Page 1

"Highest in Subcontractor Satisfaction among Water Heater/Boiler Manufacturers"

Residential Power Vent Combi2™TTW

Energy Saver Gas Water Heater System

The Combi2™TTW®FVIR Defender Safety System®Models Feature

Photo is of

C-DW2-TW50T10FBN

(50T model, only):

■ Advanced ScreenLok

rrestor is designed to prevent ignition of flammable vapor outside of the

a

water heater.

■ Flammable Vapor Sensor—Electronic sensor prevents burner operation if

flammable vapors are detected. The sensor will also prevent operation if

there is ongoing flammable vapor burn inside the combustion chamber.

■ Maintenance Free—Regular cleaning of air inlet openings or flame arrestor

is not required under normal conditions.

■ Sight Window—Offers a view of the pilot and burner operation.

■ Pedestal Base—Rugged and durable base allows easy transport and

positioning, and provides corrosion resistant contact with floor.

All Combi2™TTW®Models Feature

■ Heat Exchanger—Double wall 1

ensures separation of potable water and heating fluid.

■ Low Heat Exchanger Head Loss—Up to 10 GPM flow, with less than 5 ft.

of head loss. Greatly reduces the required pump size for heat exchange.

■ Factory installed Hydrojet

inlet sediment reducing device helps prevent sediment build up in tank.

Increases first hour delivery and minimizing temperature build up in tank.

■ Vitraglas

®

Lined Tank—Bradford White tanks are protected from the

corrosive effects of hot water by an exclusive ceramic porcelain-like coating.

■ Electronic Gas Control Valve—The integrated, immersion gas control valve

offers precise temperature control for higher first hour delivery and also

allows water temperature adjustment without removing the cover. Control is

equipped with an LED display to aid in start-up and diagnostics.

■ Spark to Pilot Ignition System—Eliminates the constant burning pilot used

on other water heaters.

■ Powerful Blower Motor—Our design has higher torque for greater

resistance to outside winds and the power to eliminate problems with

difficult venting situations. This significantly quieter motor runs cooler for a

considerably longer operational life.

■ Horizontal and Vertical Venting—With 3" or 4" PVC, ABS OR CPVC

(Maximum equivalent vent length on r

■ Thermostatic Mixing Valve—Supplied to help prevent injury due to

scalding.

■ Two Protective Aluminum Anode Rods—Provide added protection against

corrosion for long trouble-free service.

■ 2" Non-CFC Foam Insulation—Surrounds the tank surface, saving energy

by retarding loss of heat.

ater Connections—

■ W

■ Steel T

■ T&P Relief Valve—Installed.

■ Brass Drain V

■ Design Cer

ank—

Heavy gauge steel automatically for

alve

tified by CSA Inter

®

Technology Flame Arrestor Design—Flame

1

⁄2" O.D. glass coated (Vitraglas®) steel coil

®2™

Total Performance System—Cold water

everse side).

3/4" NPT factory installed true dielectric fittings.

med, r

.

national (for

merly AGA and CGA)

®

olled and welded.

.

ear Limited Tank and Heat Exchanger Warranties / 6-Year Limited Warranty on Component Parts.

10-Y

For more information on warranty, please visit www.bradfordwhite.com

For products installed in USA, Canada and Puerto Rico. Some states do not allow limitations on warranties. See complete

copy of the war

Bradfor

Study based on 882 r

experiences may var

MANUF

5,277,171; (B1)5,341,770; 5,660,165; 5,596,952; 5,682,666; 4,904,428; 5,023,031; 5,000,893; 4,669,448; 4,829,983; 4,808,356; 5,115,767; 5,092,519; 5,052,346; 4,416,222; 4,628,184; 4,861,968; 4,672,919; Re.

34,534. OTHER U.S. AND FOREIGN PATENT APPLICATIONS PENDING. CURRENT CANADIAN PATENTS: 1,272,914; 1,280,043; 1,289,832; 2,045,862; 2,112,515; 2,108,186; 2,107,012; 2,092,105.

Defender Safety System®, ScreenLok®, TTW®, Vitraglas®and Hydrojet®are registered trademarks of Bradford White®Corporation.

esponses measuring 3 water heater/boiler manufactur

y. Visit jdpower.com

ACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S. PATENTS:

eceived the highest numerical scor

d White r

e among water heater/boiler manufacturers in the proprietary J.D. Power and Associates/ McGraw-Hill Construction 2006 HVAC and Water Heater/Boiler Subcontractor Satisfaction Study

ranty included with the heater

ers and measures opinions of subcontractors. Proprietary study results are based on experiences and perceptions of subcontractors surveyed in May through July 2006. Your

7,063,133 B2; 5,954,492; 5,761,379; 5,943,984; 5,081,696; 5,988,117; 6,142,216; 5,199,385; 5,574,822; 5,372,185; 5,485,879;

.

547-B-0807-A

SM

.

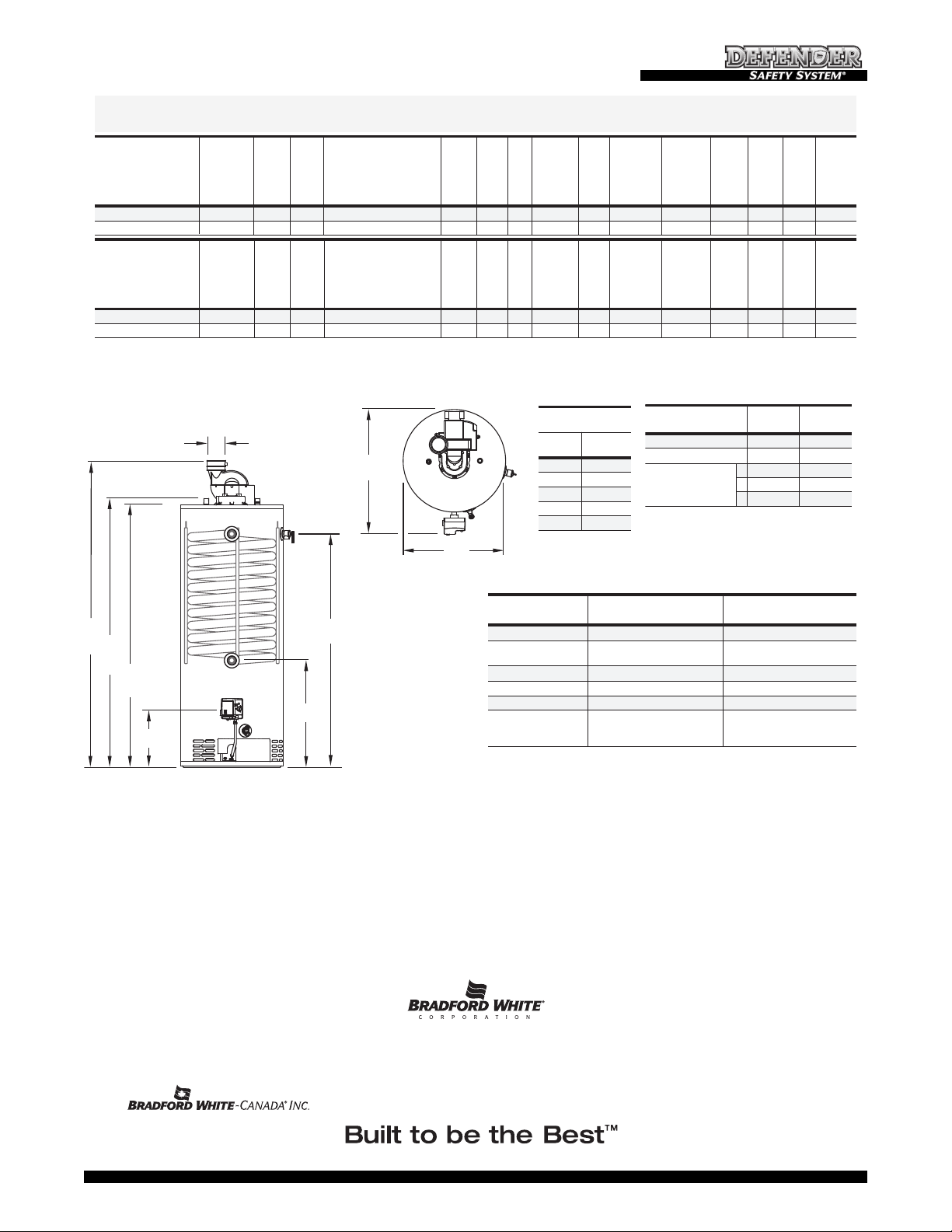

Page 2

NATURAL GAS AND LIQUID PROPANE GAS

M

odel

N

umber

Capacity

Combi2™TTW®Energy Saver Models

72 76,000 69 26 3 335307⁄8 601⁄453 611⁄2 311553

F

F

loor to

E

xchanger

Inlet

i

n.

G

F

loor to

E

xchanger

Outlet

i

n.

H

F

loor

t

o

Heater

T

op

i

n.

K

D

epth

i

n.

J

F

loor

t

o

Water

C

onn.

i

n.

Approx.

S

hipping

W

eight

l

bs.

E

F

loor

t

o

Gas

C

onn.

i

n.

A

F

loor to

V

ent

Conn.

i

n.

D

F

loor to

T

&P

Conn.

i

n.

C

V

ent

S

ize

i

n.

B

J

acket

D

ia.

i

n.

G

al.

U

.S.

I

nput

N

at.

B

TU/Hr.

82

I

nput

L

P

B

TU/Hr.

G

PH

N

at.

U

.S.

Recovery

9

0°F Rise*

75,500

M

odel

Number

Capacity

L

iters

272 22.3 306

F

F

loor to

Exchanger

Inlet

mm.

G

F

loor to

Exchanger

Outlet

mm.

H

F

loor

to

Heater

T

op

mm.

K

D

epth

mm.

J

F

loor

to

Water

C

onn.

mm.

Approx.

S

hipping

Weight

kg.

E

F

loor

to

Gas

C

onn.

mm.

A

F

loor to

Vent

Conn.

mm.

D

F

loor to

T&P

Conn.

mm.

C

V

ent

Size

mm.

B

J

acket

Dia.

mm.

I

nput

N

at.

kW

22.1

I

nput

LP

kW

H

our

Nat.

Liters/

H

our

LP

Liters/

310

Recovery

5

0°C Rise*

1772 660 76 1346 389 784 1549 1530 1562 787 152

M

eet or exceed ASHRAE 90.1b (current standard) C.E.C. Listed

80% Recovery Efficiency

4

5

61

G

al.

I

mp.

3

8 67,000 60,000 65 22

7

⁄8

3

⁄4

3

2452856

3

⁄85

0

1

⁄8 2

6

3

⁄45

7

3

⁄41

1

3

⁄45

0

1

⁄87

2

81

G

PH

L

P

U

.S.

6

5

69

G

PH

N

at.

I

mp.

6

0

67

G

PH

L

P

I

mp.

5

4

C-DW2-TW50T10FBN

C-DW2-TW75T10BN

C

-DW2-TW50T10FBN

C-DW2-TW75T10BN

170 246 1673 559 1273 298 711 1273 1432 1467 679 1117617.519.6 272

Residential Power Vent Gas Water Heater System

C

A

J

H

E

F

D & G

3"

Vent Pipe4"Vent Pipe

C-DW2-TW50T

C-DW2-TW75T

†

6

0 ft.**

7 ft.

55 ft.

50 ft.

4

5 ft.

†

1

80 ft.

15 ft.

175 ft.

170 ft.

1

65 ft.

M

ax. Equivalent Length

Min. Equivalent Length

Number 1

of 2

9

0° Elbows 3

C-DW2-TW50T10 C-DW2-TW75T10

FBNModel Number FCX BN CX

I

Water Heating❂

CA

EF

F

Space Heating

CA

AFUE

%

Max. Heating

Capacity✦

55,000

BTU/Hr.

(16.1 kW)

55,000

BTU/Hr.

(16.1 kW)

3

.65 .65 .64 .64

1

82.0 82.0 82.0 82.0

1

FHD

105

U.S. Gal.

98

U.S. Gal.

135

U.S. Gal.

133

U.S. Gal.

1

K

B

Heat Exchanger

H

ead Loss

GPM

2

5

8

10

1

2

Ft. of

Hd. Loss

trace

0

.4

2

.3

4.6

6

.9

All Propane heaters are equipped with a cast iron burner. To order a Propane heater change suffix “BN” to “CX”.

*Based on manufacturers rated recovery efficiency.

110 V.A.C Required for Power Venting / 110 V.A.C., 60HZ, 3.1 Amperes.

Subtract 5 ft. for each additional 90° elbow.

†For high altitude installations, consult the

installation instructions.

**C-DW2-TW75T maximum 3" vent length is

50ft.

Note: (C-DW2-TW75T will not have a pedestal base)

Meets NAECA Requirements

General

All gas water heaters are certified at 300 PSI test pressure (2068 kPa) and 150 PSI working pressure (1034 kPa). All potable water and heat exchanger

connections are 3⁄4" NPT (19mm) on 11" (203mm) centers. All gas connections 1⁄2" (13mm).

All models design certified by CSA International (formerly AGA/CGA), ANSI Z-21.10.1 and or 10.3 and peak performance rated.

Dimensions and specifications subject to change without notice in accordance with our policy of continuous product improvement.

Suitable for Water (Potable) Heating and Space Heating.

Toxic chemicals, such as those used for boiler treatment, shall NEVER be introduced into the potable water side. The potable side of this unit may NEVER

be connected to any existing heating system or component(s) previously used with a non-potable water heating appliance. The heat exchanger side of the

unit may be used in space heating applications.

Sales 800-523-2931 ●Fax 215-641-1670 / T

547-B-0807-A

For U.S. and Canada field ser

International:

❂ Based on ANSI Z-21.10.1 and 10.3 and DOE Test Methods.

✦ Based on ANSI/ASHRAE 124 Standar

Actual values may vary based on circulator flow rate, number of zones,

water and space heating demands. Numbers subject to change.

, PA

vice, contact your pr

echnical Suppor

Telephone 215-641-9400 ●Telefax 215-641-9750 / www.bradfordwhite.com

Sales / T

©2007, Bradford White Corporation. All rights reserved.

echnical Suppor

Ambler

ofessional installer or local Bradfor

t

800-334-3393 ●Fax 269-795-1089 ●W

t

866-690-0961 / 905-238-0100 ●Fax 905-238-0105 / www

d White sales r

ranty

ar

800-531-2111 ●Fax 269-795-1089

epresentative.

d.

.bradfor

dwhite.com

Printed in U.S.A.

Loading...

Loading...