is

recommended.

Water Pressure Gauge: Used to measure water supply pressure. Also used to determine tank

pressure by adapting to the drain valve of the heater.

Various Hand Tools:Pipe wrench, channel locks, open end wrenchs (3/8",7/16",

12" crescent wrench, Allen wrench set, screw drivers (common &

Phillips), ¼" nut driver, pliers (common & needle nose), socket set, side

cutters wire cutters, wire strippers, wire crimpers, torpedo level, small

shop vac, step ladder, flashlight and 5 gallon pail.

most electronic wholesale outlets.

capability to

½"),

Page 5

Page 6

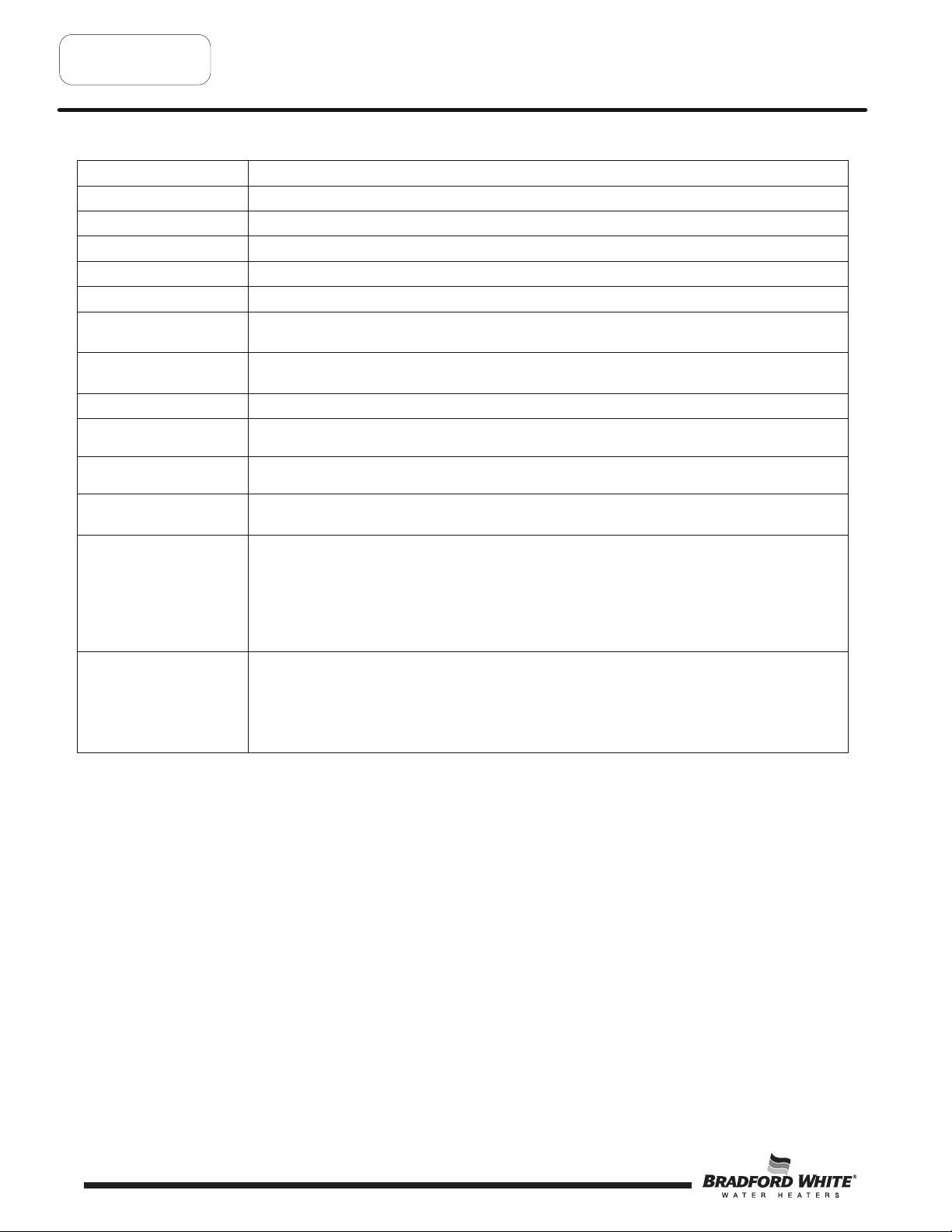

Specifications

6

Power supply Dedicated 115VAC, 60 Hz, 15A

Gas Supply Pipe Minimum 1/2" NPT (schedule 40 black iron pipe recommended)

Approved Gas Type Natural.

Gas Pressure 6.0" W.C. min. and 14.0" W.C. max.

Venting System Power vent through the wall or vertical through the roof

Approved Vent Materials PVC, CPVC or ABS

Minimum Clearance

for Servicing

Water Supply Pressure 150 PSI maximum allowable working pressure. Check local codes for supply pressure

Thermal well ECO Limit Residential 188°F (87°C), Commercial 199°F (93°C)

Residential Temperature

Set Point Range

Commercial Temperature

Set Point Range

18" from top, 24" from front, 4" sides and rear.

60°F (16°C) to 160°F (71°C) (Approximate temperatures)

80°F (27°C) to 180°F (82°C)(Approximate temperatures)

Blower Temperature Switch Normally closed, opens @ 165°F (74°C), auto reset @ 130°F (54°C).

Pressure switch

Blower

U2TW75 and UTW475S Models:

Normally open, closes on vacuum increase @-1.28, opens on vacuum decrease @-1.25

U2TW75 and UTW475S Models:

115VAC, 60Hz, 3.1 amps, 3000 RPM,68 CFM@0.4" W.C.

Page 6

Page 7

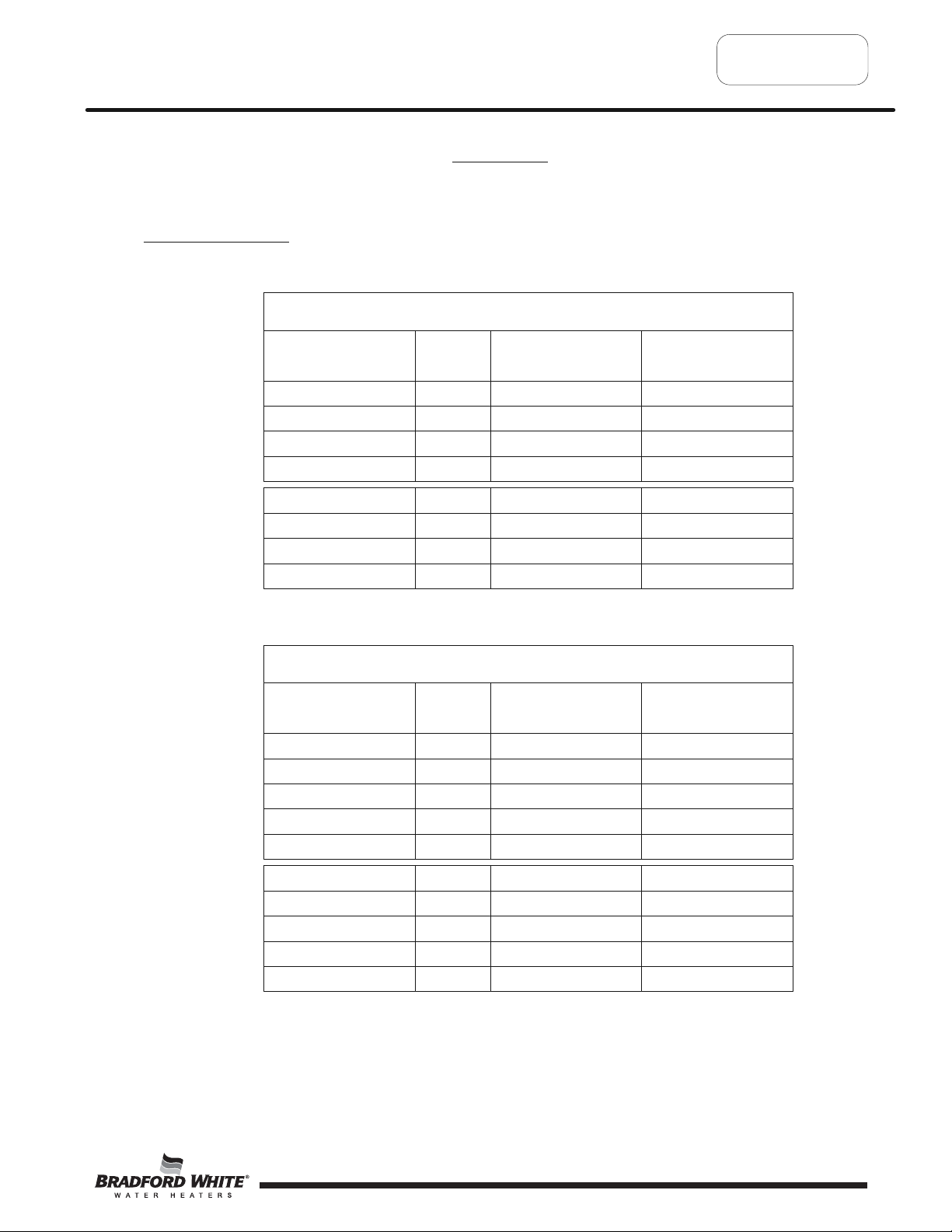

Venting Specifications:

7

Specifications

Vent Tables

3" Diameter (7.6 cm) PVC Vent Connector Lengths

Terminating

Through the Wall

# of

Elbows

1 45(13.7) 2 (.6)

Maximum

Length ft (m)

Minimum

Length ft (m)

Through the Wall 2 40(12.2) 2 (.6)

Through the Wall 3 35 (10.7) 2 (.6)

Through the Wall 4 30 (9.1) 2 (.6)

Through the Roof 0 50 (15.2) 7 (2.1)

Through the Roof 1 45(13.7) 7 (2.1)

Through the Roof 2 40(12.2) 7(2.1)

Through the Roof 3 35 (10.7) 7(2.1)

4" Diameter (10.2 cm) PVC Vent Connector Lengths

Terminating

Through the Wall

# of

Elbows

1 175 (53.3) 10 (3.1)

Maximum

Length ft (m)

Minimum

Length ft (m)

Through the Wall 2 170 (51.8) 10(3.1)

Through the Wall 3 165 (50.3) 10(3.1)

Through the Wall 4 160 (48.8) 10(3.1)

Through the Wall 5 155 (47.2) 10(3.1)

Through the Roof 0 180 (54.9) 15 (4.6)

Through the Roof 1 175 (53.3) 15(4.6)

Through the Roof 2 170 (51.8) 15(4.6)

Through the Roof 3 165 (50.3) 15(4.6)

Through the Roof 4 160(48.8) 15(4.6)

Page 7

Page 8

Specifications

8

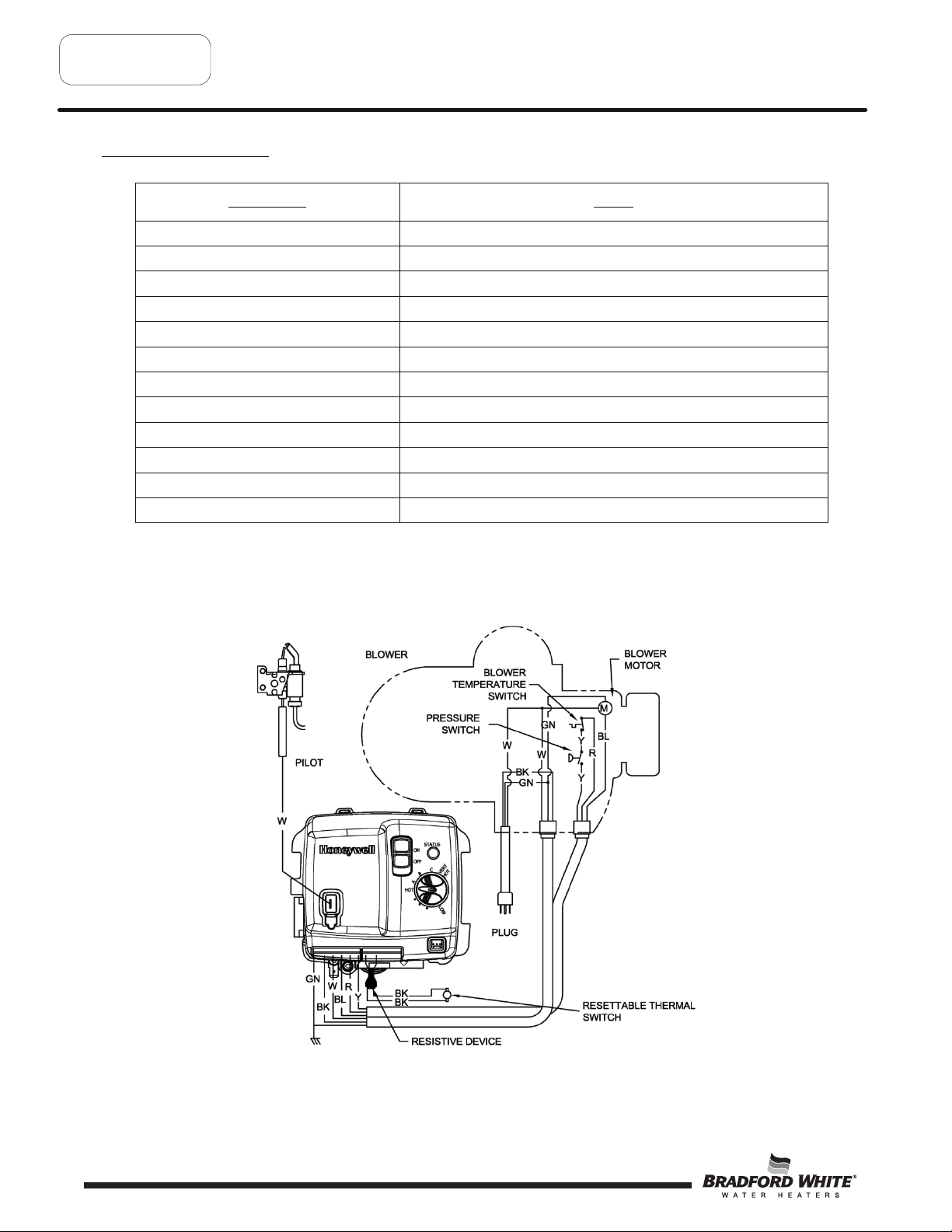

Control Timings

Pre-purge 2 Seconds

Trial for Ignition 90 Seconds

Flame Stabilization Period 3 Seconds

Inter-purge 15 Seconds

Flame Failure Response Time 1.5 Seconds (2 second. Maximum; 1 second minimum.)

Post-purge 15 Seconds

PS Fault Delay (failed open/close) Retry after 2 Minutes

Soft Lockout Retry after 5 Minutes

ECO Limit Lockout Indefinite (cycle power to restart)

Verify Resistive Delay Retry after 2 Minutes (repeats 5 times)

Simulated Resistive Load Lockout Indefinite (cycle power to restart)

Hardware Error Lockout Indefinite (self clears if fault clears for at least 15 seconds)

Ignition State Timing

Wiring Diagram

Page 8

Page 9

Sequence of Operation

9

Power up Sequence

1

Start Up.

Uponpower up, the control runs a safe-start check withatypical start-up delay of 1-5 seconds.

2

SimulatedResistive Load Device Check.

To assure no outputs are energized if the “Simulated Resistive device” is out of range, the control will test the

the device for proper operating range. If the device is within range the control resumes normal operationwith no

perceivable delay. If the device isoutofrange, the control LED immediately flashes 7 times with 3 second pause.

Normal Heating Sequence

1

Thermostat Calls for Heat.

Prior to energizing blower,gas control checks safetycircuittoinsure the circuit isopen. Normal switch positions

in the safetycircuit are as follows:

a) Pressure switch normally open.

b) Blower temperature switch normallyclosed.

If the safetycircuit is

closed, the control waits 4 seconds,gas control LED flashes 2 times with 3 second pause.

Gas control waits 2 minutes then, blower runs for 30 seconds. This cycle repeats until safetycircuitopens.

2

Blower Energizes.

3

Blower Pre-purge Period(2seconds)

4

Pressure Switch Proves Blower/Vent System Operation.

If the pressure switch does not close within 30 seconds, the control LED Flashes 3 times with 3 second pause.

The blower runs for 30 seconds every2minutes trying to get the pressure switchorblower temperature switchto

close. This cycle repeats as long as there isacall for heat.

5

Trial for Pilot Ignition(90 seconds).

a) The gas control lights the pilot by activating spark igniter and gas flow to pilot burner.

b) If flame is not sensedwithin 90 seconds, igniter and gas flow are deactivated, blower will post purgeand

control LED flashes 6 times with 3 second pause.

6

Main Burner Ignition

After pilot flame issensed, gas control activates main valve for main burner ignition. The gas control will ignore

flame and pressure switchsignals for 3 seconds allowing for main burner to stabilize.

Page 9

Page 10

Sequence ofOperation

10

Normal Heating Sequence (cont.)

Steady State Operation.

7

During Steady State Operation the Control Monitors:

Thermostat temperature sensor- When set point temperature issatisfied,gasvalveis shutdown and

blower will postpurge for 15 seconds. Control LED flashes a short flash onceevery 4 seconds (idle) status

code.

Pressure switch /Blower temperature switch- If either switch opens, pilot valve and main valveis shut

down. The blower continues to runsfor 30 seconds attempting to closethe circuit. The control LED Flashes

3 times with 3 second pause.

Flame Sensor- Ifflameis lost, pilot & main valve are shutdown,blower runsfor 15 seconds.

to re-light pilot 4 times.Ifunsuccessful,Blower is shutdown and control proceeds to 5 minute lockout. Control

re-attempts to light pilot starting at normal heatingsequence#2.

8

Thermostat Satisfies.

9

Burner Off.

10

Blower Post Purge (15 seconds).

Control attempts

Abnormal Operation

1.Simulated ResistiveDeviceFault:

a)Ifthe resistance is greater than 70,000 Ohms - the gascontrol immediately turns off all outputs. Control waits

and monitors resistance for 30 seconds.If theresistanceisgreater than 70,000 ohms after 30 seconds, the

gascontrol proceeds to verifyresistive delay

pause. This process is repeated 5 timesuntil the control either returns to normal operation or proceeds to flashing

7 times with a3second pause.

b) If the resistance is below 3000 ohms - The gascontrol immediately turns off all outp

8 times then once with three second pause. The error selfclears if theresistance returns to normal range for at

least 15 seconds.

for 2minutes and flashes 8 times then once with athree second

uts and proceeds to flash

2. Temperature Sensor Fault:

a) Temperature sensor detected open circuit - The gascontrol Immediately turns off all outputs and proceeds to

flash 8 times then twice with three second pause. The error selfclears if the fault clearsfor at least 15 seconds.

b) Temperature sensors not reading the sametemperature within ±5.5 °F - The gascontrol Immediately t

all outputs and proceeds to flash 8 times then three times with three second pause. The error selfclears if the fault

clearsfor at least 15 seconds.

c) Water temperature in excess of ECO (Energy Cut Out)limit - The gascontrol immediately turns off pilot &

main valve and proc

The set point knobshould beturned to the minimum temperature settingfor at least 6seconds and then turned

clockwise by at least45

Page 10

eeds to flash 4 times with 3 second pause. Blower continues to run until gascontrol is reset.

o

.

urns off

Page 11

Sequence of Operation

11

Abnormal Operation (cont.)

3. Pressure Switch/Blower Temperature Fault:

a) Pressure switch closed at start of call for heat - Thegas controlwaits four seconds then, proceeds to flash

2 times with 3 second pause.The controlwaits 2 minutes and then turns on blower for 30seconds. Theblower

turns off after 30seconds and the controlwaits for pressure switch to open. Any time the Pressure switch

theblower turns on (or stays on) and the control proceeds to wait for pressure switch to close.

b) Pressure switch or blower temperature switch failed open - Thegas control runs theblower for 30seconds

waiting for the pressure switch and/or blower temperature switch to close.If either sw

seconds,theblower turns off and the control flashes 3 times with 3 second pause.Thegas controlwaits two

minutes before turning on theblower for another 30seconds to see the circuit close.This cycle repeats aslong as

there is acall for heat or

c) Pressure switch or blower temperature switch opens during burner operation - Thegas control turns off the

pilot and main valve, runs blower for 15seconds (inter-purge) waiting for pressure switch and/or blower

temperature switch to close.If either switch fails to close, th

circuit closes again by the end of the inter-purge, the recyclecounter is incremented, if the recyclecount has

not reached itslimit (4), another trial for ignition begins. Ifthe recyclecount has been reached, thegas control

turns off theblower and flashes 6 times then 2 times with 3 second paus

repeating ignition sequence.

until the circuit closes.

e control proceeds as described in 3b above.Ifthe

e.Thegas controlwaits5minutes before

itch does not closein30

opens,

4. Trial For Ignition Fault:

a) Pressure switch opens during trial - Thegas control turns off igniter and pilot valve.Thegas control proceeds

as described in 3b above.Ifthe pressure switch closeswithin 30seconds thegas controlwill continue with trial for

ignition starting at blower pre-purge.

b) Flame Not Sensed - Thegas control energizes the s

flame is not sensed within 90seconds,the igniter turns off, thepilot valve is closed and thegas control runs the

blower through postpurge and flashes 6 times then once with 3 second pause.The controlwaits5minutes before

repeating the ignition sequence.

park igniter attempting to lightthepilot and prove flame.If

5. Flame Sensing Fault:

b) Flame lost during run - Thegas control turns off pilot and main valves,runs blower for 15seconds (inter purge).

Thegas control increments the recyclecount, if the recyclecount has not reached itslimit (4), another trial for

ignition begins. Ifthe recyclecount has been reached, thegas control turns off theblower and fla

then 3 times with 3 second pause.Thegas controlwaits5minutes before repeating the ignition sequence.

c) Flame sensed out of sequence - thegas control only looks for pilot flame when theblower is running.Ifflame is

present when thepilot valve is not open, thegas control proceeds to wait for flame loss

second pause.This continuesuntil flame islost, once theflame signal islost, the control flashes 6 times then 4

times with 3 second pause.The controlwaits5minutes before repeating the ignition sequence.

and flashes 5 times with 3

shes 6 times

Page 11

Page 12

Troubleshooting

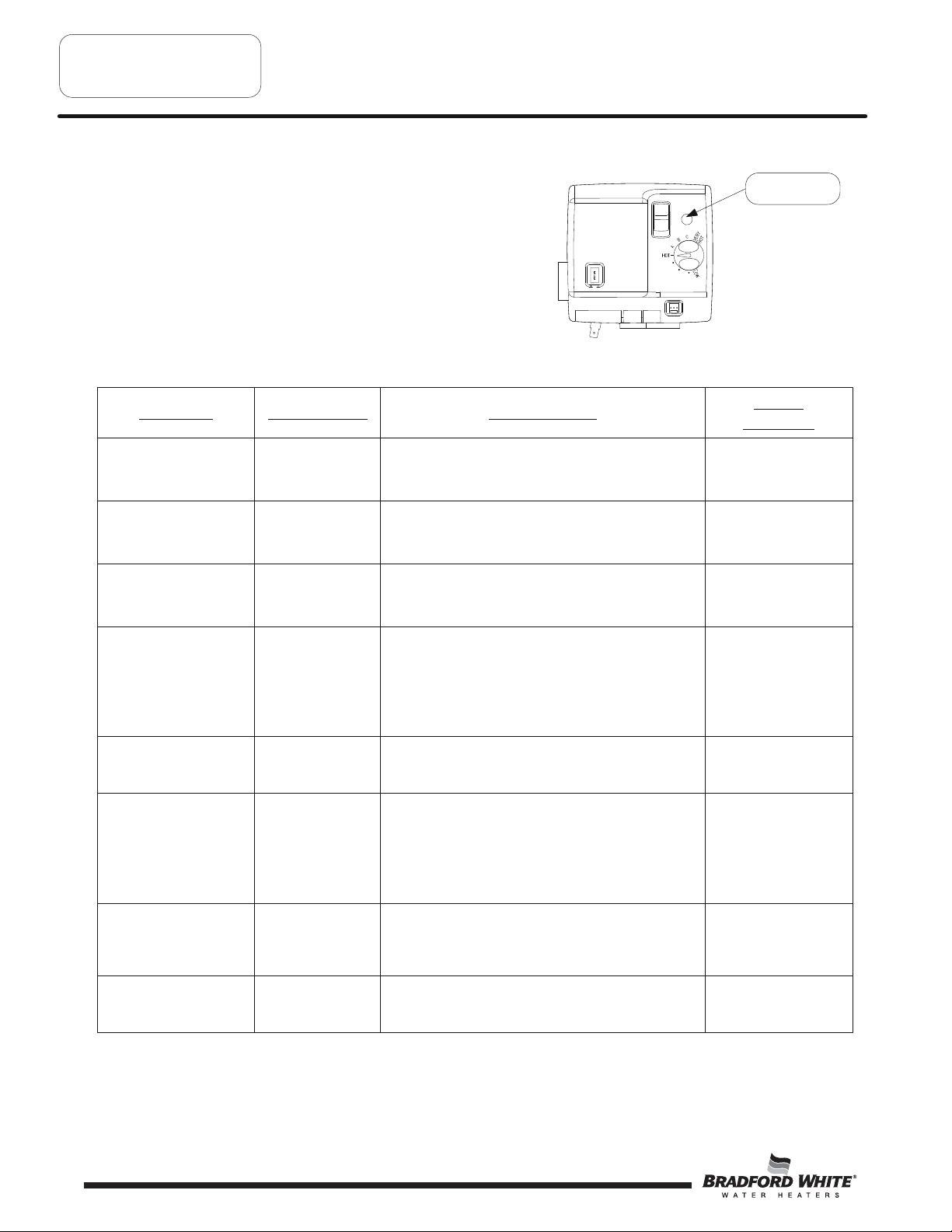

12

Observe green LED indicator on Electronic gas

control. Error flash codes are displayed with a

three second pause before repeating. Check

and repair the system as noted in the

troubleshooting table below.

LED Status

None, control LED not on

or flashing

Short flash, once every

four seconds

“Heartbeat”, alternates

bright/dim

Control Status

No electrical

power

Stand-by mode,

Waiting for call for

heat (no fault)

Thermostat calling

for heat (no fault).

Control power switch in “OFF” position.

Supply voltage interrupted.

Temperature demand is satisfied.

Tank temperature below set point of thermostat.

Probable Cause

Green LED

Indicator

Service

Procedure

Turn power on.

Normal operation.

Adjust thermostat to

temp level.

Normal operation.

Adjust thermostat to

temp level.

Short flash once per

second

Two flash, three second

pause

Three flash, three second

pause

Four flash, three second

pause

Five flash, three second

pause

Page 12

Weak pilot signal

on last call for heat.

Pressure switch not

working-closed

position.

Pressure switch or

blower temp.

switch not working

-open position.

Excessive tank

temperature.

System must be

reset.

Undesired-false

pilot flame present.

1. Unstable pilot.

2. Pilot tube blocked or restricted.

3. Oxidation build up on pilot electrode.

4. Wire damage to pilot assembly or bad

connection at

1. Pressure switch tubing kinked or blocked.

2. Blocked pressure tap on switch or blower.

3. Faulty pressure switch.

1. Vent blockage or improper vent configuration.

2. Pressure switch tubing kinked or blocked.

3. Faulty pressure switch.

4. Blower not spinning up to speed.

5. Blower temp or exhaust temp too high.

6. Faulty blower temperature switch.

1. Thermal well sensor out of calibration.

2. Faulty gas control.

3. Plumbing leak

1. Pilot valve stuck in open position.

gas valve.

1-4. Page 19

Page 20

1. Check vent or vent

tables

2 & 3. Page 20

4. Page 22

5 & 6 Page 23

1-2. Replace gas

control, page 26

Replace gas control,

page 26

Page 13

Troubleshooting

13

LED Status Control Status

Six-one flash, three

second pause

Six-two flash, three

second pause

Six-three flash, three

second pause

Failed to light pilot.

System auto resets.

Pressure switch or

blower temp switch

opened during

burner operation.

System auto resets.

Pilot flame

extinguished.

System auto resets.

Probable Cause

1. Unstable pilot.

2. Pilot tube blocked or restricted.

3. Oxidation build up on pilot electrode.

4. Wire damage to pilot assembly or bad

connection at

1. Vent blockage or improper vent configuration.

2. Pressure switch tubing kinked or blocked.

3. Faulty pressure switch.

4. Vent termination being affe

5. Blower not spinning up to speed.

6. Blower temp or exhaust temp too high.

7. Faulty blower temperature switch.

1. Unstable pilot.

2. Pilot tube blocked or restricted.

3. Oxidation build up on pilot electrode.

4. Wire damage to pilot assembly or bad

connection at

5. Insufficient combustion air.

6. Gas pressure is out of specification.

gas valve.

cted by wind.

gas valve.

Service

Procedure

1-4. Page 16

1. Check vent or vent

tables

2 & 3. Page 20

4. Refer to venting

section of

installation manual

5. Page 22

6 & 7. Page 23

1-4. Page 16

5. Refer to installation

manual

Six-four flash, three

second pause

Seven flash, three second

pause

Eight-one flash, three

second pause

Eight-three flash, three

second pause

Eight-four flash, three

second pause

Undesired-false

pilot flame sensed.

System auto resets.

Simulated Resistive

Device Harness out

of specification.

Simulated Resistive

Device Harness

specification check.

Thermal well

sensor damaged or

unplugged

Gas valve

electronics fault

detected

Gas valve fault

detected.

Pilot valve stuck in open position.

1. Simulated resistive device out of specification.

2. Resettable thermal switch open.

1. Simulated resistive device out of specification.

2. Resettable thermal switch open.

1. Damage to thermal well wire.

2. Thermal well sensor resistance out of range.

1. Control needs to be reset.

2. Control is wet or physically damaged.

1. Control needs to be reset.

2. Control is wet or physically damaged.

Replace gas control,

page 26

1. Page 28

2. Page 29

1. Page 28

2. Page 29

1 & 2. Replace gas

control, page 26

1. Interrupt power

supply

2. Replace gas control,

page 26

1. Interrupt power

supply

2. Replace gas control,

page 26

Page 13

Page 14

UTTW SERVICE PROCEDURE I

14

R

Burner and Inner Door/Gasket Removal,

Inspection, Replacement and Reinstallation

Inner Door Removal Procedure

Step1. Position gas control power switch to the “OFF”

position and unplug heater from wall outlet.

Step 2.Remove outer jacket burner access door.

Step3. Remove wire clip from main burner feedline.

Step 4. Inner Door Removal.

a)Disconnectthe spark igniter/flame sensor wireand the

simulated resistive device from the gas control (see photo 1).

b) Disconnect main burner feed line (¾” wrench), pilottube

(7/16" wrench) and igniter wire from gas con

c) Remove (2) ¼” hex drive screws from right side inner door

(see photo 3).

d) Remove (2) ¼” hex drive screws from flange section of

inner door (see photo 3).

e)Remove (3) 1/4" hexdrive screws from burner door

(see photos 4&5). The burner door and burner are

one-piece

.

3

trol (see photo 2).

Pilot Tube

Gas Control shown in the “OFF” position

1

Simulated Resistive

Device

Spark Igniter/

Flame Sensor

Wire

2

Main Burner

Feedline

Flange Hex

Drive Screws

Igniter Wire

Position #2

Position #3

Right Side

Hex Drive

Screws

Burner Door

Hex Drive

Screws

4

5

f) Remove burner and inner door and inspect perstep5.

Step 5. Fully inspect burner door and rightside inner door gaskets forthe following:

>Tears >Other imperfectionsthat will inhibit properseal

>Missing Material >Gasket adhesion to inner door

>Cr

acks >Materialleft on combustion chamber (around opening)

>Dirt or debris

If the gasket is not effectedbyany of theabove,gasketreplacement is notrequired. If replacement

required, proceed to Inner Door GasketReplacementProcedure.

Page 14

Position #1

is

Page 15

UTTW SERVICE PROCEDURE I

15

R

Burner and Inner Door/Gasket Removal,

Inspection, Replacement and Reinstallation

Inner Door Gasket Replacement Procedure

WARNING

If the information in these instructions is not

followed exactly, a fire or explosion may result causing

propertydamage, personal injury or death.

Step6. After inspection of inner door as notedinstep 5, completely remove gasket and adhesive residue from burner

door and rightside inner door as needed.

Step7. Use RTV sealant (re

commendedbead size 1/8") to secure the inner door gasketto the inner doorsections

(right &burner). The burner door gasket must be slicedinthe location shown on the illustration below in

derto slide the gasket overthe burner venturi. Referto illustration below for proper RTV sealant

or

application. Note the overlap configuration in the flangearea of the inner door.Ensur

the gasket faces outward. Setthe flange section first, this will help to achieve the proper overlapposition.

Re-installation of Inner Door With Gasket

e thatthe chamfer of

Step8. Clean any residualgasketresidue or other debris

from combustion chamb

ersurface before

re-installing the inner door/gasket assembly.

Step9. Place the burner door intoposition first. Tighten

the feed line nutto the gas control. Use the ¼”

hexdrive screwwithou

tthe built-in washerto

secure burner doorto the chamber at position #1.

Use the ¼” hex drive screws with the built-in

washerto secure the door at positions #2

(see photos 4&5, on page 14).

DO NOT OVER TIGHTEN SCREWS.

WARNING

Stripped fastener connections may allow

for seal breach of inner door. A seal

breach may result in a fire or explosion

causing propertydamage, personal injury

or death. Do not over tighten screws in

steps 9, 11 and 12.

If a fastener connection is stripped,

contact the manufacturer listed on the

water heater rating plate.

Page 15

Page 16

UTTW SERVICE PROCEDURE I

16

R

Burner and Inner Door/Gasket Removal,

Inspection, Replacement and Reinstallation

Position Thermopile Wire,

Pilot Tube and Igniter Wire

6

Step 10. Position thermopile wires, pilottubeand igniter wire

against burner door flange gasket

(see photo 6).

Step 11. Firmly place right side inner door flange against the burner door flange and secure with two ¼” drive

screws from step4d(see photo 7). DO NOT OVER TIGHTEN SCREWS.

Step12. Align rightside inner doorto combustion chamber and verify the fastener holes of the combustion

chamber arealignedwith the rightside inner

doorslottedopening (see photo 7). Verify sealintegrity around

combustion opening. Secure rightside inner door using 1/4” hex drive screws from step 4c.

DO NOT OVER TIGHTEN SCREWS. Verify bothburner and rightsides of the inner door are properly

position

ed and sealed against the combustion chamber.

Secure flange with ¼"

drive screws.

Verify threaded hole

alignment with slotted

openings in inner door.

7

Step 13. Reconnectspark igniter/flame sensor wireand simulated resistive device to the gas control (See photos 1&2

on page 14).

Step 14. Reconne

ctthe pilottube to the gas control and tighten.

Step 15. Replace outer jacket burner access door.

Step 16. To resume operation follow the instructions locatedonthe lighting instruction labelo

rthe lighting instructions

locatedinthe installation and operation manual.

Page 16

Page 17

UTTW SERVICE PROCEDURE II

17

R

Burner Operation Inspection,

Cleaning and Replacement

Main Burner Inspection, Cleaningand Replacement

At periodic intervals (not more than6months) a visualinspection should be made of the main burner for proper operation

and toinsure no debris is accumulating.

Main burnershould lightsmoot

hly from pilot and burnwith a blue flame with a minimum of yellow tips.After

approximately 5 minutes of operation the burnerscreen will become radiant and the flame will soften and turnorange.If

the burn

erscreendoes not become radiant after 5 minutes of operation it must be cleaned(see burner cleaning procedure

below).

Main burner must be free from any debris accumulation that may a

ffect burner operation (see burner cleaning procedure

below).

DANGER

Under no circumstances shall flammable materials be used or stored in the vicinity ofthe water heater. If

flammable vapors are present, a fire or explosion may result causingproperty damage,personal injury or

death.

WARNING

Inner door andburner components maybe HOT when performing this operation. Take

necessary precaution to prevent personal injury.

Burner Cleaning

Step1. Remove burner and inner door assembly per SERVICE PROCEDURE I, steps 3 through 4.

Step 2.Remove manifold cover from burner inner door by removing (2) ¼” hex drive screws and then sliding

manifold coverto the right. Useastiff brush, compressed air and/o

build up from the manifold mount.

Step3. Remove manifold brackets from burner by removing (4) ¼” hex drive screws.

rshop vacuum to removeany debris

¼” Hex Drive Manifold

Cover Screws

Manifold Cover

¼” Hex Drive Manifold

Bracket Screws

Page 17

Page 18

UTTW SERVICE PROCEDURE II

18

R

Burner Operation Inspection,

Cleaning and Replacement

Burner Cleaning (Continued)

Step4. Thoroughly inspect burnerscreen and burner venturis and removeany loose debris accumulation. Inspect

burnerscreenfor any openings largerthan the normal screenopenings

Step5. Use compressed air and/or a vacuum to removeany scale or other debris accumulation from the burnerscreen

and venturis.

.

Burner Screen

Burner Venturis

Manifold Brackets

Step6. Disconnect (unscrew) manifold brackets from main

burner orifices.

Main Burner Orifices

Step7. Remove main burner orifice from feed line (1/2"

wrench). Inspect and cleanifnecessary

Step8. Remove pilot assembly, ref

erto SERVICE PROCEDURE III for cleaning and inspection.

Step9. Reassemble burner.

Step 10. Reinstall burner and inner door per SERVICE PROCEDURE I, steps 5 through 16.

Step 11. To resume operation, follow the instructions locatedonthe ligh

instructions locatedinthe installation and operation manual.

Page 18

ting instruction labelorthe lighting

Page 19

UTTW SERVICE PROCEDURE III

19

R

Pilot testing, Cleaning and Replacement

Pilot Assembly Inspection, Testing

and Replacement

Step1. Position gas control power switch to the “OFF”

position and unplug water heater from wall outlet.

Step 2.Remove outer jacket door.

Step3. Remove burner and rightside of inner door

per SERVICE PROCEDURE I, steps

3 and 4.

Step4. Remove burner assembly from combustion chamber.

Step5. Remove pilot/electrodeassembly from burner (¼" drive tool)

Step6. Inspect pilot for kinks or cracks in the pilottube.

If found, the pilot must be replaced.

Step7. Inspec

t pilot orifice:

a)Remove 7/16" nut from bottom of pilot assembly.

b) Remove pilottubeand pilot orifice.

Gas Control shown in the “OFF” position

Pilot

Location

c) inspect pilot orifice for blockage,must be cleanedorreplaced.

¼” Hex Drive

Pilot Screw

Pilot Orifice

Pilot Tube

7/16" Pilot

Assembly Nut

Step8. Install pilot/electrodeassembly toburner, s

ecure with screwfrom step5.

Step9. Install burner and inner door per SERVICE PROCEDURE I, steps 5 through 16.

Step 10. To resume operation follow the instructions locatedonthe lighting instruction labelorthe lighting instr

locatedinthe installation and operation manual.

uctions

Page 19

Page 20

UTTW SERVICE PROCEDURE IV

20

R

Pressure Switch Testing and

Replacement

Pressure Switch Testing

WARNING

115 volt potential exposure. Use caution

Step1. Position gas control powerswitch to

making voltage checks to avoid personal injury.

the “OFF” position.

Step 2.Remove the three screws (Phillipsscrewdriver)from control access cover on blower assembly and

remove cover (see photos 1 and 2).

Step3. Care

With steps 1,2 & 3 complete,

disconnect wire leads from

pressure switch.

Use a multi-meter set to the

ohms setting. With blower off,

check across pressure

switch terminals.

Are switch contacts open?

(no electrical continuity)

fully remove pressure switch from blower housing (see photo 3).

1

Control

Access Cover

Screws

Pressure switch

wire leads

N

Y

Check tubing and pressure tap

on switch for blockage.

Is there blockage?

Y

N

3

Pressure Switch

Slide pressure switch in direction of

arrow while tilting slightly away

from blower housing.

Replace switch

(see page 21)

2

Position gas valve power

switch to the “ON” position

and adjust thermostat

to call for heat,

this will start the blower.

Check with multi-meter, do

pressure switch contacts close

with blower running?

Switch contacts are OK.

See safety circuit trace

(page 31)

Page 20

Clear blockage

Y

Check tubing and

N

Y

pressure tap on

switch for blockage.

Is there blockage?

N

Y

Is vent

system

blocked

Is vent system length

N

within vent table

specifications

listed on page 7

N

Reconfigure vent

system to be

compliant with

vent tables.

Y

Y

See blower testing

(page 22)

Is blower OK?

N

Correct blower

problem.

Page 21

UTTW SERVICE PROCEDURE IV

21

R

Pressure Switch Testing and

Replacement

Pressure Switch Replacement

WARNING

115 volt potential exposure. Use caution

to avoid personal injury.

Step1. Position gas control powerswitch to

the “OFF” position.

Step 2.Remove the three screws (Phillipsscrewdriver)from control access cover on blower assembly and

remove cover (

see photos 4 and 5).

5

4

Control Access

Cover Screws

Pressure Switch

6

Step3. Carefully remove pressure

switch from blower

housing (see photo 6).

Slide pressure switch in direction of

arrow while tilting slightly away

from blower housing.

Step4. Disconnecttubing from

7

pressure switch

(see photo 7).

Step5. Disconnect yellow wires

from pressure switch

(see photo 8).

Step6. Reconnect wires from step5tonewpressure switch.

Step7. Reconnecttubing tonewpressure switch.

Step8. Carefully position pressure switch into blower housing.

Step9. Position gas control power switch to “ON” position and verify proper heater operation.

Step 10. Replace

control access cover from step 2.

8

Page 21

Page 22

UTTW SERVICE PROCEDURE V

22

R

Blower Testing and Replacement

Blower Testing

115 volt potential exposure. Use caution when

making voltage checks to avoid personal injury.

Step1. Position gas control powerswitch

to “ON” position and adjust control to call for heat.

Step 2.Remove the three screws (Phillips Screwdriver)

from control access cover on blower assembly and

remove cover (see photos 9 and 10).

Does blower energize Within 2

minutes?

N

11 12

Does blower energize after 2

minutes, run for 30 seconds

and shut down?

N

pressure switch

Y

tubing from blower

(see photo 11).

Pressure tap

Pressure switch

See pressure switch

Y

Disconnect

tubing

testing

Page 20.

manometer to

pressure tap of

(see photo 11).

Determine voltage

problem and correct.

Connect

blower

14 15

Disconnect vent

system from top of

blower and remove

(see photo 13).

With blower running, and exhaust

adapter removed from top of blower,

is there a negative pressure of -2.15"

N

WARNING

9

Control

Access

Cover

Screws

vent adapter

to -2.30" W.C.?

N

Is there 115vac across blue

and green wires

(see photo 16)?

10

Remove exhaust

adapter

13

Y

Blower OK

Y

Replace blower

Page 22

Disconnect cord set

shown in photo 12. Is

there 115VAC across

terminals shown in photo

14?

N

Is there 115 VAC at

wall outlet?

Y

Check power cord

for damage.

N

Replace blower

Y

N

Y

Is there 115VAC across

terminals shown in

photo 15?

Incorrect supply

voltage polarity

Determine

power source

problem and

correct.

Repair or replace

power cord

Y

N

Replace

cord set

Reconnect cord set shown

in photo 12, is there

115VAC between blue wire

and green ground wire

(see photo 16).

N

Does cord set

N

have electrical

continuity?

Y

Replace gas

control

Y

Replace blower

Green ground

wire

Shown with pressure

switch removed.

16

Blue wire

Page 23

Blower Removal

23

Step1. Position gas control power switch to the “OFF”

position and unplug heater from wall outlet.

Step 2.Disconnect ventsystemfrom exhaust adapter

on top of blower.

UTTW SERVICE PROCEDURE V

R

Blower Testing and Replacement

Gas Control shown in the “OFF” position

Step3. Removeexhaust adapter from blower (bla

screwdriver) and retain for use on new blower.

de

Remove exhaust adapter

and retain for use on

new blower.

Step4. Unplug cord sets from blower.

Step5. Remove the three blower mounting screws

(¼" nut driver).

Step6. Remove blower withgasket from w

ater heater.

Blower Installation

Step7. Clean any debris from jacket headofwater heater.

Step8. Set new blower withgasket in place using locating pins on

blower flange to line up with location holes in jacket head.

Be sure nottodam

Step9. Secure blower in place using mounting screws from step6.

Step 10. Re-install exhaust adapter from step4.

Step 11. Reconnect ventsystem to

exhaust adapter.

age gasket.

Locating Pins

on blower flange

Blower Mounting

Screws

Blower

Cord Sets

Step12.Reconnect cord sets from step5.

Pin location holes in

jacket head

Step 13. Plug blower power cordintowall outlet.

Step 14. Position gas control power switch to the “ON” position.

Step 15. Verify proper blower operation.

Page 23

Page 24

UTTW SERVICE PROCEDURE VI

24

R

Blower Temperature Switch Testing

and Replacement

Blower Temperature Switch

Testing.

Step1. Position gas control powerswitch

to the “OFF” position.

Step 2.Remove the three screws (Phillips

screwdriver)from control access

cover on blower and remove cover

(see photos 17 and 18).

Step 3. Locate blowertemper

(see photo 19).

Switch Setting

Opens on rise @ approximately165°F

Auto resets on fall @ approximately 130°F

Cool switch to

below 130°F

ature switch

WARNING

115 volt potential exposure. Use caution

to avoid personal injury.

Gas Control shown in the “OFF” position

17

Control Access

Cover Screws

19

Blower temperature

switch location

18

Disconnect wire leads to

switch. Using a multi-meter

set to the ohms setting, is

there continuity between the

switch terminals?

Y

Reconnect wire leads and

observe heater operation. Do

exhaust gas temperatures rise

to or above 165°F?

N

Do switch contacts

open?

N

Switch OK

Page 24

Y

N

Y

Replace switch

(see page 25).

Replace switch

(see page 25).

N

Do switch contacts

open?

Y

temperature is too

Air mixing inlet

Exhaust

hot.

Common causes for

high exhaust temperature

1. Vent length is below minimum allowable.

2. Vent diameter not to specification.

3. Restricted dilution air inlet.

4. Missing or deteriorated flue baffle.

5. Gas pressure is out of specification.

Page 25

UTTW SERVICE PROCEDURE VI

25

R

Blower Temperature Switch Testing

and Replacement

Blower Temperature Switch

Replacement.

Step1. Position gas control power switch to the “OFF” position

and unplug water heater from wall outlet.

Step 2.Remove the three screws (Phillipsscrewdriver)from the

control access cover on blower and remove cover

(see photo 20 and 21).

20

Control Access

Cover Screws

WARNING

115 volt potential exposure. Use caution

to avoid personal injury.

Gas Control shown in the “OFF” position

21

Step 3. Locate blowertemperature switch (see photo 17)

Step4. Disconnectred and yellow wire leads from switch.

Step5. With an appropriate tool such asside cutters, snip the

retaining lug from t

he blower housing to allow removalof

temperature switch (see photo 18).

Step6. Remove switch from blower housing.

Step7. Install new switch. Be sure switch is properly seatedin

mounting area.

Step8. Reconn

ectred and yellows wirestonew switch. Wires are

interchangeable with eitherterminal.

Step9. Position gas control power switch to the “ON” position

and verify proper heater operation.

Step 10. Replace control access cover from st

ep 2.

22

23

Blower temperature

switch location

Snip retaining lug

from blower housing

Page 25

Page 26

UTTW SERVICE PROCEDURE VII

26

R

Gas Control Testing and Replacement

Gas Control Replacement

Step1. Rotate knob of the gas control

to the “OFF” position.

Step 2. Turn off gassupply towater heater.

Step3.Disconnect gassupply line from gas control.

Step4.Turn off watersupply and drain water heater completely.

ep5.Remove the wire clip from the feedline.

St

Gas Control shown in the “OFF” position

Step6.Disconnect main burner feedline, pilottube,white thermopile wireand igniter wire from gas control and bend

the main burner feedlineand pilottube out of the

way. Alsodisconnectthe redwire leading from the thermopile

from the redwire leading from the gas control.

Step7. Remove the gas control from the water heater by rotating counter-clockwise.I

t maybe necessary tousealength

of ½” NPT pipe threaded into the inlet of the gas control.

Pilot tube

Igniter wire

White thermopile

Main burner

feedline

wire

Red Wire Leads

Step8.Install newgas control into the water heater.

a)Install gas control intowater heater by rotating clockwise.DONOT useawrench on the gas contr

body or damage to the gas control may occur.Ifnecessary, use a length of ½” NPT pipe threaded into

gas inlet of gas control.

b) Position the main burner feedlineand pilottube back to the gas control and attach to the gas control.

Connec

the gas control to the resettable thermal switch and connectthe redwire from the

tthe igniter wireand the white thermopile wire to the gas control. Connectthe redwire from

thermopile to the

resettable thermal switch.

c) Gatherthe igniter wire, white thermopile wireand red thermopile wire nearthe side of the feedline.

Use the clip that wasr

emovedinStep5to secure the wiresto the feedline.

d) Connect gassupply to inlet of gas control.

Step9.Resume the watersupply to the water heater.Be sure thatthe tank is full before

operation isresumed.

Step 10. Check the main burner feedlineand pilot feedline for gas leaks.

Step 10. To resume operation follow the instructions locatedonthe lighting instruction labelorthe lighting

uctions locatedinthe installation and operation manual.

instr

Page 26

ol

Page 27

UTTW SERVICE PROCEDURE VII

27

R

Gas Control Testing and Replacement

ManifoldPressure Testing (this procedure presumes a maximum line pressure of 14.0"

w.c.)

Gas Control shown in the “OFF” position

Step1. Position gas control power switch to the “OFF” position.

Step 2.Remove pressure tap plug (3/16" hexwrench) and install

1/8" NPT pipe, coupling, & pressure tap.

Step 3. Connect manometertopressure tap.

Step 4. Follow instructions locatedonthe lighting

instructions la

burner and observe manometerreading.

Step5. Proper operating range for naturalgas is: 5.0" ±0.5" w.c.

bel and proceed to lightthe main

Step6. Ifpressure is within the range specifiedinth

e previous

step, position gas control power switch to the “OFF”

position, remove manometer and pressure tap, and

replace pressure tap plug. Check for gas leaks priorto

placing water heater back intooperation by following

the instructions

locatedonthe lighting instruction labelor

the lighting instructions locatedinthe installation and

operation manual.

Step7. Ifgas pressure is outside the specification noted above,

Pressure Tap

Plug

refer to “Gas Control Testing and Replacement” to replace

Gas Control or v

alve body.

Pressure Tap

Shown Installed

ECO (Energy Cut Out) Testing

TheHoneywell Gas Control is designedwith an ECO device that will reset.

To resetthe Gas Control after an error code (4), rotate the set-point knob to the minimum temperature sett

6 seconds and then rotate the set-point knob clockwise by at least 45o. This will resetthe gas control and return the water

heatertonormaloperation.

ing for at least

Page 27

Page 28

UTTW SERVICE PROCEDURE VIII

28

R

Simulated Resistive Device Testing

Simulated Resistive Device Testing

Step1. Position powerswitch on gas control to the

“OFF” position.

Step 2.Disconnectsimulated resistive device from

gas control.

Step3. Using a multi-metersetto the ohmssetting

check resistance of simul

device.Resistance must be within 25,000

ohms and 45,000 ohms.Ifoutside of this

range replace the simulated resistive device.

If there is no continuity test the resettabl

thermal switch by following SERVICE

PROCEDURE IX. If the resettable thermal

switch is closed replace the simulated

resistive device

ated resistive

e

Simulated

Resistive device

Page 28

Multi-meter set to

ohms setting

Electronic

“pin type”

Meter Probes

Resettable Thermal

Switch

Simulated

Resistive device

Page 29

Resettable Thermal Switch Continuity Testing

29

Step1. Remove outer jacket door.

Step 2.Disconnectredwire leads from resettable thermal switch.

UTTW SERVICE PROCEDURE IX

R

Resettable Thermal Switch Testing

and Replacement

Red Wire Leads

Step3. Using a multimeter capable of measuring con

tinuity(Ohms),

place one probe of meter on one of the brass connection tabs of

the resettable thermal switch, and the remaining probe on the

other connection tab.

Step4. Ifcontinuityi

s indicated, the switch is closed, allowing currenttopass.

Step5. Ifcontinuityis not indicated, the switch is open, possibly due to anover heating condition. The switch is

designed toopen at predetermined

temperatures.Anopen switch canbe reset by depressing the red colored

button located atthe center of the switch. The overheating condition must be determinedpriortoputting the

ter heater back in service.

wa

PROBABLE CAUSE FOR RESETTABLE THERMALSWITCH ACTIVATION

PROBABLE CAUSE CORRECTIVE ACTION

1. Inspect burner per SERVICE PROCEDURE II

Burner Failure

2. Replace burner per SERVICE PROCEDURE II

Weak switch or switch

out of calibration.

1. Replace resettable thermal switch

Page 29

Page 30

UTTW SERVICE PROCEDURE IX

30

R

Resettable Thermal Switch Testing

and Replacement

Resettable Thermal Switch Replacement

Step1. Position gas control powerswitch to

the “OFF” position.

Step 2.Remove outer jacket door.

Step3. Disconnectredwire leads from resettable thermal switch.

Step4. Remove (2) ¼” hex drive screws from the manifold

cover and slid t

assembly.

Step6. Remove resettable thermal switch from manifold

cover (Phillipsscrewdriver).

o the rightto remove from burner

Phillips Screws

Gas Control shown in the “OFF” Position

¼” Hex Drive Manifold

Cover Screws

Red Wire Leads

Manifold Cover

Step7. Place new resettable thermal switch in place.Be

sure contactsurface of resettable thermal switch and

manifold cover are free of any debris.Secure resettable thermal switch intoplace using screws from step6.

DO NO

T OVERTIGHTEN SCREWS.

Step8. Place manifold cover back in position and secure using the screws from step4.

Step9. Reconnect wire leads from gas control and thermopile to resettable th

Note: Wire termination is interchangeable with eitherresettable thermal switch connection.

Step 10. Replace outer jacket door.

Step 11. To resume oper

ation follow the instructions locatedonthe lighting instructions labelorthe lighting

instructions locatedinthe installation and operation manual.

Page 30

ermal switch.

Page 31

Safety Circuit Voltage Trace

31

U TTW SERVICE PROCEDURE X

R

Safety Circuit Voltage Trace

WARNING

115 volt potential exposure. Use caution

making voltage checks to avoid personal injury.

NOTE: This procedureassumes a cool tank.

Step1. Remove three screws (Phillips

Screwdriver)from control

access cover on blower and

remove cover (see photo 24

and 25).

Position gas control switch to the “ON”

position and adjust thermostat dial to call

for heat, Is there 10 to 13 VAC between red

wire leading to blower temperature switch

and green ground wire?

Blower must be running

voltage check

(see photo 26).

Is there 10 to 13 VAC between yellow wire

leading from pressure switch and green

ground wire

(see photo 26)?

during this

Y

Y

N

N

Is LED on gas valve flashing the

“heartbeat” code (alternating

bright/dim)

N

Verify 115VAC to gas

control (see page 32).

Y

temperature switch

24

Control Access

Cover Screws

No voltage from gas control,

call for technical support.

Is there continuity

through blower

(see page 24)?

N

25

Y

Check for loose or

broken wire connection

at switch terminals.

Do you hear or can you see

the igniter sparking?

Y

Safety circuit

voltage is OK.

If burner does not light,

observe LED flash code on

gas valve and refer to

troubleshooting section on

page 12.

Determine cause of blower

Correct igniter/

sensor problem.

N

Check igniter/sensor

(see page 19).

is igniter/sensor OK?

26

temperature switch activation

and correct.

Faulty cord set or

Y

gas control.

Green ground wire

Red wire leading to

blower temp. switch

Yellow wire

leading from

pressure switch

Page 31

Page 32

U TTW SERVICE PROCEDURE XI

32

R

115 VAC Trace

115 VAC Circuit Trace

115 volt potential exposure. Use caution

WARNING

making voltage checks to avoid personal injury.

Step1. Verify 115VAC and proper polarity at wall outlet.

Step 2. With unit plugged in and control power switch in the “ON” position verify LED status.

LED status

None, Control LED not

on or flashing.

Disconnect cord set as

shown in photo 27.

Using a volt meter set to

volts AC, is there 115VAC

across terminals shown

in photo 28?

Y

Is there 115VAC across

terminals shown in

photo 29?

N

Incorrect supply

voltage polarity

N

Y

LED status

Short flash, once every

four seconds.

Waiting for

call for heat.

Reconnect cord set

shown in photo 27.

Disconnect wire harness

from gas control

(see photo 30).

LED status

“Heartbeat”, alternates

bright/dim.

Thermostat calling

for heat

27

Check for damage to AC

supply power cord.

N

Replace Blower

28

Y

Wire harness

LED status

Various flashing error

codes.

Verify error code as

listed on page 12

Repair damage

29

30

Locate black & white wires at connector, It

may be necessary to pull back wire sheath

to identify wire colors

(see photo 31).

Is there 115VAC across

black & white wires as

shown in photo 31?

N

Call for technical

support.

Page 32

31

Wire sheath pulled back to

identify wire colors

Y

Replace gas

control.

Check for 115VAC between black & white wires.

-NOTE-

Electronic meter probes required. Use care not to

damage connector during this check.

Page 33

U TTW SERVICE PROCEDURE XII

33

R

Dip Tube

Inspection and replacement

Dip Tube Inspection and Replacement

WARNING

Water Heater components and stored water maybe HOT when performing the following

steps in this procedure. Take necessary precaution to prevent personal injury.

Gas Control shown in the “OFF” Position

Step1. Position gas control power switch to the “OFF”

position and unplug water heater from wall outlet.

Step 2. Turn off cold watersupply towater heater. Connect hose todrain valve of water heater and route to an

opendrain. Open a nearby hot water faucettovent heater for draining. Opendrain valve of water

heater and allow heatertodrain to a point below the inlet connection nipple.

Step3. Disconnect inle

t nipple from plumbing system.

Step4 With an appropriate tool such as a pipe wrench, remove inlet nipple/dip tube from the water heater.

Use caution nottodamage pipe threads.

Step5. Vi

sually inspect inlet nipple/dip tube. Inlet nipple/dip tube should be free of cracks and any blockage.

Hydro-jetslots should be open and free of any blockage.

Any damage such as cracks, restriction due todeformat

ion or unintentionalholes are not field

repairableand the inlet nipple/dip tube must be replaced.

Step6. Upon completion of inspection orsubsequentreplacement, reinstall inlet nipple/dip tube in

towater

heater. Connect nipple to plumbing system, resume watersupply and refill withwater.

Step7. To resume operation follow the instructions locatedonthe lighting instruction labelorthe lighting

tions locatedinthe installation and operation manual.

instruc

Page 33

Page 34

U TTW SERVICE PROCEDURE XIII

34

R

Anode

Inspection and replacement

Anode Inspection and Replacement

Water Heater components and stored water maybe HOT when performing the following

steps in this procedure. Take necessary precaution to prevent personal injury.

Step1. Position gas control power switch to the “OFF”

position and unplug water heater from wall outlet.

WARNING

Gas Control shown in the “OFF” Position

Step 2. Turn off cold watersupply towater heater. Connect hose todrain valve of water heater and route to an

endrain. Open a nearby hot water faucettovent water heater for draining. Opendrain valve of

op

water heater and allow water heatertodrain to a point below the outlet connection nipple

.

Step3. Disconnect outlet nipple from plumbing system.

Step4 With an appropriate tool such as a pipe wrench, remove outlet nipple/anode from the water heater. Use

caution nottodam

age pipe threads.

Step5. Visually inspect outlet nipple/anode.Outlet nipple/anode should show signs of depletion, this is

normal. If depletion is ½ofthe original anode diameter (approximately ¾” diameter), repl

acement is

recommended. If any of the steelcore of theanode is exposed, replacement isrecommended.

Step6. Upon completion of inspection orsubsequentreplacement, reinstall outlet nippl

e/anode intowater

heater. Connect nipple to plumbing system, resume watersupply and refill withwater.

Step7. To resume operation, follow the instructions locatedonthe lighting instruction labelorthe

lighting

instructions locatedinthe installation and operation manual.

Page 34

Page 35

U TTW SERVICE PROCEDURE XIV

35

R

Flue Baffle

Inspection and replacement

Remove blower to gain access to

Disconnect vent system

from exhaust adapter.

flue baffle

Step1. Position gas control power switch to the “OFF” position

and unplug water heater from wall outlet.

Step 2.Disconnect ventsystemfrom exhaust adapter on top of

blower.

Step3. Unplug cord sets from blower.(see photo 33).

p4. Remove the three blower mounting screws

Ste

(¼" nut driver)(see photo 33).

Step5. Remove blower withgasket from water heater.

Step6. Remove flue baffle from Heater (see photo 34).

Step7. Inspec

Step8. Reinstall baffle into flue tube.Be sure baffle

t baffle for deterioration, missing restrictors.

Clean any scale or debris build up. Replace withnew

baffleas necessary.

ertab are insertedintonotch location atthe

hang

top of the flue tube (see photos 35 & 36).

33

Blower

Cord Sets

34

Blower Mounting

Screws

Flue Baffle

Step9 Check Burnertoinsure no scale has accumulatedduring

this operation. See burner cleaning procedure on pag

e 14.

Step 10. Reinstall blower on water heater. Connect vent

system and cordssetto blower. Plug water heater

intowall outlet.

Step 11. To resume operation follow the lighting instruction

locatedonthe

lighting instruction labelorthe lighting

instruction locatedinthe installation and operation

manual.

35

Flue tube

notch

36

Baffle shown

installed in flue

tube notch.

Page 35

Page 36

Glossary ofTerms

36

BTU British Thermal Units

GPM Gallons per Minute

Hz Hertz

KWh Kilowatt hour

LED Light Emitting Diode

NPT National Pipe Thread

Ohms Ohms (resistance)

PSI Pounds per Square Inch

RPM Revolutions per Minute

ECO Energy Cut Out

VAC Volts Alternating Current

W.C. Inches of Water Column

°C Degrees Centigrade

°FDegrees Fahrenheit

NOTES

Page 36

Page 37

NOTES

3

37

Page

Page 38

NOTES

38

Page 38

Page 39

Parts List

39

1.Flue Baffle

2.Inlet Dip Tube

3. Inner Door Gasket Kit

4. Hot Water Outlet Anode

5. Heat Trap Inlet

6. Heat Trap Outlet

7. Blower Assembly

8. T&P Valve

9. Outer Door

10. Gas C

11. Gas Control Wire Harness

12. Brass Drain Valve

ontrol

13. Ultra Low NOx Burner

14. Right Side Inner Door Assembly

15. Pilot Assembly

16. ¼” Manifold Mount Hex Head Screw

17. Manifold Mount

18. Main Burner Orifi

19.Main Burner Feedline

20. Resettable Thermal Switch

21.ManifoldCover

22. ¼” Manifold Cover Hex Head Screw

23. Burner Door

24. Main Burner Assembly

ce

Page 39

Page 40

Loading...

Loading...