Page 1

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

1 / 93

ENGLISH

Garage Equipment Associati on

Boston Garage Equipment, 199 New Road, Rainham, Essex, RM13 8SJ, United Kingdom

USER MANUAL

D412 / D412W / +MC1

Roller Brake Tester

T: +44 (0)1708 525585 F: +44 (0)1708 525408 info@boston-ge.com www.boston-ge.com

Page 2

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

2 / 93

ENGLISH

Copyright

Copyright © 2014 Boston Garage Equipment - All rights reserved worldwide.

All information contained in this document and any drawings, pictures, images and technical descriptions

which have been made available by Boston, remain the property of the company and may not, without

written permission from the company be used (except for the operation of equipment), duplicated in any

way or made available to third parties.

Disclaimer

Although every care has been taken during the preparation of this document, neither Boston or any other

company involved in its production and / or equipment production shall be liable for any damages derived

from the use of this documentation. Boston reserves the right to modify or improve its products and

literature at any time without prior notification. Any or all pictures and images in this document are for

demonstration purposes only.

This document may contain references to, or information about Boston products or services that are not yet

available. These references or information in no way mean that Boston intends to make such products

available.

This document may neither be partly or wholly duplicated, or distributed without prior authorisation from

Boston. Requests for further copies of this document or further information should be addressed to an

authorised agent, a Boston sales representative or to its e-mail address: info@boston-ge.com.

Technical and sales documentation is available on our Internet website: http://www.boston-ge.com.

Boston may have patents or applications for patents in progress involving the matters described in this

document. Supply of this document does not imply that any license to these has been granted.

Contact Details

Boston Garage Equipment

199 New Road

Rainham

Essex

RM13 8SJ

United Kingdom

Tel: +44 (0)1708 525585 Email: info@boston-ge.com

Fax: +44 (0)1708 525408 Web: www.boston-ge.com

Page 3

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

3 / 93

ENGLISH

Contents

Chapter 1 Introduction 5

Audience 5

Scope 5

Organisation 6

Layout Conventions 6

Related Documents 7

Chapter 2 Safety 8

General Safety Instructions 8

Maintenance Safety 9

Safety Features 9

Misuse 9

Chapter 3 Product Description 10

System Overview 10

D412B Roller Bed 12

MCU-090 (Master Control Unit) 14

GCP (Global Control Platform) 16

RFC-95 (RF Remote Control) 17

MC1 (Motorcycle Testing Cover Plate) 19

Chapter 4 General Operation 20

Power On (MCU-090) 20

Power On (BPC-091) 21

Menu Navigation 21

Mouse Control 22

Keyboard Control 23

Software Version 24

Chapter 5 Standard Brake Test 25

Vehicle Data Entry

Display Layout 29

Placing Vehicle in Rollers 31

Vehicle Weight 32

Testing Front Axle 33

Testing for Imbalance 35

Testing Rear Axle 37

26

Page 4

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

4 / 93

ENGLISH

Contents

Testing the Parking Brake 37

Test Results and Printing 38

Testing 3 Wheeled Vehicles (3WV) 41

Testing Four Wheel Drive Vehicles (4WD) 42

Testing Motorcycles 45

Automated Brake Test 58

Saving Test Results 67

Chapter 6 Official Brake Tests 69

Official Tests - Data Entry 70

Manual Tests – 2WD Vehicles 74

Testing 3 Wheeled Vehicles (3WV) 79

Testing Four Wheel Drive Vehicles (4WD) 79

Testing Motorcycles 79

Official Automated Brake Test (ATL) 80

Chapter 7 DVSA Regulations UK 82

Brake Efficiency 82

Brake Imbalance 82

Efficiency Limits 83

Motorcycle Limits 84

Chapter 8 Troubleshooting and Maintenance 85

Chapter 9 Warranty / Guarantee 87

Chapter 10 Product Specifications 88

D412B Roller Bed Specification 88

RF-90 RF Remote Control Specification 89

BPC-091 Mini PC Specification 90

MCU-090 Control Unit Specification 91

CE Declaration 92

Page 5

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

5 / 93

ENGLISH

Audience

Scope

Introduction

Chapter 1

In This Chapter

Audience 5

Scope 5

Organisation 6

Layout conventions 6

Related documents 7

This manual is intended for the final users of the equipment who will operate and maintain the system

throughout its working life.

Boston Garage Equipment requires that operators of this equipment:

Have sufficient technical knowledge and experience to operate the equipment

Can recognize and prevent potential hazards

Have read and understood this manual

Have been adequately trained

Follow the procedure in this manual

The purpose of this manual is to:

Describe the operation of the system

Describe its operating principles and general construction

Explain safety features and safety precautions

Highlight possible hazards

Describe the operation procedures

Describe the maintenance procedures

Troubleshooting

Page 6

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

6 / 93

ENGLISH

Organisation

Layout Conventions

This manual is organised into:

Safety – Describes safety features of the system and safety precautions to follow when operating

the system. Read this section before operation and maintenance.

Functional Description – Contains a functional description of the system.

Operating Instructions – Contains all the procedures necessary to operate the equipment safely.

Troubleshooting and Maintenance – Contains procedures to solve problems encountered during

operation and maintenance procedures that can be carried by the user.

Parts List – Contains parts lists and drawings.

In this manual we use a number of typographical conventions to highlight particularly important

information and to guide the user through the manual. This section lists these conventions.

Two types of list are used.-

1) Lists that are numbered (like this sentence) contain actions you must carry out in sequence.

In lists that use arrow points (like this sentence), the sequence is not critical.

NOTE

Text with additional information, such as expanded explanations, hints or reminders.

CAUTION

Indicates situations that can be dangerous or cause damage.

Commands (such as menu items and buttons) are bold. Menu names are also bold.

Example: On the remote control press 4.

Information that requires special attention is shown in italic.

Example: Use the Emergency Stop button only in emergencies.

Page 7

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

7 / 93

ENGLISH

Related Documents

Document Name Document Number

SW900 User Manual BOS0320

RFC-95 User Manual BOS0423

Page 8

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

8 / 93

ENGLISH

Safety

Chapter 2

General Safety Instructions

In This Chapter

General Safety Instructions 8

Maintenance Safety 9

Safety Features 9

Misuse 9

In order to comply with your responsibilities under the Health and Safety at Work Act 1974, it is essential

that this Roller Brake Tester (RBT) and any optional accessories are sited, installed, operated, and

maintained by Boston Garage Equipment or your local authorised / approved distributor.

All persons installing, operating or maintaining the equipment and any optional accessories must be

familiar with the layout of the equipment, the safety precautions, the emergency shutdown

procedures and vehicle braking systems.

Appropriate training is required, prior to installing, using or maintaining the equipment.

The instructions in this manual must be strictly adhered to, to avoid injuries to personnel and

damage to the machine and vehicle.

Only a qualified technician should carry out work on the electrical system, and should follow

procedures pre-described by national standards.

Never remove or bypass any of the safety features.

Avoid any direct or indirect electrical contact.

The unit should be placed inside a rigid, flat and clean surface, protected against water, humidity

and weather influences.

Keep the operating environment clean and free of oil. Never leave loose objects around the RBT.

Never leave parked vehicles on the RBT overnight.

Make sure the remote control is stored safely when not in use.

The equipment may be operated only within its rated capacity. The equipment is designed for MOT

Class 1, 2, 3 & 4 vehicles.

The equipment should only be used when the operator has a good view of the whole machine.

During the test no person should stand close to the roller bed(s).

The testing area should be clear of personnel, tools and equipment before starting each stage of

the test.

Do not stand on, or walk over the rollers at any time.

Take precautions to extract exhaust in the workplace properly while testing.

Do not test a vehicle when there is insufficient light.

Never make any adjustments to the vehicle braking system when the vehicle is in the rollers.

When the RBT rollers are in operation, any key on the remote control or PC keyboard will

immediately stop the rollers, irrespective of their prescribed function.

In case of an emergency, all operations can be stopped immediately by pressing the emergency

stop button on the side of the control cabinet.

If the RBT is not working correctly, switch off immediately and refer to the user manual or contact

Boston or their local agent.

Always isolate the RBT from the power supply before maintenance.

Follow the maintenance specifications accurately.

Page 9

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

9 / 93

ENGLISH

Maintenance Safety

Safety Features

Misuse

In addition to the general safety instructions, the following instructions apply when carrying out

maintenance on the equipment:

Switch off the main electrical supply before opening any part of the equipment.

The equipment must only be operated within its rated capacity.

Protect the electrical parts of the equipment from water and humidity.

Only qualified technicians are permitted to do work on the electrical system of the equipment and

must follow procedures prescribed by national standards.

Many safety features are bypassed inside the service areas of the software. Only qualified service

personnel are permitted to use the service section of the software.

Any unauthorised modification or changes to the system will invalidate the CE-declaration and

equipment warranty.

The D412 RBT offers the following standard safety features to minimise personal risk as much as possible.

The RBT is provided with an emergency stop button on the side of the control cabinet by which any

active operation can be stopped immediately in case of an emergency. To release the emergency

stop button after operation, rotate the button.

The rollers of the RBT’s can only be started if the centre rotating measuring rollers are pressed

down, i.e. when there is a vehicle axle in the roller brake tester (except when 3-wheel or

motorcycle modes are selected).

By applying brake force and locking any wheels under test, the rollers will stop immediately.

Closed covers for the chain and electrical components are fitted as standard.

All electrical cabling is covered to reduce any direct danger or risk.

The RBT is ground wired to earth.

Cover plates are provided to cover the rollers when the brake tester is not in use.

Whenever the rollers of the RBT are in operation, any key press on the keyboard or remote control

will immediately stop the rollers irrespective of the assigned key function.

The RBT is designed for use as a brake tester for statutory testing of MOT Class 1, 2, 3 & 4 vehicles and for

brake diagnostic purposes only.

It must NOT be used for any other purpose e.g.

‘Running in’ of brake linings.

Brake adjustments.

Diagnosis of vehicle faults e.g., tyre examination etc.

Any purpose requiring the operator to be in the danger zone, other than to conduct a brake test

and/or maintenance and calibration purposes (authorised personnel only).

If access to any service area requires driving over the RBT then cover plates must be used

Page 10

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

10 / 93

ENGLISH

Product Description

Chapter 3

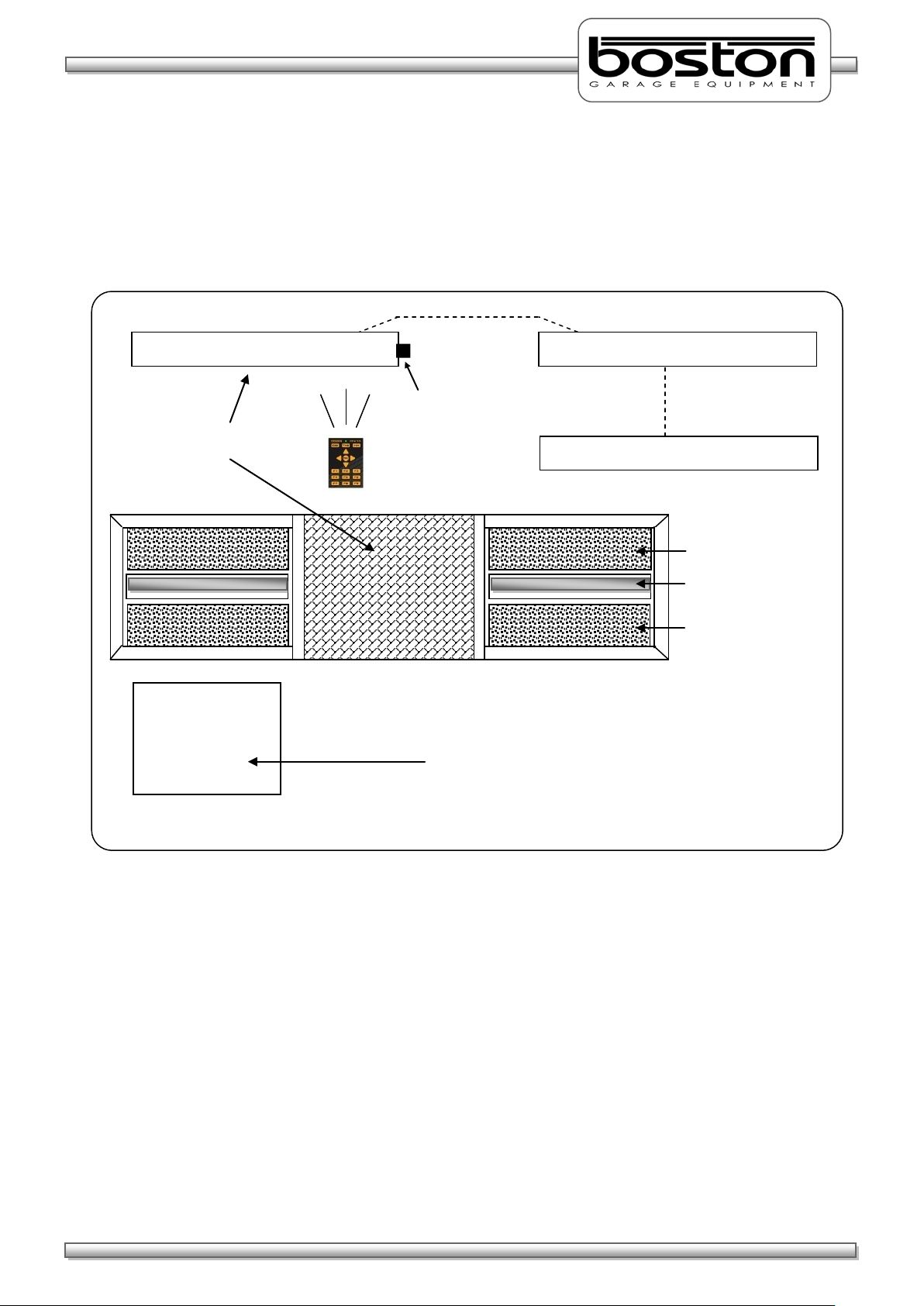

System Overview

In This Chapter

System Overview 10

D412B Roller Bed 12

MCU-090 Multi Connection Unit 14

GCP Global Control Platform 16

RFC-95 RF Remote Control 17

MC1 Motorcycle Testing Cover Plate 20

The RBT is a well-known method for analysing the efficiency of the braking system of a vehicle.

There are several main components that comprise the D412 RBT, these are listed below and are covered in

detail later on this chapter.

D412B The steel chassis floor module containing the rollers and all sensors.

MCU-090 A wall mounted cabinet containing the cable connections from the roller bed, data

acquisition circuitry and operation control relay cards.

GCP Boston’s computer control system running the SW900 control software with

mouse, keyboard LCD display monitor and laser printer.

RFC-95 An RF Remote control for remote operation of the RBT from inside the vehicle.

MC1 A small cover plate that attaches to the roller bed to enable the safe testing of

smaller motorcycle wheels.

The mechanical floor unit contains two electrical motors, two independent sets of three measuring rollers, two

brake force transducers, additional safety sensors and an optional four point vehicle weighing system fitted to

the base or installation cartridge.

During testing, the brake forces induce reaction forces on the electric motor which in turn applies force to an

electric transducer with strain gauges. Through software, the sensors are monitored and the data collected is

converted into a reading and displayed on a monitor for the operator to see. The rotating brake rollers are

coated with a wear-resistant material which provides high friction values in both wet and dry conditions. The

roller diameters are sufficiently large to keep the tyre flexing to a minimum.

The third smaller roller on each side between the wheel supporting rollers has two functions:

The first is to detect if a vehicle is present in the roller bed (a built in safety device to prevent the motor

starting without a vehicle in place). For safety purposes, the motors will not start if both the left and

right small rollers are not pushed down for more than two seconds (except when 3-wheel mode or

motorcycle mode is selected).

The second function is to detect if tyre slip on the rollers does not exceed the maximum value.

The GCP control system can be configured in two ways, either wall mounted or fitted into a mobile trolley /

cabinet stand. The GCP that controls the RBT is not connected directly to the roller bed but to the MCU

(Master Control Unit) via USB.

Page 11

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

11 / 93

ENGLISH

Emergency switch + Main switch

Wall mounted connection / control box

Measuring roller

Measuring roller

Slip detection roller

BSS2000

D412 Roller

The BSS2000 Side-Slip Meter is a separate device and

Wall mounted LCD display unit

GCP – Control System

Remote Control

The MCU is a wall mounted connection panel which the mechanical floor unit is wired to. It contains the

various components to acquire data from the sensors during braking and control relays for starting and

stopping the rollers. It has an emergency stop button and main power switch located on one side of the

panel.

Braketester

Side-Slip Meter

can easily be added to the D412 Roller Braketester.

Page 12

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

12 / 93

ENGLISH

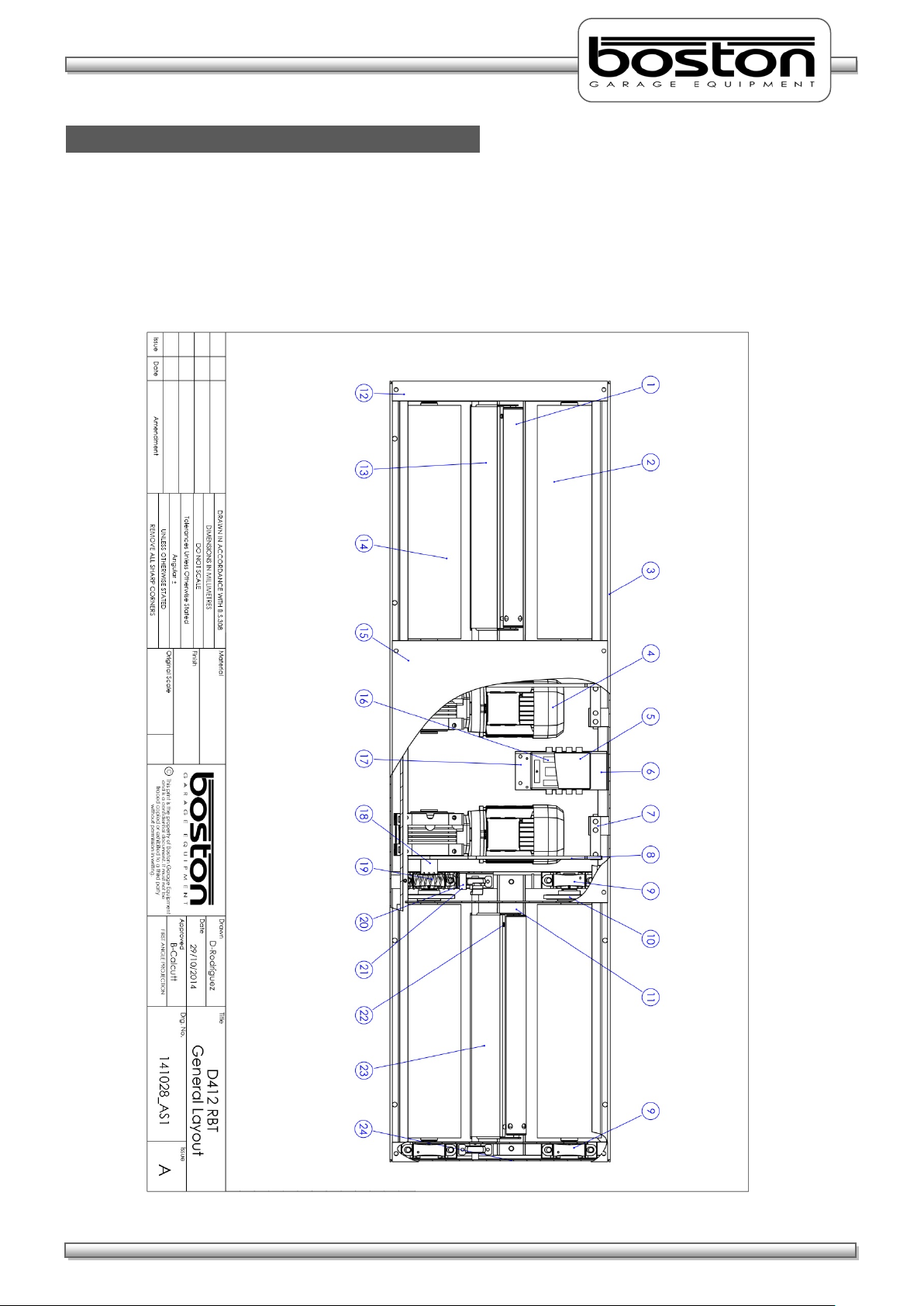

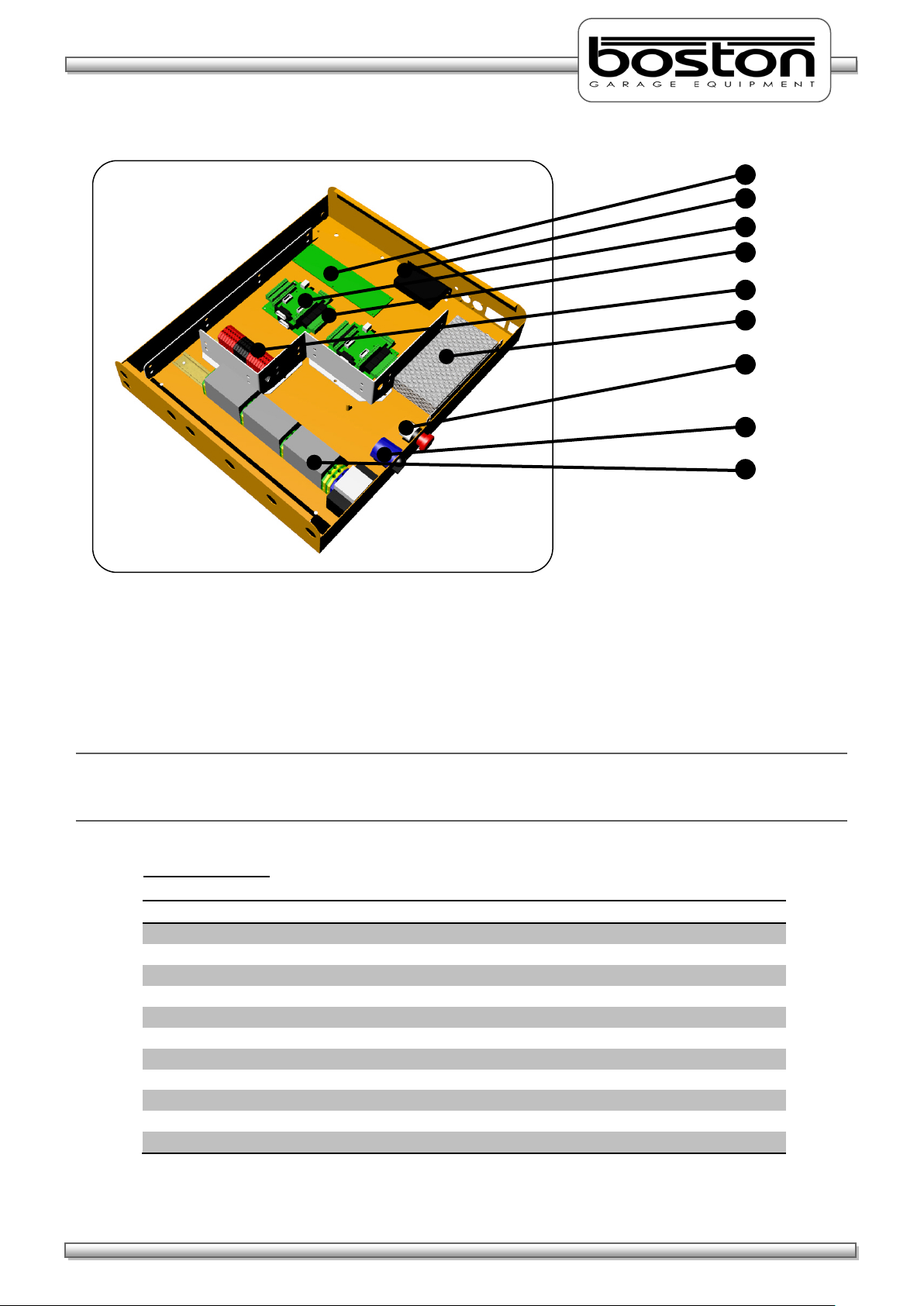

D412B Roller Bed

The D412B Roller Bed is a single chassis unit containing four high friction surface rollers and two smaller

free rolling rollers to detect wheel presence and measure wheel speed. The unit is equipped with two

brake force measurement sensors and can be fitted with an optional vehicle weighing system.

A general layout of the D412B Roller Bed is shown below.-

Page 13

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

13 / 93

ENGLISH

Item

Description

Quantity

1

Tacho roller 2 2

Front roller 2 3

Chassis 1 4

Motor 230/400V 3kW

2

5

Connection PCB Enclosure

1

6

Connection Box Support Bracket

1

7

Force Transducer

2

8

Torque Arm

2

9

Bearing Housing

4

10

Chain Roller 4 11

Protection Plate

2

12

Side Covers 2 13

Detection Frame LEFT

1

14

Rear Roller 2 15

Centre Cover Plate

1

16

Connection PCB

1

17

Ground Connector

1

18

Drive Shaft Spacer

2

19

Spring Extension

2

20

Tacho Stop Block

2

21

Rubber Stop

2

22

Proximity Switch

2

23

Detection Frame RIGHT

1

24

End Chassis 2

Component Table

Page 14

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

14 / 93

ENGLISH

MCU-090 (Master Control Unit)

The MCU-090 is an interface / connection box where the power cables for the motors and data cables for

the sensors are all connected. Although the MCU-090 is used for the control of the D412B roller bed, it can

also be used to connect and control the following components to provide a full test lane.-

• R102 Class 1,2 Motorcycle Roller Brake Tester

• R103 Class 1,2 Motorcycle Roller Brake Tester

• D402 / D402W+MC1 Class 1,2,3,4 Roller Brake Tester (Manual and Auto Testing)

• D412 / D412W+MC1 Class 1,2,3,4 Roller Brake Tester (Manual and Auto Testing)

• D403 / D403+MC2 Class 1,2,3,4 Roller Brake Tester (Manual and Auto Testing)

• D702 / D702+MC3 Class 1,2,3,4,5L,7 Roller Brake Tester (Manual and Auto Testing)

• D712 / D712+MC3 Class 1,2,3,4,5L,7 Roller Brake Tester (Manual and Auto Testing)

• S402 3T Suspension Tester

• S702 4T Suspension Tester

• SS02 4T Side-Slip Meter

• AGS200 Exhaust Gas Analyser

• AGS688 Exhaust Gas Analyser

• OPA100 Exhaust Diesel Smokemeter

• B502 Electronic Headlight Tester

NOTE

Some items listed above may be under development.

In most cases the MCU-090 will be supplied in standard configuration. This will allow control of the

majority of products above (and some others) simultaneously. Depending on specific customer

requirements, additional internal components may be required.

Page 15

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

15 / 93

ENGLISH

Item

Description

1

Connection Interface Card

2

Powered USB Hub

3

Data Acquisition Card 1 (Optional second card can be installed)

4

Relay Card 1 (Optional second card can be installed)

5

Low Voltage Connection Din Rail

6

Power Supply

7

Emergency Stop Button

8

Main Power Switch

9

High Voltage Relay Din Rail

2 8 5 3 6 4 1 9 7

The MCU-090 is connected to the GCP using a standard USB A-B connection cable. Older versions of Boston

Control Platforms may also be used to control the MCU-090, check with your local distributor for

compatibility.

NOTE

There are no user serviceable parts inside the MCU-090 and all maintenance / repairs should be carried out

by approved Boston engineers.

Component Table

Page 16

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

16 / 93

ENGLISH

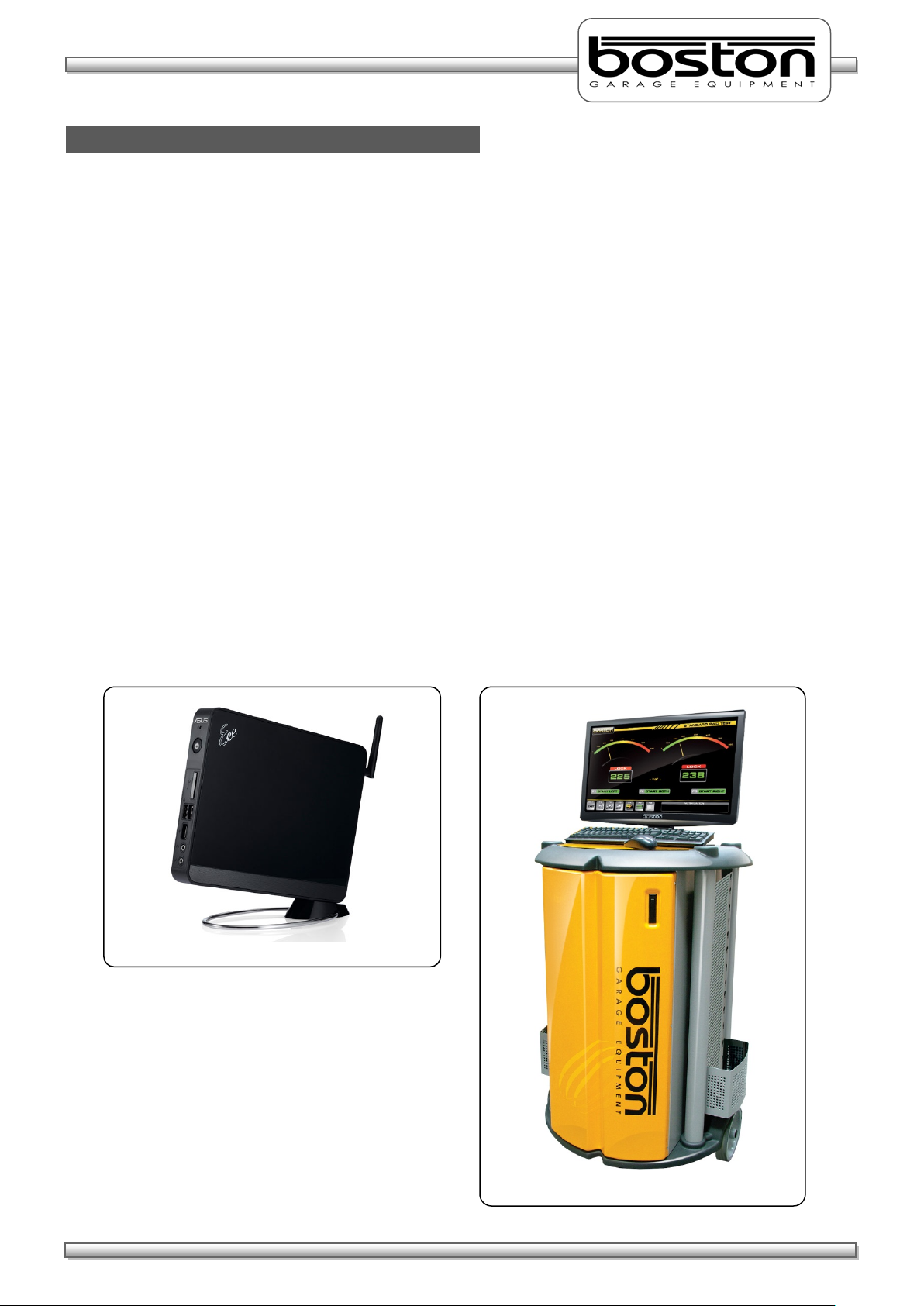

BPC-0951 Mini PC

TRO-220 Mobile Stand

GCP (Global Control Platform)

The GCP is the computer control station that connects to the MCU-090 via USB. It is a separate unit and

can be supplied in different configurations, but in most cases it is wall mounted with a display monitor and

mouse / keyboard (GCP1). A breakdown of the GCP main standard supply components is listed below.-

Mini Industrial PC with Windows OS and Internal Wifi

Boston Software SW900

Optical PC Mouse

PC Keyboard

Widescreen LED Monitor

Laser Printer

Wall mount bracket or rolling stand

The GCP can also be supplied as a mobile unit using one of Boston’s rolling cabinet stands.

GCP3 - Circular Drum-Type Mobile Stand (as shown below)

GCP2 - Standard Mobile Stand

In all cases, the GCP can also be fitted with a second display monitor up to 60” in size. Please contact

Boston or your local sales / service agent for further information.

This manual only covers the Braketester software program; another manual is available separately detailing

the operation and functions of the SW900 software installed on the GCP.

Page 17

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

17 / 93

ENGLISH

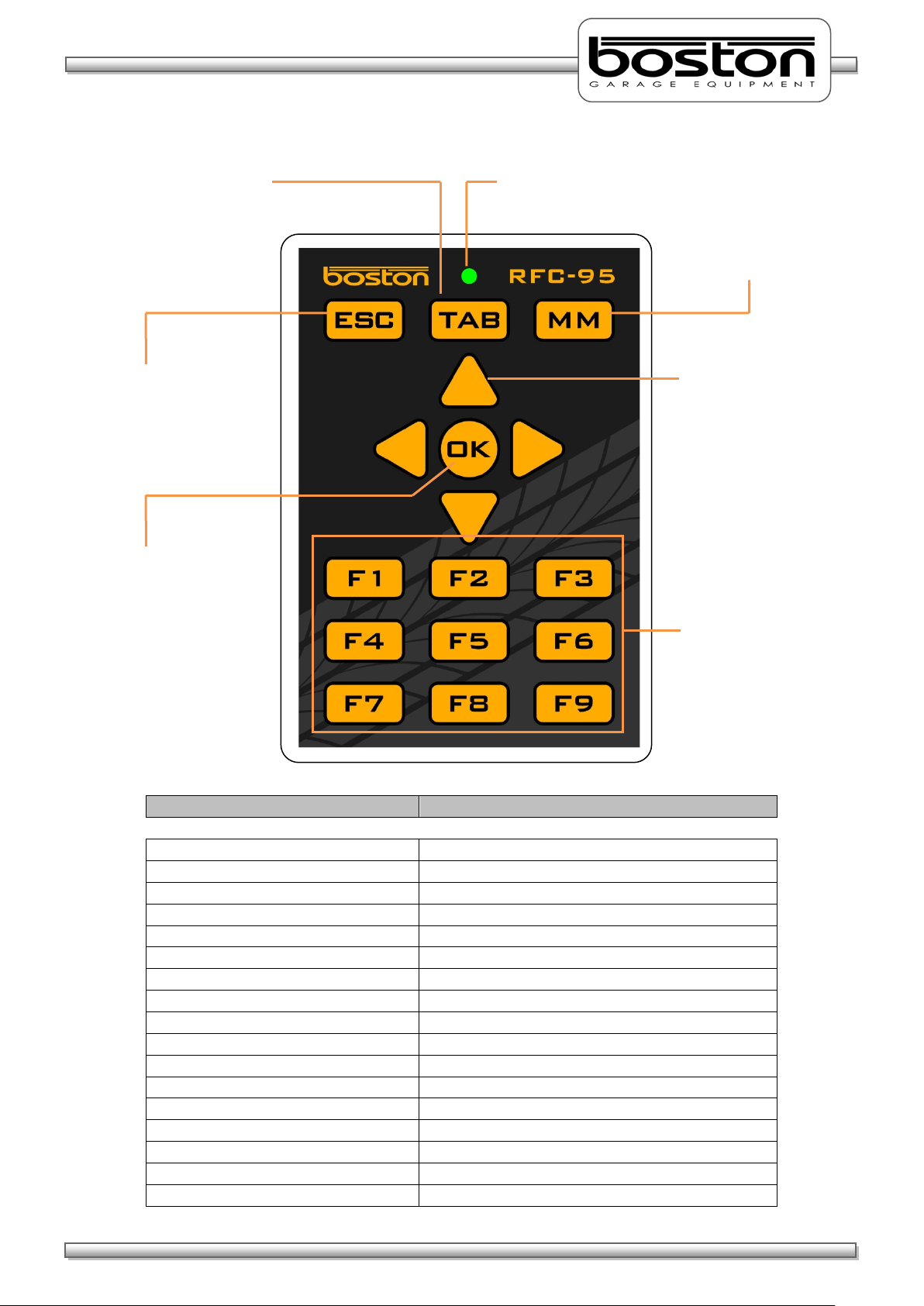

RFC-95 (RF Remote Control)

The remote control is the most commonly used control for the SW900 software. It has many of the same

functions as the keyboard but from a wireless range of approximately 50m. There is a separate User

Manual available for the Boston RF Remote Control, but the main functions are covered here.

Many remote controls operate using infra-red (IR) technology. Whilst being reliable, they are restricted to

‘line-of-sight’ operation which in some environments can make them impractical. The Boston RFC-95 is a

ruggedized control, ideally suited for the testing industry where rugged protection is required. It operates

using the latest Zigbee Radio Frequency (RF), which unlike IR doesn’t require line of sight operation. This

provides greater flexibility and allows it to be used from inside the vehicle to control different items of

equipment.

The RFC-95 button functions are shown below.

Page 18

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

18 / 93

ENGLISH

Button

Associated keyboard Function

ESC

ESCAPE

TAB

TAB

MM

MAIN MENU (SW900 Software only)

ARROW UP

ARROW UP

ARROW DOWN

ARROW DOWN

ARROW LEFT

ARROW LEFT

ARROW RIGHT

ARROW RIGHT

OK

ENTER

F1

FUNCTION KEY F1

F2

FUNCTION KEY F2

F3

FUNCTION KEY F3

F4

FUNCTION KEY F4

F5

FUNCTION KEY F5

F6

FUNCTION KEY F6

F7

FUNCTION KEY F7

F8

FUNCTION KEY F8

F9

FUNCTION KEY F9

‘TAB’ Key

‘ESC’ Button

‘MM’ Button

Arrow Keys

‘F’ Keys

‘OK’ Key

keyboard.

Transmission LED

This button duplicates

the ‘Tab’ key function on

the main keyboard.

This button duplicates

the ‘ESC’ key function

on the main keyboard.

This button duplicates

the ‘ENTER’ key

function on the main

The LED illuminates to

confirm any key press.

This button returns the

operator to the Main

Menu (only for Boston

SW-900 software).

These buttons duplicate

the arrow key functions

on the main keyboard.

These buttons duplicate

the ‘F’ key functions on

the main keyboard.

Page 19

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

19 / 93

ENGLISH

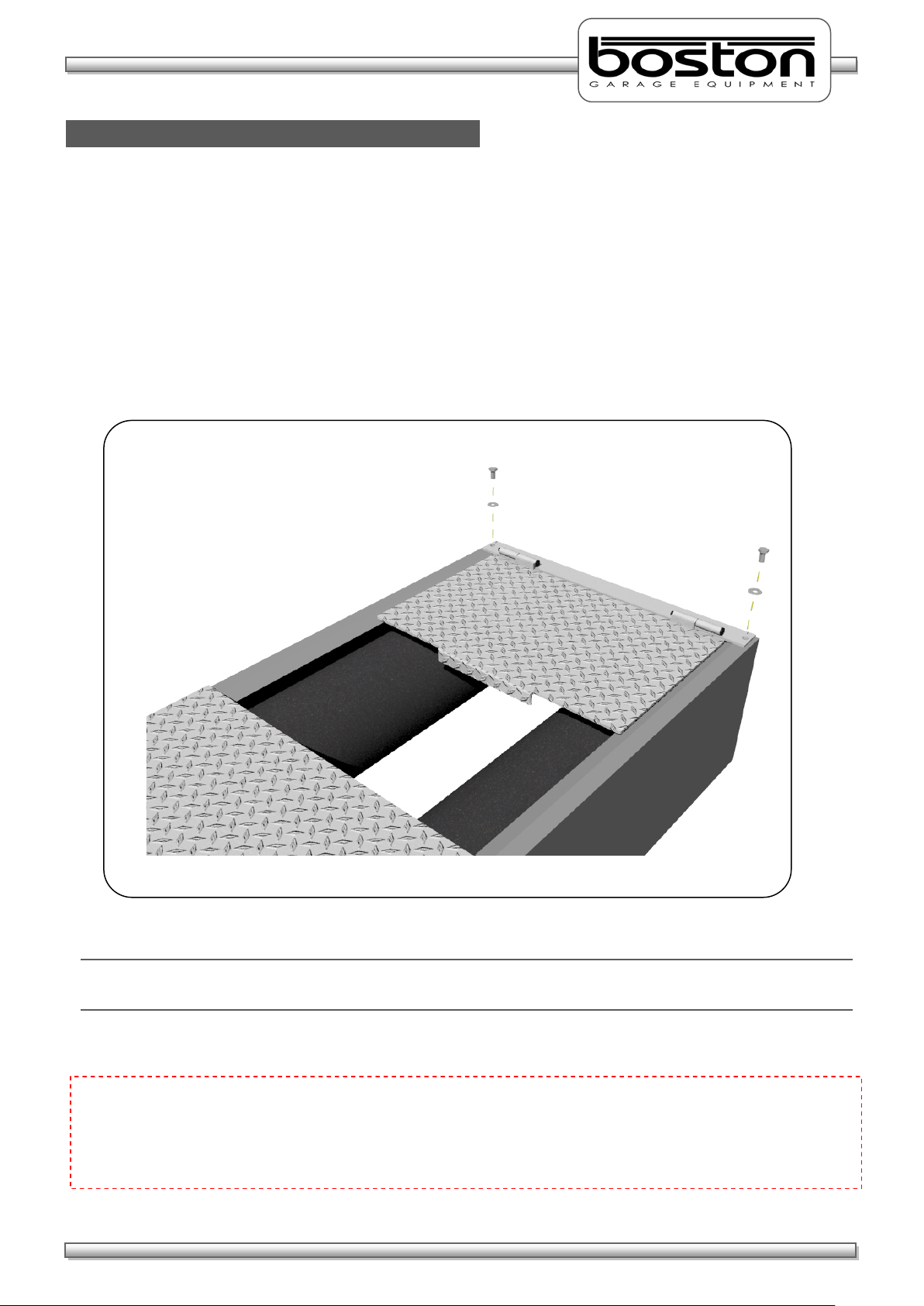

MC1 (Motorcycle Testing Cover Plate)

In order to test motorcycles, it is necessary to fit the MC1 cover plate to the required testing roller. The

cover plate is designed specifically to accommodate motorcycle wheels and safely cover the unused open

portion of the rollers. The cover plate is attached to the roller bed using two bolts and can be fitted very

quickly. It contains two hinges allowing the plate to ‘swing’ into place without the need to permanently

remove from the roller bed.

To fit the cover plate, refer to the illustration below.-

NOTE

The MC1 is a foot plate and is not intended for vehicles to drive over.

CAUTION

Motorcycle testing can only be carried out when the MC1 cover plate adapter has been fitted. The plate

limits the width of the open roller surface to accommodate the narrow wheels of motorcycles. It is

dangerous and prohibited to test motorcycles without the MC1 cover plate fitted.

Page 20

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

20 / 93

ENGLISH

General Operation

Chapter 4

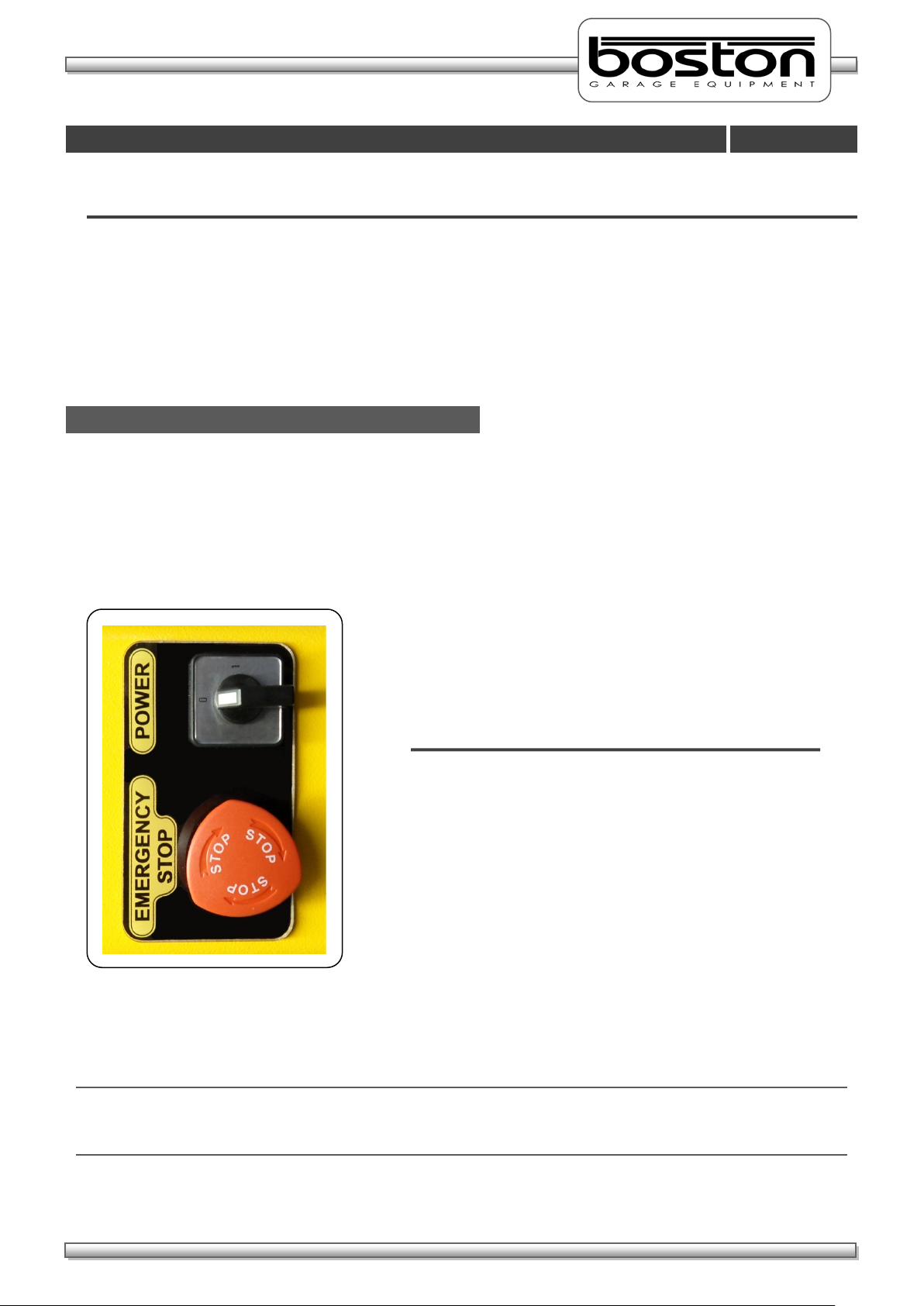

Power On (MCU-090)

MAIN POWER SWITCH - Isolates power from the

EMERGENCY STOP - Immediately stops all

In This Chapter

Power On (MCU-090) 20

Power On (BPC-091) 21

Menu Navigation 21

Mouse Control 22

Keyboard Control 23

Software Version 24

The MCU-090 has a Main Power switch and Emergency Stop button on the side of the cabinet. The Main

Power switch interrupts and isolates the power to the GCP control system and any other connected

equipment. The Emergency Stop button immediately stops all current operations and turns off the control

side of the system. It is usually left in the ‘running’ state and only used in the event of an emergency. The

operation of both these switches is shown below.-

Once power is applied to the MCU-090 the system is ready and waiting for instructions from the PC control

platform.

NOTE

In the wall-mount configuration, the power for the PC, monitor and printer is taken from the MCU-090.

When switching off the main power as described above, remember these items will also be switched off.

entire system and all other

connected equipment.

OPERATION - Rotate switch in clockwise /

anti-clockwise direction.

operations and turns off

power to the control side

of the system.

OPERATION - Press switch to activate.

Rotate clockwise to de activate.

Page 21

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

21 / 93

ENGLISH

Power On (BPC-091)

Menu Navigation

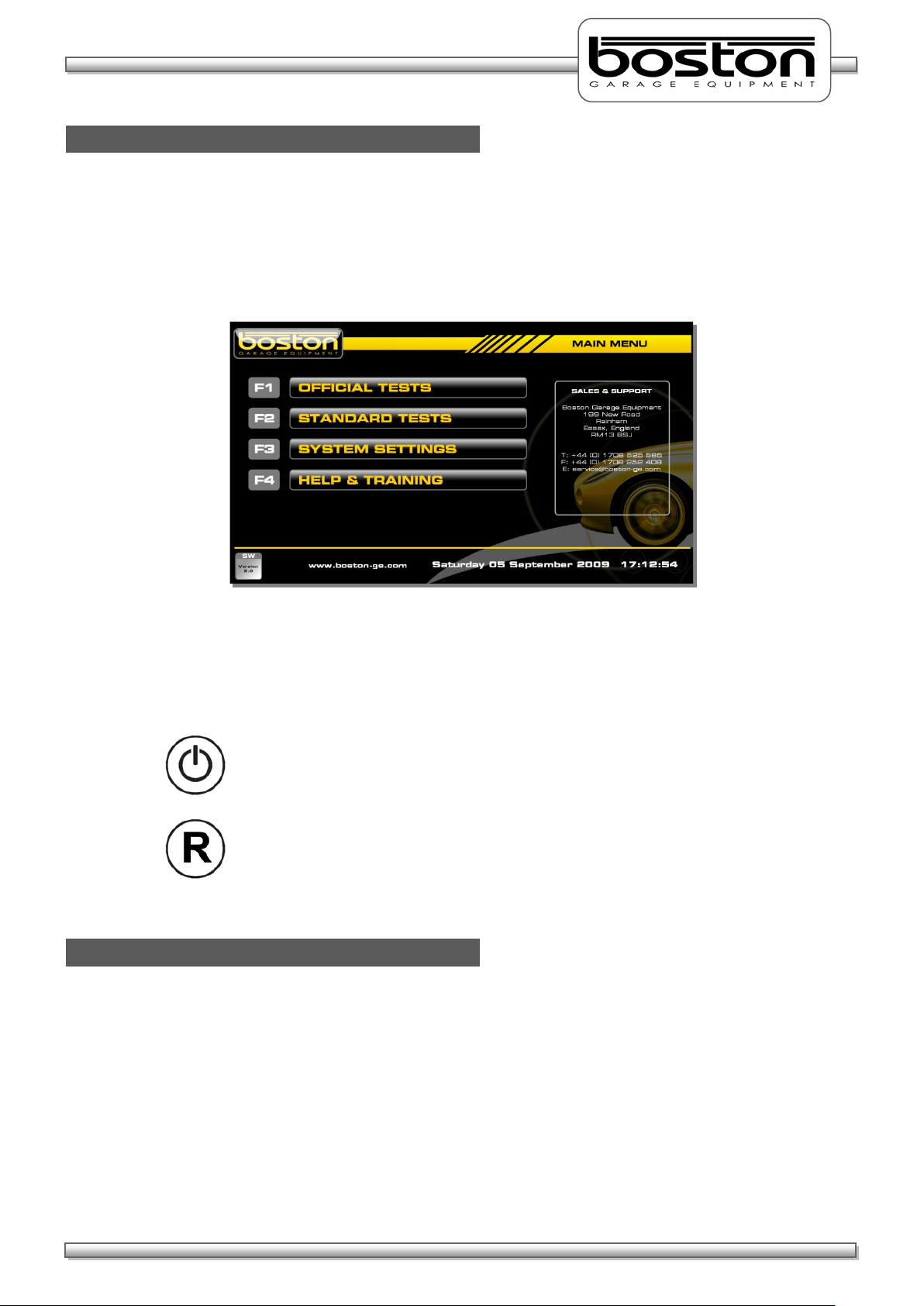

When power is applied to the BPC-091 PC, the system will automatically start-up and enter into the main

software menu page (as shown in the screenshot below). This will happen in the event of a power-cut or

even if the unit has been previously powered down and the power source removed and restored. In all

cases, when power is detected that was previously not present the system will auto-start.

There are also two power buttons on the right side of the PC. These are the main ‘POWER’ button and the

‘RESET’ button. A single press of either will perform the following function:-

POWER Button - Powers down the system. To restart, press the

POWER button again.

RESET Button - Resets the system by powering down and then re-starting

automatically.

After initial power-on, the page shown above should be displayed. From this page the user can select

whether to perform tests (options F1 and F2) or to change settings (F3) or seek assistance (F4). All options

in the SW900 software are described in detail in the SW900 User Manual available separately. For the

purpose of this manual we shall only cover the operation of the RBT program.

The software can be operated in several ways, either by using the keyboard, the mouse or the remote

control. All three options are available to the user (depending on their preference) and can be used at any

time, and anywhere within the software.

Page 22

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

22 / 93

ENGLISH

Option F1 Highlighted

Mouse Control

Click the LEFT button

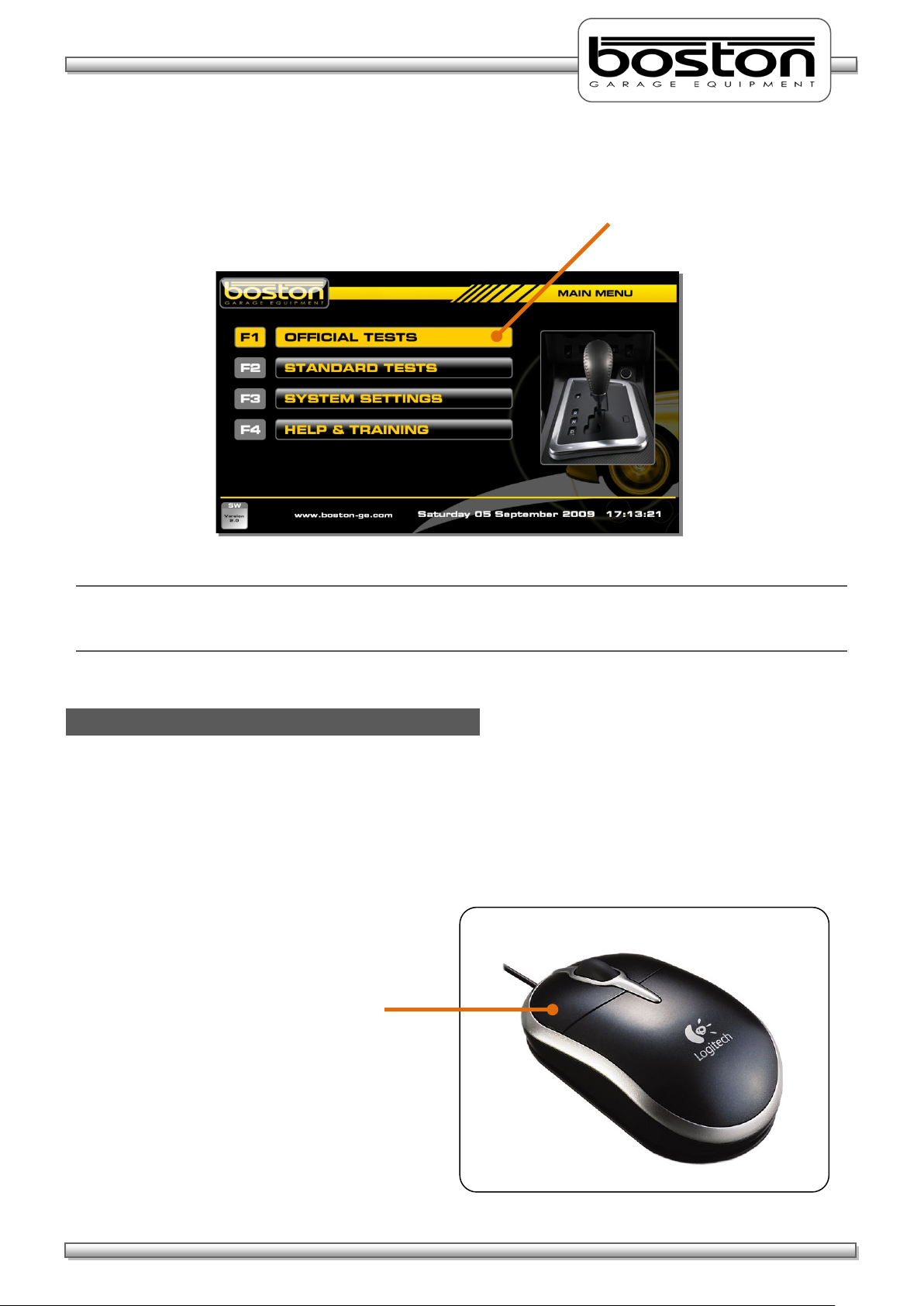

As the user scrolls through each menu option, it becomes highlighted to indicate the current selection. To

select the highlighted option press the ENTER key on the keyboard. See screenshot below.

NOTE

When using the ‘F’ keys directly, the options are not highlighted but the software continues immediately to

the selected option.

As the mouse pointer is placed on any of the different options, the option becomes highlighted in the same

way as if the keyboard arrows keys or TAB key were being used. As the mouse pointer leaves the option

the highlight is removed. To select any option, place the pointer over the desired option and click the LEFT

button on the mouse. The software will proceed to the selected option.

on the mouse to make

the selection.

Page 23

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

23 / 93

ENGLISH

↑

Keyboard Control

Arrow Keys

or to move in

different directions

‘F’ Keys

or to select the

required option directly

Tab Key

Enter Key

The software can be operated from the keyboard in several ways.

By using the

and ↓ ARROW keys to highlight and scroll through the menu options.

By using the TAB key to jump to and highlight the next menu option.

By using the ‘F’ keys along the top of the keyboard to directly select the required option.

This button allows

the operator to jump

directly to the next

menu option.

These buttons allow the

operat

without the need to scroll

through the menus.

The Enter key confirms

the highlighted selection.

These buttons allow the

operat

though the menus.

Page 24

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

24 / 93

ENGLISH

Software Version

The current software version is shown here

As new products become available and changes and additions are made to the various software

procedures, the SW900 software will require updating. To easily find out which software version is

currently being used, simply look at the bottom left-hand corner of any of the MAIN MENU pages.

By clicking on the button with the mouse, a pop-up window will be shown detailing the software version

and changes made in the current version since the previous version. See below.

Software Updates are released periodically throughout the year and it is important that your software is up

to date. Updates can be installed automatically if your system is connected to the internet. If not, your

local agent can install updates on request.

Please see the SW900 USER MANUAL for further information about updating software.

Page 25

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

25 / 93

ENGLISH

Standard Brake Test

Chapter 5

In This Chapter

Vehicle Data Entry 26

Display Layout 29

Placing Vehicle in Rollers 31

Vehicle Weight 32

Testing Front Axle 33

Testing for Imbalance 35

Testing Rear Axle 37

Testing the Parking Brake 37

Test Results and Printout 38

Testing 3WD Vehicles 41

Testing 4WD Vehicles 42

Testing Motorcycles 45

Automated Brake Test 58

Saving Test Results 67

This chapter describes how to carry out a STANDARD brake test using both the MANUAL and AUTOMATED

software procedures. The STANDARD TEST option should be used for quick unofficial testing, and the

OFFICIAL TESTS option for official tests. This manual assumes that installation of the RBT is complete and

the software is fully enabled for the user. This manual also assumes that the user is familiar with the

SW900 software and has read the SW900 software manual.

Before continuing, it is important to note and check the following:

Brake forces are indicated in kgf.

Weight input is indicated in kg.

Imbalance is indicated in %.

Brake efficiency is indicated in %.

Examine the tyres to ensure they are not under-inflated, if the tyre pattern is in good condition and

if the tyres are free from mud and stones.

Determine whether the vehicle has a single brake control system or a split (dual) brake control

system.

Ensure the roller covers are removed from the RBT.

Ensure the wheels of the vehicle are always placed centrally in the rollers before starting the test.

Understand the quick stop emergency procedures should they be required.

NOTE

All references on the software pages to the ‘F’ keys on the keyboard also relate to the same function keys on

the RF remote control. The following procedures do not relate to the remote control although the functions

of the keyboard and remote control are the same.

Page 26

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

26 / 93

ENGLISH

Vehicle Data Entry

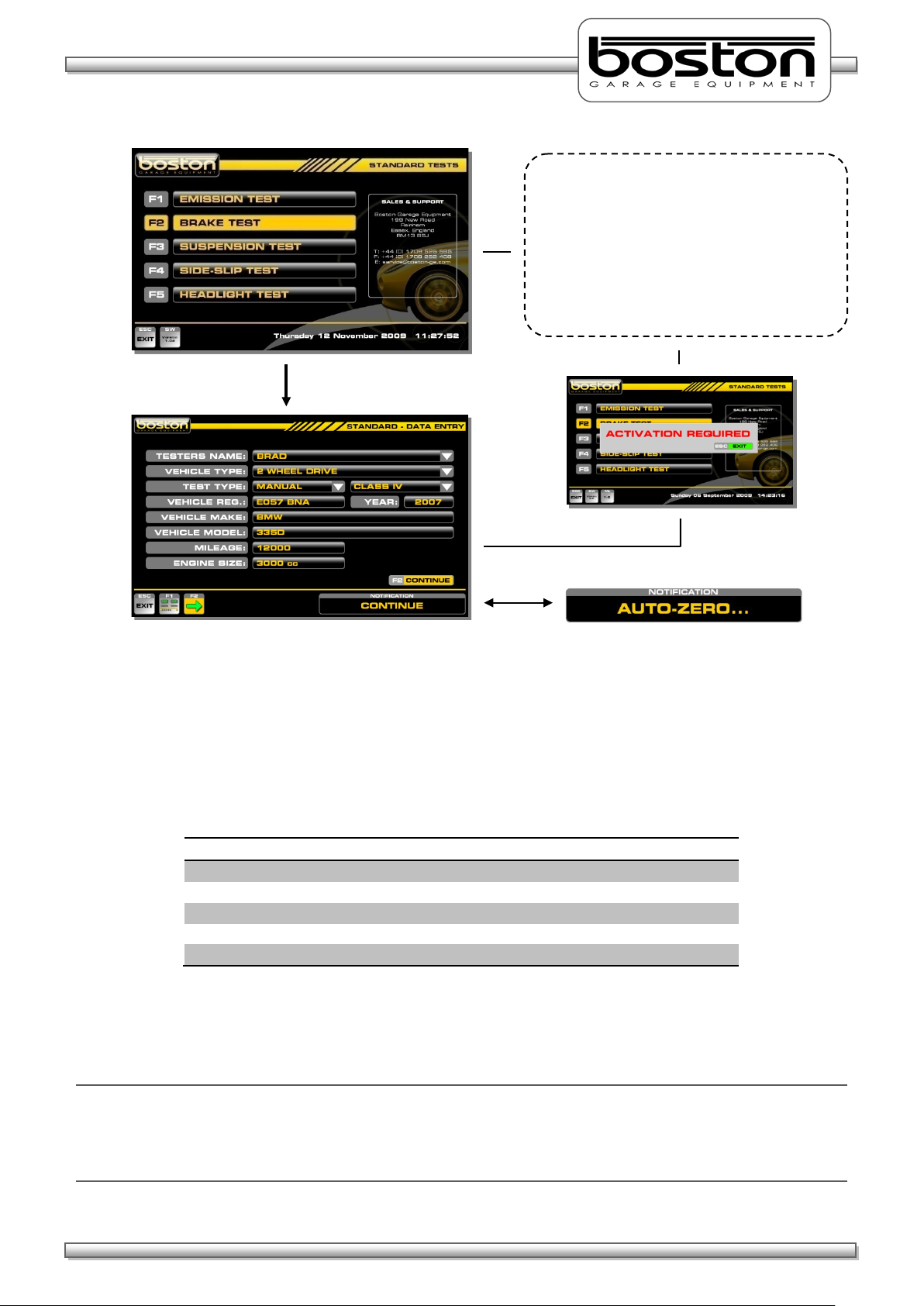

F2 – STANDARD TESTS

The STANDARD BRAKE TEST is usually performed in the following order, but the software is able to

accommodate any other order if preferred by the tester.

1. Service Brake - Front LEFT wheel

2. Service Brake - Front RIGHT wheel

3. Service Brake - Imbalance between both front wheels

4. Service Brake - Rear LEFT wheel

5. Service Brake - Rear RIGHT wheel

6. Service Brake - Imbalance between both rear wheels

7. Parking Brake - Rear LEFT wheel

8. Parking Brake - Rear RIGHT wheel

In some cases, the PARKING BRAKE may act on the front wheels, and it may be necessary to test the

PARKING BRAKE with the front wheels still in the rollers. The list above is just an example of the most

common type of test procedure and is the procedure demonstrated in this manual.

From the MAIN MENU, select option F2 ‘STANDARD TESTS’ and follow the procedure below to reach the

DATA ENTRY page.

Page 27

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

27 / 93

ENGLISH

MANUAL TEST OPTIONS

AUTOMATED TEST OPTIONS

Motorcycle Test

2 Wheel Drive Vehicle Test

2 Wheel Drive Vehicle Test

3 Wheeled Vehicle Test

4 Wheel Drive Test

From this page the user selects the type of

F2 – BRAKE TEST

test required. If the relevant hardware and

software is installed the software will

continue into the respective program, if not,

the message ‘ACTIVATION REQUIRED’ is

shown. Similarly, if no tester’s names have

been set, the message ‘SET TESTERS NAMES’

will be shown.

Whenever the DATA ENTRY page is entered, the message AUTO-ZERO will be shown briefly in the

NOTIFICATION box. Whichever item of equipment has been selected from the test selection menu will be

‘zeroed’ prior to carrying out the test. At this point, it is important that the roller bed is clear and the roller

covers are removed. If not, the software will ‘zero’ the system with an inaccurate measurement.

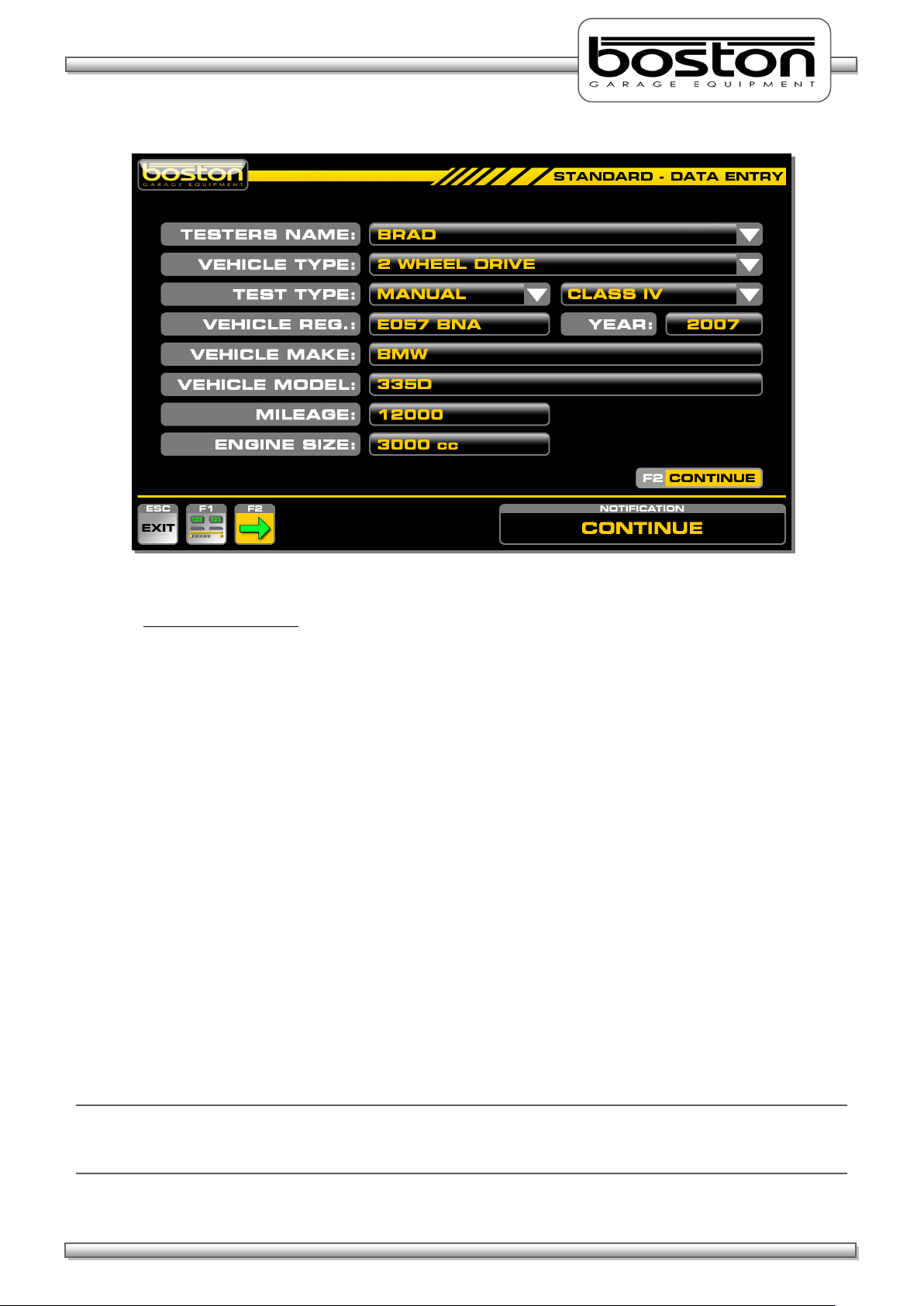

The DATA ENTRY page allows the user to enter specific vehicle data for the vehicle about to be tested. As

the software is able to test different types of vehicles, it is important to ensure that the data is correct

before selecting continue. The available types of test for MANUAL and AUTOMATED are shown below.

Using the mouse and keyboard, enter the relevant information into the DATA ENTRY page. If the operator

does not wish to enter vehicle data, the software will still allow the user to continue, but the missing

information will not be shown on the printout if required.

NOTE

It is not compulsory for the user to enter any vehicle specific data, but the VEHICLE TYPE and TEST TYPE

entry fields must be completed to allow the software to follow the correct route. The default settings for

this page are: 2 WHEEL DRIVE, MANUAL and CLASS IV. The display layout can also be set by selecting F1.

Page 28

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

28 / 93

ENGLISH

Test Selection Criteria

If the user selects MOTORCYCLE from the VEHICLE TYPE pull-down menu, the TEST TYPE will

automatically be set to MANUAL, CLASS 2.

If the user selects 4 WHEEL DRIVE as the vehicle type, the TEST TYPE is automatically set to

MANUAL. The option for AUTOMATED is not available.

If the user selects 3 WHEELED VEHICLE as the vehicle type, the TEST TYPE is automatically set to

MANUAL, CLASS 3 (CLASS 4 can still be selected by the user). The option for AUTOMATED is not

available.

If the RBT is fitted with a vehicle weighing system the WEIGHT box is not shown.

The default settings for the DATA ENTRY PAGE are 2 WHEEL VEHICLE, MANUAL and CLASS IV.

The YEAR field is completed automatically by the software depending on the registration of the

vehicle. Eg. If the registration of the vehicle is EO57 then the year is set to 2007. Although this field

is set initially, it can also be edited by the user in the event that the year cannot be ascertained

from the registration number (vehicles with old or personalised number plates).

The data entry on this page is not compulsory and the user can save time by simply selecting

CONTINUE, however, information not entered will not be shown on the printout if required.

The pull-down menus on this page can be operated using the PC mouse, the TAB / ARROW keys on

the keyboard or the remote control.

NOTE

Some of the options mentioned above may not be available. For example, MOTORCYCLE. This option will

only be shown in the pull down list if the product has been purchased and installed.

Page 29

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

29 / 93

ENGLISH

Display Layout

F1 – CHANGE DISPLAY

From this page the user selects F1 – CHANGE

Using the mouse, keyboard or remote

From the DATA ENTRY page, it is also possible for the user to select the preferred display layout. There are

three test layouts available as shown in the screenshots below.

To select a preferred layout, select F1 from the DATA ENTRY page as below.

NOTE

For the purpose of this manual, the brake test procedures will be described using the analogue needle

layout where applicable.

At any time during testing the user can change the display to a different layout by selecting F5.

DISPLAY. The following page is shown where

the user can select any of three preferred

layouts.

control, select F1, F2 or F3 to choose a layout.

The chosen layout will be shown on the first

measurement screen after the vehicle has

been placed in the rollers.

Page 30

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

30 / 93

ENGLISH

Button

Function

ESC

ESCAPE back to previous page

F1

Start LEFT roller

F2

Start BOTH rollers

F3

Start RIGHT roller

F4

Assign test results to memory

F5

Change display layout

F6

Show results page

At the bottom of the display there are a number of function buttons which are used to control and navigate

the software. The buttons are sometimes different for each page depending on the functions available for

the specific page. For the STANDARD TEST brake test screens, the buttons remain the same irrespective of

the layout chosen by the user. The function of each button is also shown in the NOTIFICATION box when

the user places the mouse over the button.

A layout of the buttons and their respective functions is shown below.

To the right of the function buttons there is a NOTIFICATION BOX. Instructions and messages are shown in

the box for the user to follow. The example below shows the text ROLLER STARTING to alert the user.

Page 31

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

31 / 93

ENGLISH

At this point the software is waiting for the

Both wheels have been placed in the rollers

Placing Vehicle in Rollers

Once the DATA ENTRY page has been completed and the preferred display layout has been selected, select

F2 to continue. The software will now ask the user to PLACE VEHICLE IN ROLLERS, see screenshots below.

Once the rollers have been depressed, the detect indicators turn green and the software enters into the

vehicle testing page. From this point onwards the testing procedures may differ depending on the vehicle

details entered on the DATA ENTRY page.

first axle to be placed in the rollers. The two

grey circles indicated as ‘L’ and ‘R’ will turn

green when the respective detection roller

has been depressed by the wheel.

as shown by the two green indicators. This

page is shown only for a few seconds before

the software moves on to the vehicle testing

page.

Page 32

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

32 / 93

ENGLISH

Vehicle Weight

The total vehicle weight should be entered

From the testing page select F1, F2 or F3 to

start the rollers. The software will

The SW900 control software automatically detects if a weighing system has been fitted to the D412B Roller

Bed. If so, the WEIGHT box on the DATA ENTRY page is not shown. If the system is not fitted with a

weighing facility then the operator should enter the total vehicle weight in the WEIGHT box on the DATA

ENTRY page. Although this is not compulsory, it is required if the user wishes the software to make the

overall brake efficiency calculations.

here if the weighing system is not fitted to

the roller bed.

The software will acquire the axle weight automatically when the user starts either roller for the first time

for each axle. The message ACQUIRING AXLE WEIGHT is shown while the system checks for a stable

weight. The acquired axle weight is shown shortly after. See screenshots below in sequence. Once the

weight has been acquired the software reverts back to the testing page and the selected roller(s) will start.

There is an audible warning and warning text in red to alert the user.

automatically acquire the axle weight.

Page 33

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

33 / 93

ENGLISH

Testing Front Axle

The user selects F1 and the rollers are about

In this example, the left roller has been

After the axle weight has been acquired the operator is warned by on-screen prompts in red and an audible

buzzer that the rollers are about to start. See below.

NOTE

Whenever the rollers are running, the corresponding results box is shown in red. This applies to all screen

layouts.

In order to quickly describe the front axle test, the test procedure below is shown in sequential list format

with simple graphical illustration.

1. Place the front wheels in the rollers as instructed by the software.

2. Select ‘F1 - START LEFT’. The software will first carry out the automatic weighing of the axle, then

an audible alarm will sound and the roller will start. The outer box on the active roller will also

flash red to indicate that the roller is running.

selected. There is an audible buzzer and

three flashes of the red box to alert the user.

The message ‘ROLLER STARTING’ is also

shown in the notification box.

to start

Page 34

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

34 / 93

ENGLISH

Left roller is running and brake force is being

Left roller has stopped due to wheel lock.

corresponding reading. The highest brake

Left roller stopped by the user using the

3. Slowly apply force to the brake pedal and observe the real-time reading increase on the display.

4. Continue to apply brake force until maximum force or wheel-lock is achieved. If wheel- lock occurs

a red indicator will be shown on the display. At the point where the tyre slips on the roller the

motor will be stopped immediately to avoid unnecessary tyre wear.

5. If wheel-lock cannot be reached while maximum brake force is being applied the rollers can be

stopped by pressing the F1 key again (or any other key).

slowly applied.

The wheel-lock indicator is shown above the

force reading achieved is shown in the results

box.

remote control or keyboard. The wheel-lock

indicator is not shown but the highest brake

force reading achieved is shown in the results

box.

Page 35

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

35 / 93

ENGLISH

Even though the RIGHT wheel was tested, the

The rollers have started and brake effort is

and analogue format using two different

Testing for Imbalance

NOTE

Whichever means of stopping the rollers was used, the display will show the highest brake force achieved

in the left hand display. The needle pointer will also indicate the same value on the analogue dial.

6. Now that the result has been obtained for the LEFT wheel, carry out the same procedure for the

RIGHT wheel using the F3 key to start the roller.

result for the LEFT wheel still remains shown

for comparison. The right wheel result is

shown in the corresponding result box.

7. Now that the service brake has been tested for both front wheels, the brake imbalance must be

checked between them. To do this, both rollers are started together and the difference in brake

force between the two wheels is measured as the brake effort is applied. Select F2 – START BOTH.

The screen design changes slightly to show a single analogue scale. Without applying the brakes,

note if any significant brake force (rolling resistance) is recorded from any wheel.

gradually applied. Both readings for LEFT and

RIGHT can be seen together in both digital

colour needle pointers. This gives a good

indication of severe imbalance if present.

Page 36

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

36 / 93

ENGLISH

The rollers have stopped and the LEFT and

Select F7 to assign all the results from the

This test does not require the user to apply maximum brake effort to the pedal. Instead, the user

should aim to stop just short of the maximum value achieved during the individual left and right

wheel brake force measurement and then slowly reduce brake effort to a minimum. The software

will automatically stop the rollers when either reading falls below 35kgf.

NOTE

The software disregards any service brake imbalance when the brake effort from each of the front wheels is

less than 40kgf. The software will show the brake imbalance when brake effort from one wheel is greater

than 40kgf.

After the rollers have stopped, the results of maximum IMBALANCE achieved throughout the test

are shown on the display. The readings shown are those which were used to calculate the

imbalance percentage as shown in the centre result box. Refer to Chapter 5 for permissible limits.

8. Once all tests have been completed for the front axle, the user can save them to be used in the

overall brake efficiency calculation. To do this, select F4 ASSIGN TEST DATA and select where to

save the results. As this is a FRONT AXLE test, select F7 to ASSIGN FRONT AXLE.

RIGHT readings display the values used to

calculate the imbalance result shown in the

centre result box.

FRONT AXLE test to memory.

Page 37

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

37 / 93

ENGLISH

Testing Rear Axle

Select F8 to assign all the results from the

Testing the Parking Brake

Select F9 to assign the results for the PARKING

9. To test the rear axle, drive the vehicle forward and place the rear wheels in the RBT. Repeat steps

1 to 8 above but when assigning the test results, select F8 ASSIGN REAR AXLE to store in the correct

memory location. If the F7 ASSIGN FRONT AXLE is selected, the previous test results will be

overwritten.

NOTE

Once the vehicle axle leaves the RBT for more than 2 seconds, the RBT will re-weigh the axle before starting

the rollers. The software recognises the need to weigh the rear axle as the time period between the front

axle exiting the RBT and the rear axle entering the RBT will always exceed 2 seconds. However, this time

period also allows the RBT to re-test the front axle should it become ejected from the rollers during a test.

As the exit duration is usually less than 2 seconds the RBT will not re-weigh the axle.

REAR AXLE test to memory.

10. The parking brake is tested in the same way as the service brake but instead the user operates

the vehicle’s parking brake (numbers 2 to 6). If the parking brake is located on the front axle then

the user should perform the parking brake test before placing the rear axle in the rollers. The same

applies if testing the rear axle first.

BRAKE to memory.

Page 38

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

38 / 93

ENGLISH

Test Results and Printing

Vehicle Specific

Vehicle Results

Once the full test has been completed and all results are saved in their respective locations, select F6 –

TEST RESULTS. The following results page will be shown.

Data

Table

The results page contains two main sections, vehicle specific information (as entered by the user at the

beginning of the test) and the results table.

The vehicle data is shown at the top of the page. If the RBT is fitted with a vehicle weighing system, the

weight for both the front and rear axles is shown individually. If the user entered the total weight at the

beginning of the test, the ‘AXLE WEIGHT’ line will not be shown.

The test results grid contains all the results as stored by the user during the test. Only if all results were

stored correctly can the software calculate the correct brake efficiencies. In the example above, all data

has been saved and we can see the efficiencies calculated on the right side of the table.

The results shown in red indicate that the wheel locked during the test, so this test shows that all wheels

locked including the parking brake. If we compare the results of this test against the MOT limits, we can

see that the vehicle has passed on SERVICE BRAKE efficiency as the total efficiency of 114% is much higher

than the 50% required. Similarly, the PARKING BRAKE achieved a total brake efficiency of 57%, more than

the minimum 25% required. Finally, as the BRAKE IMBALANCE is below 25% on the front axle, this vehicle

meets the PASS criteria for an official test.*

As this is a MANUAL UNOFFICIAL test, the software does not generate or display a PASS or FAIL result.

However, from this page the user can choose to print the results as many times as required by selecting the

F1-PRINT button. The printout contains all the same information that is shown on this page together with

the testing station information. A sample printout can be seen on the following page.

* - limits specified may change for vehicles of different ages and types

Page 39

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

39 / 93

ENGLISH

The garage logo can be

further information.

This section contains

This section contains

and the tester.

This section contains

This section contains

This section shows

D412+MC1

Sample Printout from a STANDARD TEST

placed here if required. See

the SW900 User Manual for

information about

the test equipment

and when the test

was carried out.

information about

the testing station

information about

the vehicle as

entered by the user

at DATA-ENTRY.

the test results

notes automatically

generated by the

software about the

test.

Page 40

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

40 / 93

ENGLISH

Button

Function

ESC

ESCAPE back to previous page

F1

Print results

F2

Save customer details and test results

F3

Repeat the test on the same vehicle (no data-entry required)

F4

Start a new test

The buttons at the bottom of the display offer the user some other options. A list of the button functions is

shown below.

Page 41

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

41 / 93

ENGLISH

Testing 3 Wheeled Vehicles (3WV)

Only one DETECT roller needs to be

Three wheeled vehicles can only be tested in the MANUAL mode. They are tested in much the same way as

standard four wheeled vehicles but because one axle has a single wheel, the user must choose which roller

is used to test it.

The following procedure should be followed to test three wheeled vehicles.

Complete the DATA ENTRY page as before but select 3 WHEEL VEHICLE as the vehicle type. The TEST TYPE

will be set to MANUAL and the class of test to CLASS III as default. The user can also set the class of test to

CLASS IV should the weight of the unladen vehicle exceed 450kg. Select CONTINUE.

The PLACE VEHICLE IN ROLLERS page is now shown. When testing a standard 4 wheeled vehicle, both

detect rollers must be depressed before the software will continue into the test program, when testing a 3

wheeled vehicle, either roller can be depressed and the software will continue.

Place either axle in the rollers, although usually the front axle contains the single wheel and is tested first.

When the wheel is inserted, the wheel detect indicator turns green.

depressed. The user can select either roller

for testing.

Page 42

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

42 / 93

ENGLISH

The page title at the top right will indicate

Testing Four Wheel Drive Vehicles (4WD)

After testing the single wheel, the user should save the test result to the relevant axle in the same way as

for the standard test.

Drive the vehicle out of the rollers and place the second axle to be tested in the RBT. Now perform the

individual LEFT and RIGHT SERVICE BRAKE tests as described in numbers 2 to 6 above and assign the results

to relevant axle.

Perform the IMBALANCE test on the two-wheeled axle as described in number 7 above.

To view the results select F6 and print as necessary.

Four wheel drive vehicles can only be tested in the MANUAL mode. They are tested in much the same way

as standard four wheeled vehicles but because the wheels of a single axle (or multiple axels) are sometimes

permanently connected together, it is necessary to rotate the opposite wheel under test in the opposite

direction to avoid damage to the transmission.

This means that during the testing of the FRONT LEFT wheel, the RBT will also start the FRONT RIGHT roller

but in the opposite direction.

NOTE

Always refer to the manufacturer’s specifications before testing 4WD vehicles. Some types of 4WD vehicles

cannot be tested on the RBT and as such it is the user’s responsibility for ascertaining the type of

transmission being tested. Always ensure that the correct buttons on the remote control are used.

CAUTION

During the testing of 4WD vehicles, the opposite brake roller will operate in the reverse direction.

3WV test.

For testing the single wheel, the user can

only use the roller that detected the wheel,

the other roller will not operate without a

wheel present.

Page 43

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

43 / 93

ENGLISH

Both wheels have been placed in the rollers

The following procedure should be followed to test 4WD vehicles.

Complete the DATA ENTRY page as before but select 4 WHEEL DRIVE as the vehicle type. The TEST TYPE

will be set to MANUAL. Select F2 CONTINUE.

The PLACE VEHICLE IN ROLLERS page is now shown. Insert the front axle of the vehicle into the RBT. Both

detect rollers must be depressed before the software will continue into the test program.

as shown by the two green indicators. This

page is shown only for a few seconds before

the software moves on to the vehicle testing

page.

Page 44

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

44 / 93

ENGLISH

The page title at the top right will indicate

During the testing of the FRONT LEFT wheel, the text 4x4 is shown in the right side results box. The right

side roller is also operating but in the reverse direction.

During the testing of the FRONT RIGHT wheel, the text 4x4 is shown in the left side results box. The left

side roller is also operating but in the reverse direction. In this display layout, the analogue needle pointer

is removed from the inactive measurement display.

After the LEFT and RIGHT wheels have been tested individually, the IMBALANCE test can be carried out in

the normal way.

Once the IMBALANCE test is complete and all data has been saved, drive the vehicle forward and place the

REAR wheels in the rollers.

Repeat the procedure for the SERVICE BRAKE REAR and the PARKING BRAKE, and save the data to the

relevant axle using F4 on the keyboard or remote control.

4WD test.

The text 4x4 is shown in the opposite display

when testing 4WD vehicles. The active roller

under test shows the live data.

Page 45

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

45 / 93

ENGLISH

Testing Motorcycles

Unlike most Class 4 RBT’s, the D412 is able and approved to test motorcycles (provided the motorcycle

software has been installed). This is a very useful and cost effective solution as separate roller beds for

motorcycles can be expensive. The testing procedure is similar to the standard vehicle test although only

one roller is used.

CAUTION

Motorcycle testing can only be carried out when the MC1 cover plate adapter has been fitted. The plate

limits the width of the open roller surface to accommodate the narrow wheels of motorcycles. It is

dangerous and prohibited to test motorcycles without the MC1 cover plate fitted.

For official testing, there are DVSA regulations where testing bays have specific dimensional requirements.

It is important that these are adhered to if the user intends to carry out official motorcycle testing using the

D412. This section covers STANDARD TESTS only; official testing is covered later on in the manual.

To perform a motorcycle test, ensure the MC1 cover plate is securely fitted (refer to Chapter 3 - MC1

Motorcycle Testing Cover Plate) and follow the procedures below.

Testing Motorcycles with Single Brake Control Systems

Complete the DATA ENTRY page as before but select MOTORCYCLE as the vehicle type. The TEST TYPE will

be set to MANUAL and the class of test to CLASS II. Select CONTINUE.

The PLACE VEHICLE IN ROLLERS page is now shown. When testing a standard 4 wheeled vehicle, both

detect rollers must be depressed before the software will continue into the test program, when testing a

motorcycle, either roller can be depressed and the software will continue.

Place either wheel in the rollers, although usually the front wheel is tested first. When the wheel is

inserted, the wheel detect indicator turns green. Make sure that the motorcycle is positioned in a straight

line and that it is not in gear. The rider should sit on the motorcycle as in a normal situation.

Page 46

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

46 / 93

ENGLISH

Only one DETECT roller needs to be

In this example we have used the LEFT roller

F5

At this point, whichever roller has been depressed by the user to carry out the test is the roller that should

be used for testing the whole motorcycle. The software will disable the opposite roller until a new DATA-

ENTRY page is completed and the user chooses a roller for the first time.

depressed. The user can select either roller

for testing but once selected this roller must

be used for the duration of the test.

for testing the motorcycle..

The motorcycle layout displays are a little different from the standard layouts. This is because there are no

LEFT and RIGHT readings as motorcycles only have FRONT and REAR readings (and sidecar if fitted). This

display shows a single scale to display the force from a single brake system, the weight obtained from the

wheel being tested and the efficiency result at the end of the test.

The motorcycle procedure can also be carried out using the horizontal bar display layout (as above). The

user can choose to ‘toggle’ between the two layouts by selecting F5.

Page 47

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

47 / 93

ENGLISH

Button

Function

ESC

ESCAPE back to previous page

F1

ASSIGN result to BRAKE CONTROL 1

F2

START ROLLER

F3

ASSIGN result to BRAKE CONTROL 1

F4

ASSIGN measured weight to SIDECAR

F5

Change display layout

F6

Show results page

At the bottom of the display there are a number of function buttons which are used to control and navigate

the test procedure. The buttons are sometimes different for each page depending on the functions

available for the specific page. For the STANDARD TEST motorcycle brake test screens, the buttons remain

the same irrespective of the layout chosen by the user. A layout of the buttons and their respective

functions is shown below.

To the right of the function buttons there is a NOTIFICATION BOX. Instructions and messages are shown in

the box for the user to follow. The example below shows the text ROLLER STARTING to alert the user.

Page 48

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

48 / 93

ENGLISH

From the testing page select F2 START ROLLER

F2 – START ROLLER

The user must remain steady on the

The measured weight is shown for

Testing the Front Wheel

Once the front wheel is in the rollers the following page is shown.

to start the roller. The software will

automatically acquire the axle weight.

motorcycle to ensure an accurate weight

measurement.

approximately 3 seconds before the display

returns back to the testing page.

As before, the user is alerted to the rollers starting by means of the audible buzzer and the flashing red

indicators on the display. When the roller starts, carefully position the wheel in the centre of the roller

before applying the brake. This is important with larger / heavier motorcycles as they can be difficult to

handle.

Page 49

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

49 / 93

ENGLISH

The efficiency will be calculated after the

brake force measurement has been

ASSIGN front wheel brake force measurement

With the roller running, slowly apply brake force to the first brake control (BC1) until the wheel locks or

maximum force is achieved. If the roller cannot be locked then stop the roller by pressing any key on the

remote control or keyboard. The highest brake force reading achieved will be displayed.

completed.

Once the brake force reading has been taken, the user must assign the result to memory. Select F1 or F3

depending on which brake control was used. For this example we will assume this test is the FRONT wheel

using the HAND brake control BC1.

Select F1 (BC1) and assign the reading to the FRONT by selecting F7.

from brake control 1 to the FRONT.

Page 50

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

50 / 93

ENGLISH

Brake force fluctuations (Ovality)

After the brake force measurement has been assigned, the operator can test the front wheel for brake

force fluctuations. Follow the procedure below:

Select F2 to re-start the roller (if the wheel has been removed from the roller for more than 2

seconds then weight measurement will be re-taken, but the weight value is not required for this

test).

With the roller running, slowly increase the brake force and hold it steady at a constant value of

approximately half the maximum value measured in the first test. Visually check for brake force

fluctuations on that wheel. Fluctuations are easier to see on the analogue graphical display.

The user should note and interpret any irregularities in the brake force behaviour.

Release the brake quickly and observe the way in which the braking effort reduces.

Press any key to stop the rollers

Page 51

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

51 / 93

ENGLISH

F3 – Brake Control 2

ASSIGN rear wheel brake force measurement

Testing the Rear Wheel

Drive the motorcycle forward and place the REAR wheel in the RBT. Be careful to align the wheel in the

centre of the roller.

Select F2 to start the roller. The software will take a new axle weight measurement and display the

reading. After the weight measurement, the software will show exactly the same testing page as before.

As before, the user is alerted to the rollers starting by means of the audible buzzer and the flashing red

indicators on the display. When the roller starts, carefully position the wheel in the centre of the roller

before applying the brake.

The rear wheel is usually controlled by the FOOT brake (brake control 2). Slowly apply brake force until the

wheel locks or maximum force is achieved. If the roller cannot be locked then stop the roller by pressing

any key on the remote control or keyboard. The highest brake force reading achieved will be displayed.

Once the brake force reading has been taken, the user must assign the result to memory. Select F3 (BC2)

and assign the reading to the REAR by selecting F11.

from brake control 2 to the REAR.

After the brake force measurement has been assigned for the rear wheel, the operator should again test

the rear wheel for brake force fluctuations. Follow the same Brake Force Fluctuations procedure as was

done for the front wheel.

Page 52

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

52 / 93

ENGLISH

Assign REAR wheel result to BC1 when FIRST

Assign FRONT wheel result to BC2 when

Testing Motorcycles with Linked (Dual) Brake Control Systems

If the first brake control system (BC1 – Hand Brake) also operates on the rear wheel, then the user should

select F1 (BC1) and then F8 ASSIGN REAR to assign the result from the REAR wheel to brake control 1. The

software now has two results (front and rear) for the first brake control system.

Similarly, if the second brake control system (BC2 – Foot Brake) also operates on the front wheel, then the

user should select F3 (BC2) and then F10 ASSIGN FRONT to assign the result from the FRONT wheel to

brake control 2. The software now has two results (front and rear) for the second brake control system.

brake control operates on the REAR wheel.

SECOND brake control operates on the FRONT

wheel.

NOTE

Every time the user stores a new result in BC1 or BC2, the software will overwrite the previously stored

result.

Page 53

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

53 / 93

ENGLISH

Place sidecar on the bed and wait for the

F4 – Side-Car Weight

Testing Sidecars

If the motorcycle is fitted with a sidecar, both the weight and any brake force produced by one of the two

brake control systems needs to be measured.

To enter the weight of the sidecar, follow the procedure below:

After completing the brake tests for the front and rear wheels, select F4 SIDE-CAR WEIGHT and

place the sidecar on the roller bed.

weight reading to become stable. Press

ENTER to assign the weight.

Note: If the RBT is not fitted with an

automatic weighing system, the operator

should enter the weight value manually and

press ENTER.

Page 54

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

54 / 93

ENGLISH

F2 – NO

After the sidecar weight has been acquired, the operator can choose to test the sidecar brake (if fitted and

controlled by either BC1 or BC2).

To test the brake on the sidecar, follow the procedure below:

Select F1 – YES from the WEIGHT COMPLETED screen (shown above).

Place the wheel of the sidecar in the roller. Ensure the wheel is positioned centrally in a straight

line and that the motorcycle is not in gear.

Press ENTER to start the test.

Page 55

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

55 / 93

ENGLISH

Slowly operate the brake on the sidecar (by using BC1 / BC2) until the wheel locks or maximum

force is achieved. If the roller cannot be locked then stop the roller by pressing any key on the

remote control or keyboard. The highest brake force reading achieved will be displayed.

Select F1 or F3 to assign the sidecar force measurement to either BC1 or BC2.

After the measurements have been assigned select F6 to view the results. Provided all results have

been correctly saved, the software will determine the overall efficiency for each brake control

system.

If the sidecar is not controlled by either of the two brake controls or is operated by an independent control,

only the weight of the sidecar is relevant in the overall calculations of the brake test. The weight must be

taken and entered into the system.

NOTE

During the weight measurement of the sidecar, it is important that no other part of the motorcycle is on the

roller bed, this will provide an inaccurate weight reading and the test results may not be valid.

Page 56

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

56 / 93

ENGLISH

Test Results

The screenshot below shows the results from a standard motorcycle test. The layout is exactly the same as

for the other types of vehicle tests and with the same button functions available at the bottom of the

display.

The screenshot below shows the same results page as above but with the added weight of the sidecar.

With the added weight, we can see how the efficiencies have changed.

Page 57

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

57 / 93

ENGLISH

D412+MC1

Motorcycle Sample Printout

Page 58

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

58 / 93

ENGLISH

Automated Brake Test

Complete the DATA ENTRY page as before

The next page asks the user to confirm the

NOTE: The latest DVSA procedure can be found

inside ANNEX A – Document title BOS0483

The automated brake test is only available for standard 2 wheel drive vehicles. If the user selects any other

type of vehicle from the DATA ENTRY page, the software will only allow for a manual test.

The automated program carries out the test in a different way to the standard test. For each part of the

automated test, both rollers are started together and the brake force measurement is taken at the same

time for both wheels on the axle. After each test, the software automatically saves the results and there is

no need for any user control.

The automatic test only requires that the user complete the DATA ENTRY page at the beginning of the test

and the rest of the procedure is completely automated up until the BIND, GRAB and JUDDER page.

The automated test is carried out in the following order.

1. First Axle Service Brake - LEFT and RIGHT

2. First Axle Service Brake - Imbalance between both rear wheels

3. Parking Brake (if front axle) - LEFT and RIGHT

4. Parking Brake (if rear axle) - LEFT and RIGHT

5. Second Axle Service Brake - LEFT and RIGHT

6. Second Axle Service Brake - Imbalance between both rear wheels

In some cases, the PARKING BRAKE may act on the front wheels and it may be necessary to test the

PARKING BRAKE with the front wheels still in the rollers. If the parking brake is connected to the FRONT

axle then this must be selected by the user on the pop-up window shown after completing the DATA ENTRY

page.

The AUTOMATED software procedure is shown below:

but select TEST TYPE: AUTOMATED. Select

CONTINUE.

location of the PARKING BRAKE. This is

usually fitted to the REAR axle and the

software defaults to REAR. However, if it is

fitted to the FRONT axle then select it

here. The AUTOMATED procedure is

different for each option.

Page 59

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

59 / 93

ENGLISH

The wheels have been detected and this

The software is waiting for the user to

The axle is weighed automatically. This

After completing the DATA ENTRY page select F2 to continue. From this point onwards the procedure is

automatic and the user must follow the on-screen instructions. See below.

insert the front wheels in the rollers. The

green detect indicators will light when the

corresponding wheel is detected.

page is shown for approximately 2 seconds,

page is shown for approximately 4 seconds.

The axle weight is then shown.

Page 60

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

60 / 93

ENGLISH

The message CENTRALISE WHEELS IN

The rollers will start automatically and the

operator is prompted to centralise the

wheels in the rollers. This message is

shown for 2 seconds.

For safety reasons, whenever the rollers

are running, the large outer boxes of the

digital readings are shown in red.

ROLLERS is shown for 2 seconds, the

operator is then prompted to slowly apply

the service brake to maximum.

Page 61

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

61 / 93

ENGLISH

If wheel lock is achieved, the LEFT and

After the SERVICE BRAKE test, the software

The software now checks for IMBALANCE.

automatically restarts the rollers.

Once the force has reached 75% of the

RIGHT indicators will show. If wheel lock

cannot be achieved, the software will

automatically stop the rollers when stable

readings have been measured for 3

seconds.

will re-start the rollers. The user is asked

to CHECK FOR BRAKE BINDING. This

message is shown for two seconds. There

is no software measurement for brake

binding and the user must make a note if

present.

The user must SLOWLY APPLY THE

SERVICE BRAKE until the force from either

wheel reaches 75% of the maximum force

achieved in the previous SERVICE BRAKE

test. The red needle indicates this value

and when reached, an audible bleep is

sounded by the software. If wheel lock is

achieved during this test the software

previous maximum, the message SLOWLY

REDUCE SERVICE BRAKE is shown. The

user must reduce brake effort and the

software will automatically turn off the

rollers when the brake force falls below

40kgf.

Page 62

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

62 / 93

ENGLISH

After the rollers have stopped, the

The user must now place the REAR wheels

The wheels have been detected and this

The axle is weighed automatically. This

IMBALANCE result is shown for a few

seconds before the software moves on to

test the rear wheels.

in the rollers.

If PARKING BRAKE: FRONT was selected

on the DATA ENTRY page, the software

will carry out the parking brake test

BEFORE moving to the rear wheels test.

page is shown for approximately 2 seconds.

page is shown for approximately 4 seconds.

The axle weight is then shown.

Page 63

DOC: BOS0481

D412 / D412+MC1 USE R MA NUA L

63 / 93

ENGLISH

The rollers will start automatically and the

After centralising the wheels, the operator

If wheel lock is achieved, the LEFT and

SLOWLY APPLY PARKING BRAKE