Bradford White D-80T-180-3N, D-100S-250-3NA, D-100T-250-3NA, D-38T-155-3N+, D-100S-199-3N Installation Manual

...

a plumbing prof essional.

personal injury or death.

GAS-FIRED COMMERCIAL WATER HEATER

- Do not st ore or use gasoline or ot her

- WHA T T O DO IF Y OU SMELL GAS

- For your family ’s com f ort, saf et y and

W A RNI N G: I f the informa t ion in

t hese inst r uct ions is not followed

exact ly, a f ire or explosion may

result ca using propert y dam age,

f lammable vapors and liquids in t he

vic inity of t his or any ot her appliance.

• Do not t r y to light any appliance.

• Do not t ouc h any elect ric al switch; do

not use any phone in your building.

• Immediately call y our gas supplier

f rom a neighbor’ s phone. Follow the

gas supplier’ s instructions.

• If y ou cannot reach your gas supplier,

cal l th e fi r e d epar tmen t.

conv enience, it is recomm ended this

water h eater b e i ns tal l ed and ser vi c ed b y

INSTALLATION/OPERATION MANUAL

PLACE THESE INSTRUCTIONS ADJACENT TO WATER HEATER AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE

WITH TROUBLESHOOTING GUIDE

238-47675-00F 8/18

SECTION I: IM P O RTANT INFORMATION

Thi s water h eater h as a l im i t ed warr anty. The warr an t y for thi s water h eater i s v al id o nl y if th e water h eater

any damage, injury, or loss of lif e resulting f rom alteration and/or f ailure to com ply wit h these instruct ions.

IMPORTANT-Before proceeding, please inspect the water heater and components for possible damage. DO NOT

purchased or the manufacturer listed on the rating plate for replacement parts.

NOTICE

I

IMPORTANT INFORMATION..........................2

VIII

ELECTRICAL CONNECTIONS.....................21

II

SPECIFICATIONS............................................5

IX

OPERATING INSTRUCTIONS......................23

III

GENERAL INFORMATION..............................8

X

MAINTENANCE.............................................32

DIAGNOSTIC AND TROUBLESHOOTING

GUIDE............................................................34

V

VENTING........................................................15

XII

PARTS LIST...................................................54

INSTALLATION FOR POTABLE

WATER AND SPACE HEATING...................55

VII

GAS CONNECTIONS....................................19

XIV

NOTES………………………………………….56

TA BLE OF CONTENTS

This gas-fired water heater is design certified by CSA International under the American National Standard,

READ CAREF ULLY

Indicates special instruc t ions on installation,

Indicates a pot entially hazardous sit uation, which,

WARNING

Indicates potent ially hazardous situat ion, which, if

injury or property damage.

CAUTION

Indicat es an imminent ly hazardous sit uation,

injury or substant ial property damage.

DANGER

Z21.10.3 and CAN/CGA 4.3-M (as indicated on the rating plate). These st andards are available from CSA

Standards Association, 5060 Spectrum Way Mississauga, Ontario L4W 5N6 CANADA.

This w ater heater must be installed in accordance w ith loc al codes. In the absence of local codes, it must be

installed in compliance w it h t he National Fuel Gas Code (ANSI Z223 . 1-Latest Edition), or in Canada CAN/CGA

B149.1 Natural Gas Installation Code (Latest Edition) or CAN/CGA B14 9.2 Propane Instal lat ion Co de (Lat est

Edition).

The follow ing terms are used throughout t his manual to bring at t ention t o the presence of hazards at various

risk levels, or t o import ant inf ormat ion concerning product lif e.

w hic h, if not avoided, will result in death, serious

not avoided, may result in moderate or minor

NOTICE

if not avoided, could result in death, serious injury

or substantial property damage.

has been installed, maintained and operated in accordance w it h these instructions. The warranty does not

cover damage or injury caused by t he use of any energy-saving devices (other than t hose aut horized by t he

manufact urer) in conjunct ion wit h t his wat er heater. The use of unaut horized energy-sav i ng d ev ic es m ay

dec reas e t h e l ife o f t he water heater and endanger life and/or property. The manufact urer will not be liable for

install damaged components. If damage is evident, please contact the supplier where the water heater was

operation or m aintenance, w hic h are import ant

but not related to personal injury hazards.

IV INSTALLATION INSTRUCTIONS..................10 XI

VI WATER CONNECTIONS……………………..17 XIII

2

DANGER

DO NOT store or use gas oline or other f lammable, combustible, or corrosive vapors and/or liquids in the vicinity of this

or any other appliance.

This water heater is equipped with an adjustable thermostat to control water temperature. Hot water temperatures

The slower

or to draw their own bath water. NEVER leave a child or disabled person unattended in a bathtub or shower.

Toxic chemic al, such as those used for boiler treatment, must not be introduced into potable water used for spac e

heating.

This water heater must not be connected to an existing heating system or c omponent(s) pr eviously used with a nonpotable water heating appliance.

All piping components connected to this water heater for space heating applications must be suitable for use with

WARNING

Improper installation, adjustments, alteration, service or maintenance can cause property damage, personal injury or

reference by owner and service technician.

This water heater requires regular maintenance and service to operate safely. Follow the instructions contained in this

manual.

Installation, maintenance, and service must be performed only by a qualified, skilled and knowledgeable installer or

service provider.

Installation is not complete unless a temperature and pressure relief valve is installed into the proper location at the

top of this water heater.

It is the responsibility of the installing contractor to see that all controls are correctly installed and are properly

operating when the installation is complete.

DO NOT operate this water heater without first being certain it is filled with water.

DO NOT tamper with or alter the water heater and/or controls.

DO NOT operate water heater with jumpered or absent controls or safety devices.

DO NOT operate water heater if any external part has been under water. Immediately call a qualified service

been under water.

DO NOT attempt to use this water heater with any gas other than the type listed on the rating plate. Do not attempt to

gas company if there are any questions.

For installations in high altitude regions, this water heater must be ordered from the supplier to the manufacturer’s

constructed water heaters.

Incorrect operation of this appliance may create a hazard to life and property and will nullify the warranty.

DO NOT operate this water heater if the input rate exceeds the rate shown on the water heater rating plate.

This water heater contains very hot water under high pressure. Do not unscrew any pi pe fittings nor attempt to

unless they are cool.

This water heater must be properly vented and connected to an approved vent system in good condition. DO NOT

required for automatic dishwasher and laundry use can cause scald burns resulting in serious personal injury and/or

death. The temperature at which injury occurs varies with the person’s age and the time of exposure.

response time of disabled pers ons incr eases the hazards to them . NEVER allow small children to use a hot water tap,

potable water.

loss of life. Failure to follow all instructions in the proper order can cause personal injury or death. Read and

understand all instructions, including all those provided with the appliance before installing, starting-up, operating,

maintaining or servicing this appliance. Keep this manual and literature in legible condition with this water heater for

technician to inspect the appliance and to replace any part of the control system including gas controls, which has

convert this water heater for use with a gas other than the type for which it is equipped. Failure to use the proper gas

can create an unsafe condition resulting in property damage, bodily injury, or death. Consult your local gas supplier or

specifications for that particular altitude. Contact the company listed on the rating plate when ordering high altitude

disconnect any components of this water heater without positively assuring the water is cool and is not under pressure.

Always wear protective clothing and equipment when installing, starting up or servicing this water heater to prevent

scald injuries. Do not rely on the temperature gauges to determine the temperature. Do not touch any components

operate water heater with the absence of an approved vent system. A clean and unobstructed vent system is

necessary to allow noxious fumes that could cause injury or loss of life to vent safely and will contribute toward

maintaining the water heater’s efficiency.

3

WARNING

This water heater needs fresh air for safe operation and must be installed so there are provisions for adequate

burners, and flue tubes and creates a risk of asphyxiation.

Water heater materials of construction, products of combustion and the fuel contain carbon monoxide, nitrogen oxides,

respirators and equipment when servicing or working nearby this water heater.

Flammable items, pressurized containers or any other potential fire hazardous articles must never be placed on or

with this water heater.

Insulation blankets are not required for this water heater. This water heater meet s or exceeds the ASHRAE/IES 90.1b

(latest edition) standards with respect to insulation and standby loss requirements.

Set t ing t he w at er t emperature t o t he maximum set point c an result in scalding hot water deliv er ed to th e

r a long

faucet at the time it is open.

Liquefied petroleum gases/propane gas is heavier than air and will remain at floor level if there is a leak.

D O NO T O PERATE THE APPL I AN CE U NTI L T HE LEAK A G E IS C O R REC TED !

WARNING

Prior to connecting the gas supply line to a gas fired water heater, ensure that the gas supply line does not have

WARNING

combustion and ventilation air. Insufficient air supply will cause a recirculation of combustion products resulting in

contamination that may be hazardous to life. This will result in carboning or sooting of the combustion chamber,

aldehydes and/or other toxic or harmful substanc es which can cause death or serious injur y and which are known to

the state of California to cause canc er, birth defects and other reproductive harm . Always use proper safety clothing,

adjacent to the water heater. Open containers of flamm able material should not be stored or us ed in the same room

faucets. It is highly recommended that t he maximum setpoint be adjusted t o t he lowest t emperature possible

f or t he needs of t he installation. See f ollowing section in t his Inst allat ion/Operat ion Manual t o c hange the

maximum set point limit (max setpoint ). M ak e su re th e wat er heater c on tro l di sp lay i s no t i n a p ub l ic ar ea t h at

can result in t he t emperature sett ings being improperly adjusted.

Hydrogen gas can be produced in an operating water heater that has not had water drawn from the tank fo

period of time (generally two weeks or more) . Hydrogen gas is extremely flammable. To prevent the possibility of injury

under these conditions, we recomm end the hot water faucet to be open for several minutes at the kitchen sink before

you use any electrical appliance, which is connect to the hot water system. If hydrogen is present, there will be unusual

sounds such as air escaping through the pipes as hot water begins to f low. Do not smoke or have open flame near the

moisture/water or dirt/scale inside the gas line. Commonly this check is done at the lowest point in the gas

distribution system prior to gas burning appliances.

Do not use this appliance if any external part to the tank has been submerged in water. You should contact a qualified

service technician to inspect the appliance and to replace any part of the control system including the combination gas

control which has been submerged in water. See the Gas Connections section of this manual before servicing or replacing

a water heater that has had any external part to the tank submerged in water.

Basement s, craw l spaces, closets and areas below ground level w ill serve as pockets for accumulat ion of

leak in g gas. Before lighting, smell all around the appliance area for gas. Be sure to smell next to t he f loor.

I F Y O U S MELL GA S :

• DO NOT try to light any appliance.

• DO NOT touch any elect ric sw itch; do not use any t elephone in your building.

• Immediately call your gas supplier from a telephone in another building. Follow the gas supplier’s

instructions.

• If y ou cannot reach your gas supplier, call t he fire department.

To comply with NSF requirements this water heater is to be:

a) Sealed to the floor with sealant, in a smooth and easily cleanable way, or

b) Installed with an optional leg kit that includes legs and/or extensions that provide a minimum clearance of 6”

beneath the water heater.

4

Model Description

Capacity

(GAL)

Input (BTU/hr)

Nat.

LP

100

199,999

199,999

75.00

64.75

56.50

4.63

23 6 100

250,000

250,000

75.00

64.75

56.50

4.63

23 6 100

270,000

N/A

75.00

64.75

56.50

4.63

23 6 100

300,000

300,000

75.44

64.75

56.50

4.63

23 7 80

399,999

375,000

71.50

60.25

51.50

10.25

N/A 8 80

450,000

425,000

69.00

60.25

51.50

10.25

N/A

10

80

505,000

475,000

69.00

60.25

51.50

10.25

N/A

10 Model Description

Input (kW/hr)

(Litres)

Nat.

LP

378.5

58.6

58.6

191

164

144

11.8

58.4

15.2

378.5

73.2

73.2

191

164

144

11.8

58.4

15.2

378.5

79.1

N/A

191

164

144

11.8

58.4

15.2

378.5

87.9

87.9

192

166

144

11.8

58.4

17.8

302.8

117.2

109.9

181

153

131

26.0

N/A

20.3

302.8

131.8

124.5

175

153

131

26.0

N/A

25.4

302.8

148.0

139.2

175

153

131

26.0

N/A

25.4

Model Description

Capacity

(GAL)

Input

(BTU/hr)

65

370,000

71.38

64.75

54.13

8

399,999

(NAT ONLY)

75

300,000

72.00

65.75

54.13

7

80

425,000

81.00

75.50

64.50

10

80

505,000

81.00

75.50

64.50

10 Model Description

Capacity

(Litres)

Input

(kW/hr)

246.1

108.4

181

164

137

20.3

117.2

(NAT ONLY)

283.9

87.9

183

167

137

17.8

302.8

124.5

206

192

164

25.4

302.8

148.0

206

192

164

25.4

Model Description

Capacity

(GAL)

Input

(BTU/hr)

65

370,000

73.25

64.75

54.50

8

399,999

(NAT ONLY)

75

300,000

75.88

65.75

54.13 7 80

425,000

82.75

75.50

64.50

10

80

505,000

82.75

75.50

64.50

10 Model Description

Capacity

(Litres)

Input

(kW/hr)

246.1

108.4

186

165

138

20.3

117.2

(NAT ONLY)

283.9

87.9

193

167

138

17.8

302.8

124.5

210

192

164

25.4

302.8

148.0

210

192

164

25.4

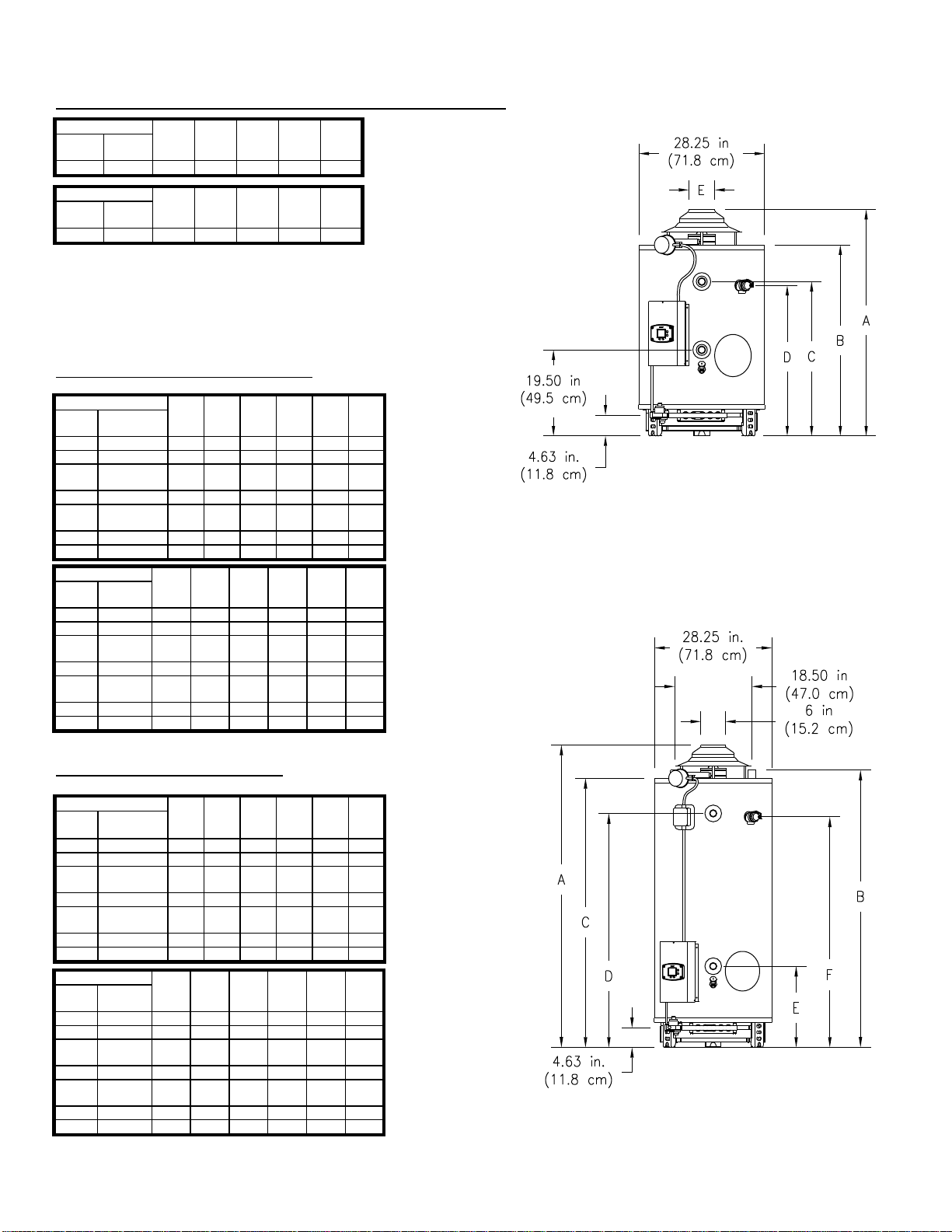

Figure 1

Figure 2

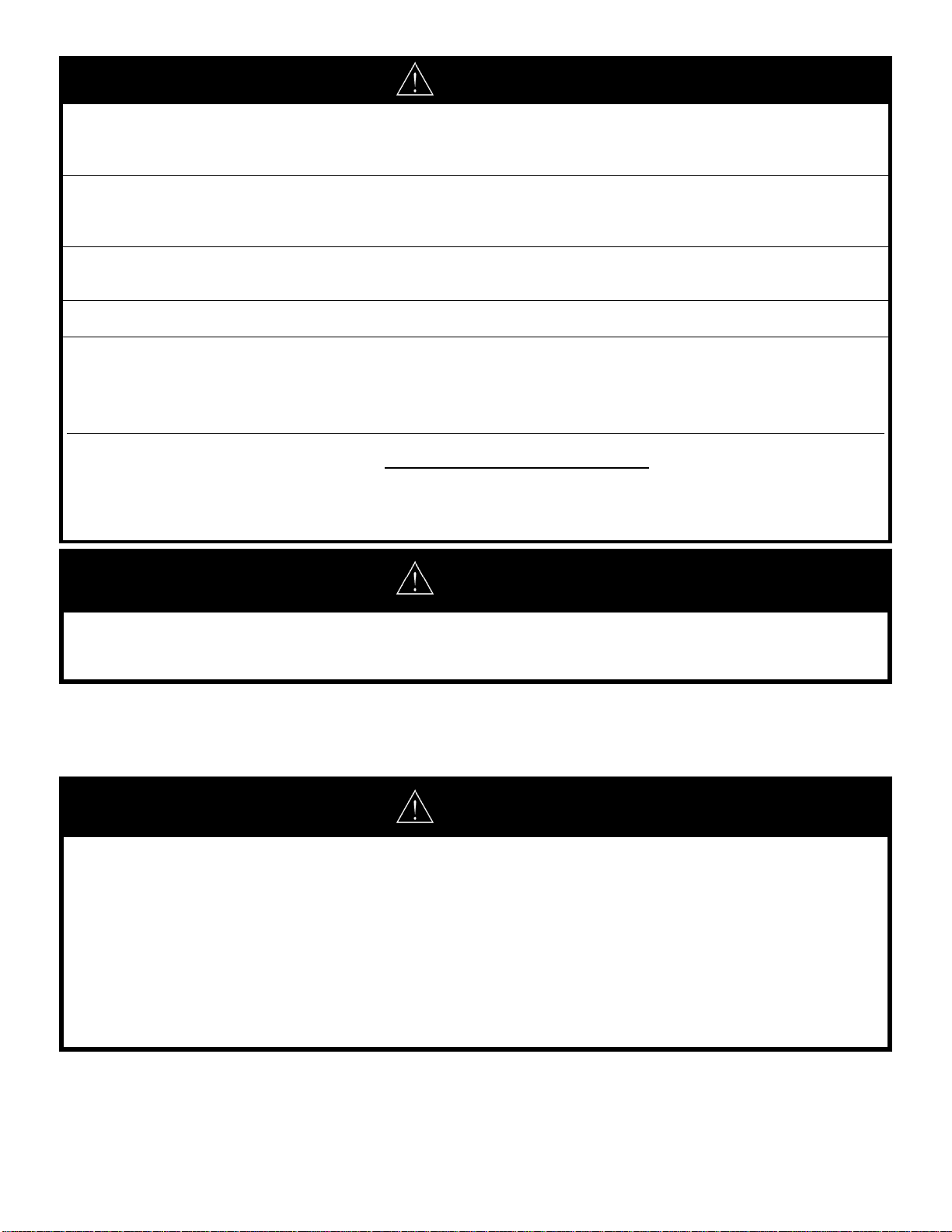

SECTION II: SPECIFICATIONS

Non-Flue Damper Models and Flue Damper Models (Figure 1)

A

(in) B (in) C (in) D (in) E (in) F (in)

F

E

D

C

B

Capacity

A

(cm)

(cm)

(cm)

(cm)

(cm)

(cm)

1. N/A - Denotes not available.

Non-Flue Damper Models (Figure 2)

A

(in.) B (in.) C (in.) D (in.)

65

246.1

71.38 64.75 54.13 8

A

(cm) B (cm) C (cm) D (cm)

181 164 137 20.3

Flue Damper Models (Figure 2)

A

(in.) B (in.) C (in.) D (in.)

65

246.1

73.25 64.75 54.50 8

A

(cm) B (cm) C (cm) D (cm)

186 165 138 20.3

5

Model Description

E

Capacity

(GAL)

Input

(BTU/hr)

38

155,000

51.00

43.50

35.00

33.75

6 Model Description

Capacity

(Litres)

Input

(kW/hr)

143.9

45.4

130

110

89

86

15.2

Model Description

Cap.

(GAL)

Input

(BTU/hr)

80

180,000

70.13

66.25

64.50

56.00

19.50

55.13

80

199,999

70.13

66.25

64.50

56.00

19.50

55.13

250,000

(235,000 LP)

98

199,999

81.13

77.25

75.50

67.00

19.50

66.13

250,000

(235,000 LP)

100

199,999

75.50

69.88

61.88

60.38

20.75

56.88

100

250,000

75.50

69.88

61.88

60.38

20.75

56.88

Model Description

Cap.

(GAL)

Input

(BTU/HR)

80

180,000

71.88

66.25

64.50

56.00

19.50

55.13

80

199,999

71.88

66.25

64.50

56.00

19.50

55.13

250,000

(235,000 LP)

98

199,999

83.38

77.25

75.50

67.00

19.50

66.13

250,000

(235,000 LP)

100

199,999

76.75

70.00

67.88

60.38

20.75

56.88

100

250,000

76.75

70.00

67.88

60.38

20.75

56.88

Model Description

Cap.

(Liters)

Input

(kW/hr)

302.8

52.8

178

169

164

142

49.5

140

302.8

58.7

178

169

164

142

49.5

140

73.3

(68.9 LP)

371.0

58.7

206

196

192

170

49.5

168

73.3

(68.9 LP)

378.5

58.7

192

177

157

153

52.7

144

378.5

73.3

192

177

157

153

52.7

144

Model Description

Cap.

(Liters)

Input

(kW/hr)

302.8

52.8

183

169

164

142

49.5

1.40

302.8

58.7

183

169

164

142

49.5

1.40

73.3

(68.9 LP)

371.0

58.7

224

196

192

170

49.5

1.68

73.3

(68.9 LP)

378.5

58.7

192

177

157

153

52.7

1.44

378.5

73.3

192

177

157

153

52.7

1.44

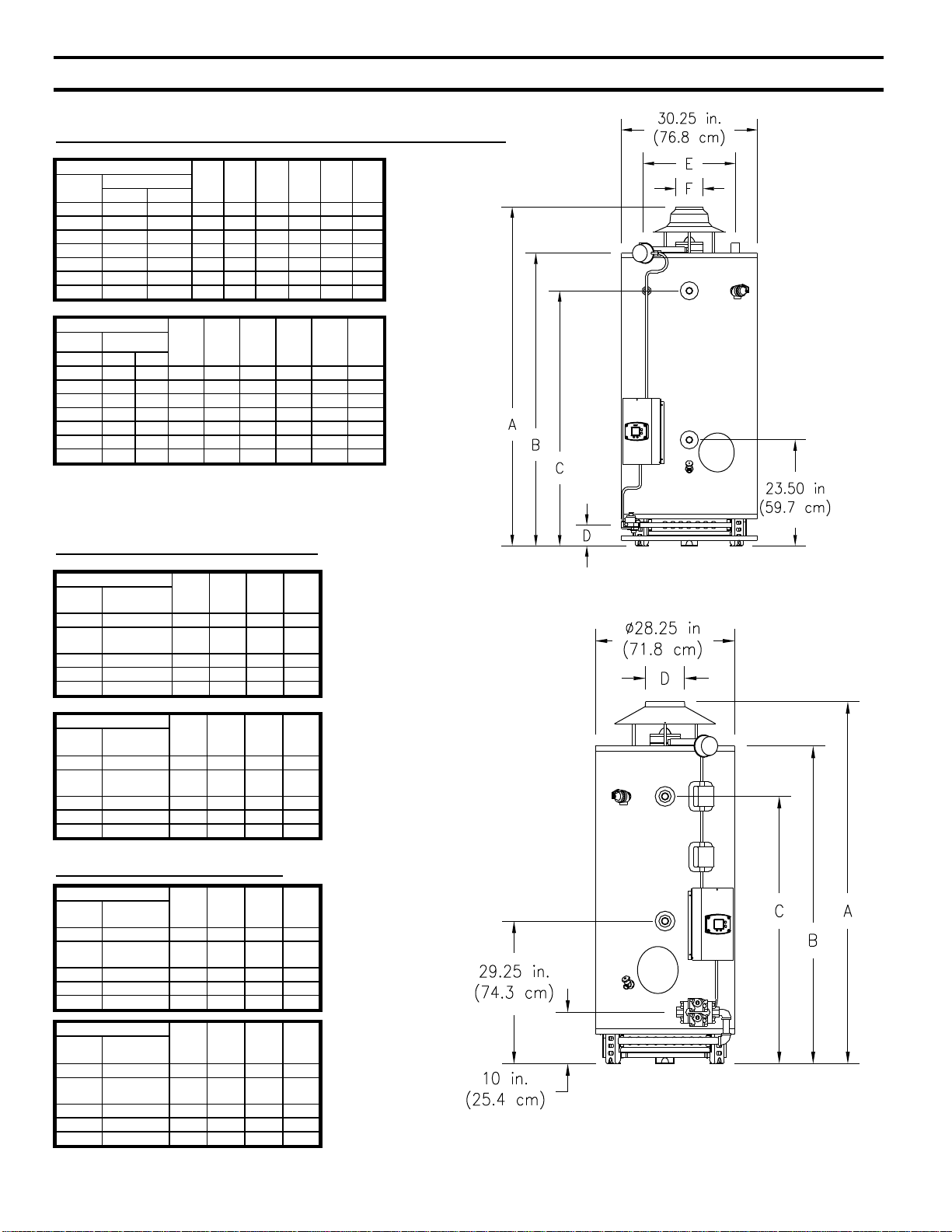

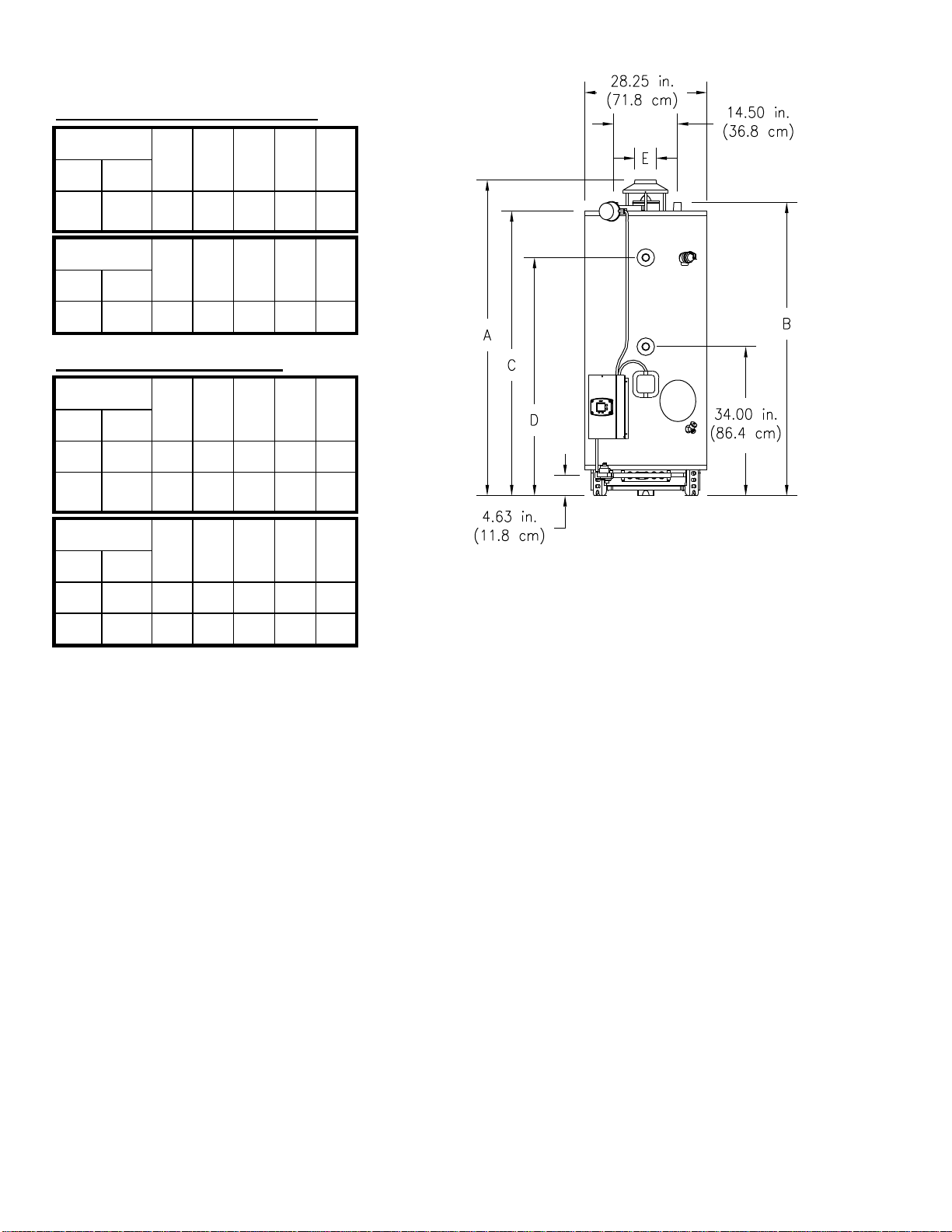

Figure 3

Figure 4

Flue Damper Models and Non-Flue Damper Models (Figure 3)

A

(in.) B (in.) C (in.) D (in.)

A

(cm) B (cm) C (cm) D (cm) E (cm)

Non-Flue Da mper Models (Figure 4 )

A

(in.) B (in.) C (in.) D (in.) E (in.) F (in.)

(in.)

80

98

302.8

371.0

70.13 66.25 64.50 56.00 19.50 55.13

82.88 77.25 75.50 67.00 19.50 66.13

A

(cm) B (cm) C (cm) D (cm) E (cm) F (cm)

178 169 164 142 49.5 140

211 196 192 170 49.5 168

Flue Damper Models (Figure 4)

A

(in.) B (in.) C (in.) D (in.) E (in.) F (in.)

80

98

71.88 66.25 64.50 56.00 19.50 55.13

88.38 77.25 75.50 67.00 19.50 66.13

302.8

371.0

A

(cm) B (cm) C (cm) D (cm) E (cm) F (cm)

183 169 164 142 49.5 1.40

224 196 192 170 49.5 1.68

6

160,000

(155,000

LP)

46.9

160,000

(155,000

LP)

(Liters)

(kW/hr)

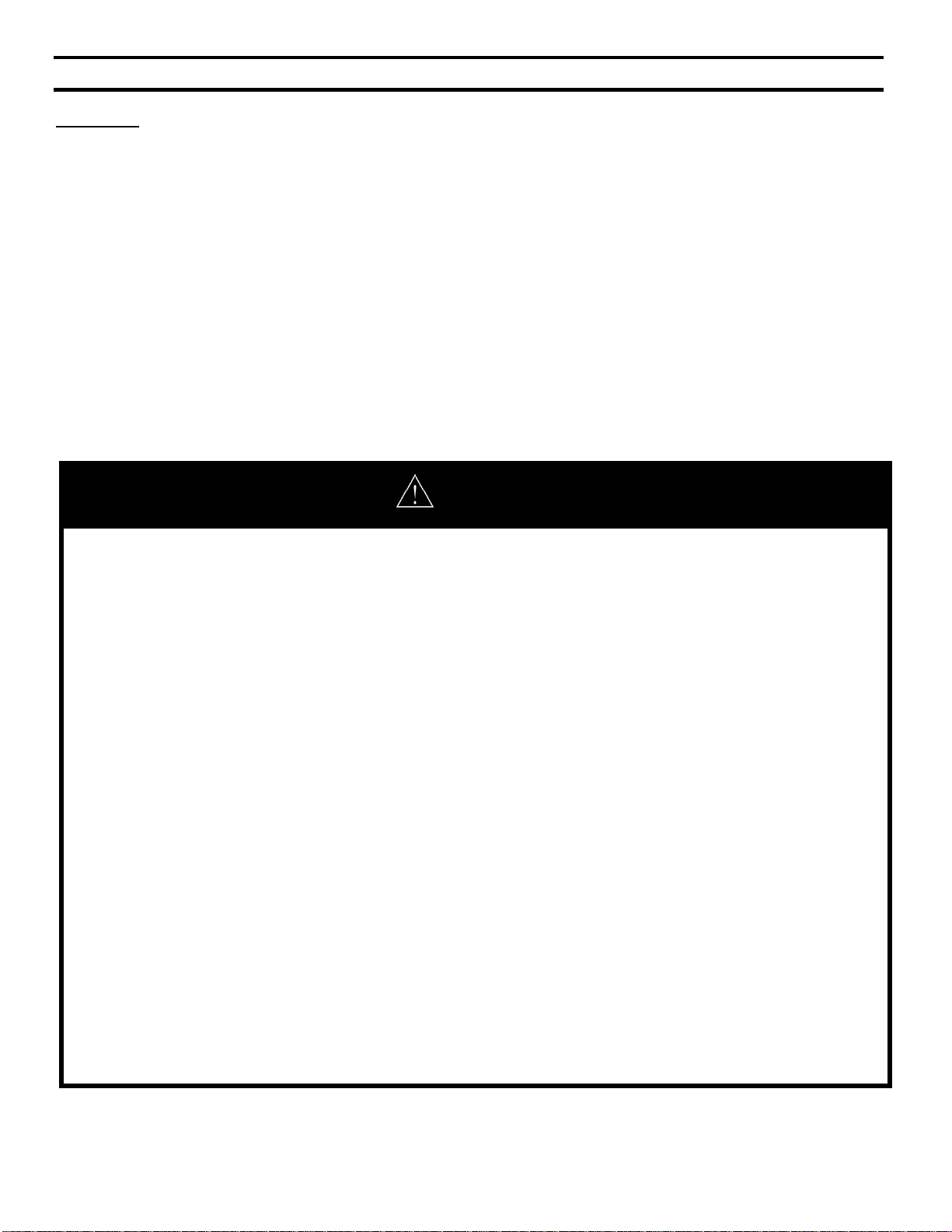

Figure 5

Non-Flue Damper Models (Figure 5)

Model Description

Capacity

(GAL)

Model Description

Capacity

(Liters)

283.9

Input

(BTU/hr)

75

Input

(kW/hr)

(45.4 LP)

A

(in.) B (in.) C (in.) D (in.) E (in.)

70.13 67.13 65.00 54.50 6

A

(cm) B (cm) C (cm) D (cm) E (cm)

178 171 165 138 15.2

Flue Damper Models (Figure 5)

Model Description

Capacity

(GAL)

Model Description

Capacity

283.9 36.6 183 171 165 138 12.7

283.9

Input

(BTU/hr)

75 125,000 72.25 67.13 65.00 54.50 5

75

Input

46.9

(45.4 LP)

A

(in.) B (in.) C (in.) D (in.) E (in.)

72.25 67.13 65.00 54.50 6

A

(cm) B (cm) C (cm) D (cm) E (cm)

184 171 165 138 15.2

The following notes apply to the tables accompanying Figures 1 - 5.

1. All models with flue dampers and/or above 400,000 BTU per hour input employ a “spark to pilot” (IID) ignition system

and requires 120 volt AC electric supply.

2. Model number may have a suffix “N” for natural gas or “X” for liquefied petroleum (LP) gases. Some models may have

“A” as a suffix for ASME. Check the rating plate on front of the water heater for model number verification.

7

Keep clear of combination temperature and pressure relief valve discharge line outlet. The discharge may be

WARNING

SECTION III: GENERAL INFORMATION

FEATURES

1. Porcelain enamel lined tank provides corrosion protection with a tough glass lining on the interior of the tank.

2. Magnesium anodes provide an extra measure of protection and extends tank life.

3. Flue Damper on 24 volt ignition models reduces standby losses on the burner off cycle saving fuel.

4. Hand Hole Cleanout allows inspection of tank interior and allows the removal of lime and sediment deposits.

5. Honeywell Integrated Water Heater Control on 24 volt models having the following features:

• Attractive digital water heater display on control panel for precisely setting and displaying the temperature setpoint.

Pressing temperature up and down buttons changes the temperature setpoint. Temperature format may be

displayed in degrees F or degrees C.

• Single control board with plug in wiring controls temperature, ignition, and flue damper operation.

• Reduced number of parts for servicing and wiring.

• Plug in wiring reduces chance of miswiring.

• Water heater display will show diagnostic codes in the event the water heater needs servicing. Aids in diagnosing

and servicing the water heater. Temperature of the tank sensors can be monitored in the Service Mode.

• Water heater display can show up to 10 previous error codes to further aid in servicing the water heater.

hot enough to cause scald injury. The water is under pressure and may splash.

For protection against excessive temperatures and pressure, install temperature and pressure protective equipment

required by local codes, but not less than a combination temperature and pressure relief valve certified by a

nationally recognized testing laboratory that maintains periodic inspection of production of listed equipment or

materials as meeting the requirements of the Standard for Relief Valves and Automatic Gas Shutoff Devices for Hot

Water Supply Systems, ANS Z21.22 and the Standard CAN1-4.4 Temperature, Pressure, Temperature and

Pressure Relief Valves and Vacuum Relief Valves. The combination temperature and pressure relief valve must be

marked with a maximum set pressure not to exceed the maximum working pressure of the water heater. The

combination temperature and pressure relief valve must also have an hourly rated temperature steam BTU

discharge capacity not less than the hourly rating of the water heater.

Install the combination temperature and pressure relief valve into the opening provided and marked for this purpose

on the water heater.

Note: Some models may already be equipped or supplied with a combination temperature and pressure relief valve.

Verify that the combination temperature and pressure relief valve complies with local codes. If the combination

temperature and pressure relief valve does not comply with local codes, replace it with one that does. Follow the

installation instructions above on this page.

Install a discharge line so that water discharged from the combination temperature and pressure relief valve will exit

within six (6) inches (15.2 cm) above, or any distance below the structural floor and cannot contact any live electrical

part. The discharge line is to be installed to allow for complete drainage of both the combination temperature and

pressure relief valve and the discharge line. The discharge opening must not be subjected to blockage or freezing.

DO NOT thread, plug or cap the discharge line. It is recommended that a minimum clearance of four (4) inches (10.2

cm) be provided on the side of the water heater for servicing and maintenance of the combination temperature and

pressure relief valve.

Do not place a valve between the combination temperature and pressure relief valve and the tank.

8

WARNING

This product contains one or more chemicals known to the State of

California to cause c ancer, birth defects, or reproductive harm.

DISHWASHING MACHINE RE QUIREMENTS

All dishwashing machines meeting the National Sanitation Foundation requirem ents are designed to operate with water

flow pressures between 15 and 25 pounds per square inch. Flow pressures above 25 pounds per square inch, or below 15

pounds per square inch, will result in improperly sanitized dishes.

The National Sanitation Foundation also recommends circulation of 180°F water. Where this is done, the circulation should

be very gentle so that it does not cause any unnecessary turbulence inside the water heater. The circulation should be just

enough to provide 180°F water at the point of take-off to the dishwashing machine. Adj ust flow by means of the valve in

the circulation line.

A sacrificial anode is used to ex tend tank life. The removal of this anode, ex cept for inspection and/or replacement, will

nullify the warranty. In areas where water is unusually active, an odor may occur at the hot water faucet due to a reaction

between the sacrificial anode and the impurities in the water. If this should happen, an alternative anode may be

purchased from the supplier that installed this water heater. This will minimize the odor while protecting the tank.

Additionally, the water heater should be flushed with appropriate dissolvers to eliminate any bacteria.

9

INSTALLATION OF THIS WATER HEATER REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED

he gas supplier

UNDER NO CIRCUMSTANCES SHALL FLAM MABLE MATERIALS, SUCH

NE OR PAINT THINNER BE USED OR STORED IN T HE VICINITY OF THIS WATER HEATER, V ENT

AIR INTAKE SYSTEM OR IN ANY LOCATION FROM W HICH FUMES COULD REACH THE W ATER HEAT ER OR

VENT-A IR IN TAK E S YS TEM .

SECTION IV: INSTALLATION INSTRUCTIONS

WARNING

TRADESM AN IN THE FIELD INVOLVED. PLU M BI N G, A I R S U PPLY , V ENTING, GAS SUPPLY A N D ELEC T R I CAL

WO RK A RE REQ U I RED .

DO NOT ATTEMPT TO LIGHT ANY GAS APPLIANCE IF YOU ARE NOT CERTAIN OF THE FOLLOWING:

• Liquefied petroleum gases/propane gas and natural gas have an odorant added by t

t hat aids in detect ion of t he gas.

• Most people recognize this odor as a ‘‘sulfur’’ or ‘‘rot t en egg’’ smell.

• Other conditions, such as ‘‘odorant fade’’ can cause the odorant t o diminish in intensity, or ‘‘fade’’,

and no t be as read il y detec tab l e.

• If you have a diminished sense of smell, or are in any way unsure of t he presence of gas, immediately

cont act your gas supplier from a t elephone in another building.

• Gas detec tor s ar e av ail abl e. Contact your gas supplier or plumbing professional for more inf ormation.

Liquefied petroleum gases/propane gas is heavier than air and w ill remain at floor level if there is a leak.

Basement s, craw l spaces, closets and areas below ground level w ill serve as pockets for accumulat ion of

leak in g gas. Before lighting, smell all ar ou nd th e app li anc e ar ea fo r g as. Be sure to smell next t o the floor.

I F Y O U S MELL GA S :

• Do not try t o light any appliance.

• Do not touch any electric sw it c h; do not use any t elephone in your building.

• Immediately call your gas supplier from a telephone in another building. Follow the gas supplier’s

instructions.

• If y ou cannot reach your gas supplier, call t he fire department.

D O NO T O PERATE THE APPL I AN CE U NTI L T HE LEAK A G E IS C O R REC TED !

This water heater must be located in an area w here leakage of the tank, water line connections, or the

co mb inati on t emp erat ur e and pres sure r elief val ve wil l n ot resu lt i n dam age t o t he ar ea adjac ent to t he w at er

heat er or to low er f loors of the struct ure. When such locations cannot be avoided, a suitable drain pan must

be inst alled under t he w at er heat er. The drain pan depth must be suitable for draining and collecting w ater,

and have a minimum length and w idth of at least f our (4) inches (10 .0 c m) measured from t he jacket of the

w ater heater. The drain pan, as described above, can be purchased from your plumbing professional. The

drain pan must be piped to an adequate drain. The piping must be at least ¾ inch (2 .0 cm) in diameter and

pit ched f or proper drainage.

Water heaters are heat producing appliances. To avoid damage or injury there must be no materials stored

agai nst t h e w at er heat er and p rop er c are must be t aken to avoid unnecessary cont act (especially by children)

w ith the water heater components.

AS GASOLI

-

10

DAMAGE TO THE WATER HEATER CAUSED BY EXPOSURE TO CORROSIVE VAPORS IS NOT COVERED BY

STORE ANY POTENTIALLY CORROSIVE COMPOUNDS IN THE VICINITY OF THE WATER HEATER.

NOTICE

The N ational Fuel Gas Code (A N SI Z 23 3.1- lat est e dit ion) or in Canada The Natural Gas or Propane

If t he buildings cold w at er supply has a back-flo w pr ev en t er , c h ec k v alv e o r w ater m et er with c hec k v al v e,

CAUTION

IF COMBUSTIBLE FLOORING IS USED, A THERMAL BREAK LEG KIT MUST BE INSTALLED BEFORE SETTING

WARNING

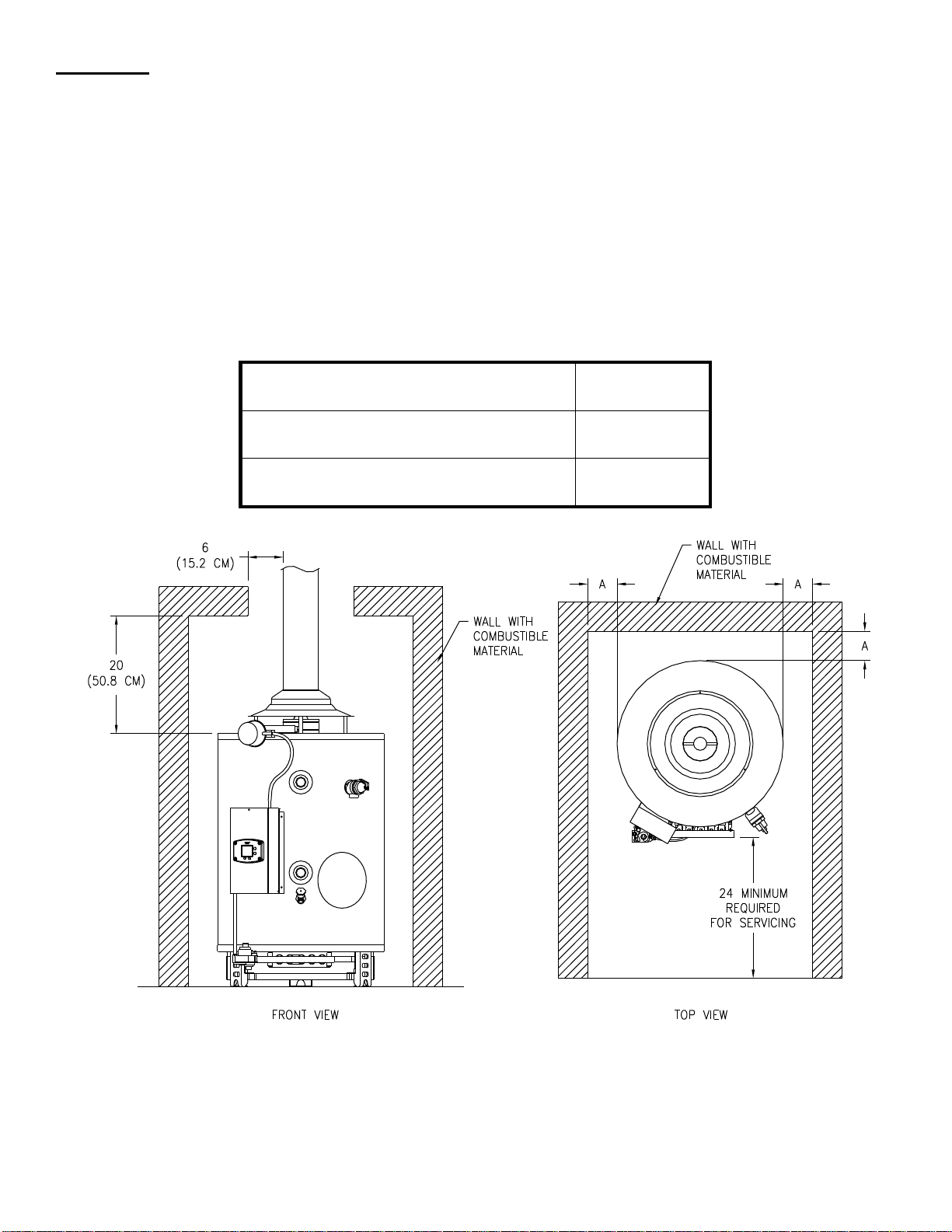

Minimum Clearances

Inst allat ion Code CAN/CGA (B149.1, B149.2- la t e st e dit ion) , e xpressly prohibit s the f ollowing:

a. Inst allation of a w at er heater in a bathroom, bedroom, or any occupied room normally kept c losed.

b. Installation of a w at er heat er in a garage, unless the unit is installed so that t he burner and ignit ion

dev i c es are at least ei gh teen (1 8) i nc h es (45.8 cm) above floor level and protect ed t o avoid damage by

a moving vehicle.

The location of this water heater is of the utmost importance. Before installing this water heater, you should read the

Installation section of these instructions. After reading these Installation and Operating Instructions, select a location for

the water heater where the floor is level and is easily accessible to water lines, gas supply (type identified on the rating

plate), an adequate open drain, and a chimney or exhaust gas vent. DO NOT locate the water heater where water lines

could be subjected to free zing temperatures. Make sure the cold water pipes are not located directly above the

gas control box or any other electrical control so that condensate dur ing humid weather does not drip on the

controls.

WATER HEATER IN PLACE. THE APPROPRIATE LEG KIT HAS BEEN INCLUDED WITH THIS WATER HEATER.

This installation must allow access to the front of the water heater and adequate clearanc e must be provided for servicing

and operating this water heater. The water heater m ay be installed on either a combus tible or non-c om bustible f loor. If the

water heater is to be installed directly on carpeting, it must be installed on top of a m etal or wood panel (or equivalent)

extending beyond the full width and depth of the appliance by at least three (3) inches (7.6 cm) in any direction or, if the

appliance is to be installed in an alcove or closet, the entire f loor must be covered by the panel. The minimum clearances

to combustibles for this water heater are given on the following pages. A minim um of 24 inches front clearance must be

provided for inspection and servicing. Adequate clearances must be provided for easy access to controls by service

personnel to enable proper cleaning, servicing, and operation of the water heater. Under no circumstances is the f ront of

the water heater to be placed in a position where the burner tray assembly cannot slide out for removal when servicing.

This water heater MUST be installed indoors out of the wind and weather.

Note: For California ins tallation this water heater mu st be braced, anchored, or strapped to avoid falling or

moving during an earthquake. See instructions for correct installation procedures. Instructions may be obtained

from DSA Headquarters Office, 1102 Q Street, Suite 5100, Sacramento, California 95811.

Water heater corrosion and component failure can be caused by the heating and breakdown of airborne chemical vapors.

Examples of some typical compounds that are potentially corrosive are: spray can propellants, cleaning solvents,

refrigerator and air conditioning refrigerants, swimming pool chemicals, calcium and sodium chloride, waxes and process

chemicals. These materials are corrosive at very low concentration levels with little or no odor to reveal their presence.

THE WARRANTY. DO NOT OPERATE THE WATER HEATER IF EXPOSURE HAS OR WILL OCCUR. DO NOT

11

UNPACKING

INSPECT SHIPMENT carefully for any signs of damage.

1. All equipment is carefully manufactured, inspected and packed.

2. Any claims for damage or shortage in shipment must be filed imm ediately with the manufacturer noted on the

rating plate label.

LOCATE WATER HEATER in front of final position before removing crate.

1. LOCATE so that venting connections will be short and direct.

2. THIS WATER HEATER IS SUITABLE FOR INSTALLATION ON CO MBUSTIBLE FLOOR . The thermal break leg

kit supplied with the water heater must be used.

3. Proper venting practices must be considered when selecting a location for this water heater. For exact venting

specifications, please consult the Venting section of these Installation and Operating Instructions.

4. It is recommended that a minimum clearance of four (4) inches (10.2 cm) be provided on the side of the water

heater for servicing and maintenance of the combination temperature and pressure relief valve.

5. Increase distances to provide clearance for servicing.

Input

Less than or equal to 300,000 BTUH 2 in. (5.1 CM)

Greater than 300,000 BTUH 6 in (15.2 CM)

Front, sides

and Rear “A”

12

IMPORTANT-The flow of combustion and ventilating air must not be obstructed.

WARNING

The draft diverter relief opening of the water heater and combustion air inlet must be in the same atmospheric

CAUTION

REMOVE CRATE

1. Remove all banding and pry off crate sides carefully so as not to damage the water heater.

2. Carefully roll/lift the water heater from the crate base.

MOVE WATER HEATER TO PERMANENT POSITION by sliding or walking. Place drain pan underneath water heater

INSTALL TEMPERATURE AND PRESSURE RELIEF VALVE (if not already installed).

This water heater must be located in an area where the general public does not have access to set temperatures.

AIR REQUIREMENTS

1. Do not obstruct the flow of ventilating air.

2. For s afe operation, adequate air is needed for com bustion and ventilation. Sooting may result in serious damage

to the water heater and risk of fir e or ex plosion. It can also create a risk of asphyxiation. Such a condition often will

result in a yellow, luminous burner flame, causing carboning or sooting of the combustion chamber, burner and

flue tubes.

MECHANICAL EXHAUSTING OF ROOM AIR - Where an exhaust fan is installed in the same room with this

water heater and combustion air is drawn from inside the room, sufficient openings for air must be provided in the

walls. UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN INTO THE ROOM THROUGH THE WATER

HEATER’S VENTING SYSTEM, CAUSING POOR COMBUSTION THAT MAY BE HAZARDOUS TO LIFE.

SOOTING MAY RESULT IN SERIOUS DAMAGE TO THE WATER HEATER AND RISK OF FIRE OR EXPLOSION,

WHICH CAN ALSO CREATE A RISK OF ASPHYXIATION. Refer to local codes and /or National Fuel Gas Code

(ANSI Z223.1-Latest Edit ion), or in Canada CAN/CGA B149 . 1 Natural Gas Installation Code (Latest Edition) or

CAN/CGA B149 . 2 Propane Inst allat ion Code (Latest Edition) for proper air opening sizing.

CONFINED SPACES

3

If the water heater is installed in a confined space (volume is less than 50 ft.

/1000 BTU (15 m3/0.29 kW) per hour of the

total input rating of all gas appliances in that space), air must be supplied through two permanent openings. One opening

must be within 12 inches (30.5 cm) from the top of the enclosure and one within 12 inches (30.5 cm) of the bottom. The

openings must be protected by metal louvers or 1/4” (6.4 mm) min. mesh metal screen. The size of the openings are as

follows:

pressure zone. Large exhaust fans in kitchens and other locations can lower the air pressure inside an enclosure and

interfere with the proper operation and venting of the water heater. In these cases, the water heater should be

installed in a separate room with the combustion and ventilation air supplied directly from outdoors as previously

described.

1. If the openings communicate directly with an additional room(s) of sufficient volume, each opening must have a

2

minimum free area opening of 1 in.

appliances in the confined space, but not less than 100 in.

/1000 BTU (2.54cm2/0.29kW) per hour of the total input rating of all gas

2

(254 cm2).

2. If the openings communicate with the outdoors through horizontal ducts, each opening must have a minimum free

2

area of 1 in.

3. If the openings communicate directly with the outdoors or through vertical ducts with the outdoors, each opening must

have a minimum free area of 1 in.

/2000 BTU (2.54cm2/0.59kW) per hour of the total rating of all gas appliances in the enclosure.

2

/4000 BTU (2.54cm2/1.18kW) per hour of the total rating of all gas appliances in

the enclosure.

13

ALL A IR FROM INSIDE THE BUILDING: The confined space must be provided with two permanent openings

communicating directly with an additional room(s) of sufficient volume so that the combined volume of all spaces meets

the criteria for an unconfined space. The total input of all gas utilization equipment installed in the combined space must be

considered in making this determination. Each opening must have a minimum free area of 1 in.

2

(2.54cm

100 square inches (254cm

/0.29kW) per hour of the total input rating of all gas utilization equipment in the confined space, but not less than

2

). One opening must be within 12 inches (30.5 cm) of the top and one within 12 inches (30.5

cm) of the bottom of the enclosure.

UNCONFINED SPACES

In unconfined spaces in buildings, infiltration may be adequate to provide air for combustion, ventilation and dilution of flue

gases. However, in buildings of tight construction (for example, weather stripping, heavily insulated, caulked, vapor barrier,

etc.), additional air may need to be provided using the methods described above under CONFINED SPACES: All Air From

Outdoors or SPECIALLY ENGINEERED INSTALLATIONS.

SPECIALLY ENGINEERED INSTALLATIONS

The requirements noted under CONFINED SPACES above must not necessarily govern when special engineering,

approved by the authority having jurisdiction, provides an adequate supply of air for combustion, ventilation, and dilution of

flue gases.

2

/1000 BTU

14

Do not t urn on elect rical pow er t o wat er heater unt il f lue damper is inst alled and w at er heater is filled w it h

CAUTION

The venting syst em must be installed properly f ollowing all local codes or in t he absence of local codes, the

in Operation’’.

SECTION V: VENTING

latest ed iti on o f th e Nati on al Fuel Gas Code (ANSI Z223.1- l atest edi ti on ), o r i n Canad a, Th e Natu ral Gas and

Propane Installation Code (B149 . 1 -0 0 l atest ed iti on ). Failure to properly install t he venting syst em could result

in property damage, personal injury, or death.

Careful ly in sp ec t th e v ent ing syst em of a replacement wat er heater installation bef ore connecting t o the

vent ing system. All joint s in the vent connect or must be securely f astened w it h screw s and fit tight ly

together. Inspect the venting syst em f or signs of det eriorat ion (rust and perforation) and replace any sect ions

t hat are not in good condition.

The chimney must be lined and in good condit ion. Check t o make sure the venting syst em is properly sized

f o r th e wat er h eat er . If t he vent ing syst em w as previously sized for another gas appl ian c e th at h as b een

removed, t he venting syst em may now be t oo large. Refer t o th e latest ed i t i o n o f the N at i o nal Fuel Gas Cod e

(ANSI Z223.1-latest edition), or in Canada, t he Nat ural Gas and Propane Installation Code (B1 4 9 . 1-00 l atest

edition) f or t he correct sizing of v ent ing systems and common vent ing wit h anot her gas appliance. Do not

vent t his w at er heater int o t he vent ing system of anot her gas appliance designed to vent under positive

pressure.

The w ater heater sh ou ld be i n stall ed as c lo se as p ract ical t o t he vent ing system t o minim ize t he vent

connect or length required. Refer to local codes for t he distance limit ations on vent connect or lengt hs. A t t he

complet ion of t he w at er heater installation, t he burner and vent ing system must be checked for proper

operation wit h all other commonly vent ed appliances in operat ion. Check f or spillage of f lue product s around

t he outside relief opening of t he draft hood af t er several minutes of operation. The flame f rom a match should

be draw n int o the draft hood. Do not use the w at er heater or connect ed equipment if spillage is detect ed unt il

t he problem is corrected. Refer to th e l at es t ed i t i on o f the N at i o nal Fuel Gas Cod e, o r i n Can ada, the N at u r al

Gas and Propane Installat ion Code f or complet e details on the ‘‘Procedure to Be Followed t o Place Equipment

This water heater has been shipped with a draft diverter for which it was designed with reference to the horizontal and

vertical planes, its certified category I, per latest ANSI Z 21.10.3-2015.CSA 4.3-2015 revision. Refer to the latest edition of

the National Fuel Gas Code (ANSI Z223.1-latest edition), or in Canada, the Natural Gas and Propane installation Code

(B149.1-00 latest edition). If removed, the draft diverter must be replaced in the same position and secured to the jacket

top by the screws with which it was installed.

This water heater must be connected to a lined masonry chimney or venting system approved by local codes or

ordinances. The vent connector used to attach the draft diverter outlet to the chimney or approved vent must be of the

same diameter as the draft diverter outlet or larger. For proper venting in certain installations, a larger vent connector may

be needed. Consult venting tables in ANSI standard (Z223.1- latest edition), National Fuel Gas Code and CAN/CGA

(B149.1 or B149.2-latest editions) Natural Gas and Propane Installation Code, or local code officials for proper application

for your area.

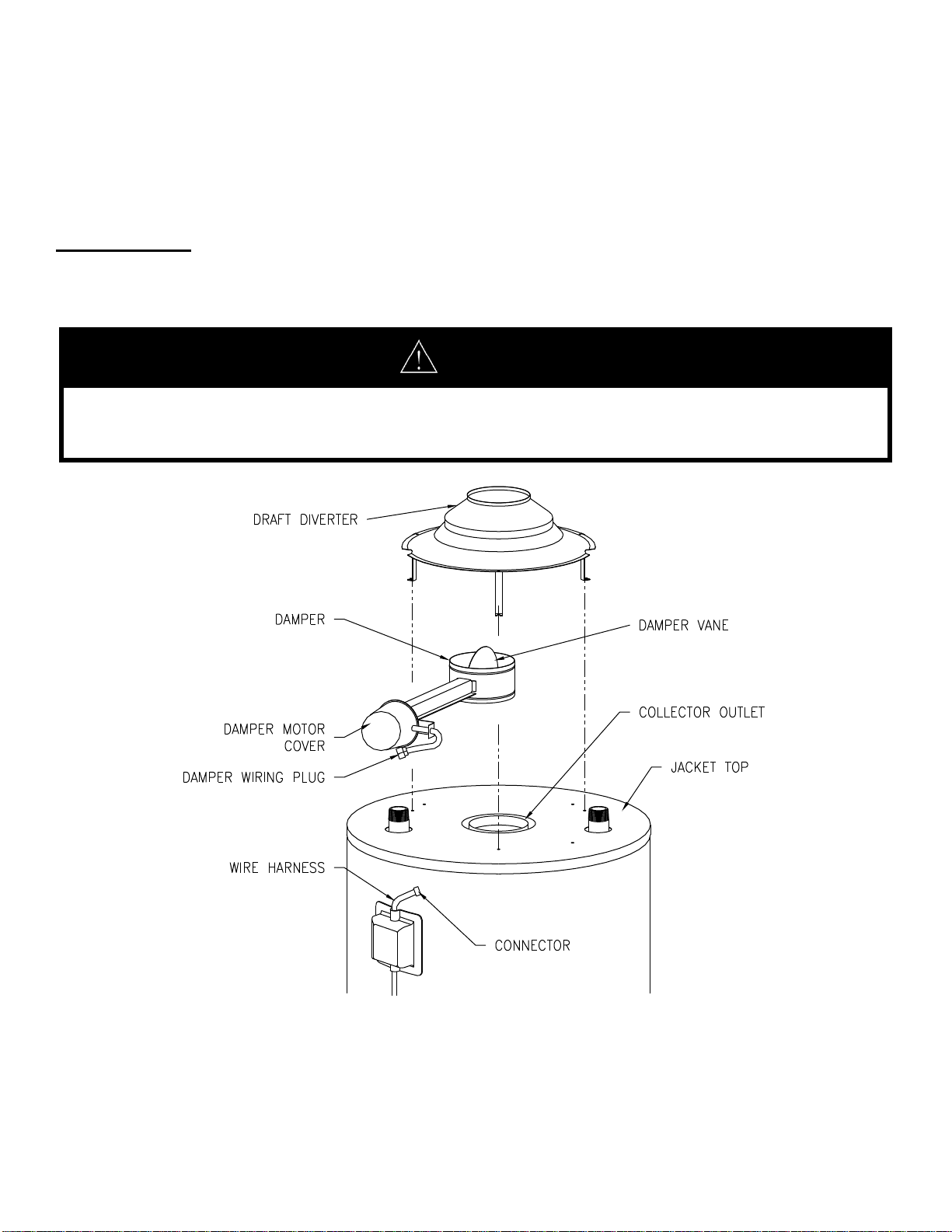

FLUE DAMPER

Refer to Figure 6 and follow these instructions:

WARNING

water.

1. Remove the damper from the accompanying box shipped within the crate.

2. Locate the collector outlet on top of the water heater. Place the damper over the collector outlet and rotate as

necessary to a position in which the damper wiring plug can be fully engaged with the connector on the side of the

water heater.

15

Modif ic ation t o the f lue damper or the draft div erter may result in personal injury, property damage or deat h.

instructions w it hout modif ic ation.

CAUTION

3. Secure the flue damper to the jacket top with sheet metal screws.

4. Connect the damper wiring plug to the damper wire harness connector on the side of the water heater. Note: The plug

and connector can only be engaged one way (polarized).

5. The Lighting and Operating instructions are outlined in this manual. The damper must be in the open position when

the water heater main burner is operating (the arrow on the damper plate is in the “up” position when open. Be certain

the arrow is in a visible position when installed).

DRAFT DIVERTER

This water heater has been shipped with a draft diverter for which it was designed. Remove the bag containing the legs

and instructions from the draft diverter. Attach the legs to the draft diverter and attach the draft diverter to the water heater

per the instructions in the bag.

The fl u e dam p er an d d raft d i v erter are to b e pl ac ed i n p o siti on an d o per ate ex ac tl y as stated in these

Figure 6

16

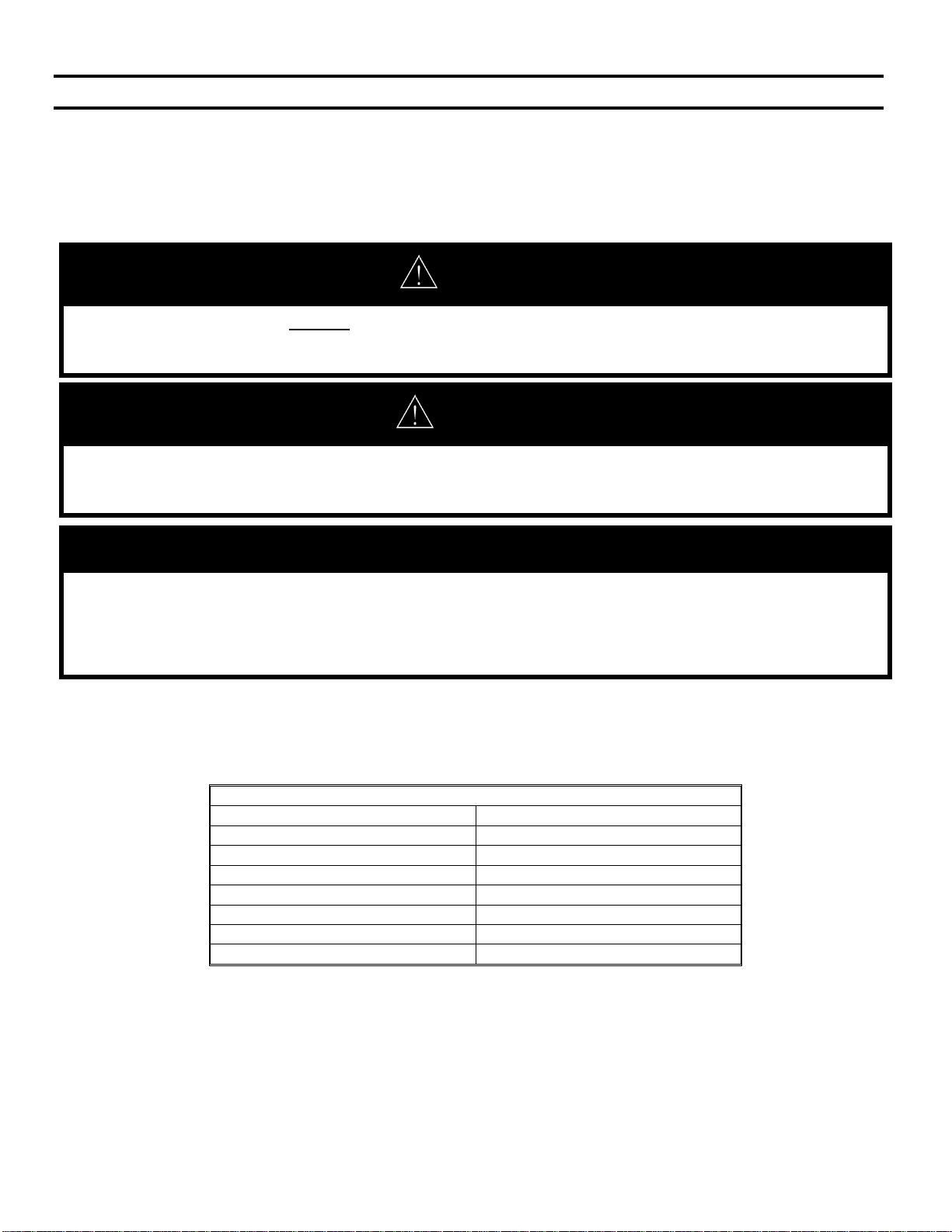

A PPR O XI MA TE TIME/TEM PERATURE REL A TIO NS HI PS I N S C AL D S

120°F (49°C)

More t han 5 minut es

125°F (52°C)

1½ t o 2 minut es

130°F (54°C)

About 3 0 seconds

135°F (57°C)

About 1 0 seconds

140°F (60°C)

Less than 5 seconds

145°F (63°C)

Less than 3 seconds

150°F (66°C)

About 1 ½ seconds

155°F (68°C)

About 1 second

If sweat fittings are to be used, DO NOT apply heat to the nipples on top or side of the water heater. Sweat the tubing

nipples containing a plastic liner.

CAUTION

FAILURE TO INSTALL AND MAINTAIN A NEW, LISTED TEMPERATURE AND PRESSURE RELIEF VALVE

TEMPERATURE AND PRESSURES.

WARNING

If this water heater is installed in a closed water supply system, such as the one having a back-flow preventer in the

contacted on how to control this situation.

NOTICE

SECTION VI: WATER CONNECTIONS

NOTE: BEFORE PROCEEDING WITH THE INSTALLATION, CLOSE THE MAIN WATER SUPPLY VALVE.

After shutting off the main water supply, open a faucet to relieve the water line pressure to prevent any water from leaking

out of the pipes while making the water connections to the water heater. After the pressure has been relieved, close the

faucet. The COLD water inlet and HOT water outlet are identified on the top and front of the water heater. Make sure the

diptube is in place before making the cold water connection. Make the proper plumbing connections between the water

heater and the plumbing system to the house. Install a shut-off valve in the cold water supply line.

to the adapter before fitting the adapter to the water heater connections. It is imperative that heat is not applied to the

WILL RELEASE THE MANUFACTURER FROM ANY CLAIM WHICH MIGHT RESULT FROM EXCESSIVE

cold water supply, provisions must be made to control thermal expansion. DO NOT operate this water heater in a

closed system without provisions for controlling thermal expansion. Warranties do not cover damages from thermal

expansions such as pressure bulges and/or deformities. Your water supplier or local plumbing inspector should be

After installation of the water lines, open the main water supply valve and fill the water heater. While the water heater is

filling, open several hot water faucets to allow air to escape from the water system. When a steady stream of water flows

through the faucets, close them and check all water connections for possible leaks. NEVER OPERATE THE WATER

HEATER WITHOUT FIRST BEING CERTAIN IT IS FILLED WITH WATER.

17

Loading...

Loading...