Page 1

HEAD OFFICE :

VIA BIBAN 56 ( Z.I. )

31030 CARBONERA

TREVISO - ITALIA

TEL. ++39 0422 445363

FAX ++39 0422 398646

EMAIL = info@bpstecnologie.com

PLEASE NOTE :

THE INSTRUCTIONS GIVEN HEREIN APPLY ONLY TO THE COUNTRY MARKED

ON THE PLATE STUCK ON THE APPLIANCE.

Page 2

1

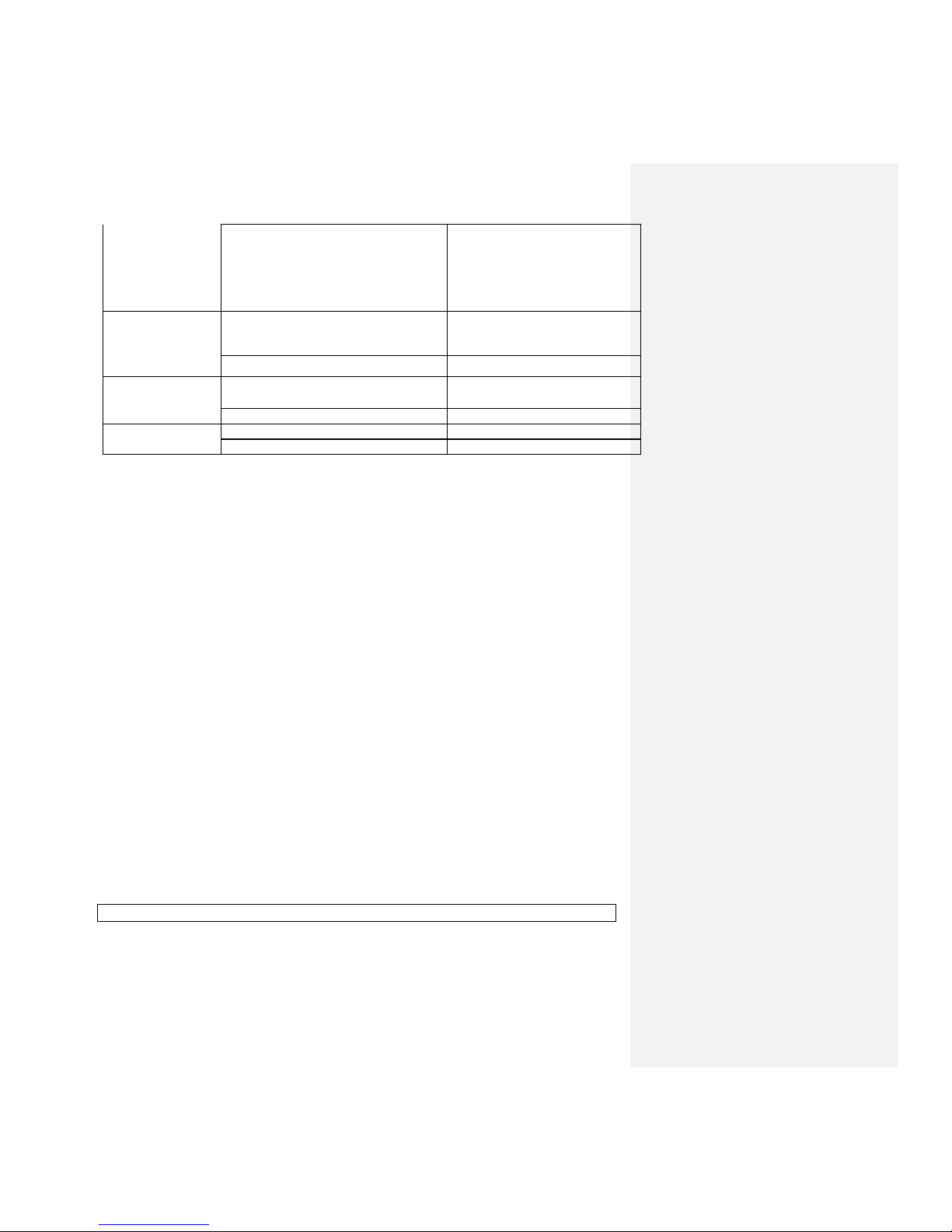

TECHNICAL FEATURES

MODEL NO. PRESTIGE 2 PRESTIGE 4

CERTIFICATION NO. CE 1312BP4187

NOMINAL THERMAL INPUT

kW 2 4

NOMINAL THERMAL OUTPUT

kW

1.8 3.6

THERMAL EFFICIENCY

µ

%

90 90

METHANE

G20 (9.45 kW)

0.22 0.42 0.42

CONSUMPTION METHANE

G25 (8.12 kW)

0.22 0.45 0.5

at + 15°C PROPANE

G31 (12.8 kW)

0.24 0.5 0.31

BUTANE

G30 /13.8 kW)

0.15 0.31 0.29

TREATED AIR

DELIVERY at +

20°C mc/h

0.14 0.29 105

65 105 145

THERMAL JUMP 85 145 84 / 55

TANGENTIAL FANS Number of revolutions/1’

64 / 45 84 / 55

1 1

VOLTAGE RATING

220 –

240 V/AC 50

-

60 Hz

INSTALLED ELECTRIC POWER Watt 80 100

NOISE LEVEL AT 3 m.

IN STANDARD INSTALLATION

dB (a) 36 38

WEIGHT

Kg. 19 26

COMBUSTION AIR REQUIRED

VOLUME

mc/h 4 8

SMOKES MASS OUTPUT gr./ sec. 1.46 2.92

FEEDING PRESSURE - mbar

COUNTRY CATEGORY G 20 G 25 G 30 G 31

ITALY II 2H3+ 20 30 37

FRANCE II 2Er3+ 20 25 28 37

BELGIUM I 2ErB/I3+ 20 25 28 37

SPAIN II 2H3+ 20 28 37

HOLLAND II 2L3B/P 25 30 30

PORTUGAL II 2H3+ 20 30 37

GERMANY II 2ELL3B/P

20 20 50 50

GREECE I 3+ 28 37

AUSTRIA II 2H3B/P 20 50 50

SWITZERLAND II 2H3B/P 20 50 50

Page 3

2

P R E S T I G E 2 GLO BAL V IEW

Pict.1

Page 4

3

PR ESTIG E 4 G LO BAL VIEW

Pict.2

Page 5

4

HOW TO INSTALL PRESTIGE 2 and PRESTIGE 4

”L” SIZE

Minimum = 300 mm

Maximum = 800 mm

SUPPLIED PIPE L = 500 mm

OPTION PIPE L = 800 mm

“L” SIZE

Minimum = 50 mm

Maximum = 300 mm

- WALL INSTALLATION -

SMOKES EXHAUST & AIR SUCTION DIRECT

TO & FROM OUTSIDE

- WALL INSTALLATION -

SMOKES EXHAUST & COMBUSTION AIR

SUCTION THROUGH THE OUTLET WINDOW

Pict.3

Page 6

5

HOW TO INSTALL PRESTIGE 2 and PRESTIGE 4

- WALL INSTALLATION -

90° HORIZONTAL SMOKES EXHAUST &

COMBUSTION AIR INSIDE THE WALL

- WALL INSTALLATION -

90° HORIZONTAL SMOKES EXHAUST &

COMBUSTION AIR CROSSING TWO WALLS

Pict.4

The heaters of the “PRESTIGE” series are independent forced air convectors, fitted with

atmospheric burner and fan, expressly designed for room heating.

These “C 13” type appliances are sealed with respect to the room where they’ve been

installed in, with concentric combustion air suction pipes and smokes exhaust pipes, wall

outlet (Pict.3-4).

They are: PRESTIGE 2 and PRESTIGE 4.

INSTRUCTIONS

Page 7

6

• Please carefully read all the instructions given in this booklet, as these are very useful for

both safe installation and proper use & maintenance.

• Installation to be carried out always strictly complying with the current standards of the

country where the device is going to be used, as well as following the instructions given

by the maker, of course. Only professionally qualified operators and authorized assistance

centers will be entitled to carry out installation. Should any wrong installation cause harm

to people or damage things, in no case the manufacturer will be held responsible for it.

• Please carefully check package and its contents before starting operating. If any doubt,

don’t use generator but ask the supplier.

•

Always keep package parts away from children reach, as those may be harmful.

•

Keep suction grids clear.

• In case of breakdown or failure: turn generator off, do not try to repair it on your own, call

operator.

• In order to ensure appliance correct working, have yearly checking and cleaning carried

out by qualified technical people only, following directions supplied by maker.

• If you’re going to leave convector off for a long time, please ensure that in no way this

would be harmful to anyone in any w

ay.

• This convector is to be used for heating purposes only. Any different use is not allowed as

it might be dangerous.

•

Always keep this handbook near convector.

• In case convector was placed in houses where disabled people and/or children live, then

place it safely away from their reach. Please note that temperature, on top of appliance,

can reach 100°C!

• In case of gas break-off, the appliance getting blocked, it would be necessary to make a

new start again ( see Start & Use chapter).

• In case of “flame checking hole” glass break, do not start the appliance. Call assistance

service.

INSTRUCTIONS for QUALIFIED INSTALLING OPERATORS

INSTALLATION

Inside the package you will find all the tools required for a correct installation, and at the end

of this manual you’ll see (page ?) the pattern required to mark holes on the wall for fixing

points and smokes outlet .

1. Mark fixing points & smokes exhaust outlet holes, depending on the heater, stay

minimum 100 mm up the floor.

2. Make holes.

3. Once you know wall width , add respectively 2 cm to the Ø 60 pipe and 4,5 cm. to the Ø

35 pipe. Connect the pipes to the heater and fix the Ø 60 pipe by the special screws

supplied.

4. Fix the heater to the wall by the plugs supplied, after having tested by a level the correct

position of the heater compared to the floor.

5. Fix the wind-proof terminal top outside by its special screws. Its smokes exhaust slots

must compulsorily be horizontal compared to the floor, while its combustion air suction

slots must be in the perpendicular way, always compared to the floor.

Fig.2 - Make holes.

Page 8

7

6. Now assemble the shell, fix the side screws.

7. Connect the heater to the gas supply, by adopting a detecting tap

8. Connect the heater to the power mains. Check the ground connection.

POWER CONNECTION

This convector has been duly manufactured in compliance with the CEE 73/23 rule.

Connection to be made by means of a H05 RR-F, 3 pole cable, section must be minimum 0,75

sq. mm. or wider. Connect through the terminal panel (Ref.19 on Pict.17), by strictly attaining

to the directions given.

= Compulsory ground connection (yellow

-

green wire)

N

= Neutral phase connection (light blue wire)

L1 = Active phase connection ( brown wire)

VERY IMPORTANT : Neutral-phase connection must necessarily be most accurate.

Wrong polarities may cause the whole machine stop, in case of phase/phase net with

high passive capacity values or serious insulating faults between line conductors and

earth. In order to ensure safe working, an insulating transformer must be used. In this

case, call assistance service.

We recommend to make connection preferably in the permanent way by means of a bi-polar

switch with contacts being at least 3 mm. far from each other. Please remember : the ground

conductor must never be cut off. In case the connection is made by means of a reverse plug,

then inform the user that the connection cannot work if the plug is turned upside down.

N.B. : ROTATE THE PLUG TO GET THE CORRECT CONNECTION,

THEREFORE THE CORRECT WORKING OF THE HEATER !

GAS CONNECTION

The heater is provided at the gas inlet point with an ISO 7/1 R1

⅜” or G S ISO 228 ⅜” thread

male nipple, depending on the country where the heater is working. The link must be made by

metal connections, complying with the current installation standards. Pay attention not to

force the nipple when making the link. At the end of the work check that it is actually sealed.

GAS TECHNICAL FIGURES

METHANE

(G20)

METHANE

(G25 – FRANCE/BELGIUM)

MODEL : PRESTIGE

2

PRESTIGE

4

MODEL : PRESTIGE 2 PRESTIGE

4

Ø of injectors in

mm.

1.2r

1.7r

Ø of injectors in

mm.

1.2r 1.7r

No. of injectors

1 1

No. of injectors

1 1

Pressure to the

injectors

in mbar

10

10

Pressure to the

injectors

in mbar

15

15

METHANE (G25)

(GERMANY – HOLLAND)

BUTANE/PROPANE

(G30/31)

MODEL : PRESTIGE

2

PRESTIGE

4

MODEL :

PRESTIGE 2 PRESTIGE

4

Page 9

8

Ø of injectors in

mm.

1.3 r 1.85 r

Ø of injectors in

mm.

0.8 r 0.7r 1.1r 1r

No. of injectors

1 1

No. of injectors

1 1 1 1

Pressure to the

injectors

in mbar

10

10

Pressure to the

injectors

in mbar

30/

37

50

30/

37 50

GAS LINE INSTALLATION DIAGRAM

The diagrams here below show both those parts being supplied along with the appliance and

those to be supplied by the installer.

G20/G25 Gas Line DIAGRAM

TO BE

ASSEMBLED BY

THE INSTALLER:

1. gas tap

2. gas filter

3. vibration-free joint

ALREADY

ASSEMBLED:

4. safety double electro-

valve in class B

G30/G31 Gas Line DIAGRAM

TO BE

ASSEMBLED BY

THE INSTALLER:

1. gas tap

2. gas filter

3. vibration-free joint

4. pressure adjuster

ALREADY

ASSEMBLED:

5. safety double electro-

valve in class B

Pict.5

APPLIANCES BELONGING TO THE 1st CATEGORY

(APPLIANCES BEING ADJUSTED FROM THE MANUFACTURING STAGE, IN THE

FACTORY - pls. refer to the label).

BURNER

BURNER

Page 10

9

-

No intervention is required. However we recommend to do as follows :

1. METHANE APPLIANCES (G20) (G25)

By a manometer on the “PV” point (Pict.6) compare the pressure value to the value stated on

the label. Should there be found a difference exceeding ±2 mbar, remove protection from

"RP" adjusting screw (Pict.6) and turn clockwise to increase, anti-clockwise to decrease,

bringing the "PV" (Pict.6) pressure value back to the values stated on the label.

2. BUTANE-PROPANE APPLIANCES (G30-31)

By a manometer on the “PV” point (Pict.7) compare the pressure value to the value stated on

the label. Should there be found a difference exceeding ±2 mbar, check the adjuster outside

the plant or have the gas mains Supplying Agency do it for you.

APPLIANCES BELONGING TO THE 2nd CATEGORY

(GAS TRANSFORMATION BY THE USER)

- Transformation From Original Adjusted Gas To A Different Type :

a) Remove outer shell by unscrewing the 2 side screws.

b) Unscrew the three piece pipe union placed beyond the gas electro-valve.

c) By a screwdriver remove injector placed inside the and replace it by the one supplied

with the heater, marked in advance according to the technical data table, always checking

the correct assembling and sealing.

d) Check and adjust the feeding pressure and write down on the label all data referring to

the change of gas that you’ve just made. Replace the label by a new one (that you’ll find

in the papers envelope) where you’ll have to specify the new working gas.

e) Pressure changes, depending on the type of gas:

- Type G20/G25 (methane) = lift the safety top from the "RP" adjusting screw (Pict.

6), turn the screw until finding the mbar figure on the "PV" pressure point (Pict. 6), as

stated on the Technical Data table (page 1).

- Type G30/31 (butane / propane) = lift the safety top from the "RP" (Pict.6) adjusting

screw, tighten well the screw and see if the figure on the "PV" pressure point (Pict.6)

corresponds to the value stated on the Technical Data table. Should there be found a

difference exceeding ± 2 mbar, you’ll have to check the adjusting device outside the

plant or have the gas Supplying Agency do it for you.

f) When the transformation is done, write down new settings on plate.

IMPORTANT FOR THE USER :

CAUTION - The appliance is provided with a maximum temperature hand reset thermostat

“24” (Pict.7), which will make the appliance block up in case of overheating of the heater.

You can reset it only after discovering and removing the reason of the trouble : only technical

operator or assistance service people will be entitled to do this.

FIRST IGNITION

Before first ignition, do as follows:

- Open the gas tap and let air leak out from the main pipeline - Warning : This

operation may cause gas escape !

- Place a manometer on the pressure point “PV” (Pict.6) of the electro-valve.

- Give voltage to the appliance.

- Set the room thermostat temperature a few degrees higher than the real one.

Page 11

10

- Bring green switch “4” to 1st position (Pict.7)

Please note : the blockage red light will stay on for about 20 seconds before the

burner’s start, however this doesn’t mean that there is a blockage but it just depends

on the electronic board. Should the blockage light stay on longer, take current off for

just a few seconds and then give current again. By doing so, you will cancel any alarm

signal that the electronic board might have put on. After a safety time, the electronic

board “20” (Pict.7) will feed the ignition device “6” (Pict.7) and the gas electro-valve

“7” (Pict.7). It may happen that because of air still left inside the piping, the electronic

board “20” (Pict. 7) blocks up. In this case it will be necessary to start up again the

appliance by clicking on the release button .

- When the burner is working, test the gas pressure value on the manometer and, if

necessary, bring this figure back to the label value, by turning either pressure

adjusting screw “RP” (Pict.6) of the electro-valve with G 20 / G 25 gas and on the

pressure reducer on the top of the appliance with G 30 / 31 gas.

- Make sure that gas consumption figure as you now can read from the gas meter is the

same as stated in the Technical Data table here above.

- Cut off the burner by clicking on the key “4” on the control board (Pict.7).

- Remove the manometer and carefully tighten well the pressure point screw “PV” in

order to avoid gas escape (Pict.6).

… AND NOW THE UNIT IS READY TO WORK.

LEGENDA :

PV = DOWNSTREAM

PRESSURE (INJECTOR)

RP = PRESSURE ADJUSTER

WHITE-RODGERS 25M42S

ELECTRO-

VALVE SET

Pict.6

TROUBLESHOOTING

MALFUNCTIONS - CAUSES & REMEDIES

In case of malfunctions in the hot air generator, first check the following points:

Electric power must be connected.

Should a rush of current occur, this mustn’t exceed +10% / -15%.

Page 12

11

Fuses must be in order.

There must be enough gas available.

Gas pressure and capacity values must be exactly as stated in the Technical Data here

above.

Here below please find the following troubleshooting list, where we explain also the reasons

and remedies to restore the correct performance of the heater.

MALFUNCTION POSSIBLE REASON REMEDY

The burner does

not start

Voltage failure Check main switch position

Check line

Check connections

Check fuses

Chokes in the smokes exhaust and the

combustion air suction pipes

Remove chokes.

Smokes pulling fan working in the

wrong way or damaged

Repair or replace it.

“LIMIT” or “RESET” thermostat

damaged

Replace it

“ROOM” thermost

at damaged

Replace it

Obstructed air inlet

Clear it.

The burner doesn’t

start, yet staying

blocked all the time

Electronic board damaged Replace it

The burner doesn’t

start, getting

blocked again after

safety time

Electronic board damaged Replace it

Air in the piping Clear it off

Electro

-

valve coil damaged or broken

Replace it

Electro

-

valve electronic card broken

Replace it

Starting electrode placed in the wrong

way or touching the burner

Take it 3 mm. away from burner

– or replace it.

After the safety time

the burner gets

blocked again after

ignition

Phase-neuter polarity problem

Change power connection or

reverse plug socket

No ground connection Make ground connection.

Detecting electrode somehow touching

the burner or placed in the wrong way

or no electric connection to the electric

panel

Place it in the right position, i.e.

2 cm. away from burner,

replace it or re-establish electric

connection.

The flame does not become stable

because of too short gas pressure

Adjust gas pressure.

The burner does

not restart after a

short rest time

Overheating in the exchanger due to

too much of gas capacity

Reset limit thermostat

Adjust values to find the correct

plate values

Adjust gas pressure

Air fan out of work

Check and remove it if broken.

See before Sudden choke in the air fan or top

slots

Remove it and clean.

Hand reset thermostat is interfering Reset it

Room thermostat damaged Replace it

Page 13

12

The burner gets off

during normal

working even

when temperature

getting below

scheduled figure

The thermal power of the heater is not

enough powerful to heat the whole

place.

Replace heater by another one

having suitable thermal power.

The heater works

no-stop, yet the

temperature is not

as high as required

Gas consumption lower than

recommended in the technical data

table

Adjust it

Dirty exchanger Clean it

The heater makes

steam and gets

dirty

Too short gas consumption Adjust sizes – see installation

details.

Smokes exhaust pipe is too long Make it shorter.

The fan doesn’t

start

Broken engine Replace

Fan thermostat damaged

Replace it

USE

This appliance has been designed to be used on trade buildings, artisan workshops,

industrial plants, leisure & sport places as well as for private houses, etc.. Never use it in

open-air, subject to atmospheric agents.

WORKING

To start up burner, put switch “4” in the “I” position (Pict.7), then rotate room thermostat

knob “1” in the positions 1, 2 or 3 as desired to obtain 15, 20 or 25°C, always a few degrees

over the actual room temperature. Now all the functions of the heater (start / stop) become

fully automatic, to get the desired room temperature.

To set the burner off, just turn room thermostat knob to “0”.

The air fan “11” (Pict.7) has got 2 speeds, being operated by the switch “2” (Pict.7). The

heater can be supplied with a timer (upon request) “5” (Pict.7), that can set working time as

desired, as follows:

a) Set the small lever on the 0 position : always off.

b) Set the small lever on the I position : always on.

c) Set the small lever on the centre of the slot : you’ve set the timer on.

d) Set working time by setting sliding staples as desired.

MAINTENANCE & CLEANING

a) Shut off gas supply.

b) Make sure that electrical power is actually disconnected.

c) Remove shell “17” (Pict.7), by unscrewing “A” fixing screws from the side of it.

d) Clean fans “8” and “11” (Pict.7), by means of a paint-brush. Remove dirt from blades.

e) Every new season, make sure that smoke exhausting and air intake pipes are thoroughly clean and

clear.

f) Once every two years (at least) call a technician to make a full check-up to the heater and, if

necessary, ask for the cleaning of the exchanger “16” (Pict.7).

P R E S T I G E G L O B AL V I E W

Page 14

13

LEGENDA

1. ROOM THERMOSTAT

2. SWITCH

3. BLOCKAGE LIGHT

4. ON-OFF SWITCH

5. TIMER (OPTION)

6. ELECTRODES

7. ELECTRO-VALVE

8. COMBUSTION FAN

9.

GAS PIPE

10. GAS 3/8” NIPPLE

11. FAN

12. ROOM THERMOSTAT

BULB

13. INSIDE COMBUSTION

AIR BAFFLE

14. BURNER

15. EYE CHECKING HOLE

16. EXCHANGER

17. SHELL

18. BAFFLE

19. TERMINAL PANEL

20. ELECTRONIC BOARD

21. CHIMNEY

22. REAR PANEL

23. AIR COLLECTOR

24. RESET ROOM

THERMOSTAT

25. AIR FAN THERMOSTAT

Pict.7

W I R I N G D I A G R A M

Page 15

14

F = Rapid Fuse 5 x 20 2A EV = Gas electro-valve

MI = Inside Terminal panel BR = Atmospheric burner

TM = Maximum thermostat EF = Smokes pulling fan

TF = Fan thermostat MV = Fan engine

TA = Room thermostat

IMT = Line switch

DV = 2 speed shunt switch

To be installed by customer :

EA = Ignition electrode IMT = Magneto-thermal switch

EI = Ionization electrode

Pict.8

W I R I N G D I A G R A M W I T H T I M ER

Commento [B1]:

Page 16

15

F = Rapid Fuse 5 x 20 2A EI = Ionization electrode

MI = Inside Terminal panel EV = Gas electro-valve

TM = Maximum thermostat BR = Atmospheric burner

TF = Fan thermostat EF = Smokes pulling fan

TA = Room thermostat MV = Fan engine

IMT = Line switch ORP = Timer

DV = 2 speed shunt switch

To be installed by customer :

EA = Ignition electrode IMT = Magneto-thermal switch

Pict.9

Commento [B2]:

Page 17

16

Pict.10

Loading...

Loading...