Page 1

Save this manual for future reference

Manual 238-50628-00A

SERVICE

MANUAL

Troubleshooting Guide

and Instructions for Service

(To be performed ONLY by

qualified service providers)

Models Covered

by This Manual:

U175S*RN

U2XR75S*RN

U100T*RN

U75T80R*N

U100T88R*N

(*) Denotes Warranty Years

Ultra Low NOx Gas Water Heaters

Atmospheric ECO-MAGNUM SERIES

™

Page 2

The Bradford White

2

Atmospheric ECO-MAGNUM

Ultra Low NOx Gas Water

Heaters

Table of Contents

Burner and Inner Door Gasket Removal, Inspection, Replacement

Page Service Procedure

---4noitcudortnI

---4ecivreSrofderiuqeRslooT

---5trahCgnitoohselbuorTlortnoCsaG

I7noitallatsnIdna

emecalpeRdnagnitseTelipomrehT

tseTedortcelEdnaretingI

nInoitarepOrenruB

dnaebuTpiD

II01tn

III21tnemecalpeRdnagninaelC,noitcepsnIylbmessAtoliP

VI31tnemecalpeRdnagni

V41tnemecalpeRdnagnitseTlortnoCsaGllewyenoH

IV61tnemecalpeRdnagninaelC,noitceps

IIV81tnemecalpeRdnagnitseThctiwSlamrehTelbatteseR

IIIV02tnemecalpeRdnanoitcepsnIedonA

---32tsiLstraPcireneG

Page 2

Page 3

ECO-MAGNUM

3

75/100-Gallon Atmospheric

WARNING

If the information in these instructions is not

followed exactly, a fire or explosion may result

causing property damage, personal injury, or

death.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable,

combustible, or corrosive vapors and liquids in

the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

x Do not touch any electrical switch; do not use any

phone in your building.

x Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

x If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

WARNING

Water heaters are heat producing appliances. To

avoid damage or injury, do not store materials

against the water heater or vent-air intake system.

Use proper care to avoid unnecessary contact

(especially by children) with the water heater and

vent-air intake components. UNDER NO

CIRCUMSTANCES MUST FLAMMABLE MATERIALS,

SUCH AS GASOLINE OR PAINT THINNER BE USED OR

STORED IN THE VICINITY OF THIS WATER HEATER,

VENT-AIR INTAKE SYSTEM OR IN ANY LOCATION

FROM WHICH FUMES COULD REACH THE WATER

HEATER OR VENT-AIR INTAKE SYSTEM.

CAUTION

If sweat fittings are to be used DO NOT apply heat to

the nipples on top of the water heater. Sweat the

tubing to the adapter before fitting the adapter to

the water connections. It is imperative that heat is

not applied to the nipples containing a plastic liner.

WARNING

Hydrogen gas can be produced in an operating water

heater that has not had water drawn from the tank

for a long period of time (generally two weeks or

more). Hydrogen gas is extremely flammable. To

prevent the possibility of injury under these

conditions, we recommend the hot water faucet to

be open for several minutes at the kitchen sink

before you use any electrical appliance which is

connected to the hot water system. If hydrogen is

present, there will be an unusual sound such as air

escaping through the pipes as hot water begins to

flow. Do not smoke or have open flame near the

faucet at the time it is open.

Incorrect operation of this appliance

CAUTION

may create a hazard to life and

property and will nullify the warranty.

DANGER

Do not store or use gasoline or other

flammable, combustible, or corrosive

vapors and liquids in the vicinity of

this or any other appliance.

IMPORTANT

Before proceeding, please inspect the

water heater and its components for

possible damage. DO NOT install any

water heater with damaged

components. If damage is evident

then please contact the supplier where

the water heater was purchased or the

manufacturer listed on the rating plate

for replacement parts.

WARNING

DO NOT ATTEMPT TO LIGHT ANY GAS APPLIANCE IF YOU

ARE NOT CERTAIN OF THE FOLLOWING:

x Liquefied petroleum gases/propane gas and natural

gas have an odorant added by the gas supplier that

aids in the detection of the gas.

x Most people recognize this odor as a “sulfur” or

“rotten egg” smell.

x Other conditions, such as “odorant fade” can cause

the odorant to diminish in intensity, or ”fade”, and

not be as readily detectable.

x If you have a diminished sense of smell, or are in

any way unsure of the presence of gas, immediately

contact your gas supplier from a neighbor's

telephone.

Gas detectors are available. Contact your gas supplier,

or plumbing professional, for more information.

WARNING

FAILURE TO INSTALL AND MAINTAIN A NEW, LISTED 3/

4” X 3/4” TEMPERATURE AND PRESSURE RELIEF VALVE

WILL RELEASE THE MANUFACTURER FROM ANY CLAIM

THAT MIGHT RESULT FROM EXCESSIVE TEMPERATURE

AND PRESSURES.

Page 3

Page 4

How to Use This Manual

4

ECO-MAGNUM

75/100-Gallon Atmospheric

Introduction

It is intendedfor this manualto be usedbyqualified service personnelfor the primarypurpose of

troubleshootingand repair ofthe BradfordWhite Atmospheric Ultra Low NOx Series ofwater

heaters.

The Honeywell Gas C

codes are listed inthe troubleshootingchartbeginningonpage 5 ofthis service manual. The

troubleshootingchartwill also indicate the p

professionalto a service procedure to properly diagnose theabnormal operation.

Contactthe BradfordWhite technical support group immediately ifdiagnosis cannotbe mad

using the methods described inthis service manual.

ontrolwill display error codes intheevent of abnormal operation. Error

robablecause for the error codeand directthe service

e

Tools Requiredfor Service

Manometer: A liquid “U” tube type or a digital type can be used.This device is used

to measure gas and/or air pressure and vacuum.

Multi-Meter:Adigital typeisstrongly recommended. This device is usedto measure

electricalvalues.The meter you selectmusthave thecapa

measure volts AC, volts DC, Amps,micro-ampsand ohms.

Electronic Probes:Insome cases, standard multi-meter probes will damage or simply

notbeeffective toobtain certainvoltage and ohm reading.Itwill b

necessary to have special electronic “pin” type multi-meter probes.

These probes are availableatmost electronic wholesaleoutlets.

bility to

e

Thermometer:Usedto measure water temperature.Anaccurate thermometer is

recommended.

Water Pressure Gage:U

Various Hand Tools:Pipe wrench, channellocks, open end wrenchs

Page 4

sedto measure water supply pressure.Also usedto determine tank

pressure by adapting to the drainvalveofthe heater.

(3/8",7/16",½"),

12" crescent wrench, Allenwrench set, screwdrivers (common&

Phillips), ¼" nut driver,pliers (common&needle nose), socket set, side

cutters,wire cutters,wire strippers,wire crimpers,torpedo level, small

shopvac, ste

pladder,flashlight and 5 gallonpail.

Page 5

pag

(

p

g

p

ECO-MAGNUM

5

75/100-Gallon Atmospheric

Gas Control Troubleshooting

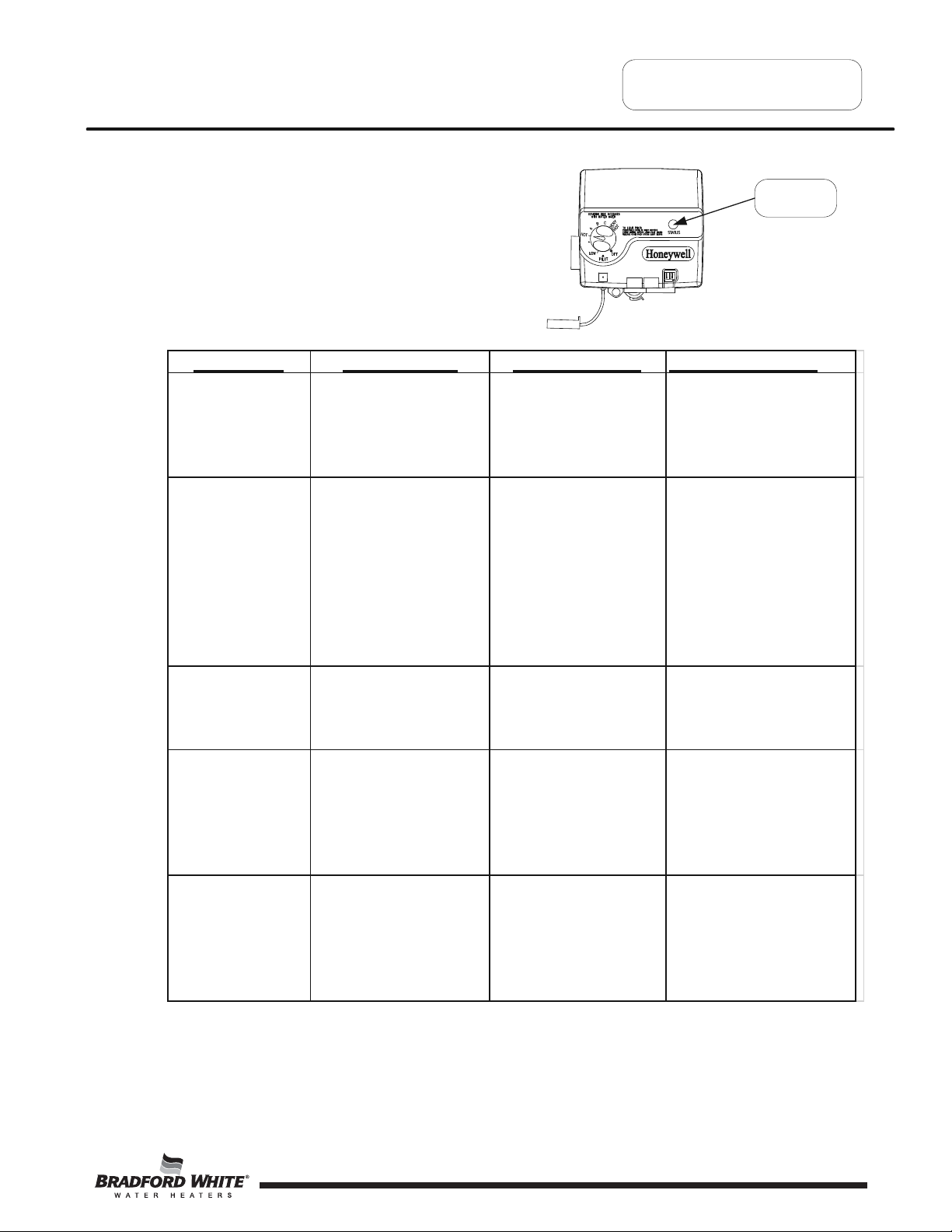

Observe green LED indicator on

gas control. Errorflashcodes are

displayedwith athree second

pause before repeating. Check

andrepair thesystem as noted in

thetroubleshooting table below.

LED Status Control Status Probable Cause Service Procedure

If the pilot will not stay lit

None (LED not on

or flashing)

One flash and

three second

pause.

LED strobe (two

quick flashes) and

three second

ause.

LED on

co nti nuously.

Two flashes and

three second

pause.

Gas valve is not

powered.

1. If set point knob is in

"PILOT" position then

pilot flame is detected.

Turn set point knob to

desired setting

2. If set point knob is at

desired

valve is waiting for a

call for heat

Thermostat calling for

been recently turned to

Wait unti l LED goes out

before attempting to

detected. Syst

reset wh en pilot flame

settin g the gas

no faults).

heat (no faults).

Set point knob has

the "OFF" position.

ht

reli

Weak pilot flame

em will

is sufficient.

1. Pilot flame is not

present. Light pilot.

1. Gas valve is

powered and waiting

for the set point knob to

be turn ed to a water

temperature setting.

2. Temperature

demand is satisfied.

Tank temperature

below setpoint of

thermostat.

Set point knob was

turned to "OFF"

position.

1. Thermopile failure

2. Unstable pilot.

3. Pilot tube block or

restricted.

4. Resettable thermal

switch has o

ened.

replace thermopile, see

page 11. If problem

pe

rsists replace gas

valve, see

Normal operation.

thermostat to desired

temperature level.

Normal operation.

LED will go out and the

control will function

normally wh en the pilot is

lit.

1. See page 10.

2&3. See page 12.

4. See page 18.

GreenLED

Indicator

e 15.

Adjust

Page 5

Page 6

p

y g

g

pag

Gas ControlTroubleshooting

6

LED Status Control Status Probable Cause Service Procedure

ECO-MAGNUM

75/100-Gallon Atmospheric

Three flashes

and th ree

second

pause.

Four flashes

and th ree

second

ause.

Five flashes

and th ree

second

pause.

Seven flashes

and th ree

second

pause.

Eight flashes

and th ree

second pause

Insufficient water

heating. System will

reset.

Excessive tank

temperature. System

must be reset.

Thermostat well fault.

Gas valve electronic

fault detected.

False pilot flame

present.

1. Thermowell

sensor and chamber

temperature sensor

out of calibration.

2. Possible short.

1. Thermowell

sensor out of

calibration.

2. Fault

1. Damage to the

thermowell wire.

2. Thermowell

sensor resist

out of ran

1. Control needs to

be reset

2. Control is wet or

physic

Pilot valve stuck in

open position.

as valve.

ance

e.

ally damaged

1&2. Rep

control, see page 15.

1. See page 14.

2. Replace gas control,

see page 15.

1&2. Replace gas

control, see page 15.

1.Turn gas control knob

to "OFF" position and

then follow lighting

instructions.

2. Replace gas control,

see

Replace gas control, see

page 15.

lace gas

e 15.

Page 6

Page 7

ECO-MAGNUM

7

75/100-Gallon Atmospheric

SERVICE PROCEDURE I

Burner and Inner Door/Gasket Removal,

Inspection, Replacement and

Reinstallation

Inner Door Removal Procedure

Step 1. Rotate the gas control knob to the “OFF”

position.

Step 2. Remove outer jacket burner access door.

Step 3. Remove wire clip from main burner feedline.

Step 4. Inner Door Removal.

a) Disconnect red thermopile lead and red gas control lead from

resettable thermal switch. Disconnect white thermopile lead

from the gas valve (see photos 1 and 2).

b) Disconnect main burner feed line (¾” wrench), pilot tube

(7/16" wrench) and igniter wire from gas control (see photo 2).

c) Remove (2) ¼” hex drive screws from right side inner door

(see photo 3).

d) Remove (2) ¼” hex drive screws from flange section of

inner door (see photo 3).

e) Remove (3) 1/4" hex drive screws from burner door

(see photos 4&5). The burner door and burner are

one-piece.

3

Gas Control KnobShownIn

“OFF” Position

Pilot Tube

1

Red Thermopile Lead

Red Gas

Control Lead

White Thermopile

Lead

2

Main Burner

Feedline

Flange Hex

Drive

Screws

Position #2

Position #3

Right Side

Hex Drive

Screws

Burner Door

Hex Drive

Screws

4

Igniter Wire

5

f) Remove burner and inner door and inspect per step 5.

Step 5. Fully inspect burner door and right side inner door gaskets for the following:

>Tears >Other imperfections that will inhibit proper seal

>Missing Material >Gasket adhesion to inner door

>Cracks >Material left on combustion chamber (around opening)

>Dirt or debris

If the gasket is not effected by any of the above, gasket replacement is not required. If replacement is

required, proceed to Inner Door Gasket Replacement Procedure.

Position #1

Page 7

Page 8

SERVICE PROCEDURE I

8

Burner and Inner Door/Gasket Removal,

ECO-MAGNUM

Inspection, Replacement and

Reinstallation

Inner Door Gasket Replacement Procedure

WARNING

If the information in these instructions is not

followed exactly, a fireor explosion may result causing

property damage, personal injuryordeath.

Step 6. After inspection of inner door as noted in step 5, completely remove gasket and adhesive residue from burner

door and right side inner door as needed.

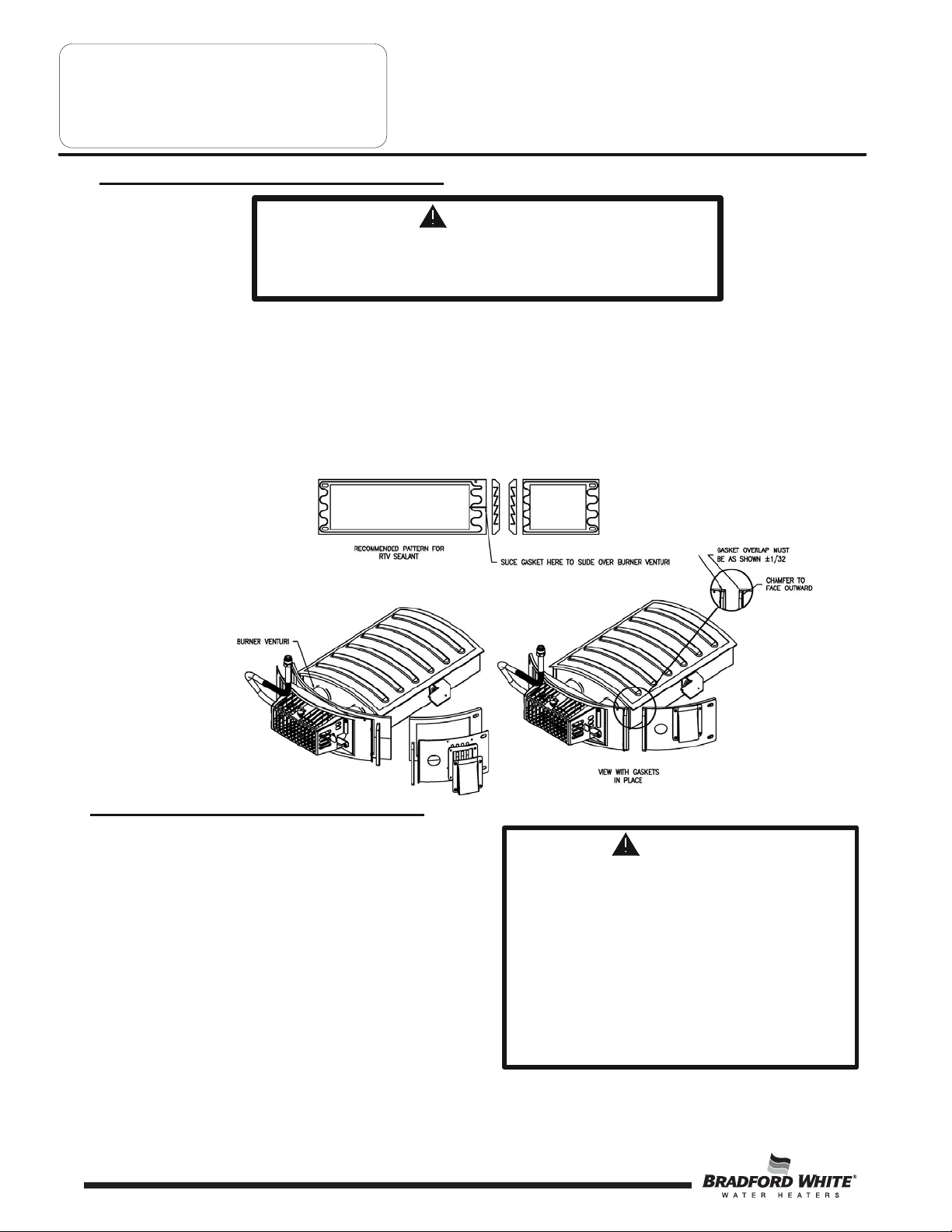

Step 7. Use RTV sealant (recommended bead size 1/8") to secure the inner door gasket to the inner door sections

(right & burner). The burner door gasket must be sliced in the location shown on the illustration below in

order to slide the gasket over the burner venturi. Refer to illustration below for proper RTV sealant

application. Note the overlap configuration in the flange area of the inner door. Ensure that the chamfer of

the gasket faces outward. Set the flange section first, this will help to achieve the proper overlap position.

75/100-Gallon Atmospheric

Re-installation of Inner Door With Gasket

Step 8. Clean any residual gasket residue or other debris

from combustion chamber surface before

re-installing the inner door/gasket assembly.

Step 9. Place the burner door into position first. Tighten

the feed line nut to the gas control. Use the ¼”

hex drive screw without the built-in washer to

secure burner door to the chamber at position #1.

Use the ¼” hex drive screws with the built-in

washer to secure the door at positions #2 & #3

(see photos 4&5, on page 7).

DO NOT OVER

Page8

TIGHTEN SCREWS.

WARNING

Stripped fastenerconnections may allow

for seal breach of innerdoor. A seal

breach may result in a fireor explosion

causing property damage, personal injury

ordeath. Do not over tighten screws in

steps 9, 11 and 12.

If a fastenerconnection is stripped,

contact the manufacturer listed on the

water heaterrating plate.

Page 9

ECO-MAGNUM

9

75/100-Gallon Atmospheric

SERVICE PROCEDURE I

Burner and Inner Door/Gasket Removal,

Inspection, Replacement and

Reinstallation

Position ThermopileWire,

Pilot Tube and Igniter Wire

6

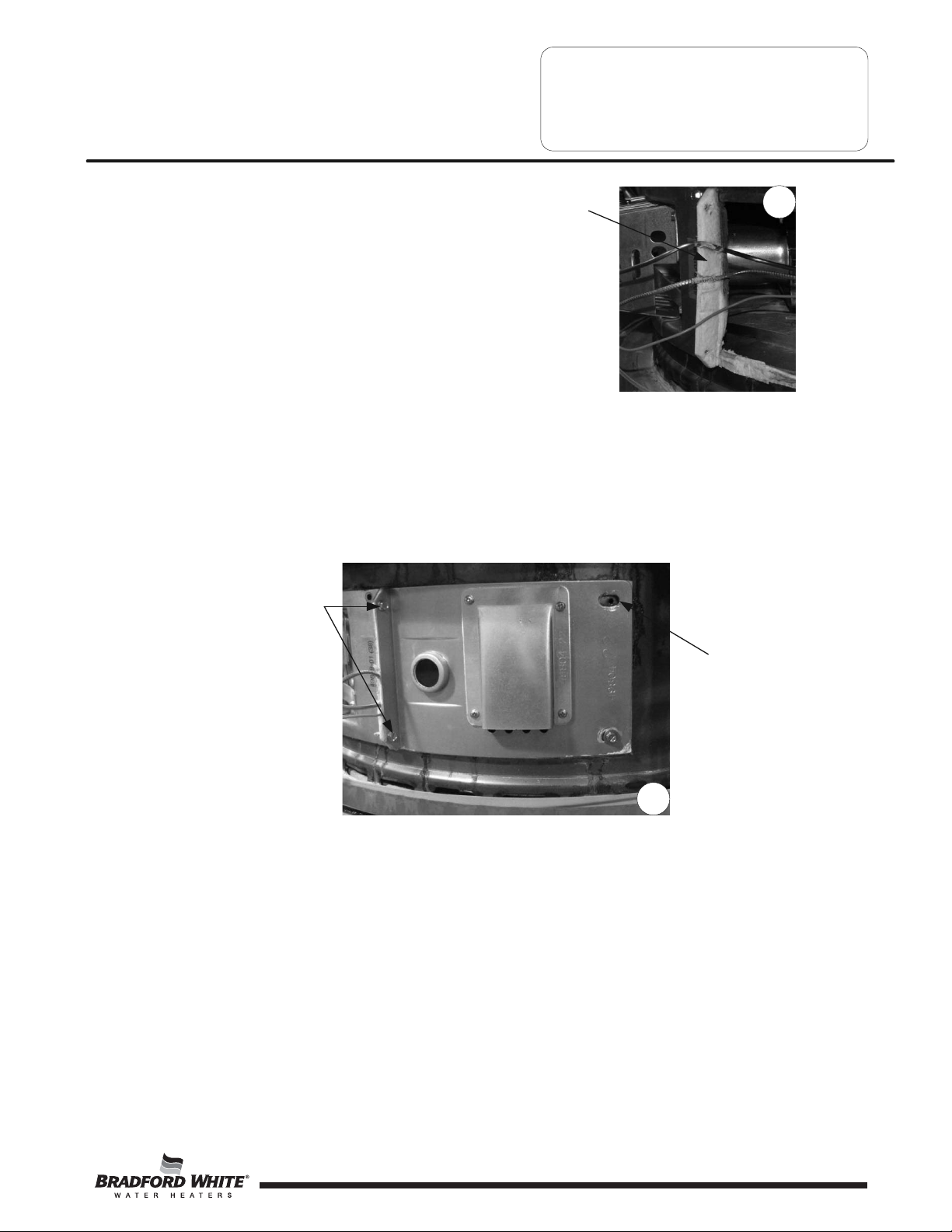

Step 10. Position thermopile wires, pilot tube and igniter wire

against burner door flange gasket

(see photo 6).

Step 11. Firmly place right side inner door flange against the burner door flange and secure with two ¼” drive

screws from step 4d (see photo 7). DO NOT OVER TIGHTEN SCREWS.

Step 12. Align right side inner door to combustion chamber and verify the fastener holes of the combustion

chamber are aligned with the right side inner door slotted opening (see photo 7). Verify seal integrity around

combustion opening. Secure right side inner door using 1/4” hex drive screws from step 4c.

DO NOT OVER TIGHTEN SCREWS. Verify both burner and right sides of the inner door are properly

positioned and sealed against the combustion chamber.

Secureflangewith¼"

drive screws.

Verify threaded hole

alignment with slotted

openings in inner door.

7

Step 13. Reconnect red gas valve lead and red thermopile lead to resettable thermal switch. Reconnect white gas

control lead to the gas valve (See photos 1&2 on page 7).

Step 14. Reconnect the pilot tube to the gas control and tighten. Reconnect the igniter wire to the gas control.

Step 15. Replace outer jacket burner access door.

Step 16. To resume operation follow the instructions located on the lighting instruction label or the lighting instructions

located in the installation and operation manual.

Page 9

Page 10

SERVICE PROCEDURE II

10

ECO-MAGNUM

Thermopile TestingandReplacement

75/100-Gallon Atmospheric

ClosedCircuit Thermopile Testing

Step 1. Closed circuit testing is the preferred method for testing thermopile. Following the lighting instruction

label on the heater, proceed to light the pilot and allow to operate for three minutes. If the pilot will not stay

lit, hold the pilot button (rotate the gas control knob to the pilot position, push and hold in) during this test.

Step 2. Open the thermopile wire access covers. Using a multimeter capable of measuring DC millivolts, place one

lead of the multi meter on the left side of the wire harness and place the second lead of the multi meter on

the right side of the wire harness.

Step 3. If the meter reads 300 DC millivolts or higher, the thermopile is OK. If reading is below 300 DC

millivolts, replace the thermopile. For maximum thermopile life the thermopile should be replaced with a

genuine Honeywell thermopile (BWC P/N 233-47063-00).

ThermopileAccess Covers

Left Side ofWireHarness

Right Side ofWireHarness

Open Circuit Thermopile Testing

Step 1. Disconnect white thermopile wire from wire harness leading to the gas valve. Disconnect the red thermopile

wire from the resettable thermal switch

Step 2. Using a multimeter capable of measuring DC millivolts,

connect one lead to the red thermopile wire and one

lead to the white thermopile wire.

Step 3. Following the lighting instruction label on the heater, proceed to light the pilot and allow to operate for

three minutes. It will be necessary to hold gas control knob down in the “PILOT” position continuously

throughout this test. Any reading over 400 DC millivolts indicates good thermopile output.

Page 10

Page 11

ECO-MAGNUM

11

SERVICE PROCEDURE II

75/100-Gallon Atmospheric

Thermopile TestingandReplacement

Thermopile Replacement

Step 1. Turn off gas supply to water heater. Rotate gas control knob to the “OFF” position.

Step 2. Remove outer jacket door.

Gas Control shown in the “OFF” position

Step 3. Remove right side inner door and burner door per SERVICE PROCEDURE I, steps 3 and 4.

Step 4 Follow the thermopile leads to the pilot bracket. Disconnect the thermopile from the pilot bracket (7/16"

wrench).

Step 5. Install new thermopile into pilot bracket and tighten the nut to the pilot bracket (7/16" wrench). Position

thermopile wire against left side inner door flange at its original position. Connect the red thermopile wire to

the red lead from the wire harness. Connect the white thermopile wire to the resettable thermal switch.

Step 6. Install burner and inner door per SERVICE PROCEDURE I, steps 5 through 16.

Step 7. To resume operation follow the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

ThermopilePosition

7/16" Thermopile

Nut

Page 11

Page 12

SERVICE PROCEDURE III

s

12

ECO-MAGNUM

Pilot Assembly Inspection, Cleaning

andReplacement

Pilot/Electrode Assembly Inspection,

Cleaning and Replacement

Step 1. Turn off gas supply to water heater. Rotate gas

control knob to the “OFF” position.

Step 2. Remove outer jacket door.

Step 3. Remove burner and right side of inner door

per SERVICE PROCEDURE I, steps

3and4.

Step 4. Remove burner assembly from combustion chamber.

Step 5. Remove pilot/electrode assembly from burner (¼" drive tool)

Step 6. Inspect pilot for the following:

75/100-Gallon Atmospheric

Gas Control shown in the “OFF” position

a) Primary air openings for blockage. Must be free from any

debris (dirt, lint, etc).

PrimaryAir

b) Kinks or cracks in the pilot tube. If found,

Opening

the pilot must be replaced.

Step 7. Inspect pilot orifice:

a) Remove 7/16" nut from bottom of pilot assembly.

b) Remove pilot tube and pilot orifice.

7/16" Pilot

Assembly

Nut

c) inspect pilot orifice for blockage, must be cleaned or replaced.

Pilot Orifice

Step 8. Install pilot/electrode assembly to burner, secure with screw from step 5.

Step 9. Install burner and inner door per SERVICE PROCEDURE I, steps 5 through 16.

Step 10. To resume operation follow the instructions located on the lighting instruction label or the lighting instruction

located in the installation and operation manual.

Page 12

Page 13

ECO-MAGNUM

13

SERVICE PROCEDURE IV

75/100-Gallon Atmospheric

Igniter and Electrode Testing and Replacement

With the pilot not in operation (no pilot flame) you can check the igniter and electrode circuit by viewing pilot

thru the sight glass located on the inner door and observing the spark action.

Step 1. Remove outer jacket door.

Step 2. Repeatedly depress the igniter button while viewing the pilot thru the sight glass. If a spark is

present, the circuit is OK. If there is no spark, proceed to step 3.

Repeatedly

Depress

Igniter

Igniter and Electrode Testing

andReplacement

Action Through

View Spark

Sight Glass

Step 3 Remove white wire from igniter. Hold the igniter lead from the gas valve to an unpainted surface

such as the feedline or gas control and depress the igniter. If there is a spark, the igniter is OK,

the pilot is not functioning and must be replaced, see SERVICE PROCEDURE II for pilot

replacement. If no spark is present the igniter is not functioning and the control must be replaced,

see SERVICE PROCEDURE V

Igniter Lead

Page 13

Page 14

SERVICE PROCEDURE V

14

ECO-MAGNUM

Gas Control Testing andReplacement

75/100-Gallon Atmospheric

ManifoldPressure Testing (this procedure presumes a maximum line pressure of 14.0" w.c.)

Step 1. Set the Gas Control to the “OFF” position.

Step 2. Remove pressure tap plug and install

1/8" NPT pipe, coupling, & pressure tap.

Gas Control shown in the “OFF” position

Step 3. Connect manometer to pressure tap.

Step 4. Follow instructions located on the lighting

instructions label and proceed to light the main

burner and observe manometer reading.

Step 5. Proper operating range for natural gas is: 5.0" ±0.5" w.c.

Step 6. If pressure is within the range specified in the previous

step, set Gas Control knob to the “OFF” position,

remove manometer and pressure tap, and replace

pressure tap plug. Check for gas leaks prior to placing

water heater back into operation by following the

instructions located on the lighting instruction label or the

lighting instructions located in the installation and

operation manual.

Step 7. If gas pressure is outside the specification noted above,

refer to “Honeywell Gas Control Testing, Disassembly,

and Replacement” to replace Gas Control or valve body.

Pressure Tap

Shown Installed

Thermopile Testing

See SERVICE PROCEDURE II

ECO (Energy Cut Out) Testing

The Honeywell Gas Control is designed with an ECO device that will reset.

To reset the Gas Control after an error code (4), turn the Gas Control knob to the “OFF” position and wait a minimum

of (5) minutes before relighting following the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

Page 14

Page 15

ECO-MAGNUM

15

SERVICE PROCEDURE V

75/100-Gallon Atmospheric

Gas Control Testing andReplacement

Gas Control Replacement

Step 1. Rotate knob of the gas control

to the “OFF” position.

Step 2. Turn off gas supply to water heater.

Step 3. Disconnect gas supply line from gas control.

Step 4. Turn off water supply and drain water heater completely.

Step 5. Remove the wire clip from the feedline.

Gas Control shown in the “OFF” position

Step 6. Disconnect main burner feedline, pilot tube, white thermopile wire and igniter wire from gas control and bend

the main burner feedline and pilot tube out of the way. Also disconnect the red wire leading from the thermopile

from the red wire leading from the gas control.

Step 7. Remove the gas control from the water heater by rotating counter-clockwise. It may be necessary to use a length

of ½” NPT pipe threaded into the inlet of the gas control.

Pilot tube

White thermopile

wire

Igniter wire

Main burner

feedline

RedWire Leads

Step 8. Install new gas control into the water heater.

a) Install gas control into water heater by rotating clockwise. DO NOT use a wrench on the gas control

body or damage to the gas control may occur. If necessary, use a length of ½” NPT pipe threaded into

gas inlet of gas control.

b) Position the main burner feedline and pilot tube back to the gas control and attach to the gas control.

Connect the igniter wire and the white thermopile wire to the gas control. Connect the red wire from

the gas control to the resettable thermal switch and connect the red wire from the thermopile to the

resettable thermal switch.

c) Gather the igniter wire, white thermopile wire and red thermopile wire near the side of the feedline.

Use the clip that was removed in Step 5 to secure the wires to the feedline.

d) Connect gas supply to inlet of gas control.

Step 9. Resume the water supply to the water heater. Be sure that the tank is full before operation is resumed.

Step 10. Check the main burner feedline and pilot feedline for gas leaks.

Step 10. To resume operation follow the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

Page 15

Page 16

SERVICE PROCEDURE VI

16

ECO-MAGNUM

Burner Operation Inspection,

75/100-Gallon Atmospheric

Cleaning and Replacement

Main Burner Inspection, Cleaning and Replacement

At periodic intervals (not more then 6 months) a visual inspection should be made of the main burner for proper operation

and to insure no debris is accumulating.

Main burner should light smoothly from pilot and burn with a blue flame with a minimum of yellow tips. After 5 minutes

of operation the burner screen will become radiant and the flame will soften and turn orange. If the burner screen does not

become radiant after 5 minutes of operation it must be cleaned (see burner cleaning procedure below).

Main burner must be free from any debris accumulation that may effect burner operation (see burner cleaning procedure

below).

DANGER

Under no circumstances shall flammable materials be used or stored inthevicinity of the water heater. If

flammable vapors are present, a fire or explosion may result causing property damage, personal injury or

death.

WARNING

Innerdoor andburnercomponents may beHOT when performing this operation. Take

necessaryprecaution to prevent personal injury.

BurnerCleaning

Step 1. Remove burner and inner door assembly per SERVICE PROCEDURE I, steps 3 through 4.

Step 2. Remove manifold cover from burner inner door by removing (2) ¼” hex drive screws and then sliding

manifold cover to the right. Use a stiff brush, compressed air and/or shop vacuum to remove any debris

build up from the manifold mount.

Step 3. Remove manifold brackets from burner by removing (4) ¼” hex drive screws.

¼” Hex Drive Manifold

Cover Screws

¼” Hex Drive Manifold

Bracket Screws

Manifold Cover

Page16

Page 17

SERVICE PROCEDURE VI

17

ECO-MAGNUM

Burner Operation Inspection,

75/100-Gallon Atmospheric

BurnerCleaning (Continued)

Step 4. Thoroughly inspect burner screen and burner venturis and remove any loose debris accumulation. Inspect

burner screen for any openings larger than the normal screen openings.

Step 5. Use compressed air and/or a vacuum to remove any scale or other debris accumulation from the burner screen

and venturis.

Cleaning and Replacement

Burner Screen

Burner Venturis

Manifold Brackets

Step 6. Disconnect (unscrew) manifold brackets from main

burner orifices.

Main Burner Orifices

Step 7. Remove main burner orifice from feed line (1/2"

wrench). Inspect and clean if necessary

Step 8. Remove pilot assembly, refer to SERVICE PROCEDURE III for cleaning and inspection.

Step 9. Reassemble burner.

Step 10. Reinstall burner and inner door per SERVICE PROCEDURE I, steps 5 through 16.

Step 11. To resume operation, follow the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

Page17

Page 18

SERVICE PROCEDURE VII

18

ECO-MAGNUM

Resettable Thermal Switch

75/100-Gallon Atmospheric

Testing and Replacement

Resettable Thermal Switch Continuity Testing

Step 1. Remove outer jacket door.

Step 2. Disconnect red wire leads from resettable thermal switch.

Step 3. Using a multimeter capable of measuring continuity (Ohms),

place one probe of meter on one of the brass connection tabs of

the resettable thermal switch, and the remaining probe on the

other connection tab.

Step 4. If continuity is indicated, the switch is closed, allowing millivolt current to pass.

Red Wire Leads

Step 5. If continuity is not indicated, the switch is open, possibly due to an over heating condition. The switch is

designed to open at predetermined temperatures. An open switch can be reset by depressing the red colored

button located at the center of the switch. The overheating condition must be determined prior to putting the

water heater back in service.

PROBABLE CAUSE FORRESETTABLE THERMALSWITCHACTIVATION

PROBABLE CAUSE CORRECTIVE ACTION

1.Inspect burner per SERVICE PROCEDURE

VI

Burner Failure

Weak switch or switch

out of calibration.

2. Replace burner per SERVICE PROCEDURE

VI

1. Replace resettable thermal switch

Page18

Page 19

ECO-MAGNUM

19

75/100-Gallon Atmospheric

Resettable Thermal Switch Replacement

Step 1. Rotate gas control knob to the “OFF” position.

SERVICE PROCEDURE VII

Resettable Thermal Switch

Testing and Replacement

Step 2. Remove outer jacket door.

Gas Control shown in the “OFF” position

Step 3. Disconnect red wire leads from resettable thermal switch.

¼” Hex Drive Manifold

Cover Screws

Step 4. Remove (2) ¼” hex drive screws from the manifold

cover and slid to the right to remove from burner

assembly.

Step 6. Remove resettable thermal switch from manifold

Red Wire Leads

cover (Phillips screw driver).

Phillips Screws

Manifold Cover

Step 7. Place new resettable thermal switch in place. Be sure contact surface of resettable thermal switch and

manifold cover are free of any debris. Secure resettable thermal switch into place using screws from step 6.

DO NOT OVER TIGHTEN SCREWS.

Step 8. Place manifold cover back in position and secure using the screws from step 4.

Step 9. Reconnect wire leads from gas control and thermopile to resettable thermal switch.

Note: Wire termination are interchangeable with either resettable thermal switch connection.

Step 10. Replace outer jacket door.

Step 11. To resume operation follow the instructions located on the lighting instruction label or the lighting instruction

located in the installation and operation manual.

Page 19

Page 20

SERVICE PROCEDURE VIII

20

ECO-MAGNUM

Dip Tube and Anode

Inspection and Replacement

Dip Tube Inspection and Replacement

WARNING

Water Heatercomponents and stored water may beHOT when performing the following

steps in this procedure. Take necessaryprecaution to prevent personal injury.

Step 1. Rotate gas control knob to the “OFF” position.

Step 2. Turn off cold water supply to water heater. Connect hose to drain valve of water heater and route to an open

drain. Open a nearby hot water faucet to vent heater for draining. Open drain valve of water heater and

allow water heater to drain to a point below the inlet connection nipple.

75/100-Gallon Atmospheric

Gas Control shown in the “OFF” position

Step 3. Disconnect inlet nipple from plumbing system.

Step 4 With an appropriate wrench, remove inlet nipple/dip tube from the water heater. Use caution not to damage

pipe threads.

Step 5. Visually Inspect inlet nipple/dip tube. Inlet nipple/dip tube should be free of cracks and any blockage.

Hydro-jets located near the bottom of the dip tube should be open and free of any blockage.

Anti-siphon hole located approximately 6" from the bottom of nipple, should be free of any blockage.

Any damage such as cracks, restriction due to deformation or unintentional holes are not field repairable

and the inlet nipple/dip tube must be replaced.

Step 6. Upon completion of inspection or subsequent replacement, reinstall inlet nipple/dip tube into heater. Connect

nipple to plumbing system, resume water supply and refill water heater with water.

Step 7. To resume operation follow the instructions located on the lighting instructions label or the lighting

instructions located in the installation and operation manual.

Page 20

Page 21

ECO-MAGNUM

21

SERVICE PROCEDURE VIII

75/100-Gallon Atmospheric

Anode Inspection and Replacement

WARNING

Heatercomponents and stored water may beHOT when performing the following steps in

this procedure. Take necessaryprecaution to prevent personal injury.

Step 1. Rotate gas control knob to the “OFF” position.

Step 2. Turn off cold water supply to heater. Connect hose to drain valve of water heater and route to an open drain.

Open a nearby hot water faucet to vent heater for draining. Open drain valve of hot water heater and allow

heater to drain to a point below the outlet connection nipple.

Dip Tube and Anode

Inspection and Replacement

Gas Control shown in the “OFF” position

Step 3. Remove the anode cover from the jacket head to access the ¾” hex head anode. With an appropriate wrench,

remove anode from the water heater.

Step 4. Visually Inspect outlet nipple/anode. Outlet nipple/anode should show signs of depletion, this is normal.

If depletion is ½ of the original anode diameter (approximately ¾” diameter), replacement is recommended.

If any of the steel core of the anode is exposed, replacement is recommended.

Step 5. Upon completion of inspection or subsequent replacement, reinstall outlet nipple/anode into heater. Connect

nipple to plumbing system, resume water supply and refill heater with water.

Step 6. To resume operation, follow the instructions located on the lighting instructions label or the lighting

instructions located in the installation and operation manual.

Page 21

Page 22

Glossary of Terms

22

BTU British Thermal Units

GPMGallons per Minute

Hz Hertz

KWh Kilo-watt hour

LED Light Emitting Diode

NPTNational Pipe Thread

Ohms Ohms (resistance)

PSI Poundsper Square Inch

RPM Revolutions per Minute

ECO EnergyCutOut

VAC Volts Alternating Cu

VDC Volts Direct Current

W.C. Inchesof Water Column

°C DegreesCentigrade

°F DegreesFahrenheit

ECO-MAGNUM

75/100-Gallon Atmospheric

rrent

NOTES

Page 22

Page 23

23

ECO-MAGNUM

75/100-Gallon Atmospheric

Parts List

75-Gallon Models

Page 24

1DraftDiverter

2Flue Baffle

3 Anode

4 Cold Water InletTube

5 Hot WaterOutlet Nipple

6T&PReleif Valve

7 Space Heating Plug

8GasValve

9 Brass Drain Valve

10 Outer Door

11 RNBurner and Door

12 RNBurner

13 Flexible GasFeedline

14 Screw #6-20 x 3/8"

15 Resettable Thermal Switch

16 Manifold Cover

17 Screw #8-18 x ¾”

18 Manifold bracket

19 Right Side Inner Door

20 Screw #10-12 x ¾

21 ASSE Approved Mixing V

22 Inner Door Gasket Set

23 Intermediate GasValve Harness

24 Gas Control Kit

25 Main Burner Orifice

26 Pilot Assembly

alve (Optional)

Page 24

24

Parts List

ECO-MAGNUM

75/100-Gallon Atmospheric

100-Gallon Models

1DraftDiverter

2Flue Core

3 Anode

4 Cold Water InletTube

5 Hot WaterOutlet Nipple

6T&PReleif Valve

7 Space Heating Plug

8GasValve

9 Brass Drain Valve

10 Outer Door

11 RNBurner and Door

12 RNB

13 Flexible GasFeedline

urner

14 Screw #6-20 x 3/8"

15 Resettable Thermal Switch

16 Manifold Cover

17 Screw #8-18 x ¾”

18 Manifold bracket

19 Right Side Inner Door

20 Screw #10-12 x ¾

21 ASSE Approved Mixing Valv

22 Inner Door Gasket Set

23 Intermediate GasValve Harness

24 Gas Control Kit

25 Main Burner Orifice

26 Pilot Assembly

e (Optional)

Page 25

Page 25

NOTES

25

Page 23

Page 26

NOTES

26

Page 23

Page 27

NOTES

27

Page 23

Page 28

Loading...

Loading...