Bradford-White M1XR403S-FBN, MI403S-F-BN, MI404T-F-BN, M450S-F-BN, MI50L-F-BN User Manual

...Page 1

SERVICE

MANUAL

Flammable Vapor Ignition Resistant Water Heater

Troubleshooting Guide

and Instruction for Service

(To be performed ONLY by qualified service providers)

For the Bradford White

Defender Safety System

™

Models:

MI30T*F(BN,CX)2

MI30S*F(BN,CX)2

MI303T*F(BN,CX)2

MI40T*F(BN,CX)2

MI403S*F(BN,CX)2

MI404T*F(BN,CX)2

MI503*F(BN,CX)2

MI50L*F(BN,CX)2

MI504S*F(BN,CX)2

M430T*F(BN,CX)2

M4403S*F(BN,CX)2

M4403T*F(BN,CX)2

M450S*F(BN,CX)

M1XR403S*F(BN,CX)2

M1XR504T*F(BN,CX)2

M2XR504T*F(BN,CX)2

M2C504T*F(BN,CX)

50T65F(BN,CX)

Manual 44943A

(*) Denotes Warranty Years.

Save this manual for future reference

Page 2

2

Flammable Vapor Ignition Resistant Water Heater

Table of Contents

Page Service Pr

ocedure

Introduction 3 - - -

Trouble shooting Chart 4 - - -

Inner Door Gasket Removal, Inspection, Replacement and Installation 5 RG-I

Thermocouple Testing and Replacement 8 RG-II

Pilot Assembly Inspection Cleaning and Replacement 10 RG-III

Piezo Igniter and Electrode Testing 11 RG-IV

Combination Thermostat/Gas Valve Testing and Replacement 12 RG-V

Burner Operation Inspection, Adjustment, Cleaning and Replacement 17 RG-VI

Resettable Thermal Switch Testing and Replacement 20 RG-VII

ScreenLok Flame Arrestor Cleaning 22 RG-VIII

Dip Tube and Anode Inspection and Replacement 23 RG-IX

Generic Parts List 25 - - -

Page 3

3

Introduction

The Bradf

ord White DEFENDER Safety System

™

The Bradford White DEFENDER Safety SystemTMwas designed to resist the ignition of flammable

vapors that can occur outside of the water heater. Use and installation are nearly identical to

previous versions of atmospherically fired and vented water heaters. A number of exclusive

design features are incorporated in the system that will require additional knowledge on the part

of the qualified service provider. The following information will instruct service professionals on

the function, proper diagnosis and repair of water heaters employing the Bradford White

DEFENDER Safety System .

Ho

w the Safety System Works

™

During normal operation, air for combustion is drawn into the water heater through the

openings in the jacket. This air travels down and around the combustion chamber and enters

through holes in the very bottom of the corrosion-resistant combustion chamber. The air then

travels up through the oriented flame arrestor plate louvers, where the velocity of the air is

increased and its direction altered. The air then mixes in a normal manner with supplied gas

and is efficiently combusted, producing very low NOx emissions. In the unlikely event trace

amounts of flammable vapors are present in the air flowing into the combustion chamber, the

vapors are harmlessly ignited by the burner / pilot flame. If flammable vapors are in sufficient

quantity to prevent normal combustion, the burner / pilot flame is shut down. Should the

flammable vapors continue to burn, the flame arrestor plate prevents the flames from traveling

backwards and igniting vapors outside of the combustion chamber. The calibrated,

multipurpose thermal switch recognizes this and shuts down the pilot and main burner. This

switch also deactivates the burner and pilot in the unlikely event of restricted airflow caused by

severe lint, dust or oil accumulation on the arrestor plate. If accumulation occurs, the

ScreenLok flame arrestor can be easily cleaned and when the inner door is properly secured

the unit can then be placed in operation. A cleaning procedure is included in this service

manual.

Page 4

4

SYMPTOM PROBABLE CA

USE

CORRECTIVE ACTION

Pilot Will

Not Light

1. No incoming gas or too

low gas pressure.

2. Gas control knob set

to wrong position.

3. Pilot light button not being fully

depressed when attempting to

light pilot.

4. Pilot orifice or pilot tube is

obstructed or kinked.

5. Pilot electrode not sparking to pilot.

6. Piezo igniter not functioning.

1. Combination thermostat/gas valve

set too low for desired water temp.

2. Combination thermostat/gas valve

temperature is satisfied.

3. Insufficient gas supply or low gas

pressure.

4. Combination thermostat/gas valve

has wide differential or is out of

calibration.

1. Insufficient combustion air supply.

2. Incorrect, clogged vent system/ vent

terminal or location.

3. Inconsistent gas supply or gas

pressure.

1. Combination thermostat/gas valve

set too low for desired water temp.

2. Cold inlet water temp. is very cold.

3. High demand periods.

4. Incorrectly sized water heater for

application.

5. Combination thermostat/gas valve is

out of calibration/not functioning.

6. Out of spec dip tube is diluting hot

water with cold water.

1. Poor thermocouple connection at

combination thermostat/gas valve.

2. Thermocouple not fully engaged in

pilot assembly bracket.

3. Pilot flame is not fully enveloping the

thermocouple “hot” junction.

4. Weak or defective thermocouple.

5. Open ECO on combination

thermostat/gas valve.

6. Defective magnet in combination

thermostat/gas valve.

7. Resettable thermal switch has

opened.

1. Turn on gas supply and/or check line pressure.

2. Review lighting instruction.

Set combination/thermostat gas valve to correct

position.

3. Review lighting instruction. Fully depress pilot

lighting button.

4. Clean, repair or replace.

5. Verify correct electrode position.

Replace pilot assembly.

6. Replace Piezo igniter.

1. See Service Procedure

RG-V, Page 12.

4. See Service Procedure

RG-III, Page 10.

5. See Service Procedure

RG-III, Page 10.

6. See Service Procedure

RG-IV, Page 11.

2. See Installation

& operation manual.

3. See Service Procedure

RG-V, Page 12.

4. See Service Procedure

RG-V, Page 12.

1. See Service Procedure

RG-VIII, Page 22.

3. See Service Procedure

RG-V, Page 12.

5. See Service Procedure

RG-V, Page 12

6. See Service Procedure

RG-IX, Page 23

4. See Service Procedure

RG-II, Page 8.

5. See ServiceProcedure

RG-V, Page 13.

6. See Service Procedure

RG-V, Page 13.

1. Adjust temperature dial on combination

thermostat/gas valve.

2. Check temperature dial setting on combination

thermostat/gas valve.

3. Check gas supply and line pressure.

4. Check combination thermostat/gas valve for

proper operation, replace if necessary.

1. Verify adequate combustion air is available to the

unit. Check and clear Jacket slot openings of any

dirt, dust, restrictions or other obstructions.

Inspect flame arrestor plate and clean with stiff

bristled brush and/or vacuum to remove any

debris accumulation.

2. Check venting for proper sizing and proper

operation

3. Check gas supply and line pressure.

1. Check dial on combination thermostat/gas valve.

2. Extremely cold water going into the heater will

decrease the amount of hot water produced.

It may be necessary to temper incoming water

supply.

3. Adjust high demand usage.

4. Contact Plumbing professional.

5. Check combination thermostat/gas valve for

proper operation, replace if necessary.

6. Inspect dip tube and replace if necessary.

1. Check connection at combination thermostat/gas

valve. Proper tightness should be finger tight

plus 1/4 turn.

2. Inspect thermocouple to ensure that it is fully

engaged into pilot bracket.

3. Adjust tip of thermocouple to be fully engulfed

by pilot flame.

4. Check thermocouple and replace if necessary.

5. Check ECO continuity and replace combination

thermostat/gas valve if necessary.

6. Check magnet operation and replace

combination thermostat/gas valve if necessary.

7. Determine cause of switch activation. To reset,

depress button on resettable thermal switch

located on inner door.

Pilot will not

stay lit when

button is

released

Pilot will light

but the main

burner will

not come on

Pilot goes out

periodically

(after heating

cycles, once a

day, once a

week etc.)

Not enough

hot water

SERVICE

PROCEDURE

Tr

oubleshooting Char

t

Flammable Vapor Ignition Resistant Water Heaters

Page 5

SERVICE PROCEDURE RG-I

Inner Door/Gasket Removal, Inspection

Replacement and Reinstallation

Inner Door Remo

v

al Procedure

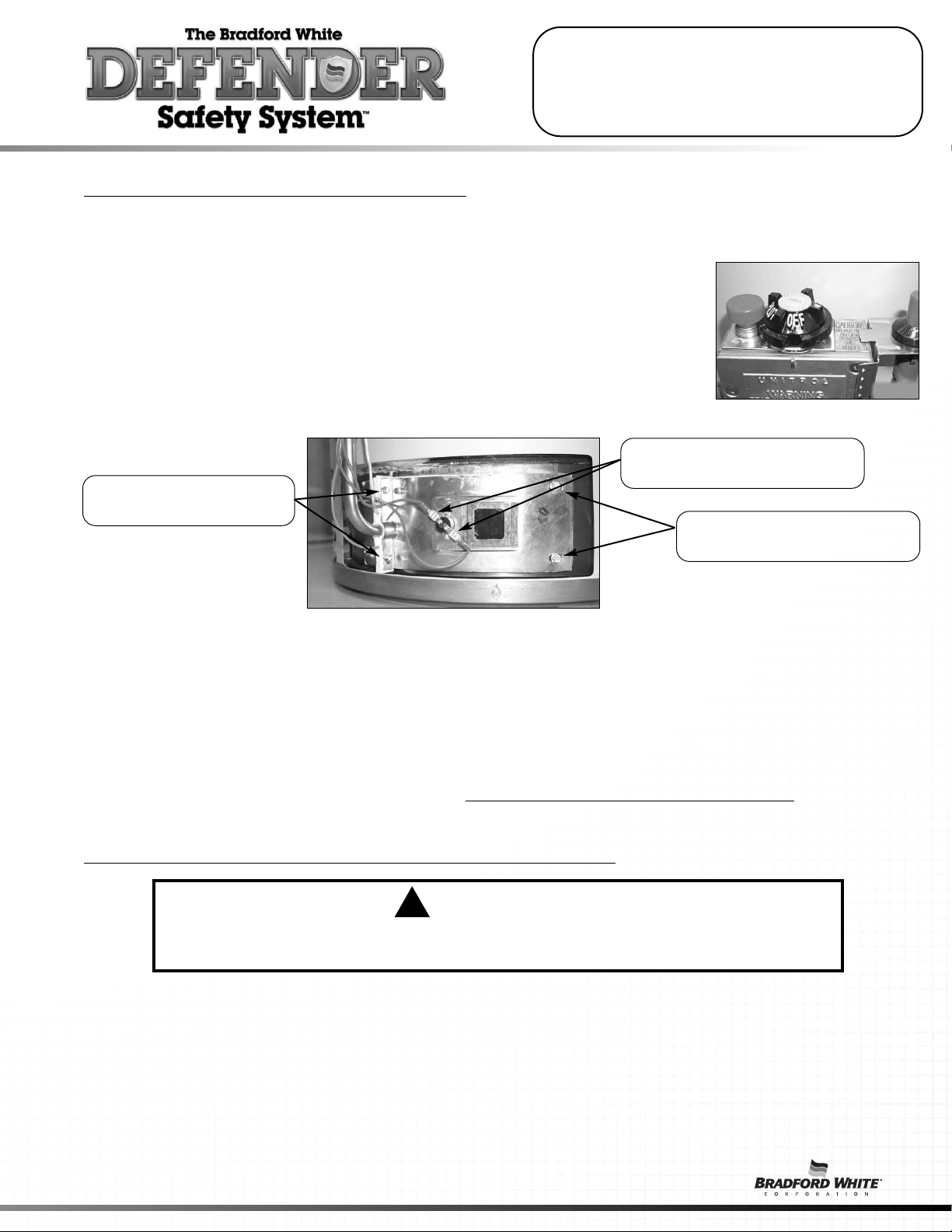

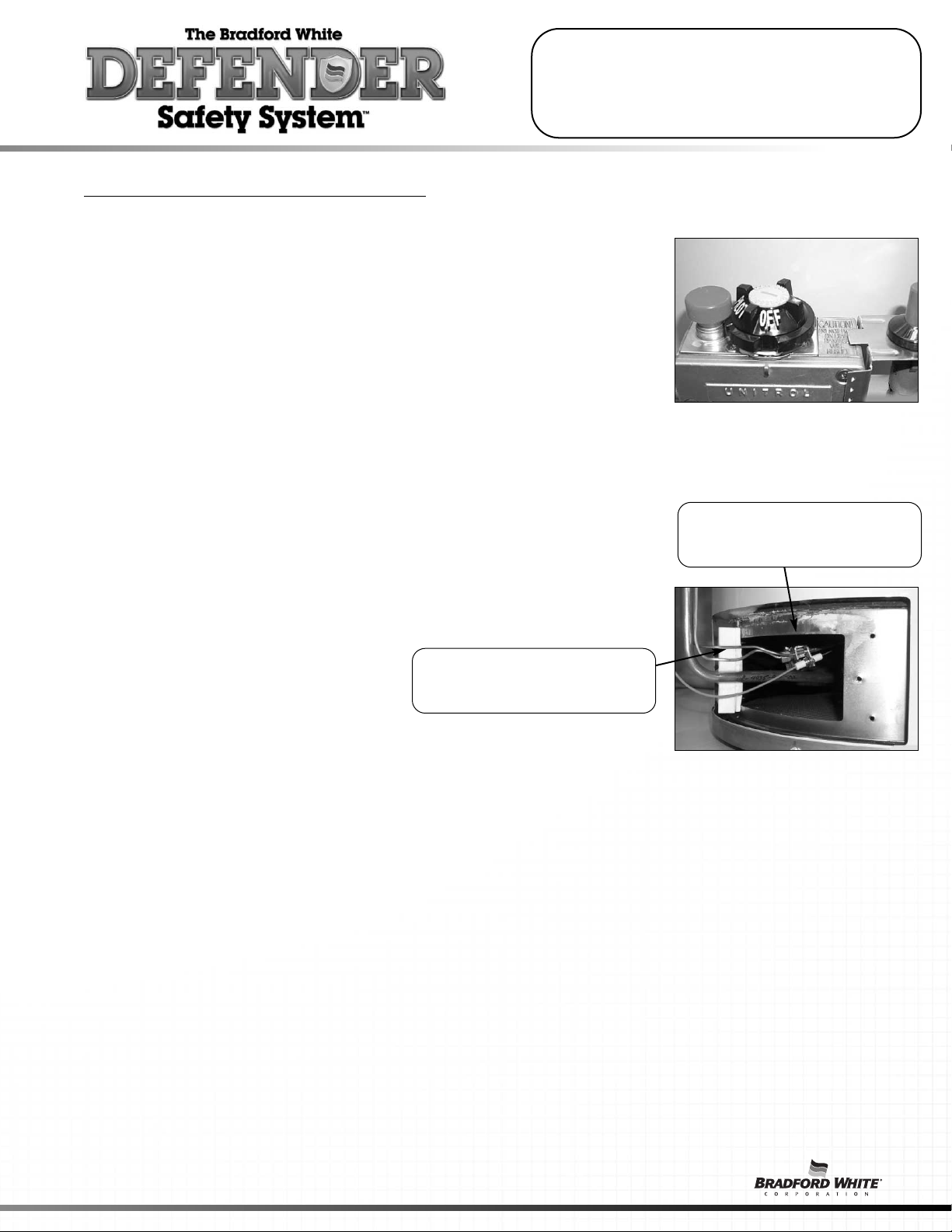

Step 1. Rotate knob of the combination thermostat/gas valve to the “OFF” position.

Step 2. Remove outer jacket burner access door

Step 3. Inner Door Removal.

a) Disconnect resettable thermal switch wire leads

(leading from combination thermostat/gas valve).

b) Remove (2) 1/4" hex drive screws from right side inner door.

c) Remove (2) 1/4" drive screws from flange section of inner door.

d) Remove (2) 1/4" drive screws from left side inner door.

e) Remove inner door and inspect per step 4.

Step 4. Fully inspect inner door gaskets for the following:

>Tears >Other imperfections that will inhibit proper seal

>Missing Material >Gasket adhesion to inner door

>Cracks >Material left on combustion chamber (around opening)

>Dirt or debris

If the gasket is not effected by any of the above, gasket replacement is not required.

If replacement is required, proceed to Inner Door Gask

et Replacement Procedure.

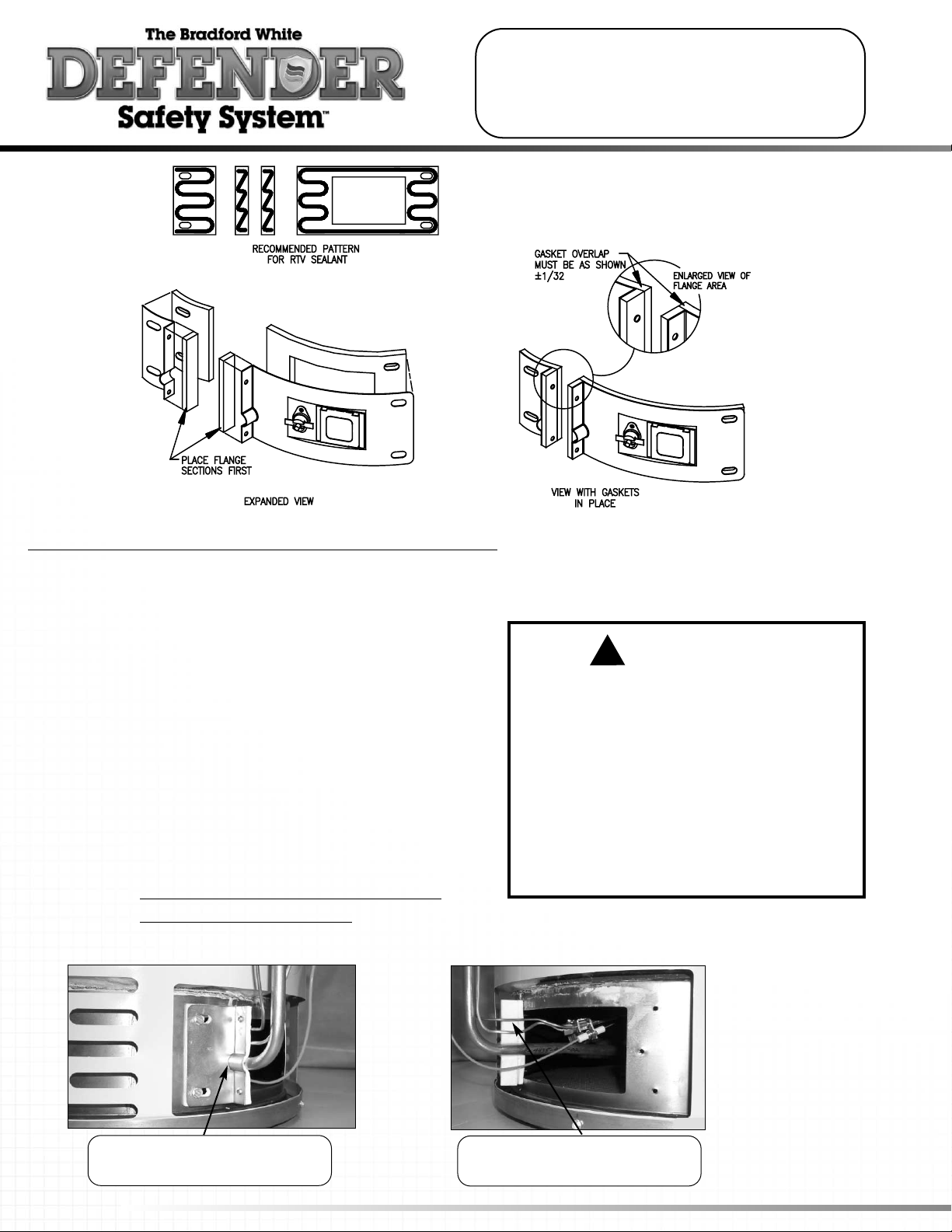

Inner Door Gasket Replacement Procedure

Step 5. After inspection of inner door as noted in step 4, completely remove gasket and adhesive

residue from right and left side inner doors as needed.

Step 6. Use RTV sealant (recommended bead size 1/8") to secure the inner door gasket to the inner

door sections (right & left). Refer to illustration on next page for proper application. Note the

overlap configuration in the flange area of the inner door. Set the flange section first, this will

help to achieve the proper over lap position.

5

! WARNING

If the information in these instructions is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

!

1/4" Hex Drive Screws at

Flange Area of Inner Door

1/4" Hex Drive Screws

Right and Left Side Inner Door

Resettable Thermal Switch

Wire Connection

Page 6

6

SERVICE PROCEDURE RG-I

Inner Door/Gasket Removal, Inspection

Replacement and Reinstallation

Installation of Inner Door with Gasket

Step 7. Clean any residual gasket residue or other debris

from combustion chamber surface before

installing the inner door/gasket assembly.

Step 8. Place the left side inner door into position first.

Firmly position the radiused channel of the inner

door around the feedline. Using the 1/4” hex

drive screws from step 3d, secure left side inner

door in place.

DO NOT OVER TIGHTEN SCREWS.

Step 9. Position thermocouple, pilot tube and Piezo wire

against left side inner door flange gasket.

DO N

OT ROUTE THROUGH RADIUSED

CHANNEL WITH FEEDLINE.

! WARNING

Stripped fastener connections may

allow for seal breach of inner door. A

seal breach may result in a fire or

explosion causing property damage,

personal injury or death. Do not over

tighten screws in steps 8, 10 and 11.

If a fastener connection is stripped,

contact the manufacturer listed on the

water heater rating plate.

!

Radiused Channel for Feedline

Position thermocouple,

pilot tube and Piezo wire

Page 7

7

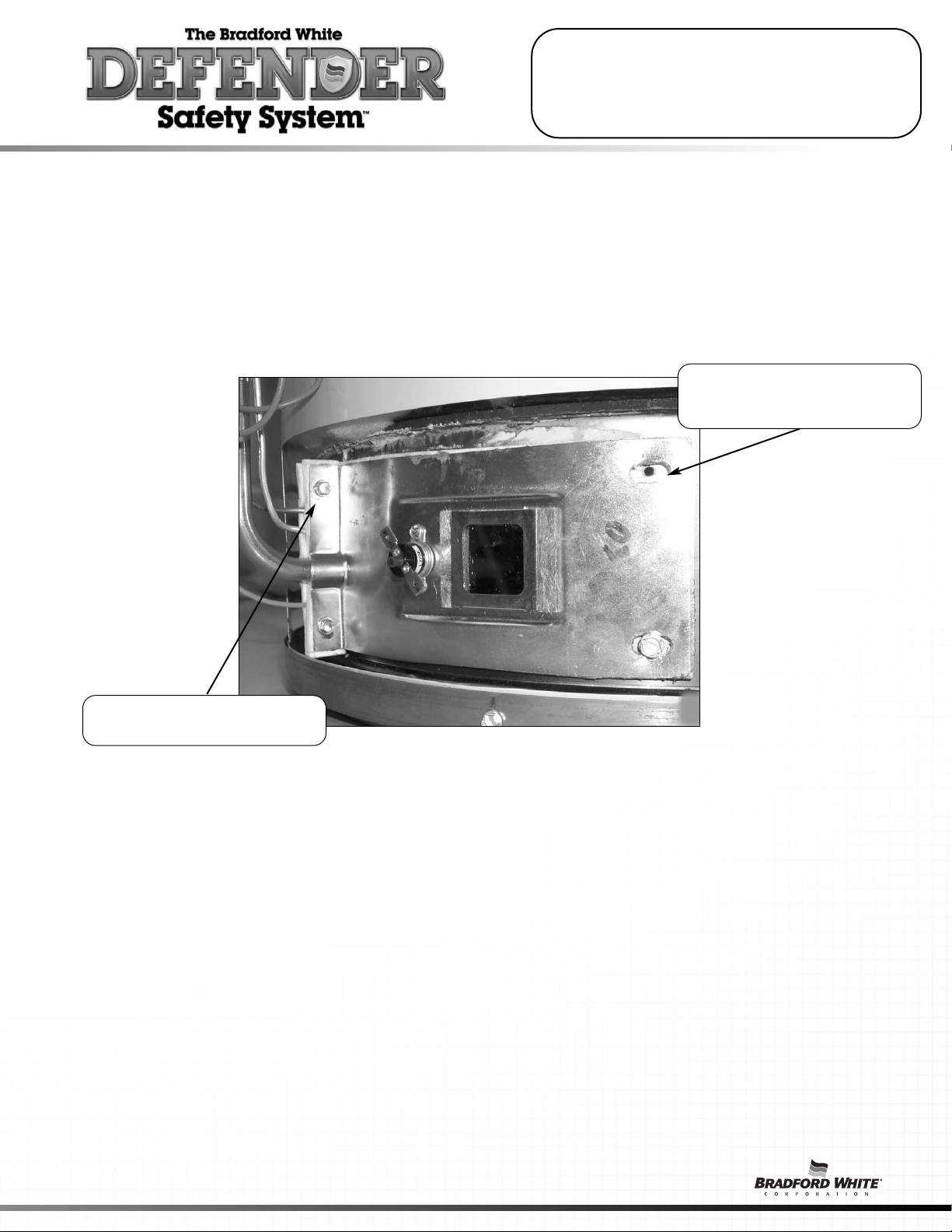

SERVICE PROCEDURE RG-I

Inner Door/Gasket Removal, Inspection

Replacement and Reinstallation

Step 10. Firmly place right side inner door flange against the left side inner door flange and secure with two

1/4” drive screws from step 3c. DO NOT OVER TIGHTEN SCREWS.

Step 11. Align right side inner door to combustion chamber and verify the fastener holes of the combustion

chamber are aligned with the right side inner door slotted opening. Verify seal integrity around combustion chamber opening. Secure right side inner door using 1/4” hex drive screws from step 3b.

DO NOT OVER TIGHTEN SCREWS. Verify both left and right sides of the inner door are properly

positioned and sealed against the combustion chamber.

Step 12. Reconnect lead wires from combination thermostat/gas valve to resettable thermal switch (See photo

in step 3). Note, wire terminations are interchangeable with either resettable thermal switch

connections.

Step 13. Replace outer jacket burner access door.

Step 14. To resume operation follow the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

Verify threaded hole

alignment with slotted

openings in inner door

Secure flange with

1/4" drive screws

Page 8

8

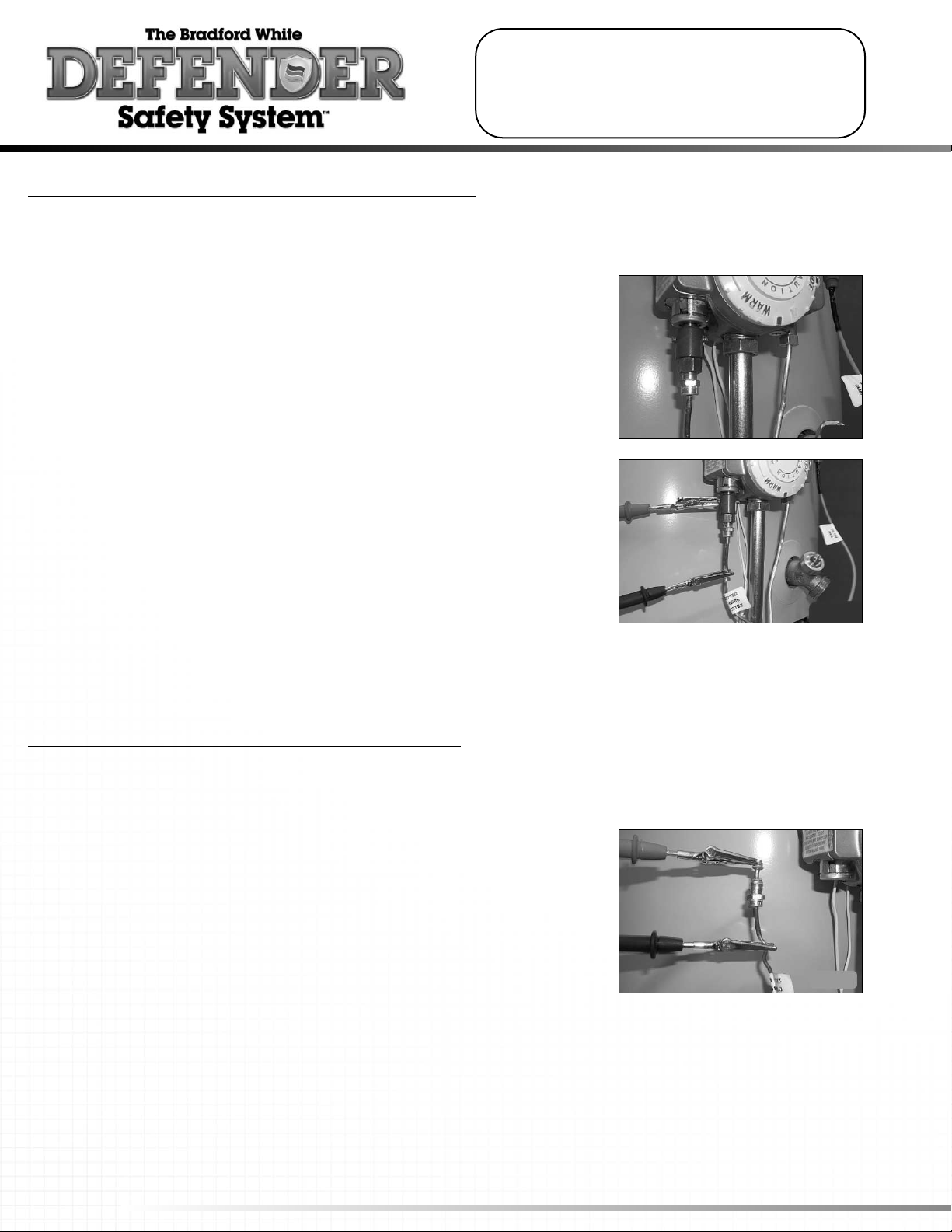

SERVICE PROCEDURE RG-II

Thermocouple Testing and Replacement

Closed Circuit Thermocouple Testing

Step 1. Disconnect thermocouple from combination thermostat/gas valve.

Step 2. Connect a thermocouple adapter (BWC P/N 239-44642-00,

Robertshaw P/N 75036) at the thermocouple location in the

combination thermostat/gas valve.

Step 3. Reconnect thermocouple to adapter. make certain all connections

are tight (finger tight plus 1/4 turn)

Step 4. Using a multimeter capable of measuring millivolts, connect one

alligator clip to the set screw of the adapter, and the other alligator

clip to copper portion of the thermocouple.

Step 5. Following the lighting instruction label on the heater, proceed to

light the pilot and allow to operate for three minutes. If the pilot

will not stay lit, hold the red reset button (located on the

combination thermostat/gas valve) down during this test.

Step 6. If meter reads 13 millivolts or higher, the thermocouple is OK. If reading is below13 millivolts replace

the thermocouple.

Open Cir

cuit Thermocouple Tes

ting

Step 1. Disconnect thermocouple from combination thermostat/gas valve.

Step 2. Using a multimeter capable of measuring millivolts, connect one

alligator clip to the end ball or contact portion of the

thermocouple, and the other alligator clip to copper portion of the

thermocouple.

Step 3. Following the lighting instruction label on the heater, proceed to

light the pilot and allow to operate for three minutes. It will be

necessary to hold the red reset button continuously

throughout this test. If meter reads 20 millivolts or higher, the thermocouple is OK. If reading is

below20 millivolts, replace the thermocouple.

Page 9

9

SERVICE PROCEDURE RG-II

Thermocouple Testing and Replacement

Thermocouple Replacement

Step 1. Turn off gas supply to water heater. Rotate knob of combination

thermostat/gas valve to “OFF” position.

Step 2. Remove outer jacket door.

Step 3. Remove right side of inner door per SERVICE PROCEDURE RG-I,

steps 3a through 3c.

Step 4. Disconnect thermocouple from combination thermostat/gas valve (3/8" wrench). Locate other end of

thermocouple inside of combustion chamber and remove from pilot bracket. Pull firmly pulling away

from the pilot assembly.

Step 5. Install new thermocouple into pilot bracket making certain the

thermocouple is fully engaged into the pilot bracket. Position

thermocouple against left side inner door flange at its original

position. Connect other end of thermocouple to combination

thermostat/gas valve (finger tight + 1/4 turn).

Step 6. Inspect inner door gasket per SERVICE PROCEDURE RG-I, Step 4.

Step 7. Install right side inner door per SERVICE PROCEDURE RG-I, Step 10 through Step 13.

Step 8. To resume operation follow the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

Position thermocouple,

in its original position

Make certain thermocouple is

fully engaged into bracket

Page 10

10

SERVICE PROCEDURE RG-III

Pilot Assembly Inspection,

Cleaning and Replacement

Pilot/Electr

ode Assembly Inspection,

Cleaning and Replacement

Step 1. Turn off gas supply to water heater. Rotate knob of combination

thermostat/gas valve to “OFF” position.

Step 2. Remove outer jacket door.

Step 3. Remove right side of inner door per SERVICE PROCEDURE RG-I,

steps 3a through 3c.

Step 4. Disconnect thermocouple from combination thermostat/gas valve (3/8"

wrench). Disconnect pilot tube from combination thermostat/gas valve

(7/16" wrench). Disconnect feedline from combination thermostat/gas valve

(3/4" wench).

Step 5. Disconnect Piezo ignition wire from Piezo igniter.

Step 6. Remove burner assembly from combustion chamber.

Step 7. Remove pilot/electrode assembly from feedline (1/4" drive tool).

Step 8. Inspect pilot for the following: (not required if replacing with new pilot)

a) Primary air openings for blockage. Must be free from any debris

(dirt, lint, etc).

b) Kinks or cracks in the pilot tube. If found, the tubing must be replaced.

Step 9. Inspect pilot orifice: (not required if replacing with new pilot)

a) Remove 1/2" nut from bottom of pilot assembly.

b) Remove pilot tube and pilot orifice.

c) inspect pilot orifice for blockage, must be cleaned or replaced.

Step 10. Install pilot/electrode assembly to feedline, secure with screw from step 7.

Step 11. Re-Install burner assembly into combustion chamber, connect feedline, pilot tube and thermocouple to

combination thermostat/gas valve.

Step 12. Install inner door per SERVICE PROCEDURE RG-I, step 4 through 13.

Step 13. To resume operation follow the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

Primary Air

Opening

Page 11

11

SERVICE PROCEDURE RG-IV

Piezo Igniter, Electrode

Testing and Replacement

Piezo Ignit

er, Electrode Testing and Replacement

With the pilot not in operation (no pilot flame) you can check the Piezo and electrode circuit by viewing pilot thru the

sight glass located on the inner door and observing the spark action.

Step 1. Remove outer jacket door.

Step 2. Repeatedly depress the Piezo igniter while viewing the pilot thru the sight glass. If a spark is present,

the circuit is OK. If there is no spark, proceed to step 3.

Step 3. Remove orange wire from Piezo igniter and install a jumper wire in its place. Hold the other end of the

jumper by the wire insulation or using an insulated tool, next to an unpainted surface such as the feed

line or gas valve and depress the Piezo igniter. If there is a spark, the igniter is OK, the pilot is not

functioning and must be replaced, see SERVICE PROCEDURE RG-III for pilot replacement. If no spark is

present the igniter is not functioning and must be replaced.

Step 4. With orange wire disconnected from Piezo igniter. Using a common screw driver, place blade of screw

driver under Piezo bracket and gently pry bracket from front of combination thermostat/ gas valve and

unhook bracket from rear of combination thermostat/gas valve.

Repeatedly

Depress Piezo

Igniter

Common

Screw Driver

View spark

Action through

Sight glass

Page 12

Combination Ther

mostat/Gas Valve Testing and Replacement

The combination thermostat/gas valve is a non repairable device. If trouble shooting has determined a problem with

the combination thermostat/gas valve, it must be replaced. If the burner and/or pilot do not function, service checks

for gas pressure, thermocouple output, magnet assembly and ECO are to be performed. If these check OK, the

combination thermostat/gas valve may be faulty.

LINE PRESSURE

The combination thermostat/gas valve is designed for a maximum line pressure of 14.0" w.c. and a minimum line pressure of 1.0"w.c. over the water heater rated manifold pressure.

MANIFOLD PRESSURE TES

TING

(this procedure assumes a maximum line pressure of 14.0" w.c.)

Step 1. Set combination thermostat/gas valve to “OFF” position.

Step 2. Remove pressure tap plug (3/16" Allen wrench) and install pressure tap (7/16 wrench)

Step 3. Connect manometer to pressure tap.

Step 4. Follow lighting instructions and proceed to light main burner.

Step 5. Manometer gauge should read 4.0" w.c. for Natural gas and 10.0" w.c. for L.P. gas.

Step 6. If adjustment is necessary proceed to step 7. If pressure is OK, set combination thermostat/gas valve

to “OFF” remove manometer and pressure tap and replace pressure tap plug. Check for gas leaks

before placing water heater back in operation.

Step 7. While burner is in operation, remove regulator access cap to expose the regulator adjusting screw .

With small screw driver, rotate adjusting screw clockwise to increase pressure and counter clockwise to

decrease pressure.

Step 8. Set combination thermostat/gas valve to “OFF”. Remove manometer and pressure tap and replace

pressure tap plug. Check for gas leaks before placing water heater back in operation.

SERVICE PROCEDURE RG-V

Combination Thermostat/Gas Valve

Testing and Replacement

12

Pressure Tap

Shown Installed

Page 13

THERMOC

OUPLE TESTING

See SERVICE PROCEDURE II

MAGNET ASSEMBLY TES

TING

Step 1. Disconnect thermocouple from combination thermostat/gas valve.

Step 2. Connect a thermocouple adapter (BWC P/N 239-44642-00, Robertshaw

P/N 75036) at the thermocouple location in the combination

thermostat/gas valve.

Step 3. Reconnect thermocouple to adapter. Make certain all connections are tight

(finger tight plus 1/4 turn).

Step 4. Using a multimeter capable of measuring millivolts, connect one alligator clip

to the set screw of the adapter and the other alligator clip to copper portion

of the thermocouple.

Step 5. Following the lighting instruction label on the heater, proceed to light the

pilot and allow to operate for three minutes.

Step 6. With a meter reading of 13 millivolts or greater, rotate knob of combination

thermostat/gas valve to the “OFF” position.

Step 7. The magnet should remain closed for a drop of at least 5 millivolts. You will here a “snap” or “click”

sound when the magnet opens, if you hear this sound prior to a drop of 5 millivolts, the magnet is

out of specification and the combination thermostat/gas valve should be replaced.

ECO (Energy Cut Off) TESTING

Step 1. Disconnect thermocouple from combination thermostat/gas valve.

Step 2. Using a multimeter capable of measuring Ohms (or continuity), attach one

lead (alligator clip) to the pilot tube. Insert the other lead (probe) fully into

the magnet opening, Be sure the probe makes contact only at the top center

of the magnet opening. Do not allow the probe to make contact with the

threaded sides of the opening.

Step 3. If continuity is indicated, the ECO is OK. If continuity is not indicated, the ECO has opened and the

combination thermostat/gas valve must be replaced.

SERVICE PROCEDURE RG-V

Combination Thermostat/Gas Valve

Testing and Replacement

13

Page 14

C

OMBINATION THERMOSTAT/GAS VALVE REPLACEMENT

Step 1. Rotate knob of the combination thermostat/gas valve to the “OFF” position.

Step 2. Turn off gas supply to water heater.

Step 3. Disconnect gas supply line from combination thermostat/gas valve.

Step 4. Turn off water supply and drain water heater completely.

Step 5. Remove outer jacket burner access door.

Step 6. Right side inner door removal.

a) Disconnect resettable thermal switch wire leads (leading from combination

Thermostat/Gas Valve) and remove wire tie from feedline.

b) Remove (2) 1/4" hex drive screws from right side inner door.

c) Remove (2) 1/4" drive screws from flange section of inner door.

d) Remove right side inner door and set aside. Be careful not to damage gasket

material on inner door.

SERVICE PROCEDURE RG-V

Combination Thermostat/Gas Valve

Testing and Replacement

14

Resettable Thermal Switch

Wire Connection

Remove Wire Tie

1/4" Hex Drive Screws shown

on Right Side Inner Door

1/4" Hex Drive Screws at

Flange section of Inner Door

Page 15

15

Step 7. Removal of combination thermostat/gas valve.

a) Disconnect main burner feedline

(3/4” wrench), pilot tube (7/16"

wrench) and thermocouple (3/8"

wrench) from combination

thermostat/gas valve & remove

from the combustion chamber.

b) Remove Piezo bracket with Piezo

igniter (refer to SERVICE

PROCEDURE RG-IV) from

combination thermostat/gas valve.

c) Remove combination thermostat/gas valve from heater, rotating counter clockwise using an

appropriately sized wrench. Use caution not to damage cast aluminum body of combination

thermostat/gas valve.

Step 8. Installation of combination thermostat/gas valve.

a) Install new combination thermostat/gas valve. Be certain not to damage the bundled wire leads.

Note: combination thermostat/gas valve must be installed in proper upright position to

assure the feedline will align properly at the inner door flange.

b) Reattach Piezo bracket with Piezo igniter to combination thermostat/gas valve.

c) Reattach main burner feedline, pilot tube and thermocouple to combination thermostat/gas valve.

d) Gather wire leads of combination thermostat/gas valve and Piezo igniter and secure along side of

feedline using new wire tie provided.

Step 9. Reinstallation of inner door assembly.

a) Prior to reinstallation of inner door, fully inspect inner door gasket for the following:

> Tears > Gasket Adhesion to inner door

> Missing material > Other imperfections that will inhibit proper seal

> Cracks > Material left on combustion chamber

> Dirt or debris

If the gasket is not affected by any of the above, gasket replacement will not be required.

If replacement is required, replace using new gasket kit following the instructions provided with kit.

SERVICE PROCEDURE RG-V

Combination Thermostat/Gas Valve

Testing and Replacement

Refer to

SERVICE PROCEDURE RG-IV

to remove Piezo igniter

Page 16

Step 9. Reinstallation of inner door assembly. (cont.)

b) Clean any gasket residue or other debris from combustion chamber surface before installing

the inner door/gasket assembly.

c) Position thermocouple, pilot tube and Piezo wire against left side inner door flange gasket.

DO N

OT R

OUTE THROUGH RADIUSED CHANNEL WITH FEEDLINE.

Be sure that

thermocouple and pilot tube are not in position to interfere with outer jacket burner access door

when reinstalled.

d) Firmly place right side inner door flange against the left side inner door flange and secure with two

1/4” hex drive screws from step 6c. DO NOT OVER TIGHTEN SCREWS.

e) Align right side inner door to combustion chamber and verify the fastener holes of the combustion

chamber are aligned with the right side inner door slotted openings. Verify seal integrity around

combustion opening. Secure right side inner door using 1/4” hex drive screws from step 6b.

DO NOT OVER TIGHTEN SCREWS. Verify both left and right sides of the inner door are properly

positioned and sealed against the combustion chamber.

Step 10. Reconnect wire leads from combination thermostat/gas valve to resettable thermal switch (See photo

in step 6). Note: wire terminations are interchangeable with either resettable thermal switch connection.

Step 11. Replace outer jacket burner access door.

Step 12. Reconnect gas supply to combination thermostat/gas valve.

Step 13. Resume water supply to water heater. Be sure tank is full of water.

Step 14. To resume operation follow the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

SERVICE PROCEDURE RG-V

Combination Thermostat/Gas Valve

Testing and Replacement

! WARNING

A seal breach may result in a fire or

explosion causing property damage,

personal injury or death.

!

16

Position thermocouple,

pilot tube and Piezo wire

Secure flange with

1/4" drive screws

Verify threaded hole

alignment with slotted

openings in inner door

Page 17

MAIN BURNER: Inspection, Adjustment, Cleaning and Replacement

At periodic intervals (not more then 6 months) a visual inspection should be made of the main burner for proper operation and to insure no debris accumulating.

Main burner should light smoothly from pilot and burn with a blue flame with a minimum of yellow tips.

Steel burner models have a self adjusting air mixture and do not have an adjustable air shutter. Cast iron burner can

have the gas and air mixture properly proportioned by adjusting the air shutter on the mixer face of the main burner

(see step 2 below).

Main burner must be free from any debris accumulation that may effect burner operation (See next page for cleaning

procedure).

CAST IRON BURNER ADJUSTMENT

Step 1. With main burner in operation, remove right side inner door per service procedure I, steps 3b & 3c.

Be sure to maintain wire connection to resettable thermal switch for this adjustment procedure.

Step 2. To adjust for proper burning, loosen the air shutter nut, rotate the shutter to close the opening in the

burner, then slowly rotate the shutter until the yellow tips disappear and the flame becomes blue.

Tighten the air shutter nut. Too much air will cause the flame to lift off the burner ports and create

noisy burner operation. Too little air (yellow tips) will result in soot formation. Place right side inner

door into proper position to confirm proper burner flame pattern and correct air shutter adjustment.

It may be necessary to allow the burner to operate for several minutes for burner flame to stabilize.

SERVICE PROCEDURE RG-VI

Burner Operation Inspection,

Adjustment, Cleaning and Replacement

! DANGER

Under no circumstances shall flammable materials be used or stored in the vicinity of the water heater.

With the inner door removed the Bradford White Defender Safety System will be inactivated.

If flammable vapors are present, a fire or explosion may result

causing property damage, personal injury or death.

Upon completion of the cast iron burner adjustment procedure, the inner door must be replaced per SERVICE

PROCEDURE RG-1, steps 4 through 14 to reactivate Bradford White Defender Safety System.

WARNING

Inner door and burner components may be HOT when performing this operation.

Take necessary precaution to prevent personal injury.

!

!

17

Air Shutter Nut

Page 18

MAIN BURNER: Inspection, Adjustment, Cleaning and Replacement (cont.)

Step 3. Fully inspect inner gasket per SERVICE PROCEDURE RG-I,

step 4. Replace gasket if required following SERVICE

PROCEDURE I, steps 5 & 6.

Step 4. Be certain that thermocouple, pilot tube and Piezo wire are

routed by inner door flange as shown and Reinstall inner

door per SERVICE PROCEDURE RG-I, step 10 and 11.

Step 5. Observe burner operation through sight glass of inner door. Burner should operate as adjusted in step

2, if not, repeat procedure compensating air shutter position for proper burner operation with inner

door in place.

Step 6. It may be necessary to clean main burner or main burner orifice to achieve proper burner operation.

If cleaning is required proceed to burner cleaning section in this procedure.

BURNER CLEANIN

G

(Steel & Cast Iron)

Step 1. Remove inner door assembly per SERVICE PROCEDURE RG-I, steps 1 through 3c.

Step 2. Disconnect main burner feed line (3/4 wrench), pilot tube (7/16 wrench) and thermocouple (3/8)

wrench from combination thermostat gas valve and remove burner assembly from combustion

chamber.

Step 3. Thoroughly inspect burner surface area and burner ports and remove any loose debris accumulation.

Step 4. On cast iron burners, inspect for

any debris build up inside burner

venturi. If found, disconnect

feedline from burner and remove

debris build up.

SERVICE PROCEDURE RG-VI

Burner Operation Inspection,

Adjustment, Cleaning and Replacement

18

Position thermocouple,

pilot tube and Piezo wire

Burner

Surface

Area

Burner

Port

Area

Burner Venturi

Opening

Feedline

Page 19

BURNER CLEANING (cont.)

Step 5. Disconnect (unscrew) main burner (stamped steel “B” burner) from main

burner orifice or on cast iron burners (“C” burner), loosen air shutter &

disconnect (unscrew) feedline from burner.

Step 6. Remove main burner orifice from feed line (1/2” wrench on steel burner,

3/8" wrench on cast iron). Inspect and clean if necessary.

Step 7. Remove pilot assembly, refer to SERVICE PROCEDURE RG-III for cleaning

and inspection.

Step 8. Reassemble burner.

Step 9. Inspect combustion chamber area of heater prior to reinstallation of

burner assembly. If cleaning is required, refer to SERVICE PROCEDURE

RG-VIII.

Step 10. Reinstall burner assembly into combustion chamber, reconnect feedline, thermocouple and pilot tube

to the combination thermostat/gas valve.

Step 11. Reinstall inner door per SERVICE PROCEDURE RG-I, steps 4 through 13.

Step 12. To resume operation, follow the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

SERVICE PROCEDURE RG-VI

Burner Operation Inspection,

Adjustment, Cleaning and Replacement

19

Page 20

RESETTABLE THERMAL SWITCH CONTINUITY TESTING

Step 1. Remove outer jacket door.

Step 2. Disconnect wire leads from resettable thermal switch.

Step 3. Using a multimeter capable of measuring continuity (Ohms), place one

probe of meter on one of the brass connection tabs of the resettable

thermal switch, and the remaining probe on the other connection tab.

Step 4. If continuity is indicated, the switch is closed, allowing millivolt current to

pass.

Step 5. If continuity is not indicated, the switch is open, possibly due to an over-

heating condition. The switch is designed to open at predetermined

temperatures depending on model. An open switch can be reset by

depressing the red colored button located at the center of the switch.

The overheating condition must be determined prior to putting the heater back in service.

SERVICE PROCEDURE RG-VII

Resettable Thermal Switch

Testing and Replacement

20

C

ORRECTIVE ACTION

1. Verify adequate combustion air supply is available.

2. Clear jacket slot openings of any dirt, dust, restrictions

or other obstructions.

3. Inspect flame arrestor plate and clean with stiff brush

and/or vacuum to remove scale deposits and debris.

1. Replace resettable thermal switch

2. Verify switch color code and approximate temperature.

1. Replace water heater.

PR

OBABLE CA

USE FOR RESETTABLE THERMAL SWITCH A

CTIVATION

PR

OBABLE CAUSE

Insufficient

combustion Air

1. Weak switch or

switch out of

calibration.

2. Incorrect switch.

Flammable vapor

incident

Color Code

Blue

Yellow

Red

Approximate

switch

activation

temperature

(open)

240˚

270˚

290˚

Resettable thermal switch

color code reference.

Page 21

RESETT

ABLE THERMAL SWITCH REPLA

CEMENT

Step 1. Rotate knob of combination thermostat gas valve to the off position.

Step 2. Remove outer jacket door.

Step 3. Disconnect wire leads from resettable thermal switch.

Step 4. Remove resettable thermal switch from inner door (Phillips screw driver).

Step 5. Place new resettable thermal switch in place. Be sure contact surface of resettable thermal switch and

inner door are free of any debris. Secure resettable thermal switch into place using screws from step 4.

DO NOT OVER TIGHTEN SCREWS.

Step 6. Reconnect wire leads from combination thermostat/gas valve to resettable thermal switch.

Note: wire termination are interchangeable with either resettable thermal switch connection.

Step 7. Replace outer jacket door.

Step 8. To resume operation follow the instructions located on the lighting instruction label or the lighting

instruction located in the installation and operation manual.

SERVICE PROCEDURE RG-VII

Resettable Thermal Switch

Testing and Replacement

21

Page 22

Scr

eenLok Flame Arrest

or Cleaning

Step 1. Rotate knob of combination thermostat gas valve to the off position.

Step 2. Remove outer jacket door.

Step 3. Remove inner door per SERVICE PROCEDURE RG-I, step 3a through 3e.

Step 4. Disconnect main burner feed line (3/4 wrench), pilot tube (7/16 wrench)

and thermocouple (3/8) wrench from combination thermostat gas valve

and remove burner assembly from combustion chamber.

Step 5. Clean ScreenLok Flame Arrestor using stiff brush, compressed air and/or

shop vacuum to remove any scale or other debris accumulation. Using a

soft brush, clear jacket openings from any dirt, dust, restrictions or other obstructions.

Step 6. Remove any debris from burner assembly per SERVICE PROCEDURE RG-V and reinstall burner

assembly into combustion chamber.

Step 7. Reconnect feedline, thermocouple and pilot tube to the combination thermostat/gas valve.

Step 8 Reinstall inner door per SERVICE PROCEDURE RG-I, steps 4 through 13.

Step 9. To resume operation follow the instructions located on the lighting instruction label or the lighting

instruction located in the installation and operation manual.

SERVICE PROCEDURE RG-VIII

ScreenLok Flame Arrestor Cleaning

22

Page 23

23

Dip T

ube Inspection and Replacement

Step 1. Rotate knob of combination thermostat/gas valve to “OFF” position.

Step 2. Turn off cold water supply to heater. Connect hose to drain spigot of water heater and route to an

open drain. Open a nearby hot water faucet to vent heater for draining. Open drain spigot of water

heater and allow heater to drain to a point below the inlet connection nipple.

Step 3. Disconnect inlet nipple from plumbing system.

Step 4. With an appropriate wrench, remove inlet nipple/dip tube from the water heater. Use caution not to

damage pipe threads.

Step 5. Visually Inspect inlet nipple/dip tube. Inlet nipple/dip tube should be free of cracks and any blockage.

Hydro-jets located near the bottom of the dip tube should be open and free of any blockage.

Anti-siphon holes located approximately 6" from the bottom of nipple, should be free of any blockage.

Any damage such as cracks, restriction due to deformation or unintentional holes are not field

repairable and the inlet nipple/dip tube must be replaced.

Step 6. Upon completion of inspection or subsequent replacement, reinstall inlet nipple/dip tube into heater.

Connect nipple to plumbing system, resume water supply and refill heater with water.

Step 7. To resume operation follow the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

SERVICE PROCEDURE RG-IX

Dip Tube and Anode

Inspection and Replacement

! WARNING

Heater components and stored water may be HOT

when performing the following steps in

this procedure. Take necessary precaution to prevent personal injury.

!

Page 24

24

Anode Inspection and R

eplacement

Step 1. Turn off water supply to water heater. Rotate knob of combination thermostat/gas valve to “OFF”

position.

Step 2. Turn off cold water supply to heater. Connect hose to drain spigot of water heater and route to an

open drain. Open a nearby hot water faucet to vent heater for draining. Open drain spigot of water

heater and allow heater to drain to a point below the outlet connection nipple.

Step 3. Disconnect outlet nipple from plumbing system.

Step 4. With an appropriate wrench, remove outlet nipple/anode from the water heater. Use caution not to

damage pipe threads.

Step 5. Visually Inspect outlet nipple/anode. Outlet nipple/anode should show signs of depletion, this is

normal. If depletion is 1/2 of the original anode diameter (approximately 3/4” diameter), replacement

is recommended. If any of the steel core of the anode is exposed, replacement is recommended.

Step 6. Upon completion of inspection or subsequent replacement, reinstall outlet nipple/anode into heater.

Connect nipple to plumbing system, resume water supply and refill heater with water.

Step 7. To resume operation, follow the instructions located on the lighting instruction label or the lighting

instructions located in the installation and operation manual.

SERVICE PROCEDURE RG-IX

Dip Tube and Anode

Inspection and Replacement

! WARNING

Heater components and stored water may be HOT

when performing the following steps in

this procedure. Take necessary precaution to prevent personal injury.

!

Page 25

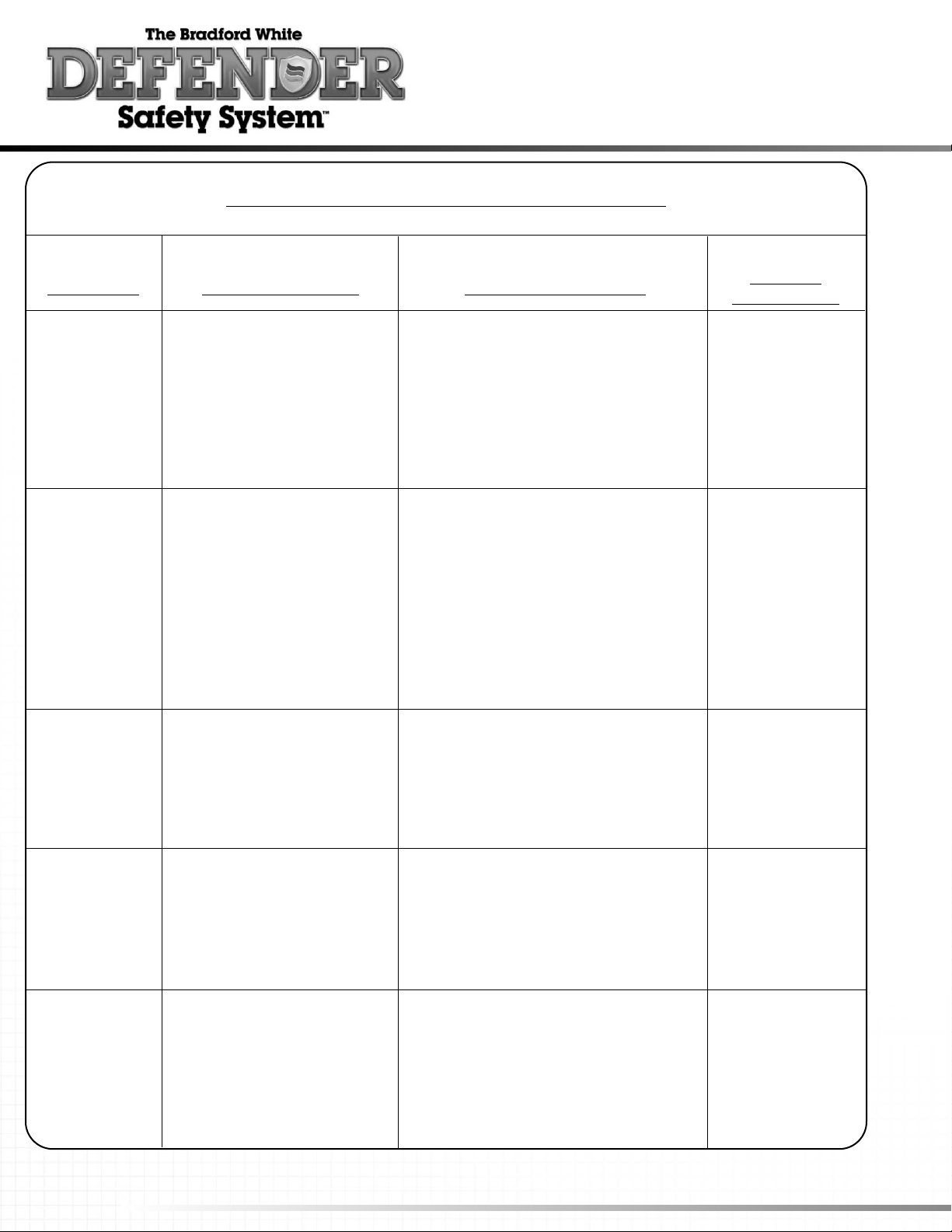

25

1 Draft Hood

2 Hot Water Outlet/Anode

3 Cold Water Inlet Tube

4 Flue Baffle

5 T&P Relief Valve

6 Thermostat

7 Piezo Igniter

8 Brass Drain Valve

9 Screw-#8-18 x 3/4 Hex Washer Head

10 Screw-#10-12 x 3/4 Hex Washer Head

11 Left Side Inner Door with Gasket

12 Complete Right Side Inner Door

12A Right Side Inner Door with Gasket

13 Sight Glass Assembly

14 Resettable Thermal Switch

15 Screw#6-20 x 3/8 PHCR

16 Outer Door

17 Complete BN Burner Assembly

18 BN Burner Only

19 Main Burner Orifice

20 Pilot Assembly

21 Pilot Orifice

22 Thermocouple

23 Feed Line

24 Complete Cast Iron Burner Assembly

25 Cast Iron Burner Only

26 Main Burner Orifice

27 Pilot Assembly

28 Pilot Orifice

29 Air Shutter

30 Air Shutter Nut

31 Thermocouple

32 Feed Line

33 ASSE Approved Mixing Valve (Optional)

34 3/4 NPT Tank Plug (XR models)

35 Inner Door Gasket Kit

36 Wire Tie

PARTS LIST

Page 26

26

Notes

Page 27

27

Notes

Page 28

Sales/800-523-2931

Fax/215-641-1670

Technical Support/800-334-3393

Fax/269-795-1089

Warranty/800-531-2111

Fax/269-795-1089

International:

Telephone/215-641-9400

Telefax/215-641-9750

Ambler, PA

888-538-7833

Fax on Demand:

bradfordwhite.comwww.

For U.S. and Canada field service,

contact your professional installer or

local Bradford White sales representative.

Sales/866-690-0961

905-238-0100

Fax/905-238-0105

Technical Support/800-334-3393

Mississauga, ON

Email

parts@bradfordwhite.com

techserv@bradfordwhite.com

www.bradfordwhite.com

www.bradfordwhitecanada.com

Loading...

Loading...