OPERATOR’S AND PARTS

MANUAL

BC60, BC72 & BC78

ROTARY CUTTERS

UNIVERSAL

SKID STEER

APPLICATIONS

SERIAL NUMBER: ___________________ Manual Number: OM636

Part Number: 75536

MODEL NUMBER: ___________________ Rev. 7

800-456-7100 I www.paladinlcg.com 503 Gay Street, Delhi, IA 52223, United States of America

8904 6-25-10-8

READ ENTIRE OPERATOR'S & PARTS MANUAL BEFORE OPERATING!

DANGER! ROTATING BLADE HAZARD! STAY BACK!

OBJECTS CAN BE THROWN!

DO NOT operate near bystanders.

DO NOT place hands or feet under deck while in operation or with engine

running.

DO NOT operate without a shatterproof door (or front shield) installed on

loader.

WARNING! Before leaving the operator's seat: Lower the lift arms against frame and

place unit on the ground. Disengage auxiliary hydraulics. Stop Engine.

Engage parking brake. Remove the key.

WARNING! Operatingthestandardowrotarycutteronahighowhydraulicsystem

may cause severe injury or death to the operator or bystanders due to the

increasedRPM.DoNOToperatethestandardowrotarycuttersonhighow

hydraulic systems.

WARNING! Lift limiting chain must be properly installed before operation.

WARNING! AVOID STALLING ROTARY CUTTER. During operation, continuous blade

rotation is required to prevent overheating of the hydraulic system. To

monitor the blade rotation, there is a window in the motor cover shield so

the operator can monitor the blade rotation indicator disk. This disk should

always be rotating during operation to prevent overheating of the hydraulic

system.

SERVICE

When servicing your rotary cutter, remember to use only manufacturer replacement

parts. Substitute parts may not meet the standards required for safe, dependable operation.

To facilitate parts ordering, record the model and serial number of your unit on the

cover or in the space provided on this page. This information may be obtained from the iden-

tication plate located on the right front of the mounting plate.

MODEL____________________________________

SERIAL NUMBER___________________________

DATE PURCHASED_________________________

The parts department needs this information to ensure that you receive the correct

parts for your specic model.

9115 10-11-06-3

TABLE OF CONTENTS

TO THE OWNER ...............................................................................................A

SAFETY PRECAUTIONS ................................................................................ B

General Information

To The Operator

Before You Start

Working With The Rotary Cutter

Transporting the Rotary Cutter

Maintenance

INTERNATIONAL SYMBOLS .......................................................................... C

PREOPERATION ............................................................................................. D

General Information

Before Operation

Skid-Steer

Major Component Nomenclature

ROTARY CUTTER ASSEMBLIES ....................................................................E

60" & 72" Standard Flow Cutter Assemblies

72" & 78" High Flow Cutter Assemblies

High Flow Drive Assembly

High Flow Hydraulic Assemblies

Wheel Kit Assembly

INSTALLATION INSTRUCTIONS ....................................................................F

OPERATING INSTRUCTIONS ........................................................................ G

General Information

Operating Tips

Operation

Troubleshooting Operating Conditions

LUBRICATION ................................................................................................. H

MAINTENANCE ................................................................................................ L

Daily

Every 40 Hours Operation

Replacing Blades

Replacing Hydraulic Motor

Replacing Gearbox/Motor Coupler

Replacing Gearbox

STORAGE ........................................................................................................ M

TROUBLESHOOTING ..................................................................................... N

BOLT TORQUE ............................................................................................... O

SPECIFICATIONS .............................................................................................P

DECALS ........................................................................................................... Q

PREDELIVERY CHECK LIST .......................................................................... R

LIMITED WARRANTY ......................................................................................S

9026 10-11-06-4

THIS PAGE

IS INTENTIONALLY

BLANK

A

A

TO THE OWNER

GENERAL COMMENTS

Congratulations on the purchase of your new rotary cutter! Your cutter was

carefully designed and manufactured to give you years of dependable service. Your

cutter will require some minor maintenance (such as cleaning) to keep it in top

working condition. Be sure to observe all safety precautions and maintenance

procedures as described in this manual.

ABOUT THIS MANUAL

This manual has been designed to help you do a better, safer job. Read this

manual carefully and become familiar with it's contents. Remember, never let

anyone operate this unit without reading the "Safety Precautions" and

"Operating Instructions" sections of this manual. (See Sections B and G

respectively.)

Unless noted otherwise, right and left sides are determined from the position

of the skid-steer operator sitting in the seat facing forward.

SAFETY ALERT SYMBOL

This is the "Safety Alert Symbol" used by this industry. This symbol is

used to warn of possible injury. Be sure to read all warnings carefully.

They are included for your safety and for the safety of others working

with you.

SERVICE

When servicing your rotary cutter, remember to use only manufacturer

replacement parts. Substitute parts may not meet the standards required for safe,

dependable operation.

To facilitate parts ordering, record the model and serial number of your unit in

the space provided on this page. This information may be obtained from the identification plate located on the right front of the mounting plate.

MODEL____________________________________

SERIAL NUMBER___________________________

DATE PURCHASED_________________________

The parts department needs this information to insure that you receive the

correct parts for your specific model.

8908

11-2-04-2

THIS PAGE

IS INTENTIONALLY

BLANK

BB

SAFETY PRECAUTIONS

TAKE NOTE! THIS SAFETY ALERT SYMBOL FOUND THROUGHOUT THIS

MANUAL IS USED TO CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING YOUR PERSONAL SAFETY OR OTHERS. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN RESULT IN INJURY OR DEATH.

THIS SYMBOL MEANS:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

SIGNAL WORDS: Note the use of signal words DANGER, WARNING, and

CAUTION with the safety messages. The appropriate signal word for each has

been selected using the following guidelines:

DANGER: Indicates an imminently hazardous situation, which if not avoided,

will result in death or serious injury. This signal word is to be limited

to the most extreme situations, typically for machine compo-

nents which, for functional purposes, cannot be guarded.

WARNING: Indicates a potentially hazardous situation, which if not avoided,

could result in death or serious injury, and includes hazards that

are exposed when guards are removed. It may also be used to

alert against unsafe practices.

CAUTION: Indicates a potentially hazardous situation, which if not avoided,

may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

6621

5-18-95

B

B

SAFETY PRECAUTIONS

ROTARY CUTTER

GENERAL INFORMATION

This section is composed of various warnings and safety tips. Read and learn

all the information in this section before you attempt to use your rotary cutter.

Also read your vehicle owner's manual before using your equipment. This knowledge

will help you operate your unit safely. Do not take this information lightly, it is pre-

sented for your benet and for the benet of others working around you.

The "Safety Alert Symbol" (as described in Section A and at the beginning of

Section B) will be used throughout this manual. It will appear with the word DANGER,

WARNING, or CAUTION above it, and a safety message pertaining to the specic topic

being covered. Take the time to read these messages as you come across them.

TO THE OPERATOR

The primary responsibility for safety with the equipment falls to the operator.

Make sure that the equipment is operated only by responsible & competent individuals

with the proper instruction. It is the skill, care, common sense, and good judgment of

the operator that will determine how efciently and safely the job is performed. Know

your equipment before you start. Know its capabilities, dimensions, and how to oper-

ate all the controls. Visually inspect your equipment before you start, and never operate

equipment that is not in proper working order.

BEFORE YOU START

1. Read the entire loader and rotary cutter operator's manuals before ever attempting to use the loader. This knowledge is necessary for safe operation.

2. Do NOT operate the standard ow rotary cutter on high ow hydraulic sys-

tems. Severe injury or death could occur due to the increased RPM.

3. Do not operate without a shatterproof (demolition) cab door or front shield

on loader.

4. Always wear safety goggles and hearing protection during operation, and

make sure ALL safety shields and chains are properly installed.

5. Follow all safety decals. Keep them clean and replace them if they become

worn, damaged, or illegible.

6. Do not paint over, remove, or deface any safety signs or warning decals on

your equipment.

7. Know your equipment inside and out. Know how to operate all controls and

know emergency shut down procedures.

8. Keep all stepping surfaces, pedals, and controls free from dirt, grease and

oil. Keep equipment clean to help avoid injury from a fall when getting on or off

equipment.

8909 10-11-06-4

B

B

SAFETY PRECAUTIONS

ROTARY CUTTER

9.

10.

11.

12.

13.

14. Never leave the unit unattended when in a raised position. Always make

15. Test all controls before you begin.

Use handholds and step plates when getting on/off . Failure to do so

could cause a fall.

Never operate the unit near bystanders, traffic, pets, livestock, or buildings. Be sure others know when and where you will be working. Make sure no

one is behind equipment or for several hyndred feet in any direction around the

cutter when in operation. Never allow anyone to approach the cutter when in

operation.

Never take passengers on your equipment. There is no safe place for a

passenger.

Never try to board equipment while it is running.

Turn off engine, remove the key and disconnect hydraulic couplers

before performing maintenance. If unit must be left raised for maintenance

or any other reason, block the unit securely to prevent accidental release of the

lifting mechanism. Serious damage or personal injury could result.

sure both skids are on the ground, and keys removed before leaving the unit

unattended.

16. Do not smoke when refueling. Allow room in the gas tank for expansion.

Wipe up any spilled fuel. Secure cap tightly when done.

WORKING WITH THE ROTARY CUTTER

1. Never operate the unit without first reading and understanding the

operator's manual.

2. Never operate the rotary cutter without the lift limiting chain(s) properly

installed. Refer to Section F.

3. Operate the unit only in daylight, or sufficient artificial light.

4. Do not carry load with arms in the raised position. Always carry loads as

close as possible to the ground.

5. Check your work area, and know where all utility lines are. Avoid hitting

underground electrical wires, cables, pipes, fence posts, gas lines, uneven

sidewalk edges, large rocks, etc.

6. Never operate equipment while under the influence of alcohol, prescription drugs, nonprescription drugs, or illegal drugs which could inhibit physical

and/or mental capacity.

7. Do not exceed rated operating capacity, as machine may become

unstable which may result in loss of control.

8. Do not operate the unit without covers and chains installed.

8910

11-2-04-3

B

B

SAFETY PRECAUTIONS

ROTARY CUTTER

9. Do not place hands or feet under deck while in operation or with engine

running.

10.

11. ALWAYS LOWER THE LOADER ARMS TO THE GROUND, SHUT OFF THE

TRANSPORTING THE ROTARY CUTTER

1.

2.

MAINTENANCE

1. Never work on equipment while it is running. Always lower the loader arms

2. Never make hydraulic repairs while the system is under pressure. Injury or

3. Observe proper maintenance schedules and repairs to keep the unit in safe

Do not raise the deck when blades are rotating.

ENGINE AND REMOVE THE KEY BEFORE GETTING OFF THE UNIT.

Follow all federal, state and local regulations when transporting the unit on

public roads.

Use extra care when loading or unloading the machine onto a truck or trailer.

Disconnect hydraulic couplers during transportation.

to the ground, shut off the engine, remove the key, and disconnect hydraulic

couplers before performing maintenance on the unit.

death could result.

working order.

4 Always wear safety goggles or glasses when working on equipment.

5. Use only manufacturer recommended replacement parts. Other parts may be

substandard in fit and quality.

WARNING! Escaping fluid under pressure can have sufficient force to penetrate

the skin causing serious personal injury. Fluid escaping from a very

small hole can be almost invisible. Use a piece of cardboard or wood,

rather that hands to search for suspected leaks.

Keep unprotected body parts,

such as face, eyes, and arms as

far away as possible from a

suspected leak. Flesh injected

with hydraulic fluid may develop

gangrene or other permanent

disabilities.

If injured by injected fluid, see a

doctor at once. If your doctor is

not familiar with this type of

injury, ask him to research it

immediately to determine proper

treatment.

HYDRAULIC HOSE

CARDBOARD

MAGNIFYING GLASS

OR FITTING

8911

11-2-04-3

CC

INTERNATIONAL SYMBOLS

As a guide to the operation of your equipment, various international

symbols have been utilized on the instruments and controls. The symbols

are shown below with an indication of their meaning.

Engine speed Alternator charge

Hours recorded Power take-off (on)

Engine water temperature Power take-off (off)

Lights "Tortoise," slow or minimum setting

Horn "Hare," fast or maximum setting

Engine oil pressure Caution

Hazard warning Control lever operating direction

Axle connect Rock shaft (raised)

Axle disconnect Rock shaft (lowered)

Continuously variable Remote cylinder (extended)

Increase Remote cylinder (retracted)

Decrease Remote cylinder (FLOAT)

Diesel fuel Differential lock

Creeper range Read operators manual

High range Neutral

Low range Forward

Reverse

3869

4-14-94-2

D

D

PREOPERATION

ROTARY CUTTER

GENERAL INFORMATION

The BRADCO Rotary Cutters were designed to be easy to use and maintain. They are operated by the skid-steer auxiliary hydraulics. The cutters mount to

the toolbar / quick attach mechanism for easy mounting.

Unless noted otherwise, right and left are determined from the position of the

skid-steer operator sitting in the operator's seat facing forward.

Remember to read the "Safety Precautions" and "Operating Instructions"

sections of the manual BEFORE you attempt to install or use the rotary cutter.

NOTE: The illustrations and data used in this manual were current (according

to the information available to us) at the time of printing, however, we reserve

the right to redesign and change the rotary cutters as may be necessary with-

BEFORE OPERATION

The primary responsibility for safety with this equipment falls to the opera-

tor. Make sure that the equipment is operated only by trained individuals that have

read and understand this manual. Don't hurry the learning process or take the unit

for granted. Practice the operation of your new equipment and become familiar with

the controls and the way it handles on your machine.

If there is any portion of this manual or function you do not understand, contact your local authorized dealer or the manufacturer.

DANGER! TO AVOID SERIOUS PERSONAL INJURY OR DEATH THE BRAD-

CO ROTARY CUTTER MUST NOT BE ATTACHED TO ANY POWER

UNIT THAT DOES NOT HAVE A SHATTERPROOF DOOR (OR

WARNING! OPERATING THE STANDARD FLOW ROTARY CUTTER ON A

HIGH FLOW HYDRAULIC SYSTEM MAY CAUSE SEVERE INJURY

OR DEATH TO THE OPERATOR OR BYSTANDERS DUE TO THE

SKID-STEER

BRADCOhasdesignedbothstandardowandhighowrotarycutters.The

standardow rotarycuttersareNOTdesignedforuseonhighowskid-steers.Operatingthestandardowonahighowsystemwillvoidtherotarycutterwarranty.

For maximum operation, see the recommended GPM for the rotary cutter you have

received.

Your skid-steer must have an auxiliary hydraulic system and a shatterproof

door or front shield to run the rotary cutter.

StandardSAEatfacehydraulicquickcouplersaresuppliedwithyourrotary

cutter. If you require an alternate set of couplers, you will need to purchase these

fromyourdealer.Thesecouplersmustta#12MBoendandconnecttoyourskid-

steer auxiliary hydraulic system.

9008 10-11-06-3

D

D

PREOPERATION

ROTARY CUTTER

NOMENCLATURE

Throughout this manual, reference is made to various rotary cutter components. The purpose of this page is to acquaint you with the various names of

these components. This knowledge will be helpful when reading through this

manual or when ordering service parts.

MOTOR COVER SHIELD

LIFT LIMITING CHAIN

QUICK ATTACH

DISCHARGE

CHUTE

BLADE

STUMP JUMPER

REAR ACCESS COVER

MOTOR

NON-SKID STEP SURFACE

BLADE ROTATION INDICATOR

GEARBOX

BLADE ACCESS

COVER

FRONT CHAIN

CURTAIN

SKID SHOE

ROTARY CUTTER DECK

9009

4-14-03

E

E

ROTARY CUTTER ASSEMBLY

60" & 72" STANDARD FLOW CUTTER ASSEMBLIES

1 2

23

18

3

4

5

4

6

20

21

22

9

1

19

10

11

12

13

14 - (TORQUE TO 450 FT. LBS.)

15

16

17

8900 10-11-06-3

E

E

ROTARYCUTTERASSEMBLY

60"&72"STANDARDFLOWCUTTERASSEMBLIES

NO REQ'D PARTNO. DESCRIPTION

1 4 1044 .38"UNCx1.25"HexCapscrew

2 1 18059 ReplacementCoverwithDecals

3 1 17941 Hinge

4 6 1953 .38"UNCX.75"FlangeHexCapscrew

5 ~ 17846 RearAccessCover-ServicePartOnly

6 1 15321 BladeAccessCover

7 1 18169 LiftLimitingChain

8 2 89968 Shackle

9 1 17879 60"Cutter

1 15329 72"Cutter

10 1 1611 CotterPin

11 1 1514 .38"FlatWasher

12 1 17902 60"FrontChainRetainer

1 17348 72"FrontChainRetainer

13 47 15326 FrontChain

59 15326 FrontChain

14 2 17390 SpecialNut(Torqueto450ft.lbs.)

15 1 15324 StumpJumperHub

16 2 18514 DoubleEdgedBlade(60"RotaryCutter)

- 17903 OptionalBananaBlade(60"RotaryCutter)

2 18515 DoubleEdgedBlade(72"RotaryCutter)

- 17847 OptionalBananaBlade(72"RotaryCutter)

17 2 17389 BladeMountingBolt

18 4 2005510 .38"UNCFlangeLockNut

19 2 1793 CotterPin

20 2 1022 .31"UNCX1.00HexCapscrew

21 2 1502 .31"LockWasher

22 2 1513 .31"FlatWasher

23 1 25453 ManualTube

89016-25-10-4

E

E

ROTARY CUTTER ASSEMBLY

60" & 72" STANDARD FLOW CUTTER ASSEMBLIES

1

3

4

2

5

6

USE WITH MOTOR #106601 ONLY

28

27

26

25

6

8

9

7

13

17

18

19

10

16

20

14

15

11

12

21

22

22

23

24

12 - (TORQUE TO

240-250 FT. LBS.)

8902 10-11-06-4

E

E

ROTARY CUTTER ASSEMBLY

60" & 72" STANDARD FLOW CUTTER ASSEMBLIES

NO REQ'D PART NO. DESCRIPTION

1 1 17921 Dust Cap

2 1 22519 Male Coupler

3 1 22518 Female Coupler

4 1 17922 Dust Cap

5 2 38081 Hose Assembly .62" x 104" 12MBo-10MBo 90°

6 - 17143 Replacement Hose Clamp

7 2 1841 .50" UNC Deformed Lock Nut

8 1 17938 60" Cutter Hydraulic Motor (6.8 Cu. In.)

1 17787 72" Cutter Hydraulic Motor (10 Cu. In.)

1 106601 60" Cutter Hydraulic Motor (25-30 GPM ONLY)

-- 5661 Replacement Key

9 1 17808 Coupler

10 1 22277 Roll Pin

11 1 17843 Blade Rotation Indicator

12 1 15302 Right Angle Gearbox Assembly

- 19701 Replacement Castle Nut

(Torque Castle Nut to 240-250 ft. lbs.)

- 19702 Replacement Input Seal

- 19703 Replacement Output Seal

- 19704 Replacement Vent

13 4 1799 .38" UNC X 1.50" Sockethead Capscrew

14 3 1501 .25" Lock Washer

15 3 1001 .25" UNC X .50" Hex Capscrew

16 1 17844 Motor Mounting Plate

17 2 1091 .50" UNC X 1.75" Hex Capscrew

18 2 1841 .50" UNC Deformed Lock Nut

19 2 1646 .50" Hard Flat Washer

20 2 6886 Rubber Bumper

21 4 10071 .62" UNC X 2.25" Hex Capscrew - Grade 8

22 8 1627 .62" Hard Flat Washer

23 4 1839 .62" UNC Deformed Lock Nut

24 1 1793 Cotter Pin

Use Item 25 through 28 with Motor #106601 ONLY

25 1 3417 90° Elbow 4MBo-6MJ

26 1 37754 Hose Assembly .25" x 116" 6FJX-6FJX

27 1 3269 Straight Connector 8MBo-6MJ

28 1 84928 Female Coupler

8903 10-11-06-3

E

E

ROTARY CUTTER ASSEMBLY

72 & 78” HIGH FLOW CUTTER ASSEMBLIES

12

11

10

4

3

7

8

1

2

5

6

7

8

9

13

9

14

15

22

23

20

21

19

24

18

17

16

21 - (TORQUE TO 450 FT. LBS.)

10799 10-11-06

E

E

ROTARY CUTTER ASSEMBLY

72 & 78” HIGH FLOW CUTTER ASSEMBLIES

NO REQ'D PART NO. DESCRIPTION

1 9 1044 .38" UNC x 1.25" Hex Capscrew

2 9 1800 .38” Hard Flat Washer

3 9 2005510 .38” UNC Flange Lock Nut

4 1 104420 Hinge Mounting Cover

5 1 17941 Hinge

6 1 108547 Replacement Cover with Decals

7 4 1021 .31” UNC X .75” Hex Capscrew

8 4 1502 .31” Lock Washer

9 4 1513 .31” Flat Washer

10 1 25453 Manual Tube

11 1 89968 Shackle

12 1 18169 Lift Limiting Chain

13 1 17846 Rear Access Cover (72” Cutter Service Part ONLY)

2 1953 .38" UNC X .75" Flange Hex Capscrew

14 1 15321 Blade Access Cover

2 1953 .38" UNC X .75" Flange Hex Capscrew

15 1 15329 72" Cutter

1 106299 78” Cutter

16 59 15326 Front Chain (72” Cutter)

63 15326 Front Chain (78” Cutter)

17 1 17348 72" Front Chain Retainer

1 106342 78” Front Chain Retainer

18 1 1514 .38" Flat Washer

19 1 1611 Cotter Pin

20 2 1793 Cotter Pin

21 2 17390 Special Nut (Torque to 450 ft. lbs.)

22 1 15324 Stump Jumper Hub

23 2 18515 Double Edged Blade (72" Rotary Cutter)

- 17847 Optional Banana Blade (72" Rotary Cutter)

2 106312 Double Edged Blade (78" Rotary Cutter)

24 2 17389 Blade Mounting Bolt

10800 6-25-10-2

E

ROTARY CUTTER ASSEMBLY

72 & 78” HIGH FLOW DRIVE ASSEMBLY #104740

16

17

13

14

7

15

18

19

E

25

24

23

22

21

10

12

20 (TORQUE TO

240-250 FT. LBS.)

11

4

5

3

1

6

8

9

2

10801 10-11-06

E

E

ROTARY CUTTER ASSEMBLY

72 & 78” HIGH FLOW DRIVE ASSEMBLY #104740

NO REQ'D PART NO. DESCRIPTION

1 1 100928 High Flow Hydraulic Motor (17.9 Cu. In.)

- 5661 Replacement Key

2 1 3269 Straght Connector 8MBo-6MJ

3 1 30292 Straght Adapter 16MBo-12FB

4 1 22600 90° Elbow 12MBo-12MJ

5 1 30051 90° Elbow 16MBo-12MJ

6 4 1839 .62” UNC Deformed Lock Nut

7 4 10071 .62” UNC X 2.25” Hex Capscrew

8 1 104561 Left Motor Mount

9 1 104562 Right Motor Mount

10 4 6886 Bumper

11 4 1841 .50” UNC Deformed Lock Nut

12 4 1799 .38” UNC X 1.50” Socket Head Capscrew

13 4 1837 .38” UNC Deformed Lock Nut

14 1 22277 .50” X 2.50” Roll Pin

15 1 100917 Coupler

16 1 17843 Blade Rotation Indicator

17 3 1001 .25” UNC X .50” Hex Capcrew

18 3 1501 .25” Lock Washer

19 1 1793 Cotter Pin

20 - 19701 Replacement Castle Nut

21 4 1141 .75” UNC X 2.50” Hex Capscrew

22 8 1649 .75” Hard Flat Washer

23 4 1936 .75” UNC Lock Nut

24 1 101508 Right Angle Gearbox Assembly

25 1 7781 Breather Plug

10802 6-25-10-2

E

E

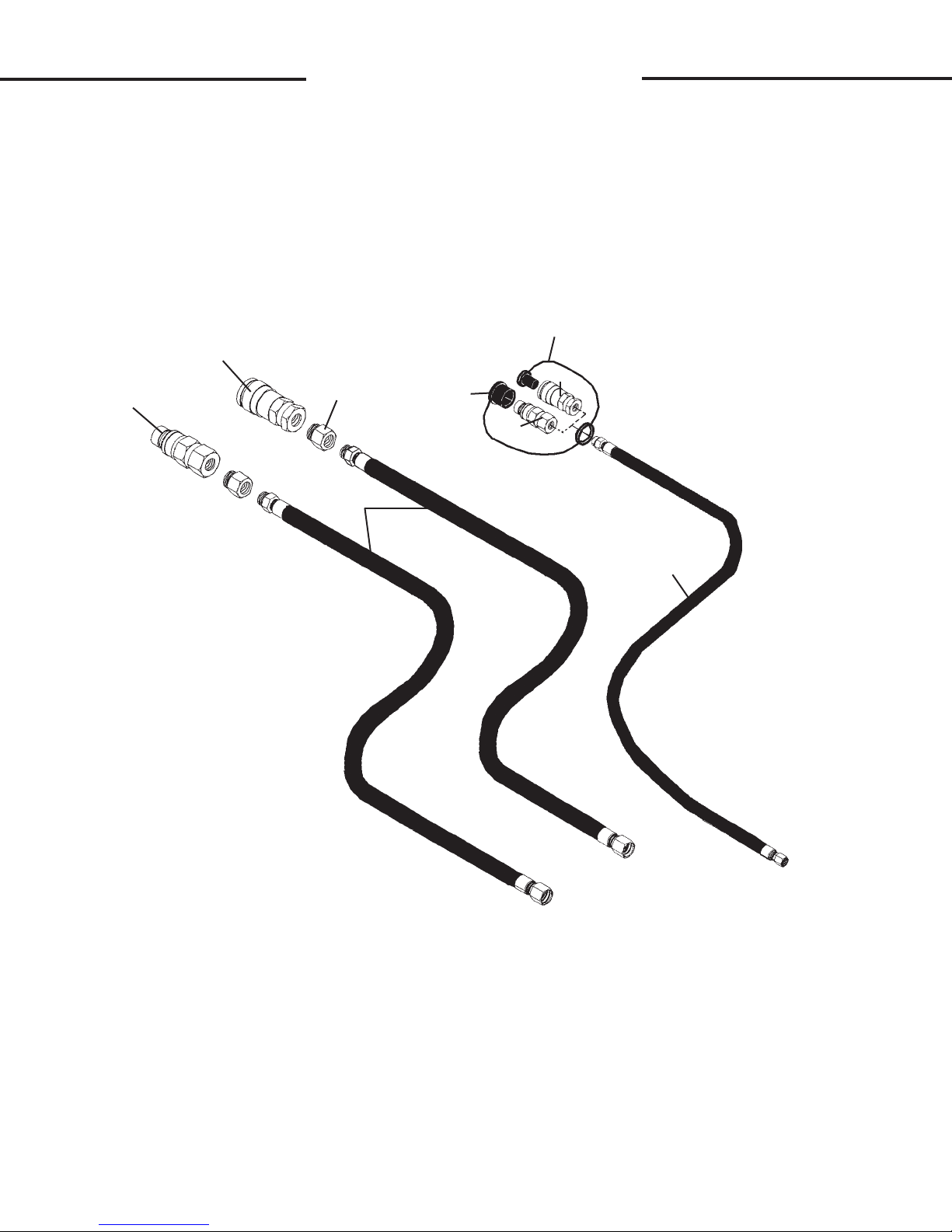

HYDRAULIC ASSEMBLY

HYDRAULIC ASSEMBLIES FOR HIGH FLOW DRIVES

8

2

7

1

9

3

6

5

4

10803 10-12-06

E

E

HYDRAULIC ASSEMBLY

HYDRAULIC ASSEMBLIES FOR HIGH FLOW DRIVES

HYDRAULIC KIT #105779

NO REQ'D PART NO. DESCRIPTION

1 1 19638 Male Coupler .75” Body 12FBo

2 1 22520 Female Coupler .75” Body 12FBo

3 2 37060 Hose Assembly .75” X 88” 12MBo-12FJX

4 1 38151 Hose Assembly .38” X 94” 6FJX-8MBo

5 1 84923 Male Coupler .38” Body 8FBo

6 1 32549 Dust Cap

HYDRAULIC KIT #105780

NO REQ'D PART NO. DESCRIPTION

1 1 84922 Male Coupler .62” Body 12FBo

2 1 84921 Female Coupler .62” Body 12FBo

3 2 37769 Hose Assembly .75” X 108” 12MBo-12FJX

4 1 38162 Hose Assembly .38” X 112” 6FJX-8MBo

5 1 84923 Male Coupler .38” Body 8FBo

6 1 32549 Dust Cap

HYDRAULIC KIT #105781

NO REQ'D PART NO. DESCRIPTION

1 1 22519 Male Coupler .50” Body 12FBo

2 1 22518 Female Coupler .50” Body 12FBo

3 2 37060 Hose Assembly .75” X 88” 12MBo-12FJX

4 1 38151 Hose Assembly .38” X 94” 6FJX-8MBo

5 1 84923 Male Coupler .38” Body 8FBo

6 1 32549 Dust Cap

HYDRAULIC KIT #105782

NO REQ'D PART NO. DESCRIPTION

1 1 19638 Male Coupler .75” Body 12FBo

2 1 22520 Female Coupler .75” Body 12FBo

3 2 37060 Hose Assembly .75” X 88” 12MBo-12FJX

4 1 38151 Hose Assembly .38” X 94” 6FJX-8MBo

7 1 84928 Female Coupler .38” Body 8FBo

8 1 32548 Dust Plug

HYDRAULIC KIT #105783

NO REQ'D PART NO. DESCRIPTION

1 1 16434 Male Coupler 1.00” Body 16FBo

2 1 16433 Female Coupler 1.00” Body 16FBo

3 2 37060 Hose Assembly .75” X 88” 12MBo-12FJX

4 1 38151 Hose Assembly .38” X 94” 6FJX-8MBo

5 1 14176 Male Coupler 50” Body 8FBo

6 1 17921 Dust Cap

9 2 30292 Straight Adapter 12FBo-16MBo

10804 10-12-06

E

MOUNTING KIT INSTALLATION

WHEEL KIT ASSEMBLY #24518

10

11

9

E

7

1

2

3

4

12

5

6

13

8

14

15

16

15

10041

6-25-10-2

E

MOUNTING KIT INSTALLATION

WHEEL KIT ASSEMBLY #24518

ITEM REQ’D PART NO. DESCRIPTION

1 1 101414 Spindle Dust Cap

2 1 10047 1.00” UNC Castle Nut

3 1 1706 1.00” Hard Flat Washer

4 1 33715 Tapered Roller Bearing

5 1 1614 Cotter Pin

6 1 33714 Tapered Roller Bearing

7 1 15511 Seal

8 1 101115 Wheel Yoke

9 1 24513 Support Arm

10 5 1092 .50” UNC x 2.00 Hex Capscrew, Grade 8

11 10 1516 .50” Hard Flat Washer

12 1 24530 .38” x 9.00” x 21.00 Plate

13 5 1841 .50” UNC Locknut, Grade 8

14 1 101195 Foam Filled Wheel & Tire Assembly

1 6616 Replacement Zerk

15 1 10105 Wheel Shaft/Nut Assembly

E

16 Varies 6562 Spring Washer

10042

6-25-10-2

F

F

INSTALLATION INSTRUCTIONS

GENERAL INFORMATION

The following instructions will help you to mount your rotary cutter onto your

skid-steer loader. The rotary cutter uses the quick-attach system for ease of installation. Therefore, if you know how to attach your loader bucket, attaching the rotary cutter

should prove no problem.

Remember to read all safety warnings, decals and operating instructions before

operating the attachment. If there is any portion of this manual that you do not understand, contact your dealer.

DANGER! TO AVOID SERIOUS PERSONAL INJURY OR DEATH THE BRAD-

CO ROTARY CUTTER MUST NOT BE ATTACHED TO ANY POWER

UNIT THAT DOES NOT HAVE A SHATTERPROOF DOOR (OR FRONT

SHIELD) INSTALLED.

WARNING! OPERATING THE STANDARD FLOW ROTARY CUTTER ON A HIGH

FLOW HYDRAULIC SYSTEM MAY CAUSE SEVERE INJURY OR DEATH

TO THE OPERATOR OR BYSTANDERS DUE TO THE INCREASED

RPM. DO NOT OPERATE THE STANDARD FLOW ROTARY CUTTERS

ON HIGH FLOW HYDRAULIC SYSTEMS.

INSTALLATION INSTRUCTIONS

NOTE: Before attaching the rotary cutter to your skid-steer loader, make sure a shatterproof door (or front shield) has been installed onto the front of your skid-steer loader. This

is required to protect the operator from possible thrown objects.

1. Remove the shipping banding from around the rotary cutter and skid.

2. Remove any attachments from the front of the loader.

3. Following all standard safety practices and the instructions for installing an attachment

in your skid-steer operator's manual, install the rotary cutter onto your skid-steer.

NOTE: It is important to make sure the locking mechanism on your quick attach is

engaged, therefore locking the attachment onto the skid-steer.

4. Connect the Lift Limiting Chain to your skid-steer. The back of the rotary cutter should

never be more than 1 foot off the ground for proper and safe cutting. (Raise the unit

to 1 foot above ground level. Route the end of the Lift Limiting Chain through the "D"

ring on the back of the rotary cutter and then through the tie down mechanism(s)

on the front of your skid-steer loader. Tie the chain securely back to itself with the

shackle provided, to limit the lifting capabilities of the cutter to 1 foot maximum.)

5. Lower the unit to the ground and remove the key.

6. After making sure that there is not any foreign matter on the hydraulic couplers,

connect the couplers to the auxiliary hydraulic system of your skid-steer loader.

IMPORTANT: Do not operate the BRADCO standard ow rotary cutter on High Flow

Hydraulic systems. Doing so will void the standard ow rotary cutter warranty.

9021 10-11-06-3

G

G

OPERATING INSTRUCTIONS

ROTARY CUTTER

GENERAL INFORMATION

The BRADCO rotary cutter is perfect for cutting tall grass and brush up to

4" in diameter.

The rotary cutter attaches to the toolbar/quick-attach mechanism of your

skid-steer loader. Due to this arrangement, thorough knowledge of the skid-steer

controls is necessary for machine operation. Read and understand your skidsteer operator's manual for information regarding skid-steer operation before

attempting to use the rotary cutter.

Follow all installation instructions in Section F for the proper installation of

the unit onto your skid-steer before attempting to operate your rotary cutter.

OPERATING TIPS

• Increase the life of your bi-directional blades by cutting brush in one direction and cutting grass and smaller vegetation in the other. (This will keep

the blades sharp for cutting grass.)

• If your preferred direction of blade rotation is not set up correctly for your

skid-steers "detent", the hydraulic hoses may be reversed at the motor

end.

• Continuous rotation of the blades is required during operation to prevent

overheating of the hydraulic system. The rotary cutter is equipped with a

blade rotation indicator disk to assist in monitoring blade rotation. If the

rotary cutter stalls, disengage auxiliary hydraulics, and remove cutter from

debris before restarting.

• Engage and disengage the hydraulic system with the skid-steer at idle.

WARNING! Before leaving the operator's seat: Lower the lift arms against

frame and place unit on the ground. Disengage auxiliary hydraulics. Stop Engine. Engage parking brake. Remove the key.

DANGER! ROTATING BLADE HAZARD! STAY BACK!

OBJECTS CAN BE THROWN!

DO NOT operate near bystanders.

DO NOT place hands or feet under deck while in operation or

with engine running.

DO NOT operate without a shatterproof door (or front shield)

installed on loader.

WARNING! Operatingthestandardowrotarycutteronahighowhy-

draulic system may cause severe injury or death to the operator or bystanders due to the increased RPM. Do NOT operate

thestandardowrotarycuttersonhighowhydraulicsystems.

WARNING! Lift limiting chain must be properly installed before operation.

9022 10-11-06-4

G

G

OPERATING INSTRUCTIONS

ROTARY CUTTER

CUTTING OPERATION

1. Raise the back of the unit off of the ground approximately 4" to allow the

material to clear from under the cutting deck as you travel forward.

2. Place the front skid shoes 1-2 inches off the ground. This is the preferred

position for cutting grass and heavy vegetation.

• Never drive your skid-steer with the front of the rotary cutter tilted to the point

your view is obstructed. Always make sure you can see what you are cutting.

• Check the work area. Never operate the rotary cutter in populated areas

where thrown objects could injure persons or damage property.

• Never raise the unit and expose yourself or anyone else to the rotating

blades. If you can see the blades then the back of the unit is raised too high.

3. Activate the auxiliary hydraulics with the engine at idle. Increase engine

speed.

4. Be sure the rotary cutter is operating smoothly and at full speed, and then

start forward travel while monitoring blade rotation.

NOTE: The rotary cutter has a window in the motor cover shield so the

operator can see the blade rotation indicator disk. This disk should always

be rotating during operation to prevent a drop in hydraulic pressure or

overheating of the hydraulic system.

CUTTING LARGE BRUSH UP TO 3-4" IN DIAMETER:

When cutting large brush, roll the front of the rotary cutter up 1-2 feet. DO

NOT LIFT THE BACK OF THE CUTTER! Slowly drive into the tree and use the

hydraulic tilt function on the skid-steer to bend or push the tree over. As the tree

bends, the blades will cut it off. The tree can now be mulched by rotating the front up,

drive forward several feet, roll the front down onto the tree and backdrag. Repeat, if

necessary. Remember do not lift the back of the cutter.

AVOID STALLING ROTARY CUTTER: Continuous rotation is required to prevent

overheating of the hydraulic system. The rotary cutter is equipped with a blade

rotation indicator disk to assist in monitoring blade rotation. If the rotary cutter stalls,

see "TO RESTART BLADE ROTATION".

TO RESTART BLADE ROTATION: Return engine speed to idle and disengage

auxiliary hydraulics. Remove rotary cutter from debris. Engage auxiliary hydraulics to

start blade rotation. (Be sure the rotary cutter is operating smoothly and at full

speed, and then start forward travel while monitoring blade rotation.)

9023

11-2-04-3

G

G

OPERATING INSTRUCTIONS

ROTARY CUTTER

REPEATED STALLING OF ROTATING BLADES: Return engine speed to idle

and disengage auxiliary hydraulics. Remove rotary cutter from debris. Review

operating conditions and the size/density of material being cut. Make necessary

corrections. Engage auxiliary hydraulics to start blade rotation. (Be sure the

rotary cutter is operating smoothly and at full speed, and then start forward travel

while monitoring blade rotation.)

TROUBLESHOOTING OPERATING CONDITIONS:

Below are listed a few operating conditions that may cause repeated

stalling of your rotary cutter, and suggestions on how to correct them.

GRASS TOO LONG OR THICK: If cutting heavy vegetation, you may need to slow

travel speed or make smaller passes (less than full cut) to prevent overloading and

stalling the unit.

BRUSH TOO BIG IN DIAMETER: The rotary cutter is NOT designed to cut trees

larger than 3-4" in diameter. If brush is smaller than 3-4" in diameter and the cutter is

stalling, check sharpness of the blades (see "Maintenance" Section L) and cut using

the procedure described earlier in this section for "Cutting Large Brush".

BRUSH TOO THICK OR HEAVY: If cutting heavy or thick brush, you may need to

slow travel speed or make smaller passes (less than full cut), to prevent overloading.

If the blades seem to be unable to handle the volume of brush, slow down the travel

speed until the unit reaches full speed before proceeding.

SCALPING THE GROUND or BOTTOMING OUT: Be aware of changes in the

terrain. Stay alert for drop-off and holes. Check the terrain and the deck position

before restarting and continuing cutting.

STRIKING FOREIGN OBJECTS: Stay alert for rocks, fencing, abandoned

wells, septic tanks or other foreign objects. If the rotary cutter comes into contact

with a foreign object, stop the unit, shut off the engine and disconnect the hydraulic couplers from the skid-steer. Inspect the unit and repair any damage

before restarting and continuing cutting. (Never try to weld or straighten damaged blades.) Inspect the work area for any other items, and if they are too large to

be removed from the area, they should be flagged clearly.

9024

11-2-04-2

H

H

LUBRICATION

GENERAL INFORMATION

Economical and efficient operation of any machine is dependent upon

regular and proper lubrication of all moving parts with a quality lubricant. Neglect

leads to reduced efficiency, wear, breakdown, and needless replacement of parts.

WEEKLY

The oil level in the gear box should be checked once a week. Fill as

necessary with 80-90 weight gear lubricant.

TO CHECK:

Remove pipe plug from end of gearbox. Lubricant should be at the same

level as the plug.

TO ADD:

Remove pipe plug from end of gearbox. Remove filler plug from top end of

gearbox and add 80-90 weight gear lubricant up to the same level as the pipe

plug. Replace pipe plug and filler plug.

IMPORTANT: DO NOT OVERFILL, AS TOO MUCH LUBRICANT MAY RUPTURE THE GEAR BOX SEALS.

FILLER PLUG

GEARBOX

PIPE PLUG

ADD LUBRICANT TO

THIS LEVEL

9011

4-15-03

L

L

MAINTENANCE

ROTARY CUTTERS

GENERAL INFORMATION

Regular maintenance is the key to long equipment life and safe operation. Maintenance requirements have been reduced to an absolute minimum. However,

it is very important that these maintenance functions be performed as described below.

WARNING! Avoid serious injury. Lower the rotary cutter to the ground, set the

parking brake, stop the skid-steer engine, and remove the key before

leaving the operator's seat. If unit must be left raised for maintenance,

block the unit securely to prevent accidental release of the lifting mechanism. Disconnect the hydraulic couplers.

DAILY

• Check skid-steer loader hydraulic system to ensure an adequate level of hydraulic oil.

• Check gearbox castle nut and torque to min. 250 - max 350 ft. lbs.

• Check mounting hardware on blades and torque to 450 ft. lbs.

• Check all other hardware and tighten, if necessary. See Section O.

• Check hydraulic system for hydraulic oil leaks.

• Check gearbox power shaft for foreign material wrapped around the shaft and re-

move, if necessary.

• Check blades for damage and replace or sharpen as needed.

• Check all safety guards and ensure that all devices are installed correctly.

• Check for missing or illegible Safety / Warning Decals.

WARNING! Escaping fluid under pressure can have sufficient force to penetrate the

skin, causing serious personal injury. Fluid escaping from a very small

hole can be almost invisible. Use a piece of cardboard or wood, rather

than hands to search for suspected leaks.

Keep unprotected body parts, such as face, eyes, and arms as far away

as possible from a suspected leak. Flesh injected with hydraulic fluid may

develop gangrene or other permanent disabilities.

If injured by injected fluid, see a doctor at once. If your doctor is not

familiar with this type of injury, ask him to research it immediately to

determine proper treatment.

CARDBOARD

HYDRAULIC HOSE

OR FITTING

MAGNIFYING GLASS

• Check oil level in gearbox and add if necessary. (See Section H)

EVERY 40 HOURS

9013

11-2-04-3

L

L

MAINTENANCE

ROTARY CUTTERS

WARNING! Avoid serious injury. Lower the rotary cutter to the ground, set

the parking brake, stop the skid-steer engine, and remove the

key before leaving the operator's seat. If unit must be left

raised for maintenance, block the unit securely to prevent

accidental release of the lifting mechanism. Disconnect the

hydraulic couplers.

REPLACING BLADES

When replacing, changing, or sharpening the blades, the unit must be

blocked securely off the ground to gain access to the blades.

The blades should be inspected regularly (every 8 hours) to ensure they

are sharp, tightened correctly, and intact. Always replace both blades at the same

time and NEVER try to weld or straighten damaged blades, as loss of blade integrity may result.

Removing Blades:

1. With unit securely blocked off the ground and hydraulic couplers discon-

nected, loosen the capscrews on the blade access cover and swing cover

open.

2. Position one of the blades under the

access panel and remove the cotter

pin and special nut. You can now

remove the blade mounting bolt and

the blade.

3. Repeat step #2 for the remaining

blade.

Installing Blades:

1. With unit securely blocked off the

ground and hydraulic couplers dis-

connected, loosen the capscrews on

the blade access cover and swing

cover open.

2. Position the blade with the key of the

mounting bolt in alignment with the key

way, and either prop up in place or

have an assistant hold in place while

the special nut is installed onto the

bolt through the blade access panel.

Torque nut to 450 ft. lbs. and install

cotter pin.

REMOVE COTTER

PIN

BLADE ACCESS

COVER

SPECIAL

NUT

BLADE

3. Repeat step #1 for the second blade.

9014

11-2-04-3

L

L

MAINTENANCE

ROTARY CUTTERS

WARNING! Avoid serious injury. Lower the rotary cutter to the ground,

set the parking brake, stop the skid-steer engine, and remove

the key before leaving the operator's seat. If unit must be left

raised for maintenance, block the unit securely to prevent

accidental release of the lifting mechanism. Disconnect the

hydraulic couplers.

REPLACING HYDRAULIC MOTOR

When replacing the hydraulic motor the unit should be setting on the ground

with the hydraulic couplers disconnected.

NOTE: Field replacement of the internal motor seals voids warranty.

1. With unit setting on the ground and hydraulic couplers disconnected, tag and

disconnect the hydraulic hoses and ttings from the hydraulic motor. Note

the hose routing for re-installation.

2. Loosen the four sockethead capscrews on the coupler and slide the motor

out of the coupler.

3. Remove the capscrews holding the motor to the motor mounting plate(s),

and remove the motor.

4. Install the new motor onto the mounting plate(s) using the existing hardware.

5. Slide the motor with the mounting plate(s) into the coupler and retighten the

sockethead capscrews. Torque all hardware to specication. See Section O.

6. Re-connect the hydraulic hoses and ttings to the new motor.

STANDARD FLOW

CUTTER SHOWN

BLADE ROTATION

INDICATOR

SOCKET HEAD

CAPSCREWS

HYDRAULIC

MOTOR

TAG HYDRAULIC

HOSES

COUPLER

MOTOR MOUNTING

PLATE

.50" UNC X 1.75" CAPSCREW

.50" LOCK WASHER

.50" UNC HEX NUT

9015 10-11-06-3

L

MAINTENANCE

ROTARY CUTTERS

WARNING! Avoid serious injury. Lower the rotary cutter to the ground, set

the parking brake, stop the skid-steer engine and remove the

key before leaving the operator's seat. If unit must be left

raised for maintenance, block the unit securely to prevent

accidental release of the lifting mechanism. Disconnect the

hydraulic couplers.

REPLACING GEARBOX/MOTOR COUPLER

When replacing the coupler the unit should be setting on the ground with

the hydraulic couplers disconnected.

1. With unit setting on the ground and hydraulic couplers disconnected,

loosen the four sockethead capscrews on the coupler and remove the

motor with the motor mounting plate still installed.

2. Remove the roll pin holding the

coupler to the gearbox, and the three

capscrews holding the blade rotation

indicator to coupler.

ROLL

.25" UNC X .50"

CAPSCREWS

PIN

COUPLER

HYDRAULIC

MOTOR

L

3. Replace the coupler on the gearbox

shaft, and reinstall the roll pin and the

blade rotation indicator using the

existing hardware.

4. Reinstall the motor into the coupler,

and retighten the sockethead cap-

screws. Torque to specification.

See Section O.

GEARBOX

BLADE

ROTATION

INDICATOR

SOCKETHEAD

CAPSCREWS

WARNING! Avoid serious injury. Lower the rotary cutter to the ground, set the

parking brake, stop the skid-steer engine, and remove the key

before leaving the operator's seat. If unit must be left raised for

maintenance, block the unit securely to prevent accidental release

of the lifting mechanism. Disconnect the hydraulic couplers.

REPLACING GEARBOX

When replacing the gearbox, the unit must be blocked securely off the ground

to gain access to the castle nut holding the stump jumper to the lower end of the

gearbox.

1. With unit securely blocked off the ground and hydraulic couplers discon-

nected, remove the cotter pin and castle nut holding the stump jumper to

the lower end of the gearbox. NOTE: Be prepared for the weight of the

stump jumper with the blades attached to fall when the castle nut is

removed.

9016

11-3-04-2

L

L

MAINTENANCE

ROTARY CUTTERS

2. Remove the roll pin holding the coupler to the gearbox and the three cap-

screws holding the blade rotation indicator to coupler.

3. Loosen the four socket head capscrews on the coupler and slide the cou-

pler along with the motor assembly off of the gearbox drive shaft.

4. Remove the four capscrews securing the gearbox to the rotary cutter

deck, and lift the gearbox off the cutter.

5. Install the new gearbox with the existing hardware removed in Step #4.

6. Position the stump jumper onto the lower end of the gearbox and reinstall

the castle nut. Torque nut to 230 ft. lbs. Continue to tighten until the next

nut castellation aligns with cross pin hole in the output shaft. Final torque

range must be between 240 - 250 lt. lbs. Reinstall cotter pin.

7. Install the blade rotation indicator onto the gearbox followed by the cou-

pler/motor assembly.

8. Reinstall the .25" capscrews securing the blade rotation indicator to the

coupler, reinstall the roll pin, and tighten the four sockethead capscrews

specication. See Section O.

9. Check lubrication level in the gearbox and add as needed. See Section H.

STANDARD FLOW

CUTTER SHOWN

GEARBOX

BLADE

ROTATION

INDICATOR

ROLL

PIN

REMOVE COUPLER AND

MOTOR ASSEMBLY

TOGETHER

SOCKETHEAD

CAPSCREWS

.25" UNC X .50" CAPSCREWS

.25" LOCK WASHERS

9017 10-11-06-4

M

M

STORAGE

ROTARY CUTTER

GENERAL INFORMATION

The following storage procedure will help you to keep your rotary cutter in

top condition. It will also help you get off to a good start the next time your cutter

is needed. We therefore strongly recommend that you take the extra time to

follow these procedures whenever your unit will not be used for an extended

period of time.

PREPARATION FOR STORAGE

1. Clean the unit thoroughly, removing all mud, dirt, and grease.

2. Sharpen or replace blades. Replace all blades at the same time and do

not try to weld or straighten damaged blades; loss of integrity may result.

3. Inspect for visible signs of wear, breakage, or damage. Order any parts

required, and make the necessary repairs to avoid delays when starting next

season. NOTE: Purchase only approved replacement parts from your

authorized BRADCO dealer.

4. Tighten all loose nuts, capscrews, and hydraulic connections.

5. Check the gear box for proper lubricant level.

6. Connect the hydraulic couplers together to protect the hydraulic system

from contaminates.

7. Touch up all unpainted and exposed areas with paint, to prevent rust.

8. Replace decals if damaged, or in unreadable condition.

9. Apply a rust-preventive spray to all moving parts and to the bottom of the

deck.

10. Store the unit in a dry and protected place. Leaving the unit outside will

materially shorten its life.

REMOVING FROM STORAGE

1. Remove all protective coverings.

2. Check hydraulic hoses for deterioration, and replace if necessary.

3. Check all nuts and bolts for proper tightness, especially those securing

the motor, gearbox and blades.

9010

6-4-03-2

N

N

TROUBLESHOOTING

ROTARY CUTTER

PROBLEM

Loss of Power.

POSSIBLE CAUSE

Skid-steer auxiliary valve

not engaged.

Relief valve setting

adjusted too low.

Inadequate hydraulic

flow from skid-steer.

Low oil supply.

Couplers not engaged.

Air in hydraulic lines.

Broken hose.

Obstruction in hydraulic

lines.

Loose or damaged

hydraulic connection.

Broken gearbox pin.

POSSIBLE REMEDY

Engage auxiliary valve.

Refer to skid-steer operator's

manual.

Check hydraulic flow to rotary

cutter.

Add oil.

Engage couplers.

Activate system until air is

purged from system.

Replace damaged hose.

Remove obstruction and

replace if necessary.

Tighten or replace fittings.

Replace pin.

PROBLEM

Excessive vibration.

PROBLEM

Leaking oil.

Hydraulic motor damaged or seal blown.

POSSIBLE CAUSE

Dull, broken or damaged

blades.

Bent gearbox shaft.

Stump Jumper out of

balance.

POSSIBLE CAUSE

Loose or damaged

hydraulic line.

Ruptured gearbox seal.

Bent gearbox shaft.

Loose or missing gearbox plug.

Call Bradco service department for instructions.

POSSIBLE REMEDY

Sharpen or replace.

Call Bradco service department for instructions.

Call Bradco service department for instructions.

POSSIBLE REMEDY

Tighten or replace.

Call Bradco service department for instructions.

Call Bradco service department for instructions.

Tighten or replace.

Hydraulic motor damaged or seal blown.

Call Bradco service department for instructions.

9012

11-3-04-2

O O

BOLT TORQUE

GENERAL TORQUE SPECIFICATION TABLE

Use the foll owing torques when special torques are not given. These values appl y to fasteners as

received from suppliers, dry, or when lubricated with normal engine oil. They do not apply if special

graphi ted or moly disulphi de greases or other extreme pressure lubricants are used. T his appli es to both

UNF and UNC threads. Remember to always use grade fi ve or better when replacing bolts.

SAE Grade No. 2 5 8*

Bolt head identification

marks as per grade.

NOTE: Manufactur ing

Marks Will Vary

Inches Millimeters Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.

5/16 7.94 10 12 13.6 16.3 17 20.5 23.1 27.8 24 29 32.5 39.3

7/16 11.11 30 25 40.7 47.4 54 64 73.2 86.8 70 84 94.9 113.9

9/16 14.29 65 75 88.1 101.6 110 132 149.2 179.0 160 192 217.0 260.4

1-1/8 25.58 - - - - 800 880 1084.8 1193.3 1280 1440 1735.7 1952.6

1-1/4 31.75 - - - - 1120 1240 1518.7 1681.4 1820 2000 2467.9 2712.0

1-3/8 34.93 - - - - 1460 1680 1979.8 2278.1 2380 2720 3227.3 3688.3

1-1/2 38.10 - - - - 1940 2200 2630.6 2983.2 3160 3560 4285.0 4827.4

TORQUE TORQUE TORQUE

Bolt Size

1/4 6.35 5 6 6.8 8.13 9 11 12.2 14.9 12 15 16.3 30.3

3/8 9.53 20 23 27.1 31.2 35 42 47.5 57.0 45 54 61.0 73.2

1/2 12.70 45 52 61.0 70.5 80 96 108.5 130.2 110 132 149.2 179.0

5/8 15.88 95 105 128.7 142.3 150 180 203.4 244.1 220 264 298.3 358.0

3/4 19.05 150 185 203.3 250.7 270 324 366.1 439.3 380 456 515.3 618.3

7/8 22.23 160 200 216.8 271.0 400 480 542.4 650.9 600 720 813.6 976.3

1 25.40 250 300 338.8 406.5 580 696 786.5 943.8 900 1080 1220.4 1464.5

Pounds Feet Newton-Meters Pounds Feet

METRIC BOLT TORQUE SPECIFICATIONS

Coarse Thread Fine Thread

Siz e of Screw Grade No. Ptich (mm) Pounds Fee t Ne wton-Meters Pitch (mm) Pounds Feet Newton-Me ters

5.6 3.6-5.8 4.9-7.9 - -

M6 8.8 1.0 5.8-9.4 7.9-12.7 - - -

10.9 7.2-10 9.8-13.6 - -

5.6 7.2-14 9.8-19 12-17 16.3-23

M8 8.8 1.25 17-22 23-29.8 1.0 19-27 25.7-36.6

10.9 20-26 27.1-35.2 22-31 29.8-42

5.6 20-25 27.1-33.9 20-29 27.1-39.3

M10 8.8 1.5 34-40 46.1-54.2 1.25 35-47 47.4-63.7

10.9 38-46 51.5-62.3 40-52 54.2-70.5

5.6 28-34 37.9-46.1 31-41 42-55.6

M12 8.8 1.75 51-59 69.1-79.9 1.25 56-68 75.9-92.1

10.9 57-66 77.2-89.4 62-75 84-101.6

5.6 49-56 66.4-75.9 52-64 70.5-86.7

M14 8.8 2.0 81-93 109.8-126 1.5 90-106 122-143.6

10.9 96-109 130.1-147.7 107-124 145-168

5.6 67-77 90.8-104.3 69-83 93.5-112.5

M16 8.8 2.0 116-130 157.2-176.2 1.5 120-138 162.6-187

10.9 129-145 174.8-196.5 140-158 189.7-214.1

5.6 88-100 119.2-136 100-117 136-158.5

M18 8.8 2.0 150-168 203.3-227.6 1.5 177-199 239.8-269.6

10.9 175-194 237.1-262.9 202-231 273.7-313

5.6 108-130 146.3-176.2 132-150 178.9-203.3

M20 8.8 2.5 186-205 252-277.8 1.5 206-242 279.1-327.9

10.9 213-249 288.6-337.4 246-289 333.3-391.6

BOLT TO RQUE SPECIFI CATIONS

Newton-Meters

* Thick Nuts must be used with Grade 8 bolts

Pounds Feet

Newton-Meters

6-8-95-2

3915

P

P

SPECIFICATIONS

ROTARY CUTTERS

C

A

E

D

B

SPECIFICATIONS AND DESIGN ARE SUBJECT TO CHANGE WITHOUT NOTICE AND WITHOUT LIABILITY THEREFOR.

SPECIFICATIONS

STANDARD HIGH FLOW

DESCRIPTION BC60 BC72 BC60* BC72 BC78

A. Overall Height................................22.50" ......... 22.50" ......... 22.50" .......... 22.50" ..........22.50"

B. Overall Width .................................72.00" ......... 85.00" ......... 72.00" .......... 85.00" ..........91.00"

C. Overall Length ..............................78.25" ......... 90.25" .........78.25" .......... 90.25" ..........96.00"

D. Cutting Width ................................. 60.00" ......... 72.00" .........60.00" .......... 72.00" ..........78.00"

E. Minimum Cutting Height 2.00" ........ 2.00" ............ 2.00 ............ 2.00" ............2.00" ............2.00"

(Skid Shoes on Ground)

Cutting Capacity (Max. Cutting Diameter) ....4.00" ........... 4.00" ........... 4.00" ............4.00" ............4.00"

Deck Thickness ................................. 1/4" Steel ....1/4" Steel .... 1/4" Steel .... 1/4" Steel .... 1/4" Steel

Recommended GPM ............................ 15-20...........18-22 ...........25-30 ...........32-40 .......... 32-40

Required Skid-Steer Lift Capacity ........1300# ..........1700#.......... 1300# .......... 1700# ..........1800#

Weight ..................................................1230# ..........1610#.......... 1230# .......... 1610# ..........1666#

* (SPECIFICATIONS FOR BC60 WITH SPECIAL MOTOR #106601 ONLY)

9025

11-3-04-2

Q

DECALS

DECAL PLACEMENT

GENERAL INFORMATION

The diagrams on this page show the location of the decals used on the

BRADCO Rotary Cutter. The decals are identied by their part numbers, with

reductions of the actual decals located on the following pages. Use this information to order replacements for lost or damaged decals. Be sure to read all decals

before operating the unit. They contain information you need to know for both

safety and longevity.

#40678

#40590

STANDARD

FLOW ONLY

#40151

#40676

Q

#40092

#40179

#40679

#40677

#40673

#4105

#40673

#4105

#4338

#40673

#40179

#40161

#40749

#40307

SERIAL NUMBER

TAG LOCATION

IMPORTANT: Keep all safety signs clean and legible. Replace all missing, illegible, or damaged

safety signs. When replacing parts with safety signs attached, the safety signs must also be

replaced unless otherwise noted.

REPLACING SAFETY SIGNS: Clean the area of application with nonammable solvent, then

wash the same area with soap and water. Allow the surface to fully dry. Remove the backing from

the safety sign, exposing the adhesive surface. Apply the safety sign to the position shown in the

diagram above, and smooth out any bubbles.

#40803

#40804

#40937

8905 10-11-06-4

Q

Q

DECALS

DANGER! ROTATING BLADE

PART #40673

WARNING! HIGH PRESSURE FLUID

PART #40151

SAFETY INSTRUCTIONS

PART #40677

WARNING! BEFORE LEAVING

OPERATOR'S SEAT

PART #40678

WARNING! LIFT LIMITING CHAIN

PART #40679

DANGER! GUARD MISSING

PART #40307

8906

6-4-03-2

Q

DANGER STAND CLEAR

DANGER STAND CLEAR

PART #4105

BLADE ROTATION INDICATOR

PART #40676

BC60

BC72 MODEL NUMBER

PART #40803

Q

DECALS

STAND CLEAR

STAND CLEAR

PART #40161

CAUTION! DO NOT OPERATE

PART #40590

BC72

BC60 MODEL NUMBER

PART #40804

BC78

BC78 MODEL NUMBER

PART #40937

MADE IN USA

MADE IN USA

PART #4338

ROTATION INDICATOR

PART #40749

BRADCO LOGO

PART #40092

BRADCO LOGO (VERTICAL)

PART #40179

8907 10-11-06-3

R

R

PREDELIVERY CHECKLIST

GENERAL INFORMATION

The following is a list of areas that should be inspected by the dealer prior to

delivery of the Rotary Cutter to the customer. The customer should check the list and

make sure that the dealer has completed the inspection. Completion of this checklist will help insure that the customer receives the rotary cutter in complete working

order, ready to install.

PREDELIVERY CHECKLIST - CHECK AND ADJUST AS NECESSARY

1. ______ Visually inspect the unit for bent, loose, cracked, damaged or missing

parts. Check for any other irregularities.

2. ______ Check and lubricate, if necessary. See "Lubrication" Section H.

3. ______ Check bolts for tightness. Retighten after the first four working hours,

and after every eight working hour intervals thereafter. See "Bolt

Torque", Section O.

4. ______ Check all hydraulic connections for leaks and all hoses for proper

positioning to reduce pinching, chafing and binding.

5. ______ Make sure decals are not damaged or missing and are in their cor-

rect location. See "Decals" Section Q.

6. ______ Make sure the customer has the necessary couplers to attach the unit

to the skid-steer auxiliary hydraulic couplers.

7. ______ Complete and return the manufacturer's "Warranty Validation Form"

and sign your dealership predelivery checklist.

9018

11-3-04-2

THIS PAGE

IS INTENTIONALLY

BLANK

Limited Warranty

Except for the Excluded Products as described below, all new products are warranted to be free from defects

in material and/or workmanship during the Warranty Period, in accordance with and subject to the terms and

conditions of this Limited Warranty.

1. Excluded Products. The following products are excluded from this Limited Warranty:

(a) Any cable, part that engages with the ground (i.e. sprockets), digging chain, bearing, teeth, tamping

and/or demolition head, blade cutting edge, pilot bit, auger teeth and broom brush that either constitutes or is part

of a product.

(b) Any product, merchandise or component that, in the opinion of Paladin Light Construction1, has been

(i) misused; (ii) modied in any unauthorized manner; (iii) altered; (iv) damaged; (v) involved in an accident; or (vi)

repaired using parts not obtained through Paladin Light Construction.

2. Warranty Period. The Limited Warranty is provided only to those defects that occur during the Warranty

Period, which is the period that begins on the rst to occur of: (i) the date of initial purchase by an end-user, (ii) the

date the product is rst leased or rented, or (iii) the date that is six (6) months after the date of shipment by Paladin

Light Construction as evidenced by the invoiced shipment date (the “Commencement Date”) and ends on the date

that is twelve (12) months after the Commencement Date.

3. Terms and Conditions of Limited Warranty. The following terms and conditions apply to the Limited Warranty

hereby provided:

(a) Option to Repair or Replace. Paladin Light Construction shall have the option to repair or replace

the product.

(b) Timely Repair and Notice. In order to obtain the Limited Warranty, (i) the product must be repaired

within thirty (30) days from the date of failure, and (ii) a claim under the warranty must be submitted to Paladin Light

Construction in writing within thirty (30) days from the date of repair.

(c) Return of Defective Part or Product. If requested by Paladin Light Construction, the alleged

defective part or product shall be shipped to Paladin Light Construction at its manufacturing facility or other location

specied by Paladin Light Construction, with freight PRE-PAID by the claimant, to allow Paladin Light Construction

to inspect the part or product.

Claims that fail to comply with any of the above terms and conditions shall be denied.

LIMITATIONS AND EXCLUSIONS.

THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

WITHOUT LIMITATION THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE

AND ANY WARRANTY BASED ON A COURSE OF DEALING OR USAGE OF TRADE.

IN NO EVENT SHALL PALADIN LIGHT CONSTRUCTION BE LIABLE FOR CONSEQUENTIAL OR SPECIAL

DAMAGES.

IN NO EVENT SHALL PALADIN LIGHT CONSTRUCTION BE LIABLE FOR ANY LOSS OR CLAIM IN AN

AMOUNT IN EXCESS OF THE PURCHASE PRICE, OR, AT THE OPTION OF PALADIN LIGHT CONSTRUCTION,

THE REPAIR OR REPLACEMENT, OF THE PARTICULAR PRODUCT ON WHICH ANY CLAIM OF LOSS OR

DAMAGE IS BASED. THIS LIMITATION OF LIABILITY APPLIES IRRESPECTIVE OF WHETHER THE CLAIM

IS BASED ON BREACH OF CONTRACT, BREACH OF WARRANTY, NEGLIGENCE OR OTHER CAUSE AND

WHETHER THE ALLEGED DEFECT IS DISCOVERABLE OR LATENT.

1

Attachment Technologies Inc., a subsidiary of Paladin Brands Holding, Inc. (PBHI) is referred to herein as Paladin Light

Construction.

February 10, 2010

Loading...

Loading...