BOURNS CM45, CM32, CM25, CM20, CM16 Service Manual

...

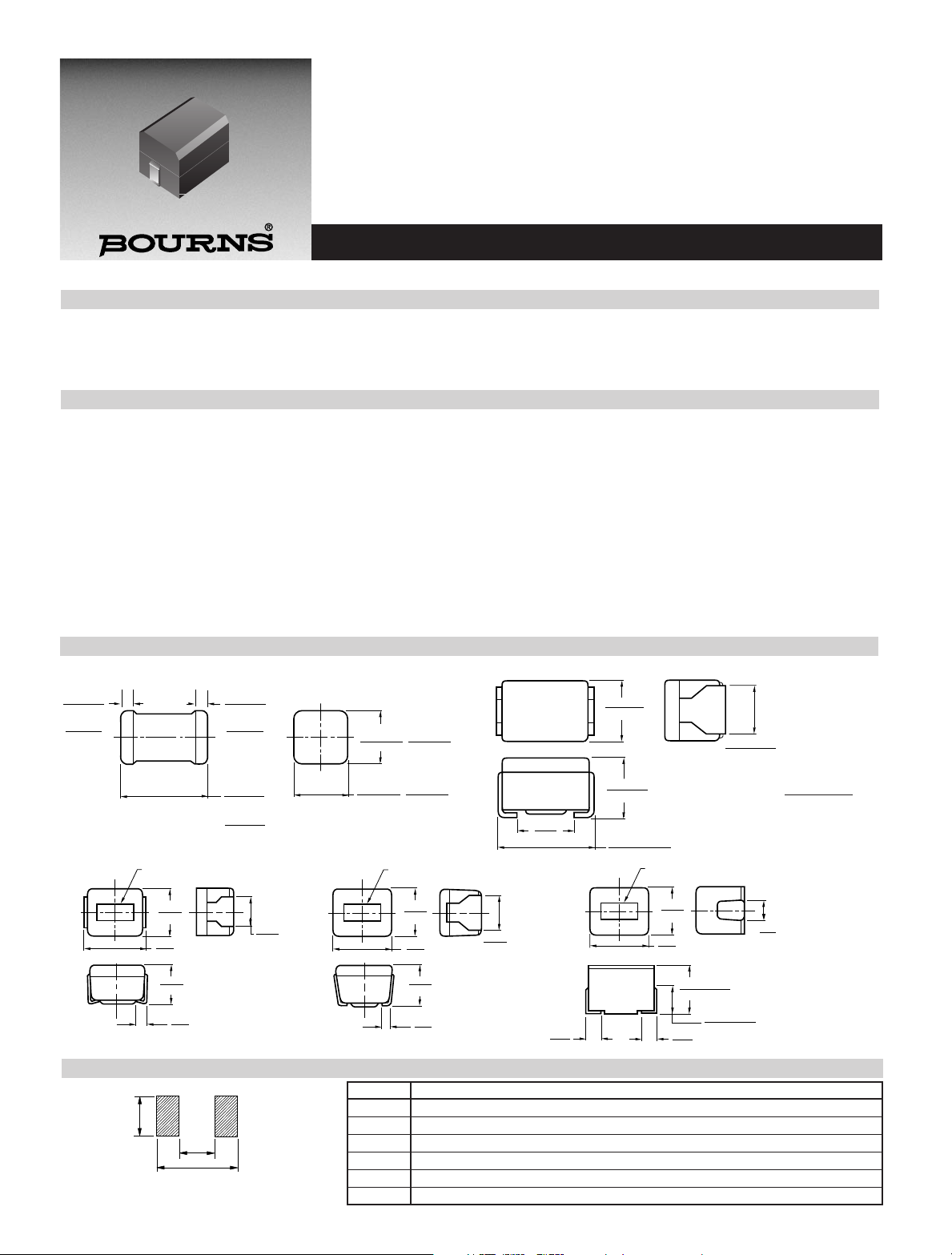

220K

0.2 ± 0.1

(.008 ± .004)

0.3 ± 0.15

(.012 ± .006)

1.0 ± 0.1

(.040 ± .004)

0.5 ± 0.1

(.020 ± .004)

CM10:

0.80 ± 0.15

(.032 ± .006)

CM16:

0.5 ± 0.1

(.020 ± .004)

CM10:

CM10:

CM10:

CM16:

0.2 ± 0.1

(.008 ± .004)

0.3 ± 0.15

(.012 ± .006)

CM10:

CM16:

1.6 ± 0.15

(.063 ± .006)

CM16:

0.80 ± 0.15

(.032 ± .006)

CM16:

1.27 ± 0.30

(.050 ± .012)

1.27 ± 0.20

(.050 ± .008)

2.0 + 0.30 - 0.20

(.079 + .012 - .008)

1.20

(.047)

1.00 ± 0.10

(. 039 ± .004)

2.5

(.10)

2.0

(.079)

1.2

(.047)

1.6

(.063)

0.4

(.016)

Marking

3.2

(.126)

2.5

(.079)

1.9

(.075)

2.2

(.086)

0.6

(.024)

Marking

4.5

(.177)

3.2

(.125)

Marking

1.2

(.047)

1.7 ± 0.2

(.066 ± .008)

3.2 ± 0.2

(.125 ± .008)

1.0

(.039)

1.0

(.039)

CM100505, CM160808

CM201212

CM252016

CM322522 CM453232

a

c

b

Features

■ High resistance to heat and humidity

■ Resistance to mechanical shock and

pressure

Applications

■ Mobil phones

■ Cellular phones

■ CTV, VCR, HIC, FDD

■ Accurate dimensions for automatic

surface mounting

■ Wide inductance range

(1.0nH to 1000uH)

CM45, CM32, CM25, CM20, CM16, CM10 SMT Chip Inductors

General Specifications

Temperature Rise...........................................................................................................................................................................20˚C max.

Ambient Temperature ................................................................................................................................................................... 80˚C max.

Operating Temperature ........................................................................................................................................................-20°C to +100°C

Storage Temperature ..........................................................................................................................................................-40°C to +100°C

Resistance to Soldering Heat ............................................................................................................................................260˚C, 5 seconds

Materials

Core Material

CM10, CM16....................................................................................................................................................................Alumina Ceramic

CM20 .................................................................................................................................................................Polymer 3.9nH to 1000nH

CM25 ....................................................................................................................................................................Polymer 10nH to 180nH

CM32 ....................................................................................................................................................................Polymer 47nH to 180nH

Ferrite Core

CM25 ................................................................................................................................................................................220nH to 100uH

CM32 .............................................................................................................................................................................................220nH +

CM45.......................................................................................................................................................................................................All

Coil Type

CM10, CM16 .......................................................................................................................................................................Copper plating

CM20, CM25, CM32, CM45....................................................................................................................................................Copper wire

Enclosure

CM10, CM16 ......................................................................................................................................................................................Resin

CM20, CM25, CM32, CM45.....................................................................................................................................................Epoxy resin

Product Dimensions

Recommended Land Pattern Dimensions

DIMENSIONS ARE:

Model a b c

CM10 0.5 to 0.6 (.019 to .023) 1.5 to 1.7 (.059 to .067) 0.5 to 0.6 (.019 to .023)

CM16 0.8 to 1.0 (.032 to .039) 2.0 to 2.6 (.079 to .102) 0.7 to 0.9 (.028 to .035)

CM20 1.0 to 1.2 (.039 to .047) 3.0 to 3.8 (.118 to .150) 0.9 to 1.3 (.028 to .051)

CM25 1.4 to 1.5 (.055 to .059) 3.5 to 4.0 (.138 to .157) 1.2 to 1.6 (.047 to .063)

CM32 1.6 to 2.0 (.063 to .079) 4.0 to 4.6 (.157 to .181) 1.9 to 2.4 (.075 to .094)

CM45 2.4 to 2.6 (.094 to .102) 5.5 to 6.0 (.217 to .236) 2.0 to 3.0 (.079 to .118)

Specifications are subject to change without notice.

METRIC

(INCHES)

CM45, CM32, CM25, CM20, CM16, CM10 SMT Chip Inductors

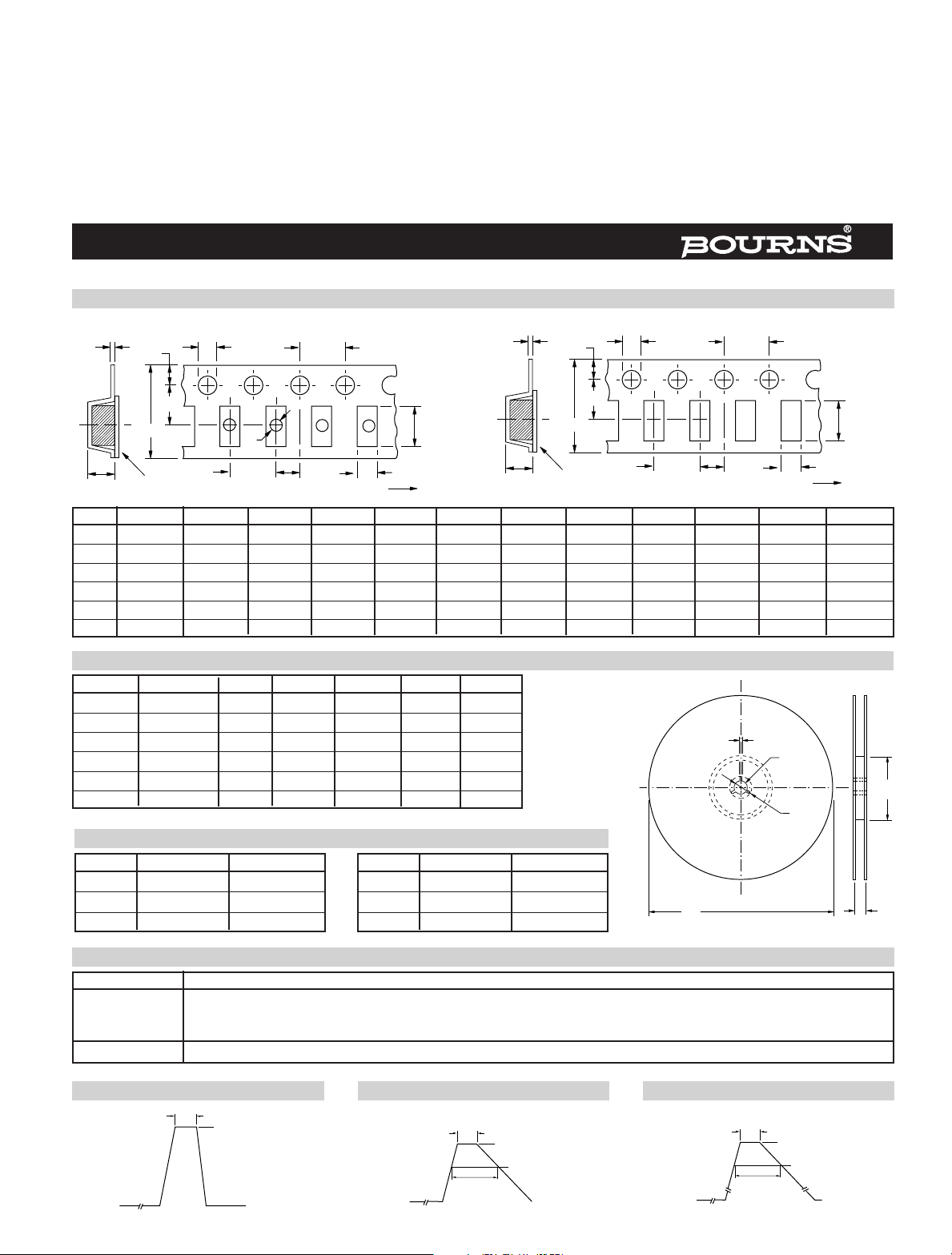

10 seconds max.

260°C

Preheat:

100 to 150°

2 minutes

min.

Preheat:

100 to 150°

2 minutes

min.

10 seconds max.

230°C

200°C

30 seconds max.

Preheat:

100 to 150°

2 minutes

min.

10 seconds max.

220°C

215°C

30 seconds max.

B

A

W

D

C

E

P1

P2

P3

A

D1

DIA.

B

flDo

W

F

E

t2

t1

Tape running direction

Chip

Component

P1

P2

P3

A

B

flDo

W

F

E

t2

t1

Chip

Component

Tape running direction

Packaging Specifications

CM10, CM16, CM20, CM25, CM32

Model A B W F E P1 P2 P3 øD0 øD1 t1 t2

CM10 0.71 (.027) 1.21 (.047) 8.00 (.315) 3.50 (.138) 1.75 (.069) 4.00 (.157) 2.00 (.079) 4.00 (.157) 1.50 (.059) 0.60 (.024) 0.27 (.011) 1.20 (.047)

CM16 1.00 (.039) 1.80 (.071) 8.00(.315) 3.50 (.138) 1.75 (.069) 4.00 (.157) 2.00 (.079) 4.00 (.157) 1.50 (.059) 0.60 (.024) 0.27 (.011) 1.20 (.047)

CM20 1.45 (.057) 2.25 (.089) 8.00(.315) 3.50 (.138) 1.75 (.069) 4.00 (.157) 2.00 (.079) 4.00 (.157) 1.50 (.059) 1.00 (.039) 0.25 (.010) 1.55 (.061)

CM25 2.40 (.094) 2.90 (.114) 8.00(.315) 3.50 (.138) 1.75 (.069) 4.00 (.157) 2.00 (.079) 4.00 (.157) 1.50 (.059) 1.10 (.043) 0.25 (.010) 1.85 (.073)

CM32 2.80 (.110) 3.60 (.142) 8.00(.315) 3.50 (.138) 1.75 (.069) 4.00 (.157) 2.00 (.079) 4.00 (.157) 1.50 (.059) — 0.25 (.010) 2.40 (.094)

CM45 3.60 (.142) 4.90 (.193) 12.00(.472) 5.50 (.217) 1.75 (.069) 8.00 (.315) 2.00 (.079) 4.00 (.157) 1.50 (.059) — 0.30 (.012) 3.50 (.138)

Reel Dimensions

Model A B C D E W

CM10 178 (7.008) 60 min. 13 (.512) 21 (.827) 2 (.079) 9 (.354)

CM16 178 (7.008) 60 min. 13 (.512) 21 (.827) 2 (.079) 9 (.354)

CM20 178 (7.008) 60 min. 13 (.512) 21 (.827) 2 (.079) 9 (.354)

CM25 178 (7.008) 60 min. 13 (.512) 21 (.827) 2 (.079) 9 (.354)

CM32 178 (7.008) 60 min. 13 (.512) 21 (.827) 2 (.079) 9 (.354)

CM45 178 (7.008) 60 min. 13 (.512) 21 (.827) 2 (.079) 13 (.512)

CM45

Packaging

Model Quantity Weight

CM10 10000 pcs 150g

CM16 3000 pcs 90g

CM20 3000 pcs 90g

Model Quantity Weight

CM25 2000 pcs 100g

CM32 2000 pcs 190g

CM45 500 pcs 100g

Soldering

Flow Soldering 260°C maximum for 5 seconds (2 wave solder method)

Infra-red 200°C for a maximum of 30 seconds. Peak of 240°C for a maximum of 5 seconds.

If the solder does not reflow simultaneously under each terminal, there may be a misalignment of the component on the

board. For this reason, it is recommended that the inductor be adhered to the board prior to reflow.

Vapor-phase 215°C for a maximum of 30 seconds.

Flow Soldering Infra-red Soldering Vapor-phase Soldering

Specifications are subject to change without notice.

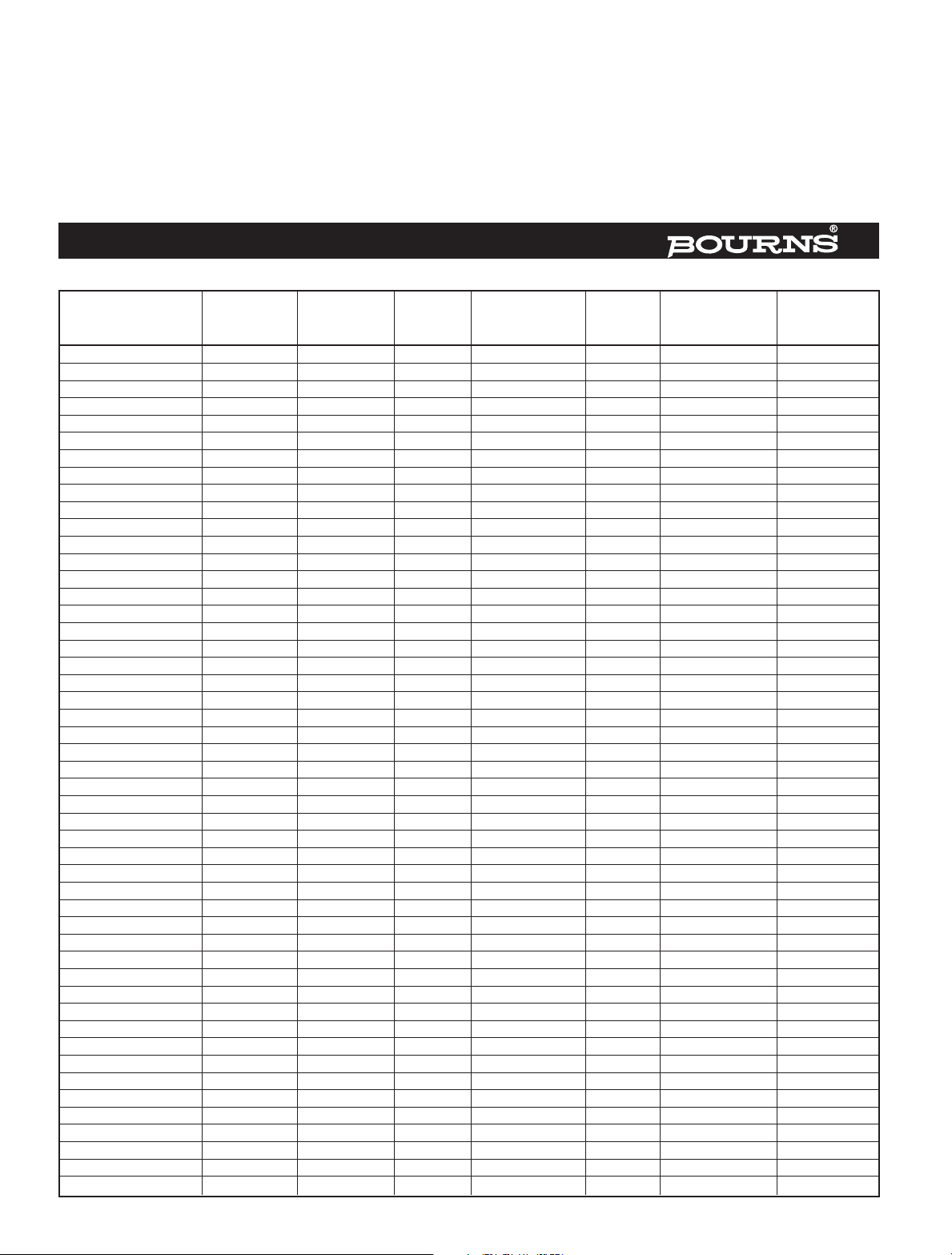

Chip Inductor - CM453232 Series Wirewound

Part number uH Tolerance min. MHz MHz ohm max mA max

CM453232-R10M 0.10 ±20% 35 25.2 300 0.18 800

CM453232-R12M 0.12 ±20% 35 25.2 280 0.2 770

CM453232-R15M 0.15 ±20% 35 25.2 250 0.22 730

CM453232-R18M 0.18 ±20% 35 25.2 220 0.24 700

CM453232-R22M 0.22 ±20% 40 25.2 200 0.25 665

CM453232-R27M 0.27 ±20% 40 25.2 180 0.26 635

CM453232-R33M 0.33 ±20% 40 25.2 165 0.28 605

CM453232-R39M 0.39 ±20% 40 25.2 150 0.30 575

CM453232-R47M 0.47 ±20% 40 25.2 145 0.32 545

CM453232-R56M 0.56 ±20% 40 25.2 140 0.36 520

CM453232-R68M 0.68 ±20% 40 25.2 135 0.40 500

CM453232-R82M 0.82 ±20% 40 25.2 130 0.45 475

CM453232-1R0K 1.0 ±10% 50 7.96 100 0.50 450

CM453232-1R2K 1.2 ±10% 50 7.96 80 0.55 430

CM453232-1R5K 1.5 ±10% 50 7.96 70 0.60 410

CM453232-1R8K 1.8 ±10% 50 7.96 60 0.65 390

CM453232-2R2K 2.2 ±10% 50 7.96 55 0.70 380

CM453232-2R7K 2.7 ±10% 50 7.96 50 0.75 370

CM453232-3R3K 3.3 ±10% 50 7.96 45 0.80 355

CM453232-3R9K 3.9 ±10% 50 7.96 40 0.90 330

CM453232-4R7K 4.7 ±10% 50 7.96 35 1.00 315

CM453232-5R6K 5.6 ±10% 50 7.96 33 1.10 300

CM453232-6R8K 6.8 ±10% 50 7.96 27 1.2 285

CM453232-8R2K 8.2 ±10% 50 7.96 25 1.4 270

CM453232-100K 10 ±10% 50 2.52 20 1.6 250

CM453232-120K 12 ±10% 50 2.52 18 2 225

CM453232-150K 15 ±10% 50 2.52 17 2.5 200

CM453232-180K 18 ±10% 50 2.52 15 2.8 190

CM453232-220K 22 ±10% 50 2.52 13 3.2 180

CM453232-270K 27 ±10% 50 2.52 12 3.6 170

CM453232-330K 33 ±10% 50 2.52 11 4 160

CM453232-390K 39 ±10% 50 2.52 10 4.5 150

CM453232-470K 47 ±10% 50 2.52 10 5 140

CM453232-560K 56 ±10% 50 2.52 9 5.5 135

CM453232-680K 68 ±10% 50 2.52 9 6 130

CM453232-820K 82 ±10% 50 2.52 8 7 120

CM453232-101K 100 ±10% 40 2.52 8 8 110

CM453232-121K 120 ±10% 40 0.796 6 8 110

CM453232-151K 150 ±10% 40 0.796 5 9 105

CM453232-181K 180 ±10% 40 0.796 5 9.5 102

CM453232-221K 220 ±10% 40 0.796 4 10 100

CM453232-271K 270 ±10% 40 0.796 4 12 92

CM453232-331K 330 ±10% 40 0.796 3.5 14 85

CM453232-391K 390 ±10% 40 0.796 3 18 80

CM453232-471K 470 ±10% 40 0.796 3 26 62

CM453232-561K 560 ±10% 30 0.796 3 30 50

CM453232-681K 680 ±10% 30 0.796 3 30 50

CM453232-821K 820 ±10% 30 0.796 2.5 35 30

CM453232-102K 1000 ±10% 30 0.252 2.5 40 30

TIGHTER TOLERANCE AVAILABLE ON REQUEST. CONSULT FACTORY.

Inductance Q Test Frequency SRF min. RDC IDC

Specifications are subject to change without notice.

Loading...

Loading...