Page 1

Commercial ASME Electric Water Heaters

The ASME Electric Models feature:

n A.S.M.E. Code Tank Construction—Standard.

n Immersion Thermostats—Immersion type for accurate temperature control

from up to 180°F (82°C) with manual reset high limit control.

n Factory Installed Hydrojet

inlet sediment reducing device helps prevent sediment build up in the tank.

n Vitraglas

®

Lining—An exclusively engineered enamel formula that provides

superior tank protection from the highly corrosive effects of hot water. This

formula (Vitraglas

®

) is fused to the steel surface by firing at a temperature of

over 1600°F (871°C.

n Water Connections— Factory-installed true dielectric fittings extend water

heater life and simplify water line connections.

n Elements—screw in style. Low watt density INCOLOY

minimize dry fire and prevents lime build up.

n Insulation System—Non-CFC foam covers the sides and top of the tank,

reducing heat loss. This results in less energy consumption, improved

efficiencies, and jacket rigidity.

n Protective Magnesium Anode Rod—Provides added protection against

corrosion for long-term, trouble-free service.

n Completely Pre-wired—With pressure lug terminal block eliminating need

for splicing or taping of wires.

n Hand Hole Cleanout—(20 (76L) thru 120 (454L) gallon models only).

n T&P Relief Valve—Installed.

n Low Restriction Brass Drain Valve—Durable tamper proof design.

n NSF Construction Available on All Models.

®

Sediment Reduction System—Cold water

®

material helps to

Photo is of

CEA30-36-3

3 or 5-Year Limited Tank Warranties / 1-Year Limited Warranty on Component Parts.

For more information on warranty, please visit www.bradfordwhite.com

For products installed in USA, Canada, and Puerto Rico. Some states do not allow limitations on warranties.

See complete copy of the warranty included with the heater.

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S. PATENTS: 5,682,666; 7,634,976; 5,660,165; 5,954,492; 6,056,542; 6,935,280; 5,372,185; 5,485,879; 5,574,822; 7,971,560; 7,992,526; 6,684,821;

7,334,419; 7,866,168; 7,270,087; 7,007,748; 5,596,952; 6,142,216; 7,699,026; 5,341,770; 7,337,517; 7,665,211; 7,665,210; 7,063,132; 7,063,133; 7,559,293; 7,900,589; 5,943,984; 8,082,888; 5,988,117; 7,621,238;

7,650,859; 5,761,379; 7,409,925; 5,277,171; 8,146,772; 7,458,341; 2,262,174. OTHER U.S. AND FOREIGN PATENT APPLICATIONS PENDING. CURRENT CANADIAN PATENTS: 2,314,845; 2,504,824; 2,108,186;

2,143,031; 2,409,271; 2,548,958; 2,112,515; 2,476,685; 2,239,007; 2,092,105; 2,107,012. Vitraglas

®

and Hydrojet® are registered trademarks of Bradford White® Corporation.

430-B-1219

Page 2

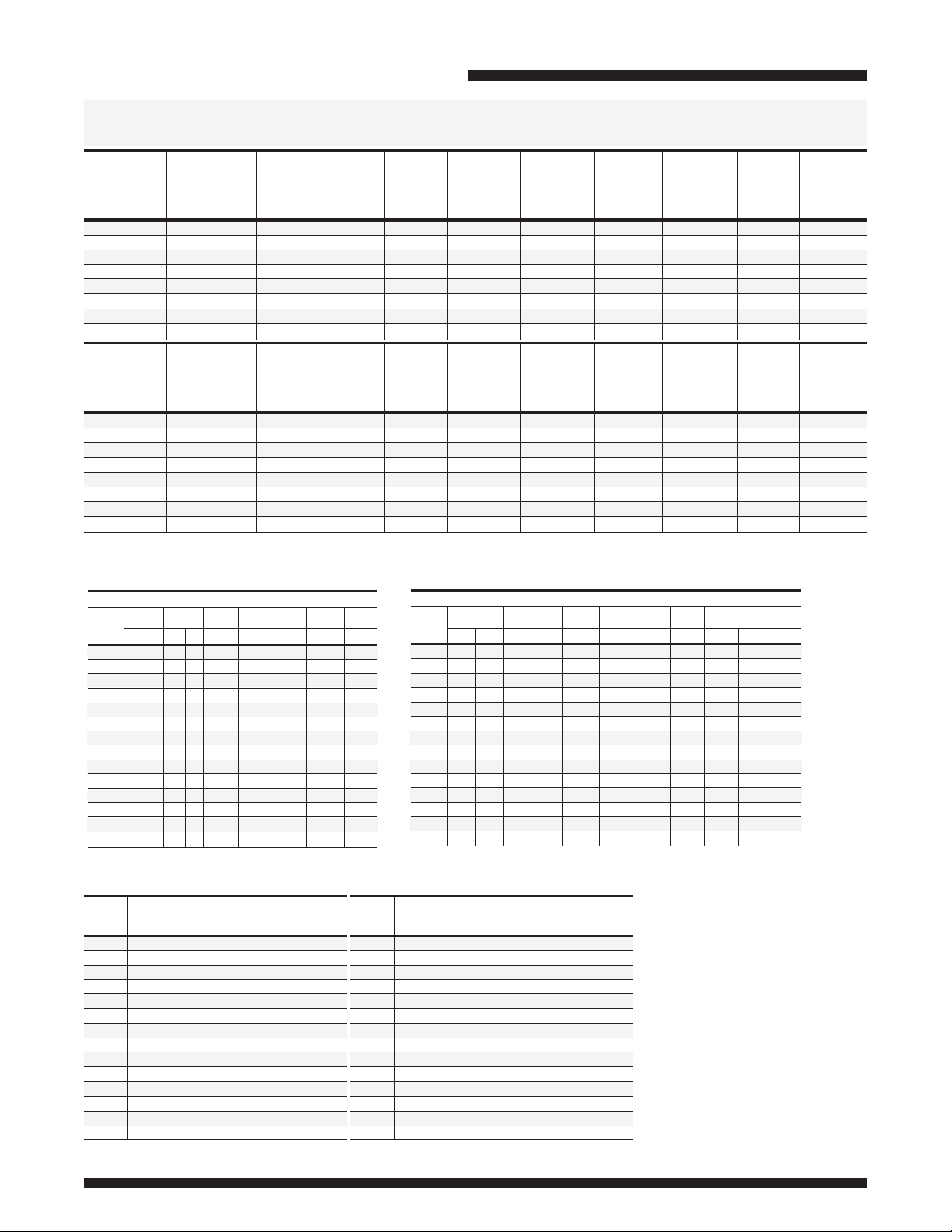

Liters

Commercial Electric Water Heater

Number of Elements (Fused Models)*

Full Load Current Amperes (Fused Models)*

kW Input

ASME Electric Models

Model

Number

CEA6-kW-3

CEA12-kW-3

CEA20-kW-3

CEA30-kW-3

CEA40-kW-3

CEA50-kW-3

CEA80-kW-3

CEA120-kW-3

Model

Number

CEA6-kW-3

CEA12-kW-3

CEA20-kW-3

CEA30-kW-3

CEA40-kW-3

CEA50-kW-3

CEA80-kW-3

CEA120-kW-3

Nominal

Gal.

Capacity

U.S.

Gal.

6

12

19

30

40

48

78

119

Nominal

Capacity

Liter

Min. - Max.

Imp.

Gal. lbs.

5

10

17

25

33

40

65

100

Min. - Max.

23

45

72

114

152

182

295

451

kW

Input

Range

3

3 - 9

3 - 18

13.5 - 36

13.5 - 36

13.5 - 81

13.5 - 81

13.5 - 81

kW

Input

Range

3

3 - 9

3 - 18

13.5 - 36

13.5 - 36

13.5 - 81

13.5 - 81

13.5 - 81

A

Floor to

Top of

Heater

in.

1

17

/8

28

5

27

/8

38

11

48

/16

493/8

607/8

651/8

A

Floor to

Top of

Heater

mm.

435

711

702

965

1237

1254

1546

1654

B

Jacket

Dia.

in.

16

16

20

20

20

24

26

1

30

B

Jacket

Dia.

mm.

406

406

508

508

508

610

661

766

C

Floor to

Hot

Water

Conn.

in.

181/4

29

1

28

/2

39

11

49

/16

497/8

623/8

/4

667/16

C

Floor to

Hot

Water

Conn.

mm.

464

737

724

991

1262

1267

1584

1688

Meet or exceed ASHRAE 90.1b (current standard) C.E.C. Listed

E

Floor to

C/L of

Cold Water

Conn.

in.

1

6

/8

61/8

61/8

61/8

61/8

75/8

75/8

75/8

E

Floor to

C/L of

Cold Water

Conn.

mm.

156

156

156

156

156

194

194

194

Voltage and phase must be specified when ordering. Example: CEA80-18-3, 240 Volt, 3 phase.

Minimum kW inputs for 30 gallons through 119 gallons is 13.5 kW.

F

Floor to

T&P

Conn.

in.

181/16

2815/16

28

1

40

/4

509/16

413/8

527/8

551/4

F

Floor to

T&P

Conn.

mm.

459

735

711

1022

1284

1051

1343

1403

G

Floor to

Top of

Control

Box

in.

17

28

27

38

7

38

/16

471/8

471/8

507/8

G

Floor to

Top of

Control

Box

mm.

432

711

686

965

976

1197

1197

1292

Water

Conn.

NPT

in.

3

/4

3

/4

3

/4

3

/4

3

/4

11/2

11/2

11/2

Water

Conn.

NPT

mm.

19

19

19

19

19

38

38

38

Approx.

Shipping

Weight

83

118

145

180

220

270

335

430

Approx.

Shipping

Weight

kg.

38

54

66

82

100

123

152

195

240V

208V

Phase

Phase

Input

kW

3

6

9

12

13.5

15

18

24

27

30

36

45

54

81

13

1

1

3

3

3

3

3

3

3

3

3

3

3

3

4

6

6

6

6

6

6

6

9

9

9

9

9

9

13

1

3

3

3

3

3

3

4

6

6

6

9

9

9

ASME units with amperage draw of 120 amps or more require factory installed internal fusing. *If the number of elements on non-fused models

is different, it is located in parentheses ( ), following the amp draw.

40

50

3

31

124

140

155

186

248

279

310

372

465

558

852

25

62

50

93

74

99

112

124

149

199

223

248

298

372

447

671

9

12

13.5

15

18

24

27

30

36

45

54

81

6

277V

Phase

1

1

1

3

3

3

3

3

3

3

3

3

3

3

3

4

6

6

6

6

6

6

6

9

9

9

9

9

9

Recovery

GPH Temperature Rise °F

60

70

21

18

41

35

62

53

83

71

93

80

103

89

124

106

164

142

186

160

207

177

248

213

310

266

372

319

558

477

Phase

80

16

31

47

62

70

78

93

124

140

155

186

233

279

418

Phase

3

1

3

3

3

3

3

3

6

6

6

6

9

9

9

90

100

14

28

42

55

62

69

83

110

124

112

138

124

165

149

207

186

248

223

371

334

415V

380V

12

25

37

50

56

62

74

99

3

1

3

3

3

3

3

3

4

6

6

6

9

9

9

480V

Phase

13

1

3

3

3

3

3

3

4

6

6

6

9

9

9

120

10

21

31

41

47

52

62

83

93

103

124

155

186

278

106

133

160

238

140

18

27

35

40

44

53

71

80

89

1

3

3

3

3

3

3

6

6

6

6

9

9

9

9

600V

Phase

3

1

3

3

3

3

3

3

6

6

6

6

9

9

9

kW Input

3

6

9

12

13.5

15

18

24

27

30

36

45

54

81

117

235

352

469

530

587

704

939

1056

1173

1408

1760

2112

3225

208V

Phase

Input

kW

13

3

14

6

29(2)

9

43

12

58

13.5

65

15

72

18

87

24

115

27

130

30

144

36

173

45

216

54

260

81

389

LPH Temperature Rise °C

23

28

34

95

79

189

155

280

235

375

314

424

352

469

390

564

469

753

621

844

704

939

784

1128

939

1408

1173

1692

1408

2540

2112

14

17

25

33

37

42

50

67

75

83

100

125

150

225

Recovery

40

68

132

201

269

303

337

401

538

606

670

806

1007

1208

1806

240V

Phase

13

13

25(2)

38

50

56

63

75

100

113

125

150

188

225

338

45

61

117

106

178

159

235

208

265

235

295

261

352

314

469

416

530

469

587

522

704

625

882

784

1056

939

1582

1404

108

130

195

50

53

33

N/A

8

13

17

19

21

25

33

38

42

50

63

75

113

480V

Phase

13

6

6

13(2)

7

19

11

25(2)

14

28

16

31

18

38

22

50

29

56

32

63

36

75

43

94

54

113

65

169

97

600V

Phase

3

2.8

6

9

12

13

14

17

23

26

29

35

43

52

78

277V

380V

Phase

Phase

1

11

22(2)

33

43(2)

49

54

65

87

97

108

130

163

195

292

117

155

178

197

235

314

352

390

469

587

704

1052

3

5

9

14

18

21

23

27

36

41

46

55

68

82

123

67

78

38

34

79

68

102

132

151

167

201

269

303

337

401

503

606

901

13

14

22

29

32

36

43

58

65

72

87

56

45

95

140

189

212

235

280

375

424

469

564

704

844

1264

400V

Phase

8

9

13

17

20

22

26

35

39

43

52

65

78

117

415V

Phase

Page 3

)

CEA20, CEA30, CEA40

CEA12

CEA6

)

CEA120

CEA80

COLD

(mm)

CEA50

DRAIN

B

ANODE

T&P VALVE

OUTLET

B

CLEANOUT

NOT

AVAILABLE

ON 6/12 GAL.

Commercial Electric Water Heater

OUTLET

(23/45L)

T&P VALVE

C

G

E

(mm)

8"

(203)

DRAIN

75°

75°

T&P

13"

(330)

COLD

DRAIN

A

87°

F

87°

8"

13"

(203)

T&P

(330)

COLD

DRAIN

78°

78°

10"

(254)

14 1/2"

ANODE

T&P

(368

COLD

58°

63°

(305)

12"

18 1/2"

(470)

COLD

52°

13"

(330)

19 1/2"

(495)

56°

COLD

45°

15 1/8"

(384

(562)

22 1/8"

47°

Page 4

Commercial Electric Water Heater

Optional Components

n High and Low Water Pressure Controls—The Controls interrupt the electrical current to the contactor coil when the

pressure settings are exceeded.

n Low Water Level Control—This Control will interrupt the electrical current to the contactor coil when a low water

level condition is sensed inside the water heater tank. When the low water level condition is corrected the control will

automatically sense the new situation and electrical current will again energize the contactor coil. Normal water heater

operation will be resumed.

n Alarm Horn—The Alarm Horn is an option specified when the installation desires an audible signal to immediately sound

an alert when the water heater operation is interrupted for certain faults. Referring to the control circuit wiring diagram,

the alarm will activate when any one of the following events occur:

-- The Hi-Limit control has been tripped

-- The High Water Pressure Control senses excessive pressure

-- The Low Water Pressure Control senses insufficient pressure

-- The Low Water Level Control senses an insufficient quantity of water

n Modulating Controls—Heating element sequencers are available in order to stage the activation of the heating

elements thereby, reducing the inrush current to the water heater. The sequencers will control one or two contactor coils

depending upon the water heater voltage, phase, and kW.

n Electrical Door Lock—An electrical door lock is offered in order to secure the access to the water heater control

cabinet. This device will lock the control cabinet door when the 120VAC control circuit voltage is applied to it.

n Temperature and Pressure Gauge—Displays approximate temperature of the water and approximate pressure inside

the tank.

n BMS Relays—Allows BMS to supply power to the water heater on and off and view if the elements are in operation

-- Relay 1- When energized by the BMS supply voltage, this will allow water heater operation (enable/disable)

-- Relay 2- Sends signal to BMS to show if the elements are in operation or not.

Sample Specification

The water heater shall be a Bradford White model with a rated storage capacity of not less than_______gallons (_______liters), a minimum

kW input of _______kW (_______ BTU/Hr.), a minimum recovery of _______GPH (_______ LPH). The tank shall be Vitraglas

®

lined and have a

bolted hand hole cleanout. The tank shall have _______magnesium anode rods installed in separate tank head couplings. The heater shall

have 3” Non-CFC foam insulation, and come equipped with an ASME rated T&P relief valve, a cold water inlet Hydrojet

®

Sediment Reduction

System. It shall be design certified by ETL for 180ºF (82ºC) application, either with or without a separate storage tank, and comply with

state and local codes and ordinances.

General

All electric water heaters are certified at 300 PSI test pressure (2068 kPa) and 150 PSI working pressure (1034 kPa). All models are design

certified by ETL, for up to 180°F (82°C) application as an Automatic Storage Heater, and an Automatic Circulating Tank Heater. As an

Automatic Storage Heater, all models are complete, self-contained water heating systems. It needs no separate storage tank, pump, wiring

or elaborate piping network. When equipped with a mixing valve, it will supply 180°F (82°C) sanitizing and lower temperature general purpose

hot water simultaneously. These models can be used either as a single unit or in multiples connected in series or parallel (recommended).

Dimensions and specifications subject to change without notice in accordance with our policy of continuous product improvement.

For field service, contact your professional installer or local Bradford White sales representative.

Ambler, PA

Sales 800-523-2931 n Fax 215-641-1612

Technical Support 800-334-3393

Warranty 800-531-2111

International: Telephone 1-215-641-9400 n Email international@bradfordwhite.com / www.bradfordwhite.com

n

n

Email techserv@bradfordwhite.com

Email warranty@bradfordwhite.com

©2019, Bradford White Corporation. All rights reserved.

Printed in U.S.A.430-B-1219

Loading...

Loading...