Page 1

Internet Version for Reference Only

Installation and Operation Instructions Document 2144

C O R P O R A T I O N

B WRADFORD HITE

®

Installation and Operation

Instructions for

Copper Brute

Volume Water Heaters

Model B4

Sizes 500-1825

These instructions are to be stored in the pocket provided on the heater.

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualied in hot water heater installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in ue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not followed exactly, a re or explosion may result

causing property damage, personal injury or loss of life.

Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this or

any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the re department.

Installation and service must be performed by a qualied installer, service agency, or gas

supplier.

H2317100-

Page 2

Internet Version for Reference Only

Page 2

B4 Volume Water Heater

Page 3

BRADFORD WHITE

TABLE OF CONTENTS

SECTION 1.

General Information

1.1 Introduction.................................................... 3

1.2 Heater Identication.......................................3

1.3 Flow Requirements........................................3

1.4 Water Chemistry............................................ 4

SECTION 2.

Installation

2.1 Heater Placement ......................................... 4

2.2 Installation of Indoor Heaters.........................4

2.2.1 Combustion Air Supply ..................................4

2.2.2 Venting........................................................... 6

2.3 Installation of Outdoor Heaters...................... 7

2.4 Gas Supply and Piping..................................7

2.5 Electrical Wiring............................................. 8

2.6 Water Piping of System.................................8

2.7 Water Expansion ........................................... 9

2.8 Pump Performance and Installation ..............9

2.9 Water Pressure............................................10

2.10 Tank Installation........................................... 10

2.11 Two-Temperature System............................ 11

SECTION 3.

Operation

3.1 Controls - General ....................................... 14

3.1.1 Electronic Ignition Control............................14

3.1.2 Operating Control ........................................ 14

3.1.3 High Limit Controls ...................................... 14

3.1.4 Flow Switch .................................................14

3.1.5 Low Water Cut-Off (Optional) ......................14

3.2 Initial Start-Up.............................................. 14

3.3 To Start Up System......................................15

3.3.1 Start Up Heater............................................15

3.3.2 To Set Temperature and High Limit

Control....................................................15

3.4 To Turn Off Heater ....................................... 16

3.5 To Shut Down System ................................. 16

SECTION 4.

Maintenance

.....................................................................16

SECTION 5.

Troubleshooting and Analysis of

Service Problems

.....................................................................17

Page 3

Internet Version for Reference Only

B4 Volume Water Heater

Page 3

SECTION 1.

General Information

1.1 Introduction

This manual provides information for the

installation and operation of Bradford White volume

water heaters. It is strongly recommended that all

application and installation procedures be reviewed

completely before proceeding with the installation.

Consult the Bradford White factory, or local factory

representative, with any problems or questions

regarding this equipment. Experience has shown that

most problems are caused by improper installation.

Some accessory items are shipped in separate

packages. Verify receipt of all packages listed on the

package slip. Inspect everything for possible damage

upon delivery, and inform the carrier of any shortages

or impairments. Any such claims should be led with

the carrier. The carrier, not the shipper, is responsible

for shortages and damage to the shipment whether

visible or concealed.

WARNING

All volume water heaters must be installed in

accordance with the procedures outlined in

this manual. The warranty does not apply to

heaters not installed or operated in accordance

with these procedures. Consult local building

and safety codes before proceeding with

work. The installation must conform to the

requirements of the authority having jurisdiction

or, in the absence of such requirements, to

the latest edition of the National Fuel Gas

Code; ANSI Z223.1, National Electrical Code

ANSI/NFPA 70 and/or in Canada CSA B149.1

requirement.

When required by the authority having

jurisdiction, the installation must conform to

the Standard for Controls and Safety Devices

for Automatically Fired Boilers, ANSI/ASME

CSD-1. Any modication to the water heater,

its gas controls, gas orices, wiring or

draft diverter may void the warranty. If eld

conditions require such modications, consult

factory.

1.2 Heater Identication

Consult rating plate on the heater. The following

example simplies the heater identication.

1 2 3 4 5 6

B4 1670 I N 09 C

1. Basic heater model.

2. Input rate X 1000 BTU/hr.

3. Indoor (I) or Outdoor (E) installation.

4. Gas type: Natural (N) or Propane (P).

5. Ignition system: I.I.D. (09) or continuous pilot

(16).

6. Firing rate: On/Off (C), 2-stage (K), 4-stage (L).

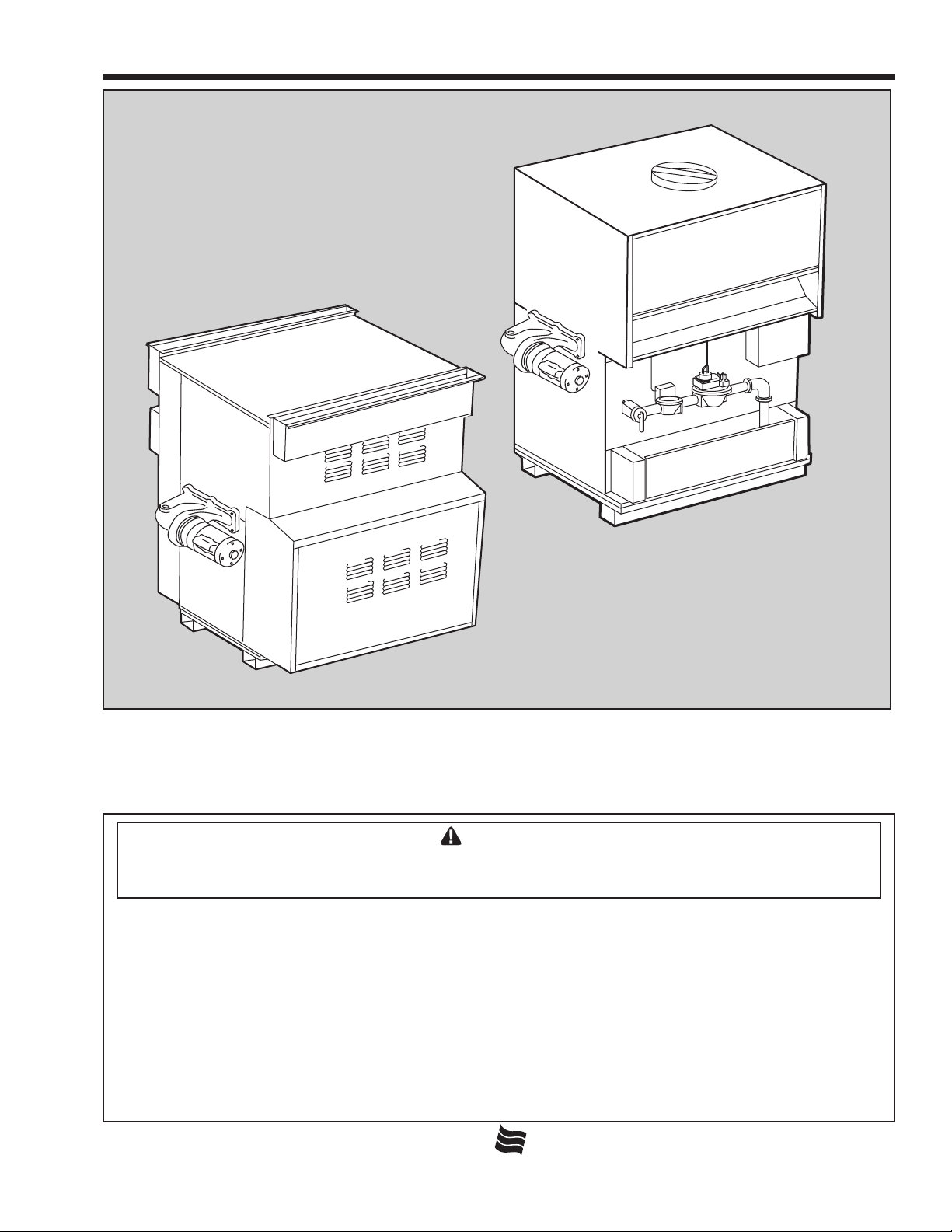

Bradford White commercial water heaters are

available in two models: an indoor version and an

outdoor version. Both are available from the factory

(see Figure 1).

1.3 Flow Requirements

For proper operation, all low volume hot water

heaters must have continuous ow through the heat

exchanger when ring. The system pump must be

capable of developing sufcient pressure to overcome

the resistance of the heater plus the entire circulating

system at the designed ow rate.

12

(311)

A

Pump

Front

Gas

Conn.

Top

58

V

(1473)

10

(260)

B

17

(432)

295/

8

(752)

Out In

17

(197)

28

(718)

Side

C

Rear

29

(737)

Pump

30

19

Gas

(483)

Inlet

12

(305)

Figure 1. Heater Conguration.

A

Front

(781)

7

(197)

Out In

41

(1060)

Side

14

(356)

4

(102)

61

(1549)

Page 4

Internet Version for Reference Only

Page 4

B4 Volume Water Heater

Page 5

BRADFORD WHITE

1.4 Water Chemistry

Bradford White equipment is designed for use in

a wide variety of water conditions. The water velocity

maintained in the heat exchanger tubes is kept high

enough to prevent scaling from hard water and low

enough to avoid corrosion from soft water. Ninety-ve

percent of the urban areas in the country have water

that is compatible with this equipment, but in some

areas a water supply will contain a large quantity of

scaling chemicals or the water may be extremely soft

and corrosive. In rare situations the water will contain

both scaling chemicals and corrosive chemicals such

as calcium or sodium chloride. These conditions may

be the result of a nearby well or pumping station and

the particular condition may not be characteristic of

the entire city water system.

If an installer observes damage from these

conditions to any water handling equipment in the

area, a factory representative should be contacted

immediately for assistance in minimizing maintenance

costs. If erosion is present, the pump impeller can be

replaced to reduce water velocity. If scaling conditions

are bad, tube cleaning maintenance schedules can be

established to prevent tube burn-out and cracking.

Neglecting the problem could mean serious damage to

the heater and water system.

Scaling can be recognized as a layer deposited

on the inner walls of the tube which reduces the inner

diameter of the tube. Scale can be any color or texture;

smooth or rough, granular or amorphous. Signs of

erosion are generally pitting, cavitation, ridges and

“islands” on the inner walls of the tubes. Since this

condition results from extremely soft water sources,

or as a result of a water softening program, the

internal copper surfaces will be extremely shiny. Other

chemicals, such as chlorine or chlorides in the water,

will cause dark surfaces of erosion.

In areas where the water supply is extremely

corrosive, it is advisable to order the heater with

cupro-nickel tubes in the exchanger.

Damage From Scaling, Corrosion, or Erosion is

Not Covered by the Warranty.

SECTION 2.

Installation

2.1 Heater Placement

The heater must be placed to provide specic

clearances on all sides for maintenance and inspection.

There must also be minimum distances maintained

from combustible surfaces. These clearances also

apply to non-combustible materials because the heater

requires air circulation for proper operation.

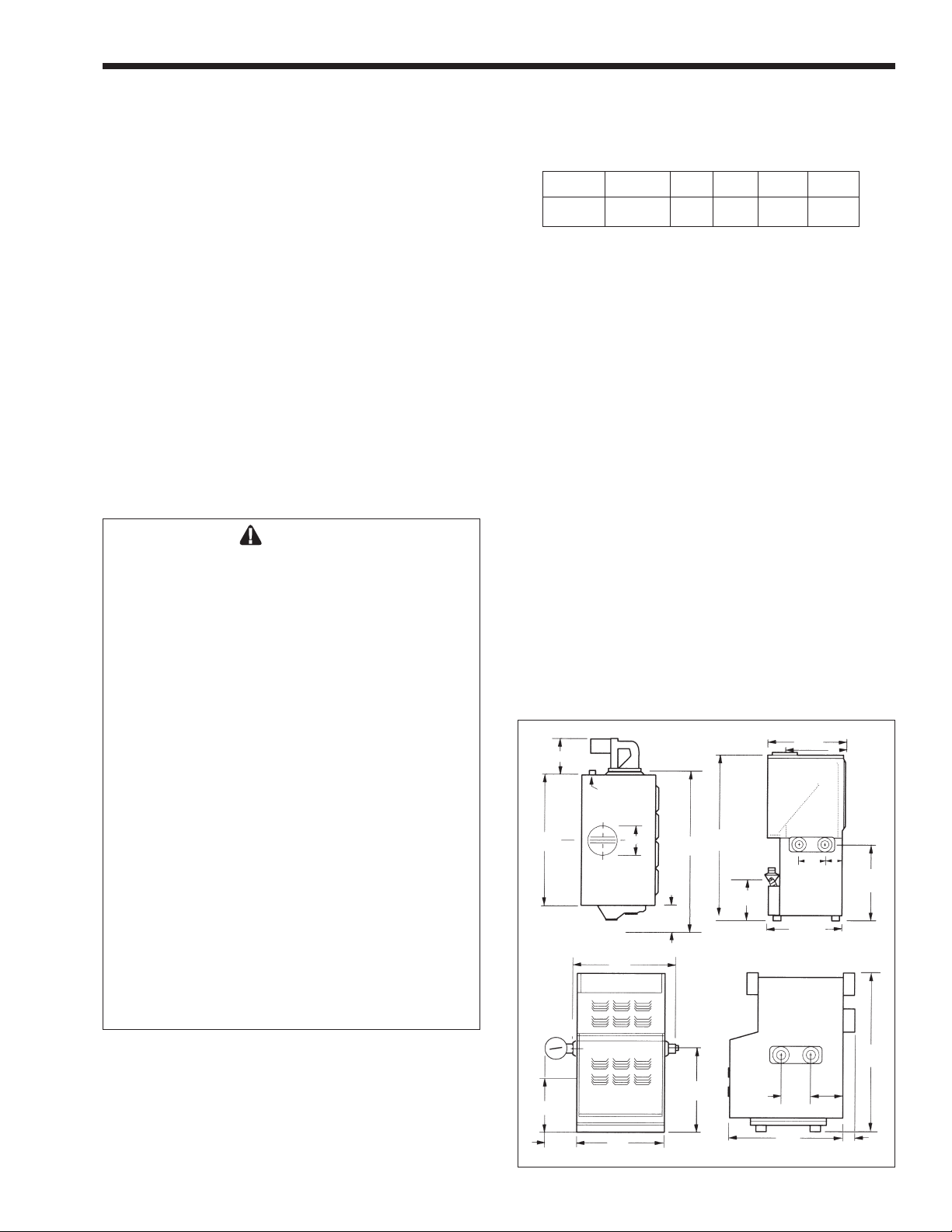

Heater should be mounted on a level surface.

An integral combustible ooring base is provided

as standard equipment on outdoor models. Indoor

models can be installed on a combustible oor with

a special base assembly which is available from the

factory, or with a base that complies with local code

requirements. See rating plate for part number of the

base assembly.

Do not install a heater on carpeting.

Under the National Fuel Gas Code, ANSI

Z223.1, it is permissible to place the heater on oors

other than non-combustible when the installation

complies with the American Insurance Code.

Figures 2, 3, 4 and 5 show common installation on

combustible ooring.

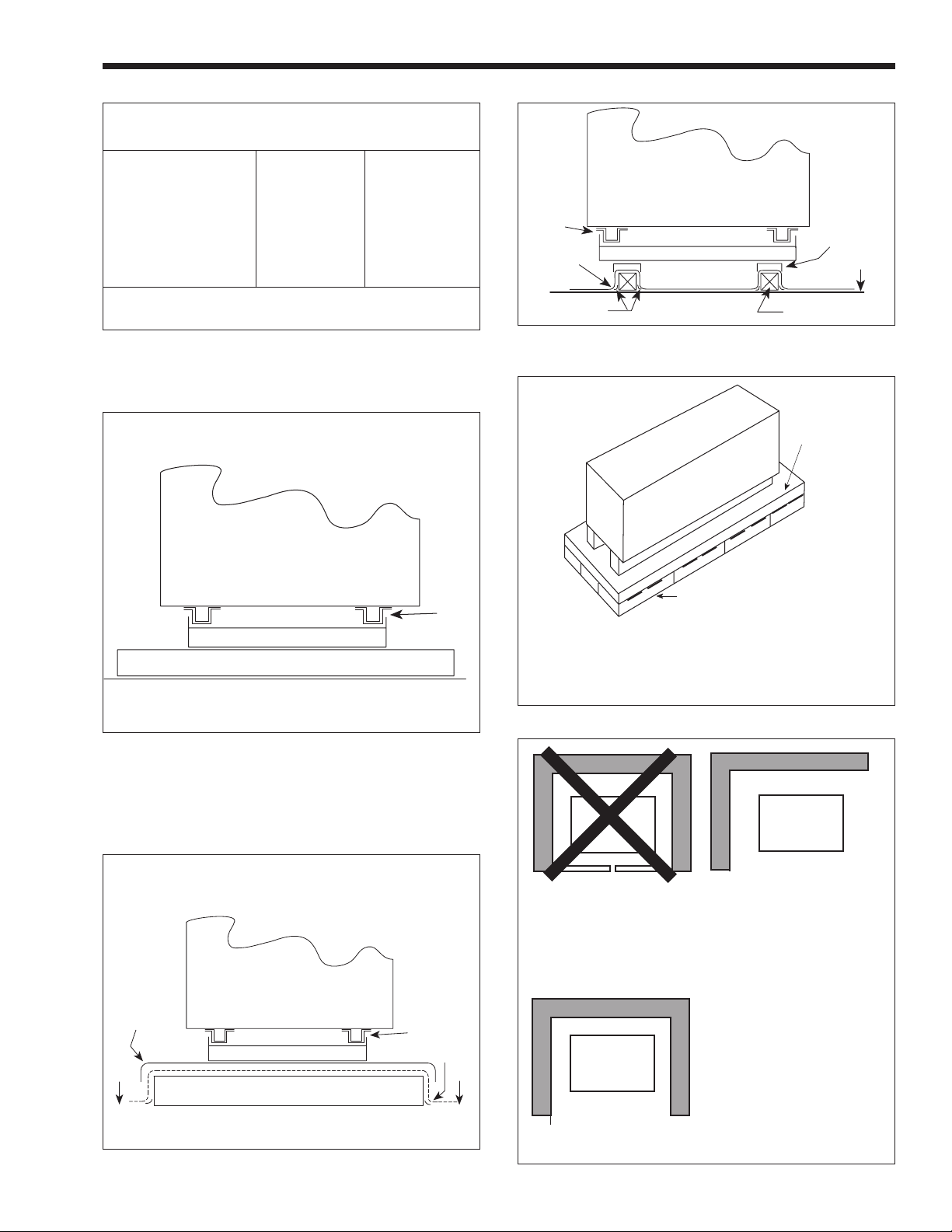

2.2. Installation of Indoor Heaters

1. Locate the water heater to provide adequate

clearance for inspection and service on all sides

(see Table 1). We recommend minimums of 24"

from front (for proper access to and service of

controls) and 18" at water connection end. For

alcove installation (see Figure 6).

2. Install the heater on a waterproof oor with an

adequate oor drain and a 6" minimum curb on

all four sides to protect the building if heater

repairs are required. The manufacturer will

not be held liable for any water damage in

connection with this heater.

2.2.1 Combustion Air Supply

1. Copper Brute water heaters must have provisions

for combustion and ventilation air in accordance

with section 5.3, Air for Combustion and

Ventilation, of the National Fuel Gas Code,

ANSI Z223.1, or Sections 7.2, 7.3 or 7.4 of

CSA B149.1, Installation Codes, or applicable

provisions of the local building codes.

A Copper Brute heater may receive combustion

air from the space in which it is installed, or

it can be ducted directly to the unit from the

outside. Ventilation air must be provided in either

case.

2. In the United States, the most common

requirements specify that the space shall

communicate with the outdoors in accordance

with method 1 or 2, which follow. Where ducts

are used, they shall be of the same cross-sectional

area as the free area of the openings to which

they connect.

Method 1: Two permanent openings, one

commencing within 12 inches (30 cm) of the top

and one commencing within 12 inches (30 cm)

of the bottom, of the enclosure shall be provided.

The openings shall communicate directly, or by

ducts, with the outdoors or spaces that freely

communicate with the outdoors. When directly

communicating with the outdoors, or when

communicating to the outdoors through vertical

Page 5

Internet Version for Reference Only

B4 Volume Water Heater

Concrete Slab Must Extend Out A

Base For Combustible Floors

Concrete Slab - 4

" Minimum

Minimum Of

12" On All Sides

Roof - W

ood & Steel Construction

Unit

(End

View)

Base

Rail

Base For Combustible Floors

Raised Mounting

Platform (W

ood)

Mounting Platform Must Extend Out

A

Minimum Of 12" On All Sides

Unit

(End

View)

Base

Rail

20 GA

Galvanized

Sheet Metal

Cap

Flashing

Roof

Roof

Base Must Extend Out

Min. 12" On All Sides

Of Heater Frame

Met

al Plate 20

Ga. Min.

Under Entire

Heater

Concrete Blocks Or

Tile

Min.

7" High With 3" Min.

Air Openings

Blocks must provide solid base and be

braced so they cannot slip out of place. Air

openings in blocks must be arranged to

provide unobstructed opening through entire

width or length of base.

Unit

(Front

View)

20 GA

Galvanized

Sheet Met

al

Cap

Flashing

Roof

Roofing

4X4

Stringer

Base

Rail

Base

for Combustible Floors

Clearance Indoor Outdoor

From (inches) (inches)

Top 30 Unobstructed

Water Conn. Side 12 24

Opposite Side 6 24

Front Alcove Unobstructed

Rear 8 24

Vent Pipe* 6 —

Hot Water Pipes Per Code Per Code

*1" when using type B Vent (refer to Manufacturer's

Instructions

Table 1. Minimum Heater Clearances

From Combustible Surfaces.

Page 5

Figure 4. Typical Heater Installation with Base for Combustible Floors, Example C.

Figure 2. Typical Heater Installation with Base for Combustible Floors, Example A.

Figure 3. Typical Heater Installation with Base for Combustible Floors, Example B.

Figure 5. Installation on Concrete Blocks or Tile.

Water

Heater

CLOSET INSTALLATION

(UNACCEPTABLE)

A closet is any 4 sided enclosure

which is less than 16* times the total

volume of all the gas red appliances

within the enclosure.

Water

Heater

When the ceiling height exceeds 8 feet, you are only allowed to consider 8

*

feet when calculating the total volume of the enclosure.

ROOM INSTALLATION

(ACCEPTABLE)

A room is any enclosure which is at

least 16* times greater than the total

volume of all the gas red appliances

within the enclosure.

ALCOVE INSTALLATION

(ACCEPTABLE)

An alcove suitable for the installation of a water heater is a restricted

section of a room not separated from

the room by a door or partition and

which meets the minimum clearances

for the specic model water heater

listed below.

Figure 6. Alcove Installation.

Page 6

Internet Version for Reference Only

Page 6

B4 Volume Water Heater

Page 7

BRADFORD WHITE

ducts, each opening shall have a minimum free

area of 1 square inch per 4000 Btu/hr (5.5 square

cm/kW) of total input rating of all equipment

in the enclosure. When communicating to the

outdoors through horizontal ducts, each opening

shall have a minimum free area of not less than

1 square inch per 2000 Btu/hr (11 square cm/

kW) of total input rating of all equipment in the

enclosure. Table 2 shows data for this sizing

method, for each Copper Brute model.

Method 2: One permanent opening,

commencing within 12 inches (30 cm) of the

top of the enclosure, shall be permitted. The

opening shall directly communicate with the

outdoors or shall communicate through a vertical

or horizontal duct to the outdoors or spaces that

directly communicate with the outdoors and shall

have a minimum free area of 1 square inch per

3000 Btu/hr (7 square cm/kW) of the total input

rating of all equipment located in the enclosure.

This opening must not be less than the sum of the

areas of all vent connectors in the conned space.

Other methods of introducing combustion

and ventilation air are acceptable, providing they

conform to the requirements in the applicable

codes listed above.

In Canada, consult local building and safety

codes or, in absence of such requirements, follow

CSA B149.1.

Heater Each Opening*

Model (Square Inches)

500 125

600 150

715 179

850 213

1010 253

1200 300

1430 358

1670 418

1825 457

*Net Free Area in Square Inches

Area indicated is for one of two openings; one at

oor level and one at the ceiling, so the total net

free area could be double the gures indicated.

For special conditions refer to the latest edition of

ANSI Z223.1. or CSA B149.1

Consult factory if not communicating directly

through the walls with the outdoors.

Note: Check with louver manufacturers for

net free area of louvers. Correct for screen

resistance to the net free area if a screen is

installed. Check all local codes applicable to

combustion air.

IMPORTANT: In beauty shops, barber shops,

cleaning establishments and self-service laundries with

dry cleaning equipment, it is important that the water

heater be installed in a location where combustion and

ventilation air is received from a source outside the

building. Please refer to the most recent edition of the

National Fuel Gas Code, ANSI Z223.1, or in Canada,

CSA requirements.

3. (a) In the United States: Exhaust Fans or

Vents: Any equipment which exhausts air from

the heater room can deplete the combustion air

supply or reverse the natural draft action of the

venting system. This could cause ue products

to accumulate in the heater room. Additional air

must be supplied to compensate for such exhaust.

The information in Table 2 is not applicable in

installations where exhaust fans or blowers of

any type are used. Such installations must be

designed by qualied engineers.

(b) In Canada: Follow Canadian standard, CSA

B149.1 or local codes.

4. If a blower or fan is used to supply air to the

heater room, the installer should make sure it

does not create drafts which could cause nuisance

shutdowns of the pilot. If a blower is necessary to

provide adequate combustion air to the heater, a

suitable switch or equivalent must be wired into

the heater control circuit to prevent the heater

from ring unless the blower is operating.

5. The heater must be completely isolated and

protected from any source of corrosive chemical

fumes such as trichlorethylene, perchlorethylene,

chlorine, etc.

2.2.2 Venting

1. Bradford White heaters have built-in draft

diverters for natural draft operation and must not

be connected to any portion of a mechanical draft

system under positive pressure. The ue outlet

must be connected to a clear, unobstructed vent

of adequate capacity ending above the highest

point of the building with an approved vent cap.

The venting system should be installed according

to the latest edition of ANSI Z223.1 and/or, in

Canada, CSA B149.1 requirement and any local

codes having jurisdiction.

IMPORTANT NOTE: Do not use sheet metal

screws at the snap lock joints of Type B gas

vents.

2. Do not weld or fasten the vent pipe to the heater

draft hood. The weight of the stack must not rest

on the heater. The draft hood and heater top must

be easily removable for normal heater service

and inspection.

Table 2. Minimum Recommended

Air Supply to heater.

Page 7

Internet Version for Reference Only

B4 Volume Water Heater

Window

Or Grill

Indoor

Room

WRONG

3. Avoid using long horizontal runs of the vent

pipe, and too many 90° elbows, reductions or

restrictions. Horizontal runs should have at least

a 1/4" rise per foot in the direction of ow. A vent

connector should be supported for the design

and weight of the material used to maintain

clearances and prevent physical damage and

separation of joints.

4. Avoid ending heater vents near air conditioning

or air supply fans. The fans can pick up exhaust

ue products from the heater and return them

inside the building, creating a possible health

hazard. A minimum of 4 feet horizontal distance

must be maintained from electrical meters, gas

meters, and relief equipment.

5. Always use double-wall or insulated vent

pipe (Type B or equivalent). In cold weather,

uninsulated outside vents can chill the rising ue

products, blocking the natural draft action of the

venting system. This can create a health hazard

by spilling ue products into the heater room.

6. Avoid oversize vent piping or extremely long

runs of the pipe which may cause excessive

cooling and condensation. Rule of Thumb: The

total length of the vent, including the connector

and any offset, should not exceed 15 feet for

every inch of vent diameter. Longer total lengths

shown in venting tables are based on maximum

capacity, not condensation factors.

7. When the installation of a draft fan is necessary

in connecting a venting system to a the heater,

the installation should be engineered by

competent personnel following good engineering

practices. The draft fan supplier should be

consulted for correct size. The installation

should be in accordance with the latest edition

of ANSI Z223.1 and/or, in Canada, CSA

B149.1 requirement and any local codes having

jurisdiction. When a draft fan is installed, a

suitable draft switch must be wired into the

heater control circuit at terminal designated

“Field Interlock” to prevent ring of the heater

unless a positive draft has been established.

Page 7

Figure 7. Incorrect Outdoor Installation.

etc. which connect in any way with an inhabited

area of a building. This includes other structures

such as garages or utility rooms (see Figure 7).

4. Although these models are CSA designed

certied for outdoor installations, such

installations are not recommended in areas

where the danger of freezing exists unless proper

precautions are taken for freeze protection.

2.4 Gas Supply and Piping

Review the following instructions before

proceeding with the installation.

1. Verify that the heater is tted for the proper type

of gas by checking the rating plate. Bradford

White heaters are normally equipped to operate

below a 2000 foot altitude. Heaters equipped

to operate at higher altitudes have appropriate

stickers or tags attached.

2.3 Installation of Outdoor Heaters

1. Locate the heater to provide the minimum

clearances as listed in Table 1, “Placement of

Heater”.

2. Do not place the heater in an enclosure or wall

recess. Avoid locations where wind deection off

structures might cause down draft. When such

wind conditions are possible, place the heater at

least three (3) feet from the structures.

3. Never install the heater under any kind of roof

overhang. Do not place the heater below or

adjacent to any doors, windows, louvers, grills,

Note: These gures are for Natural Gas (.65 Sp. Gr.), and are

based on 1/2" water column pressure drop. Check supply pressure with a manometer, and local code requirements for variations. For LPG, reduce pipe diameter one size, but maintain a 1"

minimum diameter. A normal number of Tees and elbows have

been taken into allowance.

Table 3. Gas Piping Sizes.

Page 8

Internet Version for Reference Only

B4 Volume Water Heater

Page 9

Gas Supply

Inlet

Te

e

Fitting

3" Min.

Nipple

Cap

To

Equipment

Inlet

Page 8

Figure 8. T-Fitting Sediment Trap Installation.

BRADFORD WHITE

8. Before operating the heater, the complete gas

supply system and all connections must be tested

for leaks using a soap solution. Do not use raw

ame.

Caution

Since some leak test solutions (including soap

and water) may cause corrosion or stress

cracking, the piping must be rinsed with water

after testing, unless it has been determined

that the leak test solution is noncorrosive.

2. Use the gures in Table 3 to provide adequate

gas piping from the gas meter to the heater.

3. A trap (drip leg) must be provided ahead of

the gas controls (see Figure 8 ). A manual gas

shutoff valve must also be provided for service

convenience and safety. Check the local codes.

4. The heater and its individual shutoff valve must

be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures in excess of 1/2 psig. The heater

must be isolated from the gas supply piping

system by closing its individual manual gas

shutoff valve during any pressure testing of the

gas supply piping system at test pressures equal

to or less than 1/2 psig.

5. Provide gas supply pressure to the heater as

follows:

Natural Gas LPG

Min. (inches

water column)

Max. (inches

water column)

9 14

Per Rating Plate

Note: The heater and all other gas appliances

sharing the heater gas supply line must be ring

at maximum capacity to properly measure the

inlet supply pressure. Low gas pressure could be

an indication of an undersized gas meter and/or

obstructed gas supply line.

6. The correct burner manifold gas pressure is

stamped on the rating plate. The regulator is

preset at the factory and normally requires no

further adjustment.

7. The gas manifold and control assembly was

tested and conform to the safe lighting and

other performance criteria specied in the latest

editions of ANSI Z21.13, Low Pressure Boiler

Standard.

2.5 Electrical Wiring

WARNING

The heater must be electrically grounded in

accordance with the most recent edition of

the National Electrical Code, ANSI/NPA 70.

In Canada, all electrical wiring to the heater

should be in accordance with the Canadian

Electrical Code, CSA C22.1 Part 1. Do not rely

on the gas or water piping to ground the metal

parts of the heater. Oftentimes, plastic pipe or

dielectric unions isolate the heater electrically.

Service and maintenance personnel who work

on or around the heater may be standing on

wet oors and could be electrocuted by an

underground heater.

1. Check heater wiring and pump for correct

voltage, frequency and phase. If the pump circuit

is other than 115V, check to see that the heater is

provided with an appropriate transformer.

2. Wire the heater and pump exactly as shown in

the wiring diagram supplied with the heater.

3. The pump and heater must be electrically

interlocked so the heater cannot come on unless

the pump is running.

4. All eld installed electrical safety devices and

all eld installed devices (draft switches, relays,

timers, outdoor temperature reset devices, etc.)

can be connected to the heater wiring at points

shown in the wiring diagram designated “Field

Interlock”.

2.6 Water Piping of System

1. Be sure to provide valves at the inlet and outlet

of the heater so it can be readily isolated for

service. A buttery or similar type of valve is

recommended.

2. The pressure relief valve installed in the tapped

opening provided in the outlet header (see

Page 9

Internet Version for Reference Only

B4 Volume Water Heater

Pressure

Relief

Valve

Hot

Water

Hot

Water

Storage

Tank

Floor

Automatic

Tempering

Valve

Cold

Water

Tempered Water

24"

Figure 9. Pressure Relief Valve Location.

Figure 9), must be piped, but not fastened, to a

drain or oor sink. The drain pipe must be the

same size as the valve outlet and must pitch

downward from the valve.

Special attention must be given to relief valve

settings in installations where the heater is

located on the ground oor of a tall building. The

static pressure of the system is elevated and could

cause the relief valve to leak. Where no special

setting of the relief valve is ordered, the factory

will furnish a 125 psi setting. Never reduce the

relief valve openings.

3. Pressure relief valve lever must be tripped at

least once a year to insure that waterways are

clean. When manually operating lever, water will

discharge through drain line. Precautions must be

taken to avoid contact with hot water and water

damage.

4. The weight of all water and gas piping should be

supported by suitable hangers or oor stands.

5. Check piping diagrams with local applicable

plumbing, heating and building safety codes.

6. All two-temperature systems using temperature

valves must have forced recirculation in the low

temperature building loop.

7. A check valve installed at the hot water inlet to

the tempering valve will prevent cold water from

being drawn in reverse through the tempering

valve into the hot water.

8. When installing a tempering valve, place at

bottom of antithermosyphon loop at least 24"

high to prevent excessive hot water from entering

mixed water supply. Bring the cold water supply

up from the oor to the valve (see Figure 10).

Page 9

Figure 10. Tempering Valve Installation.

2.7 Water Expansion

When cold water is heated the water expands. If

no water is being used during the heat-up period the

expanded water will normally back up into the city

mains.

A water pressure reducing valve installed in the

incoming cold water line may act as a check valve and

prevent the expanded water from moving backward.

This will cause pressure to rise in the heater, which

will be relieved by the pressure relief valve.

If the relief valve pops frequently a mineral

deposit may build up on the valve seat, causing it to

leak.

Th e following suggestions may sol ve the

problem:

1. Install a properly sized expansion tank.

2. Replace the installed water pressure reducing valve

with a suitable valve having a back ow port. These

valves have a back ow port which allows water

to ow backwards when the pressure in the system

exceeds the pressure in the mains.

3. Install an auxiliary small relief valve set at 25 psi

less than the main relief valve. The valve must

be piped to a drain and may require occasional

cleaning. It will bleed off the expanded water

and protect the main pressure relief valve from

becoming fouled.

2.8 Pump Performance and Installation

1. The factory provided pumps on all Copper Brute

heaters are sized to provide proper circulation

through the heater and heater-to-tank circulation

loop (see Figures 11 and 12). If the heater-to-tank

circulating loop does not contain more than 6

elbows or 30 feet of pipe, use pipe ttings in the

loop no smaller than the following:

Model Pipe Size

500 through 850 2"

1010 through 1825 2-1/2"

Page 10

Internet Version for Reference Only

Page 10

B4 Volume Water Heater

Page 11

BRADFORD WHITE

If the heater-to-tank circulating loop contains

more than 6 elbows or 30 feet of pipe, use

pipe or ttings in the loop no smaller than the

following:

Model Pipe Size

500 through 850 2-1/2"

1010 through 1825 3"

Pump performance requirements are provided in

Table 4 for reference purposes.

To assure free circulation, do not use globe

valves, side outlet tee connections or other

restrictive ttings in heater-to-tank loop.

2. Copper Brute heaters are not suitable for heating

swimming pools or any other application where

temperature of the water owing through the

heater remains below the dew point (110°F).

In applications requiring the rapid use of

measured volumes of water, the recovery of the

heater between the time intervals of use must

equal the volume used.

2.9 Water Pressure

It is very important that water pressure in the

system be maintained above 30 psi. If the system

pressure should drop below this, the vapor pressure

of water in the suction side of the pump can cause

hammer and cavitation in the pump and damage the

heater through lack of water circulation.

2.10 Tank Installation

1. Be sure the oor is waterproof and structurally

capable of supporting the tank when it is lled

with water.

2. The tank should be placed so that manholes,

inspection covers, nameplates and drain valves

are accessible.

3. Be sure the tank is suitable for the water in the

system. Some water is corrosive and requires a

protected tank with a special lining.

4. If the tank is glass-lined, it should be equipped

with a suitable magnesium anode. It is good

practice to replace the anode when it is

approximately 50% used. The factory warranty

on a glass-lined tank will be void if a satisfactory

anode is not in place at the time of a failure or if

it is consumed by cathodic action.

5. Make sure the tank connections in the heatertank circulating loop are the proper size as listed

in Section 2.8. If tappings are smaller than the

recommended pipe size, a larger pump may be

required. Consult the factory if in doubt.

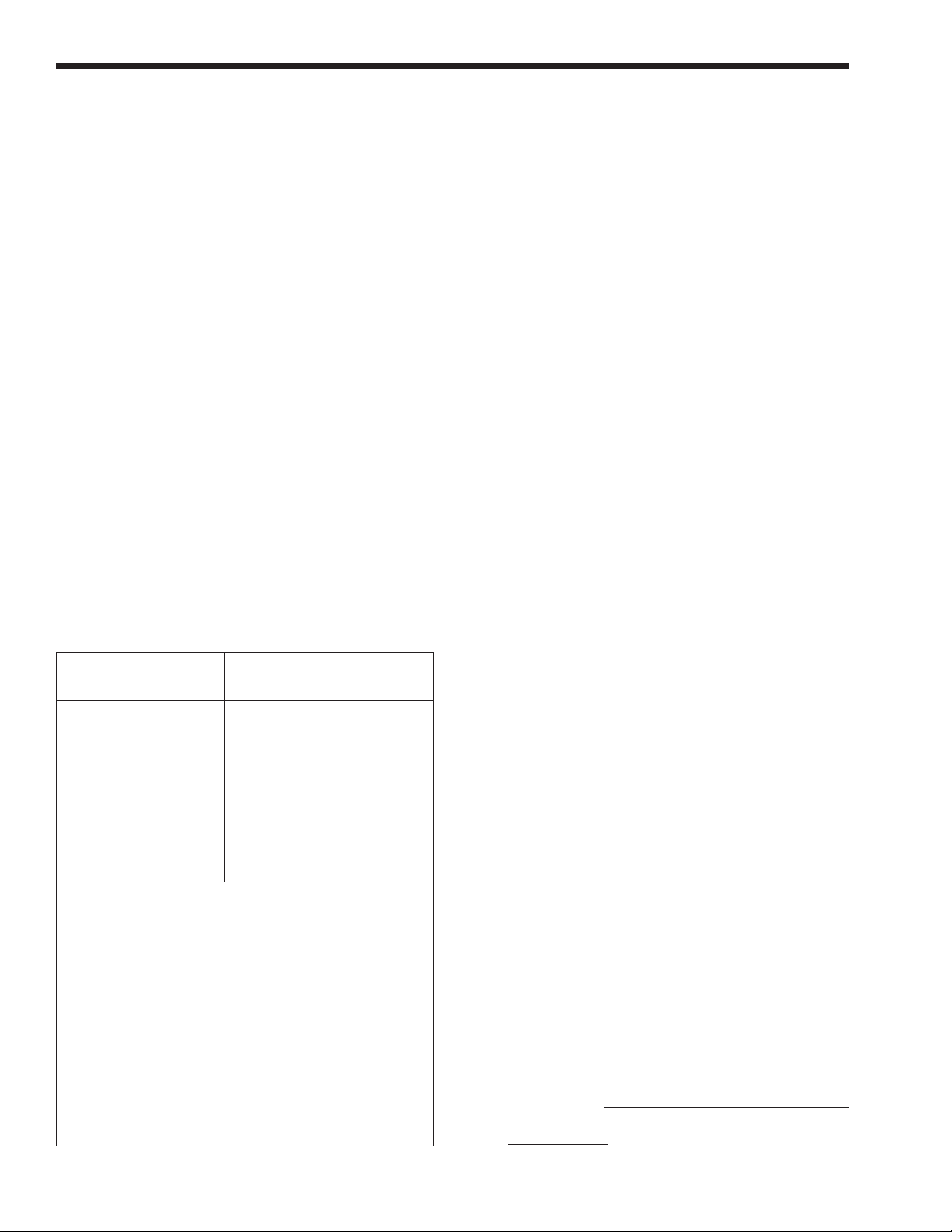

Flow Head* Temp. Rise

Water Rate Loss Across

Model Category (GPM) (ft.) Heater, (°F)

Soft 45 5.0 17

500 Normal 68 9.9 11

Hard 90 15.7 8

Soft 45 5.1 20

600 Normal 68 10.0 14

Hard 90 15.9 10

Soft 45 5.3 24

715 Normal 68 11.0 16

Hard 90 17.8 12

Soft 45 5.4 30

850 Normal 68 11.1 20

Hard 90 18.1 15

Soft 45 3.9 35

1010 Normal 68 7.5 23

Hard 90 11.7 18

Soft** 68 7.8 27

1200 Normal 68 7.8 27

Hard 90 12.2 21

Soft** 68 8.1 32

1430 Normal 68 8.1 32

Hard 90 12.6 24

Soft** 68 8.3 37

1670 Normal 68 8.3 37

Hard 90 13.0 28

Soft** 90 13.5 30

1825 Normal** 90 13.5 30

Hard 90 13.5 30

Water Category Grain Hardness per Gal.

Soft 1 through 7.5

Normal 7.6 through 17

Hard Over 17

* Pressure drop includes loss through 30 feet of pipe and normal ttings when

heater is installed with storage tank. Pipe and ttings are assumed to be 2" on

Models (500-850) and 2 1/2" on Models (1010-1825)

** To prevent erosion, these models must be ordered with cupro-nickel heat

exchanger tubes.

Table 4. Pump Performance Requirements.

6. Install a pipe in the tank drain tting that goes to

a oor sink, and install a drain valve. If a oor

sink is not available, install a hose bib.

7. Hot water tanks in an existing installation are

likely to have a deposit of silt on the bottom.

Therefore, it is important to extend the pump

suction pipe in the tank to a position near the top.

Pipe the return from the heater to the bottom of

the tank.

8. Incorrect installation can cause rapid failure

of water tanks due to electrolysis. Tanks must

be installed with dielectric connections to

electrically isolate the tank from stray current.

Note that the use of brass or bronze connectors

does not replace the need for dielectric

connections.

Page 11

Internet Version for Reference Only

B4 Volume Water Heater

5

1

2

3

4

CWMU

SUPPL

Y

RECIRC

5

1

2

3

4

RECIRC.

CWMU

SUPPL

Y

Page 11

2.11 Two-Temperature System

See Figures 13 and 14 for piping schematics.

This system is designed to maintain the tempered

water circulating loop at the desired temperature

during idle periods as well as when there is a

demand for hot water. It is recommended for general

purpose water supply including shower and bathing

applications. Water at 180°F is available directly from

the tank.

With

Vertical

Tank

With

Horizontal

Tank

Figure 11. Hot Water Supply System

Page 12

Internet Version for Reference Only

Page 12

B4 Volume Water Heater

Page 13

5

3

2

1

2

4

CWMU

SUPPL

Y

CIRC. RETURN

D

B

K

J

C

C

H

C

H

J

180°F

Water

To

Bldg.

Conventional

Tank

140°F Water

To Bldg.

To

Drain

To Drain

Cold

Water

To

Drain

Pump

140°F

Water

Return From

Bldg.

180°F

Water

Return From

Bldg.

Cold

Water

Pump

BRADFORD WHITE

Figure 12. Hot Water Supply System with Dual Tanks, Building Loop Return and Circulating Pump.

Legend

B - Check Valve

C - Check Valve

D - Tempering Valve

H - Throttling Valves in Building Loop Returns

J - Circulating Pump for Return Loop

K - Service Valves to Isolate Heater and Pump

for Service

Figure 13. Two-Temperature Hot Water Supply System with Vertical Tank.

Page 13

Internet Version for Reference Only

B4 Volume Water Heater

Cold

Water

180°

Water

To

Bldg.

Conventional

Tank

To

Drain

24" Min.

To Drain

Pump

140°

Water

To

Bldg.

140°

Water

Return

From Bldg.

180°

Water

Return

From Bldg.

H

H

C

C

B

D

K

K

E

J

Cold

Water

180°

Water

To

Bldg.

Conventional

Tank

To Drain

140°

Water

To

Bldg.

To

Drain

Pump

180°Water

Return

From Bldg.

140°Water

Return

From Bldg.

B

D

E

K

J

I

H

H

C

C

Page 13

With

Horizontal

Tank

Legend

B - Check Valve in Hot Water Supply

to Tempering Valve

C - Check Valve in Return Line from

Building Loop

D - Tempering Valve

E - Venturi (Suction) Tee

H - Throttling Valves in Building Loop

Returns

I - Circulating Pump for 180° Building

Loop

J - Circulating Pump for 140° Building

Loop

K - Service Valves to Isolate Heater

and Pump for Service

With

Vertical

Tank

Legend

B - Check Valve in Hot Water Supply

to Tempering Valve

C - Check Valve in Return Line from

Building Loop

D - Tempering Valve

E - Venturi (Suction) Tee

H - Throttling Valves in Building Loop

Returns

I - Circulating Pump for 180° Building

Loop

J - Circulating Pump for 140° Building

Loop

K - Service Valves to Isolate Heater

and Pump for Service

Figure 14. Two-Temperature Hot Water Supply System.

Page 14

Internet Version for Reference Only

Page 14

B4 Volume Water Heater

Page 15

Rating Plate

Ignition Control

Pressure Relief

Valve

Flow Switch

In

Out

Transformer

Terminal Strip

Operating Control

(Aquast

at)

Hi-Limit

Operating

Gas Valve

Manual

Pilot

Valve

Manual

Main

Gas

Valve

Safety

Gas

Valve

BRADFORD WHITE

SECTION 3.

Operation

3.1 Controls - General

See Figure 15 for control locations.

3.1.1 Electronic Ignition Controls:

a. Intermittent Ignition:

Pilots are automatically lit when the

operating aquastat calls for heat (System

#9).

The unit performs its own safety check and

opens the main valves only after the pilot is

proven to be lit. Whenever the pilot ame

is interrupted, the main gas valve closes

within 0.8 seconds.

b. Electronically Supervised Standing Pilot

System (System #16):

When pilot ame fails, the ignition control

module responds in less than 0.8 seconds

and provides 100% safety shutdown.

3.1.2 Operating Controls:

Electrically Operating Controls:

Copper Brute units are equipped with operating

temperature. The temperature sensing bulb is

located in the heater inlet.

3.1.3 High Limit Controls:

The manual reset high limit switches are

provided as standard equipment on all heaters.

Automatic reset switches are optionally provided.

The temperature sensing bulb of the switch is

always located in the heater outlet. Burners will

automatically shut down whenever overheating

of water occurs.

3.1.4 Flow Switch:

Standard on all models, the switch is mounted

directly in the header outlet. The ow switch

shuts down all burners in case of low water

condition or pump failure.

3.1.5 Low Water Cut Off: (Optional)

The low water cut off automatically shuts off the

heater whenever the water level drops below the

probe. The probe is located at the heater inlet.

3.2 Initial Start-Up

Before placing the heater in operation, be certain

that the heater is lled with water and all air is purged

from the system. Once the heater is connected to the

gas supply, the automatic safety shutoff devices must

be checked.

1. Before beginning the tests, make sure the main

manual gas valve, and any other heater ring

valves are in the “OFF” position.

Figure 15. Control Components.

Page 15

Internet Version for Reference Only

B4 Volume Water Heater

Pilot Valve

ON POSITION

ON

ON

OFF

OFF

ON

ON

OFF POSITION

Main Gas Valve

Main Gas

Valve

Pilot

Valve

OFF

ON

ON

2. Make sure the heater’s power switch is in the

“ON” position. After placing the manual pilot

gas valve in the open position and resetting all

safety devices, (high limit, pressure switch, lowwater cutoff, etc.) pilot(s) can be lit following the

procedure located on the heater rating plate.

3. Once the pilot(s) is lit and has been established

for ve minutes, the ame failure response time

should be checked as follows:

System 9 - (Intermittent ignition): With this

system pilots are automatically lit when the operating

controls call for heat. If the pilot ame fails for any

reason, the main valve is shut off within one second

and the pilot spark ignition is initiated until the pilot

ame has been reestablished. On propane systems, unit

locks out for safety. This sequence should be checked

by turning off the manual pilot gas valve, and, at the

same time, monitoring the audible sparking at the pilot

burner and signal interruption to the main valve.

Caution

Propane gas is heavier than air and sinks to

the ground. Exercise extreme care in lighting

the heater when so equipped.

Page 15

Figure 16. Gas Manual Valves.

System 16 - (Electronically supervised standing

pilot system): Extinguish the pilot ame by placing

the manual pilot valve in the closed position, and at

the same time, begin recording the time it takes for the

output signal from the electronic ignition control to

be interrupted. The signal interruption can be detected

either with a test light or a voltmeter. The response

time should never exceed one second.

4. With the pilots lit, initial activation of the main

burners can be achieved by slowly opening

the main manual valve. The result should be a

smooth lighting of the main burners.

Hi-Limit Checkout:

After running the heater for a long enough

period, bring the water temperature within the range of

the hi-limit and slowly back off the high limit setting

until the heater shuts off. The main burners should

reignite when the hi-limit is reset and turned back up

to its original setting. The heater should now run until

it shuts off automatically on operating aquastat.

3.3 To Start Up System:

3.3.1 Start Up Heater

Be certain system pump is running, then proceed

as follows:

1. Turn off main electrical switch.

2. Turn off all manual gas valves and wait ve

3. Set operating control to lowest setting.

minutes (see Figure 16).

4. Slowly turn manual gas valve to “ON”.

5. Reset all safety valve switches (manual reset high

limit and low water cut off).

6. Open manual pilot valve. Turn on main electrical

switch.

7. Set temperature controller to desired temperature.

Pilot will light automatically to ignite main

burners whenever the aquastat calls for heat.

For standing pilot system, press on pilot relay

knob, see Figure 17, light pilot and keep relay knob

depressed for one minute then release. Once the pilot

is lit, the power is supplied through the aquastat to the

main gas valve.

3.3.2 To set the temperature and high-

limit controls:

When using a tank aquastat:

Set the tank aquastat to the desired tank

temperature. Set the heater temperature control 20°F

higher than tank aquastat. Set the manual reset high

limit 50°F higher than tank aquastat. Example: If

desired temperature is 140°F, set the tank aquastat at

140°F, set the heater temperature control at 160°F, and

set the manual reset high limit at 190°F. If the heater

is equipped with a pump time delay, the three-position

switch on the side of the heater can be put into the

“Auto Pump” position, so that the pump will only run

when the tank aquastat calls for heat. Then, when the

call for heat is satised, the heater will turn off, but

the pump will run for the set amount of delay time

(adjustable between 0.1 and 10 minutes).

Page 16

Internet Version for Reference Only

B4 Volume Water Heater

Page 17

Pilot Reset

Page 16

Figure 17. Pilot Safety Relay.

When a tank aquastat is not used:

The pump on the heater must run continuously,

so the heater's temperature control will sense the tank's

water temperature. Set the heater temperature control

to the desired tank temperature. Set the manual reset

high limit 50°F higher than the heater temperature

control. Example: If desired temperature is 140°F, set

the heater temperature control at 140°F, and set the

manual reset high limit at 190°F.

BRADFORD WHITE

3.4 To Turn Off Heater:

1. Turn off main electric switch.

2. Close all manual gas valves.

3.5 To Shut Down System:

To shut down heater, turn off all manual gas

valves and electrical disconnect switches. Whenever

danger of freezing exists, shut off water supply and

remove drain plug in the bottom of front header

cover. Drain every part of system subject to freezing

temperature.

SECTION 4.

Maintenance

1. Lubricate the water circulating pump (see

instructions found on the pump).

2. If a strainer is employed in a pressure reducing

valve or in piping, clean it every six (6) months.

3. At start-up and every six (6) months thereafter,

the pilot and main burner ame should be

observed for proper performance (see Figure 18).

See attached lighting and shut-down instructions

for proper pilot ame pattern). If ame has the

appearance of “sooting” tips, check for debris

near orices. Call serviceman.

4. Inspect the venting system for obstruction,

leakage and corrosion at least once each year.

Figure 18. Main Burner Flame Pattern.

5. Keep heater area clear and free from combustible

material, gasoline and other ammable

vapors and liquids (see Table 1 for minimum

clearances).

6. Be certain all combustion air and ventilation

openings are unobstructed.

7. Check for fouling on the external surfaces of

the heat exchanger every six months. (NOTE:

After installation and rst start-up, check the heat

exchanger for fouling after the following periods

of operation: 24 hours, 7 days, 30 days, 90 days,

and once every six months thereafter).

Fouling on the external surfaces of the heat

exchanger is caused by incomplete combustion

and is a sign of combustion air and/or venting

problems. As soon as any fouling is observed,

the cause of the fouling should be corrected (see

Section 5, Troubleshooting Guide). The heat

exchanger can be checked by locating a mirror

under the burners with a ashlight. An alternate

method is to remove the venting and top panel as

necessary to inspect from above. Also check the

vent system for defects at this time.

a. If cleaning is required, shut off all electrical

and gas supply to the heater.

b. To expose the heat exchanger:

Indoor Models:

Remove ue pipe, top of unit, rear upper jacket,

ue collector rear panel and heat exchanger

bafes.

Outdoor Models:

Remove vent top assembly, rear upper jacket,

ue collector rear panel and heat exchanger

bafes.

c. Remove all burners:

It is usually more convenient to remove

the burner tray assembly. Disconnect

sensor wire, ignition cable (or thermocouple

generator) and pilot gas line. Disconnect

manifold inlet union(s). Remove the four

(4) retaining screws. Grasp burner/pilot

assembly rmly at the front. Push it back,

disengaging it from the gas orice. Lower

the front of the burner (to avoid damaging

pilot shield) then remove the burner tray.

Page 17

Internet Version for Reference Only

B4 Volume Water Heater

Caution

Black carbon or green soot on a dirty heat

exchanger can, under certain conditions, be

ignited by a random spark or open ame. To

prevent this unlikely occurrence, dampen the

soot deposits with wet brush or ne water

spray before servicing or cleaning the heat

exchanger.

With a wire brush, remove soot and loose scale

from heat exchanger. Clean fallen debris from

bottom of heater. Make sure burner ports are

clear and pilot assembly is free of debris.

d. Reassemble in reverse order: Be sure the

heat exchanger bafes are replaced.

8. The gas and electric controls installed on heaters

are engineered for both dependable operation

and long life, but the safety of this equipment

completely depends on their proper functioning.

It is strongly recommended that the basic items

be checked by a competent serviceman every

year and replaced when necessary. The basic

controls are:

a. Water temperature controls.

b. Pilot safety system.

c. Automatic electric gas valve(s).

d. Flow sensing safety device.

9. Low water cutoffs should be inspected every six

(6) months, including ushing of oat types.

NOTE: Warranty does not cover any damage

caused by lack of required maintenance or improper

operating practices.

10. Both modulating and stage valve are adjusted at

the factory for minimum permissible rates and

should not be readjusted.

Page 17

c. Tube cleaning kit consisting of reamer,

stainless steel brush, speed handle and

handle extensions.

d. Heater thermometer (with 1/2" NPT well)

100-240°F.

2. In addition, the heater should be equipped with

a system pressure gauge with proper ranges for

heater operation.

I. HEATER WILL NOT FIRE.

Possible Cause What To Do

A. Electric power is off A. Check to see that main power

switch is “ON.” Use testing

device to trace power to

heater junction box.

B. Operating or safety control B. Turn off power. Use continuity

has opened circuit to electric across terminals of each

gas valve. operating and safety control

switch up to the electric gas

valve. Replace effective

control.

C.Pilot ame is out. C.Relight pilot per instruction.

D.Manual reset device has D. Follow instructions for start tripped. up. Reset Pilot safety and all

manual reset safety switches

and reset manual safety gas

valve.

E. No gas pressure to burners. E.Trace gas line to service

shutoff cock. If service cock is

open, trace gas line to meter.

If no pressure is present at

meter, call for public utility

service. If gas is present in

heater inlet, check pressures

in following sequence:

(1) downstream from pressure

regulator. (2) downstream

from electric gas valve.

Replace or adjust as

necessary.

SECTION 5.

Troubleshooting and Analysis of

Service Problems

1. For proper service and problem diagnosis of the

heater and heater system, the following tools are

required:

a. Gas pressure test kit with range from zero

to 14 W.C. Either a slack tub manometer or

an accurate gas pressure gauge is acceptable

with proper adapters which will connect to

the available ttings in the line and on the

gas valve.

b. Multi-meter with the following ranges:

0 to 500 volts A.C.

0 to 1000 ohms continuity.

F. Electric gas valve operator is F. Disconnect wiring harness at

burned out or shortened. gas valve terminals. Check

continuity to actuator coil. If

open circuit or short is

Page 18

Internet Version for Reference Only

Page 18

B4 Volume Water Heater

Page 19

BRADFORD WHITE

II. HEATER IS POUNDING, KNOCKING OR EMITTING STEAM FROM RELIEF VALVES.

Possible Cause What To Do

A. Low or no water ow. A. This condition is usually

caused by lack of adequate

water ow through heater.

Check the following:

1. Is the heater wired into the

pump circuit so that the heater

cannot re unless the pump is

running?

2. Check to see that all valves

in system are open to be

sure that water can circulate

through the heater and the

system.

3. If the system has automatic

water valves (2-way or 3-way)

that can cut off the water ow

through the heater check to

see that they are equipped with

end-switches which shut the

heater down when the water

ow through the heater is

reduced by 70% from full ow.

4. Examine pump for clogged

impeller.

B. Low or no system pressure. B. Clean strainer in pressure

reducing valve. Look for closed

valve water line or a leak in the

system.

C.Clogged “Y” strainer. C. Remove strainer element and

clean screen.

D.Debris from system piping D. Remove header covers.

is blocking tubes. Examine all tubes and

waterways. Use new gaskets

when reassembling. Clean

out tubes.

E. Scale has formed in tubes. E. This is always caused by the

inow of raw water into the

system. Clean tubes with tube

cleaning kit. Determine

hardness. Check water ow,

replace pump for modied

ow if necessary.

III. WATER DRIPPING

IN FIREBOX.

Possible Cause What To Do

Tube in heat exchanger has A tube failure is almost always

overheated and ruptured. caused by (a) scale formation

in the tube or (b) inadequate

water ow through the heater.

IV. PRESSURE RELIEF VALVES LEAKING INTERMITTENTLY OR STEADILY.

Possible Cause What To Do

A.Static pressure in system A. Calculate height of water in

exceeds setting of relief valve. system above heater. Install

new valve with psi setting 25%

above required static system

working pressure. Do not

exceed 160 psi.

B. Expansion tank is water- B. Drain expansion tank, then

logged (if installed). reopen it to the system. Look

for leaks in expansion tank

or ttings. Calculate required

volume of expansion tank in

relation to system to determine

if tank is adequate.

V. SOOT IN FLUEWAYS OR IN TUBES, OR NOXIOUS FUMES INDICATIVE OF BAD COMBUSTION.

Possible Cause What To Do

A. Combustion air supply to A. Check air supply opening.

heater room is inadequate. Look for debris in screen or

louvre which covers combus-

tion air opening, or for material

blocking the opening.

B. Stack or vent is blocked or B. Look for blocked stack and

restrictive. excessive number of elbows in

stack or excessive length of

horizontal runs.

C.Severe down draft is causing C.Check for (1) proper vent cap

spillage of ue products into on stack; (2) adequate height

room. of stack above roof;

(3) equipment exhausting air

from inside of building; and

(4) proper installation of draft

diverter.

D.Gas pressure to burners is D.Check gas pressure with

excessive. nanometer, and adjust with

heater ring at full rate.

E. Heater not tted for the fuel E. See nameplate for correct fuel.

supplied.

F. Heater installed at high F. Installations at altitudes in

altitude without proper excess of 2000 ft. above sea

derating. level are subject to jurisdiction

of the local inspection

authorities.

Page 19

Internet Version for Reference Only

B4 Volume Water Heater

Page 19

This page intentionally left blank.

Page 20

Internet Version for Reference Only

Page 20

C O R P O R A T I O N

B W

RADFORD HITE

®

BRADFORD WHITE

®

Ambler, PA 19002

Tech. Service (800) 334-3393

Service Parts (800) 538-2020

Warranty Service (800) 531-2111

H2317100-

www.Bradford White.com

Litho in U.S.A. © Bradford White 0602 Document 2144

Loading...

Loading...