Page 1

PLA Filament 1.75 mm

PLA (Polylactic acid) is the best material for getting started

with your 3D printer, as it:

– Hardens quickly

– Has minimal thermal tension

– Has minimal deformation

– Does not require Kapton tape

– Does not require heated bed

–Acetone-resistant

BQ PLA filament is made from 100% PLA.

PLA is a biodegradable product obtained from plant-derived sugars.

SKU: F000097

Coral

SKU: 05BQFIL023

Aubergine

SKU: F000098

Turquoise

SKU: 05BQFIL024

Magenta

SKU: F000099

Violet

SKU: 05BQFIL025

Sky blue

Filament Diameter: 1.75 mm

Thickness: 1.24 g/cm³ (ASTM D792)

Weight: 1 kg

Spool Size: 195 mm x 73 mm

Spool axle diameter: 52 mm

Compatible with: any printer that uses

1.75 mm filament

SKU: F000100

Sulphur yellow

SKU: 05BQFIL026

Coal black

SKU: F000101

Topaz blue

SKU: 05BQFIL027

Pure white

SKU: 05BQFIL028

Vitamine orange

SKU: 05BQFIL033

Transparent

SKU: 05BQFIL029

Ruby red

SKU: 05BQFIL034

Sunshine yellow

SKU: 05BQFIL030

Grass green

SKU: 05BQFIL031

Bottle green

SKU: 05BQFIL032

Ash grey

Page 2

PLA filament: technical datasheet

PROPERTY VALUE UNITS TEST METHOD

General properties

Specific gravity 1.24 g/cm

3

ASTM D792

Mechanical properties

Flexural elastic modulus 3600 MPa ISO 178

Flexural Strength 108 MPa ISO 178

Hardness, Sh D 85 Sh D ASTM D2240

Thermal properties

Heat distortion temperature HDT B (0,45MPa) 56 °C ISO 75/2B

Melting temperature 145-160 °C ASTM D3418

Glass Transition Temperature 56-64 °C ASTM D3418

In addition to the described properties, we have performed tensile tests on tensile specimen printed with our PLA

and on injection moulded tensile specimen in order to ascertain the mechanical properties of the final printed object.

The following table contains the results:

Mechanical properties

Injection moulded

tensile specimen

Printed tensile

specimen

ª

Printed tensile

specimen

b

Units

Test

method

Tensile strength at break 52 50 39 MPa ISO 527

Tensile elongation at break 5 9 4 % ISO 527

Tensile modulus 1320 1230 1120 MPa ISO 527

a

Stretch-direction is parallel to the layers.

b

Stretch-direction is perpendicular to the layers.

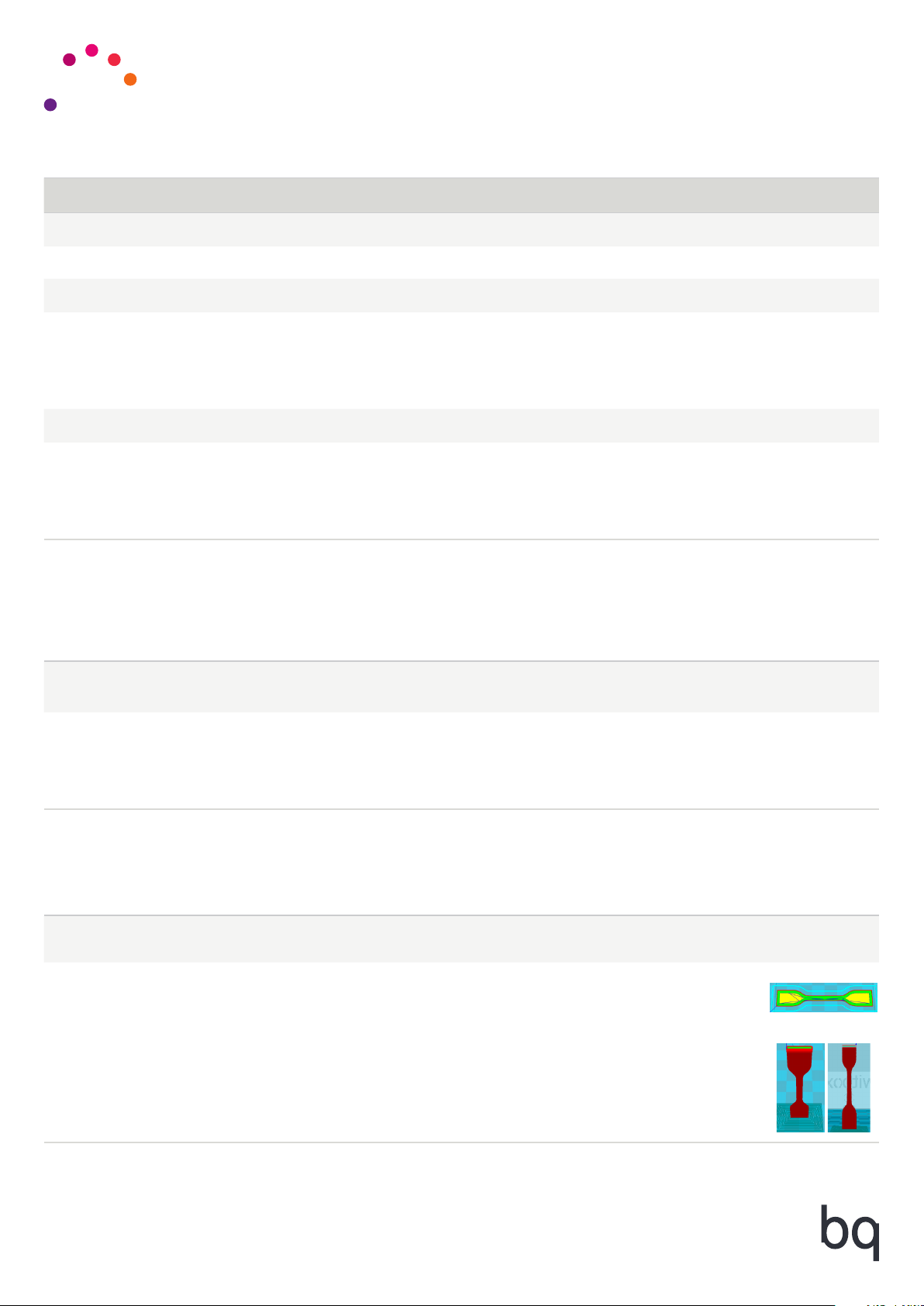

Tensile specimen

Tensile specimen print-direction is

parallel to the layers

Tensile specimen print-direction is

perpendicular to the layers

Layer height

(mm)

0.2 2 0.2 100

0.3 1 0.3 100

Shell thickness

(mm)

Bottom/top

thickness (mm)

Fill density

(%)

Print design

Loading...

Loading...