BOURNS SF-0603S Service Manual

SinglFuse™ SF-0603S Series Features

■ Surface mount packaging for automated

assembly

*RoHS COMPLIANT

■ Single blow fuse for overcurrent

protection

■ 1608 (EIA 0603) miniature footprint

■ Slow blow fuse

■ UL listed

■ RoHS compliant* and halogen free**

■ Thin fi lm chip fuse

SF-0603S Series - Slow Blow Surface Mount Fuses

Electrical Characteristics

Model

Rated Current

(Amps)

Fusing Time

SF-0603S050 0.50

SF-0603S063 0.63 130

SF-0603S080 0.80 93 0.024

SF-0603S100 1.00 65 0.026

SF-0603S125 1.25 47 0.057

SF-0603S150 1.50 36 0.081

SF-0603S160 1.60 34 0.086

SF-0603S200 2.00 26 0.115

Open within 5 sec.

at 250 % rated

current

SF-0603S250 2.50 20 0.200

SF-0603S300 3.00 16 0.210

SF-0603S315 3.15 15 0.279

SF-0603S400 4.00 12 0.326

SF-0603S500 5.00 9 0.622

Resistance

(mΩ) Typ.***

Rated Voltage Breaking Capacity

175 DC 50 V

DC 32 V

DC 50 V

50 A

DC 32 V

50 A

Typical

2

I

t (A2s)

0.009

0.017

***Resistance value was measured with less than 10 % of rated current.

Reliability Testing

Parameter Requirement Test Method

Carrying Capacity ..................................... No fusing ....................................................Rated current, 4 hours

Fusing Time .............................................. Within 5 seconds ........................................250 % of its rated current

Interrupting Ability ..................................... No mechanical damages ...........................After the fuse is interrupted, rated voltage applied for

30 seconds again

Bending Test ............................................. No mechanical damages ...........................Distance between holding points: 90 mm,

Bending: 3 mm,1time, 30 seconds

Resistance to Solder Heat ........................ ±20 % .........................................................260 °C ±5 °C,10 seconds ±1 second

Solderability .............................................. 95 % coverage minimum ...........................235 °C ±5 °C, 2 ±0.5 second

245 °C ±5 °C, 2 ±0.5 second (lead free)

Temperature Rise .....................................<75 ° ..........................................................100 % of its rated current, measure of surface

temperature

Resistance to Dry Heat............................. ±20 % .........................................................105 °C ±5 °C,1000 hours

Resistance to Solvent ............................... No evident damage on protective ..............23 °C ±5 °C of isopropyl alcohol, 90 seconds coating

and marking

Residual Resistance ................................. 10k W or more ...........................................Measure DC resistance after fusing

Thermal Shock .........................................DR < 10 % .................................................-20 °C / +25 °C /+125 °C /+25 °C, 10 cycles

Typical Part Marking

Represents total content. Layout may

vary.

RATING CURRENT (A)

F = 0.50

I = 0.63

K = 0.80

L = 1.00

M = 1.25

P = 1.50

N = 1.60

* RoHS Directive 2002/95/EC Jan 27 2003 including Annex.

** Bourns is using the defi nition that appears to be the prevalent defi nition used as the industry standard at this time. The Bourns defi nition of “halogen-free” is:

Bromine (Br) content: ≤ 900 ppm; Chlorine (Cl) content: ≤ 900 ppm; Total Br + Cl content: ≤1500 ppm.

“SinglFuse” is a trademark of Bourns, Inc.

Specifi cations are subject to change without notice.

The device characteristics and parameters in this data sheet can and do vary in different applications and actual device performance may vary over time.

Users should verify actual device performance in their specifi c applications.

S = 2.00

T = 2.50

3 = 3.00

U = 3.15

W = 4.00

Y = 5.00

How to Order

SF - 0603 S 050 - 2

SinglFuse™

Product Designator

SMD Footprint

1608 (EIA 0603) size

Fuse Blow Type

F = Fast acting

S = Slow blow

Rated Current

050-500 (500 mA - 5.00 A)

Packaging Type

- 2 = Tape & Reel (5,000 pcs./reel)

Asia-Pacifi c:

Tel: +886-2 2562-4117

Fax: +886-2 2562-4116

Europe:

Tel: +41-41 768 5555

Fax: +41-41 768 5510

The Americas:

Tel: +1-951 781-5500

Fax: +1-951 781-5700

www.bourns.com

SinglFuse™ SF-0603S Series Applications

■ Portable memory

■ LCD monitors

■ Disk drives

■ PDAs

■ Digital cameras

■ DVDs

■ Cell phones

■ Rechargeable battery packs

■ Battery chargers

■ Set top boxes

■ Industrial controllers

SF-0603S Series - Slow Blow Surface Mount Fuses

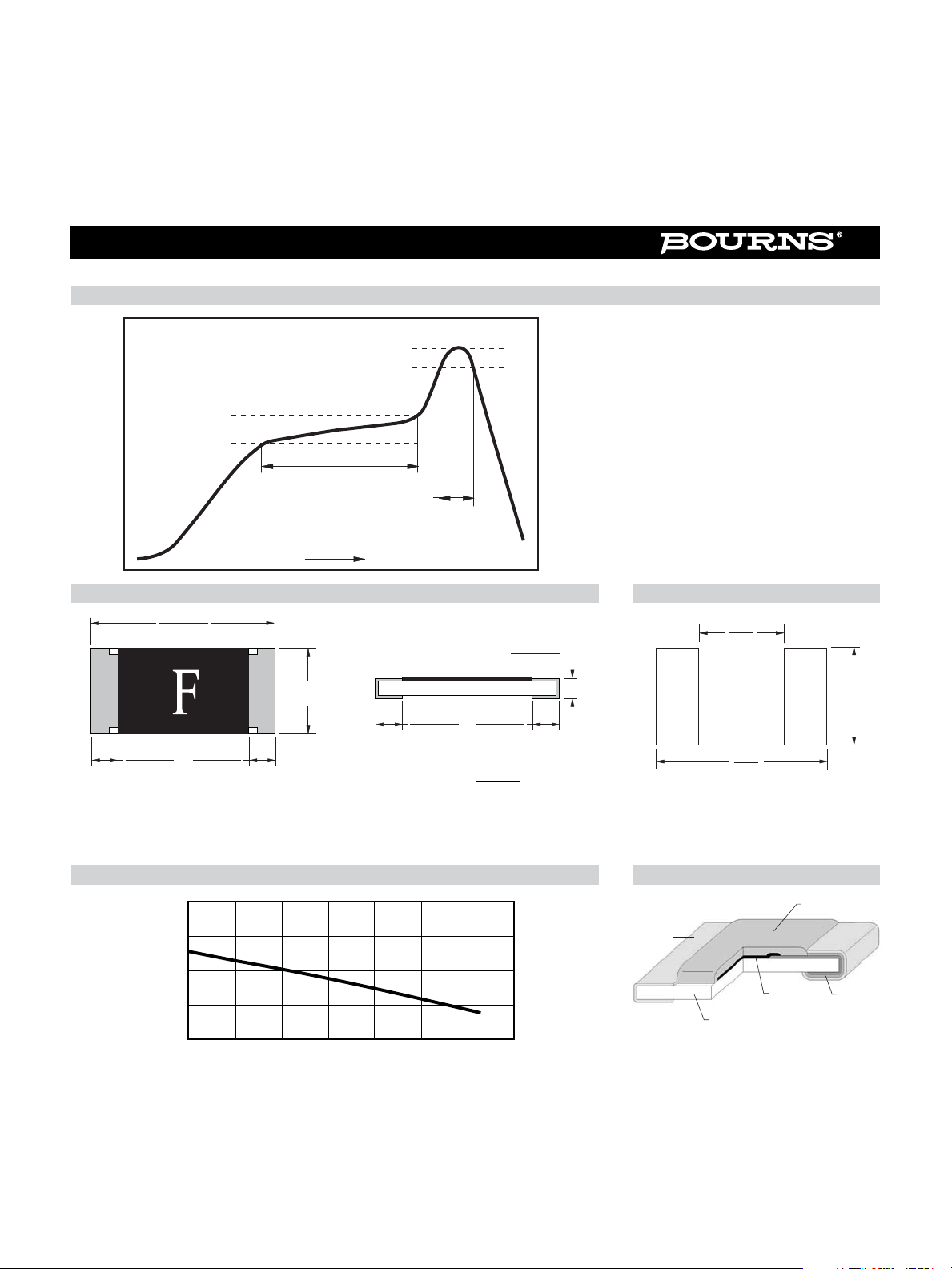

Solder Refl ow Recommendations

250

200

150

TEMPERATURE (°C)

100

50

180 °C

150 °C

Peak: 250 +0/-5 °C

230 °C or higher

PRE-HEATING ZONE

90 ± 30 Seconds

30 ± 10 Seconds

HEATING TIME

PEAK: 250 +0/-5 °C, 5 seconds

PRE-HEATING ZONE: 150 to 180 °C, 90 ± 30 seconds

SOLDERING ZONE: 230 °C or higher, 30 ± 10 seconds

SOLDERING ZONE

Product Dimensions Recommended Pad Layout

1.6 ± 0.1

(.063 ± .004)

0.3 ± 0.2

(.012 ± .008)

0.3 ± 0.2

(.012 ± .008)

PACKAGING: 5,000 pcs./reel

0.8 ± 0.1

(.031 ± .004)

0.35 ± 0.2

(.014 ± .008)

DIMENSIONS:

(INCHES)

0.35 ± 0.2

(.014 ± .008)

MM

0.45 ± 0.1

(.018 ± .004)

1.02

(.040)

2.54

(.010)

1.09

(.043)

Thermal Derating Curve

120

110

100

90

80

-20 0 20 40

PERCENT OF RATING (%)

60 80 100 120

AMBIENT TEMPERATURE (°C)

Operating Temperature .................................................................................. -40 °C to +105 °C

Storage Conditions

Temperature ................................................................................................+5 °C to +35 °C

Humidity...........................................................................................................40 % to 75 %

Shelf Life........................................................................... 2 years from manufacturing date

The device characteristics and parameters in this data sheet can and do vary in different applications and actual device performance may vary over time.

Users should verify actual device performance in their specifi c applications.

Construction & Material Content

OVERCOAT

Sn PLATING

FUSE ELEMENT

CERAMIC SUBSTRATE

Specifi cations are subject to change without notice.

Cu / Ni PLATING

Loading...

Loading...