HP-200P SERIES

UPS’s

HP-206P

HP-210P

HP-215P

6 – 10 – 15 kVA

3 Phase Input – 1 Phase Output

USER MANUAL

CONTENTS

I. GENERAL DESRCIPTION.......................................................................................1

1.1 Introduction........................................................................................................1

1.1.1 Cautions for service personal.................................................................1

1.1.2 Battery cautions......................................................................................1

1.2 HP-200P UPS block diagram.............................................................................1

1.3 Technical Specifications....................................................................................5

II. FRONT PANEL........................................................................................................6

2.1 Introduction .......................................................................................................6

2.2 Front Panel Menu Descriptions..........................................................................6

2.2.1 Main Menu .............................................................................................7

2.2.2 COMMAND Menu items.........................................................................7

2.2.3 MEASURES Menu items........................................................................8

2.2.4 ALARMS Menu items.............................................................................8

2.2.5 USER OPTIONS Menu items.................................................................9

2.2.6 TIME Menu items ..................................................................................10

2.2.7 CALIBRATION Menu items...................................................................10

2.2.8 ADJUST MODE submenu......................................................................10

2.2.9 INFORMATION Menu items...................................................................10

2.3 STATUS Messages...........................................................................................11

2.4 SHUTDOWN MESSAGES ...............................................................................11

2.5 Fault messages and quick troubleshooting........................................................12

III. PARALLEL OPERATION........................................................................................14

3.1 Introduction........................................................................................................14

3.1.1 Redundancy...........................................................................................14

3.1.2 Power Increase ......................................................................................14

3.2 Parallel Operation Mode...................................................................................14

3.2.1 Redundant Parallel Mode.......................................................................15

3.3 Parallel Operation Mode Fault Codes................................................................15

3.4 Parallel System Accessories..............................................................................15

3.5 Effects of the parallel configuration on HP-200P series UPS.............................17

3.6 Taking off the parallel devices from a UPS........................................................17

IV. UPS INSTALLATION...............................................................................................18

4.1 Introduction........................................................................................................18

4.2 Unpacking .........................................................................................................18

4.3 Equipment Positioning.......................................................................................18

4.4 Connecting The UPS Power Cables..................................................................19

4.4.1 Safety Earth ...........................................................................................19

4.4.2 Cable connection procedure...................................................................20

4.4.3 Description of connection terminals of the UPS .....................................20

4.4.4 Battery Installation..................................................................................21

V. OPERATING INSTRUCTIONS.................................................................................22

5.1 First operating and Power ON ...........................................................................22

5.2 Power down.......................................................................................................22

5.3 Switching into maintenance bypass mode.........................................................22

5.4 Switching from maintenance bypass into normal operation................................22

VI. MAINTENANCE ......................................................................................................23

6.1 Scheduled Maintenance....................................................................................23

6.2 Daily checks......................................................................................................23

6.3 Weekly checks...................................................................................................23

6.4 Annual maintenance..........................................................................................24

6.5 UPS Storage and transportation........................................................................24

VII. FAULTS AND TROUBLESHOOTING.....................................................................25

7.1 General procedure for fault checking and troubleshooting.................................25

VIII. UPS’s REMOTE CONTROL CONNECTION .........................................................26

8.1 Using Serial Port................................................................................................26

8.2 Serial port connection cable...............................................................................26

8.3 Remote control/connection with a modem ........................................................26

8.3.1 Hardware Configuration..........................................................................27

8.3.2 Functioning Principle..............................................................................27

8.3.3 Modem programming procedure ...........................................................27

8.3.3.1 Smart Modem (SM) configuration (programming)....................28

8.3.4 Modem connection cables......................................................................28

8.4 UPS Remote monitoring panel connection........................................................28

IMPORTANT SYMBOLS

Symbols used in a UPS are classified as SAFETY and OPERATING categories as shown

below.

Kg

Pb H2 SO4

HIGH VOLTAGE.

WEIGHT.

ISOLATED LEAD

–

ACID BATTERY.

ATTENTION, FOLLOW INSTRUCTIONS BELOW.

READ INSTRUCTION MANUAL.

SAFETY SYMBOLS

OPERATING SYMBOLS

1

ı. GENERAL DESRCIPTION

1.1 Introduction

Messages displayed on the front panel are subject to change depending on the developments in UPSs. But

the Axx codes in front of the alarm messages are always the same. To be informed by the latest

developments in software. Please contact the service center.

1.1.1 Cautions for service personal

High voltage exists inside the UPS. Touching such points is very dangerous and hazardous. Accidental

electric arcs can be very hazardous while working inside the UPS (Only trained personal).

Some electrical components are heavy. If replacement is required please use suitable and helpful apparatus.

Otherwise injuries may occur.

Energy storage devices such as batteries and capacitors are used in the UPS. Before maintenance turn off

the device and wait at least 3 minutes to completely discharge the capacitors. Make sure batteries are

disconnected.

Unfortunate accidents may occur, therefore we advise a second helping service element nearby.

Take of any metal objects such as rings ot bracelets that can make a short circuit.

1.1.2 Battery cautions

Ni Cd batteries are used in the UPS’s. If not so, then the type of the batteries is lead acid. Therefore, use

protecting wear or hand gloves while maintaining batteries. Keep a fire extinguisher nearby the batteries

against any probable fire due to arcs.

Batteries are polluting elements. Therefore, be careful when disposing.

1.2 HP-200P UPS block diagram

Inverter

Rectifier /

Charger

Static Transfer Switch

Maintenance Bypass

3 Phase

AC

Input

1 Phase

AC

Output

Battery

MB

S

F2

F3-F4-F5

F1-F0

Figure 1 Electrical Block Diagram

On-Off

Micro switch

F6

2

Switches

F1-F0

: Battery circuit breaker switch & fuses

F2

: ON – OFF and By Pass switch & fuse

F3-F4-F5

: Rectifier input switch – Input switch & fuse

MBS

: Maintenance By Pass switch.

F6

: Output switch & fuses

• F1-F0 – Battery circuit breaker switch & fuse

Located at the input side of the device. It protects the other side of the system against any faults may occur

on the battery or the device.

• F2 – ON – OFF switch & fuse

F2 is basically a fuse on the bypass input line and it has an integrated micro switch which is used for turning

ON and OFF the UPS. Therefore, F2 will be mentioned as ON – OFF switch.

• F3-F4-F5 – Rectifier input fuse (switch)

These switches connect the line input to the input of the rectifier/charger. All power supplies in the equipment

connected to this switch.

• MBS – Mechanical maintenance bypass switch

There is no fuse on the line of mechanical by pass.

When the UPS is faulty or during the maintenance period this switch is used to connect the load, directly to

the bypass line.

• F6 – Output switch & fuses

This switch connects the output of the UPS to the load. This switch must be turne

d OFF after the

maintenance bypass switch is turned on properly according to its procedure. Maintenance bypass line is

connected to the output of this switch.

General description of UPS parts:

RECTIFIER/CHARGER: The first conversion stage (from AC to DC) uses a 3 phase, 6 pulse, fully controlled

rectifier to convert the incoming mains supply into a regulated DC BUS BAR. The DC BUS BAR produced by

the rectifier provides both battery charging power and power to the inverter section.

BATTERY GROUP: It keeps as an reserve DC power supply, for the inverter in case of mains failure.

Note : To increase the lifetime of the batteries keep them in room temperature (20oC-25 oC).

INVERTER: It is made by utilizing the latest technology of power transistor (IGBT) and pulse width

modulation (PWM). Inverter converts dc bus voltage into (second conversion) an alternative voltage like line

voltage. And provides this voltage and frequency being fixed.

STATIC TRANSFER SWITCH (STATIC BY-PASS): The circuit block annotated contains an electronically

controlled switching circuit, which enables the critical load to be connected either to inverter output or to a bypass power source via the” static by-pass line”.

MECHANIC TRANSFER SWITCH (MAINTENANCE BY-PASS): Manually controlled, ”maintenance by-pass”

supply is also incorporated into the UPS design. Its purpose is to enable the critical load to be powered from

the mains (by-pass) supply while the UPS is shut down for maintenance or troubleshooting.

3

F0-F1

Battery Fuses

F2

ON - OFF Switch

F3-F4-F5

Input Switch

MBS

Maintenance

ByPass Switch

( RS232 / SNMP )

Communication

Select Switch

(optional)

RS232 Communication

Socket (DB9 Female)

Emergency

Stop Switch I/P

F6

Output Switch

Figure

2-1

6 Kva Fuse and Switch Locations

Parallel Port

4

F0-F1

Battery Fuses

F2

ON - OFF Switch

F3-F4-F5

Input Switch

MBS

Maintenance

ByPass Switch

( RS232 / SNMP )

Communication

Select Switch

(optional)

RS232 Communication

Socket (DB9 Female)

Emergency

Stop Switch I/P

F6-F7

Output

Switch & Fuses

Figure

2-2

10-15 Kva Fuse and Switch Locations

Parallel Port

5

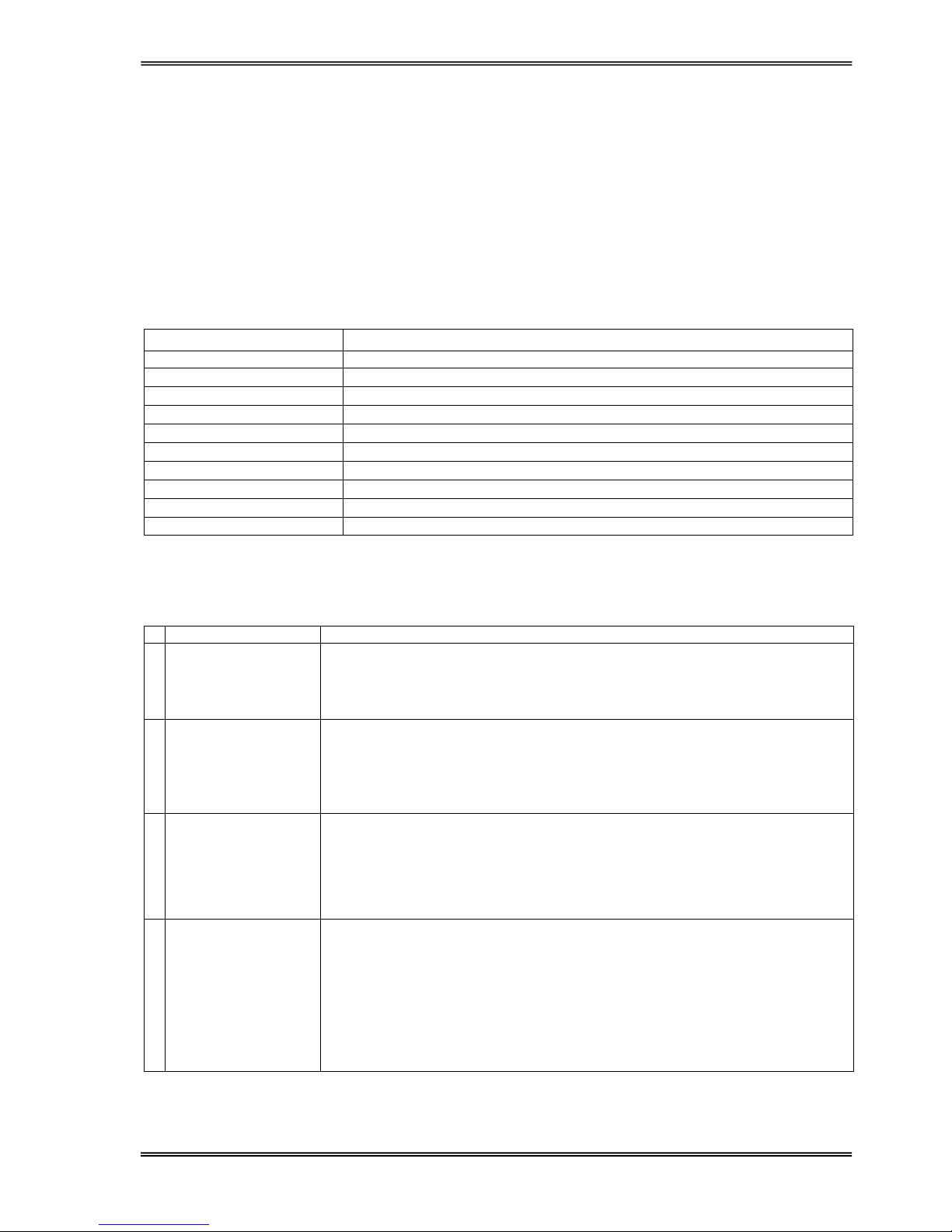

1.3 Technical Specifications

MODEL HP-206P HP-210P HP-215P

Output kVA 6 10 15

Output kW 4.2 7 10.5

Output Power Factor 0,7

Parallel Operation Equipment Available

Battery charging temperature compensation Available

Serial Communication RS232 (optional SNMP, RS485 or MODBUS)

INPUT

Input voltage 230/400Vac 3 Phase, N

Voltage tolerance

± 15%

By-Pass voltage 230Vac, N

Input frequency

50 Hz. ± 5%

RFI Level EN 50091

OUTPUT

Nominal output voltage 230Vac, N

Voltage regulation tolerance

±1%

Nominal output frequency 50 Hz.

Output frequency tolerance (Line syncron)

± 1%

Output frequency tolerance (Free running)

± 0,2%

Efficiency 100% Load 88-90 %

Load Crest factor 3:1

Overload

100%-125% load 10 min.

125%-150% load 1 min.

> 150% by-pass

Total Harmonic Distortion (THD) <%3

BATTERY

Type of Batteries Ni Cd

Number of Cells 242

Float charge voltage 340 Vdc

End of discharge voltage 273 Vdc

Battery Charging Current 20A 25A 46A

ENVIRONMENT

Maximum Temperature

0°C - 40°C

Audible noise <60dBA

Weight (approx) 165 Kgs 190 Kgs 200 Kgs

Dimensions (HxWxD) (mm) 1265x545x740

Protection Class IP 32

OTHER

Serial communication RS232 (standard) RS485 (optional)

Alarm contacts Standard

UPS SNMP Adaptor Optional

Remote Monitoring Panel Optional

6

II. FRONT PANEL

WARNING! The messages in this section are applicable for equipments having software version Y11PAR2.

If the version changes, the messages and functions will change as well.

2.1 Introduction

The front panel of UPS, consisting of a 2 lines alphanumeric display, 2 status lamps, plus 4 function keys,

allows the complete monitoring of the UPS status. The mimic flow diagram helps to comprehend the operating

status of the UPS. By using the function keys operator can move on menus and change some parameters.

Figure 3

L1

: If lamp is lit static bypass is active and load is connected to mains voltage

L2

: If lamp is lit inverter supplies the load

There are 4 function keys on front panel these are ENTER, UP, DOWN and (↔↔↔↔).

UP and DOWN keys help moving on menus, (↔↔↔↔) key selects options, ENTER key means the selected option

or menu is valid.

NOTE : During parameter settings, “+” sign will change into “—“ sign if “↔↔↔↔” button is pressed for 3 seconds

and the parameter values will start decreasing.

2.2 Front Panel Menu Descriptions

By using menu buttons on the front panel you can move on main menu functions. You can enter the submenu

of the item seen on the LCD panel (MEASURES, ALARMS, INFORMATION) and navigate within it by using

again ↓↓↓↓, ↑↑↑↑, ↵↵↵↵ (Enter) buttons.

MEASURES submenu

LD% (output load percentage)

OPV (output voltage)

FREQU (output frequency)

IPV (input voltages)

BYP (bypass source voltage)

BATT (battery voltage and current)

...... etc

L1

L2

ENTER

7

SAMPLE menu selection:

If you want to go to MEASURES menu use UP and DOWN keys and find MEASURES MENU, press ENTER

key, now you can move on MEASURES menu subitems by UP and DOWN keys.

At the end of sub menus ENTER (EXIT) message is available and while reading this message, if you press

ENTER key you can go back to MAIN menu.

In ALARMS MENU you can see LOG HISTORY, log events are recorded with event time and date.

PASSWORD Menu is used for service purposes. This menu requires a three digit password and should be

used only by qualified service personnel..

2.2.1 Main Menu

Main menu items are described below, navigation through them can be performed using up and down

buttons.

Main menu items Function

STATUS

The status message which shows the UPS status

COMMAND MENU

→ Enter “go to Command submenu”

MEASURES MENU

→ Enter “go to Measures submenu”

ALARMS MENU

→ Enter “go to Alarms submenu”

USER OPTIONS

→ Enter “go to User Option submenu”

TIME MENU

→ Enter “go to Time submenu”

CALIBRATION MENU

→ Enter “go to Calibration submenu”

ADJUST MENU

→ Enter “go to Adjust submenu”

INFORMATION MENU

→ Enter “go to Information submenu”

Go to STATUS MENU

2.2.2 COMMAND Menu items

This menu is used to give commands to the UPS or perform tests on it.

Submenu item Function

1

SOUND : ON/OFF

(is available)

Used for turning on/off alert sound.

If you press ENTER key the option will change, one press ON, one press OFF.

If the OFF option is selected sound alert is turned off but if a new alarm, UPS

changes the option to ON state.

2 ENTER <BYPASS>

If you press ENTER for 3 seconds, the load is transferred to BYPASS

automatically and the submenu item changes to ENTER <INVERTER> this time.

If you press ENTER for 3 seconds, the load is transferred back to Inverter.

3 ENTER B.TEST>405

If you press enter for 3 seconds battery test starts and lasts for 15 seconds.

If battery test fails A6 BATT FAULT message is shown on panel and this

message stays until you press ENTER key for 3 seconds.

The value on at the right shows the battery voltage during battey test.

Starting time of battery test recorded to log event menu if the test is successful

you can see only BATTERY TEST message on log records..

4 ENTER <BOOST>

If you press ENTER key for 3 seconds boost charge starts. The given time for

boost charge is 10 hours. At the end of this time UPS stops the boost charge.

If the boost charge is active this submenu item changes to STOP BOOST>

005H message the 005H shows that boost charge is going on for 5 hours.

If the number is 10 boost charge stops. If you press ENTER key boost charge

stops immediately.

Boost charge starting and boost charge end times are recorded to log event

menu.

If boost is active UPS beeps each 15 seconds

8

Submenu item Function

5 SIMULATION OFF

The purpose of this submenu to check dry contact connections. Normally to

check line failure contact you must turn off mains power. This is not

necessary with this utility. 3 options are available.

SIMULATION OFF simulation mode is off

SIM:LINE FAILURE if you press ENTER key for 3 seconds the line failure

lamp on interface board is turned on.

SIM:LIN.F+BT.LOW if you press enter key for 3 seconds the line failure and

battery low lamps on interface are turned on.

SIM:BYPASS if you press ENTER key for 3 seconds the bypass (aux) lamp

on interface board is turned on.

So you can check dry contact connections

6 ENTER FAULT RESET

Faults reset selection.

7 ENTER EXIT

→ Enter (↵↵↵↵ ) exit from submenu

Goto first submenu item

2.2.3 MEASURES Menu items

All the measurements of the UPS can be monitored via this menu, navigation through the items is performed

using up and down buttons.

Submenu item Function

1 LD%: 060

Output load percentage

2 OP CURR : 011A

Output current

3 OPV: 236

Output voltage

4 IPV: 400 400 400

3 Phase input voltages

5 BATT: 340 V

Battery voltage

6 BYP: 230

By-pass voltage

7 FREQU: 50.0 Hz 50.0 Hz

Input frequency – Output frequency

8 TEMP: 030 c

UPS Internal temperature

9 ENTER EXIT

→ Enter (↵↵↵↵ ) exit from submenu

Goto first submenu item

2.2.4 ALARMS Menu items

The last 64 events can be monitored in this menu.

Submenu item Function

1 UPS STATUS

Alarm status at that instant.

2 000>311201 23:15

Monitoring past alarms:

First 3 digit number indicates the event number, 000 event is the last one.

Date is in ddmmyy and time is in hh:mm format.

On the second line, the alarm events on the first line are listed. Using ↔

button 128 events can be viewed.

3 PARR.ERR.NR : 017

Parallel controller board error (If parallel hardware exists)

If this value is 0 then the parallel is OK

4 ENTER EXIT

→ Enter (↵↵↵↵ ) exit from submenu

Goto first submenu item

9

2.2.5 USER OPTIONS Menu items

From this menu the user selects some important parameters and apply them.

Submenu item Function

1 MODE: ONLINE

4 Operating modes can be selected using up and down buttons.

ONLINE: normal operating mode.

PARALLEL: Symmetric parallel operation mode of 2 UPS’s.

HOT STANDBY: 1 UPS is master and 1 UPS is redundant operating mode.

REDUNDANT: 2 UPS’s redundant operating mode.

→ Press ENTER for 3 seconds to save the selected mode.

2 UPS No : 001

By using PLUS and MINUS keys you can change number 0 to 3.

In parallel operation select different numbers for each UPS. If you select the

same number DUBL UPS NUMBER message tells the fault.

→ press ENTER for 3 seconds and then the selection is valid

3 BYP.PROTECT ON

By using ↔ key you can change on and off options.

ON: if the bypass source is out of tolerance, UPS turns off load power in

case of a fault or overload..

OFF : UPS turn off load power only during bypass moves. If bypass period is

completed UPS continues to supply the load.

→ press ENTER for 3 seconds and then the selection is valid

4 RESTART:ON/OFF

By using ↔ key you can change on and off options.

ON : during mains failure at the and of battery discharge UPS shutdowns

,after mains restored UPS starts again.

(battery trip out is on every time)

OFF: after mains restoration UPS doesn’t start again.

(battery trip out is off)

→ press ENTER for 3 seconds and then the selection is valid

5 REMOTE : ENABLE

By using ↔ key you can change enable and disable options.

Enable : remote battery test, shutdown and bypass functions are enabled

disable : these functions are disabled

→ press ENTER for 3 seconds and then the selection is valid

6

CENTER-EDGE

LANGUAGE

Turkish – English is selected.

7 BOOST TIME

Quick charge period of 1-15 hours is configured. Boost is disabled if 0 is

entered while boost charge.

8 BOOST

Manual – automatic modes are selected using ↔ key. Normal charge mode

operates in manual selection. In automatic mode, if the line is off, at each

time input line voltage is restored the boost charge starts automatically.

9 DIRECT START: ON

ON: UPS at the beginning starts automatically.

OFF: The inverter is in standby.

The inverter starts and the output forms when ENTER is pressed. Until this

moment the load is supplied from the by-pass.

10 XFER MOD: CURRENT

CURRENT: Switches into bypass without delay when the current is zero

DELAY: If the UPS is not synchron , switching into bypass takes place with

15 ms. Delay.

11 RELAY COMMON

12 RL4 COMMON

Alarms: COMMON, RL4, BATT. LOW, OUTPUT HĐGH, OVERLOAD, LĐNE

FAILURE, OVER TEMP., OVER CURRENT, OUTPUT LOW, BATTERY

HĐGH, BATT. FAULT, BY-PASS BAD, BOOST CHARGE, MANUEL BYP,

ROT. PHASE, OUTP. OFF, UPS FAILURE.

RL4 relay can be defined for any desired alarm.

13 RL5 COMMON

Alarms: COMMON, RL4, BATT. LOW, OUTPUT HĐGH, OVERLOAD, LĐNE

FAILURE, OVER TEMP., OVER CURRENT, OUTPUT LOW, BATTERY

HĐGH, BATT. FAULT, BY-PASS BAD, BOOST CHARGE, MANUEL BYP,

ROT. PHASE, OUTP. OFF, UPS FAILURE.

RL5 relay can be defined for any desired alarm.

14 ENTER EXIT

→ Enter (↵↵↵↵ ) exit from submenu

Goto first submenu item

10

2.2.6 TIME Menu items

You can see date and time of RTC (real time clock) on UPS. And you can adjust date and time.

Submenu item Function

1 TIME : 23 :15

time

2 DATE : 11-10-2006

date

3 SET HOURS: 11

(+) and (-) adjust hours (0-23)

4 SET MINS : 38

(+) and (-) adjust minutes (0-59)

5 SET DAY : 21

(+) and (-) adjust day (1-31)

6 SET MONTH : 06

(+) and (-) adjust month(1-12)

7 SET YEAR : 2006

(+) and (-) adjust year (2000-2099)

8 ENTER <UPDATE>

→ Enter update new date and time

9 ENTER EXIT

→ Enter (↵↵↵↵ ) exit from submenu

Goto first submenu item

2.2.7 CALIBRATION Menu items

This menu is used to adjust time and date of the UPS.

Submenu item Function

1

(Password required ) System adjustments.

ENTER EXIT

→ Enter (↵↵↵↵ ) exit from submenu

Goto first submenu item

2.2.8 ADJUST MODE submenu

This menu is used to adjust time and date of the UPS.

Submenu item Function

1

(Password required ) System adjustments.

ENTER EXIT

→ Enter (↵↵↵↵ ) exit from submenu

Goto first submenu item

2.2.9 INFORMATION Menu items

This menu gives information about the UPS

Submenu item Function

1 COMM :OK SYNC :OK

If the UPS is operating syncron to mains SYNC:OK ,if not syncron

SYNC:-If communication is active COMM:OK ,if not active COMM:--

2 POWER: 10000 VA

The maximum power rating of the UPS

3 VERSION : Y11PAR2

Shows the UPS software version

4 SPARE MASTE 006

5 ENTER EXIT

→ Enter (↵↵↵↵ ) exit from submenu

Goto first submenu item

11

2.3 STATUS Messages

This message group simply shows the UPS STATUS at the upper line of LCD PANEL.

RECTIFIER START ! : UPS started the rectifier

ENTER START : Press ENTER to start the UPS.

INVERTER START ! : UPS started the inverter.

MAINT SWITCH ON ! : Maintenance bypass switch is on

STATUS NORMAL ! : UPS is operating.

EMERGENCY STOP ! : External emergency stop signal is applied to UPS.

WAITING SYNC ! : Inverter started waiting for mains synchronization.

STATUS FAULT ! : Fault status

RECTIFIER START :

At start up the UPS controller board checks for input voltage, frequency, battery voltage for starting ,if these

parameters normal, UPS starts.

INVERTER START :

If the inverter stops from any reason, controller board tries to start inverter again, during inverter start this

message appears on first line of LCD PANEL

MAINT SWITCH ON:

Maintenance bypass switch is connected from input to the output of UPS directly .Đf the maintenance bypass

switch is on (1 position) controller stops inverter for accidental short circuits between mains voltage and

inverter output. If the user turn off maintenance switch inverter starts again.

EMERGENCY STOP :

If an external EPO switch is installed to system (connected to interface board), to stop all UPS parts (rectifier,

static bypass ,inverter ,etc….) is possible . After pressing EPO switch all parts of the UPS stops, for restart

turn off S1 (inverter input) switch and turn on again.

FAULT STATUS :

In some cases controller checks events but can not find solutions, in this case controller decide to stop

system, for restart user must turn off S1 (inverter input) switch and turn on again.

2.4 SHUTDOWN MESSAGES :

HP-200P series UPS’s can operate interactive with operating system, you can send commands to UPS from

operating system by using some softwares .UPS takes this commands and produces some messages these

are:

WAITING SHUTDOWN : Shutdown command is performed from operating system and UPS is waiting

for a certain delay for shutdown.

UPS SHUTDOWN : UPS is in shutdown status

WAITING RESTART : UPS is shutdown but it is waiting for a certain delay for restart

PAR.SHUTDOWN : In parallel system the other UPS send shutdown command and UPS is in

shutdown status.

CANCEL SHUTDOWN : Shutdown command is cancelled.

Only operating system or a PC computer can send this commands.

If the shutdown command is performed during line failure UPS shutdowns and is the mains is okay UPS starts

again automatically.

12

2.5 Fault messages and quick troubleshooting

All alarms contained in Y11PAR2 version are listed in the following table.

ALARM POSSIBLE CAUSE

A1 BYPASS FAILURE

Bypass system failure. Bypass elements may be broken.

A2 INVERTER FAILURE

Inverter digital start system is failed. Call the service.

A3 3 OVERTEMP

Overtemperature in UPS repeated 3 times in 30 min.

1) Check for UPS air inlets and outlets for any blocking by dust etc.

2) Fan failure

3) Bad UPS location

4) Check for Overload

A4 OUT FAILURE

UPS output voltage is out of tolerance at 3 times in 30 min. Call the service.

A5 BATT AUT END

Batteries are completely discharge wait for restoration of electric power

input.This message occurs only at line failure

A6 CHARGER FAULT

Rectifier could not produce DC bus voltage.

A7 BATTERY LOW

Battery voltage is low.

1) UPS operation for a long time when line out

2) Charger system failure

A8 OUTPUT HIGH

Inverter output voltage is over than max. tolerated value.

Inverter is stopped

1) Inverter failure

A9 OVERLOAD

UPS loaded over than max. %100 load level.

A10 LINE FAILURE

Line failure.

1) Maybe line out

2) Check 3 input phases.

3) Check UPS input fuses.

A11 HIGH TEMPER

Over temperature. (inverter or rectifier section)

1) Overload for inverter

2) Over temperature

3) Fan failure or dirty air inlets

4) Bad UPS settling. There is not enough ventilation area.

A12 OVERCURRENT

Inverter output system failure

1) Internal overcurrent

2) Short circuit.

3) UPS failure. Call the service.

A13 OUTPUT LOW

Inverter output voltage is below the min tolerated value.

Inverter is stopped.

A14 BATTERY HIGH

Battery voltage is over than max. tolerated value.

If the mains is off the tolerance when switching into bypass. The UPS turns

off the output voltage and waits until the inverter starts again to prevent the

load.

A16 BYP INPUT BAD

During transfer to bypass, Voltage or frequency value of bypass source is

incorrect and the UPS turns off the load power.

During normal (inverter) operation some times you can see this message.

During bypass if the bypass protection option is on, and if the bypass

source is out of tolerance UPS turns off the static bypass for load

protection.

A19 REPLACE BATT

Battery test aborted. And batteries are not OKAY

UPS gives beep sound within 15 sec

You can clear this message by pressing 3 seconds to ENTER key

1) Rectifier fault

2) Damaged battery cells

3) POOR battery connections

A20 BOOST CHARGE

Boost charge is active for 10 hours. At the end of this time UPS stops the

boost charge.

UPS gives beep sound every 15 sec

13

ALARM POSSIBLE CAUSE

A21 ROTATE PHASE

UPS input phases sequence is not correct

1) Turn off the UPS and rotate phase sequence

2) Turn on UPS again

A22 OUTPUT OFF

Output OFF alarm

- Output switch may be off.

- A fault may be in the output. Check the output components.

A23 MODE FAILURE

In parallel operation the slave device tries to operate as the same mode as

the master device, If the modes are different this message will appear.

Change the mode of the slave UPS from USER OPTION MENU. Press

ENTER button for 3 seconds after mode selection, then restart the UPS.

A24 P.FAILURE 10

RS485 failure

A25 PAR. PSP FAIL

Power supply error in parallel controller board.

A26 4 CABLE FAIL

Master-Slave digital cable connection error.

A27 P.FAILURE 13

Parallel controller board failure, online UPS found in parallel system.

A28 PLUG IN DIG.

Digital connection cable plug in failure

A31 DUBL UPS NUMBER

Parallel UPS numbers are same change one of them

A40 CANT FIND PR

Parallel mode is selected but main controller could not find parallel control

board.

Select ONLINE mode from SETTING MENU.

Turn off the ups and turn on again.

A41 P.BAL.FAILURE

In parallel operation current sharing is not okay

A42 BATTERY TEST

Performing battery test

A43 P.SYNC.FAIL

In parallel system SLAVE UPS is not synchronized to MASTER UPS

1) Wait for 10 seconds the UPS will be restart

A48 STATIC BYPS.

Load is transferred statically to bypass

A50 EMERGE.STOP

Emergency stop button is pressed.

A51 MAINT SW.ON

Maintenance bypass switch is open. (optional)

A53 CHECK +6V

Check +6V on them main controller board.

A54 CHECK DC1

Battery voltage is below the lower limit.

A55 PDLY FAIL

Parallel delay fault

A59 REF FAILURE

2.5 V ADC reference voltage on MPB211 main controller board exceeds

predefined tolerances.

14

III. PARALLEL OPERATION

3.1 Introduction

Two of HP-200P UPS can be used in parallel mode, the purpose of parallel use:

• Redundancy

• Power increment purpose.

3.1.1 Redundancy

Even if UPS designs are perfect sometimes some failures are possible. Also the lifetime of batteries and

some parts are limited. In such a case, the second UPS installed on the system will be working on.

3.1.2 Power Increase

Some load systems always develop and the power need increases, the cheapest solution is to install one

more UPS to the system.

3.2 Parallel Operation Mode

NOTE: Parallel control board and some accessories are not installed in a standard HP-200P series UPS, but

parallel operation option is available for these models.

User can select parallel operation mode as an option according to purpose. If parallel control board is installed

in your UPS, you can select operation mode from SETTINGS MENU. In this chapter you can find parallel

operation mode information.

The general diagram of parallel connection is shown below:

Figure 3-1 Parallel connected UPS’s

MB1

SB1

UPS1

CB1

AC/DC -1

BATT.1

INVERTER 1

SB2 CB2

MB2

SB3

UPS2

CB3

AC/DC -2

BATT.2

INVERTER 2

SB4 CB4

OUTPUT

LINE

S1

S2

S3

S4

S1

S2

S3

S4

15

3.2.1 Redundant Parallel Mode

At this mode if one of the UPS’s fails the other UPS continues to supply the load.

Assume that UPS1 on figure 3-1 is failed, SB1 and SB2 static switches will turn off and the UPS 1 is isolated

from load. The SB4 static switch of the UPS 2 will stay in conducted position and it continues to supply the

load.

If UPS 1 is okay after a delay this UPS will join the system.

If two UPS’s are in failure SB1 and SB3 static switches will turn on and load is transferred to bypass

This is a 3 level redundancy UPS1+UPS2, UPS2, mains

Current sharing is active in this mode.

In this mode the power of load must be lower than 1 UPS power.

3.3 Parallel Operation Mode Fault Codes

A23 MODE FAILURE

The modes of the two UPS’s are different, change the modes.

The SLAVE UPS always requires to be in the same mode with MASTER UPS.

Change the mode of SLAVE UPS to be the same as the MASTER’s mode.

Do not forget to press ENTER key.

Turn off the SLAVE UPS and then turn on.

A24 P.FAILURE 10

RS485 failure between parallel UPS’s.

A25 PAR. PSP. FAIL

Parallel board failure.

A26 4 CABLE FAIL

Parallel digital cable failure.

A27 P.FAILURE 13

Another ON-LINE UPS exists.

A28 PLUG IN DIG

Socket unplugged,

A31 DUBL UPS NR.

The same UPS number is selected for SLAVE UPS, you must assign different

UPS numbers to each one in parallel systems.

Go to SETTINGS menu and change the UPS number.

Do not forget to press ENTER key.

Turn off the SLAVE UPS and then turn on.

A40 CANT FIND PR

Parallel mode was selected from the front panel but the main controller couldn’t

find parallel control board.

Select ONLINE mode from SETTINGS menu (ENTER key for 3 Sec.)

Turn off then on.

A41 P.BAL.FAILURE

Current sharing failed in parallel operation.

A43 P.SYNC.FAIL

In parallel system SLAVE UPS is not synchronized to MASTER UPS

3.4 Parallel System Accessories

At standard HP-200P series there is no installed parallel components but they can install. For parallel

operation the following parts are necessary:

• Parallel control board

• Digital connection cable (PCC04)

• Parallel interface board

During order, the customer should give information about any options and accessories, to factory.

IMPORTANT NOTE: Parallel system installation is much more complex from stand-alone UPS installation, it

needs qualified service personnel.

You have to keep 2 m distance between two UPS’s for service purposes.

Add 20% tolerance to power cable sizes, fuses and circuit breakers in parallel connection.

In figure 3-2, the connections of 2 parallel UPS’s and load distribution panel are shown.

16

AC INPUT

AC OUTPUT

ANALOG / DIGITAL

CABLES

Neutral

Ground

AC INPUT

DISTRIBUTION

BOARD

Battery

Input

Battery

Input

AC INPUT

LOAD

UPS 1

UPS 2

AC OUTPUT

DISTRIBUTION

BOARD

Figure 3-2 Parallel UPS Connection.

NOTE : OUTPUT CONNECTIONS MUST BE OF EXACTLY THE SAME LENGTH.

CAUTION :

During operation do not turn off CB1 or CB2, first turn off the UPS output switch then

turn off the CB1 or CB2.

17

3.5 Effects of the parallel configuration on HP-200P series UPS

If the parallel card is installed on a HP-200P series UPS some calibrations of the UPS will be changed. ( e.g.:

output voltage and symmetry adjustment)

Do not select ONLINE mode if the UPS is parallel configured, please select REDUNDANT MODE, in this

case, if digital PARALLEL communication connector is not connected the UPS, it gives A28I PLUG IN DIG.

Alarm. To cancel this alarm some modifications must be done. These are:

1) If digital parallel communication (PCC04) cable is given connect this cable to the parallel digital

communication plug and select REDUNDANT mode.

2) If digital parallel communication cable is not given connect pin 15 and pin 16 to each other on this

plug and select REDUNDANT mode.

3) Take off parallel configuration and work at ONLINE mode.

NOTE: The above condition occurs when a parallel UPS operates alone in ONLINE mode.

HP-200P series requires only a parallel control board to operate in parallel mode.

3.6 Taking off the parallel devices from a UPS

1) Shift to the ON – LINE mode.

2) Switch off the UPS (all switches must be in 0 position)

3) Remove the parallel connection cable.

4) Remove the connection between CN3 on MPB211 main controller board and CN7 on PARA22-R1 parallel

controller board.

5) Remove the source cable from PARA22 parallel controller board (CN8 – CN9).

6) Turn on the UPS.

NOTE : The output voltage of the UPS will be changed if the parallel board is disconnected from main board

please re adjust the output voltages of the inverter

In this status the main controller board controls all functions of the UPS.

NOTE: After take off the parallel ports from UPS for stand alone online operation you must connect

maintenance switch and manual bypass switch to the VCS3P board.

CN6 pin 2-4 maintenance bypass switch

CN6 pin 3-4 manual bypass switch

UNPLUG CN2 from PARA22 board, plug to VCS3P CN6.

IN ONLINE MODE OUTPUT SWITCH IS NOT CONNECTED.

18

IV. UPS INSTALLATION

4.1 Introduction

WARNING!!!

• Do not apply electrical power to the UPS equipment before the arrival of authorized service personnel.

• The UPS equipment should be installed by a qualified service personnel.

• The connection of the batteries and the maintenance should be done by the qualified service personnel.

• Do not make short- circuit to the batteries poles. Because of the high short-circuit current, it has the danger

of electrical shock or burn.

• Eye protection should be worn to prevent injury from accidental electrical arcs. Remove rings, watches and

all metal objects. Only use tools with insulated handles. Wear rubber gloves.

This chapter contains location installation information of the UPS and the batteries. All the establishments

have their own specialties and needs. So in this part the installation procedure is not being explain step by

step. Instead general procedure and the applications are explained for the technical personnel.

4.2 Unpacking

The UPS is packed and enclosed in a structural cardboard carton to protect it from damage.

1) Inspect for damage that may have occurred during the shipment If any damage is noted, call the shipper

immediately and retain the shipping carton and the UPS.

2) Carefully open the carton and take the UPS out.

3) Retain the carton and packing material for future use.

Unit package contents:

1) A user manual and Guarantee certificate.

2) Battery cabinet and/or shelf (Optional)

3) Battery connection cables.

4) Battery Circuit Breaker (Optional)

4.3 Equipment Positioning

1) The equipment’s installation place must be an easy serving place.

2) Install the UPS in a protected area with adequate air flow and free of excessive dust.

3) You must therefore allow for a minimum gap of 250 mm behind the unit to allow adequate air flow

4) Select a suitable place (temperature is between 0°C and 40°C) and the relative humidity (%90 max)

5) It is recommended to air-conditioned the room (24°C)

6) Temperature is a major factor in determining the battery life and capacity. Battery manufacturers

quote figures for an operating temperature of 20°C. On a normal installation the battery temperature

is maintained between 15°C and 25°C. Keep batteries away from main heat sources or main air inlets

etc.

7) In case of an operating the UPS in a dusty place, clean the air with a suitable air filtration system.

8) Keep out of your equipment from the explosive and flammable items.

9) Avoid direct sunlight, rain, and high humidity.

WARNING!!! Check the capacity of the forklift if it is available for lifting.

DO NOT MOVE THE BATTERY CABINET WHILE THE BATTERIES ARE INSTALLED.

19

4.4 Connecting The UPS Power Cables

WARNING!!! A separate line should be used to supply the UPS AC input. Never use the same line to supply

another electrical devices. Do not use any additional cable to increase the length of the UPS’s

input cable. It is advised to use an MCCB suitable for the input current on the UPS’s input line.

The connection of the electrical panel should be supplied by a grounded outlet.

Otherwise, the UPS and the load connected to the output will be left ungrounded. The

grounding system must be controlled, and must be strengthen if required. Potential difference

between ground and neutral must be less than 3V AC.

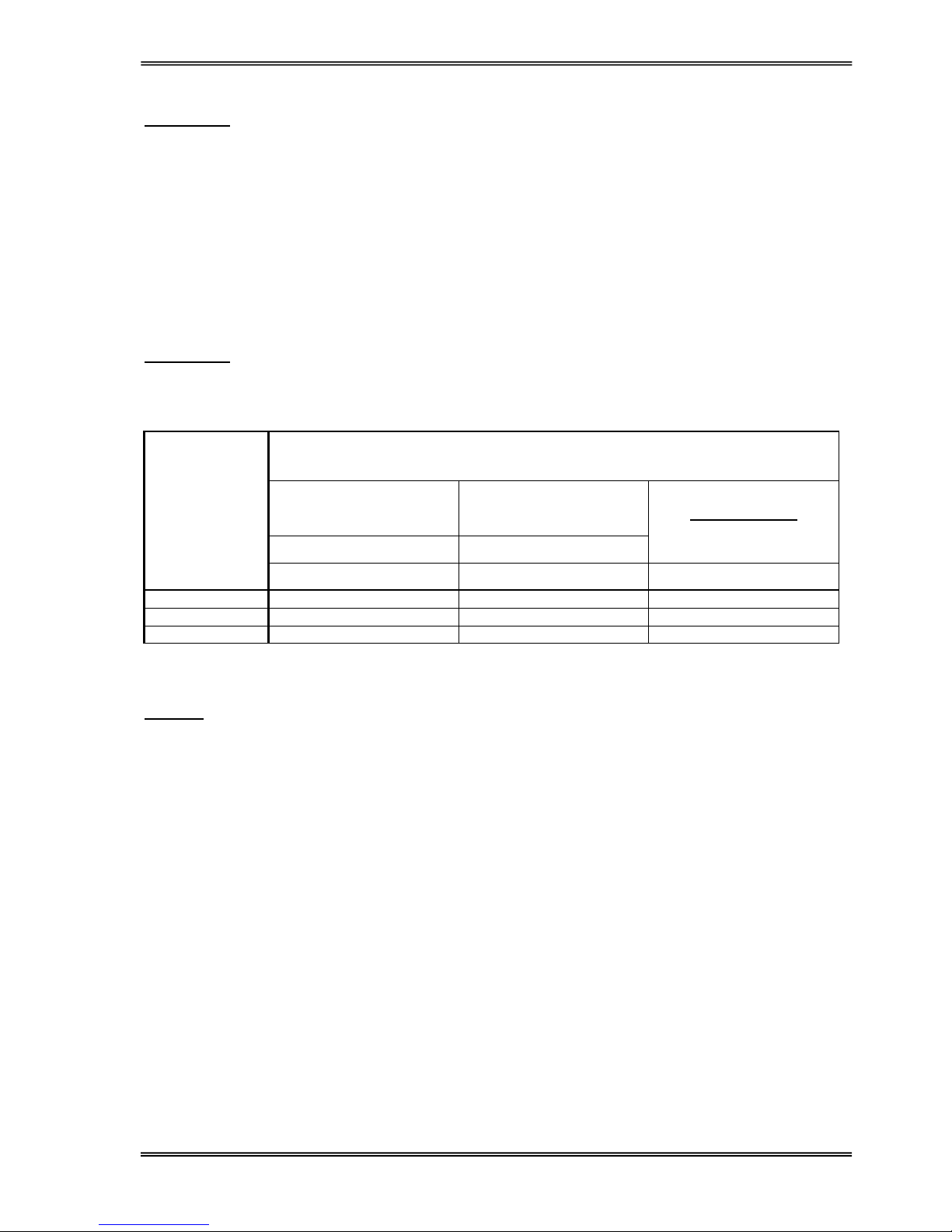

Descriptions of the UPS input output cable connection terminals are shown in figure 4-1, 4-2, 5-1 and 5-2.

Plugs connected to the UPS must be different from regular plugs. Advised input line cable and fuse types are

given in the table below.

WARNING!!! This series of UPSs are A class. These devices can interfere with other equipment. In these

cases the use must take additional precautions.

NOMINAL CURRENT : Amperes / Recommended cable cross-section (mm2)

Input line

Full capacity recharge

Bypass/output

At full load

400V 230V

Battery Current

At min. battery voltage

UPS Power

(kVA)

A / mm2 A / mm2 A / mm2

6 30A / 10 26A / 10 17A / 16

10 41A / 16 43 / 16 26A / 16

15 50A / 16 65A / 25 40A / 25

NOTES: The neutral conductor should be sized for 1,5 times the output/bypass phase current. The Earth

conductor should be sized at 2 times the output/bypass conductor (this is dependent on the

fault rating, cable lengths, type of protection etc.) These recommendations are for guideline

purposes only and are superceded by local regulations and codes of practice.

4.4.1 Safety Earth

The safety earth cable must be connected to the earth BUS BAR and bonded to each cabinets in the system

and also the earthing and neutral bonding arrangements must be in accordance with the local laws.

ATTENTION!!! Failure to follow adequate earthing procedures can result in electric shock hazard to

personnel, or the risk of fire.

20

4.4.2 Cable connection procedure

WARNING!!! All connections of the UPS must be done by a qualified service personal.

After positioning the UPS, the cables must be connected as described below:

1. Verify all switches of the UPS in “0” position.

2. Connect the AC input coming from the mains distribution panel to the input terminals in correct phase

sequence.

WARNING!!! Make sure phase order is correct.

If there is any incorrect connection in the phase sequence, the UPS will not run. In this case the

phase sequence must be corrected.

If A21 ROTATE PHASE, message appears on the LCD panel, change the phase sequence.

3. Connect the output of the UPS to the load distribution panel.

4. Connect the battery group, refer to battery installation section.

WARNING: DO NOT TURN ON THE BATTERY FUSES (F1-F0) BEFORE STARTING THE UPS

5. Connect the copper earth bus, which is under the safety earth and the cables power connection.

Note: The earth and the neutral connections must be in accordance to the local Rules.

4.4.3 Description of connection terminals of the UPS :

6 kVA

Figure 4-1 Standard connection

Figure 4-2 Split (external) by-pass source connection

To be removed part

To be removed part

21

10-15 kVA

Figure 5-1 Standard connection

Figure 5-2 Split (external) by-pass source connection

For Split bypass,

a. Remove the connection between K2, K3 and K4, K5 as shown in figure 7 and 9.

b. Connect the phase and neutral from by-pass source to K2 and K4 terminals.

c. Connect 3 phase input power cable to U1-V1-W1 terminals.

4.4.4 Battery Installation

WARNING!!! Becareful while connecting batteries.

ATTENTION!!! Remove the battery fuse before making the connection of the battery circuit breaker box

during the battery installation.

The batteries associated with the UPS equipment are usually contained in a purpose-built battery cabinet,

which sits alongside the main UPS equipment. Sealed, maintenance-free batteries are normally used in this

type of installations.

Where battery racks are used, they should be sited and assembled in accordance with the battery

manufacturer’s recommendations. In general, batteries require a well-ventilated, clean and dry environment at

reasonable temperatures to obtain efficient battery operation.

In general a minimum space of 10 mm must be left on all vertical sides of the battery block. A minimum

clearance of 20 mm should be allowed between the cell surface and any walls. A clearance of minimum150

mm should be allowed between the top of the cells and the underside of the shelf above (this is necessary for

monitoring and servicing the cells). All metal racks and cabinets must be earthed. All live cell connections

must be shrouded.

1. Unpack each battery and check its terminal voltage. If any battery has terminal voltage less than 10,5 V it

must be charged before continuing.

2. Please check the battery connecting hardware.

3. Please locate suitable number of batteries at each rack.

4. Start locating the batteries from top to the bottom on the racks.

5. Becarefull about the connection between the racks and polarities.

To be removed part

To be removed part

22

6. After interconneting the batteries, connect the (+) and (-) poles to the battery input terminals on the UPS.

Be careful to connect the batteries correctly and do not turn on (F1-F0) before checking all connections

and turn F1-F0 on only after starting the UPS.

V. OPERATING INSTRUCTIONS

5.1 First operating and Power ON :

1. Battery switch must be off. (“0” position)

2. MBS (Maintenance by-pass) switch must be in “0” position.

3. F3-F4-F5 switches must be in “1” position.

4. Turn F6 (Output) switch into “1” position.

5. Turn F2 (ON – OFF) switch into “1” position. (The front panel will run)

WARNING: Energy will form at the output through the static by-pass.

RECTIF START message will appear on the front panel.

6. When START message appears on the front panel, turn F! battery switch into “1” position.

7. Press enter button in the front panel, INVERTER START message will appear.

After a few seconds the bypass LED (red) will turn off and the UPS LED (green) will turn on.

The UPS is ready when “STATUS NORMAL/ONLINE MODE” message appears on the front panel.

5.2 Power down:

1. Turn F6 output switch into “0” position.

2. Turn F1-F0 battery fuses into “0” position.

3. Turn F2 (ON – OFF) switch into “0” position.

4. Trun F3-F4-F5 switches into “0

” position.

5.3 Switching into maintenance bypass mode

1. Press down button until COMMAND MENU appears, then press enter. Press down button until ENTER

(BY-PASS) message appears, Again press enter button. The UPS will switch into by-pass mode.

“MANUAL BYPASS” and “A52 MANU:BYPASS” messages will appear on the screen.

2. Remove the lock of MBS (Maintenance bypass) switch and turn it into “1” position.

3. Immediately turn off F0-F1-F2-F3-F4-F5-F6 switches.

5.4 Switching from maintenance bypass into normal operation:

1. Turn F3-F4-F5 switches into “1”position.

2. Turn F6 (Output) switch into “1” position.

3. Turn F2 (ON – OFF) switch into “1” position.

4. After static by –pass LED lights, turn MBS switch into “0” position, and lock it.

5. Turn F1-F0 battery fuses into “1” position when (ENTER) START message appears on the screen.

6. Press enter button, “INVERTER START” message will appear. After a few seconds by-pass LED (red) will

turn off and the UPS LED (green) will turn on.

“STATUS NORMAL/ONLINE MODE” message will appear when the UPS is ready, loss on the load.

NOTE: Switching between maintenance by-pass and UPS will not cause any power unless the mains line is

off.

23

VI. MAINTENANCE

WARNING!!! DO NOT OPEN the cover of the UPS because there is no part that can be maintained by the

user. DO NOT TOUCH battery leads. There is high voltage even if the UPS is off. Therefore no

one should open the cover of the UPS except the service personal. Otherwise, serious injuries

may occur.

6.1 Scheduled Maintenance

Some semiconductor devices inside the UPS do not require any maintenance. Only cooling fans are moving

parts. If the environment is clean and cool enough, the planed maintenance program will be at minimum level.

Even though, periodic check and maintenance based on a well prepared documents (a good guide) will

increase the performance of the UPS and prevent some small faults (errors) to become unhandlable ones.

The equipment was designed to require little amount of maintenance numbers. The user should do

the following instructions.

6.2 Daily checks

Check the UPS everyday and becareful about the following:

1. Check the operator control panel. Verify that all LEDs and parameter measurements are normal and there

is no alarm message on the indicator panel.

2. Check if the device is overheated.

3. Check the cooling fans’ rotations.

4. Check if there is any change in the equipments noise level .

5.

Check if there is any stoppage on the ventilation path. If so, clean the dust using a vacuum cleane.

6. Make sure that there is nothing placed on the UPS.

6.3 Weekly checks

1. Record the results on the indicator panel.

2. Measure and record voltages on each phase.

3. Measure and record currents on the output of the UPS.

4. Check batteris’ status by performing a manual battery test. Use a dry humid gland to clean the cover of

the UPS.

Record the observations if possible. Check if there is any difference with the previous records (observations).

If the last recorded values are significantly differ from previous records, please check If the load has been

changed, and if so please record the type, size, and position of this load. These information will be very

valuable in helping the service personal in determining any probable errors.

If there is a significant change in the parameter values without any reason please immediately call the

qualified service personal.

24

6.4 Annual maintenance

To get reliable and efficient performance from the UPS, please call the qualified service personal once a year.

6.5 UPS Storage and transportation

1- Check the batteries charge by performing manual battery test before storage. If the charge is not enough

then charge the batteries at least for 12 hours.

2- Qualified service personal should disconnect the connections.

3- Batteries should be charged every six months during storage period.

4- Keep the UPS and batteries in dry and cool place.

UPS ideal storage temp.: 0 0C ~ 40 0C max.

Battery ideal storage temp.: 10 0C ~ 35 0C max.

5- The UPS must be placed on a suitable palette for transportation purposes.

25

VII. FAULTS AND TROUBLESHOOTING

7.1 General procedure for fault checking and troubleshooting

UPS contains complicated electronic control circuits. In order to locate any fault occurring circuits, an

advanced knowledge about the circuitry and its operation principles must be known. The aim of this section is

to give the knowledge required at the first intervention.

There is no practical way to locate any possible fault. Most of the faults do not occur as a performance

decrement. Generally, the UPS operates normally or switches into by-pass mode. But in order to determine

any change in load or the system the parameters must be recorded regularly as mentioned previously.

Generally, the output voltage can deviate %2 from the predefined values. If values differ more than this

percentage then reasons must be investigated.

The following general structure must be systematically followed while trying to indicate the error:

Fault determination: First step is to record the messages, indicator panel LEDs, operating parameter

values and last status of switches. This must be done before attempting to press

any button.

Fixing interventions: After recording all indications, check the meaning of the fault and alarm messages

using “The operator control indicator panel”. If anything related, follow the related

procedure.

Reporting the fault: Service personal must clearly report the work done. Hence, if any other error

occurs there will be enough information to fix it.

26

VIII. UPS’s REMOTE CONTROL CONNECTION

Following external connections are available at HP-200P series

• Communication By serial port connection

• Dry contact (interface board) connection

8.1 Using Serial Port

A standart Serial communication port is installed to all HP-200P series UPS, by using this port user can take

all information about UPS. All measured parameters, alarms can monitor by this port. This port is interactive

and some commands for UPS is available these commands are listed below.

• Switch to BYPASS

• Switch to INVERTER

• SOUND on/off

• Adjust UPS time and date

• Start SIMULATION mode

• Quick BATTERY TEST

• BATTERY TEST until battery low alarm

• CANCEL battery test

• Turn off UPS output voltage immediately (SHUTDOWN)

• Turn off UPS output voltage after delay (WAITING SHUTDOWN)

• Turn off UPS output voltage (SHUTDOWN) and turn on UPS output voltage (WAITING RESTART)

• CANCEL SHUTDOWN

• RENAME UPS

Special softwares are required to use the serial port. Some of the commands above are special functions.

These can be used only with TMON software.

8.2 Serial port connection cable

RS485 cables connections are as follows:

UPS Side Panel Side

9 Tx 2 Rx

7 Gnd 5 Gnd

6 Rx 3 Tx

8.3 Remote control/connection with a modem

The UPS connects to a phone line using its RS232 port and a modem. The operator connects to the UPS by

a computer containing TMON program and a modem. By this way a modem can be monitored using a

telephone line.

27

8.3.1 Hardware Configuration

All needs for modem connection is as follows:

• PC with modem

• WINDOWS 98

• Available UPS control software

• DUMP modem which is connected to UPS

The UPS, has AT command set to switch the DUMP modem into auto – answer mode. To perform this

process go to COMMAND MENU and then goto ENTER:MODEM INIT subitem and press enter button for 3

seconds after installing the hardware. A short warning beep will be heard after pressing the button. Modem’s

RX and TX LEDs will start operating. Then, the modem will be configured to answer incoming calls. To test

this, call the phone number connected to the modem and hear modem’s voice.

8.3.2 Functioning Principle

The remote operator, by means of a PC and a modem device and using the remote connection function of the

control software, calls the UPS through the number to which this is connected.

The dumb modem device, connected to the UPS, will answer the call and convert the data coming from UPS

serial on the telephone line. This way all measures and controls allowed by the RS232 serial port can be

carried out.

8.3.3 Modem programming procedure

Smart modem (SM) is the one connected to PC, and (DUMB) DM is the one connected to the UPS. Standard

Hayes AT programming language is the suitable language for modems. In applications a modem which uses

AT command set must be selected.

The NULL modem connected to the UPS by connecting to a PC should be programmed, Connect the null

modem to the PC’s modem using a standard modem connection cable, then run Hyperterminal program and

send AT commend group to the modem, the AT command set used in configuration is given in the following

table:

AT Command Description

ATS0=1 Modem will auto-answer after one ring.

AT&K0 Flow control disable in some modem models (Check for equivalents in other types)

AT&D0 DTR signal usage.

AT&Y0 Load 0th setting values at the modem start.

Speed

configuration

string

Look for speed configuration table (Below)

AT&W0 Save the values in table as 0th setting.

Different modem models can use different command sets. Below communication speed configuration of some

modem models are given. Select the one suitable for your mode, if your modem’s model is not listed then try

each command one by one. If your modem supports the command you will receive <OK> answer from the

NULL modem in the hyperterminal, otherwise you will get <ERROR>

Speed configuration table

Modem model Speed configuration string

US ROBOTICS sportster voice AT&N3

APACHE AE56SP-R ATN0S37=6

BOCAMODEM V.32 BIS ATN0S37=6

28

The configuration flow in Hyperteminal will be as follows:

ATS0=1 <enter>

OK answer from the modem

AT&K0 <enter>

OK answer from the modem

AT&D0 <enter>

OK answer from the modem

AT&Y0 <enter>

OK answer from the modem

AT&N3 <enter> (US ROBOTICS ICIN)

OK answer from the modem

AT&W0 <enter>

OK answer from the modem

8.3.3.1 Smart Modem (SM) configuration (programming)

Smart modem will configure itself from the program when using TMON.

The default settings are as follows:

B0 E1 F1 M1 Q0 V1 X3

BAUD = 2400 PARITY = N WORDLEN = 8

DIAL = PULSE (TONE which can be programmed)

&A3 &B1 &C1 &D0 &H1 &I0 &K1 &M4

&N0 &R2 &S0 &T5 &Y1

This configuration is done by TMON program.

8.3.4 Modem connection cables

A standard modem connection cable is used to connect SM to a PC. This cable is required if an external

modem is used, but instead if an internal modem is used then no need for this cable.

The connection cable between the UPS and DM must as follows:

UPS DB9 Pin

MODEM

DB25 Male

6 3

7 7

9 2

8.4 UPS Remote monitoring panel connection

Remote monitori

ng panel is used to monitor the UPS from 400m distance. This panel is installed to

control/monitor room. If the distance is less than 25m then RS232 cable is used, and RS485 for larger

distances. Additional adaptor is required for RS485.

The remote monitoring panel transfers the data to the user from the UPS. The remote monitoring panel

requires 230Vac 50Hz AC voltage to operate, and it is better to use the output of the ups as a power supply.

29

AGKK6933 12/2007

Loading...

Loading...