Bradford White EFT-6500-4-S-10, EFT-5500-4-S-10, EFT-8300-2-S-10, EFT-7500-4-S-10, EFT-9500-4-S-10 Installation Manual And Owner's Manual

...

ELECTRIC INSTANTANEOUS WATER

HEATER

INSTALLATION GUIDE AND OWNERS MANUAL

“THERMOSTATIC”

MODELS COVERED:

EFT-5500-4-S-10 240V

EFT-6500-4-S-10 240V

EFT-7500-4-S-10 240V

EFT-9500-4-S-10 240V

EFT-8300-2-S-10 208V

EFT-6000-5-S-10 277V

EFT-8000-5-S-10 277V

EFT-9000-5-S-10 277V

EFT-10000-5-S-10 277V

READ THIS MANUAL CAREFULLY BEFORE ATTEMPTING TO INSTALL OR OPERATE

THIS WATER HEATING UNIT. IF YOU DO NOT FOLLOW THE SAFETY RULES, THE

UNIT WILL NOT OPERATE PROPERLY AND COULD CAUSE DEATH, SERIOUS

BODILY INJURY AND OR PROPERTY DAMAGE.

READ ALSO THE ENCLOSED WARRANTY CARD. WARRANTY OF THIS WATER

HEATING UNIT WILL DEPEND ON PROPER INSTALLATION AND OPERATION. THE

WARRANTY SHALL BE VOID IF THE DESIGN HAS BEEN ALTERED IN ANY WAY

WHATSOEVER. THE MANUFACTURER OF THIS UNIT WILL NOT BE LIABLE FOR

ANY DAMAGES BECAUSE OF FAILURE TO COMPLY WITH THE INSTALLATION AND

OPERATING OUTLINED ON THE FOLLOWING PAGES.

THE INSTALLATION MUST CONFIRM WITH THE INSTRUCTIONS IN THIS MANUAL;

ELECTRIC COMPANY RULES; AND LOCAL CODES, OR IN THE ABSENCE OF LOCAL

CODES, WITH THE LATEST EDITION OF THE NATIONAL ELECTRICAL CODE. A

COPY OF THE NATIONAL ELECTRICAL CODE IS AVAILABLE FROM

UNDERWRITERS LABORATORIES, 333 PFINGSTEN ROAD, NORTHBROOK, IL,

60062.

IF ASSISTANCE IS REQUIRED OR ANY QUESTIONS ARISE RELATING TO THE

INSTALLATION OR THE PERFORMANCE OF THIS UNIT, CONTACT TECHNICAL

SERVICE DEPARTMENT TOLL FREE AT 1-800-334-3393.

HAVE THE INFORMATION LISTED BELOW BEFORE CALLING:

MODEL NO. SERIAL NO. INSTALL DATE .

GENERAL

This “Thermostatic” water heating unit is specifically designed to take in cold or pre-heated water and

heat it to temperatures suitable for domestic usage up to a maximum of 140°F (60°C). To obtain

optimum performance and energy savings. The unit should be located as near as possible to the point of

use.

The unit is supplied with compression rings and nuts suitable for direct coupling to standard 1/2” (5/8”

outside diameter) copper or plastic piping. There is no need for additional screwed fittings and under no

circumstance shall a blow torch be used on the pipe while the pipe is connected to the unit (serious

damage to the electronic flow switch will result).

Also, ensure that pipes are clear of installation debris before fitting to the unit.

THIS UNIT MUST HAVE ITS OWN INDEPENDENT CIRCUIT, USING CORRECTLY

RATED WIRES AND CIRCUIT BREAKERS. THE CIRCUIT SHOULD BE PROVIDED

WITH A “GROUND FAULT INTERUPTER” WHERE REQUIRED BY LOCAL, STATE

AND NATIONAL ELECTRICAL CODES.

FAILURE TO GROUND THIS UNIT MAY RESULT IN DEATH OR SERIOUS INJURY

MOUNTING THE UNIT

1) The unit should be mounted as close to the point of use as possible. For example, directly beneath a

sink is ideal. Do not install the unit above a faucet as a siphoning effect will drain the unit causing heating

element burn out.

2) This unit must only be mounted in a vertical position with the water fittings at the bottom of the unit.

Mounting other than in the vertical position WILL cause heating element burn out.

3) The cold water inlet is on the right hand side and the hot water outlet is on the left hand side(as viewed

from the front of the unit). Under NO circumstances can these be reversed.

4) Leave a minimum of 8’’ ABOVE the unit for easy replacement of the heating element.

5) The unit should be fixed to the wall using screws in the four mounting holes at each corner of the

backplate.

NOTE: The unit should be installed below the level of all hot water outlets serviced by this unit.

NOTE: PRESSURE AND TEMPERATURE RELIEF VALVE

This unit is not required to have a Pressure and Temperature safety relief valve(PTPV). Consult

local codes to find out if one is required in your area. If local codes require the use of a

temperature and pressure valve one should be installed on the hot water outlet pipe, before the

ball valve

Plumbing Connections

NOTE:

ALL MOUNTING AND PLUMBING MUST BE COMPLETED BEFORE PROCEEDING

WITH THE ELECTRICAL HOOK-UP.

TEST THE INSTALLATION FOR LEAKS BEFORE CONNECTING THE ELECTRICAL

SUPPLY.

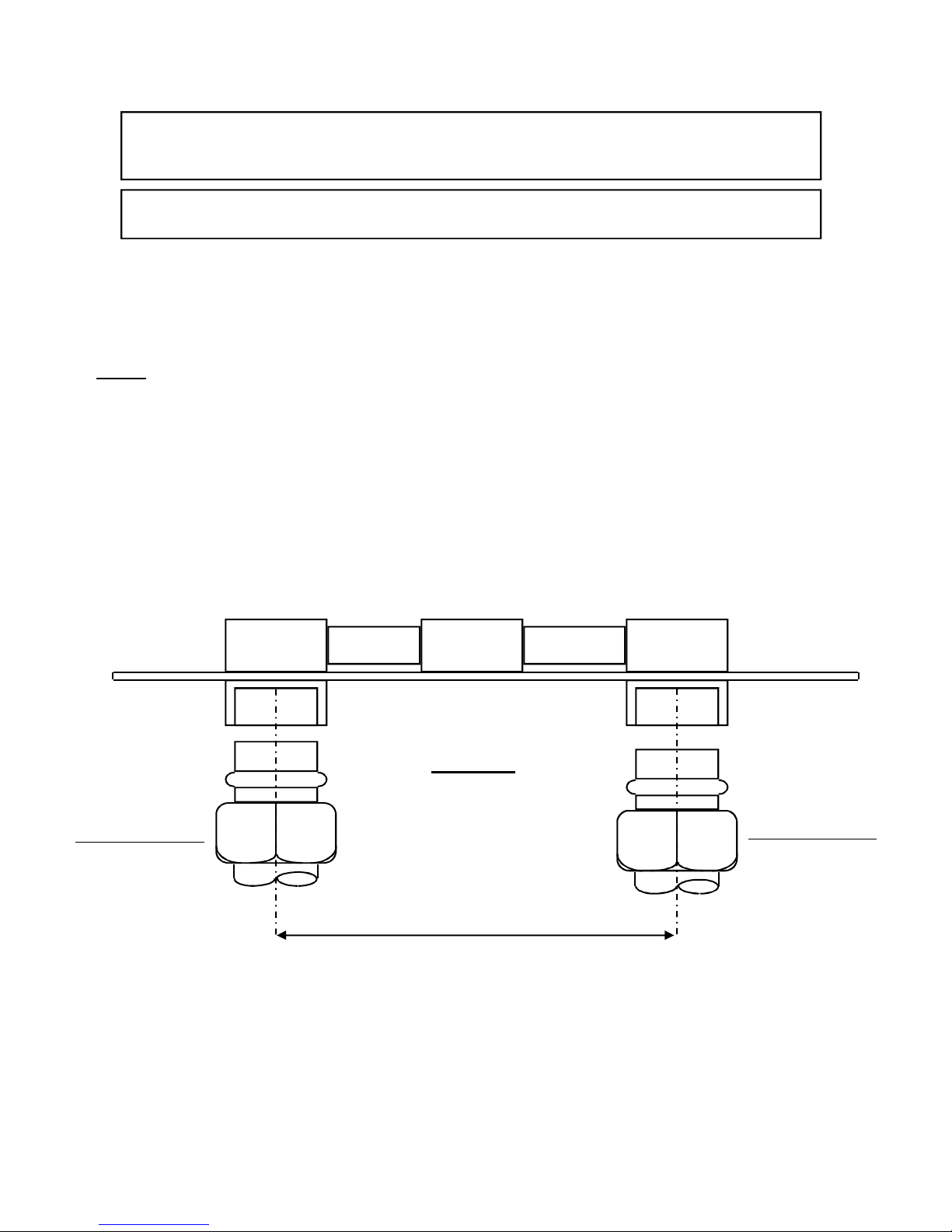

1) This unit is supplied with compression fittings, USE THESE; DO NOT USE TAPERED THREAD PIPE

FITTINGS AND DO NOT SOLDER PIPE TO THE INLET OR OUTLET(SEE FIGURE 1).

2) Ensure that the pipes are correctly aligned with the inlet and outlet bosses in order to avoid excessive stress

on the heater body molding.

NOTE: When soldering pipe joints, remove the unit from the wall. Serious damage can occur if any soldering is

done while pipes are connected to the unit. Run water through the supply pipe to remove all debris from the

pipe before connecting the unit. Failure to do so could cause damage to the flow switch.

3) Install isolating valves (full flow ball valve type) in both the inlet and outlet lines. This allows the unit to be

isolated for maintenance (figure 2).

4) When all plumbing is complete, inspect the system for water leaks at all the plumbing connections. If a water

leak is present take corrective action. If a water leak is at the compression fitting, slowly tighten compression nut

until it the water leak ceases.. Fully open both inlet and outlet BALL VALVES.

Run all hot water outlets fed by this unit, one at a time until the water flow is continuous and free from “gulping”

and all visible air pockets.

HOT WATER

OUTLET

COMPRESSION

FITTING

DO NOT SOLDER

Figure 1

COLD WATER

INLET

COMPRESSION

FITTING

DO NOT SOLDER

1 1/2”

Loading...

Loading...