Page 1

"Highest in Subcontractor Satisfaction among Water Heater/Boiler Manufacturers"

Light Duty Commercial Through-The-Wall

Energy Saver Gas Water Heaters

Photo is of

TW4-65S-70FB-3N

The TTW®4 FVIR Defender Safety System®Models Feature (50 and 65 gallon models, only):

■ Advanced ScreenLok

®

Technology Flame Arrestor Design—Flame arrestor is designed

to prevent ignition of flammable vapor outside of the water heater

■ Flammable Vapor Sensor—Electronic sensor prevents burner operation if flammable

vapors are detected. The sensor will also prevent operation if there is ongoing flammable

vapor burn inside the combustion chamber.

■ Maintenance Free—No regular cleaning of air inlet openings or flame arrestor is required

under normal conditions.

■ Sight Window—Offers a view into the combustion chamber to observe the operation of the

pilot and burner.

■ Pedestal Base—Rugged and durable base allows easy transport and positioning, and

provides corrosion resistant contact with floor.

All TTW®4 Models Feature:

■ Powerful Blower Motor—Our design has higher torque for greater resistance to outside

winds and the power to eliminate problems with difficult venting situations. This significantly

quieter motor runs cooler for a considerably longer operational life.

■ Spark-to-Pilot Ignition System—Eliminates the constant burning pilot used on other water

heaters. This device results in savings of pilot gas during standby periods (110 VAC required

to heater).

■ Electronic Gas Control Valve—The integrated, immersion gas control valve offers more

precise temperature control for higher first hour delivery and also allows water temperature

adjustment without removing the cover. The control is equipped with an LED to display

heater status and aid in diagnostics.

■ Horizontal and Vertical Venting—With 3" or 4" PVC, ABS, or CPVC (Maximum equivalent

vent length on reverse side).

■ Vitraglas

®

Lining—Bradford White water heater tanks are protected from the corrosive

effects of hot water by a ceramic porcelain-like coating. The exclusive high silica ceramic

lining provides a tough interior surface for our water heater tank.

■ More Precise Temperature Control—With an adjustable temperature up to 180° F. Not

recommended for 180° F sanitizing.

■ Stainless Steel Flue baffle—Designed to maximize the amount of heat absorbed in the

lower portion of tank. Reduces air movement in the heater during standby periods to retard

heat loss up the flue.

■ Steel Tank—Heavy gauge steel automatically formed, r

olled and welded to assur

e a

continuous seam for glass lining.

■ Side Connections—Side tappings allow easy connection for space heating applications.

■ Protective Magnesium Rod—Provides added protection against corrosion for long

trouble-free service.

■ Factory Installed Hydrojet

®2™

Total Performance System—Cold water inlet sediment

reducing device. Helps prevent sediment build up in tank. Increases first hour delivery of hot

water while minimizing temperature build up at top of tank. (TW4-75S has Factory Installed

Hydrojet®).

■ Factor

y Installed Heat T

raps—

Design incorporates a flexible disk that r

educes heat loss in

piping and eliminates the potential for noise generation.

■ Water Connections—3⁄4" NPT factory installed true dielectric fittings. Extends water heater

life and eases installation.

■ 2" Non-CFC Foam Insulation—Saves energy by retarding loss of heat.

■ Brass Drain V

■ T&P Relief Valve Installed.

■ Design Cer

alve

.

tified by CSA Inter

national (for

merly AGA and CGA)

.

3 or 5-Year Limited Tank Warranties / 1-Year Limited Warranty on Component Parts.

For more information on warranty, please visit www.bradfordwhite.com

oducts installed in USA, Canada and Puer

For pr

copy of the warranty included with the heater.

Bradford White received the highest numerical score among water heater/boiler manufacturers in the proprietary J.D. Power and Associates/ McGraw-Hill Construction 2006 HVAC and Water Heater/Boiler Subcontractor Satisfaction StudySM.

Study based on 882 r

experiences may vary. Visit jdpower.com

MANUFACTURED UNDER ONE OR MORE OF THE FOLLOWING U.S. PATENTS: 7,063,133 B2; 5,954,492; 5,954,492; 5,761,379; 5,943,984; 5,081,696; 5,988,117; 6,142,216; 5,199,385; 5,574,822; 5,372,185;

5,485,879; 5,277,171; (B1)5,341,770; 5,660,165; 5,596,952; 5,682,666; 4,904,428; 5,023,031; 5,000,893; 4,669,448; 4,829,983; 4,808,356; 5,115,767; 5,092,519; 5,052,346; 4,416,222; 4,628,184; 4,861,968;

4,672,919; Re. 34,534. OTHER U.S. AND FOREIGN PATENT APPLICATIONS PENDING. CURRENT CANADIAN PATENTS: 1,272,914; 1,280,043; 1,289,832; 2,045,862; 2,112,515; 2,108,186; 2,107,012; 2,092,105..

Defender Safety System®, ScreenLok®, TTW®, Vitraglas®and Hydrojet®are registered trademarks of Bradford White®Corporation.

esponses measuring 3 water heater/boiler manufactur

ers and measur

es opinions of subcontractors. Pr

to Rico. Some states do not allow limitations on warranties. See complete

esults are based on experiences and perceptions of subcontractors surveyed in May through July 2006. Your

y study r

oprietar

355-B 0407

Page 2

NATURAL GAS AND LIQUID PROPANE GAS

M

odel

N

umber

Capacity

6

5 70,000 24 3 22213

1

⁄2 5

9

1

⁄25

3

1

⁄2 6

0

3

⁄4 2

8

3

⁄41

1

3

⁄46

953

1

⁄2

F

F

loor to

S

pace

Heating

R

eturn

i

n.

G

F

loor to

S

pace

Heating

O

utlet

i

n.

H

F

loor

t

o

Heater

T

op

i

n.

K

D

epth

i

n.

J

F

loor

t

o

Water

C

onn.

i

n.

Approx.

S

hipping

W

eight

l

bs.

E

F

loor

t

o

Gas

C

onn.

i

n.

A

F

loor to

V

ent

Conn.

i

n.

D

F

loor to

T

&P

Conn.

i

n.

C

V

ent

S

ize

i

n.

B

J

acket

D

ia.

i

n.

G

al.

U

.S.

I

nput

N

at.

B

TU/Hr.

6

8

I

nput

L

P

B

TU/Hr.

G

PH

U

.S.

Recovery

1

00°F Rise*

75 76,000

6

3,000

75,500 26 3 27717

3

⁄4 31601⁄4 611⁄25315693⁄4 5374

T

W4-50S-67FB-3N

T

W4-65S-70FB-3N

T

W4-75S-76B-3N

T

W4-50S-67FB-3N

TW4-65S-70FB-3N

TW4-75S-76B-3N

M

odel

Number

C

apacity

L

iters

246 20.5 231

F

F

loor to

Space

H

eating

Return

mm.

G

F

loor to

Space

H

eating

Outlet

mm.

H

F

loor

to

H

eater

Top

mm.

K

D

epth

mm.

J

F

loor

to

W

ater

Conn.

mm.

A

pprox.

S

hipping

Weight

kg.

E

F

loor

to

G

as

Conn.

mm.

A

F

loor to

Vent

C

onn.

mm.

D

F

loor to

T&P

C

onn.

mm.

C

V

ent

Size

mm.

B

J

acket

Dia.

mm.

I

nput

Nat.

kW

18.5

I

nput

LP

kW

5

7

G

PH

I

mp.

H

our

Liters/

R

ecovery

5

6°C Rise*

284 22.3 276

1753

1772

610

6607676

1360

1346

320

381

343

451

1360

1346

1511

1530

1543

1562

730

787

101

12622.1

61

M

eet or exceed ASHRAE 90.1b (current standard) C.E.C. Listed

80% Recovery Efficiency

4

8

5

4

G

al.

I

mp.

62

4

0 67,000 60,000 65 22

7

⁄8

3

18813

1

⁄2

1

⁄8

3

⁄85

6502657

3

⁄4

3

⁄41

1

3

⁄45

0

1

⁄86

5

6

1

73

5

8

182 220 1673 560 1273 320 343 1273 1432 1467 679 857617.619.6

5

4

Nat.Nat.

5

1

G

PH

I

mp.

60

4

9

LP

G

PH

U

.S.

LP

LP

257

H

our

Liters/

280

246

Nat.

Light Duty TTW®4 Energy Saver Models

Commercial Through-The-Wall Gas Water Heater

3"

Vent Pipe4"Vent Pipe

TW4-50S-67

TW4-65S-70

TW4-75S-76

†60 ft.**

7 ft.

55 ft.

50 ft.

45 ft.

Max. Equivalent Length

Min. Equivalent Length

Number 1

of 2

90° Elbows 3

†180 ft.

15 ft.

175 ft.

170 ft.

165 ft.

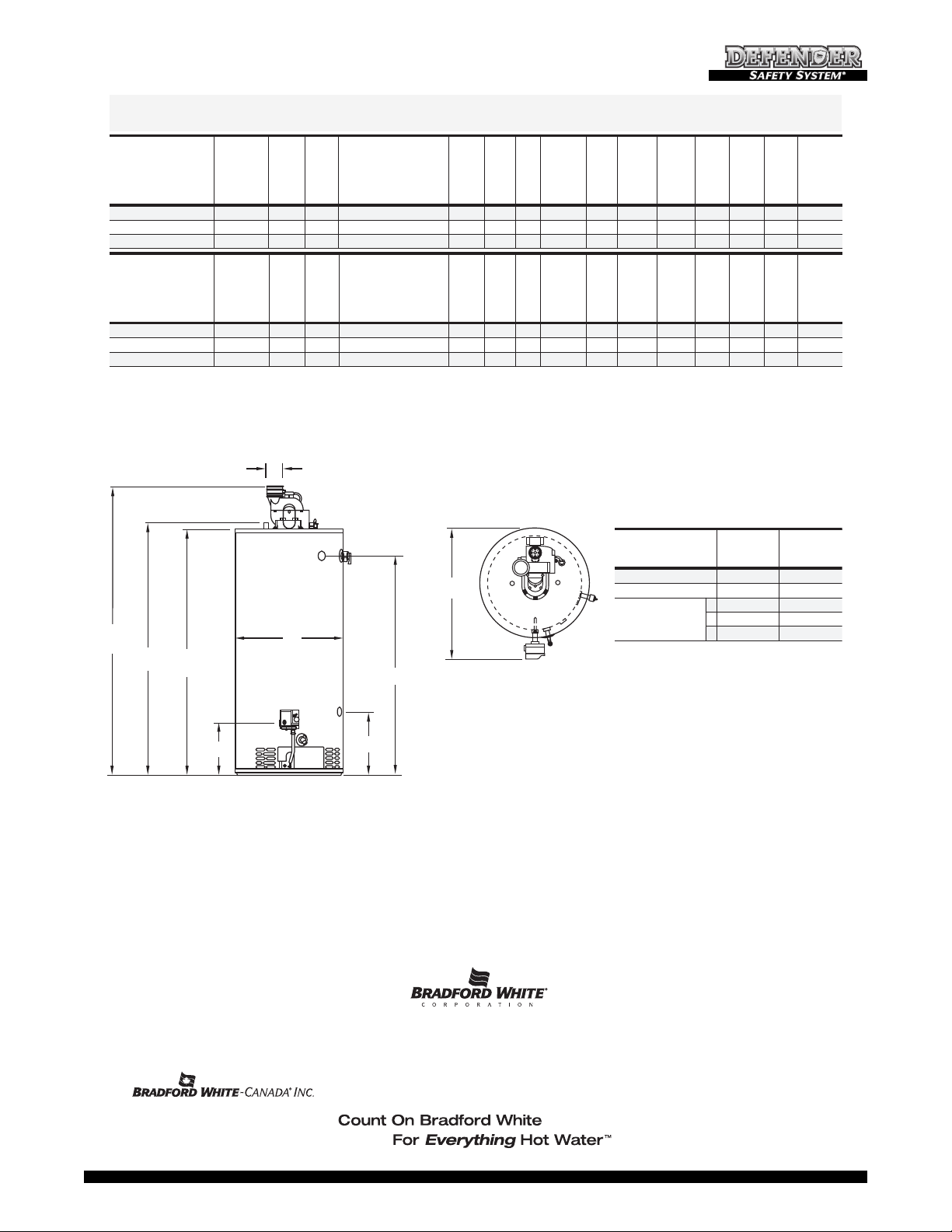

C

A

J

H

E

F

B

D & G

K

All propane heaters are equipped with a cast iron burner. To order a propane heater replace the suffix “B” with “C” and change the suffix “N” to “X”.

For 5 year models, change suffix from “3” to “5”.

*Based on manufacturers rated recovery efficiency.

110 V.A.C. Required for Power Venting / 110 V.A.C. 60HZ 3.1 Amperes.

NSF constr

uction available.

Note: (TW4-75S will not have a pedestal base).

All natural gas models meet SCAQMD Requirements. Meets NAECA Requirements.

General

All gas water heaters are certified at 300 PSI (2068 kPa) test pressure and 150 PSI (1034 kPa) working pressure.

All water connections are 3⁄4" NPT (19mm) on 11" (279mm) centers, all gas connections are 1⁄2" (13mm).

All models design cer

tified by CSA Inter

national (formerly AGA/CGA), ANSI Z-21.10.1 and/or 10.3 and peak performance rated.

Dimensions and specifications subject to change without notice in accordance with our policy of continuous product improvement.

Suitable for Water (Potable) Heating and Space Heating

oxic chemicals, such as those used for boiler tr

T

existing heating system or component(s) previously used with a non-potable water heating appliance.

national:

Inter

T

Sales / Technical Support 866-690-0961 / 905-238-0100 ●Fax 905-238-0105 / www.bradfordwhite.com

355-B 0407

For U.S. and Canada field service, contact your professional installer or local Bradford White sales representative.

Sales 800-523-2931 ●Fax 215-641-1670 / Technical Support 800-334-3393 ●Fax 269-795-1089 ●Warranty 800-531-2111 ●Fax 269-795-1089

eatment, shall NEVER be intr

elephone

©2007, Bradfor

215-641-9400 ●T

d White Corporation. All rights reserved.

Ambler

elefax

, PA

Subtract 5ft. for each additional 90° elbow

†For high altitude installations, consult the

installation instructions.

**TW4-75S Max. 3" vent length is 50ft.

oduced into this system. This unit may NEVER be connected to any

215-641-9750 / www

.bradfor

dwhite.com

Printed in U.S.A.

Loading...

Loading...