Bradford White C-SW2-TW50T10FBN, C-SW2-TW75T10BN Installation Manual

PO WER VEN T GAS WATER HEATER

A Spanish language version of these instructions is available by contacting the

company listed on the rating plate.

La version espanola de estas instrucciones se puede obtener al escribirle a la

fabrica cuyo nombre aparece en la placa de especificaciones.

INSTALLATION AND OPERATION

INSTRUCTION M ANUA L

WARNING: If the information in these instruct i ons i s not

followed exactly, a fir e or expl osi on m ay result causi ng

property damage, personal injury, or death.

FOR YOUR SAFETY

Do not store or use gasoline or other f l am m abl e,

combustible, or corrosive vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas suppl ier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

Installation and service must be perfor m ed by a qualifi ed

installer, service agency or the gas supplier.

For your family’s comfort, safety and convenience we

recommend this water heater be inst alled and serviced by a

plumbing professional.

238-45637-00T REV 5/18

2

CONGRATULATIONS!

You have just purchased one of the finest water heat ers on

the market today!

This installation, operation and i nst r uct ion manual will

explain in detail the instal lation and maintenance of your

new Power Vent ed G as W at er Heat er . We strongly

recommend that you contact a plumbing professional f or

the installation of thi s water heater.

We require that you carefully read this manual, as well as

the enclosed warranty, and refer t o i t when questions arise.

If you have any specific questions concerning your

warranty, please consult the plum bi ng pr ofessional from

whom your water heater was purchased. For your records

we recommend that you wr ite the model, serial number and

installation date of your w at er heat er i n t he m ai ntenance

section in the back of this manual.

This manual should be kept with the water heater.

Special Flammable Vapor Ignition Resistant System:

This water heater is equipped with a Flammable Vapor Ignition Resistant System. In

the event of improper usage or storage of gasoline or other flammable materials in

the location where the water heater is installed, the technology will resist ignition of

the flammable vapors outside the confines of the water heater.

The Flammable Vapor Ignition Resistant System features:

• Advanced Flame Arrestor Design.

• Flammable Vapor Sensor.

• Automatic Ignition Device.

• Sight Window to observe operation of pi lot and burner.

FOR YOUR SAFETY: Activation of the Flammable Vapor Ignition Resistant System

occurs when flammable vapors are drawn into the water heater and are combusted.

If flammable vapors are detected and/or sensed:

• Do not try to light any appliance.

• Do not touch any electrical switch; Do not use any phone in your building.

• Leave the premises and immediately call the fire department from a

Once the flammable vapor has been evacuated, contact your plumbing professional

or the manufacturer for further instructions. Replacement of a Flammable Vapor

Ignition Resistant System equipped water heater due to a flammable vapor

shutdown is not covered under the terms of the limited warranty.

neighbor’s phone. Follow the fire department’s instructions.

3

TABLE OF CONTENTS

GENERAL INFORMATION ................................................................. 4

INSTALLATION. .................................................................................. 5

Locating The Water Heater ......................................................... 5

Minimum Clearances ................................................................... 8

Venting .......................................................................................... 8

Specifications for

48 Gal (181.6 L)

65 Gal (246.0 L) ................................................................ 12

Specifications for

40 Gal (151.4 L)

50 Gal (189.2 L)

60 Gal (227.1 L) ................................................................ 19

Vent Pipe Preparation and Joining ............................................ 25

Combustion Air Supply ............................................................... 27

Water Connections ...................................................................... 29

Gas Connections .......................................................................... 32

Electrical Connections ................................................................ 33

Wiring Diagram ...................................................................... 34

GENERAL OPERATION ..................................................................... 35

Lighting and Shutdown Instructions ......................................... 36

Thermostat Adjustment ............................................................... 37

Burner Flame Check .................................................................... 38

MAINTENANCE ................................................................................... 39

TROUBLESHOOTING ......................................................................... 43

PARTS LIST DRAWING ...................................................................... 46

PARTS LIST ......................................................................................... 46

INSTALLATION INSTRUCTIONS FOR POTABLE WATER AND

SPACE HEA TING ................................................................................ 47

NOTES…………………………………………………………………….. 48

page

4

CAUTION

Incorrect operation of this appliance may create a hazard to life and

property and will nullify the warranty.

WARNING

Prior to connecting the gas supply line to a gas fired water heater,

point in the gas distribution system prior to gas burning appliances.

DANGER

Do not store or use gasoline or other flammable, combustible, or

corrosive vapors and liquids in the vicinity of this or any other appliance.

GENERAL INFORMATION

This gas-fired water heater’s design is certified by CSA International under the

American National Standard Z21.10.1 and CSA 4.1-M, most current editions at

the time of manufacture. This is a category III water heater.

This water heater must be installed in accordance with local codes or, in the

absence of local codes, the National Fuel Gas Code, ANSI Z223.1-Latest

Edition) and/or in Canada CAN/CGA B149 Installation Codes (Latest Editions).

The warranty for this water heater is in effect only when the water heater is

installed, adjusted, and operated in accordance with these Installation and

Operating Instructions. The manufacturer will not be held liable for any damage

resulting from alteration and/or failure to comply with these instructions.

This water heater is not design certified for installation in a mobile home. Such

an installation may create a hazardous condition and will nullify the warranty.

ensure that the gas supply line does not have moisture/water or

dirt/scale inside the gas line. Commonly this check is done at the lowest

Do not use this appliance if any external part to the tank has been submerged in

water. You should contact a qualified service technician to inspect the appliance

and to replace any part of the control system including the combination gas

control which has been submerged in water. See the Gas Connections section

of this manual before servicing or replacing a water heater that has had any

external part to the tank submerged in water.

IMPORTANT

Before proceeding, please inspect the water heater and its components for

possible damage. DO NOT install any water heater with damaged

components. If damage is evident then please contact the supplier where the

water heater was purchased or the manufacturer listed on the rating plate for

replacement parts.

5

General Information continued-

CAUTION

This water heater must not be used as a source of construction heat or

during the construction phase of any building.

WARNING

This product contains one or more chemicals known to the State of

California to cause cancer, birth defects, or reproductive harm.

WARNING

Water heaters are heat producing appliances. To avoid damage or

WATER HEATER OR VENT-AIR INTAKE SYSTEM.

Make sure that you check the rating plate and combination gas control on the

water heater to be certain that the type of gas being supplied corresponds with

the marking on the rating plate and combination gas control.

A sacrificial anode(s) is used to extend tank life. Removal of any anode, except

for inspection and/or replacem ent, will nullify the warranty. In areas where water

is unusually active, an odor may occur at the hot water faucet due to a reaction

between the sacrificial anode and impurities in the water. If this should happen,

an alternative anode(s) may be purchased from the supplier that installed this

water heater. This will minimize the odor while protecting the tank. Additionally,

the water heater should be flushed with appropriate dissolvers to eliminate any

bacteria.

INSTALLATION

Locat ing the Water Heater

injury, do not store materials against the water heater or vent-air intake

system. Use proper care to avoid unnecessary contact (especially by

children) with the water heater and vent-air intake components. UNDER

NO CIRCUMSTANCES MUST FLAMMABLE MATERIALS, SUCH AS

GASOLINE OR PAINT THINNER BE USED OR STORED IN THE

VICINITY OF THIS WATER HEATER, VENT-AIR INTAKE SYSTEM

OR IN ANY LOCATION FROM WHICH FUMES COULD REACH THE

DO NOT install the water heater in a n y location where gasoline or

flammable vapors are likely to be present.

Water heaters in residential garages must be installed and located, or

protected, to avoid physi cal damage. For other installations refer to local

codes. In the absence of local codes, the water heater must be installed in

compliance with the National Fuel Gas Code, (ANSI Z223.1- Latest

Edition), or in Canada CAN/CGA B149.1 Natural Gas Installation Code

(Latest Edition) or CAN/CGA B149.2 Propane Installation Code (Latest

Edition).

6

Installation (Locating The Water Heater) continued-

WARNING

Liquefied petroleum gases/propane gases are heavier than air and

CORRECTED!

The location of this water heater is of the utmost importance. Before installing

this water heater, read the installation section of these instructions. After

reading these installation and operating instructions, select a location for the

water heater where the floor is level and is easily accessible to gas and water

supply lines. DO NOT locate the water heater where water lines could be

subjected to freezing temperatures. Make sure the cold water pipes are

not located directly above the gas control so that condensate d uring

humid weather does not drip on the controls.

Water heater corrosion and component failure can be caused by the heating

and breakdown of airborne chemical vapors. Examples of some typical

compounds that are potentially corrosive are: spray can propellants, cleaning

solvents, refrigerator and air conditioning refrigerants, swimming pool

chemicals, calcium and sodium chloride, waxes and process chemicals. These

materials are corrosive at very low concentration levels with little or no odor to

reveal their presence. NOTE: DAMAGE TO THE WATER HEATER CAUSED

BY EXPOSURE TO CORROSIVE VAPORS IS NOT COVERED BY THE

WARRANTY. DO NOT OPERATE THE WATER HEATER IF EXPOSURE HAS

OR WILL OCCUR. DO NOT STORE ANY POTENTIALLY CORROSIVE

COMPOUNDS IN THE VICINITY OF THE WATER HEATER.

To comply wit h NSF requirements t hi s water h eat er i s t o b e:

a) Sealed to t h e flo or wi t h seal ant, i n a sm o oth an d easil y c lean ab le

way , o r

b) Installed w it h an optional leg kit that includes legs and/or

ext ensions t hat prov ide a minimum clearance of 6 ’’ b eneath the

water heater.

will remain at floor level if there is a leak. Basements, crawl spaces,

closets, and areas below ground level will serve as pockets for

accumulation of leaking gas. Before lighting, smell al l around the

appliance area for gas. Be sure to smell next to the floor.

IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any te lephone in

your building.

• Immediately call your gas supplier from a neighbor’s

telephone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplie r, call the fire department.

DO NOT OPERATE APPLIANCE UNTIL THE LEAKAGE IS

7

Installation (Locating The Water Heater) continued-

WARNING

DO NOT ATTEMPT TO LIGHT ANY GAS APPLIANCE IF YOU ARE

professional, for more information.

NOT CERTAIN OF THE FOLLOWING:

• Liquefied petroleum gases/propane gas and natural gas have an

odorant added by the gas supplier that aids in the detection of the

gas.

• Most people recognize this odor as a “sulfur” or “rotten egg” smell.

• Other conditions, such as “odorant fade” can cause the odorant to

diminish in intensity, or “fade”, and not be as readily detectable.

• If you have a diminished sense of smell, or are in any way unsure of

the presence of gas, immediately contact your gas supplier from a

neighbor’s telephone.

Gas detectors are available. Contact your gas supplier, or plumbing

The water heater must be located close enough to the outside wall to keep the

venting distance within the maximum distance described in the installation

instructions. Locate the water heater as close as possible to the vent opening.

Read the venting section in this installation instruction manual before locating

the water heater.

This water heater must be located in an area where leakage of the tank or water

line connections and the combination temperature and pressure relief valve will

not result in damage to the area adjacent to the water heater or to lower floors

of the structure. When such locations cannot be avoided, a suitable drain pan

adequately piped for proper drainage must be installed under the water heater.

The pan must not restrict combustion air flow. The drain pan must have a

minimum length and width of at least 4 in. (10.2 cm) greater than the diameter

of the water heater and must not restrict proper combustion air flow to the water

heater. The drain pan, as described above, can be purchased from your

plumbing professional. The drain pan must be piped to an adequate drain. The

piping must be at least 3/4 inch (1.9 cm) in diameter and pitched for proper

drainage.

It is recommended that a minimum clearance of four (4) inches (10.2 cm) be

provided on the side of the water heater for servicing and maintenance of the

combination temperature and pressure relief valve.

This water heater MUST be installed indoors out of the wind and weather.

Note: For California inst allation this w at er heat er must be braced,

anchored, or st rapped to a void f a lling or moving during an eart hqua ke. See

instruct ions f or correct inst alla t ion procedures. I nstructions may be

obt ained f rom t he DSA H eadquart ers Office: 110 2 Q Street , Suite 510 0 ,

Sacramento CA 95811.

8

WARNING

Failure to adhere to these installation and operating instructions

warranty.

Minimum Clearances

may create a hazard to life and property and will nullify the

This installation must allow access to the front of the water heater and adequate

clearance must be provided for servicing and operating this water heater. The

water heater may be installed on either a combustible or non-combustible floor.

If the water heater is to be installed directly on carpeting, it must be installed on

top of a metal or wood panel extending beyond the full width and depth of the

appliance by at least three (3) inches (7.6 cm) in any direction or, if the

appliance is to be installed in an alcove or closet, the entire floor must be

covered by the panel. The minimum clearances to combustibles for this water

heater are: zero (0) inch (0 cm) from the sides and rear, five (5) inches (12.7

cm) from the front of the jacket, zero (0) inch (0 cm) from the vent connector

and fifteen (15) inches (38.1 cm) from the jacket top. Increased distances

provide greater clearances for servicing.

Venting

This venting section is divided int o two part s. Part I will c ove r ve nt ing

specificat ions f or 48 Gal (181.6 L) and 65 Ga l (246.0 L) models. Part I I will

cover v ent ing specif ic at ions f or 4 0 Gal (151.4 L), 50 Gal (189.2 L), and 60

Gal (227.1 L) models. Refer to t he rating plat e located on the w at er heater

for c orrect mode l ident if ica t ion.

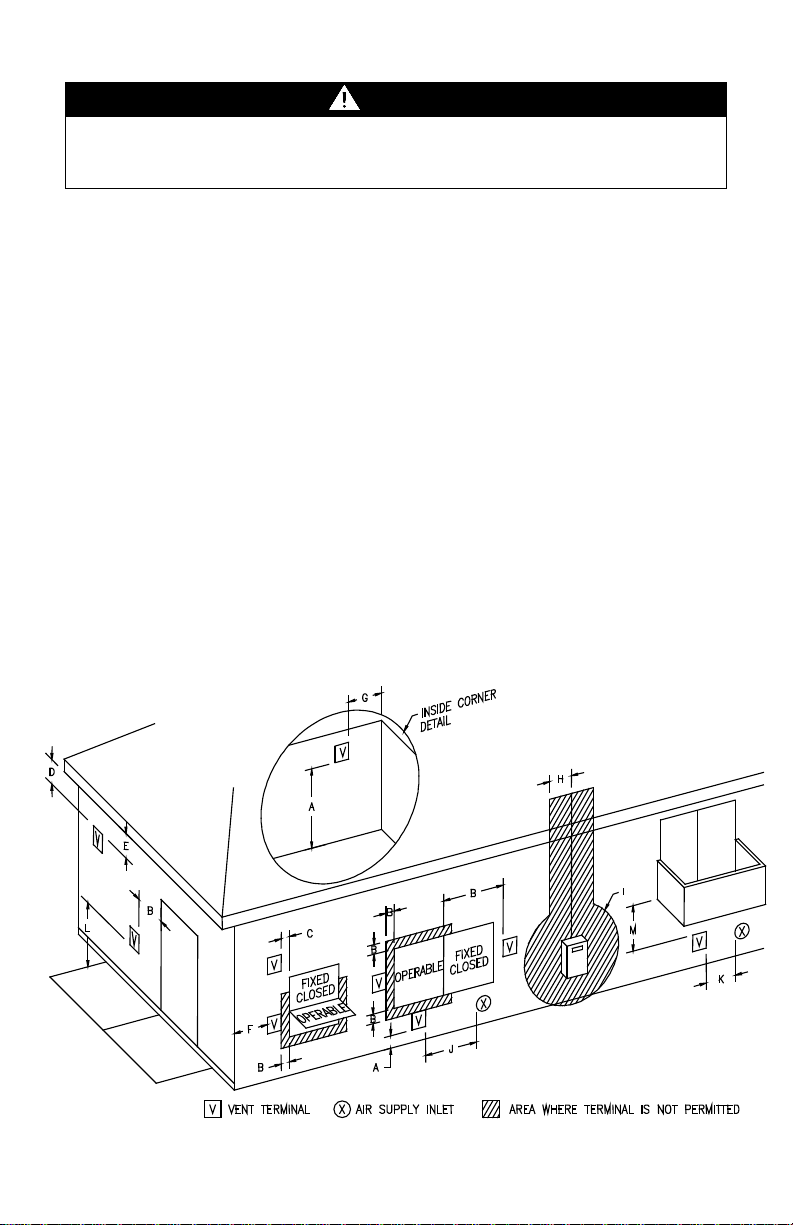

Figure 1 - Vent T erminal Clearances

9

Venting continued-

Canadian

US Installations2

A=

Clearance above grade, veranda,

porch, deck or balcony

12 inches

(30 cm)

12 inches

(30 cm)

B=

Clearance to window or door that may

12 inches

4 feet (1.2 m) below or

opening

C=

Clearance to permanently closed

window

*b

*b

D=

Vertical clearance to ventilated soffit

from the center line of the terminal

*b

*b

E=

Clearance to unventilated soffit

*b

*b

F=

Clearance to outside corner

*b

*b

G=

Clearance to inside corner

*b

*b

H=

Clearance to each side of center line

3 feet (91 cm)

assembly

*b

I=

Clearance to service regulator vent

outlet or oil tank vent

36 inches

(91 cm)

*b

J=

Clearance to non-mechanical air

appliance

12 inches

4 feet (1.2m) below or to

opening.

K=

Clearance to a mechanical air supply

6 feet

3 feet (91 cm) above if

horizontally

L=

Clearance above paved sidewalk or

property

7 feet

7 feet

M=

Clearance under a veranda, porch,

deck, or balcony

12 inches

30 cm) ‡

*b

Installations1

be opened

located above the terminal within a

horizontal distance of 2 feet (61 cm)

extended above meter/regulator

assembly

supply inlet to building or the

combustion air inlet to any other

inlet

paved driveway located on public

1

In accordance with the current CAN/CGA-B149 Installat ion Codes.

2

In accordance with the current A NSI Z22 3.1-(Lates t ed i ti o n) / N FPA 54 Nat ional Fuel Gas Code.

(30 cm)

within a height

15 feet (4.6 m)

above the

meter/regulator

(30 cm)

(1.83 m)

(2.13 m)†

to the side of opening;

12 inches (30 cm) above

side of opening; 12

inches (30 cm) above

within 10 feet

(2.13 m)†

† A v en t s hal l n ot t er m i n ate d i rectl y ab o v e a s id ew al k or p av ed d ri vew ay th at i s l o c ated betw een tw o

single-family dwellings and serves both dwellings.

‡ Permitted only if a v eranda, porch, deck or balcony is f ully open on a minimum of t w o sides beneath

the f l oor.

* a) A minim um clearance value determined by test ing in acc ordance wit h section 2 . 2 0.

* b) ‘‘Cl ear an c e i n ac cor d anc e w i th l o cal inst allat ion codes and the requirements of t he gas supplier’’.

The vent system must terminate so that proper clearances are maintained as cited

in local codes or the latest edition of the National Fuel Gas Code, ANSI

Z223.1.73.4e and 7.8a, b as follows:

1. Do not terminate near soffit vents or crawl space or other area where condensate

or vapor could create a nuisance or hazard or cause property damage.

2. Do not terminate the exhaust vent terminal where condensate or vapor could cause

damage or could be detrimental to the operation of regulators, relief valves, or

other equipment.

3. Do not terminate the exhaust vent terminal over public area or walkways where

condensate or vapor can cause nuisance or hazard.

4. The vent shall terminate a minimum of 12” (25.4 cm) above expected snowfall level

to prevent blockage of vent termination.

10

Venting continued-

Clearance to combustibles for all venting pipes and terminals

For installations in the CANADA

for clearances to combustibles

DO NOT place insulation or other materials in the required clearance spaces

WARNING

Risk of carbon monoxide poisoning or fire due to joint separati on

or pipe breakage.

This water heater must be properly vented and connected to an

dependent upon full compliance with these installation instructions.

Venting system must not pass through rated fire separations.

The venting system must be free to expand and contract. This venting

system must be supported in accordance with these instructions.

NOTICE

For installations in Canada, field supplied vent piping must comply with

to be used within their marked time limitations.

Vent pipes serving power vented appliances are classified by building codes as “vent

connectors”. Required clearances from combustible materials must be provided in

accordance with information in this manual under “Locating the Water Heater” and

“Minimum Clearances”, and with National Fuel Gas Code and local codes.

For installations in the US

0” minimum

Refer to vent pipe and terminal

manufacturer’s installation instructions

between the venting to combustible material unless otherwise specified.

approved vent system in good condition. DO NOT operate water heater

with the absence of an approved vent system. A clean and unobstructed

vent system is necessary to allow noxious fumes that could cause injury

or loss of life to vent safely and will contribute toward maintaining the

water heater’s efficiency. The acceptance of the venting system is

CAN/CGA B149.1 (latest edition) and be certified to the Standard For

Type BH, Class II, 65°C, Gas Venting Systems, ULC S636.

Components of this listed system shall not be interchanged with other

vent systems or unlisted pipe/fittings. All components and specified

primers and cements of the certified vent system must be from a single

system manufacturer and not intermixed with other system

manufacturer’s vent system parts. The supplied vent connector and vent

termination are certified under ULC S636 and are also certified as part

of the water heater. Refer to the following tables for approved venting

materials, primers, and cements. All approved primers and cements are

11

Venting continued-

For installations in the US

D2661)

For installations in CANADA

A pprov ed Prim ers and Cement s

For installations in the US

(ASTM D-2235)

For installations in CANADA

NOTICE

Use of cellular core PVC (ASTM F891), cellular core CPVC, or Radel

®

covering non-metallic venting with thermal insulation is prohibited.

A pprov ed Venting M at erials

only

• PVC DWV (ASTM D-2665)

• PVC Sch. 40, 80, 120 (ASTM-

D1785)

• CPVC Sch. 40, 80 (ASTMF441)

• CPVC (ASTM D2846)

• ABS Sch. 40 DWV (ASTM

only

• PVC and CPVC Primer (ASTMF656)

• PVC Cement (ASTM D-2564)

• CPVC Cement (ASTM F493)

• ABS Primer and Cement

(polyphenosulfone) in non-metallic venting systems is prohibited, and

• ULC S636 approved PVC for

flue gas venting rated Class II,

65°C

• ULC S636 approved CPVC for

flue gas venting rated Class II,

65°C

• ULC S636 approved Primer and

Cement for flue gas venting

rated Class II, 65°C

12

Venting continued-

V ent ing Sy st em Conde nsat ion

Condensate format ion does not oc cur in all installations of power vented

w at er heat ers, but should be protect ed against on inst allations w here

condensat ion can f orm in t he vent ing system.

Formation of c ondensat ion in t he venting syst em of Power Vent ed w at er

heaters i s dep endent upon inst allation condit ions including, but not lim it ed

to:

ambient t emperat ure and humidity of inst allation locat ion;

ambient t emperat ure and humidity of v ent ing space;

vent distance and slope;

and product usage.

In order t o ef f ect ively control con den sate f r o m ad v er sely affectin g t h e

mec h ani c al c o m po n ents of th e water h eater sev er al m etho ds m ay b e

employed:

1. For horizontal installations t he vent pipe can be installed w it h a

dow nward slope (not less t han 1/ 8 " (3 cm )) an d aw ay f r o m the

blower.

2. In order to prevent c ondensat e from draining back int o the blow er

(vertical or horizontal runs), an optional condensate kit is available

as a serv i c e par t (Con den sate ki t, p/n 2 39 -45875-00). A factory

supplied exhaust adapter w it h drain out let m ount s directly t o t he

blow er out let and is secured with two hose clamps, one to t he

blow er and the ot her to the vent pipe. Tubing is provided to drain

any ac c u mu l at ed c o nd ensate away fro m th e water h eater and to a

suitable drain. The kit com es complete w it h inst ruct ions f or proper

installation.

Par t I - Ve nting S pec ific ations f or:

4 8 Gallon (181.6 L)

65 Gallon (246.0 L)

This w ater heater is a power vent ed appliance and is designed t o vent it s

product s of combust ion t hrough 3 ’’ (7.6 cm) or 4’’ (10.2 cm) diameter

vent pipe to t he out doors. Th i s water h eat er m ay be ei ther v ented

horizontally t hrough t he w all or vert ically t hrough t he roof . Us e a 3 ’’ (7.6

cm) to 4 ’’ (10.2 cm) reducer to connect to the vent out let when using 4’’

(10.2 cm) v ent pipe. A pply t he proper cement at t he joint locat ions. Table

1 list s t he maximum vent lengths f or t his wat er heat er using 3’’ (7.6 cm)

vent pipe. If possible, locate t he w at er heat er so that the vent ing length

and number of elbow s are kept t o t he minimum dist ance necessary t o

reach t he out side. If t he installation requires vent ing lengths t hat exc eed

t he lengths listed for 3 ’’ (7.6 cm) v ent pipe in Table 1, then use 4’’ (10.2

cm) v ent pipe f or t he vent c onnect or.

13

Venting (Part I) continued-

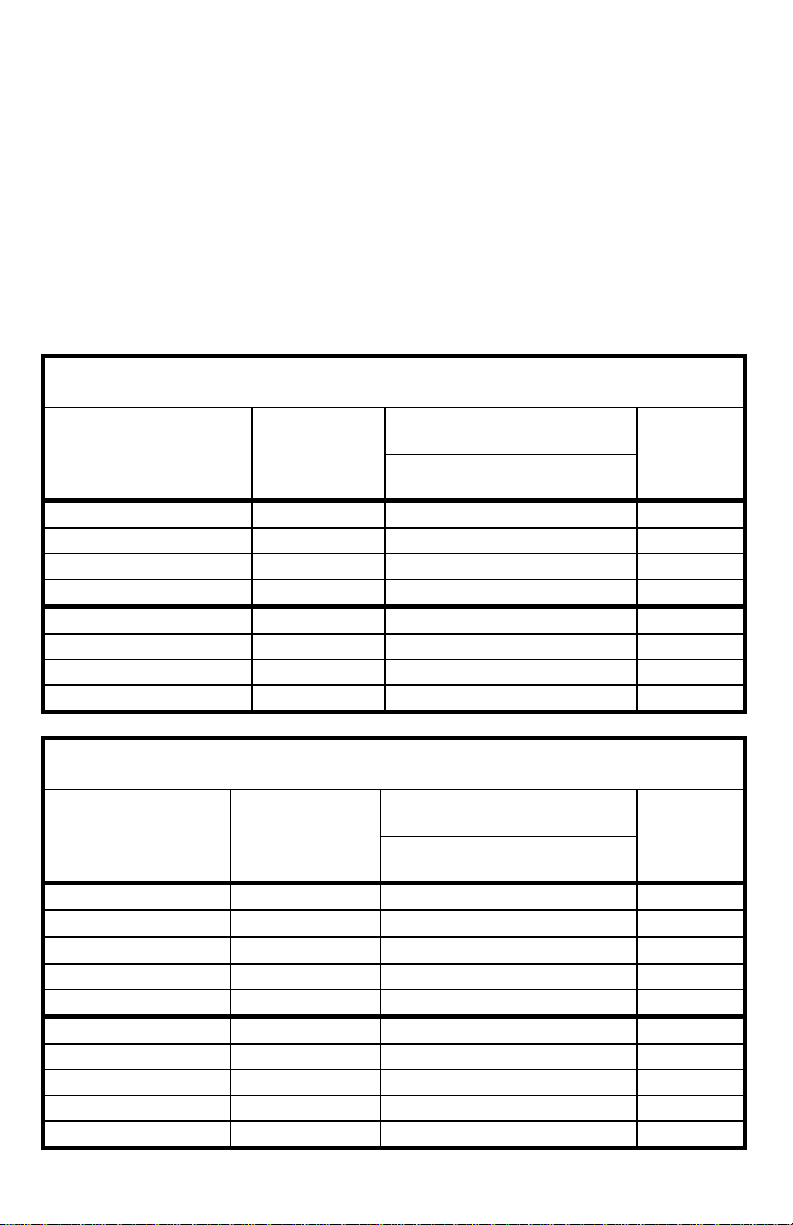

T ABLE 1 - V ENT CONNECTOR LENGTHS

FO R 3’’ (7.6 cm) D I AMETER VEN T PI P E

Terminating

# of Elbows

Maximum straight

Length ft (m)

Minimum

ft (m)

48, 65 gal.

Through the Wall

1

55 (16.8)

2 (.6)

Through the Wall

2

50 (15.2)

2 (.6)

Through the Wall

3

45 (13.7)

2 (.6)

Through the Wall

4

40 (12.2)

2 (.6)

Through the Roof

0

60 (18.3)

7 (2.1)

Through the Roof

1

55 (16.8)

7 (2.1)

Through the Roof

2

50 (15.2)

7 (2.1)

Through the Roof

3

45 (13.7)

7 (2.1)

T ABLE 2 -VENT CONNECTOR LENGTHS

F O R 4’’ (10.2 cm) D I AMETER VEN T PI P E

Terminating

# of 90°

Maximum straight

Length ft (m)

Min

ft (m)

48, 65 gal.

Through the Wall

1

175 (53.3)

10 (3.1)

Through the Wall

2

170 (51.8)

10 (3.1)

Through the Wall

3

165 (50.3)

10 (3.1)

Through the Wall

4

160 (48.8)

10 (3.1)

Through the Wall

5

155 (47.2)

10 (3.1)

Through t he Roof

0

180 (54.9)

15 (4.6)

Through the Roof

1

175 (53.3)

15 (4.6)

Through the Roof

2

170 (51.8)

15 (4.6)

Through the Roof

3

165 (50.3)

15 (4.6)

Through the Roof

4

160 (48.8)

15 (4.6)

Table 2 list s t he venting dist ances allowed wit h 4’’ (10.2 cm) diameter

vent pipe. W hen v ent ing wit h 4 ’’ (10.2 cm) v ent pipe , us e a 4 ’’ (10.2 cm)

t o 3’’ (7.6 cm) reducer to exit t hrough t he building w all wit h 3 ’’ (7.6 cm)

vent pipe. Use th e 3 ’’ (7.6 cm) vent t erminal supplied w it h the water

heater to term in ate on t he outside of the building. If t he length of 3 ’’ (7.6

cm) v ent pipe needed to go through the wall is greater than 14 ’’ (35.5

cm), u se 4 ’’ (10.2 cm) t o go t hrough t he wall and reduce t o 3 ’’ (7.6 cm)

v ent pi pe i m m edi at el y aft er ex i t i n g the o u t si d e wall . Refer t o the vent ing

illustrat ions on the f ollowing pages. M ak e su re the ven t pi pe term i nal

elbow f itting is at least 1 ’’ (2.5 cm) away fr o m the ed g e of th e wal l.

straight

Length

Elbow s (ex cl.

vent t erm. )

straight

Length

14

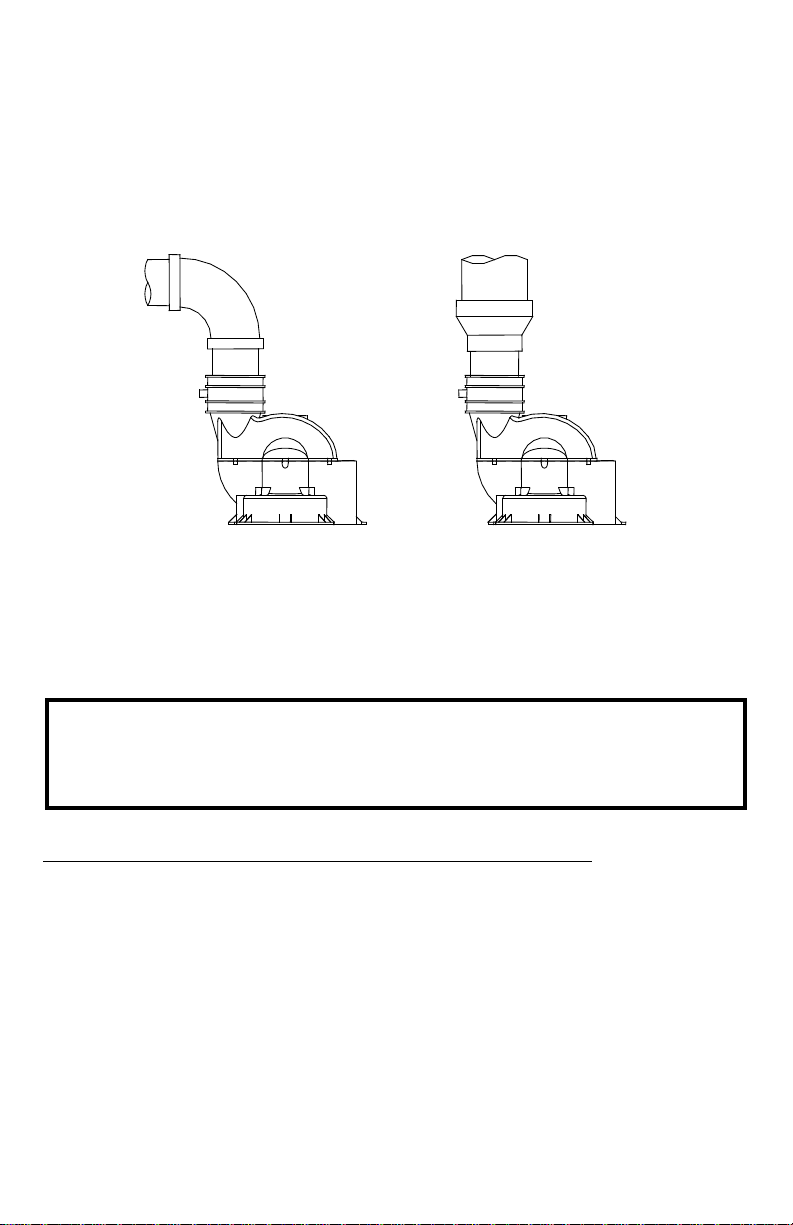

CONNECTION TO A 3” (7.6 CM) TO

4” (10.2 CM) REDUCER

CONNECTION TO 3” (7.6 CM)

VENT PIPE

Venting (Part I) continued-

NOTE: When using 4” (10.2 cm) vent pipe, use a 4” (10.1 cm) to 3” (7.6 cm)

reducer and exit the building wall with 3” (7.6 cm) vent pipe using the

3” (7.6 cm) 90° vent terminal supplied. Two 45° elbows are equivalent to

one 90

° elbow.

Figure 2

IMPORTANT

All of the Venting connections must be leak checked with a soap and

water solution upon initial start up of the water heater. Any leaks must

be repaired before continuing operation of the water heater.

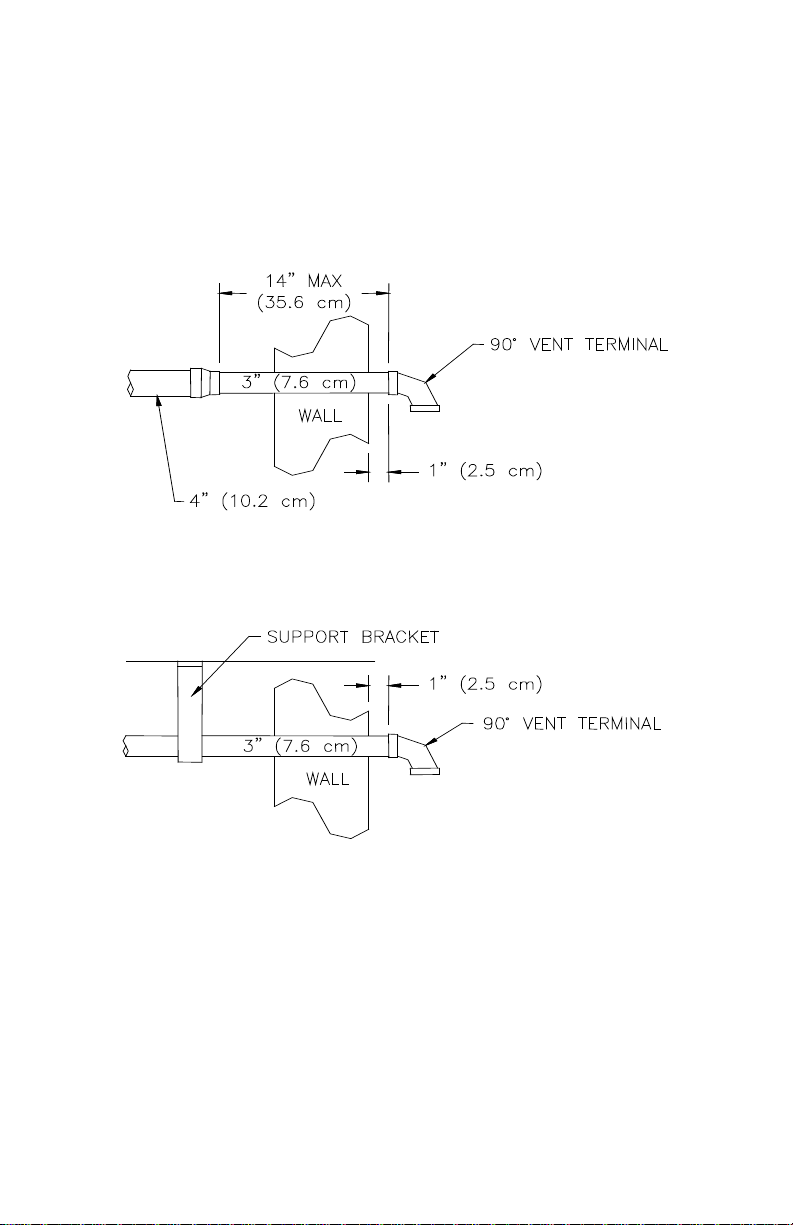

THROUGH THE W ALL V ENTING: (HORIZONTAL VENTING)

Cut a 3 1/2 in. (8.9 cm) d iam eter h ol e in the wal l at th e p oi nt wh ere the

vent connect or is going to pass through t he wall. Use the proper cement t o

secu r e t h e 9 0° v en t term i nal pr o v id ed w ith the wat er heater to the v en t

connector. Th e d istanc e b etw een the edges of the 9 0° v ent terminal and

t h e ex terio r wall (see Fig ur e 3 ) mu st be 1 in. (2.5 cm). Use the proper

cement and assembly procedures t o secure the vent connect or joint s

between the terminal and the blow er out let. Provide support bracket s for

ev ery 5 feet (1.5 m) of horizont al vent.

15

4” VENT INSTALLATION

3” VENT INSTALLATION

Venting (Part I) continued-

Figure 3

Loading...

Loading...