Boston D412, D412W+MC1 User Manual

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

1 / 93

ENGLISH

Garage Equipment Associati on

Boston Garage Equipment, 199 New Road, Rainham, Essex, RM13 8SJ, United Kingdom

USER MANUAL

D412 / D412W / +MC1

Roller Brake Tester

T: +44 (0)1708 525585 F: +44 (0)1708 525408 info@boston-ge.com www.boston-ge.com

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

2 / 93

ENGLISH

Copyright

Copyright © 2014 Boston Garage Equipment - All rights reserved worldwide.

All information contained in this document and any drawings, pictures, images and technical descriptions

which have been made available by Boston, remain the property of the company and may not, without

written permission from the company be used (except for the operation of equipment), duplicated in any

way or made available to third parties.

Disclaimer

Although every care has been taken during the preparation of this document, neither Boston or any other

company involved in its production and / or equipment production shall be liable for any damages derived

from the use of this documentation. Boston reserves the right to modify or improve its products and

literature at any time without prior notification. Any or all pictures and images in this document are for

demonstration purposes only.

This document may contain references to, or information about Boston products or services that are not yet

available. These references or information in no way mean that Boston intends to make such products

available.

This document may neither be partly or wholly duplicated, or distributed without prior authorisation from

Boston. Requests for further copies of this document or further information should be addressed to an

authorised agent, a Boston sales representative or to its e-mail address: info@boston-ge.com.

Technical and sales documentation is available on our Internet website: http://www.boston-ge.com.

Boston may have patents or applications for patents in progress involving the matters described in this

document. Supply of this document does not imply that any license to these has been granted.

Contact Details

Boston Garage Equipment

199 New Road

Rainham

Essex

RM13 8SJ

United Kingdom

Tel: +44 (0)1708 525585 Email: info@boston-ge.com

Fax: +44 (0)1708 525408 Web: www.boston-ge.com

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

3 / 93

ENGLISH

Contents

Chapter 1 Introduction 5

Audience 5

Scope 5

Organisation 6

Layout Conventions 6

Related Documents 7

Chapter 2 Safety 8

General Safety Instructions 8

Maintenance Safety 9

Safety Features 9

Misuse 9

Chapter 3 Product Description 10

System Overview 10

D412B Roller Bed 12

MCU-090 (Master Control Unit) 14

GCP (Global Control Platform) 16

RFC-95 (RF Remote Control) 17

MC1 (Motorcycle Testing Cover Plate) 19

Chapter 4 General Operation 20

Power On (MCU-090) 20

Power On (BPC-091) 21

Menu Navigation 21

Mouse Control 22

Keyboard Control 23

Software Version 24

Chapter 5 Standard Brake Test 25

Vehicle Data Entry

Display Layout 29

Placing Vehicle in Rollers 31

Vehicle Weight 32

Testing Front Axle 33

Testing for Imbalance 35

Testing Rear Axle 37

26

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

4 / 93

ENGLISH

Contents

Testing the Parking Brake 37

Test Results and Printing 38

Testing 3 Wheeled Vehicles (3WV) 41

Testing Four Wheel Drive Vehicles (4WD) 42

Testing Motorcycles 45

Automated Brake Test 58

Saving Test Results 67

Chapter 6 Official Brake Tests 69

Official Tests - Data Entry 70

Manual Tests – 2WD Vehicles 74

Testing 3 Wheeled Vehicles (3WV) 79

Testing Four Wheel Drive Vehicles (4WD) 79

Testing Motorcycles 79

Official Automated Brake Test (ATL) 80

Chapter 7 DVSA Regulations UK 82

Brake Efficiency 82

Brake Imbalance 82

Efficiency Limits 83

Motorcycle Limits 84

Chapter 8 Troubleshooting and Maintenance 85

Chapter 9 Warranty / Guarantee 87

Chapter 10 Product Specifications 88

D412B Roller Bed Specification 88

RF-90 RF Remote Control Specification 89

BPC-091 Mini PC Specification 90

MCU-090 Control Unit Specification 91

CE Declaration 92

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

5 / 93

ENGLISH

Audience

Scope

Introduction

Chapter 1

In This Chapter

Audience 5

Scope 5

Organisation 6

Layout conventions 6

Related documents 7

This manual is intended for the final users of the equipment who will operate and maintain the system

throughout its working life.

Boston Garage Equipment requires that operators of this equipment:

Have sufficient technical knowledge and experience to operate the equipment

Can recognize and prevent potential hazards

Have read and understood this manual

Have been adequately trained

Follow the procedure in this manual

The purpose of this manual is to:

Describe the operation of the system

Describe its operating principles and general construction

Explain safety features and safety precautions

Highlight possible hazards

Describe the operation procedures

Describe the maintenance procedures

Troubleshooting

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

6 / 93

ENGLISH

Organisation

Layout Conventions

This manual is organised into:

Safety – Describes safety features of the system and safety precautions to follow when operating

the system. Read this section before operation and maintenance.

Functional Description – Contains a functional description of the system.

Operating Instructions – Contains all the procedures necessary to operate the equipment safely.

Troubleshooting and Maintenance – Contains procedures to solve problems encountered during

operation and maintenance procedures that can be carried by the user.

Parts List – Contains parts lists and drawings.

In this manual we use a number of typographical conventions to highlight particularly important

information and to guide the user through the manual. This section lists these conventions.

Two types of list are used.-

1) Lists that are numbered (like this sentence) contain actions you must carry out in sequence.

In lists that use arrow points (like this sentence), the sequence is not critical.

NOTE

Text with additional information, such as expanded explanations, hints or reminders.

CAUTION

Indicates situations that can be dangerous or cause damage.

Commands (such as menu items and buttons) are bold. Menu names are also bold.

Example: On the remote control press 4.

Information that requires special attention is shown in italic.

Example: Use the Emergency Stop button only in emergencies.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

7 / 93

ENGLISH

Related Documents

Document Name Document Number

SW900 User Manual BOS0320

RFC-95 User Manual BOS0423

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

8 / 93

ENGLISH

Safety

Chapter 2

General Safety Instructions

In This Chapter

General Safety Instructions 8

Maintenance Safety 9

Safety Features 9

Misuse 9

In order to comply with your responsibilities under the Health and Safety at Work Act 1974, it is essential

that this Roller Brake Tester (RBT) and any optional accessories are sited, installed, operated, and

maintained by Boston Garage Equipment or your local authorised / approved distributor.

All persons installing, operating or maintaining the equipment and any optional accessories must be

familiar with the layout of the equipment, the safety precautions, the emergency shutdown

procedures and vehicle braking systems.

Appropriate training is required, prior to installing, using or maintaining the equipment.

The instructions in this manual must be strictly adhered to, to avoid injuries to personnel and

damage to the machine and vehicle.

Only a qualified technician should carry out work on the electrical system, and should follow

procedures pre-described by national standards.

Never remove or bypass any of the safety features.

Avoid any direct or indirect electrical contact.

The unit should be placed inside a rigid, flat and clean surface, protected against water, humidity

and weather influences.

Keep the operating environment clean and free of oil. Never leave loose objects around the RBT.

Never leave parked vehicles on the RBT overnight.

Make sure the remote control is stored safely when not in use.

The equipment may be operated only within its rated capacity. The equipment is designed for MOT

Class 1, 2, 3 & 4 vehicles.

The equipment should only be used when the operator has a good view of the whole machine.

During the test no person should stand close to the roller bed(s).

The testing area should be clear of personnel, tools and equipment before starting each stage of

the test.

Do not stand on, or walk over the rollers at any time.

Take precautions to extract exhaust in the workplace properly while testing.

Do not test a vehicle when there is insufficient light.

Never make any adjustments to the vehicle braking system when the vehicle is in the rollers.

When the RBT rollers are in operation, any key on the remote control or PC keyboard will

immediately stop the rollers, irrespective of their prescribed function.

In case of an emergency, all operations can be stopped immediately by pressing the emergency

stop button on the side of the control cabinet.

If the RBT is not working correctly, switch off immediately and refer to the user manual or contact

Boston or their local agent.

Always isolate the RBT from the power supply before maintenance.

Follow the maintenance specifications accurately.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

9 / 93

ENGLISH

Maintenance Safety

Safety Features

Misuse

In addition to the general safety instructions, the following instructions apply when carrying out

maintenance on the equipment:

Switch off the main electrical supply before opening any part of the equipment.

The equipment must only be operated within its rated capacity.

Protect the electrical parts of the equipment from water and humidity.

Only qualified technicians are permitted to do work on the electrical system of the equipment and

must follow procedures prescribed by national standards.

Many safety features are bypassed inside the service areas of the software. Only qualified service

personnel are permitted to use the service section of the software.

Any unauthorised modification or changes to the system will invalidate the CE-declaration and

equipment warranty.

The D412 RBT offers the following standard safety features to minimise personal risk as much as possible.

The RBT is provided with an emergency stop button on the side of the control cabinet by which any

active operation can be stopped immediately in case of an emergency. To release the emergency

stop button after operation, rotate the button.

The rollers of the RBT’s can only be started if the centre rotating measuring rollers are pressed

down, i.e. when there is a vehicle axle in the roller brake tester (except when 3-wheel or

motorcycle modes are selected).

By applying brake force and locking any wheels under test, the rollers will stop immediately.

Closed covers for the chain and electrical components are fitted as standard.

All electrical cabling is covered to reduce any direct danger or risk.

The RBT is ground wired to earth.

Cover plates are provided to cover the rollers when the brake tester is not in use.

Whenever the rollers of the RBT are in operation, any key press on the keyboard or remote control

will immediately stop the rollers irrespective of the assigned key function.

The RBT is designed for use as a brake tester for statutory testing of MOT Class 1, 2, 3 & 4 vehicles and for

brake diagnostic purposes only.

It must NOT be used for any other purpose e.g.

‘Running in’ of brake linings.

Brake adjustments.

Diagnosis of vehicle faults e.g., tyre examination etc.

Any purpose requiring the operator to be in the danger zone, other than to conduct a brake test

and/or maintenance and calibration purposes (authorised personnel only).

If access to any service area requires driving over the RBT then cover plates must be used

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

10 / 93

ENGLISH

Product Description

Chapter 3

System Overview

In This Chapter

System Overview 10

D412B Roller Bed 12

MCU-090 Multi Connection Unit 14

GCP Global Control Platform 16

RFC-95 RF Remote Control 17

MC1 Motorcycle Testing Cover Plate 20

The RBT is a well-known method for analysing the efficiency of the braking system of a vehicle.

There are several main components that comprise the D412 RBT, these are listed below and are covered in

detail later on this chapter.

D412B The steel chassis floor module containing the rollers and all sensors.

MCU-090 A wall mounted cabinet containing the cable connections from the roller bed, data

acquisition circuitry and operation control relay cards.

GCP Boston’s computer control system running the SW900 control software with

mouse, keyboard LCD display monitor and laser printer.

RFC-95 An RF Remote control for remote operation of the RBT from inside the vehicle.

MC1 A small cover plate that attaches to the roller bed to enable the safe testing of

smaller motorcycle wheels.

The mechanical floor unit contains two electrical motors, two independent sets of three measuring rollers, two

brake force transducers, additional safety sensors and an optional four point vehicle weighing system fitted to

the base or installation cartridge.

During testing, the brake forces induce reaction forces on the electric motor which in turn applies force to an

electric transducer with strain gauges. Through software, the sensors are monitored and the data collected is

converted into a reading and displayed on a monitor for the operator to see. The rotating brake rollers are

coated with a wear-resistant material which provides high friction values in both wet and dry conditions. The

roller diameters are sufficiently large to keep the tyre flexing to a minimum.

The third smaller roller on each side between the wheel supporting rollers has two functions:

The first is to detect if a vehicle is present in the roller bed (a built in safety device to prevent the motor

starting without a vehicle in place). For safety purposes, the motors will not start if both the left and

right small rollers are not pushed down for more than two seconds (except when 3-wheel mode or

motorcycle mode is selected).

The second function is to detect if tyre slip on the rollers does not exceed the maximum value.

The GCP control system can be configured in two ways, either wall mounted or fitted into a mobile trolley /

cabinet stand. The GCP that controls the RBT is not connected directly to the roller bed but to the MCU

(Master Control Unit) via USB.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

11 / 93

ENGLISH

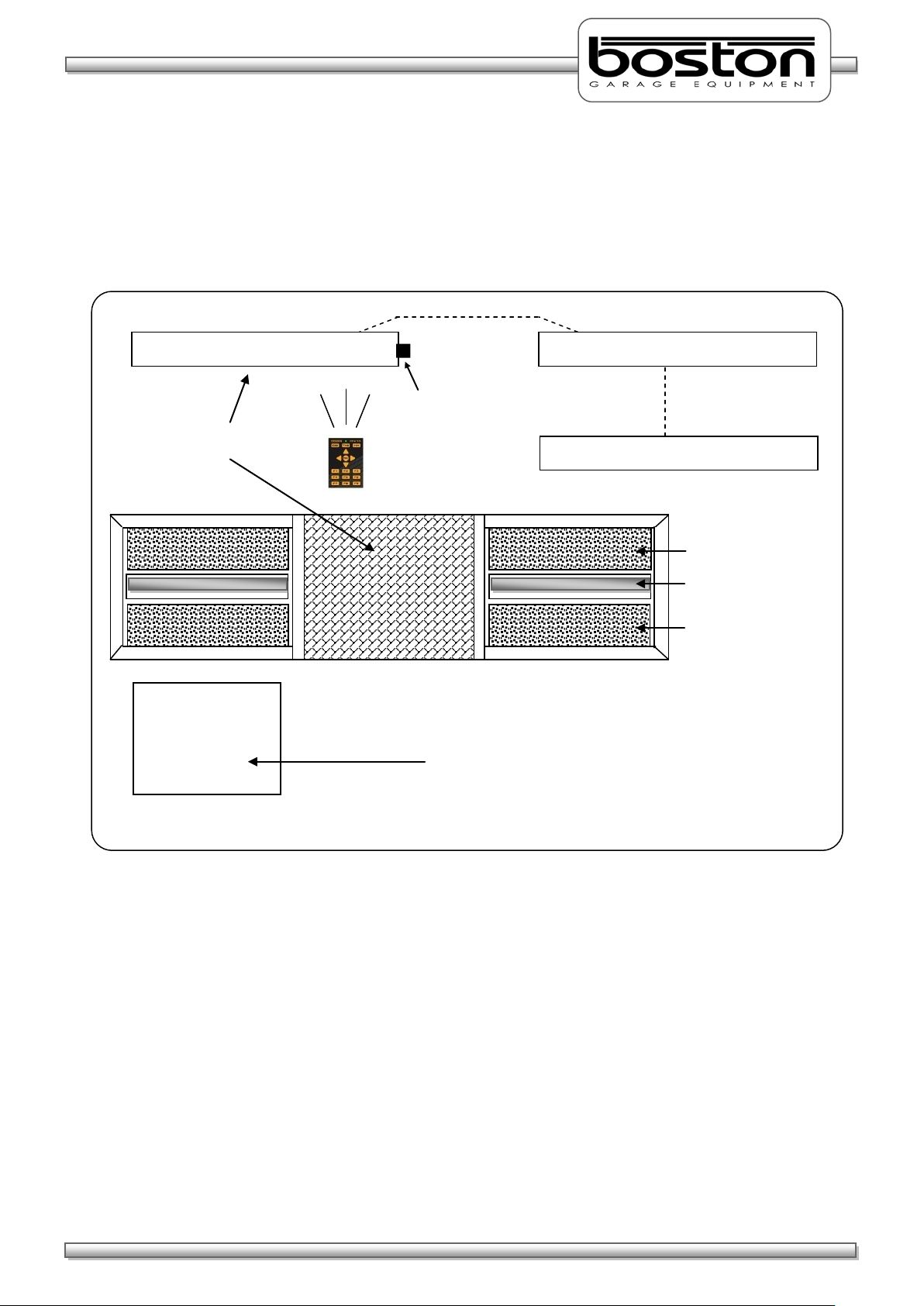

Emergency switch + Main switch

Wall mounted connection / control box

Measuring roller

Measuring roller

Slip detection roller

BSS2000

D412 Roller

The BSS2000 Side-Slip Meter is a separate device and

Wall mounted LCD display unit

GCP – Control System

Remote Control

The MCU is a wall mounted connection panel which the mechanical floor unit is wired to. It contains the

various components to acquire data from the sensors during braking and control relays for starting and

stopping the rollers. It has an emergency stop button and main power switch located on one side of the

panel.

Braketester

Side-Slip Meter

can easily be added to the D412 Roller Braketester.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

12 / 93

ENGLISH

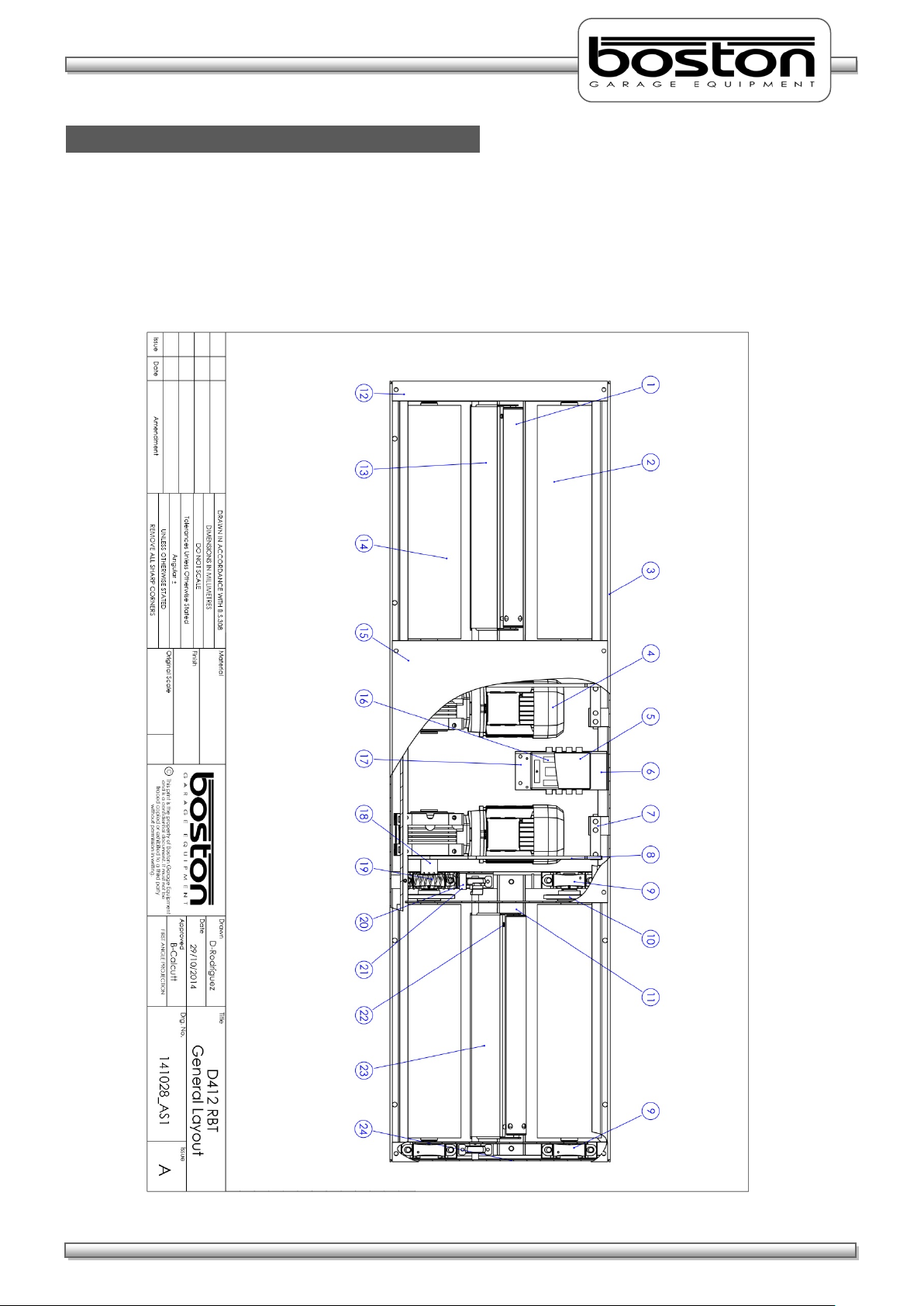

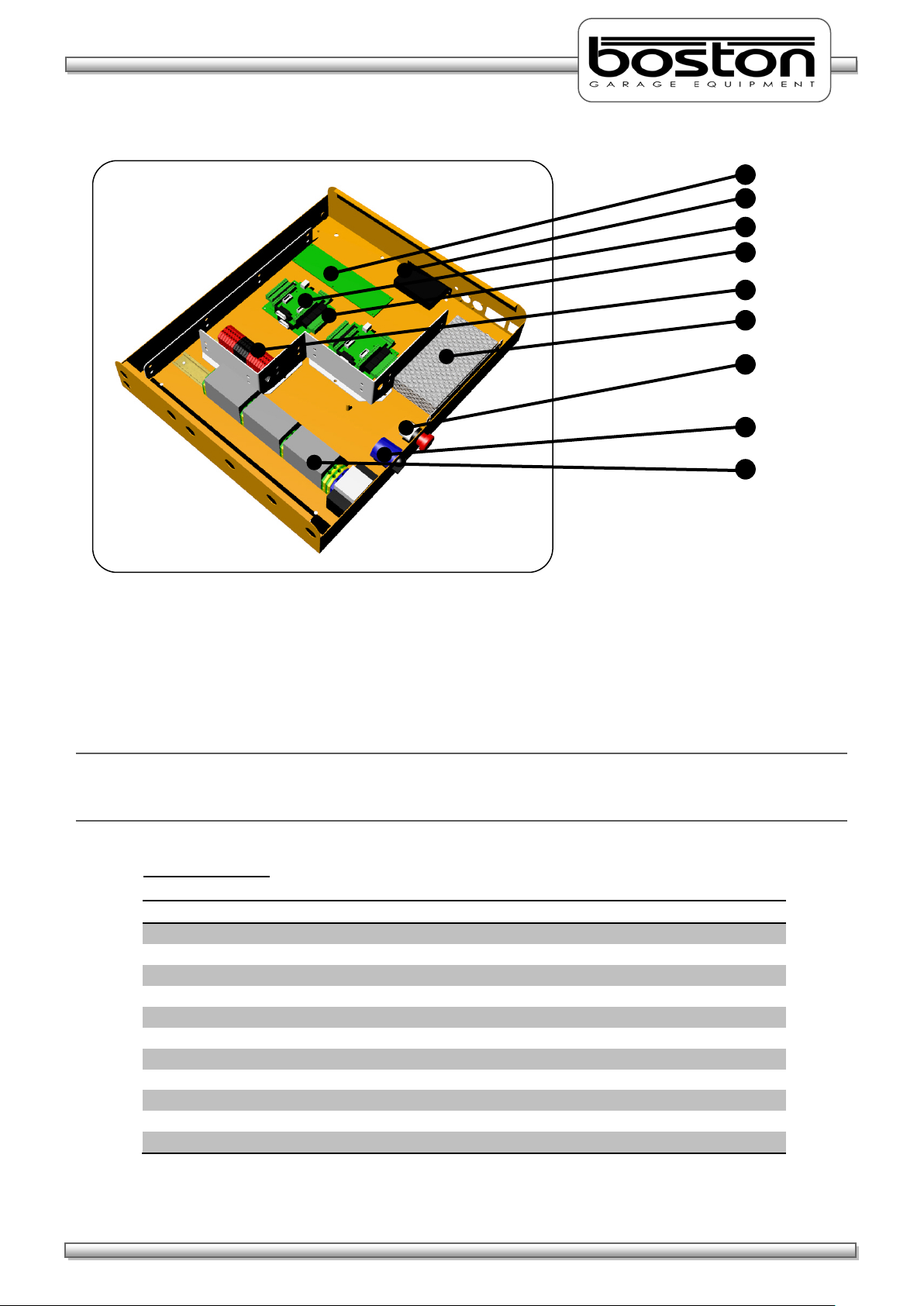

D412B Roller Bed

The D412B Roller Bed is a single chassis unit containing four high friction surface rollers and two smaller

free rolling rollers to detect wheel presence and measure wheel speed. The unit is equipped with two

brake force measurement sensors and can be fitted with an optional vehicle weighing system.

A general layout of the D412B Roller Bed is shown below.-

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

13 / 93

ENGLISH

Item

Description

Quantity

1

Tacho roller 2 2

Front roller 2 3

Chassis 1 4

Motor 230/400V 3kW

2

5

Connection PCB Enclosure

1

6

Connection Box Support Bracket

1

7

Force Transducer

2

8

Torque Arm

2

9

Bearing Housing

4

10

Chain Roller 4 11

Protection Plate

2

12

Side Covers 2 13

Detection Frame LEFT

1

14

Rear Roller 2 15

Centre Cover Plate

1

16

Connection PCB

1

17

Ground Connector

1

18

Drive Shaft Spacer

2

19

Spring Extension

2

20

Tacho Stop Block

2

21

Rubber Stop

2

22

Proximity Switch

2

23

Detection Frame RIGHT

1

24

End Chassis 2

Component Table

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

14 / 93

ENGLISH

MCU-090 (Master Control Unit)

The MCU-090 is an interface / connection box where the power cables for the motors and data cables for

the sensors are all connected. Although the MCU-090 is used for the control of the D412B roller bed, it can

also be used to connect and control the following components to provide a full test lane.-

• R102 Class 1,2 Motorcycle Roller Brake Tester

• R103 Class 1,2 Motorcycle Roller Brake Tester

• D402 / D402W+MC1 Class 1,2,3,4 Roller Brake Tester (Manual and Auto Testing)

• D412 / D412W+MC1 Class 1,2,3,4 Roller Brake Tester (Manual and Auto Testing)

• D403 / D403+MC2 Class 1,2,3,4 Roller Brake Tester (Manual and Auto Testing)

• D702 / D702+MC3 Class 1,2,3,4,5L,7 Roller Brake Tester (Manual and Auto Testing)

• D712 / D712+MC3 Class 1,2,3,4,5L,7 Roller Brake Tester (Manual and Auto Testing)

• S402 3T Suspension Tester

• S702 4T Suspension Tester

• SS02 4T Side-Slip Meter

• AGS200 Exhaust Gas Analyser

• AGS688 Exhaust Gas Analyser

• OPA100 Exhaust Diesel Smokemeter

• B502 Electronic Headlight Tester

NOTE

Some items listed above may be under development.

In most cases the MCU-090 will be supplied in standard configuration. This will allow control of the

majority of products above (and some others) simultaneously. Depending on specific customer

requirements, additional internal components may be required.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

15 / 93

ENGLISH

Item

Description

1

Connection Interface Card

2

Powered USB Hub

3

Data Acquisition Card 1 (Optional second card can be installed)

4

Relay Card 1 (Optional second card can be installed)

5

Low Voltage Connection Din Rail

6

Power Supply

7

Emergency Stop Button

8

Main Power Switch

9

High Voltage Relay Din Rail

2 8 5 3 6 4 1 9 7

The MCU-090 is connected to the GCP using a standard USB A-B connection cable. Older versions of Boston

Control Platforms may also be used to control the MCU-090, check with your local distributor for

compatibility.

NOTE

There are no user serviceable parts inside the MCU-090 and all maintenance / repairs should be carried out

by approved Boston engineers.

Component Table

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

16 / 93

ENGLISH

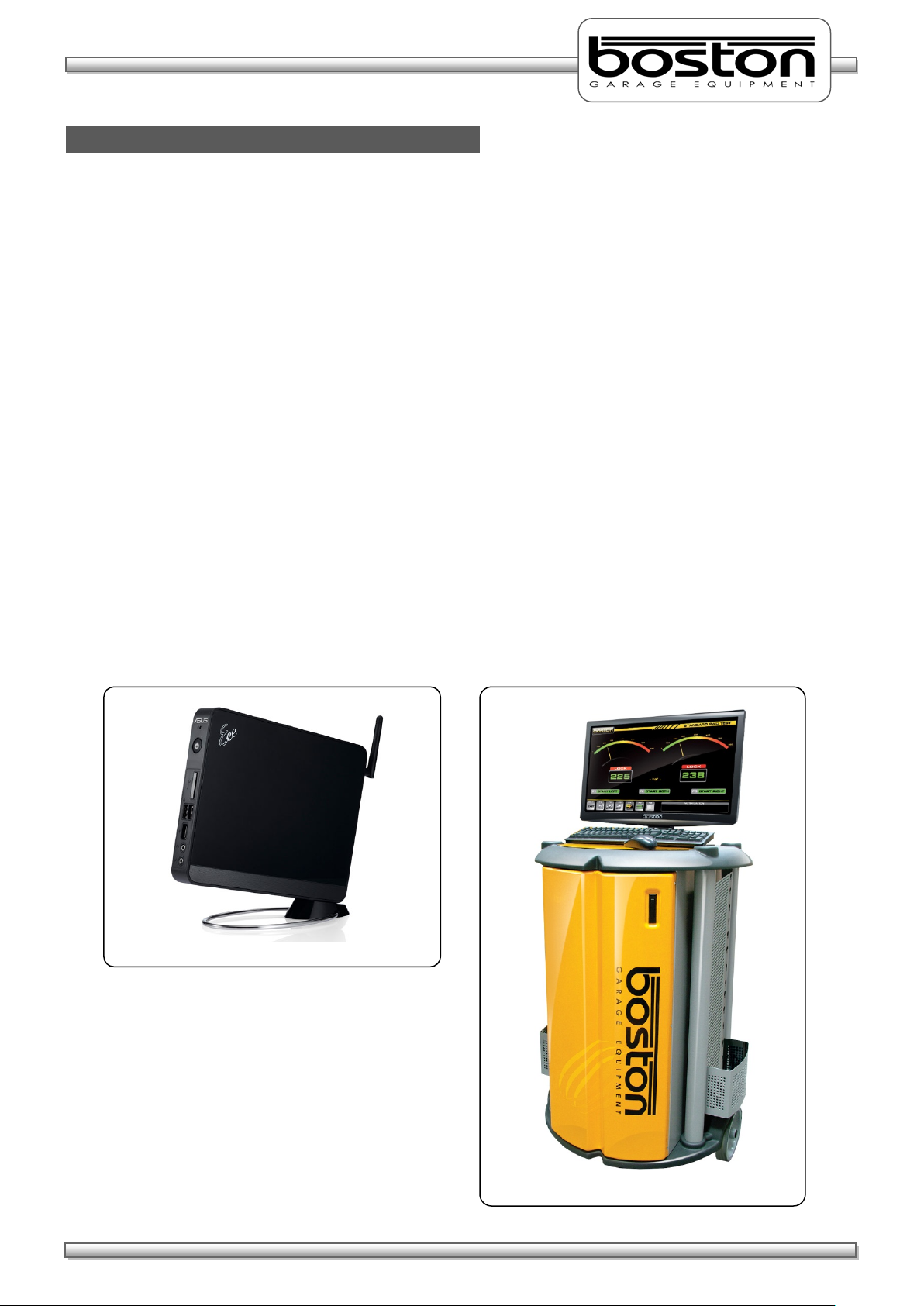

BPC-0951 Mini PC

TRO-220 Mobile Stand

GCP (Global Control Platform)

The GCP is the computer control station that connects to the MCU-090 via USB. It is a separate unit and

can be supplied in different configurations, but in most cases it is wall mounted with a display monitor and

mouse / keyboard (GCP1). A breakdown of the GCP main standard supply components is listed below.-

Mini Industrial PC with Windows OS and Internal Wifi

Boston Software SW900

Optical PC Mouse

PC Keyboard

Widescreen LED Monitor

Laser Printer

Wall mount bracket or rolling stand

The GCP can also be supplied as a mobile unit using one of Boston’s rolling cabinet stands.

GCP3 - Circular Drum-Type Mobile Stand (as shown below)

GCP2 - Standard Mobile Stand

In all cases, the GCP can also be fitted with a second display monitor up to 60” in size. Please contact

Boston or your local sales / service agent for further information.

This manual only covers the Braketester software program; another manual is available separately detailing

the operation and functions of the SW900 software installed on the GCP.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

17 / 93

ENGLISH

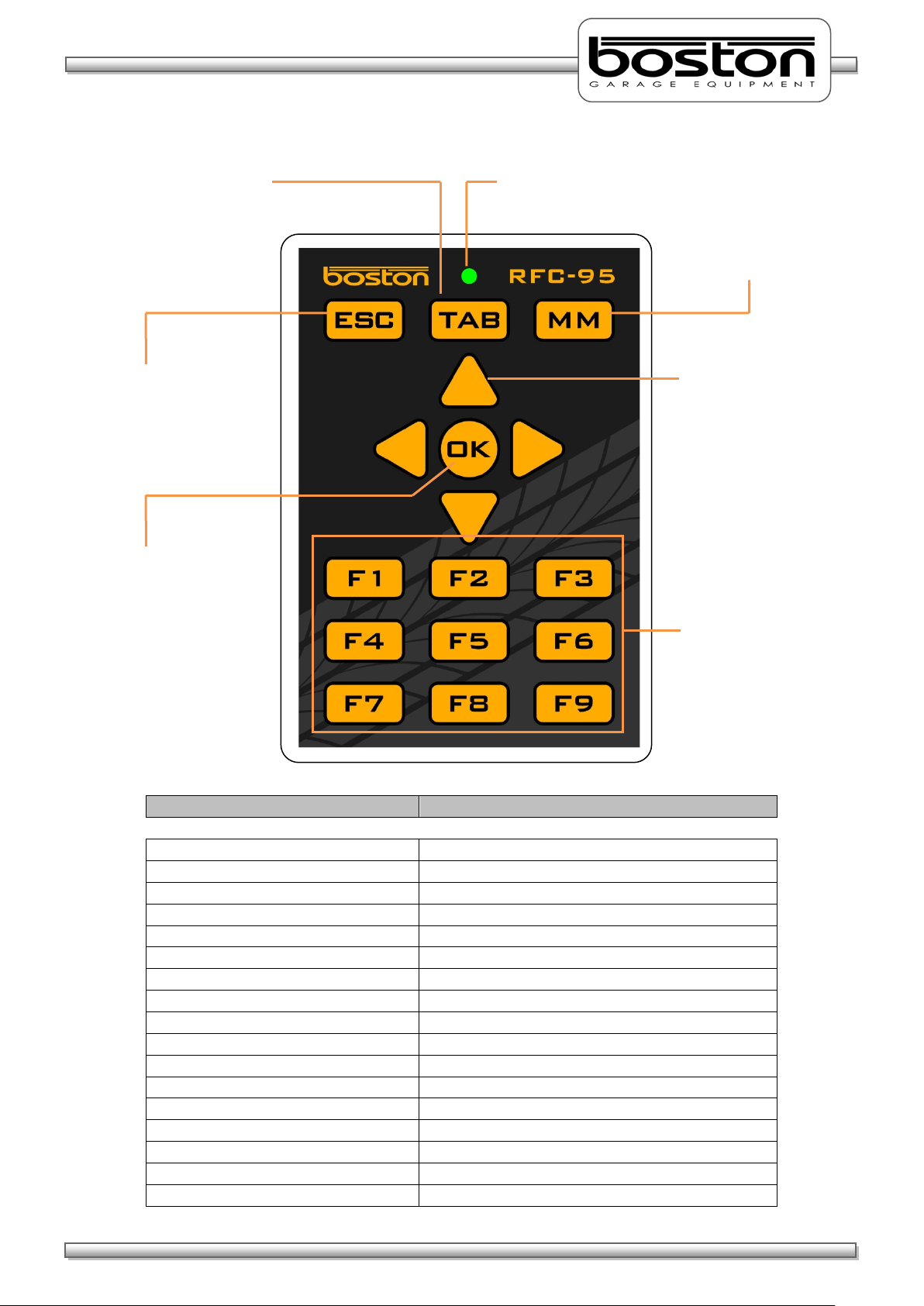

RFC-95 (RF Remote Control)

The remote control is the most commonly used control for the SW900 software. It has many of the same

functions as the keyboard but from a wireless range of approximately 50m. There is a separate User

Manual available for the Boston RF Remote Control, but the main functions are covered here.

Many remote controls operate using infra-red (IR) technology. Whilst being reliable, they are restricted to

‘line-of-sight’ operation which in some environments can make them impractical. The Boston RFC-95 is a

ruggedized control, ideally suited for the testing industry where rugged protection is required. It operates

using the latest Zigbee Radio Frequency (RF), which unlike IR doesn’t require line of sight operation. This

provides greater flexibility and allows it to be used from inside the vehicle to control different items of

equipment.

The RFC-95 button functions are shown below.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

18 / 93

ENGLISH

Button

Associated keyboard Function

ESC

ESCAPE

TAB

TAB

MM

MAIN MENU (SW900 Software only)

ARROW UP

ARROW UP

ARROW DOWN

ARROW DOWN

ARROW LEFT

ARROW LEFT

ARROW RIGHT

ARROW RIGHT

OK

ENTER

F1

FUNCTION KEY F1

F2

FUNCTION KEY F2

F3

FUNCTION KEY F3

F4

FUNCTION KEY F4

F5

FUNCTION KEY F5

F6

FUNCTION KEY F6

F7

FUNCTION KEY F7

F8

FUNCTION KEY F8

F9

FUNCTION KEY F9

‘TAB’ Key

‘ESC’ Button

‘MM’ Button

Arrow Keys

‘F’ Keys

‘OK’ Key

keyboard.

Transmission LED

This button duplicates

the ‘Tab’ key function on

the main keyboard.

This button duplicates

the ‘ESC’ key function

on the main keyboard.

This button duplicates

the ‘ENTER’ key

function on the main

The LED illuminates to

confirm any key press.

This button returns the

operator to the Main

Menu (only for Boston

SW-900 software).

These buttons duplicate

the arrow key functions

on the main keyboard.

These buttons duplicate

the ‘F’ key functions on

the main keyboard.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

19 / 93

ENGLISH

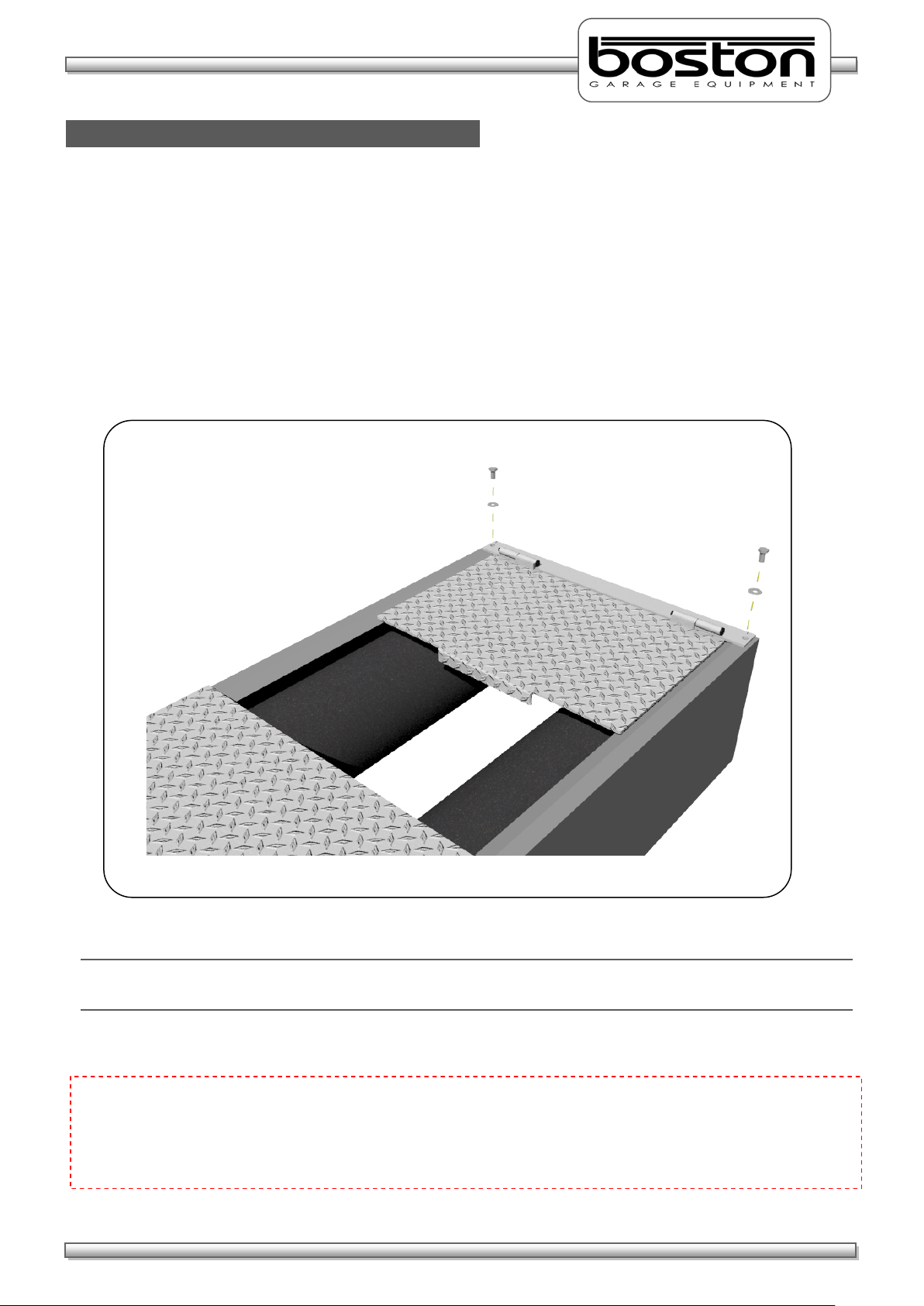

MC1 (Motorcycle Testing Cover Plate)

In order to test motorcycles, it is necessary to fit the MC1 cover plate to the required testing roller. The

cover plate is designed specifically to accommodate motorcycle wheels and safely cover the unused open

portion of the rollers. The cover plate is attached to the roller bed using two bolts and can be fitted very

quickly. It contains two hinges allowing the plate to ‘swing’ into place without the need to permanently

remove from the roller bed.

To fit the cover plate, refer to the illustration below.-

NOTE

The MC1 is a foot plate and is not intended for vehicles to drive over.

CAUTION

Motorcycle testing can only be carried out when the MC1 cover plate adapter has been fitted. The plate

limits the width of the open roller surface to accommodate the narrow wheels of motorcycles. It is

dangerous and prohibited to test motorcycles without the MC1 cover plate fitted.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

20 / 93

ENGLISH

General Operation

Chapter 4

Power On (MCU-090)

MAIN POWER SWITCH - Isolates power from the

EMERGENCY STOP - Immediately stops all

In This Chapter

Power On (MCU-090) 20

Power On (BPC-091) 21

Menu Navigation 21

Mouse Control 22

Keyboard Control 23

Software Version 24

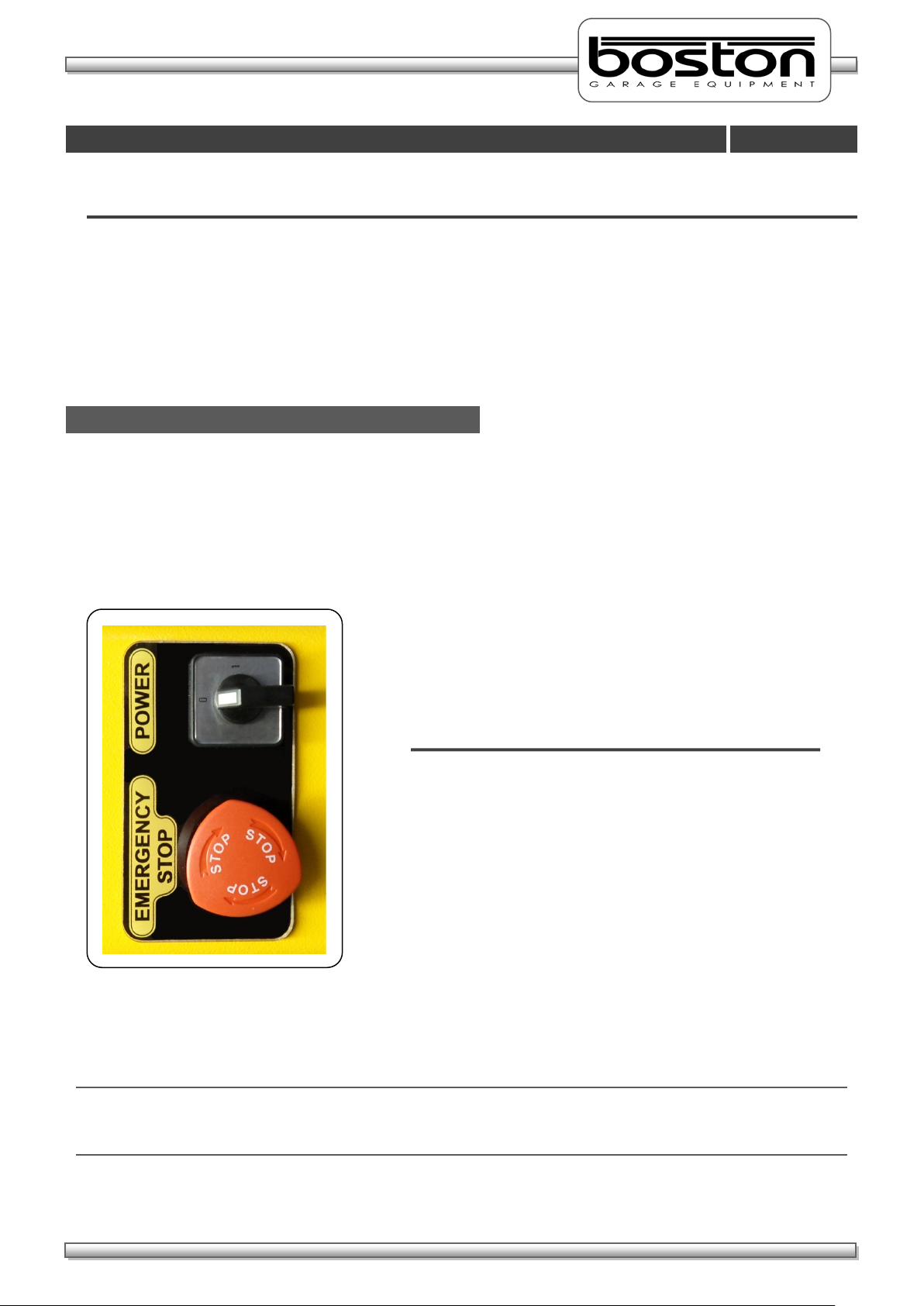

The MCU-090 has a Main Power switch and Emergency Stop button on the side of the cabinet. The Main

Power switch interrupts and isolates the power to the GCP control system and any other connected

equipment. The Emergency Stop button immediately stops all current operations and turns off the control

side of the system. It is usually left in the ‘running’ state and only used in the event of an emergency. The

operation of both these switches is shown below.-

Once power is applied to the MCU-090 the system is ready and waiting for instructions from the PC control

platform.

NOTE

In the wall-mount configuration, the power for the PC, monitor and printer is taken from the MCU-090.

When switching off the main power as described above, remember these items will also be switched off.

entire system and all other

connected equipment.

OPERATION - Rotate switch in clockwise /

anti-clockwise direction.

operations and turns off

power to the control side

of the system.

OPERATION - Press switch to activate.

Rotate clockwise to de activate.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

21 / 93

ENGLISH

Power On (BPC-091)

Menu Navigation

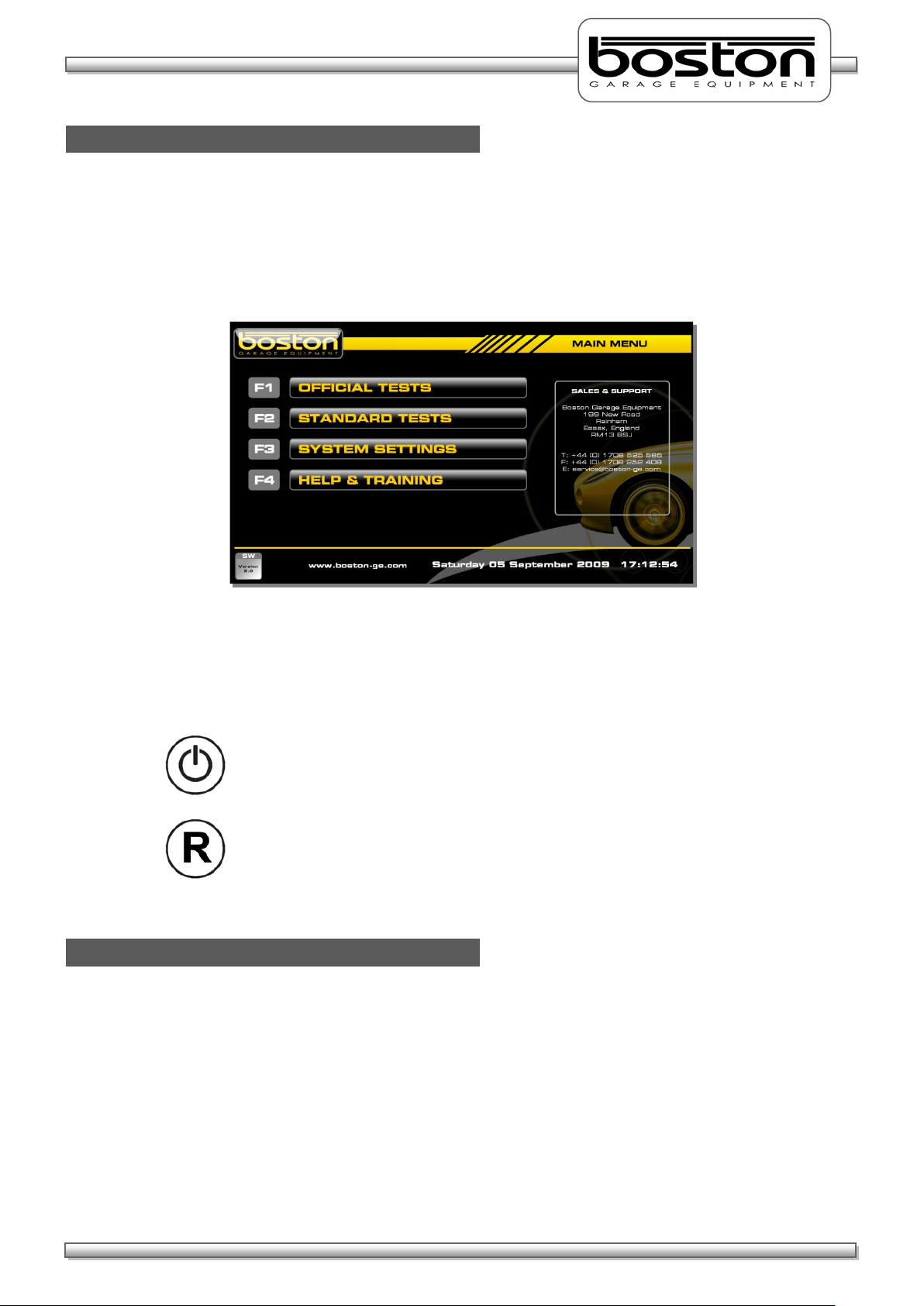

When power is applied to the BPC-091 PC, the system will automatically start-up and enter into the main

software menu page (as shown in the screenshot below). This will happen in the event of a power-cut or

even if the unit has been previously powered down and the power source removed and restored. In all

cases, when power is detected that was previously not present the system will auto-start.

There are also two power buttons on the right side of the PC. These are the main ‘POWER’ button and the

‘RESET’ button. A single press of either will perform the following function:-

POWER Button - Powers down the system. To restart, press the

POWER button again.

RESET Button - Resets the system by powering down and then re-starting

automatically.

After initial power-on, the page shown above should be displayed. From this page the user can select

whether to perform tests (options F1 and F2) or to change settings (F3) or seek assistance (F4). All options

in the SW900 software are described in detail in the SW900 User Manual available separately. For the

purpose of this manual we shall only cover the operation of the RBT program.

The software can be operated in several ways, either by using the keyboard, the mouse or the remote

control. All three options are available to the user (depending on their preference) and can be used at any

time, and anywhere within the software.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

22 / 93

ENGLISH

Option F1 Highlighted

Mouse Control

Click the LEFT button

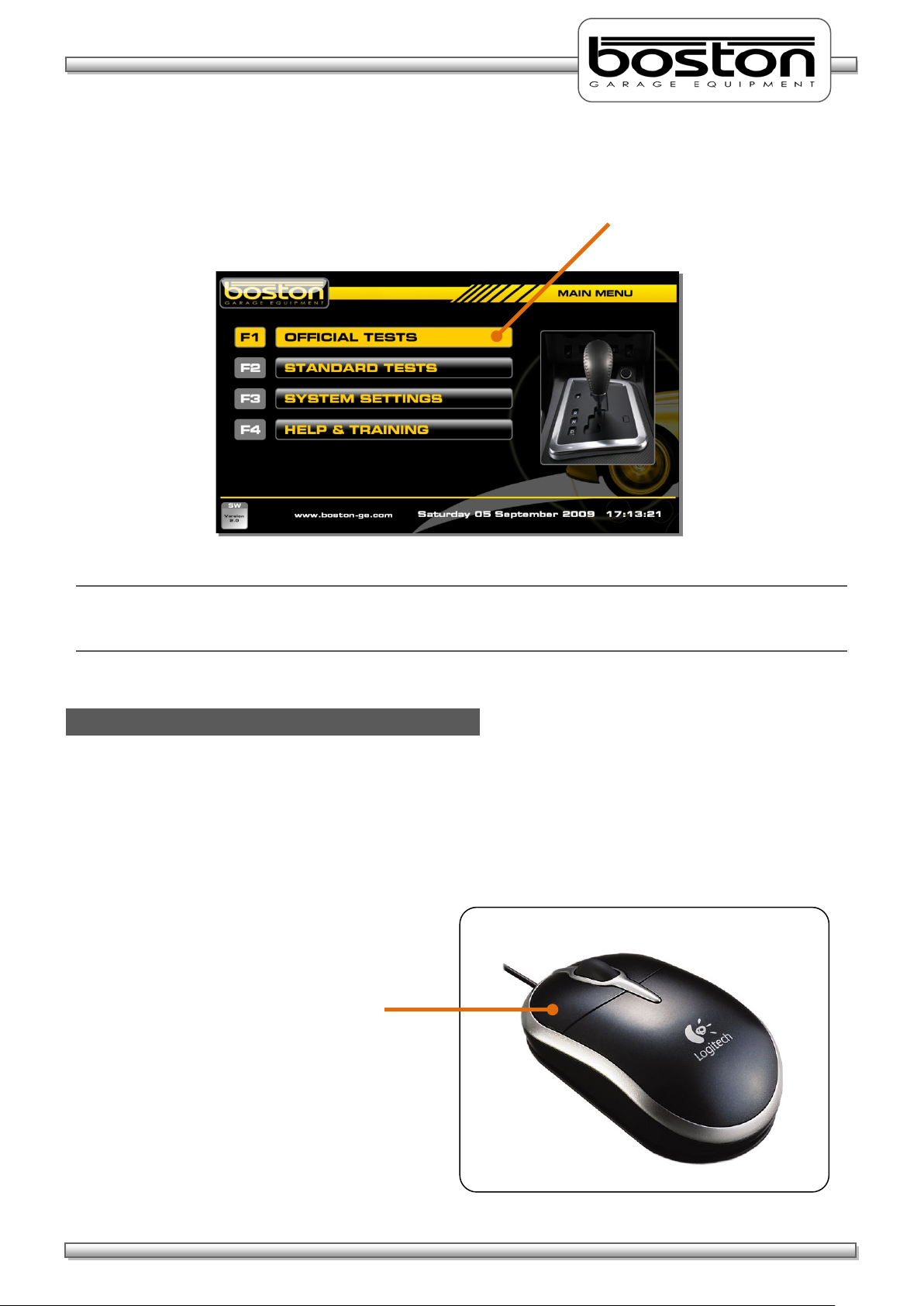

As the user scrolls through each menu option, it becomes highlighted to indicate the current selection. To

select the highlighted option press the ENTER key on the keyboard. See screenshot below.

NOTE

When using the ‘F’ keys directly, the options are not highlighted but the software continues immediately to

the selected option.

As the mouse pointer is placed on any of the different options, the option becomes highlighted in the same

way as if the keyboard arrows keys or TAB key were being used. As the mouse pointer leaves the option

the highlight is removed. To select any option, place the pointer over the desired option and click the LEFT

button on the mouse. The software will proceed to the selected option.

on the mouse to make

the selection.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

23 / 93

ENGLISH

↑

Keyboard Control

Arrow Keys

or to move in

different directions

‘F’ Keys

or to select the

required option directly

Tab Key

Enter Key

The software can be operated from the keyboard in several ways.

By using the

and ↓ ARROW keys to highlight and scroll through the menu options.

By using the TAB key to jump to and highlight the next menu option.

By using the ‘F’ keys along the top of the keyboard to directly select the required option.

This button allows

the operator to jump

directly to the next

menu option.

These buttons allow the

operat

without the need to scroll

through the menus.

The Enter key confirms

the highlighted selection.

These buttons allow the

operat

though the menus.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

24 / 93

ENGLISH

Software Version

The current software version is shown here

As new products become available and changes and additions are made to the various software

procedures, the SW900 software will require updating. To easily find out which software version is

currently being used, simply look at the bottom left-hand corner of any of the MAIN MENU pages.

By clicking on the button with the mouse, a pop-up window will be shown detailing the software version

and changes made in the current version since the previous version. See below.

Software Updates are released periodically throughout the year and it is important that your software is up

to date. Updates can be installed automatically if your system is connected to the internet. If not, your

local agent can install updates on request.

Please see the SW900 USER MANUAL for further information about updating software.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

25 / 93

ENGLISH

Standard Brake Test

Chapter 5

In This Chapter

Vehicle Data Entry 26

Display Layout 29

Placing Vehicle in Rollers 31

Vehicle Weight 32

Testing Front Axle 33

Testing for Imbalance 35

Testing Rear Axle 37

Testing the Parking Brake 37

Test Results and Printout 38

Testing 3WD Vehicles 41

Testing 4WD Vehicles 42

Testing Motorcycles 45

Automated Brake Test 58

Saving Test Results 67

This chapter describes how to carry out a STANDARD brake test using both the MANUAL and AUTOMATED

software procedures. The STANDARD TEST option should be used for quick unofficial testing, and the

OFFICIAL TESTS option for official tests. This manual assumes that installation of the RBT is complete and

the software is fully enabled for the user. This manual also assumes that the user is familiar with the

SW900 software and has read the SW900 software manual.

Before continuing, it is important to note and check the following:

Brake forces are indicated in kgf.

Weight input is indicated in kg.

Imbalance is indicated in %.

Brake efficiency is indicated in %.

Examine the tyres to ensure they are not under-inflated, if the tyre pattern is in good condition and

if the tyres are free from mud and stones.

Determine whether the vehicle has a single brake control system or a split (dual) brake control

system.

Ensure the roller covers are removed from the RBT.

Ensure the wheels of the vehicle are always placed centrally in the rollers before starting the test.

Understand the quick stop emergency procedures should they be required.

NOTE

All references on the software pages to the ‘F’ keys on the keyboard also relate to the same function keys on

the RF remote control. The following procedures do not relate to the remote control although the functions

of the keyboard and remote control are the same.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

26 / 93

ENGLISH

Vehicle Data Entry

F2 – STANDARD TESTS

The STANDARD BRAKE TEST is usually performed in the following order, but the software is able to

accommodate any other order if preferred by the tester.

1. Service Brake - Front LEFT wheel

2. Service Brake - Front RIGHT wheel

3. Service Brake - Imbalance between both front wheels

4. Service Brake - Rear LEFT wheel

5. Service Brake - Rear RIGHT wheel

6. Service Brake - Imbalance between both rear wheels

7. Parking Brake - Rear LEFT wheel

8. Parking Brake - Rear RIGHT wheel

In some cases, the PARKING BRAKE may act on the front wheels, and it may be necessary to test the

PARKING BRAKE with the front wheels still in the rollers. The list above is just an example of the most

common type of test procedure and is the procedure demonstrated in this manual.

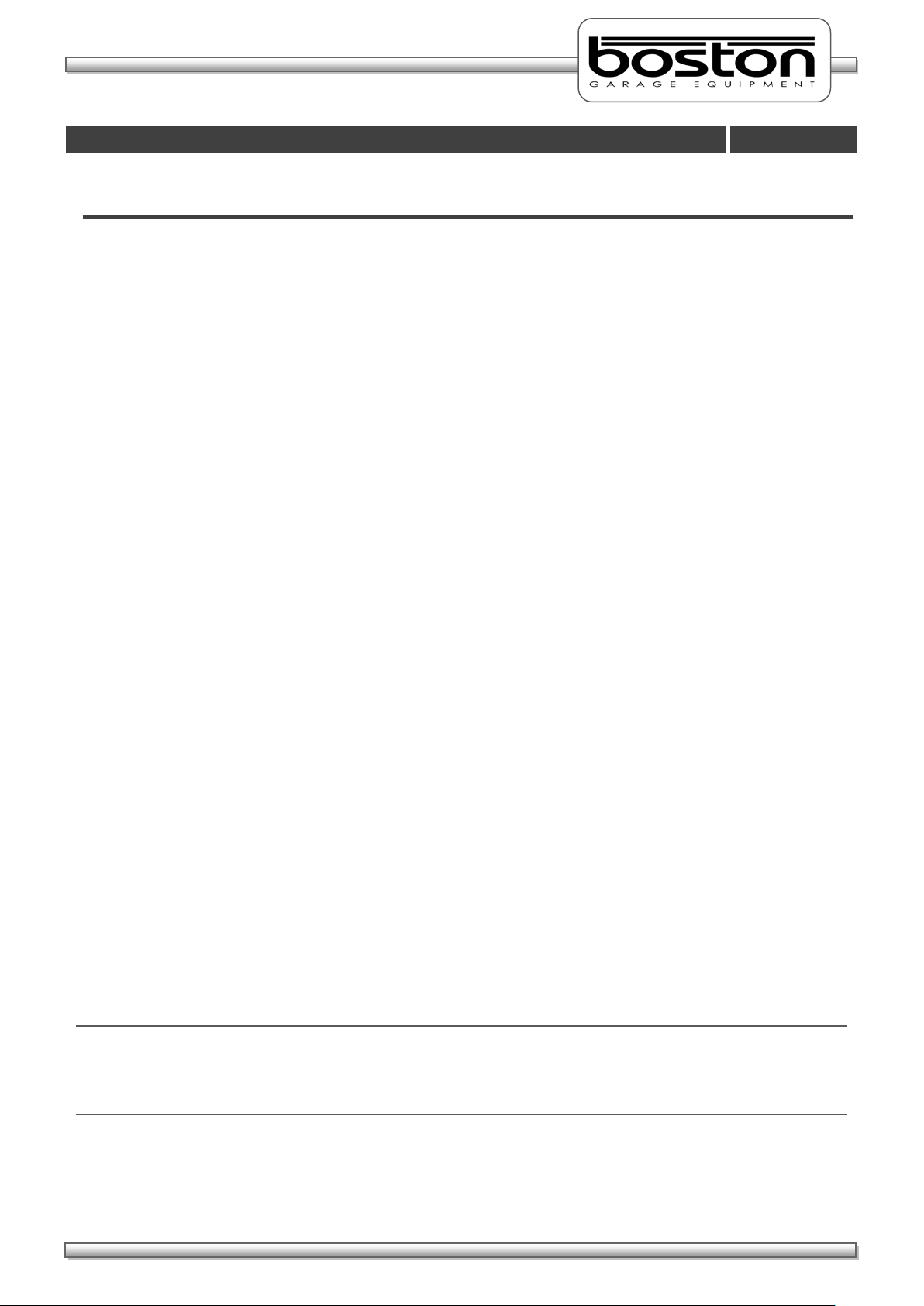

From the MAIN MENU, select option F2 ‘STANDARD TESTS’ and follow the procedure below to reach the

DATA ENTRY page.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

27 / 93

ENGLISH

MANUAL TEST OPTIONS

AUTOMATED TEST OPTIONS

Motorcycle Test

2 Wheel Drive Vehicle Test

2 Wheel Drive Vehicle Test

3 Wheeled Vehicle Test

4 Wheel Drive Test

From this page the user selects the type of

F2 – BRAKE TEST

test required. If the relevant hardware and

software is installed the software will

continue into the respective program, if not,

the message ‘ACTIVATION REQUIRED’ is

shown. Similarly, if no tester’s names have

been set, the message ‘SET TESTERS NAMES’

will be shown.

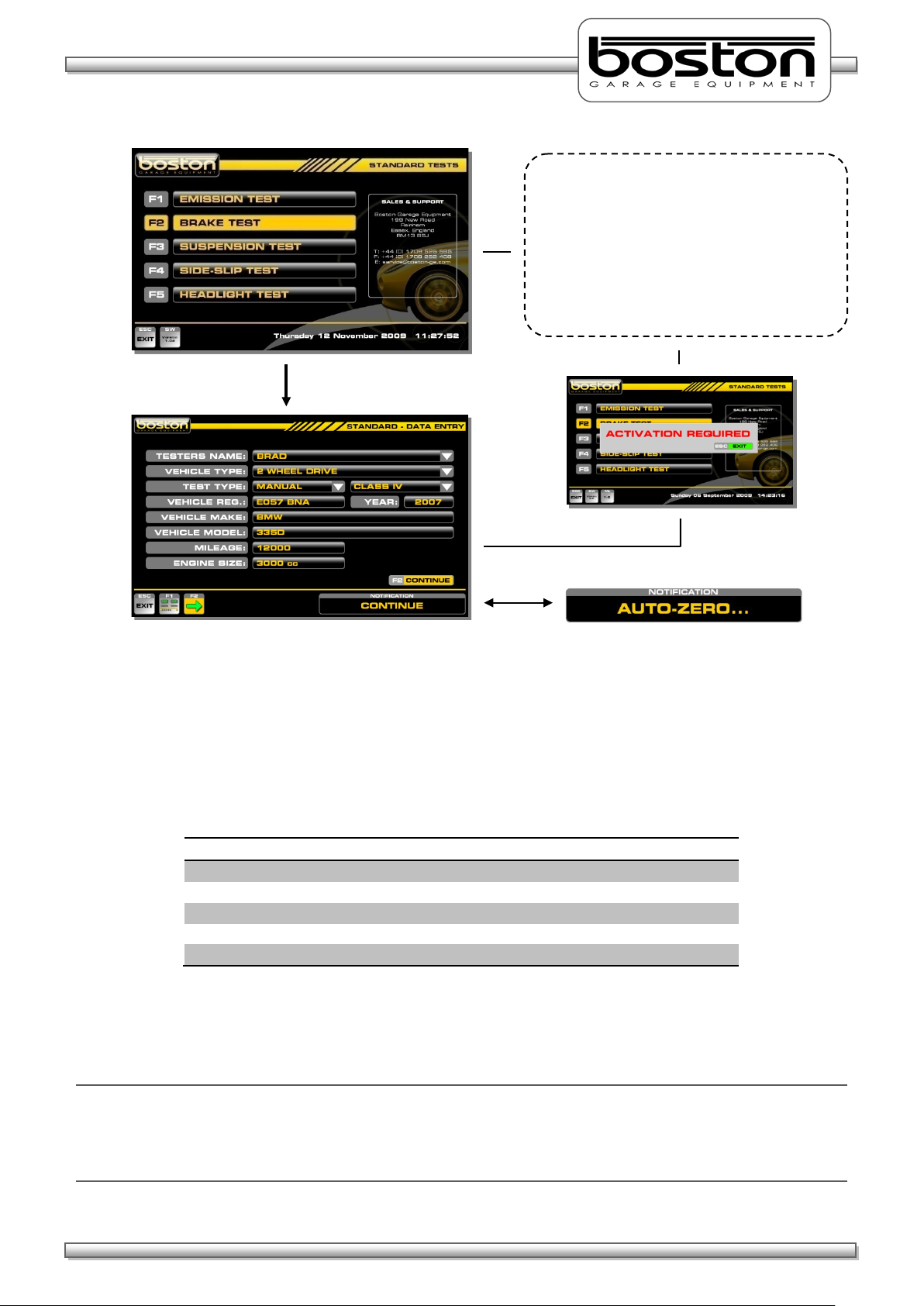

Whenever the DATA ENTRY page is entered, the message AUTO-ZERO will be shown briefly in the

NOTIFICATION box. Whichever item of equipment has been selected from the test selection menu will be

‘zeroed’ prior to carrying out the test. At this point, it is important that the roller bed is clear and the roller

covers are removed. If not, the software will ‘zero’ the system with an inaccurate measurement.

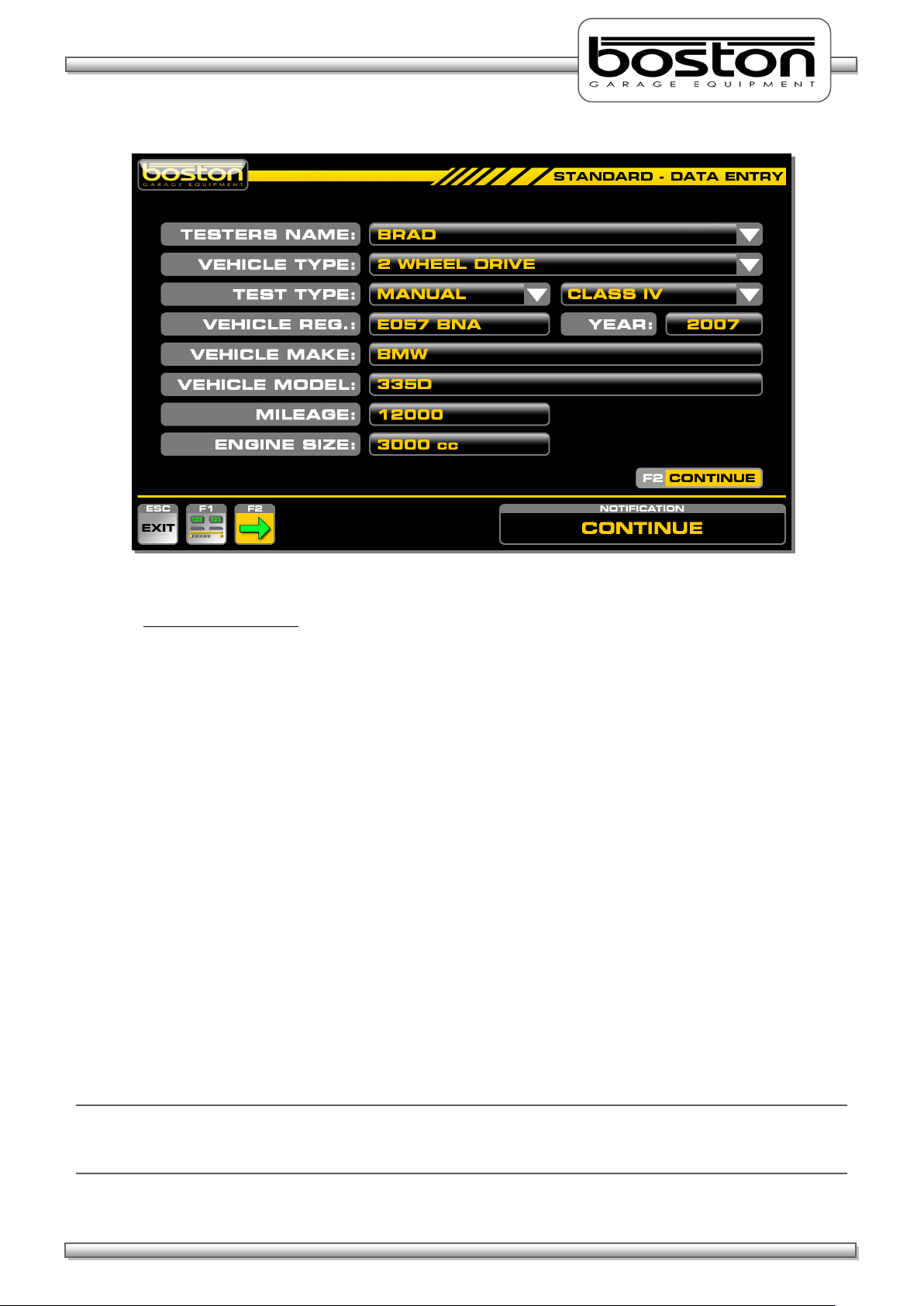

The DATA ENTRY page allows the user to enter specific vehicle data for the vehicle about to be tested. As

the software is able to test different types of vehicles, it is important to ensure that the data is correct

before selecting continue. The available types of test for MANUAL and AUTOMATED are shown below.

Using the mouse and keyboard, enter the relevant information into the DATA ENTRY page. If the operator

does not wish to enter vehicle data, the software will still allow the user to continue, but the missing

information will not be shown on the printout if required.

NOTE

It is not compulsory for the user to enter any vehicle specific data, but the VEHICLE TYPE and TEST TYPE

entry fields must be completed to allow the software to follow the correct route. The default settings for

this page are: 2 WHEEL DRIVE, MANUAL and CLASS IV. The display layout can also be set by selecting F1.

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

28 / 93

ENGLISH

Test Selection Criteria

If the user selects MOTORCYCLE from the VEHICLE TYPE pull-down menu, the TEST TYPE will

automatically be set to MANUAL, CLASS 2.

If the user selects 4 WHEEL DRIVE as the vehicle type, the TEST TYPE is automatically set to

MANUAL. The option for AUTOMATED is not available.

If the user selects 3 WHEELED VEHICLE as the vehicle type, the TEST TYPE is automatically set to

MANUAL, CLASS 3 (CLASS 4 can still be selected by the user). The option for AUTOMATED is not

available.

If the RBT is fitted with a vehicle weighing system the WEIGHT box is not shown.

The default settings for the DATA ENTRY PAGE are 2 WHEEL VEHICLE, MANUAL and CLASS IV.

The YEAR field is completed automatically by the software depending on the registration of the

vehicle. Eg. If the registration of the vehicle is EO57 then the year is set to 2007. Although this field

is set initially, it can also be edited by the user in the event that the year cannot be ascertained

from the registration number (vehicles with old or personalised number plates).

The data entry on this page is not compulsory and the user can save time by simply selecting

CONTINUE, however, information not entered will not be shown on the printout if required.

The pull-down menus on this page can be operated using the PC mouse, the TAB / ARROW keys on

the keyboard or the remote control.

NOTE

Some of the options mentioned above may not be available. For example, MOTORCYCLE. This option will

only be shown in the pull down list if the product has been purchased and installed.

Loading...

Loading...