Page 1

Photo is of

D-65T-625-3NA

Commercial Induced Draft

Gas Water Heater

The Induced Draft Models feature:

■ ICON HD

codes, and system ignition functions into a single control board with a digital LCD

display. Control panel cover tilts down for ease of wiring and service.

■ Operation Mode—Two different digitally displayed operation modes have the

capability of adjusting the temperature setting up to 180ºF (82ºC), and adjusting

the degree setting (ºF to ºC, or ºC to ºF).

■ Service Mode—Eight different digitally displayed service modes can be easily

cycled through by pressing the select button. There is the capability of adjusting

the temperature setting up to 180ºF (82ºC), adjusting the degree setting (ºF to

ºC, or ºC to ºF), locking the maximum temperature setting that can be adjusted

in operation mode, displaying the average water temperature (if water heater

has two sensors), displaying the upper temperature sensor, displaying the lower

temperature sensor, displaying the flame current of the pilot flame, and displaying

diagnostic codes.

■ Electronic Ignition—High voltage, low current electricity is sent to the pilot

electrode initiating a spark to ignite the pilot gas. This results in savings of pilot

gas during stand-by periods because the pilot flame only operates when there’s a

call for heat.

■ Factory Installed Hydrojet

sediment reducing device helps prevent sediment build up in the tank.

■ Vitraglas

superior tank protection from the highly corrosive effects of hot water. This

formula (Vitraglas

1600°F (871°C).

■ Insulation System—2" (51mm) Non-CFC foam insulation covers the sides and

top of the tank, reducing heat loss. This results in less energy consumption,

improved efficiencies, and jacket rigidity.

■ Potable Water Connections—1

fittings extend water heater life and eases installation.

■ Protective Magnesium Anode Rods—Provide added protection against

corrosion for long-term, trouble-free service.

■ Hand Hole Cleanout—Allows inspection of tank interior and removal of sediment

deposits.

■ E.C.O.—An automatic reset Energy Cut Out (E.C.O.) shuts off all gas in event of

an overheat condition. This automatically resets when operation conditions are

back to normal.

■ Sanitizing Capability—Temperature setting up to 180ºF (82ºC).

■ NSF Construction Available.

■ ASME Code Available.

■ T&P Relief Valve—Installed.

■ Low Restrictive Brass Drain Valve—Durable tamper proof design.

■ Design Certified by CSA International (Formerly AGA and CGA).

™

—Intelligent proven design combines temperature control, diagnostic

®

Sediment Reduction System—Cold water inlet

®

Lining—An exclusively engineered enamel formula that provides

®

) is fused to the steel surface by firing at a temperature of over

1

⁄2" (38mm) NPT factory installed true dielectric

3 or 5-Year Limited Tank Warranties / 1-Year Limited Warranty on Component Parts.

For more information on warranty, please visit www.bradfordwhite.com

For products installed in USA, Canada, and Puerto Rico. Some states do not allow limitations on warranties. See complete

copy of the warranty included with the heater.

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S. PATENTS: 5,682,666; 7,634,976; 5,660,165; 5,954,492; 6,056,542; 6,935,280; 5,372,185; 5,485,879; 5,574,822; 7,971,560; 7,992,526;

6,684,821; 7,334,419; 7,866,168; 7,270,087; 7,007,748; 5,596,952; 6,142,216; 7,699,026; 5,341,770; 7,337,517; 7,665,211; 7,665,210; 7,063,132; 7,063,133; 7,559,293; 7,900,589; 5,943,984; 8,082,888;

5,988,117; 7,621,238; 7,650,859; 5,761,379; 7,409,925; 5,277,171; 8,146,772; 7,458,341; 2,262,174. OTHER U.S. AND FOREIGN PATENT APPLICATIONS PENDING. CURRENT CANADIAN PATENTS: 2,314,845;

2,504,824; 2,108,186; 2,143,031; 2,409,271; 2,548,958; 2,112,515; 2,476,685; 2,239,007; 2,092,105; 2,107,012. Vitraglas

®

and Hydrojet® are registered trademarks of Bradford White® Corporation.

308-B-0418

Page 2

Nat. & LP

BTU/Hr.

Input

625,000

725,000

Approx.

Shipping

Weight

lbs.

ASME

Approx.

Shipping

Weight

kg.

ASME

Liters

Nat. & LP

kW

Input

183

212.3

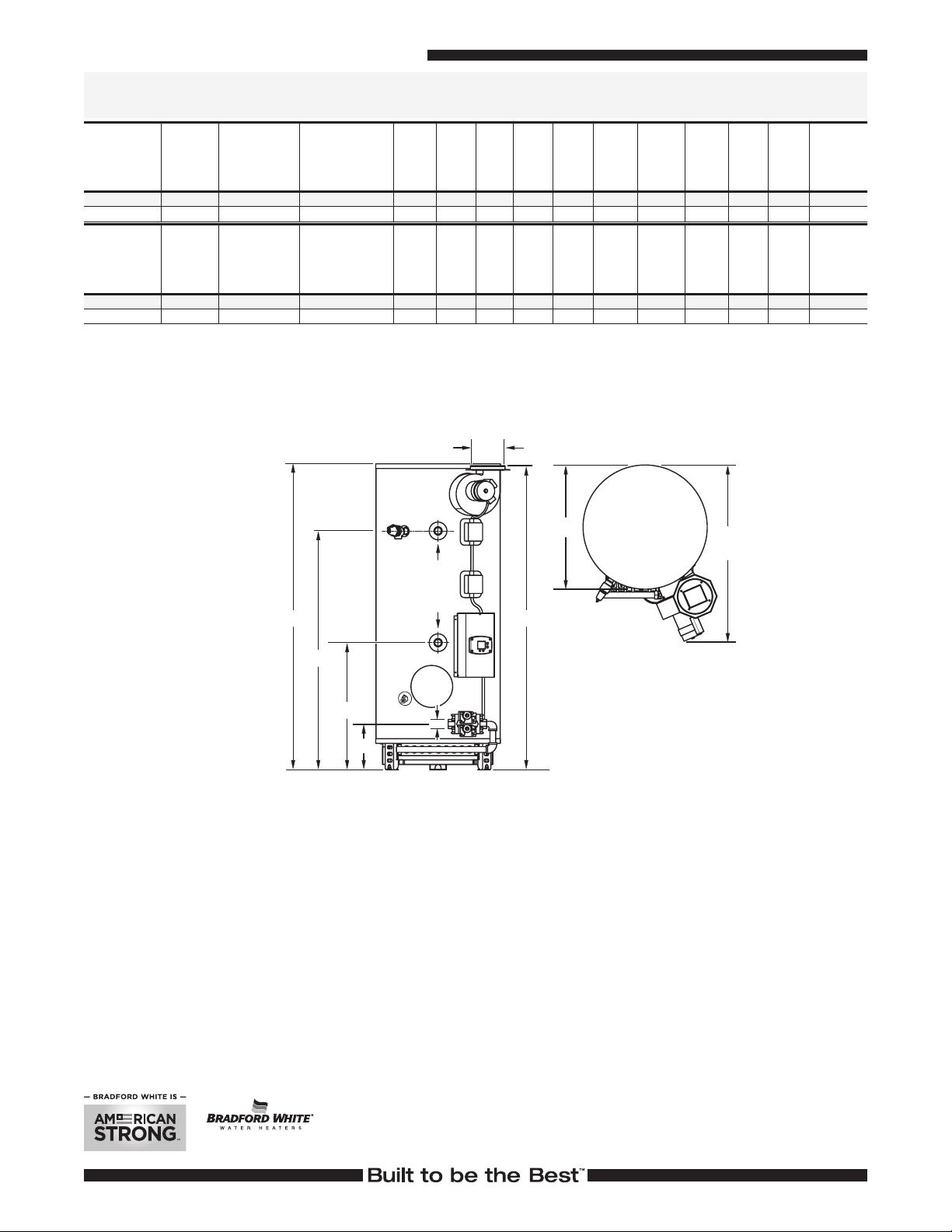

Commercial Gas Water Heater

397/8"

DEPTH

B

Induced Draft Models

NATURAL GAS AND LIQUID PROPANE GAS

A

to

Vent

in.

A

to

Vent

M

B

Jacket

Dia.

in.

1

/4

28

281/4

B

Jacket

Dia.

mm.

724

724

C

Model

Number

D-65T-625-3N(A)

D-80T-725-3N(A)

Model

Number

D-65T-625-3N(A)

D-80T-725-3N(A)

Nominal

Gal.

Capacity

U.S.

Gal.

65

80

Nominal

Liter

Capacity

246

303

Imp.

BTU/Hr.

Gal.

Input

5466625,000

725,000

kW

Input

183

212.3

LP

BTU/Hr.

Input

625,000

725,000

LP

kW

Input

183

212.3

GPH Recovery*

at Degree Rise

40°F

100°F

1515

606

1757

703

LPH Recovery*

at Degree Rise

22°C

56°C

5734

2294

6652

2661

140°F

433

502

78°C

1638

1901

Floor

Conn.

733/8

8315/16

Floor

Conn.

mm.

1864

2132

* Recoveries are based on Natural Gas input and 80% Thermal Efficiency.

For Propane(LP) Gas Models change suffix “N” to “X”.

† LP Gas Connection 3/4” (76 mm).

(A)=ASME Construction Available.

For 5 year models, change suffix “3” to “5”.

C

Vent

Size

in.

8

8

C

Vent

Size

mm.

203

203

Meet or exceed ASHRAE 90.1b (current standard) C.E.C. Listed

80% Recovery Efficiency

D

Floor

to

T&P

Conn.

in.

581/8

683/16

D

Floor

to

T&P

Conn.

mm.

1476

1732

Floor

Gas

Conn.

in.

6

61/4

Floor

Gas

Conn.

mm.

159

159

B

E

F

Floor

to

Top of

Heater

in.

3

/8

73

8315/16

F

Floor

to

Top of

Heater

mm.

1864

2132

Floor to

Cold

Water

Conn.

in.

32

323/4

Floor to

Cold

Water

Conn.

mm.

832

832

to

1

/4

E

to

L

G

Floor to

Water

Hot

Conn.

Water

Conn.

in.

3

1

58

/4

/8

683/16

L

G

Floor to

Water

Hot

Conn.

Water

Conn.

mm.

1476

1732

397/8"

DEPTH

M

NPT

in.

1

1

11/2

M

NPT

mm.

38

38

Approx.

S

Shipping

Gas

Size

in.

1†

1†

S

Gas

Size

mm.

25†

25†

Weight

lbs.

Std.

720

800

Approx.

Shipping

Weight

kg.

Std.

326

363

ASME

775

880

ASME

352

399

Conn.

/2

Conn.

M

F

A

D & L

G

Sample Specification

The water heater shall be a Bradford White model with a rated storage capacity of not less than_______gallons (_______liters), a minimum gas input of

_______BTUHr. (_______ kW), a minimum recovery of _______GPH (_______ LPH). The tank shall be Vitraglas® lined and have a bolted hand hole cleanout.

A digital LCD display shall be integrated into the front control box, and the control shall be an adjustable electronic thermostat to any temperature up to

180ºF (82ºC), and must have an automatic re-set Energy Cut-off (E.C.O), which shuts off all gas in an event of a overheat condition. The tank shall have

_______magnesium anode rods installed in separate tank head couplings. The heater shall have Non-CFC foam insulation, electronic ignition, and come

equipped with an ASME rated T&P relief valve, a cold water inlet Hydrojet

for atmospheric venting (115V AC required). It shall be design certified by CSA International for 180ºF (82ºC) application, either with or without a separate

storage tank, and comply with state and local codes and ordinances.

General

All gas water heaters are certified at 300 PSI test pressure (2068 kPa) and 150 PSI working pressure (1034 kPa). All models are design certified by CSA

International (formerly AGA/CGA), ANSI standard Z-21.10.3, for up to 180° (82°C) application as an Automatic Storage Heater, and an Automatic Circulating

Tank Heater. As an Automatic Storage Heater, all models are complete, self-contained water heating systems. It needs no separate storage tank, pump,

wiring or elaborate piping network. When equipped with a mixing valve, it will supply 180°F (82°C) sanitizing and lower temperature general purpose hot water

simultaneously. These models can be used either as a single unit or in multiples connected in series or parallel (recommended).

Dimensions and specifications subject to change without notice in accordance with our policy of continuous product improvement.

E

For field service, contact your professional installer or local Bradford White sales representative.

Sales 800-523-2931 n Fax 215-641-1612

Technical Support 800-334-3393

Ambler, PA

Warranty 800-531-2111

S

®

Sediment Reduction System, and an induced draft blower with integral damper

n

n

Email techserv@bradfordwhite.com

Email warranty@bradfordwhite.com

International: Telephone 1-215-641-9400 n Email international@bradfordwhite.com / www.bradfordwhite.com

©2018, Bradford White Corporation. All rights reserved.

Printed in U.S.A.308-B-0418

Loading...

Loading...