REV. 5

OM495

617 TRENCHER

ALL SKID STEER

APPLICATIONS

5759 9-8-04-5

Printed in U.S.A.

COPYRIGHT 2-92

OPERATOR'S

75395

MANUAL

BRADCO®

P.O. Box 266 · Delhi, Iowa 52223 USA

(319) 922-2981 ·(800) 922-2981

Fax 319-922-2130

TABLE OF CONTENTS

Section

TO THE OWNER............................................................................................ A

SAFETY PRECAUTIONS ................................................................................B

To The Operator

Before You Start

During Trencher Operation

Transporting The Trencher

Maintaining The Trencher

INTERNATIONAL SYMBOLS ........................................................................ C

PREOPERATION ............................................................................................ D

General Information

Options

Trencher Major Component Nomenclature

MOUNTING KIT INSTALLATION...................................................................E

Mounting Kits

Mounting Instructions

TRENCHER INSTALLATION...........................................................................F

OPERATING INSTRUCTIONS ....................................................................... G

Controls

Operating Techniques

TRENCHER ASSEMBLY ..................................................................................I

DIGGING CHAIN OPTIONS............................................................................J

MAINTENANCE ..............................................................................................L

STORAGE ......................................................................................................M

TROUBLE SHOOTING ................................................................................... N

BOLT TORQUE .............................................................................................. O

SPECIFICATIONS ...........................................................................................P

DECALS ......................................................................................................... Q

PREDELIVERY CHECK LIST.......................................................................... R

LIMITED WARRANTY ................................................................................... S

4410

2-26-92-2

A

A

TO THE OWNER

GENERAL COMMENTS

Congratulations on the purchase of your new trencher! Your trencher

was carefully designed and manufactured to give you many years of dependable service. Your trencher will require some minor maintenance (such

as cleaning and lubricating) to keep it in top working condition. Be sure to

observe all safety precautions and maintenance procedures as described in

this manual.

ABOUT THIS MANUAL

This manual has been designed to help you do a better, safer job.

Read this manual carefully and become familiar with it's contents. Remem-

ber, never let anyone operate this trencher without reading the "Safety

Precautions" and "Operating Instructions" sections of this manual. (See

Sections B and G respectively.)

Unless noted otherwise, "right-hand" and "left-hand" sides are determined from the position of the skid steer operator sitting in the seat facing

forward.

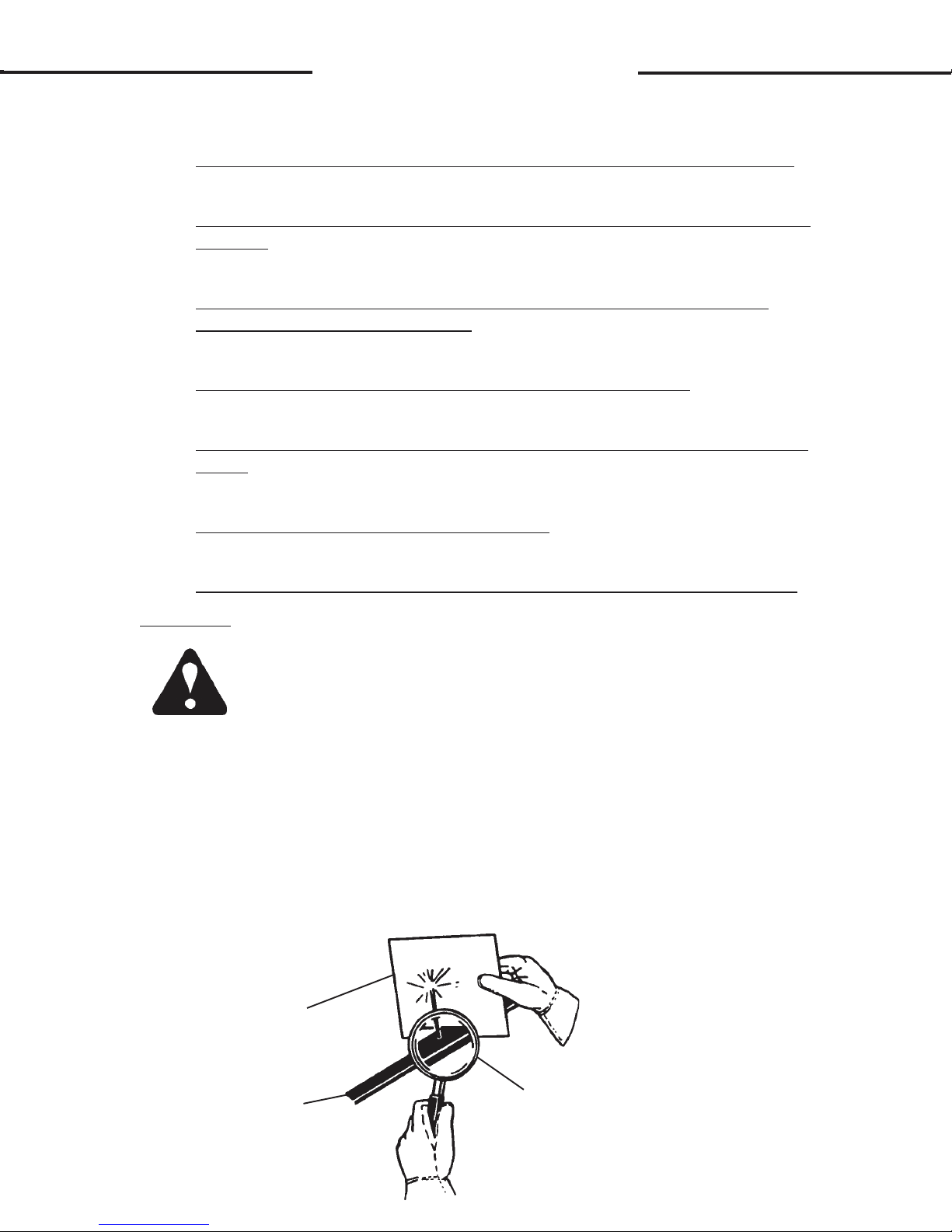

SAFETY ALERT SYMBOL

This is the "Safety Alert Symbol" used by this industry. This

symbol is used to warn of possible injury. Be sure to read all

warnings carefully. They are included for your safety and for

the safety of others working with you.

SERVICE

When servicing your trencher, remember to use only manufacturer

replacement parts. Substitute parts may not meet the standards required

for safe, dependable operation.

To facilitate parts ordering, record the model and serial number of

your trencher in the space provided on this page. This information may be

obtained from the trencher identification plate located on the right side of

the trencher main frame.

MODEL DATE PURCHASED

SERIAL NO.

MOUNTED ON

Your parts dealer needs this information to insure that you receive the correct parts for your specific trencher.

4411

2-25-92-2

B

B

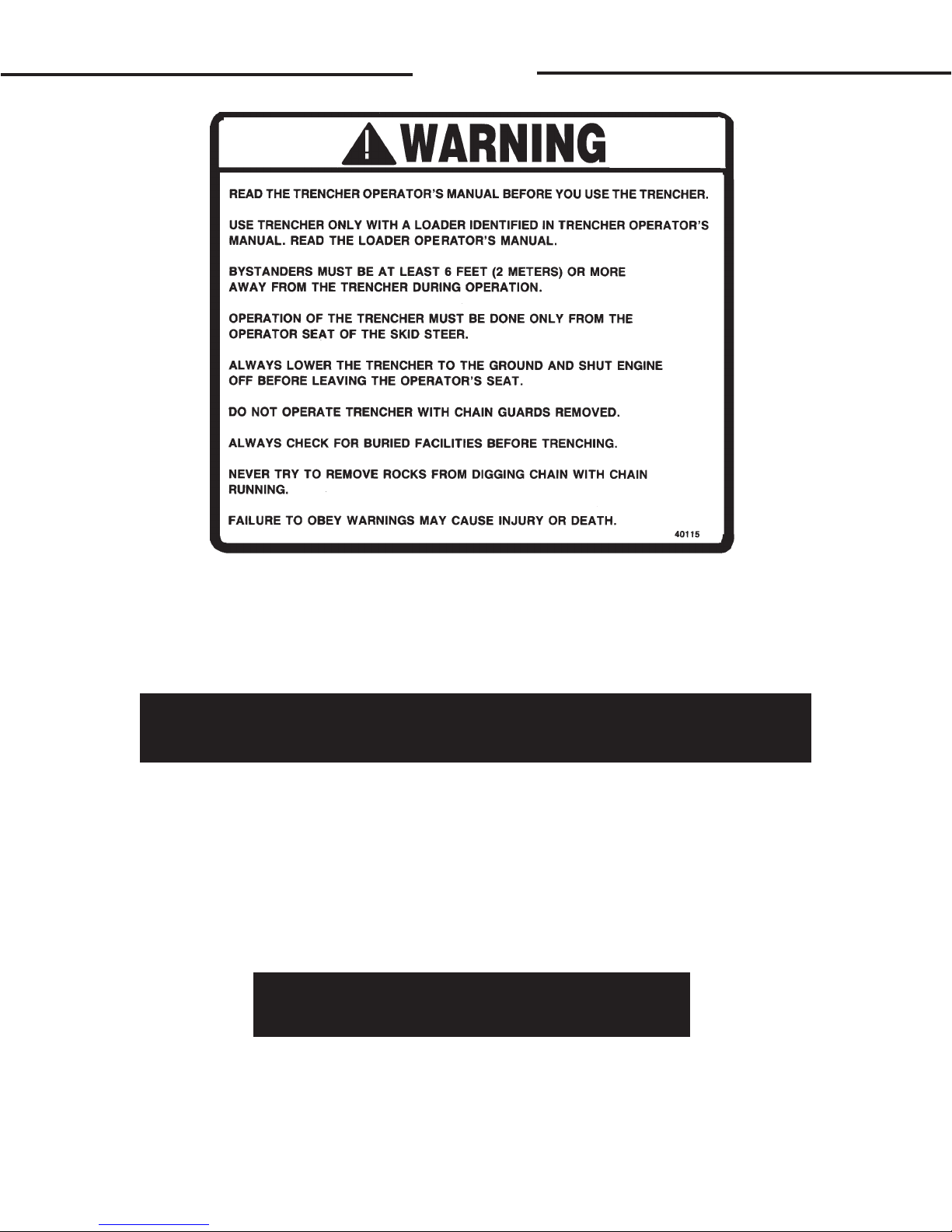

SAFETY PRECAUTIONS

TAKE NOTE! THIS SAFETY ALERT SYMBOL FOUND THROUGHOUT THIS

MANUAL IS USED TO CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING YOUR PERSONAL SAFETY OR OTHERS. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN RESULT IN INJURY OR DEATH.

THIS SYMBOL MEANS:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

SIGNAL WORDS: Note the use of signal words DANGER, WARNING, and CAU-

TION with the safety messages. The appropriate signal word for each has been

selected using the following guidelines:

DANGER: Indicates an imminently hazardous situation, which if not avoided, will

result in death or serious injury. This signal word is to be limited to the

most extreme situations, typically for machine components

which, for functional purposes, cannot be guarded.

WARNING: Indicates a potentially hazardous situation, which if not avoided, could

result in death or serious injury, and includes hazards that are

exposed when guards are removed. It may also be used to

alert against unsafe practices.

CAUTION: Indicates a potentially hazardous situation, which if not avoided, may

result in minor or moderate injury. It may also be used to alert

against unsafe practices.

6621

5-18-95

SAFETY PRECAUTIONS

TRENCHERS

GENERAL INFORMATION

This section is composed of various warnings and safety tips. Read and

learn all the information in this section before you attempt to use your tren-

cher. Also read your vehicle owner's manual before using your equipment. This

knowledge will help you operate your unit safely. Do not take this information

lightly, it is presented for your own benefit and for the benefit of others

working around you.

The "Safety Alert Symbol" , as previously described, will be used throughout

this manual. It will appear with one of the words

TION above it, and a safety message pertaining to the specific topic being covered.

Take the time to read these messages as you come across them.

TO THE OPERATOR

DANGER, WARNING, or CAU-

BB

The primary responsibility for safety with the equipment falls to the

operator. It is the skill, care, common sense, and good judgment of the

operator that will determine how efficiently and safely the job is performed.

Know your equipment before you start. Know its capabilities, dimensions,

and how to operate all the controls. Visually inspect your equipment before

you start, and never operate equipment that is not in proper working order

with all safety devices intact.

BEFORE YOU START

1.

2.

3.

Wear the right clothing and gear for the job. Protective equipment

such as hard hat, steel toed shoes, leather gloves, or safety glasses

may be in order. They can protect you from needless injury.

Do not wear loose clothing, or things such as rings and watches

around the equipment. They could get caught in moving parts, and

lead to serious injury or death.

Know your equipment inside and out. Know how to operate all con-

trols, and know emergency shutdown procedures. Make sure all

safety devices are in place and working.

4.

Keep all step plates, grab bars, pedals, and controls free of dirt,

grease, and oil. Keep equipment clean to help avoid injury from a fall

when getting on or off equipment.

4213

4-14-05-3

SAFETY PRECAUTIONS

TRENCHERS

BB

5.

6. Know your work area before you begin. Observe any potential hazard

7.

8.

9.

10. Always use your seatbelt and safety ROPS (Roll-Over-Protective

Do not use the trencher or crumber bar as a step, or grab the digging

chain when climbing on or off the trencher. Damage to the equip-

ment or personal injury could result.

areas such as soft ground, drop-offs, rocks and other obstacles.

Know where all utility lines are. Observe overhead electrical and

phone lines. Be sure equipment will safely clear them. Know the

location of underground cables, wires, gas and water lines, tanks,

etc. Contact with electrical lines could cause electrocution. Hitting a

gas line or underground tank could cause an explosion.

Be alert to others in the work area. Be sure others know when and

where you will be working. Make sure no one is underneath or behind

equipment.

Never try to board equipment while it's moving.

Structure) that are on the equipment. They could save your life in the

event of a mishap.

11.

12. Test all controls before you start. This includes safety equipment and

DURING TRENCHER OPERATION

1.

2.

3.

4.

Never take passengers on your equiment. There is no safe place for

riders.

devices.

Be alert to what is going on around you. Watch for others who may

not be watching out for themselves.

Never operate equipment while under the influence of alcohol, or

prescription drugs which could inhibit physical and or mental capac-

ity.

Stop the trencher and shut off the engine if anyone approaches the

equipment while it's in motion. They may not be familiar with the

equipment and get in the way of moving parts.

Be alert to changes in the work area. Changes in weather and soil

conditions could turn a safe work site into a hazardous area.

4214

2-25-92-2

SAFETY PRECAUTIONS

TRENCHERS

5. Keep equipment away from the trencher after it has been dug. The

weight of the unit could cause a cave-in.

BB

6.

7.

8.

9.

10.

TRANSPORTING THE TRENCHER

Never drop a boom with a rapidly moving digging chain on the

ground. The force of the trencher may cause the vehicle to move

suddenly and unexpectedly. Have the chain moving slowly, and

lower the boom carefully when starting a new cut.

Use caution when digging on a slope. The natural vibration of the

trencher will make the unit creep sideways downhill. Try to dig with

the trencher in a level position.

Never try to make sharp turns while trenching. The trencher boom

could become wedged in the trench and damaged.

Never attempt to free a stuck chain with the unit running. If the

trencher does become jammed, stop the unit and visually inspect the

situation.

Check the trencher frequently for loose hardware and fittings. The

natural vibration of the unit will cause fasteners to loosen during

operation.

1.

2. Use a SMV (Slow Moving Vehicle) sign on the vehicle when trans-

3.

4.

5. Follow factory recommended shut down procedures for equipment.

6.

Follow all federal, state, and local regulations when transporting the

unit on public roads.

porting. This will help alert others to your presence.

Be sure all lights and turn signals are in working order. Use them as

required.

When parking, park the unit on hard level ground and lower the tren-

cher boom. Block the wheels, and set the parking brake. Shut off the

engine.

Stop the trencher and vehicle before dismounting.

4215

2-26-92-2

SAFETY PRECAUTIONS

MAINTAINING THE TRENCHER

BB

TRENCHERS

1.

2. Lower the trenching boom, and shut off the engine before working on

3.

4. Use only manufacturer recommended replacement parts. Other parts

5.

6. Observe proper maintenance schedules. Proper maintenance can help

7.

Replace all safety shields and guards when performing maintenance.

Do not operate the trencher with protective equipment removed.

the unit. Never perform maintenance on a trencher while it is run-

ning.

Make sure all operating and residual pressures are relieved before

working on a hydraulic system. Shut engine off, and operate all the

controls to relieve any pressure.

may be substandard in fit and quality.

Do not set any relief valve higher than recommended by the manufac-

turer. Relief valves should be checked and adjusted only by a trained

service technician. Do not remove or block a relief valve.

prevent a hazardous condition.

Always wear safety goggles or glasses when working on equipment.

WARNING! Escaping fluid under pressure can have sufficient force to pen-

etrate the skin, causing serious personal injury. Fluid escaping

from a very small hole can be almost invisible. Use a piece of

cardboard or wood, rather than hands to search for suspected

leaks.

Keep unprotected body parts, such as face, eyes, and arms as

far away as possible from a suspected leak. Flesh injected

with hydraulic fluid may develop gangrene or other permanent

disabilities.

If injured by injected fluid, see a doctor at once. If your doctor

is not familiar with this type of injury, ask him to research it

immediately to determine proper treatment.

CARDBOARD

HYDRAULIC HOSE

OR FITTING

MAGNIFYING GLASS

4216

2-26-92-2

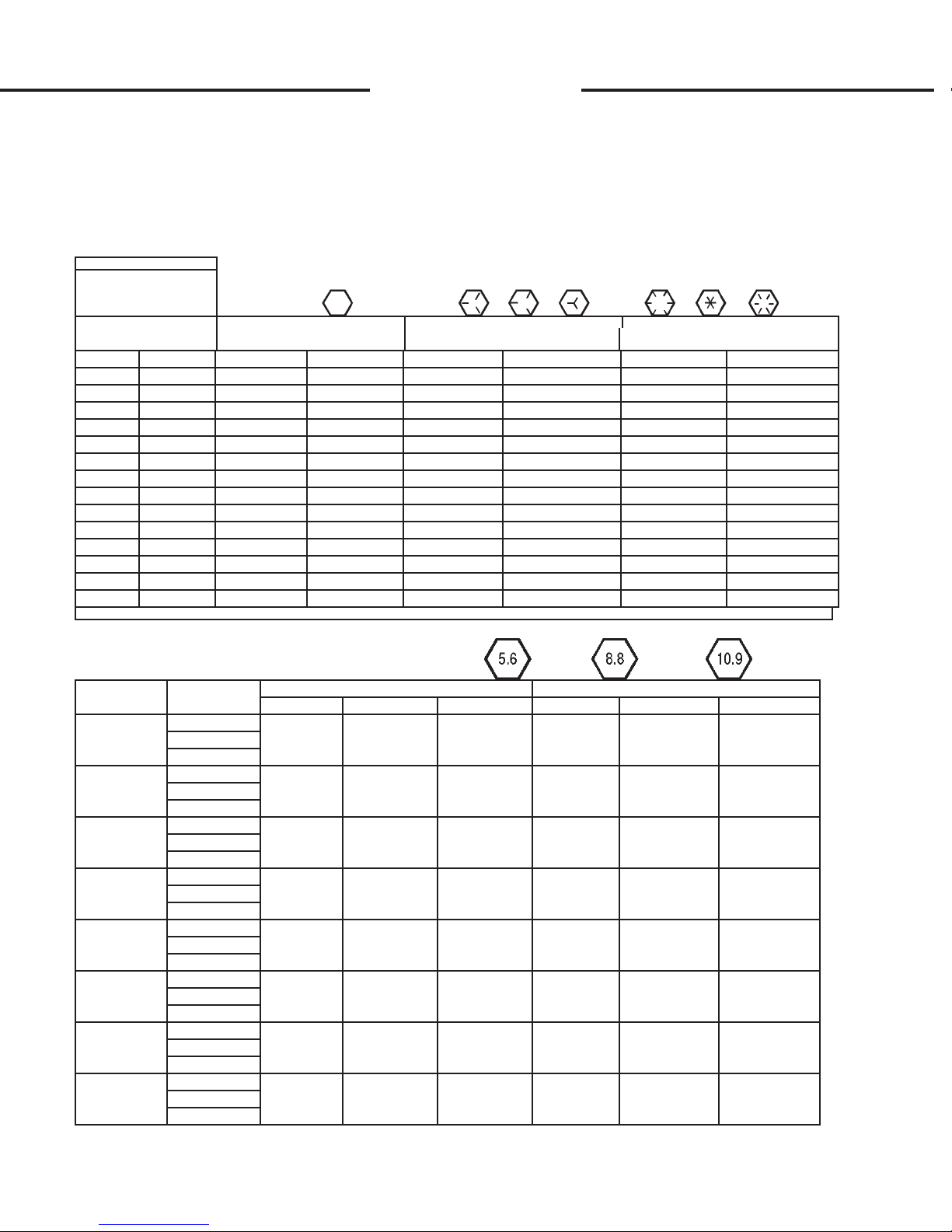

CC

INTERNATIONAL SYMBOLS

As a guide to the operation of your equipment, various international

symbols have been utilized on the instruments and controls. The symbols

are shown below with an indication of their meaning.

Engine speed Alternato r char g e

Hours recorded Power take-off (on)

Engine water temperature Power take-off (off)

Lights "Tortoise," slow or minimum setting

Horn "Hare," fast or maximum setting

Engine oil pressure Caution

Hazard warning Control lever operating direction

Axle connect Rock shaft (raised)

Axle disconnect Rock shaft (lowered)

Continuously variable Remote cylinder (extended)

Increase Remote cylinder (retracted)

Decrease Remote cylinder (FLOAT)

Diesel fuel Differential lock

Creeper range Read operators manual

High range Neutral

Low range Forward

Reverse

3869

4-14-94-2

DD

PREOPERATION

617 TRENCHER

GENERAL INFORMATION

The 617 trencher was designed to be easy to use and maintain. The

trencher mounts to the toolbar/attachment plate of the skid steer. The

mount incorporates the quick attach mechanism of the skid steer for fast,

easy mounting.

The trencher is powered by the skid steer's auxiliary hydraulic system. Your skid steer

trencher. If your unit does not have an auxiliary hydraulic system, contact

your skid steer dealer reguarding the possible addition of such a system.

An adapter is needed to attach the trencher to the skid steer. Most

trenchers are shipped with the adapter already mounted to the trencher. If

yours was not shipped this way, see Section E for mounting kit installation.

To install the trencher on the skid steer see Section F. Operating instructions are covered in Section G.

MUST have an auxiliary hydraulic system to run the

Use the chart below to determine which trencher assembly is needed

for your specific skid steer. A diagram and parts list of all mounting and

hydraulic kits can be found in Section E and the trencher assembly can be

found in Section I.

FIT-UP CHART

COMPLETE MOUNTING &

SKID STEER TRENCHER ASSEMBLY HYDRAULIC

(Including Mtg. & Hyd. Kit) KIT ONLY

ASV Posi-Track 4500/4520 79090 79093

Bobcat 700/800/2000 79090 79093

Case 1835C/1840/1845C 79090 79093

Case 75XT/85XT/90XT/95XT 79090 79093

Case 1845B 79092 79105

Daewoo 601/801 79090 79093

Ford NH 775/778/779/784/785 79094 79106

Ford NH 553/555 79095 79108

Ford NH 465/485/565/665/865/885/985 79090 79093

Gehl 4510/4610/4515/4615 79310 79314

Gehl 4625/5625 79309 79311

Gehl 5635/6635 79090 79093

Hydra Mac 1700/2250/2650 (Universal Hitch) 79090 79093

JCB 165 79090 79093

JCB 185/1105 85494 85493

John Deere 675 79095 79108

John Deere 875 79094 79106

John Deere 4475/6675/7775/8875 79090 79093

5760

11-16-98-3

D

D

PREOPERATION

617 TRENCHER

COMPLETE MOUNTING &

SKID STEER TRENCHER ASSEMBLY HYDRAULIC

(Including Mtg. & Hyd. Kit) KIT ONLY

Mustang 342/442/552/930/940/960 79096 79110

Mustang 2040/2050/2060/2070 Single Pin 79096 79110

Mustang 2040/2050/2060/2070 Dual Pin 79090 79093

Prime Mover L1300 79238 79240

Takeuchi TL26 79090 79093

Thomas T133 79097 79111

Thomas T173/T233 79098 79112

Thomas T173S IIQA/T243S IIQA/T245 79090 79093

Toyota 2SDK6/2SDK7/2SDK8 80268 80871

Trak 1050/1350 79097 79111

Trak 1650/2150 79098 79112

Trak 1300HD/1700HD/1300C/1700C 79090 79093

Trak 1500C/1800C/2300C 79090 79093

OPTIONS

Eventually you may wish to dig a trench of a depth or width other

than what your unit was originally equipped to dig. The 617 trencher can

be fitted with optional booms, digging chains, sprockets, and crumber assemblies to allow you to dig a variety of different sized trenches with a

digging chain option of a tooth every station or every other station. The

chart below will give you an idea of the different trench depths and widths a

properly equipped unit is capable of digging. For more detailed information

on trencher options see Sections I & J of this manual.

TRENCH DEPTHS* TRENCH WIDTHS

30" Depth 6.00" 8.00" 10.00" 12.00"

36" Depth 6.00" 8.00" 10.00" NA

42" Depth 6.00" 8.00" 10.00" NA

48" Depth 6.00" 8.00" NA NA

*Trench depths are given with the digging boom at an optimum 65°

diggging angle and the skid shoe touching the ground. Trenches of

various depths can be made by varying the digging angle and raising

the trencher up higher. These methods are less efficient however.

NOTE: The illustrations and data used in this manual were current

(according to the information available to us) at the time of

printing, however, we reserve the right to redesign and change the

trenchers as may be necessary without notification.

5761

11-16-98-3

D

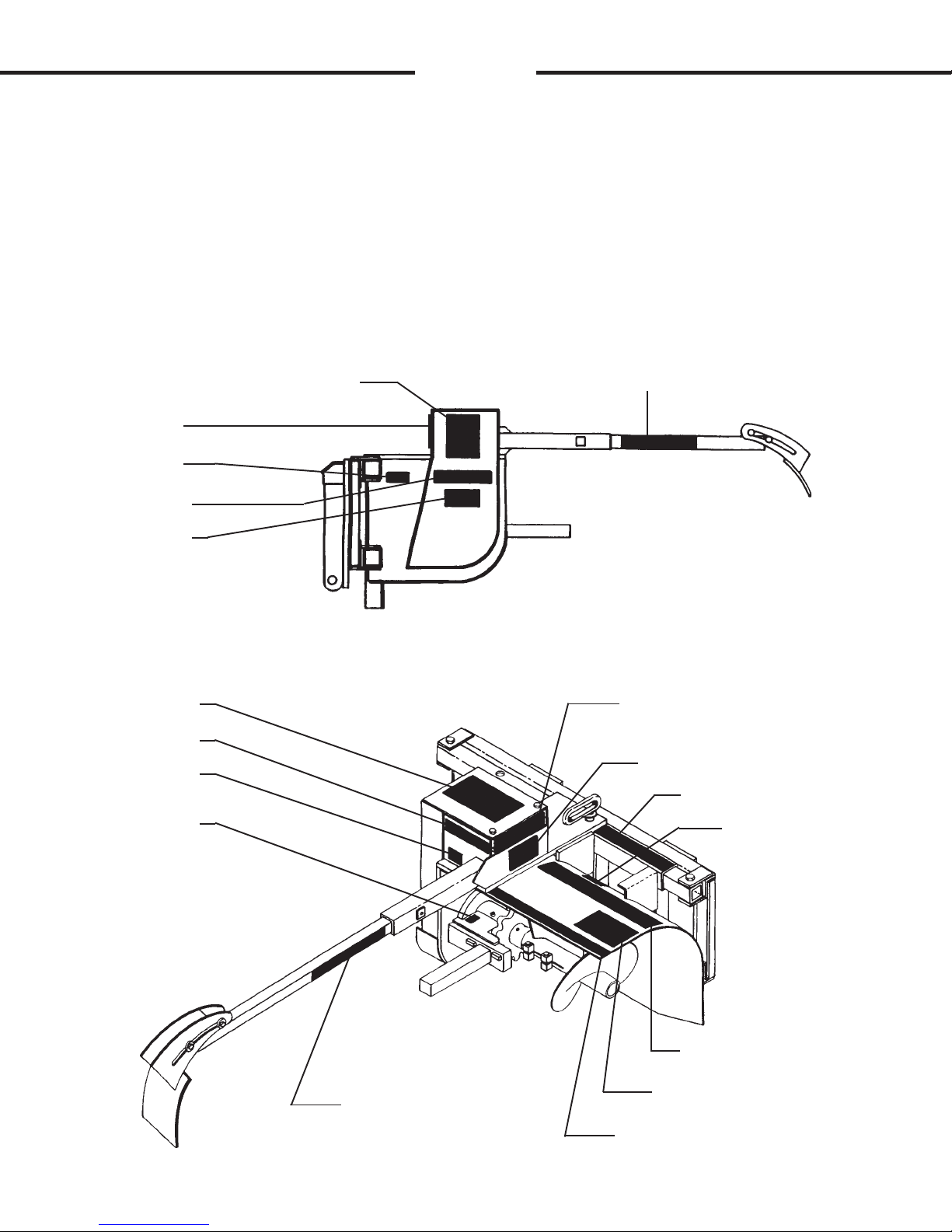

PREOPERATION

TRENCHER MAJOR COMPONENT NOMENCLATURE

617 TRENCHER

GENERAL INFORMATION

The purpose of this page is to acquaint you with the trencher and the

names of its various components. This knowledge will be helpful when

reading through this manual or when ordering service parts.

HYDRAULIC MOTOR

SIDE SHIFT

CHAIN GUARD

CRUMBER BOOM

ADJUSTMENT

LOCKING PIN

SIDE SHIFT

MOUNTING

FRAME

D

BUILT-IN SKID

SHOE

CRUMBER BOOM

CRUMBER END

CRUMBER

SHOE

HEADSHAFT

AUGER

TOOTH

CHAIN TENSION

ADJUSTMENT

DIGGING CHAIN

DIGGING BOOM

5762

2-7-92

E

E

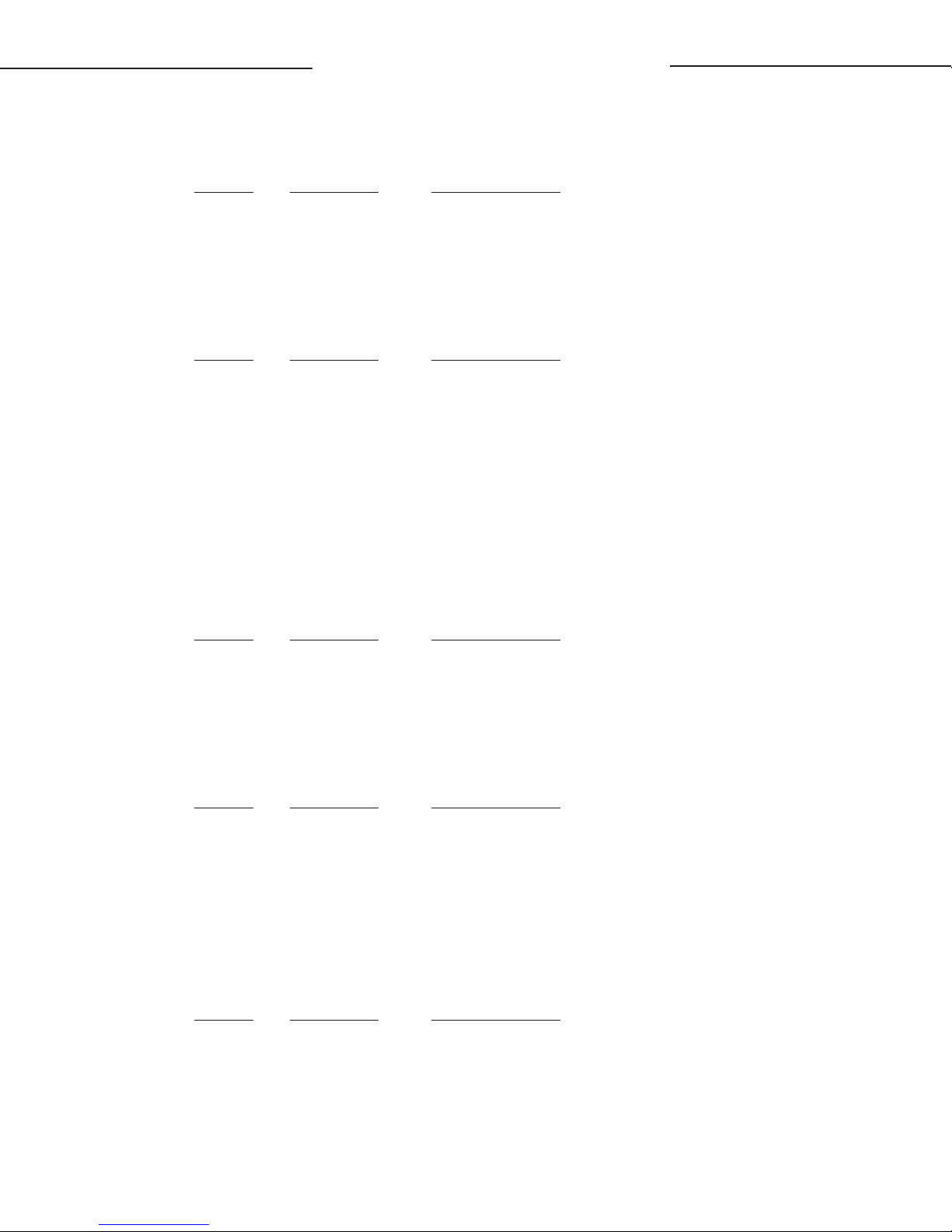

MOUNTING KIT INSTALLATION

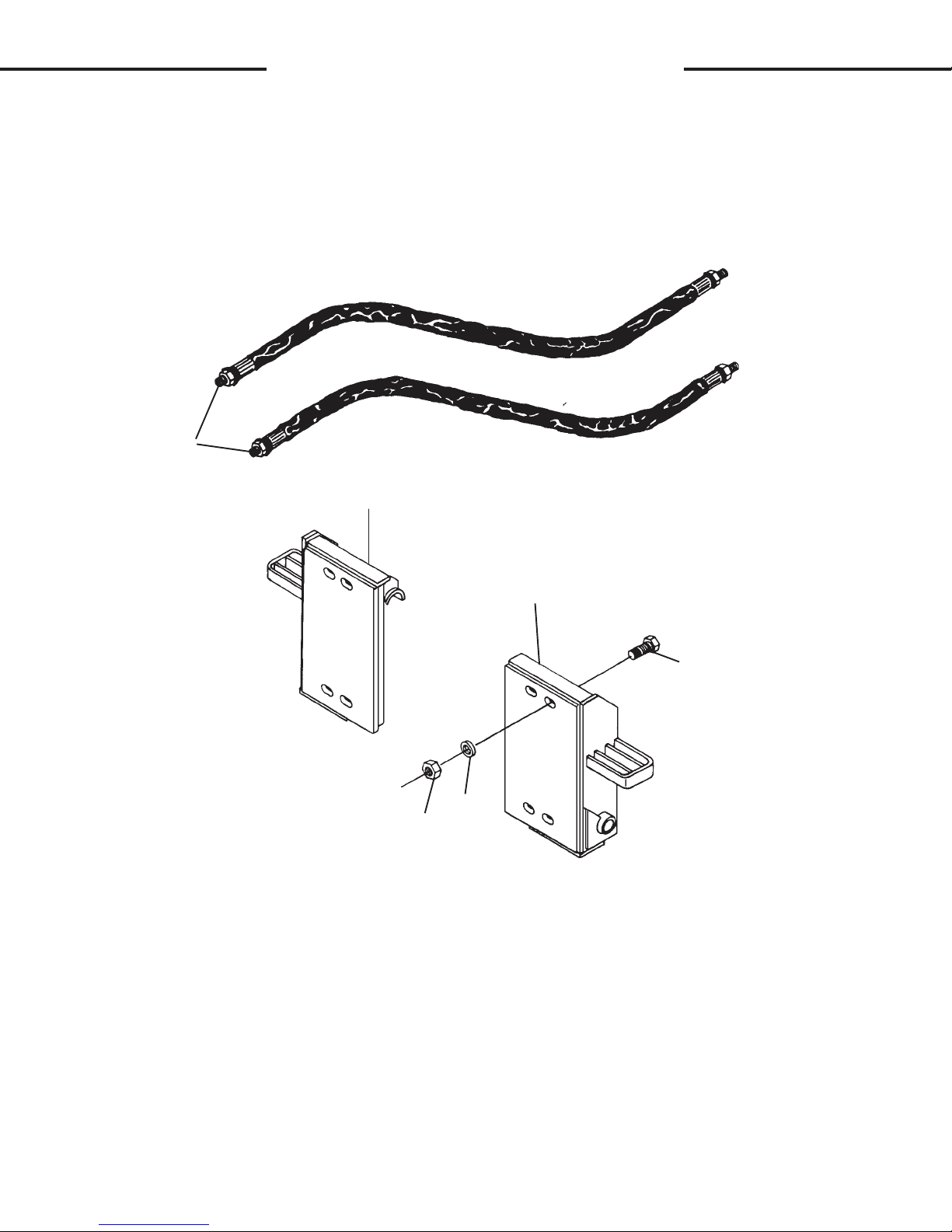

TRENCHER MOUNTING KIT #79093

1

2

3

4

5

6

5763

6-13-94-2

E

E

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79093

NO REQ'D PART NO. DESCRIPTION

1 2 35792 Hose Assembly, .62" x 82"

(SAE 100R2-2Wire) 8MP-10MB-HS

2 1 78259 Right Trencher Mount

3 1 78260 Left Trencher Mount

4 8 1140 .75" UNC x 2.25" Hex Capscrew

5 8 1649 .75" Hard Flat Washer

6 8 1231 .75" UNC Hex Nut

5764

6-13-94-2

E

E

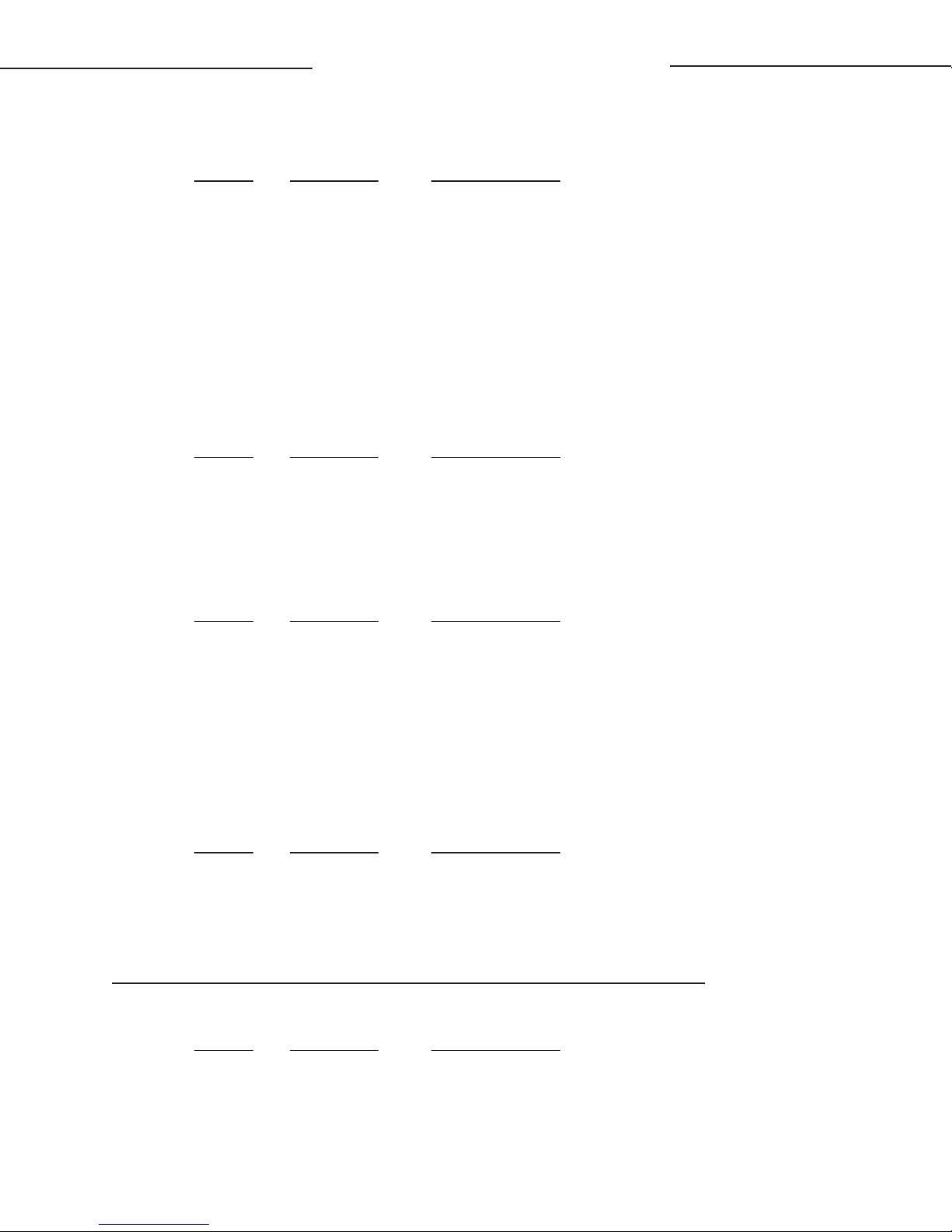

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79105

1

8

9

2

3

4

2

5

6

7

5765

2-13-92

E

E

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79105

NO REQ'D PART NO. DESCRIPTION

1 2 35792 Hose Assembly, .62" x 82"

(SAE 100R2-2Wire) 8MP-10MB-HS

2 2 59065 Pin

3 1 68935 Trencher Attaching Bracket

4 8 1089 .50" UNC x 1.25" Hex Capscrew

5 8 1516 .50" Flat Washer

6 8 1505 .50" Lock Washer

7 8 1228 .50" UNC Hex Nut

8 8 1649 .75" Hard Flat Washer

9 8 1137 .75" UNC x 1.50" Hex Capscrew

5766

2-13-92

E

E

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79106

1

2

3

4

5

5767

2-13-92

E

E

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79106

NO REQ'D PART NO. DESCRIPTION

1 2 37449 Hose Assembly, .62" x 112"

(SAE 100R2-2Wire) 12MP-10MB-HS

2 1 78046 Trencher Attaching Bracket

3 8 1866 .75" UNC x 2.25" Socket Head Capscrew

4 8 1649 .75" Hard Flat Washer

5 8 1231 .75" UNC Hex Nut

5768

6-10-94-3

E

E

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79108

1

2

3

4

5

5769

2-13-92

E

E

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79108

NO REQ'D PART NO. DESCRIPTION

1 2 37366 Hose Assembly, .50" x 112"

(SAE 100R2-2Wire) 8MP-10MB-HS

2 1 78046 Trencher Attaching Bracket

3 8 1866 .75" UNC x 2.25" Socket Head Capscrew

4 8 1649 .75" Hard Flat Washer

5 8 1231 .75" UNC Hex Nut

5770

6-10-94-2

E

E

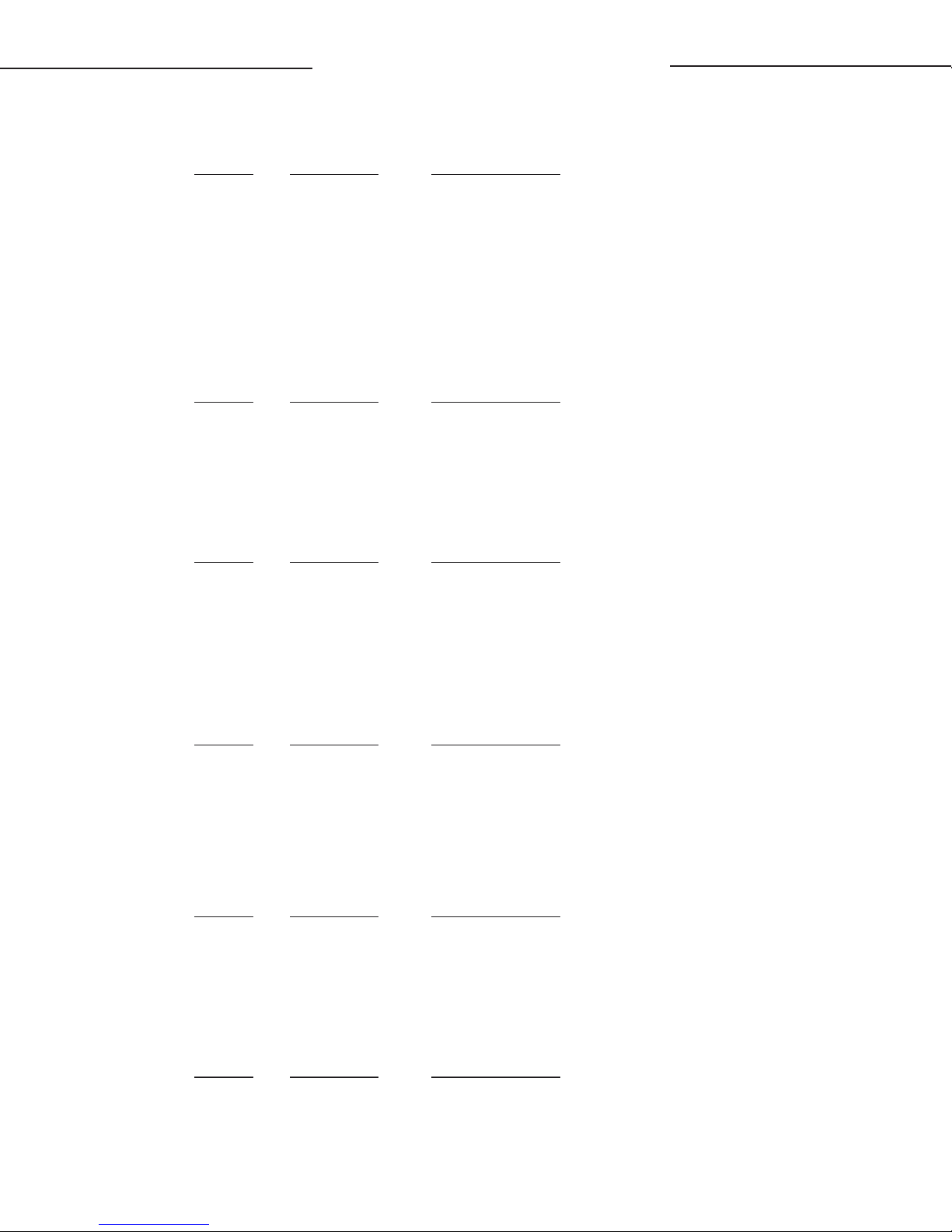

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79110

1

2

3

5

4

5771

2-13-92

E

E

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79110

NO REQ'D PART NO. DESCRIPTION

1 2 35792 Hose Assembly, .62" x 82"

(SAE 100R2-2Wire) 8MP-10MB-HS

2 1 78232 Trencher Attaching Bracket

3 8 1140 .75" UNC x 2.25" Hex Capscrew

4 8 1649 .75" Hard Flat Washer

5 8 1231 .75" UNC Hex Nut

5772

2-13-92

E

E

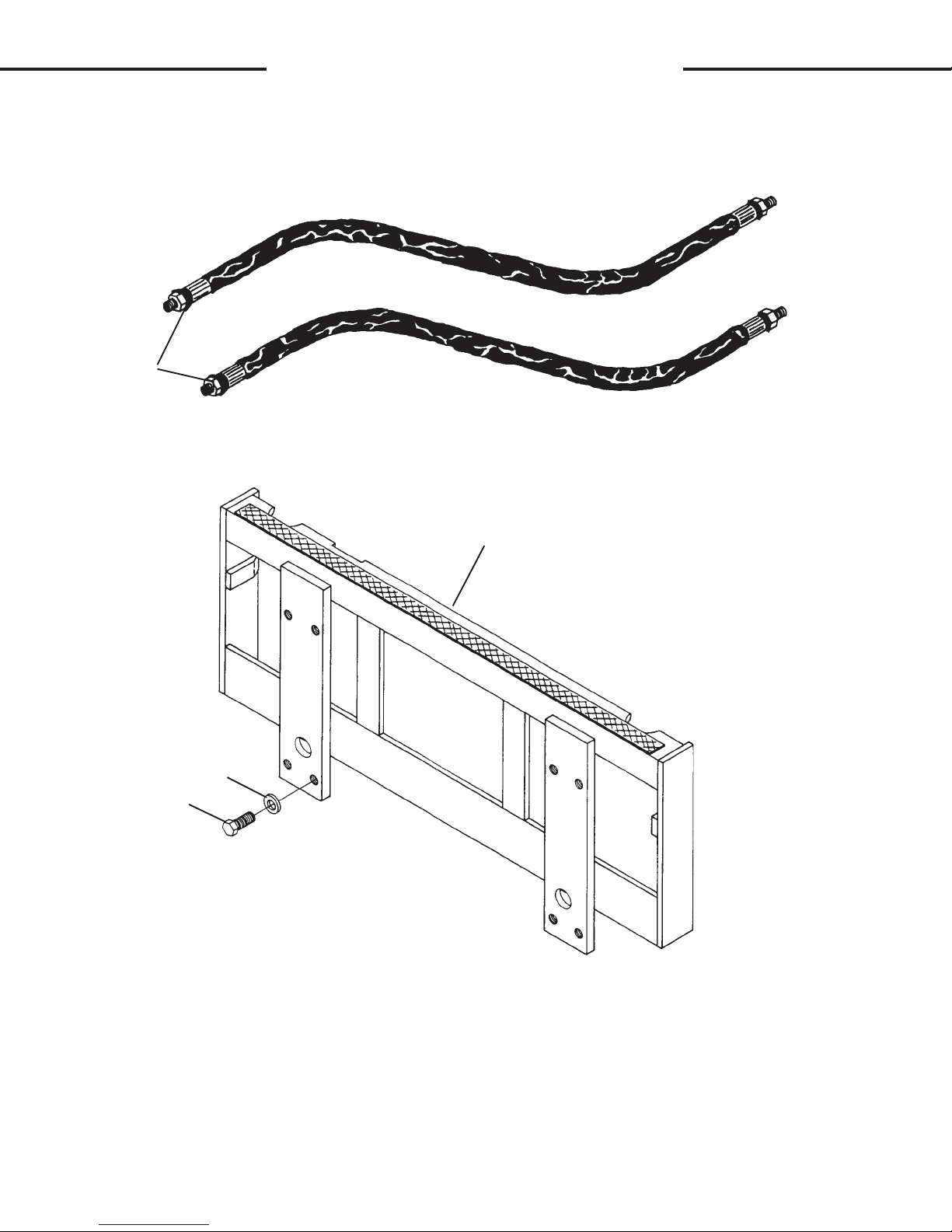

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79111

1

2

3

4

5

6

5773

6-10-94-2

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79111

NO REQ'D PART NO. DESCRIPTION

1 2 35792 Hose Assembly, .62" x 82"

(SAE 100R2-2Wire) 8MP-10MB-HS

2 1 78247 Right Trencher Mount

3 1 78248 Left Trencher Mount

4 8 1140 .75" UNC x 2.25" Hex Capscrew

5 8 1649 .75" Hard Flat Washer

6 8 1231 .75" UNC Hex Nut

EE

5774

6-10-94-2

EE

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79112

1

2

3

5

6

4

5775

6-13-94-2

E

E

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79112

NO REQ'D PART NO. DESCRIPTION

1 2 37367 Hose Assembly, .62" x 97"

(SAE 100R2-2Wire) 8MP-10MB-HS

2 1 78252 Right Trencher Mount

3 1 78253 Left Trencher Mount

4 8 1140 .75" UNC x 2.25" Hex Capscrew

5 8 1649 .75" Hard Flat Washer

6 8 1231 .75" UNC Hex Nut

5776

6-13-94-2

E

E

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79240

1

2

4

3

5850

4-7-92

E

E

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79240

NO REQ'D PART NO. DESCRIPTION

1 2 35792 Hose Assembly .62" x 82"

(SAE 100R2-2Wire) 8MP-10MB-HS

2 1 69701 Trencher Attaching Bracket

3 8 1137 .75" UNC X 1.50" Hex Capscrew

4 8 1649 .75" Hard Flat Washer

5851

4-7-92

EE

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79311

1

2

3

4

5

6

5852

6-13-94-2

E

E

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79311

NO REQ'D PART NO. DESCRIPTION

1 2 35792 Hose Assembly .62" x 82"

(SAE 100R2-2Wire) 8MP-10MB-HS

2 1 67050 Right Trencher Mount

3 1 67049 Left Trencher Mount

4 8 1140 .75" UNC X 2.25" Hex Capscrew

5 8 1649 .75" Hard Flat Washer

6 8 1231 .75" Hex Nut

5853

6-13-94-2

E

E

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79314

1

2

3

4

5

5854

4-7-92

E

E

MOUNTING KIT INSTALLATION

TRENCHER MOUNTING KIT #79314

NO REQ'D PART NO. DESCRIPTION

1 2 35792 Hose Assembly .62" x 82"

(SAE 100R2-2Wire) 8MP-10MB-HS

2 1 78226 Trencher Attaching Bracket

3 8 1866 .75" UNC X 2.25" Socket Head Capscrew

4 8 1649 .75" Hard Flat Washer

5 8 1231 .75" Hex Nut

5855

6-13-94-2

E

E

MOUNTING KIT INSTALLATION

617 TRENCHER

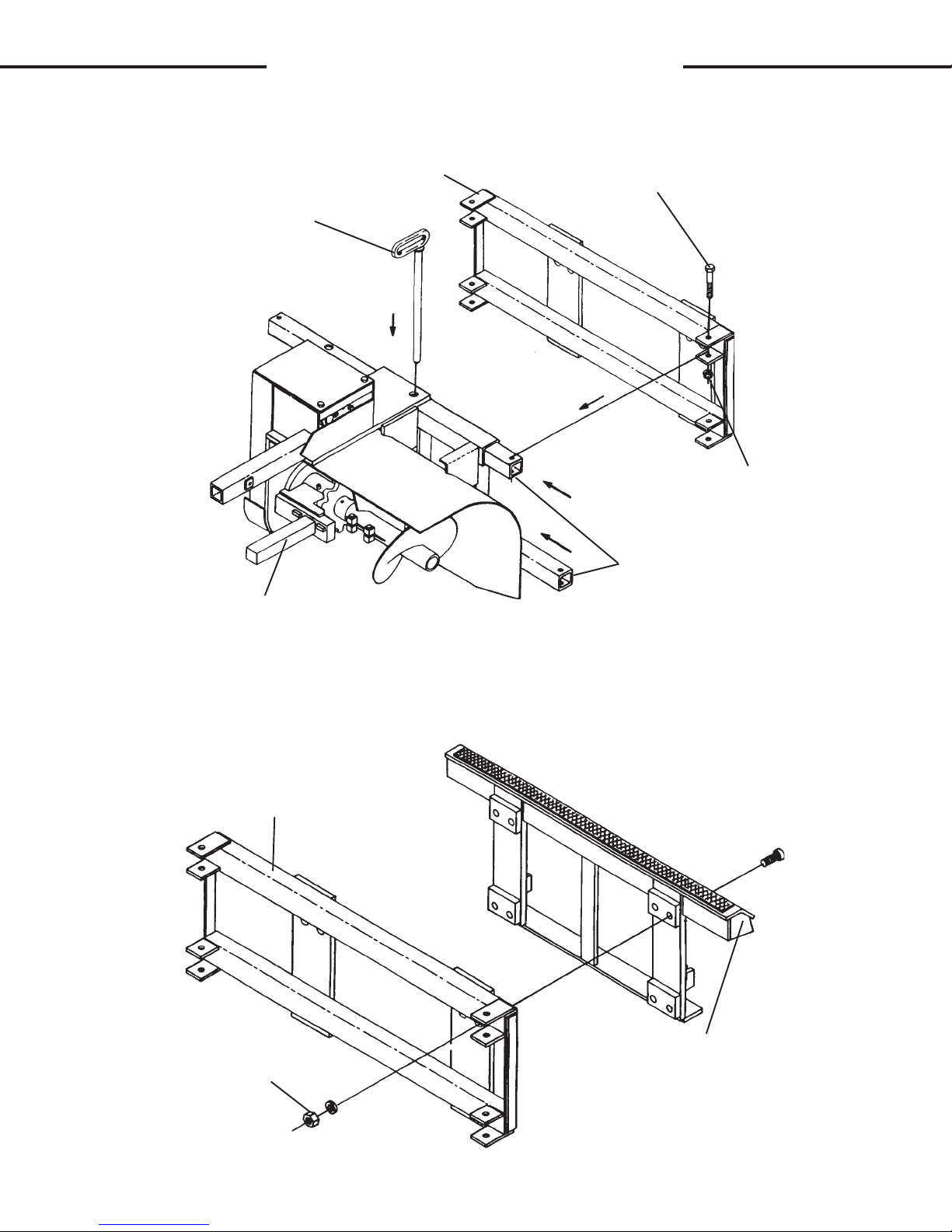

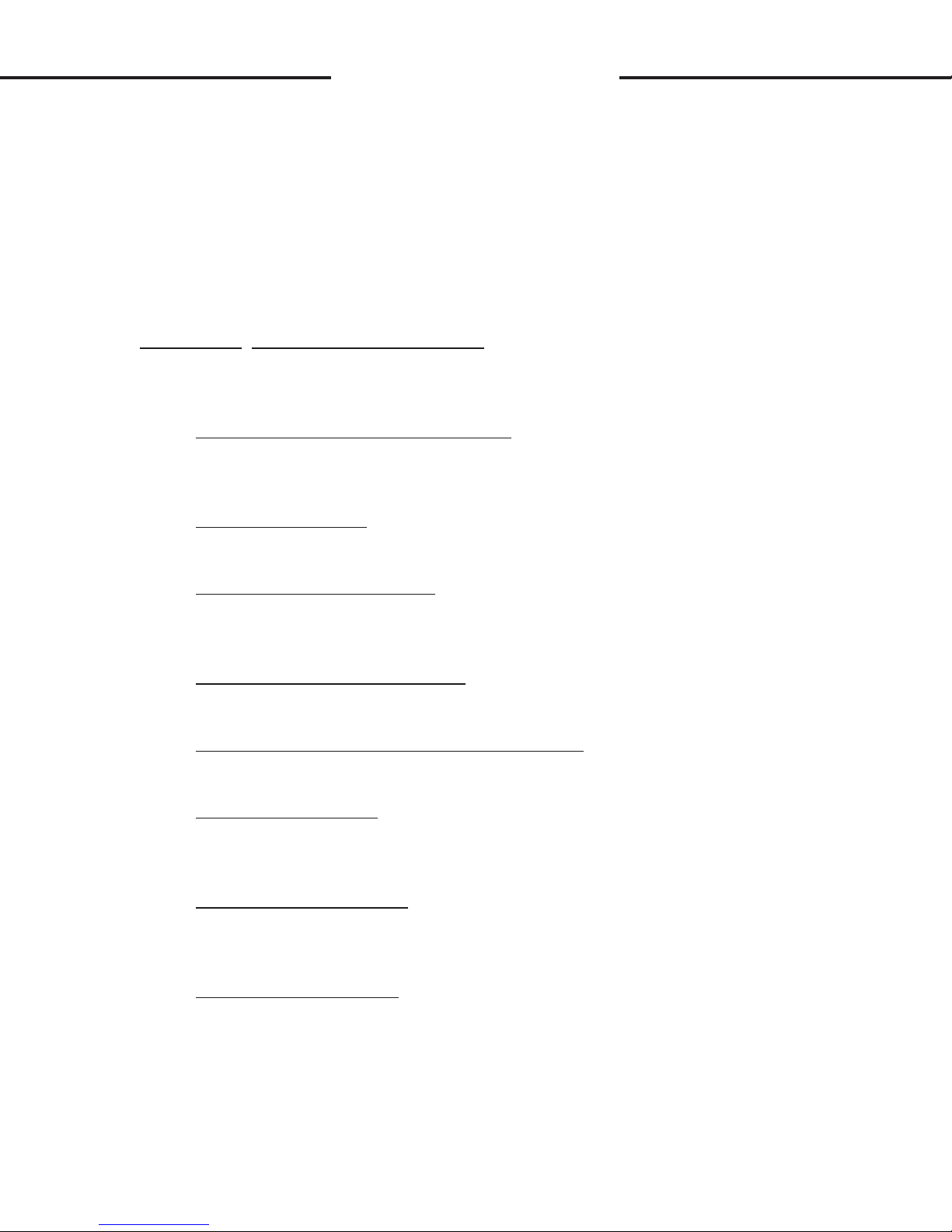

GENERAL INFORMATION

A mounting kit is required to attach the trencher to the skid steer.

Your trencher may have been shipped with the mounting kit installed. The

following instructions are provided here to help you install the mounting kit

in the case that yours was not installed at the factory.

This manual contains a diagram and parts list of the mounting kits

located in the front of this section. To determine which mounting kit you

need for your skid steer, refer to the chart in Section D. Study the diagram

and familiarize yourself with the names of the various parts. This knowledge will assist you in understanding these instructions. Read the complete

mounting instructions that follow before you begin. Read all safety warnings before operating the trencher.

In addition to the complete trencher assembly which includes the

mounting and hydraulic kit, you will also need a pair of couplers (one male

and one female) to hook-up the hydraulic hoses. The couplers must fit the

male hydraulic hose ends. The couplers must also mate up to the skid

steer's auxiliary hydraulic system couplers. You should be able to purchase

such couplers from your skid steer dealer.

MOUNTING INSTRUCTIONS

1. Remove all shipping banding from the trencher and attaching

bracket(s). Remove any other mounting kit components from their

packaging.

2 . NOTE: The side shift mounting frame may have been shipped already

installed. In the event yours was not installed -attach the side shift

mounting frame to the trencher by sliding the two side shift inner

tubes (part #78824) through the trencher mount lining up one set of

side shift holes and installing the lock pin (part #79113). Attach the

side shift mounting frame to the side shift inner tubes using the four

.75"UNC x 4.50" capscrews and lock nuts provided. (See Figure #1)

5777

2-21-92

E

E

MOUNTING KIT INSTALLATION

617 TRENCHER

FIGURE #1

SIDE SHIFT MOUNTING FRAME

LOCK PIN

BASIC TRENCHER ASSEMBLY

.75"UNC X 4.50 CAPSCREW

.75"UNC LOCK NUT

SIDE SHIFT INNER TUBES

3. Mount the attaching bracket(s) to the side shift mounting frame on the tren-

cher using the .75" hardware provided. Use the mounting kit assembly

diagram and parts list at the front on this section as a reference for the

correct hardware needed. (See Figure #2)

FIGURE #2

SIDE SHIFT MOUNTING FRAME

ATTACHING BRACKET

.75" HARDWARE

5778

2-21-92

E

E

MOUNTING KIT INSTALLATION

617 TRENCHER

4. Attach the two hydraulic hoses supplied in the kit to the trencher as shown in

Figure #3.

5. Attach the appropriate couplers to their corresponding hydraulic hoses. See

your skid steer owner's manual for proper identification of auxiliary hydraulic

coupler flow. Flow through the hydraulic hoses is noted in Figure #3.

FIGURE #3

HYDRAULIC MOTOR

TRENCHER

POWER TO TRENCHER

RETURN FROM TRENCHER

5779

2-21-92

F

F

TRENCHER INSTALLATION

617 TRENCHER

GENERAL INFORMATION

The following instructions will help you to mount your trencher on your skid

steer. The trencher uses the skid steer's quick-change attaching system for ease

on installation. Therefore, if you know how to attach the skid steer loader bucket,

attaching the trencher should prove no problem.

You must install the mounting kit prior to installing the trencher. If you have

not installed the mounting kit, turn to Section E and do it now. Remember to read all

safety warnings, decals, and operating instructions before operating the skid steer

or trencher.

MOUNTING INSTRUCTIONS

1. If you haven't done so already, remove the steel shipping banding from

around the trencher and skid.

2. Set the quick-change attaching lock on the skid steer toolbar to the unlocked

position. Lower the skid steer loader arms and tilt the toolbar down low

enough to pass under the top lip of the mounting kit adaptor plate.

3. Following all standard safety practices, start the skid steer and slowly drive it

in back of the trencher. Position the skid steer so that the top of the toolbar

is in under the lip on the adaptor plate. (See Figure #1)

FIGURE #1

SKID STEER

ADAPTOR PLATE

TRENCHER

DRIVE FORWARD

TOOLBAR

5780

2-21-92

F

F

TRENCHER INSTALLATION

617 TRENCHER

4. Tilt the toolbar back to hook the trencher onto the toolbar. It may be neces-

sary to lift the loader arm somewhat.

5. Set the quick-change attaching lock to the locked position to secure the

trencher. It may be necessary to raise, lower, or tilt the toolbar in order for the

trencher mount and toolbar to properly align so the locking mechanism can

be activated.

6. With the auxiliary hydraulic system turned off, route the trencher hydraulic

hoses over the top of the mount and toolbar and connect to their proper

auxiliary couplers.

7. Complete the predelivery check list located in the back of this manual (Sec-

tion R). Trencher installation is now complete.

5781

2-21-92

G

G

OPERATING INSTRUCTIONS

CONTROLS

617 TRENCHER

GENERAL INFORMATION

Simplicity of operation is one of the key features of the 617 trencher. The

trenchers themselves have no controls, just a few adjustments to check. It is important however, to be familiar with, and know the controls and adjustments on both the

trencher and the skid steer. Such knowledge is crucial for safe, efficient operation

of equipment. Take the time to learn how they operate now.

SKID STEER

Your trencher mounts to the toolbar / attachment plate of the skid steer. Due

to this arrangement, thorough knowledge of the skid steer controls is necessary for

trencher operation. Read your skid steer owner's manual for information regarding

skid steer operation before attempting to use the trencher.

RAISING / LOWERING THE TRENCHER

Raise / lower the trencher unit by raising / lowering the skid steer loader arms

through their appropriate skid steer controls. (See Figure #1)

CAUTION! Become aware of any overhead power or telephone lines, tree

limbs, etc., that the raised trencher could come into contact

with. Contact with electrical lines could cause serious injury or

death.

FIGURE #1

RAISE

SKID STEER

LOADER ARM

TRENCHER

LOWER

5782

2-23-92

G

G

OPERATING INSTRUCTIONS

CONTROLS

617 TRENCHER

TILTING THE TRENCHER

Tilt the trencher unit up or down by tilting the toolbar / attachment plate back

or forward through its skid steer control. We recommend a 60° digging angle for

general trenching as measured from ground level (the horizon). (See Figure #2)

SIDE SHIFTING THE TRENCHER

FIGURE #2

SKID STEER LOADER ARM

UP

TOOLBAR / ATTACHMENT

PLATE

(LOCATED INSIDE ADAPTOR)

DOWN

Your trencher has an adjustment to shift the whole unit to the side on its own

mount. To shift the unit sideways, first remove the locking pin from the back of the

unit.

Lower trencher until trencher frame is resting on the ground, then counterrotate the tires so that the skid steer moves in a sideways motion. Continue moving

until side shift holes are aligned and replace locking pin.

IMPORTANT: Always reinstall the locking pin to prevent the trencher from

shifting sideways during operation.

NOTE: Slight shifting of the trencher from side to side may be necessary to

align the side shift holes for reinstalling the locking pin.

5783

2-23-92

G

G

OPERATING INSTRUCTIONS

CONTROLS

617 TRENCHER

STARTING AND STOPPING THE TRENCHER

Power to the trencher is supplied by oil from the skid steer auxiliary hydraulic

system, which passes through the hydraulic hoses and into the trencher's hydraulic

motor.

The trencher unit itself does not have an on/off control but is operated by the

skid steer auxiliary hydraulic control mechanism. The start the trencher, engage the

auxiliary hydraulics. (This is usually done by a pedal located in the middle of the

skid steer floor. See your skid steer owner's manual.) To stop the trencher, disengage the auxiliary hydraulics.

TRENCHER SPEED CONTROL

Again it may be noted that power to the trencher is supplied by the skid

steer's auxiliary hydraulics. Trencher speed and power are determined by the flow

of oil coming out of the auxiliary system, which in turn is dependent upon skid steer

engine speed. To increase trencher speed, increase skid steer engine speed, to

decrease trencher speed, decrease skid steer engine speed.

When first starting a trench throttle down the skid steer engine to half throttle.

This will reduce the shock to the skid steer and trencher when the digging teeth first

contact the ground. Once the trench is started, set the engine back to full throttle.

For general use operate the trencher with the skid steer engine at full throttle

to provide maximum power to the auxiliary hydraulics and thus the trencher.

AUGER HEIGHT

The auger is fixed to the trencher mainframe and has no separate adjustment. To raise the auger, raise the trencher as previously described. This will raise

the auger and thus leave the dirt or spoil closer to the trench.

Lowering the trencher will cause the auger to lower, moving the spoil away

from the trench. The built-in skid shoe on the 617 trencher will prevent the auger

from being lowered to the extent that the auger itself starts to dig in the ground as

this will greatly reduce efficiency.

5784

2-23-92

G

G

OPERATING INSTRUCTIONS

CONTROLS

617 TRENCHER

It should be noted that raising or lowering the trencher to change the auger

height will also change the trenching depth. You will need to compensate for this by

changing the tilt of the trencher down or up accordingly. (See Figure #3)

FIGURE #3

TRENCHER

AUGER

AUGER

SPOIL

SPOIL

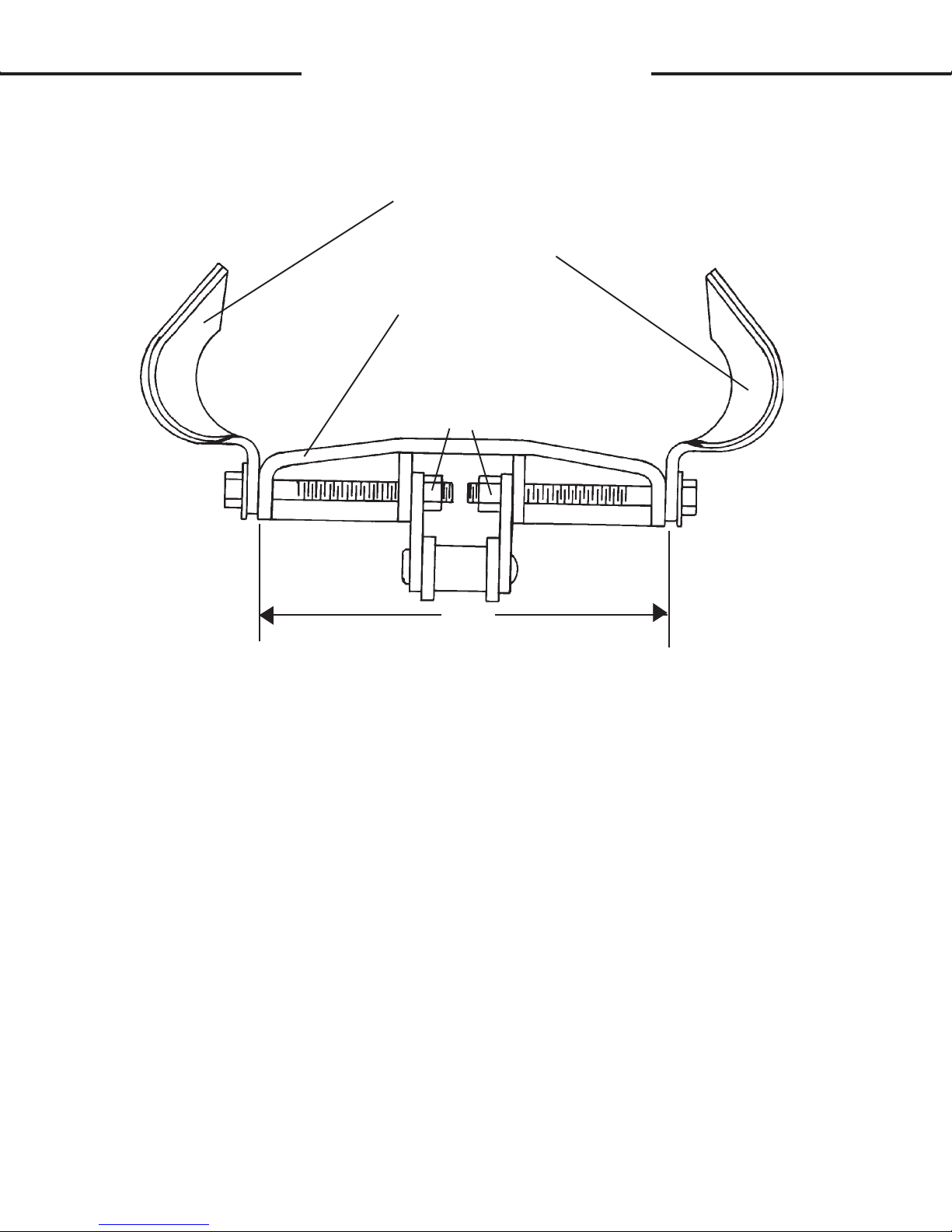

CRUMBER SHOE/BAR ADJUSTMENT

The purpose of the crumber shoe is to keep any loose dirt in the trench close

enough to the digging chain so that the digging teeth can grab it and remove it. This

will give you a cleaner finished trench. Your trencher has an adjustable crumber bar

that can be lengthened or shortened to bring the crumber shoe closer or farther from

the digging chain.

To adjust the crumber bar length, loosen the two jam nuts found at the end of

the mainframe crumber bar tube. Slide the bar in or out to achieve the desired

spacing (we suggest a distance of about 4" between crumber shoe and digging

teeth for best overall results). Tighten the set screws and jam nuts when finished.

(See Figure #4 on the next page)

5785

2-23-92

G

G

OPERATING INSTRUCTIONS

CONTROLS

617 TRENCHER

FIGURE #4

MAINFRAME CRUMBER

BAR TUBE

SET SCREW

CRUMBER BAR

JAM NUT

CHAIN TENSION ADJUSTMENT

When trenching, the digging chain tension should be adjusted so that

the chain is as loose as possible, without jumping off the sprocket or idler

wheel. To do this, an adjustment is provided on the digging boom.

These booms have an adjusting bolt on each side at the trencher end

of the boom. The head of the bolts are kept from rotating by special tubes

welded onto the mainframe. The end of the bolt rests in a tube welded to

the boom. Each bolt has a jam nut and a .75" hex nut on it. To tighten the

chain, "back off" the jam nut from the regular nuts. Now turn the standard

nuts off the adjusting bolts. This will push the boom out and thus tighten

the chain. Retighten the jam nut when finished. To loosen the chain, follow the same procedure, except turn the hex nut onto the adjusting bolt.

(See Figure #5)

ADJUSTING BOLTS

FIGURE #5

TRENCHER

MAINFRAME

.75" JAM NUT

.75" HEX NUT

DIGGING BOOM

5786

2-23-92

G

G

OPERATING INSTRUCTIONS

CONTROLS

617 TRENCHER

This procedure must be done simultaneously to both adjusting bolts to

prevent the boom from becoming wedged onto its mount.

CAUTION! Never work on, or make adjustments to any part of the tren-

cher while the unit is running. You could get caught in the

digging teeth which could cause severe injury or death.

It is common for your trencher to need its digging chain tightened

after the first 10 to 20 minutes of operation as the chain and sprocket seat

themselves.

5787

2-23-92

G

G

OPERATING INSTRUCTIONS

OPERATING TECHNIQUES

SKID STEER TRENCHERS

GENERAL INFORMATION

The design of your trencher makes it relatively simple to use. With

the help of the information in this section and a little practice you should

become proficient in it's operation in no time. Observe the following points

to obtain the best results with the least amount of wear on the machine.

Read the "Safety Precautions" section of this manual before you begin.

(See Section B)

CAUTION! Operate the trencher only when seated at the skid steer con-

trols.

Do not operate the skid steer without proper ROPS (Roll-Over-

Protective-Structure), seat belt, and hard hat.

Pay attention to the job at hand. Be alert to the possibilities of

others in the work area.

Never let anyone work around, or perform maintenance on the

trencher while it is running.

Always use a crumber assembly on the trencher.

BEFORE YOU START TRENCHING

Before any excavating is started, it is always a good idea to plan out

the job first. Various things need to be considered and taken into account

prior to the actual trenching. The operator should inspect the job site and

take notice on any potential hazards in the area. He should have a complete

understanding of the task he is expected to perform. Figure out what will

be done with the spoil (excavated soil), will it be used to backfill or be

trucked out? What are the soil conditions like? Will you have to work

around others? Etc.

WARNING! Check the prospective trenching area for hidden utility lines

before operating the trencher. Contacting a utility line with the

trencher could cause electrocution resulting in death. Call all

utility companies and have them plot out all their lines first. If

you damage a utility line, shut off the equipment at once and

contact the affected utility immediately.

Once you have become familiar with the job site and understand the

job requirements it is time to set up for the actual trenching. Check the soil

type (hard, soft, rocky, etc.) and the trenching requirements (how deep,

wide, etc.). Install the proper digging chain, sprocket, boom, crumber bar

and shoe for the job at hand. Information on chains, sprockets, booms,

crumber bars and shoes may be found in Sections I and J.

5788

2-26-92

G

G

OPERATING INSTRUCTIONS

OPERATING TECHNIQUES

SKID STEER TRENCHERS

Locate the trencher on the mount with the side shift mechanism (as

explained earlier in this section) where it will be most efficient and easy to

use.

Mark off the area to be trenched out. This can be done with powdered lime, chalk, or a guide string and stakes. Block off the area from all

bystanders if possible.

STARTING THE TRENCH

Position the skid steer with the trencher boom directly over the center

of the trench layout. It will take about 4' of trenching before the trencher

will be able to operate at the desired level, so plan for this and position the

trencher about 4' behind where you want the actual trench to start.

NOTE: The skid steer is driven in

trench driving the skid steer forward.

Raise the trencher with the skid steer loader arms and tilt the trencher

at a 45° angle. (See Figure #6) Position the unit so that the digging teeth

are just above ground level.

Set the skid steer throttle at half speed. Start the digging chain by

engaging the skid steer auxiliary hydraulic system.

FIGURE #6

TILT DOWN 45°

TRENCHER

reverse when trenching. You cannot

TOOLBAR

RAISE

LOADER ARM

SKID STEER

5789

2-26-92

G

OPERATING INSTRUCTIONS

OPERATING TECHNIQUES

SKID STEER TRENCHERS

CAUTION! When lowering a moving digging chain to the ground the force

of the teeth grabbing the ground will try to pull the trencher

suddenly forward.

steer set to help counteract the force.

Slowly lower the digging chain into the ground to start the trench.

Do this by lowering the trencher with the loader arms. Continue lowering

the unit until the crumber end rolls all the bay back on the crumber bar

(See Figure #7)

IMPORTANT: After the crumber end has rolled all the way back, do not

lower the trencher any farther without moving the skid steer in reverse.

Failure to do so could result in bending of the crumber boom, which is

covered by warranty.

Be prepared. Have the brake on the skid

not

G

FIGURE #7

CRUMBER BOOM

CRUMBER END

Once the crumber end has "bottomed out", begin slowly creeping the

skid steer in

ing the required depth, stop lowering and tilt the trencher to a 60° to 65°

angle. A 60° - 65° angle works best for general trenching. (See Figure #8)

reverse while continuing to lower the loader arms. When near-

LOADER ARM

LOWER

WARNING! Be alert to what is happening around you. Look behind you

before reversing the skid steer to trench. Be aware of any

person or thing in the path of the skid steer. Observe any

terrain changes such as drop-offs or soft ground.

5790

2-26-92

G

G

OPERATING INSTRUCTIONS

OPERATING TECHNIQUES

SKID STEER TRENCHERS

FIGURE #8

CREEP IN REVERSE

LOWER

When trenching, remember to keep in mind the spoil placement.

Position the trencher so that the auger floats at ground level to move spoil

away from the trench. (See Figure #9)

FIGURE #9

NOTE DIGGING ANGLE

TRENCH

SPOIL PILE

AUGER AT

GROUND LEVEL

5791

2-26-92

G

G

OPERATING INSTRUCTIONS

OPERATING TECHNIQUES

SKID STEER TRENCHERS

Raise the trencher so that the auger rides above the ground level to

leave the spoil beside the trench. The higher the auger, the closer to the

trench the spoil will be placed. You may find that it generally takes less

power to run the digging chain if the auger runs 3" - 6" (inches) off the

ground, and thus increasing the potential footage of trench produced per

hour. The higher you want the auger, the more vertical you will have to tilt

the trencher to achieve the same trench depth. (See Figure #10)

FIGURE #10

TRENCH

With the desired trench depth reached, advance the skid steer throttle

to the desired engine RPM (we suggest full throttle for maximum digging

power). Continue creeping the skid steer in reverse. Monitor the skid steer

hydraulic oil pressure and temperature gauges as you trench. If hydraulic

oil temperature or pressure gets too high, reduce skid steer creeping speed

to reduce the load on the auxiliary hydraulic system.

INCREASED DIGGING ANGLE TO

ACHIEVE THE SAME TRENCH DEPTH

WITH AUGER RAISED AS IN FIGURE #9

SPOIL PILE

AUGER RAISED ABOVE

GROUND LEVEL

IMPORTANT: Trying to trench at a speed faster than the auxiliary hydraulic

system can handle could cause the trencher to stall. Continued stalling in a

short period of time can cause excessive oil temperature which can lead to

pump failure. Do not try to trench too much too quickly. If oil temperature

becomes too hot, stop the trencher and allow the oil to cool.

STALLING THE TRENCHER

If the trencher stalls while digging, move the skid steer forward

slightly to free the trencher. You may be able to free up the digging chain

by changing its direction of travel with the auxiliary hydraulic controls.

Repeated stalling of the trencher will cause oil to overheat rapidly and

should be avoided.

5792

2-26-92

G

G

OPERATING INSTRUCTIONS

OPERATING TECHNIQUES

SKID STEER TRENCHERS

TURNING WHILE TRENCHING

Gradual turns can be made while trenching. However, the tightness

of the turn is directly proportional to the angle and length of the boom. In

other words the greater the angle of the trencher boom to the ground level,

the sharper the turn that can be trenched. (See Figures #11 & #12) Also

the shorter the boom length the sharper the possible turn. Remember, the

greater the increase in boom angle the higher the unit will have to be raised

out of the trench to keep a unified trench depth. Shallow boom angles will

severely limit turning ability.

IMPORTANT: Turning too tightly while trenching will cause the trencher to

jam in the trench and stall, leading to excessive oil temperatures. Turning

too tightly can also cause the trencher boom to bend. Take it easy when

turning. Proceed slowly with caution.

FIGURE #11

FIGURE #12

TURNING WITH THE BOOM

AT A 90° DIGGING ANGLE

TOP VIEW

TURNING WITH THE BOOM AT

A 60° DIGGING ANGLE

TOP VIEW

5793

2-26-92

G

G

OPERATING INSTRUCTIONS

OPERATING TECHNIQUES

SKID STEER TRENCHERS

MAKING SHARP TURNS

To make sharp turns and 90° angles you will have to dig two

trenches. Dig the first trench as you normally would. Then reposition the

unit and dig the second trench at the appropriate angle. Be sure to take

into account the extra lead-in space needed for the trencher to get down to

the desired trench depth. (See Figure #13)

FIGURE #13

TOP VIEW

2nd TRENCH

1st TRENCH

LEAD-IN

RECOMMENDED DIGGING ANGLES

A 90° digging angle is recommended for use in rock and frost conditions, and when trenching sharp corners. The 90° angle reduces excessive

side pressure on the boom and digging chain when trenching corners. (See

Figure #14)

A 60° - 65° digging angle is recommended for normal trenching. At

this angle there will be less carry-over, and a cleaner trench bottom can be

maintained than at a 90° angle. (See Figure #14)

FIGURE #14

90° DIGGING

ANGLE

GROUND LEVEL /

HORIZON

65° DIGGING

ANGLE

5794

2-26-92

GG

OPERATING INSTRUCTIONS

OPERATING TECHNIQUES

SKID STEER TRENCHERS

TRENCHING WITHOUT THE CRUMBER ASSEMBLY

WARNING! The crumber bar and crumber shoe assembly are there for a

reason, YOUR SAFETY! There are a few instances where

removal may be necessary however. In these cases operate

with extreme caution. Reinstall the crumber bar and crumber

shoe as soon as possible.

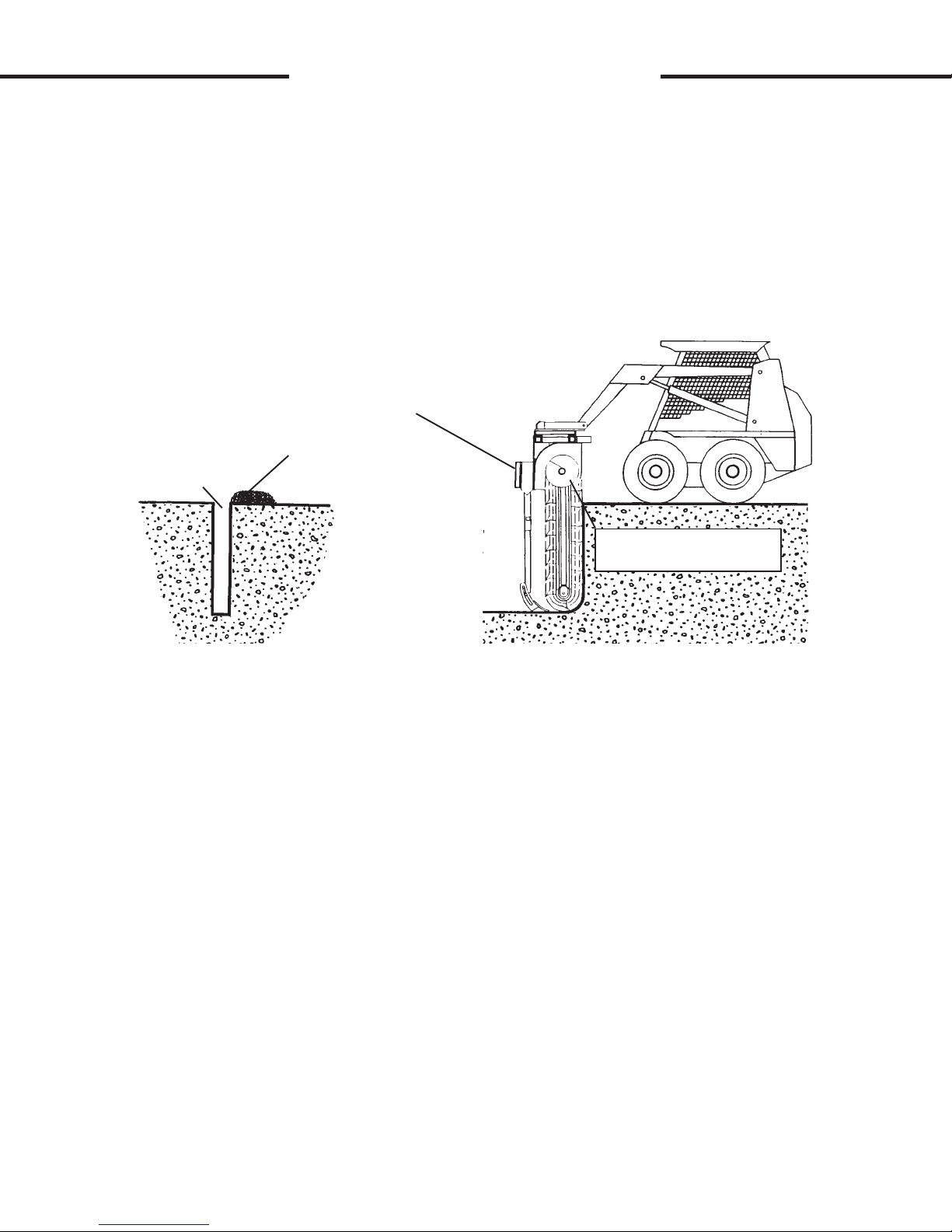

You can use your trencher to dig under obstacles such as sidewalks.

To do so, remove the crumber shoe and bar assembly and start your trench

as before within a foot of the sidewalk. With the crumber bar and shoe

removed you can start the trench vertically without any lead-in space.

When the desired depth has been reached, tilt the trencher at a 60°

angle while digging, then creep the skid steer

sidewalk. Be careful not to contact the edge of the sidewalk with the digging teeth.

forward and trench under the

After you have gone as far as you can without contacting the sidewalk, drive the skid steer in reverse to clear the sidewalk and remove the

trencher from the trench. Line up the unit on the other side of the walk and

continue to trench as described above until the two trenches are connected.

(See Figure #15)

FIGURE #15

CREEP FORWARD

CRUMBER BAR AND SHOE

ASSEMBLY REMOVED. REPLACE

AS SOON AS POSSIBLE

SIDEWALK

1st TRENCH

2nd TRENCH

AVOID CONTACTING SIDEWALK

Reinstall the crumber bar and crumber shoe assembly immediately.

Some spoil will be left in the trench since the crumber was removed during

the operation.

5795

2-26-92

GG

OPERATING INSTRUCTIONS

OPERATING TECHNIQUES

SKID STEER TRENCHERS

ENDING A TRENCH

When you have dug your trench, remember that the trencher boom is

at an angle, and that you must continue trenching until the end of the boom

has dug past the proposed end of the trench. Once the end of the trench

has been dug, keep the trencher running and lift the skid steer loader arms

to lift the unit clear of the trench. When the trencher has cleared the

trench, disengage the auxiliary hydraulics to stop the trencher. Drive the

skid steer away from the trench.

TRANSPORTING THE TRENCHER

When transporting the trencher, remember to keep the trencher as

low to the ground as is practical. The lower the trencher rides, the more

stable the skid steer will be. You do not want the trencher so low that the

digging teeth touch the ground in rough terrain. Shut off the trencher before moving it away from the trench. Never transport the trencher around

the job site or anywhere else while the digging chain is moving.

TRENCHER PERFORMANCE

Remember that your trencher's performance is directly related to the

power available at you skid steer's auxiliary hydraulic system. If the trencher seems to lack power or speed, it may be due to your skid steer's lack

of sufficient auxiliary power.

Trencher performance is also related to how well it's maintained,

digging tooth wear, and type and size of digging chain, crumber boom and

shoe used. For more information on proper maintenance and chain wear

see Section L. For information on chain, sprocket, boom, and crumber

options see Sections I and J. If problems arise see "Trouble Shooting"

Section N.

5796

2-26-92

II

TRENCHER ASSEMBLY

617 TRENCHER

ASSEMBLY #78820

5753

3-4-92

I

I

TRENCHER ASSEMBLY

617 TRENCHER

ASSEMBLY 78820

NO REQ'D PART NO. DESCRIPTION

1 1 79113 Lock Pin

2 1 78806 Side Shift Mounting Frame

3 4 1148 .75" UNC x 4.50" Hex Capscrew

4 4 1534 .75" UNC Lock Nut

5 2 78824 Side Shift Inner Tube

6 4 1021 .31" UNC x .75" Hex Capscrew

7 4 1502 .31" Lock Washer

8 4 1513 .31" Flat Washer

9 1 78840 Chain Guard

10 1 1364 .62" UNF x 1.50" Hex Capscrew

11 1 1506 .62" Lock Washer

12 1 1517 .62" Flat Washer

13 1 78823 Sleeve Spacer

14 1 78821 Driver Sprocket

15 1 67799 Key (.312" x .275" x 1.25")

16 4 1091 .50" UNC x 1.75" Hex Capscrew

2 1092 .50" UNC x 2.00" Hex Capscrew

17 2 78844 Adjusting Bolt

18 1 78838 Motor Mounting Plate

19 1 72333 Hydraulic Motor

20 8 1505 .50" Lock Washer

21 8 1228 .50" UNC Hex Nut

22 4 1516 .50" Flat Washer

23 1 78769 Mainframe

24 1 78837 Drive Chain (#80 - 52 Pitches)

25 1 53298 Connecting Link

26 2 1769 .50"UNC x 1.00" Sq. Head Setscrew

27 2 1242 .50" UNC Jam Nut

28 1 1651 Snap Ring

29 Varies 6622 Thrust Washer

30 1 78822 Driven Sprocket

31 3 1572 .50"-13UNC x .50" Set Screw

32 1 53744 Key (.50" x .50" x 2.00")

33 1 78809 Headshaft Spacer

34 1 1681 Snap Ring

35 1 78841 Bearing

36 1 6616 Grease Zerk

37 1 8085 Bearing

38 1 1601 Snap Ring

39 1 78833 Dirt Guard

40 1 78808 Headshaft

41 1 53742 Key (.38" x .38" x 3.00")

42 1 78832 Sprocket

43 2 1095 .50" UNC x 2.75" Hex Capscrew

44 1 78828 Auger

5754

1-18-94-2

II

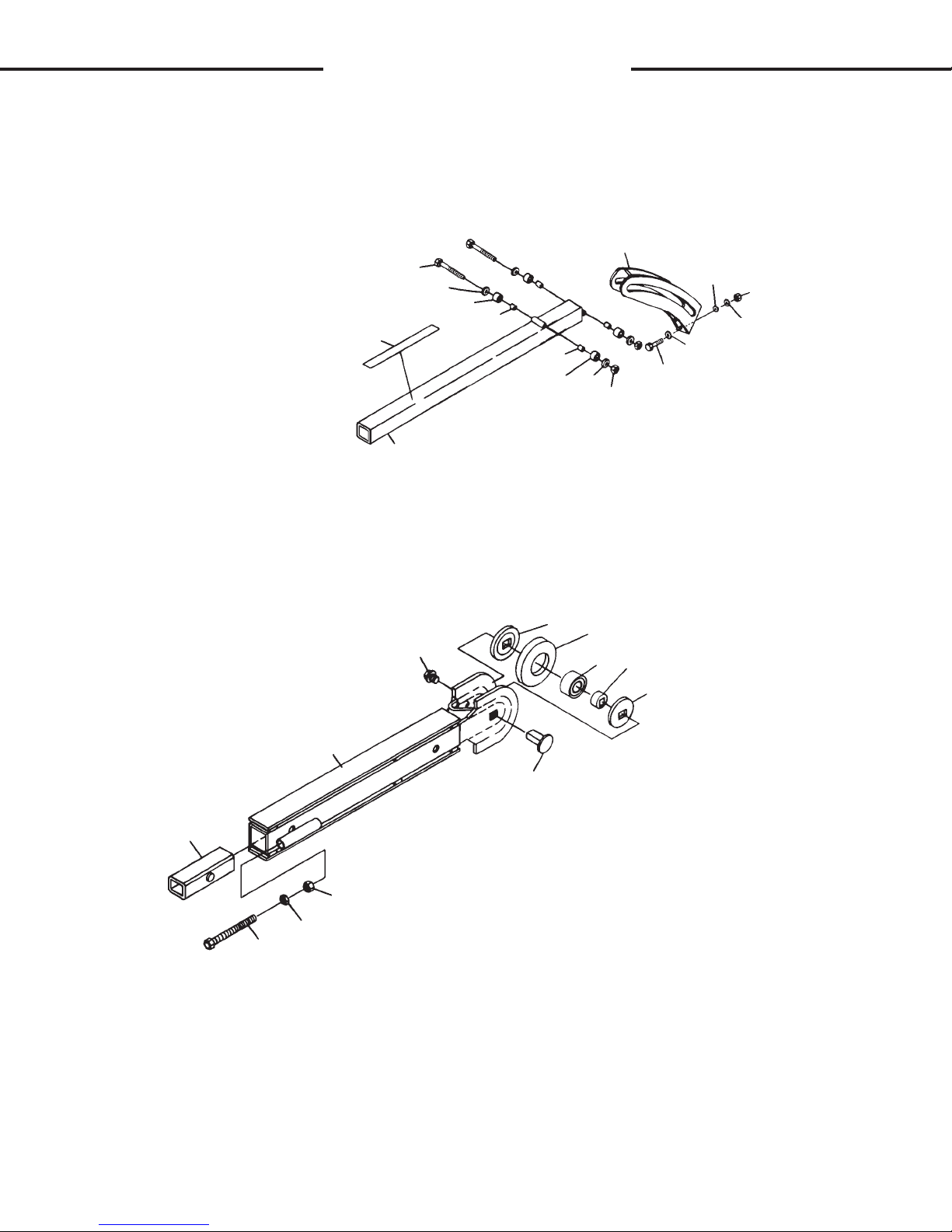

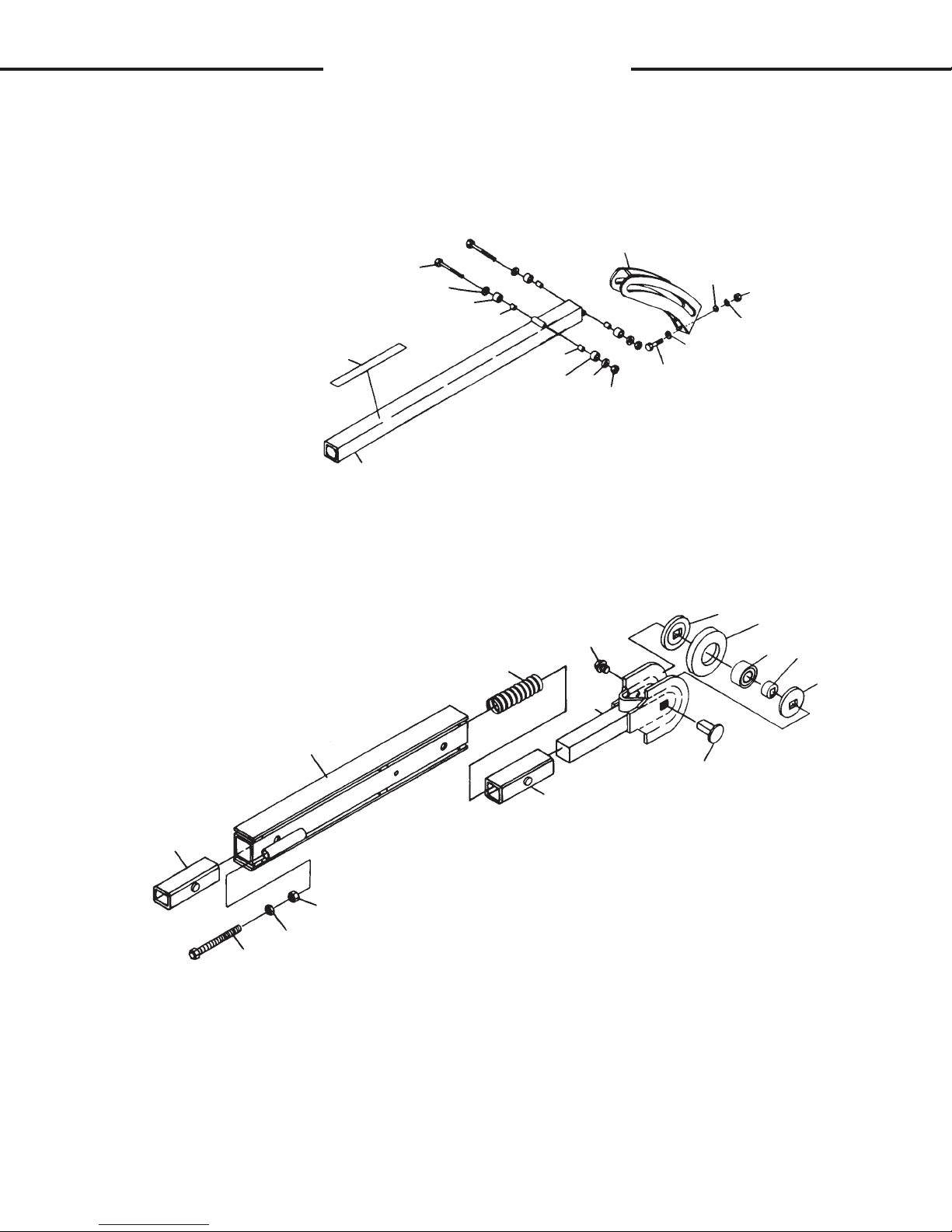

TRENCHER ASSEMBLY

30" BOOM AND CRUMBER

ASSEMBLY #79117

6

14

15

1

2

3

4

4

3

2

5

9

2

7

8

2

16

20

21

17

22

19

18

10

11

12

13

10

6911

4-17-96

I

I

TRENCHER ASSEMBLY

30" BOOM AND CRUMBER

ASSEMBLY #79117

NO REQ'D PART NO. DESCRIPTION

1 2 1054 .38" UNC x 3.75" Hex Capscrew

2 8 1514 .38" Flat Washer

3 4 53038 Crumber Roller

4 4 53039 Crumber Roller Bushing

5 2 1536 .38" UNC Nylock Nut

6 1 53087 Crumber End

7 2 1226 .38" UNC Hex Nut

8 2 1503 .38" Lock Washer

9 2 1044 .38" UNC x 1.25" Hex Capscrew

10 2 54067* Idler Spacer

11 1 79103* Idler Wheel

12 1 8085* Idler Bearing

13 1 53988* Idler Bearing Hub

14 2 40161 Decal - Stand Clear

15 1 53070 30" Crumber Bar / Personal Restraint Bar

16 1 53138 Boom Bushing

17 1 80087 30" Boom

18 1 53132 1.12" Square Pin

19 1 1548 .75" UNC x 1.25" Nylock Capscrew

20 2 62702 Adjusting Bolt

21 2 1245 .75" UNC Jam Nut

22 2 1231 .75" UNC Nut

NOTE: Idler Roller Assembly Repair Kit #80868 includes all parts marked

with an asterisk (*).

6912

4-17-96

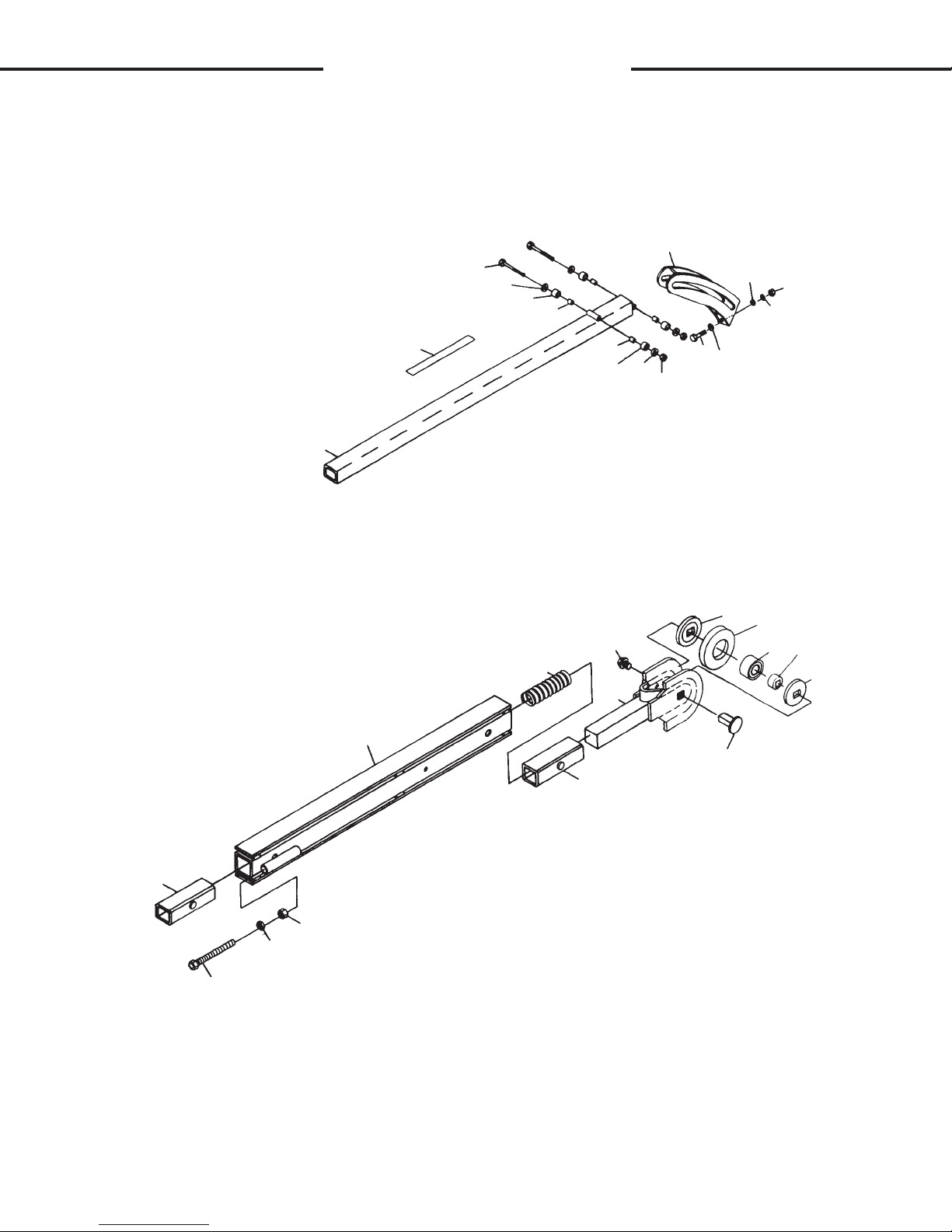

II

TRENCHER ASSEMBLY

36" BOOM AND CRUMBER

ASSEMBLY #79083

6

14

15

1

2

3

4

4

3

2

5

9

2

7

8

2

16

22

23

17

24

18

16

21

20

19

10

11

12

13

10

5757

2-3-92

I

I

TRENCHER ASSEMBLY

36" BOOM AND CRUMBER

ASSEMBLY #79083

NO REQ'D PART NO. DESCRIPTION

1 2 1054 .38" UNC x 3.75" Hex Capscrew

2 8 1514 .38" Flat Washer

3 4 53038 Crumber Roller

4 4 53039 Crumber Roller Bushing

5 2 1536 .38" UNC Nylock Nut

6 1 53087 Crumber End

7 2 1226 .38" UNC Hex Nut

8 2 1503 .38" Lock Washer

9 2 1044 .38" UNC x 1.25" Hex Capscrew

10 2 54067* Idler Spacer

11 1 79103* Idler Wheel

12 1 8085* Idler Bearing

13 1 53988* Idler Bearing Hub

14 2 40161 Decal - Stand Clear

15 1 53069 36" Crumber Bar / Personal Restraint Bar

16 2 53138 Boom Bushing

17 1 79085 36" Boom

18 1 53188 Spring

19 1 53132 1.12" Square Pin

20 1 62717 Boom End

21 1 1548 .75" UNC x 1.25" Nylock Capscrew

22 2 62702 Adjusting Bolt

23 2 1245 .75" UNC Jam Nut

24 2 1231 .75" UNC Nut

NOTE: Idler Roller Assembly Repair Kit #80868 includes all parts marked

with an asterisk (*).

5758

4-17-96-4

II

TRENCHER ASSEMBLY

42" BOOM AND CRUMBER

ASSEMBLY #82113

6

15

14

1

2

3

4

4

3

2

5

2

7

8

9

2

16

22

23

24

17

18

16

21

20

19

10

11

12

13

10

6671

10-2-95

I

I

TRENCHER ASSEMBLY

42" BOOM AND CRUMBER

ASSEMBLY #82113

NO REQ'D PART NO. DESCRIPTION

1 2 1054 .38" UNC x 3.75" Hex Capscrew

2 8 1514 .38" Flat Washer

3 4 53038 Crumber Roller

4 4 53039 Crumber Roller Bushing

5 2 1536 .38" UNC Nylock Nut

6 1 53087 Crumber End

7 2 1226 .38" UNC Hex Nut

8 2 1503 .38" Lock Washer

9 2 1044 .38" UNC x 1.25" Hex Capscrew

10 2 54067* Idler Spacer

11 1 79103* Idler Wheel

12 1 8085* Idler Bearing

13 1 53988* Idler Bearing Hub

14 2 40161 Decal - Stand Clear

15 1 82125 42" Crumber Bar / Personal Restraint Bar

16 2 53138 Boom Bushing

17 1 82124 42" Boom

18 1 53188 Spring

19 1 53132 1.12" Square Pin

20 1 62717 Boom End

21 1 1548 .75" UNC x 1.25" Nylock Capscrew

22 2 62702 Adjusting Bolt

23 2 1245 .75" UNC Jam Nut

24 2 1231 .75" UNC Nut

NOTE: Idler Roller Assembly Repair Kit #80868 includes all parts marked

with an asterisk (*).

6672

10-2-95

I

I

TRENCHER ASSEMBLY

48" BOOM AND CRUMBER

ASSEMBLY #79084

6

15

14

1

2

3

4

4

3

2

5

2

7

8

9

2

16

22

23

24

17

18

16

21

20

19

10

11

12

13

10

5755

2-3-92

TRENCHER ASSEMBLY

48" BOOM AND CRUMBER

ASSEMBLY #79084

NO REQ'D PART NO. DESCRIPTION

1 2 1054 .38" UNC x 3.75" Hex Capscrew

2 8 1514 .38" Flat Washer

3 4 53038 Crumber Roller

4 4 53039 Crumber Roller Bushing

5 2 1536 .38" UNC Nylock Nut

6 1 53087 Crumber End

7 2 1226 .38" UNC Hex Nut

8 2 1503 .38" Lock Washer

9 2 1044 .38" UNC x 1.25" Hex Capscrew

10 2 54067* Idler Spacer

11 1 79103* Idler Wheel

12 1 8085* Idler Bearing

13 1 53988* Idler Bearing Hub

14 2 40161 Decal - Stand Clear

15 1 53068 48" Crumber Bar / Personal Restraint Bar

II

16 2 53138 Boom Bushing

17 1 79088 48" Boom

18 1 53188 Spring

19 1 53132 1.12" Square Pin

20 1 62717 Boom End

21 1 1548 .75" UNC x 1.25" Nylock Capscrew

22 2 62702 Adjusting Bolt

23 2 1245 .75" UNC Jam Nut

24 2 1231 .75" UNC Nut

NOTE: Idler Roller Assembly Repair Kit #80868 includes all parts marked

with an asterisk (*).

5756

4-17-96-4

COMBINATION ROCK AND FROST CHAIN

2.00" PITCH - TOOTH EVERY STATION

SERVICE PARTS

STATION #1 STATION #3STATION #2

11

2

15

14

10

4

13

1

15

10

3

12

10

STATION #4 STATION #5 STATION #6

4

15

STATION #7 STATION #8 STATION #9

13

11

11

13

12

10

16

13

10

2

1

16

6

11

14

11

14

3

15

10

5

10

STATION #10 STATION #11 STATION #12

4

14

10

15

18

15

3

8

10

11

14

10

17

10

4

7

10

9

14

17

3

19

9

6824

1-26-96

COMBINATION ROCK AND FROST CHAIN

2.00" PITCH - TOOTH EVERY STATION

SERVICE PARTS

NO PART NO. DESCRIPTION

1 83802 Carbide Bit Holder - 4" Right

2 83801 Carbide Bit Holder - 4" Left

3 54432 Cup Cutter - Right

4 54431 Cup Cutter - Left

5 83804 Carbide Bit Holder - 5" Right

(1) Weld Spot on Top for Identifying Purposes

6 83803 Carbide Bit Holder - 5" Left

(1) Weld Spot on Top for Identifying Purposes

7 83806 Carbide Bit Holder - 6" Right

(2) Weld Spots on Top for Identifying Purposes

8 83805 Carbide Bit Holder - 6" Left

(2) Weld Spots on Top for Identifying Purposes

9 83800 Spacer - 6" Cut

10 1692 .50" UNF Hex Nut

11 51547 Carbide Bit

12 83798 Tube Spacer

(Inside Mount Carbide Bit Holder)

13 54628 Tube Spacer

(Inside Mount Cup Cutter)

14 54440 Tube Spacer

(Outside Cup or Carbide Bit Holder)

15 1347 .50" UNF X 3.25" Hex Capscrew

16 1349 .50" UNF X 3.75" Hex Capscrew

17 1351 .50" UNF X 4.50" Hex Capscrew

18 1348 .50" UNF X 3.50" Hex Capscrew

19 1350 .50" UNF X 4.00" Hex Capscrew

NOTE: There are weld spots located on the top of the 5" and 6" Carbide

Bit Holders to assist in parts identification. One weld spot on the 5" Holders and two weld spots on the 6" Holders.

6825

1-26-96

J

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

GENERAL INFORMATION

This section is devoted to digging chain options for your trencher. In

it you will find a listing of all the chain options available. You will also find

information on replacement parts, chain assembly, and chain conversion.

These options will increase the flexibility of your equipment, and make your

trenching job easier.

There is some basic information about the trencher and it's digging

components that you should know before you try to order any options. This

information is given here for your convenience. With it you will be able to

better understand the rest of this section.

CHAIN PITCH

J

The digging chains may be divided into groups by pitch. The pitch of

the chain is the distance between the centers of the holes in the chain links

(See Figure 1). The word pitch can also be used to describe the length of

the chain.

FIGURE #1 FIGURE #2

8 PITCH OF CHAIN

DISTANCE BETWEEN HOLE

CENTERS = PITCH

The 617 Trencher has a heavy weight chain with a tensil strength of

50,000 pounds and a pitch of 2.00".

There is one thing that you must understand about chain pitch. You

can not intermix components of different pitches. You cannot substitute

chain links of different pitches in a digging chain. Nor can you use a digging chain of one pitch, with a driver sprocket of a different pitch. Attempting to do so will cause the chain to "jump" off the sprocket continuously.

5802

10-10-00-2

J

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

COMPONENT SIZE

The size of the digging component is based on the depth of the

trench it will dig with auger at ground level and a 60° boom digging angle

(See Figure 3). For example, a 36" boom is not necessarily 36" long. The

36" length means it will dig a trench 36" deep with the augers in their float

position and at a 60° digging angle.

FIGURE #3

J

36" BOOM

60°

BOOM DIGGING ANGLE

DIGGING STATIONS

Digging chains are made up of a series of individual links pinned

together. Every link has a special "Digging Station" link. These links are

designed so that the digging teeth can be attached to the basic chains (See

Figure 4). Digging chains may be purchased in any length, with or without

teeth. All chains, teeth, spacers and assorted digging hardware may be

purchased separately.

FIGURE #4

MOUNTING HARDWARE

DIGGING TOOTH

AUGER AT GROUND LEVEL

36"

DIGING STATIONS

This completes the basic information on digging chain options. The

rest of this section contains specific information on digging chains and parts

available, complete with part numbers. Again it may be noted that these

options are designed to increase the flexability of your equipment and to

make your trenching jobs easier. We offer them to better serve your trenching needs.

DIGGING CHAIN

5803

2-27-92

J

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

2.00" PITCH DIGGING CHAIN ASSEMBLIES

GENERAL INFORMATION

This page contains a listing of all of the 2.00" pitch digging chain

assemblies offered for your trencher. Each chain assembly comes with all

necessary teeth and spacers already installed. Just thread the chain onto the

trencher and fasten the two ends together with the pin and keeper pin included

in the assembly. A crumber shoe of the appropriate width is also included in

the chain assembly.

Before you order a new chain, be sure to check for compatibility with

corresponding components. You may need to order more than just a chain

assembly. You must use a digging boom of the same digging depth as the chain.

The crumber bar must also be of the same digging depth. The digging sprocket

must also be of the same pitch as the chain. All of these components must

match for the trencher to function properly.

Bare 2.00" pitch digging chain (without teeth, spacers, or hardware) can

be ordered in any desired length under the part number 79018. Just use this

number and then specifiy the length desired in pitches (example, 54 pitches of

chain would be needed for a 36" boom).

J

2.00" PITCH DIGGING CHAIN ASSEMBLIES

Complete chain assemblies. Includes chain with all teeth

and spacers attached. Also includes appropriate width crumber

shoe.

CHAIN ASSEMBLIES WITH A TOOTH EVERY STATION

DESCRIPTION LENGTH OF CHAIN TENSIL PART

(boom used X trench width) (in 2.00" pitches) STRENGTH NO.

For 30" Boom 6" Wide 48 Pitch 50,000# 79154

For 30" Boom 8" Wide 48 Pitch 50,000# 79155

For 30" Boom 10" Wide 48 Pitch 50,000# 79156

For 30" Boom 12" Wide 48 Pitch 50,000# 79157

For 36" Boom 6" Wide 54 Pitch 50,000# 79099

For 36" Boom 8" Wide 54 Pitch 50,000# 79100

For 36" Boom 10" Wide 54 Pitch 50,000# 79158

For 42" Boom 6" Wide 62 Pitch 50,000# 82114

For 42" Boom 8" Wide 62 Pitch 50,000# 82115

For 42" Boom 10" Wide 62 Pitch 50,000# 82116

For 48" Boom 6" Wide 68 Pitch 50,000# 79101

For 48" Boom 8" Wide 68 Pitch 50,000# 79102

5804

10-10-00-3

J

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

2.00" PITCH DIGGING CHAIN ASSEMBLIES

2.00" PITCH DIGGING CHAIN ASSEMBLIES

Complete chain assemblies. Includes chain with all teeth

and spacers attached. Also includes appropriate width crumber

shoe.

CHAIN ASSEMBLIES WITH A TOOTH EVERY OTHER STATION

DESCRIPTION LENGTH OF CHAIN TENSIL PART

(boom used X trench width) (in 2.00" pitches) STRENGTH NO.

For 30" Boom 6" Wide 48 Pitch 50,000# 79181

For 30" Boom 8" Wide 48 Pitch 50,000# 79182

For 30" Boom 10" Wide 48 Pitch 50,000# 79183

For 30" Boom 12" Wide 48 Pitch 50,000# 79184

For 36" Boom 6" Wide 54 Pitch 50,000# 79185

For 36" Boom 8" Wide 54 Pitch 50,000# 79186

For 36" Boom 10" Wide 54 Pitch 50,000# 79187

J

For 42" Boom 6" Wide 62 Pitch 50,000# 82117

For 42" Boom 8" Wide 62 Pitch 50,000# 82118

For 42" Boom 10" Wide 62 Pitch 50,000# 82119

For 48" Boom 6" Wide 68 Pitch 50,000# 79188

For 48" Boom 8" Wide 68 Pitch 50,000# 79189

5805

10-10-00-4

J

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

2.00" PITCH CHAIN REPLACEMENT PARTS

GENERAL INFORMATION

You can purchase individual chain links and pins for your trencher.

These can be used to repair a damaged chain, or lengthen and modify an

existing chain. Below is a diagram of the chain’s basic components with

their descriptions and corresponding part numbers. Use these numbers

when ordering. You can also order a complete bare chain (without teeth

and spacers) in any length desired. The chain is ordered under part number

79018 for 2.00" Pitch. Just specify the length you want in pitches. (See

“2.00” PITCH DIGGING CHAIN ASSEMBLIES” chart located in this section.)

When pinning links of chain together, first tap the pin through the

connector link with the perfectly round holes and then on through the inner

link. Place the second connector link in position, you will note that the end

of the pin has one side flattened. Rotate the pin until its flat side lines up

with the corresponding flat side of the connector link hole and tap the pin

on through. Place the chain keeper pin into the hole at the end of the main

pin and tap down tight. Finally, bend the end of the keeper pin over to

secure it in place.

J

NO. REQ’D PART NO. DESCRIPTION

1 Varies 54757 Inner Link

2 Varies 54731 Pin

3 Varies 54732 Chain Keeper Pin

4 Varies 54730 Connector Link includes (2) Pins #54731 and (2)

Chain Keeper Pins #54732

5806

10-4-95

J

J

DIGGING CHAIN OPTIONS

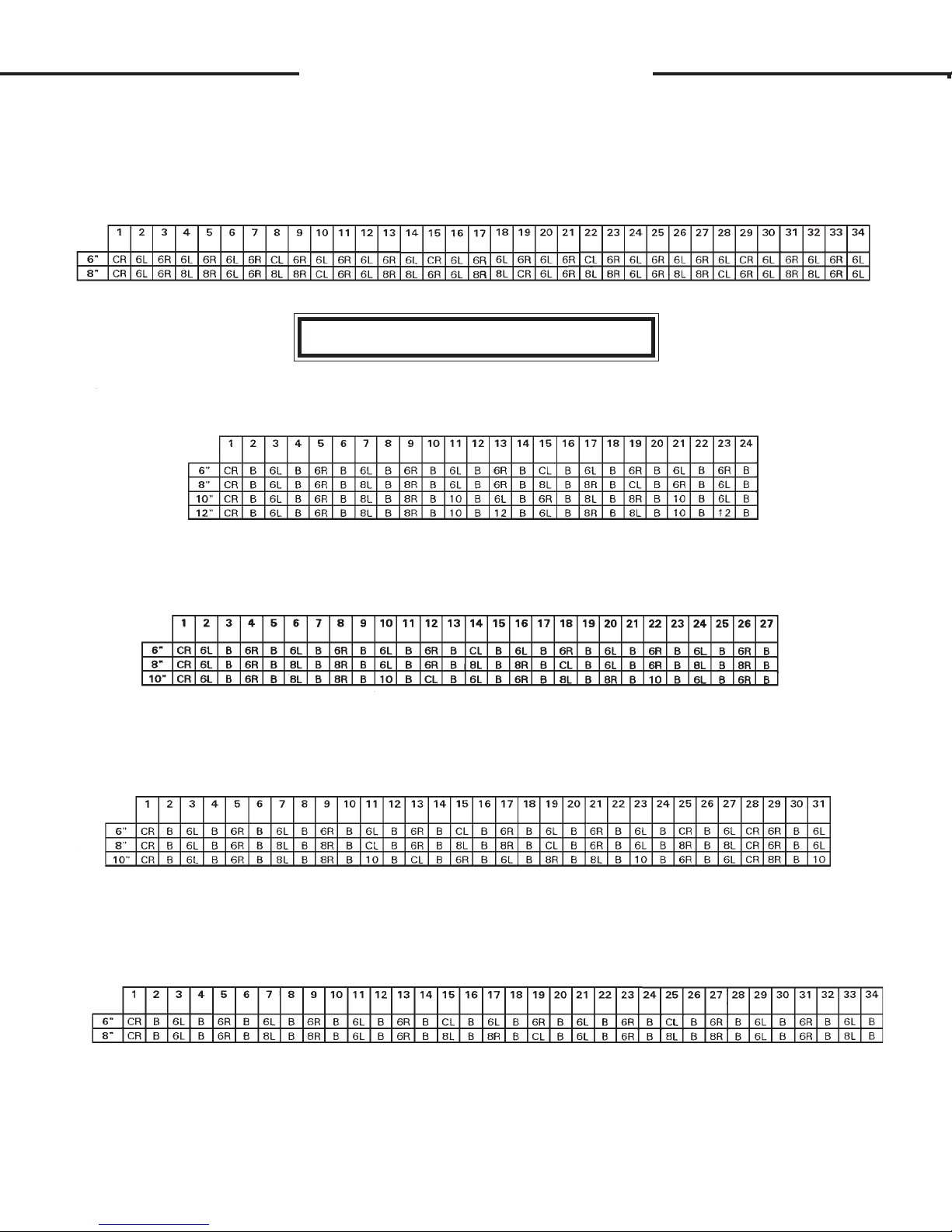

2.00" PITCH DIGGING TOOTH STATION SEQUENCE

GENERAL INFORMATION

Every second link on a digging chain is a special link called a digging

station. These digging station links are designed so that digging teeth can

be bolted onto them in a variety of configurations. It is the number and the

make up of these different digging stations that make each chain unique.

The following tables show the number of digging stations there are in

each available 2.00" pitch digging chain. The digging tooth make up of

each digging station is given in code. The key to the code is located at the

below. Thus these charts will tell you what kind of digging tooth arrangement is at each digging station on each digging chain assembly. The actual

parts break down on each digging tooth arrangement is shown on the "Digging Tooth Station Break Down" diagrams located in this section following

the charts.

DIGGING TOOTH STATION KEY

CR - CENTER CUTTER, RIGHT 6R - 6" RIGHT STATION 8R - 8" RIGHT STATION

CL - CENTER CUTTER, LEFT 6L - 6" LEFT STATION 8L - 8" LEFT STATION

10 - 10" STATION 12 - 12" STATION B - BLANK STATION

TOOTH EVERY STATION

TRENCH

WIDTH

TRENCH

WIDTH

DIGGING TOOTH STATIONS

DIGGING TOOTH STATIONS

30" BOOM

36" BOOM

TRENCH

WIDTH

42" BOOM

DIGGING TOOTH STATIONS

5807

7-24-4

J

J

DIGGING CHAIN OPTIONS

2.00" PITCH DIGGING TOOTH STATION SEQUENCE

TRENCH

WIDTH

TRENCH

WIDTH

TRENCH

WIDTH

48" BOOM

DIGGING TOOTH STATIONS

TOOTH EVERY OTHER STATION

30" BOOM

DIGGING TOOTH STATIONS

36" BOOM

DIGGING TOOTH STATIONS

TRENCH

WIDTH

TRENCH

WIDTH

42" BOOM

DIGGING TOOTH STATIONS

48" BOOM

DIGGING TOOTH STATIONS

5808

7-24-02-3

JJ

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

2.00" PITCH DIGGING TOOTH STATION BREAK DOWN

GENERAL INFORMATION

The following diagrams are the complete parts break downs of all the

different digging tooth arrangements used on the digging stations for 2.00" pitch

chains. The diagrams are frontal views according to the digging chain direction

of travel. All 2.00" pitch chains are made up of a combination of some or all of

these various digging tooth arrangements. See the "2.00" Pitch Digging Tooth

Station Sequence Charts" (located earlier in this section) to find out how the

arrangements are used for the various digging chains.

DIRT TOOTH, LEFT

PART #54431

DIRT TOOTH, RIGHT

1.56" SPACER TUBE

3.25" CAPSCREW

WITH NUT #1692

CENTER CUTTER, LEFT

DIRT TOOTH, LEFT

DIRT TOOTH, RIGHT

1.81" SPACER TUBE

PART #54432

PART #54628

PART #1347

CENTER CUTTER, RIGHT

PART #54431

PART #54432

PART #54440

6" LEFT STATION 6" RIGHT STATION

3.25" CAPSCREW

PART #1347

WITH NUT #1692

5809

3-2-92

J

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

2.00" PITCH DIGGING TOOTH STATION BREAK DOWN

DIRT TOOTH, LEFT

PART #54431

DIRT TOOTH, RIGHT

PART #54432

SPACER BAR

PART #54439

1.81" SPACER TUBE

PART #54440

4.50" CAPSCREW

PART #1351

WITH NUT #1692

J

8" RIGHT STATION8" LEFT STATION

DIRT TOOTH, LEFT

PART #54431

DIRT TOOTH, RIGHT

PART #54432

10" CHAIN SPACER

PART #54441

3.25" CAPSCREW

PART #1347

WITH NUT #1692

6.50

10" STATION

5810

3-2-92

J

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

2.00" PITCH DIGGING TOOTH STATION BREAK DOWN

DIRT TOOTH, LEFT

PART #54431

DIRT TOOTH, RIGHT

PART #54432

12" CHAIN SPACER

PART #54442

4.50" CAPSCREW

PART #1351

WITH FLAT WASHER #1527

AND NUT #1692

J

8.50

12" STATION

5811

3-2-92

J

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

2.00" PITCH DIGGING CHAIN WIDTH CONVERSIONS

GENERAL INFORMATION

Digging chains can be modified to dig trenches in a variety of widths. By modifying an

existing chain, it can be used to dig the width you want and thus save going the expense of a whole

new digging chain assembly. This can be a considerable cost savings, however it is more work

than just installing a new digging chain assembly.

The information given below is a complete listing of all the possible chain width conversions

for 2.00" pitch chain for your trencher. Included in the listing is a break down of all the parts

(including part numbers and quantities) needed to make the conversion. Simply install the new

parts (and rearrange the old parts) so that the finished chain construction follows that described

in the “Digging Tooth Station Sequence” chart and the “Digging Tooth Station Break Down”

diagrams for 2.00" pitch chain (located elsewhere in this section).

It should be noted that this information only applies to modifying chains of the same length

and pitch. All components must be of the same pitch. You cannot intermix components of different

pitch.

J

CHAIN CONVERSIONS FOR 30" BOOMS - TOOTH EVERY STATION

1) FROM 6" WIDE TO 8" WIDE

REQ’D PART NO. DESCRIPTION

20 1351 .50"UNF X 4.50" Capscrew

2 54440 Space r Tube

10 54439 8" Spacer

1 53055 8" Crumber S hoe

2) FROM 8" WIDE TO 6" WIDE

REQ’D PART NO. DESCRIPTION

20 1347 .50"UNF X 3.25" Capscrew

2 54628 Space r Tube

1 53054 6" Crumber S hoe

3) FROM 6" WIDE TO 10" WIDE

REQ’D PART NO. DESCRIPTION

8 1692 .50" UNF High Hex Nut

16 1351 .50"UNF X 4.50" Capscrew

2 54431 Left Tooth

2 54432 Right Tooth

4 54441 10" Chain Spacer

1 53058 10" Crumber Shoe

8 54439 8" Spacer

6673

10-4-95

J

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONS

DIGGING CHAIN OPTIONSDIGGING CHAIN OPTIONS

2.00" PITCH DIGGING CHAIN WIDTH CONVERSIONS

4) FROM 10" WIDE TO 6" WIDE

REQ’D PART NO. DESCRIPTION

8 1347 .50"UNF X 3.25" Capscrew

4 54628 Space r Tube

4 54440 Space r Tube

1 53054 6" Crumber S hoe

5) FROM 6" WIDE TO 12" WIDE

REQ’D PART NO. DESCRIPTION

12 1692 .50" UNF High Hex Nut

28 1351 .50"UNF X 4.50" Capscrew

12 1527 .50" SAE Flat Washer

3 54431 Left Tooth

3 54432 Right Tooth

3 54441 10" Chain Spacer

3 54442 12" Chain Spacer

1 53059 12" Crumber Shoe

8 54439 8" Spacer

J

6) FROM 12" WIDE TO 6" WIDE

REQ’D PART NO. DESCRIPTION

16 1347 .50"UNF X 3.25" Capscrew

4 54628 Space r Tube

8 54440 Space r Tube

1 53054 6" Crumber S hoe

7) FROM 8" WIDE TO 10" WIDE

REQ’D PART NO. DESCRIPTION

8 1692 .50" UNF High Hex Nut

12 1347 .50"UNF X 3.25" Capscrew

2 54431 Left Tooth

2 54432 Right Tooth

4 54441 10" Chain Spacer

1 53058 10" Crumber Shoe

8) FROM 10" WIDE TO 8" WIDE

REQ’D PART NO. DESCRIPTION

4 1351 .50"UNF X 4.50" Capscrew

2 54628 Space r Tube

6 54440 Space r Tube

2 54439 8" Spacer

1 53055 8" Crumber S hoe

6674

10-4-95

J