Page 1

MFN-200

MANUAL FLOORING NAILER

CLAVADORA MANUAL PARA PISOS

CLOUEUSE MANUELLE À PLANCHER

OPERATION AND MAINTENANCE MANUAL

MANUAL DE OPERACIÓN Y DE MANTENIMIENTO

MANUEL D’INSTRUCTIONS ET D’ENTRETIEN

BEFORE OPERATING THIS TOOL, ALL OPERATORS SHOULD STUDY THIS MANUAL TO

UNDERSTAND AND FOLLOW THE SAFETY WARNINGS AND INSTRUCTIONS. KEEP THESE

INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE. IF YOU HAVE ANY QUESTIONS,

CONTACT YOUR BOSTITCH REPRESENTATIVE OR DISTRIBUTOR.

ANTES DE OPERAR ESTA HERRAMIENTA,TODOS LOS OPERADORES DEBERÁN ESTUDIAR

ESTE MANUAL PARA PODER COMPRENDER Y SEGUIR LAS ADVERTENCIAS SOBRE

SEGURIDAD Y LAS INSTRUCCIONES. MANTENGA ESTAS INSTRUCCIONES CON LA

HERRAMIENT

SU REPRESENTANTE DE BOSTITCH O CON SU DISTRIBUIDOR.

LIRE ATTENTIVEMENT LE PRÉSENT MANUEL AVANT D’UTILISER L’APPAREIL. PRÉTER UNE

ATTENTION TOUTE PARTICULIÈRE AUX CONSIGNES DE SÉCURITÉ ET AUX

AVERTISSEMENTS. GARDER CE MANUEL AVEC L’OUTIL POUR FUTUR RÉFÉRENCE. SI VOUS

AVEZ DES QUESTIONS, CONTACTEZ VOTRE REPRÉSENTANT OU VOTRE

CONCESSIONNAIRE BOSTITCH.

175616REVB 04/07

A PARA FUTURA REFERENCIA, SI TIENE ALGUNA DUDA, COMUNÍQUESE CON

ST

ANLEY FASTENING SYSTEMS L.P.

Page 2

INTRODUCTION

BOSTITCH tools are precision-built tools, designed for precise, high volume nailing. These tools will deliver efficient,

dependable service when used correctly and with care. As with any fine tool, for best performance the manufacturer’s

nstructions must be followed.Please study this manual before operating the tool and understand the safety warnings

i

nd cautions. The instructions on installation, operation and maintenance should be read carefully, and the manual

a

kept for reference. NOTE: Additional safety measures may be required because of your particular application of the

tool. Contact your BOSTITCH representative or distributor with any questions concerning the tool and its use.

BOSTITCH, East Greenwich, Rhode Island 02818.

INDEX

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ool Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

T

oading the Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

L

Tool Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Fastener Depth & Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Other BOSTITCH Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

NOTE:

BOSTITCH tools have been engineered to provide excellent customer satisfaction and are

designed to achieve maximum performance when used with precision BOSTITCH fasteners

engineered to the same exacting standards.

product performance if our tools are used with fasteners or accessories not meeting the

specific requirements established for genuine BOSTITCH nails, staples and accessories.

BOSTITCH cannot assume responsibility for

7-YEAR LIMITED WARRANTY — U.S. and Canada Only

Effective December 1, 2005 Bostitch, L.P. warrants to the original retail purchaser that the product purchased is free

from defects in material and workmanship, and agrees to repair or replace, at Bostitch’s option, any defective Bostitch

branded pneumatic stapler or nailer for a period of seven (7) years from date of purchase (one (1) year from the date

of purchase for compressors and tools used in production applications). Warranty is not transferable. Proof of

purchase date required. This warranty covers only damage resulting from defects in material or workmanship;it does

not cover conditions or malfunctions resulting from normal wear, neglect, abuse, accident or repairs attempted or

made by other than our national repair center or authorized warranty service centers. Driver blades, bumpers, o-rings,

pistons and piston rings are considered normally wearing parts. For optimal performance of your Bostitch tool always

use genuine Bostitch fasteners and replacement parts.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. BOSTITCH SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states and countries do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation

of incidental or consequential damages, so the above limitations or exclusions may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state and country to

country.

To obtain warranty service in the U.S. return the product, together with proof of purchase, to the U.S.Bostitch National

or Regional Independent Authorized Warranty Service Center. In the U.S. you may call us at 1-800-556-6696 or visit

www.BOSTITCH.com for the location most convenient for you. In Canada please call us at 1-800-567-7705 or visit

www.BOSTITCH.com.

2

Page 3

SAFETY INSTRUCTIONS

E

YE PROTECTION which conforms to ANSI specifications and provides protection against

flying particles both from the FRONT and SIDE should ALWAYS be worn by the operator and

others in the work area when loading, operating or servicing this tool. Eye protection is

required to guard against flying fasteners and debris, which could cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards Institute,

A

NSI Z87.1 and provide both frontal and side protection. NOTE: Non-side shielded

spectacles and face shields alone do not provide adequate protection.

CAUTION: Additional Safety Protection will be required in some environments.For example,

the working area may include exposure to noise level which can lead to hearing damage.

The employer and user must ensure that any necessary hearing protection is provided and

used by the operator and others in the work area. Some environments will require the use

o

f head protection equipment.When required, the employer and user must ensure that head

protection conforming to ANSI Z89.1 is used.

N

EVER USE MALLET WITH A LOOSE HEAD OR SPLINTERED HANDLE.

C

U

A

TION:Replace worn or damaged parts immediately.

UTION: To avoid accidental injury, to yourself and others, bystanders must maintain a

CA

CA

CA

CA

safe distance from you, during use of this tool especially when swinging the

mallet

UTION: The operator should always wear safety shoes.

UTION: Use only cleats from Bostitch.

UTION: Never hit the plunger with the metal face of the mallet.

LOADING TOOL

When loading tool: 1.) Never place a hand or any part of body in fastener discharge area of

tool; 2.) Never point the tool at anyone.

OPERATION

Always handle the tool with care: 1.) Never engage in horseplay; 2.) Never actuate the tool

unless fastener discharge area of tool is directed toward the work; 3.) Keep others a safe

distance from the tool while tool is in operation as accidental actuation may occur, possibly

causing injury.

Keep hands and body away from the discharge area of the tool.

Do not drive fasteners on top of other fasteners or with the tool at an overly steep angle as

y cause deflection of fasteners which could cause injury.

this ma

Do not drive fasteners close to the edge of the work piece as the wood may split, allowing

the fastener to be deflected possib

This tool produces SPARKS during operation. NEVER use the tool near flammable

substances, gases or vapors inc

glues or any other material that is - or the vapors, fumes or by-products of which

mastics,

are -- flammable, combustible or explosive. Using the tool in any such environment could

cause an EXPLOSION resulting in personal injury or death to user and bystanders.

ly causing injury.

luding lacquer, paint, benzine, thinner, gasoline, adhesives,

MAINTAINING THE TOOL

When working on tools note the warnings in this manual and use e

evaluating problem tools.

3

xtra care when

Page 4

MFN-200 TOOL SPECIFICATIONS

ll dimensions in inches unless otherwise specified

A

MMFFNN--22000

Description Manual Flooring Nailer

Fastener Type “L”Type 16 Gauge Flooring Cleats

Magazine Capacity 150 cleats

Length 13-1/2” (342.9mm)

Width 3-1/2” (89mm)

H

eight 17-1/2” (444.5mm)

W

eight 9.71 lbs (4.40kg)

0

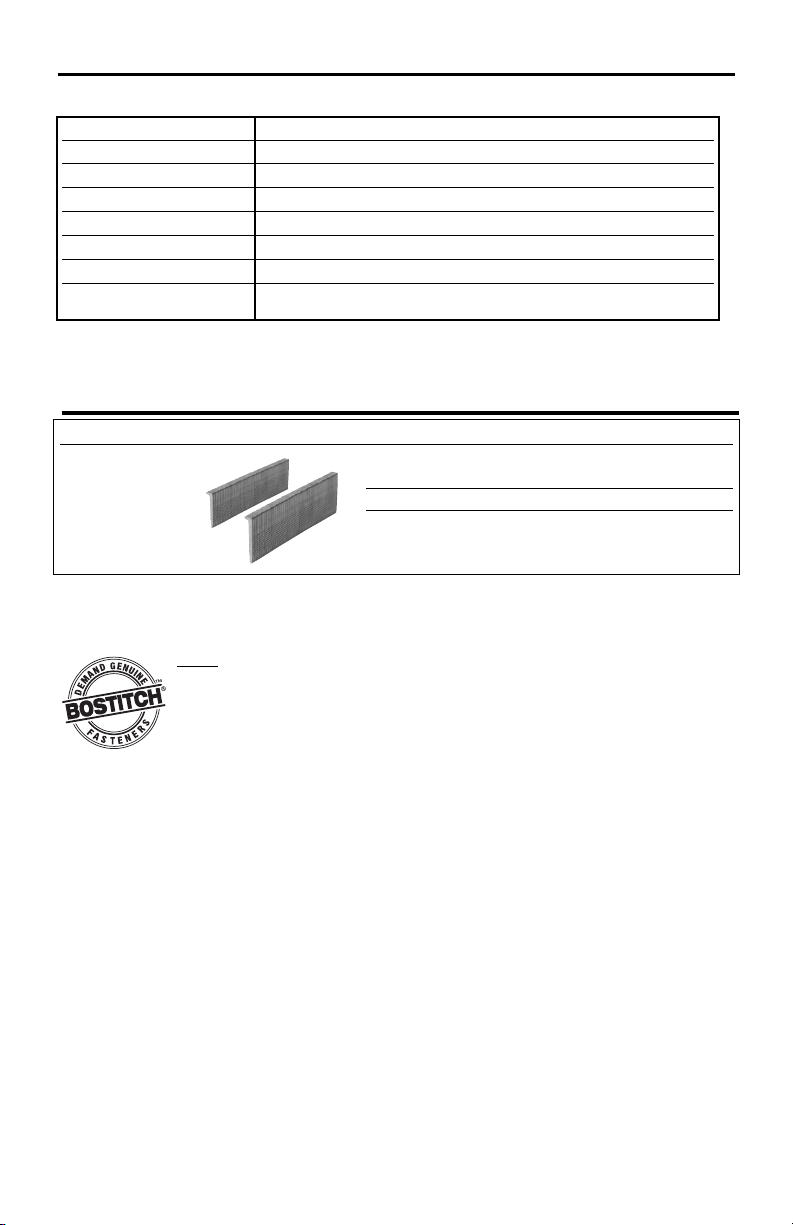

MFN-200 FASTENER SPECIFICATIONS

Tool Model Fastener Type Fastener SKU Gauge Length

MFN-200 Manual FLN-150 16 1-1/2”

Flooring Nailer FLN-200 16 2”

NOTE:

BOSTITCH tools have been engineered to provide superior customer satisfaction and are

designed to achieve maximum performance when used with precision BOSTITCH fasteners

engineered to the same exacting standards. BOSTITCH cannot assume responsibility for

product performance if our tools are used with fasteners or accessories not meeting the

specific requirements established for genuine BOSTITCH fasteners and accessories.

4

Page 5

LOADING THE MFN-200

EYE PROTECTION which conforms to ANSI specifications and provides protection against

flying particles both from the FRONT and SIDE should ALWAYS be worn by the operator

and others in the work area when loading, operating or servicing this tool. Eye protection

is required to guard against flying fasteners and debris, which could cause severe eye

injury.

T

he employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards Institute,

ANSI Z87.1 and provide both frontal and side protection.NOTE: Non-side shielded spectacles

and face shields alone do not provide adequate protection.

TO PREVENT ACCIDENTAL INJURIES:

Never place a hand or any other part of the body in nail discharge area of tool.

•

• Never point the tool at anyone else.

• Never engage in horseplay.

Always handle the tool with care.

•

Do not contact the actuator while loading the tool.

•

LOADING THE TOOL

1. Release the pusher spring clip and remove the pusher blade.

2. Load the fasteners into guide channel.

3. Insert rounded end of pusher blade into channel to retain fasteners.

4. Latch pusher spring clip to notched end of pusher blade. Ensure sufficient engagement of pusher blade for

smooth fastener feeding.

1.

3.

Fastener may not feed consistently if pusher blade is not installed.

BEFORE HANDLING OR OPERATING THIS TOOL READ AND UNDERSTAND THE WARNINGS

CONTAINED IN THIS MANUAL.

2.

4..

5

Page 6

OPERATION

EYE PROTECTION which conforms to ANSI specifications and provides protection against

flying particles both from the FRONT and SIDE should ALWAYS be worn by the operator

and others in the work area when loading, operating or servicing this tool. Eye protection

is required to guard against flying fasteners and debris, which could cause severe eye

injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards Institute,

ANSI Z87.1 and provide both frontal and side protection.NOTE: Non-side shielded spectacles

and face shields alone do not provide adequate protection.

The MFN-200 was designed to install 3/4” tongue and groove hardwood flooring.

NOTE: Always test on a scrap piece of flooring.

TION: NEVER HIT THE PLUNGER WITH THE METAL END OF THE MALLET.

CAU

1. Position the flooring per the manufacture’s specifications.

2. Place the tool with the guide plate above the tongue and firmly against the forward face of the flooring material.

3. Ensure that the composite foot is firmly held against the top surface of the flooring.

4. Using the rubber face of the mallet strike the top end of the metal plunger.

2.

NOTE: Sufficient force is required to completely drive a single fastener with one strike of the mallet.

REGARDING THE USE OF THIS TOOL TO INSTALL PRE-FINISHED FLOORING

NOTE:

The BOSTITCH MFN-200 has been precisely engineered to be compatible with today’s vast array of hardwood

flooring products, including pre-finished flooring. Due to the ever changing products and manufacturing

processes used in producing pre-finished hardwood flooring, caution must be used to ensure that the flooring

finish is not damaged by the tool. Always test the tool and installation technique on a sample section of flooring

to be certain that both the tool and the installation technique do not damage the pre-finished flooring. This

procedure should be followed before each job due to variations in flooring and tool condition.

cannot assume responsibility for any flooring damage.

4.

BOSTITCH

6

Page 7

FASTENER DEPTH

NDER DRIVEN FASTENER

U

ROPERLY DRIVEN FASTENER

P

Floor

If the plunger does not fully return the nail has not been completely driven. When this happens, use the

ubber face of the mallet to strike the top end of the metal plunger again. When the nail is completely driven

r

the ratcheting mechanism will allow the plunger to return.

Fastener

Sub Floor

MAINTENANCE

Tool

As with any quality tool regular maintenance will improve its operation and life span. BOSTITCH

replacement parts are recommended. Do not use modified parts or parts which will not give equivalent

performance to the original equipment.

1. To inspect of replace any parts of the plunger, first remove the retaining clip and pull out the locking pin.

2. Pull out the plunger assembly.

3. Clean old grease, dirt and abrasive particles off of all parts.

4. Lightly grease the plunger and the plunger spring.

5. Replace all damaged or worn parts.

CAUTION: WHEN REPLACING THE DRIVER BLADE, ENSURE THAT THE WORD “FRONT” STAMPED

ON THE BLADE IS VISIBLE AFTER YOU HAVE INSTALLED IT ON THE PLUNGER.

Mallet

Over time the rubber face on the mallet may became worn, cracked, or chipped. These are signs that a new

rubber face will need to be installed.

Remove old rubber face:

1. Secure the rubber face in a bench vise.

2. Pull upward on the handle till the rubber face is released from the

steel stud.

To install a new rubber face on the mallet, we recommend doing it in

the shop with the use of an arbor press. If you must do it manually

follow these instructions.

1. Secure the mallet head in a bench vise.

2. Put the rubber cap slightly inclined on top of the steel stud, push

downward with a twisting motion to engage the rubber cavity

over the edge of the steel stud.

3. Once fully engaged over the edge, you can release the mallet

from the vise and hit it on solid surface to properly seat the rubber

face on the mallet head.

7

Page 8

BOSTITCH FLOORING PRODUCTS

MIIIFS/MIIIFN

Pneumatic Flooring Tools

SX150-BHF-2

18 Gauge

Hardwood Flooring Stapler

LHF97125

20 Gauge

Hardwood Flooring Stapler

MIIIFN-KIT

MIIIFS Cleat Nailer

Conversion Kit

MIIIFOOT-KIT

MIIIFS/MIIIFN Pre-Finished

Flooring Adapter Foot Kit

For more information log on to:

www.BOSTITCH.com

N62FNK-2

15 Gauge

Oil-Free Finish Nailer Kit

8

Page 9

INTRODUCCIÓN

Las herramientas BOSTITCH son herramientas construidas a precisión, diseñadas para clavar con exactitud un alto

volumen de clavos. Estas herramientas entregan un servicio eficiente y fiable cuando se usan correctamente y con

uidado. Al igual que con toda herramienta de calidad, deben seguirse las instrucciones del fabricante para obtener

c

l óptimo rendimiento. Estudie este manual antes de operar la herramienta y tome nota de las advertencias y

e

precauciones de seguridad. Deben leerse en detalle las instrucciones sobre la instalación, operación y mantenimiento,

y debe conservarse el manual para referencia. NOTA: Pueden necesitarse medidas adicionales de seguridad según

la aplicación particular de la herramienta. Diríjase al representante o distribuidor de BOSTITCH si tiene alguna

regunta referente a la herramienta y su uso.BOSTITCH, East Greenwich, Rhode Island 02818.

p

ÍNDUCE

I

nstrucciones de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Especificaciones de la herramienta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Carga de la herramienta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

F

uncionamiento de la herramienta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

L

a profundidad de la fijación & mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

O

tros productos BOSTITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

NOTA

Las herramientas BOSTITCH se han diseñado para brindar una satisfacción excelente al cliente y lograr máximo

rendimiento al utilizarse con fijaciones de precisión Bostitch diseñadas con las mismas normas estrictas.

BOSTITCH no puede asumir responsabilidad alguna por el rendimiento del producto si se utilizan

nuestras herramientas con fijaciones o accesorios que no reúnen los requisitos específicos establecidos

para los clavos, grapas y accesorios genuinos de BOSTITCH.

GARANTÍA LIMITADA DE 7 AÑOS — Sólo EE.UU. y Canadá

A partir del 1 de diciembre de 2005 Bostitch, L.P. garantiza al comprador del comerciante original que el producto

comprado está exento de defectos en material y fabricación, y se compromete a reparar o reemplazar, a opción de

Bostitch, cualquier engrapadora o clavadora neumática defectuosa de marca Bostitch por un período de siete (7) años

desde la fecha de compra (un (1) año de la fecha de compra en el caso de compresores y herramientas utilizadas en

aplicaciones de producción). La garantía no es transferible. Se requiere presentar evidencia de la fecha de compra.

Esta garantía solamente cubre daños resultantes de defectos en material o fabricación, y no cubre condiciones o

desperfectos resultantes del desgaste normal, negligencia, abuso, accidente o reparaciones intentadas o efectuadas

por terceros ajenos a nuestro centro nacional de reparaciones o a los centros de servicio bajo garantía. Las aspas del

impulsor, topes, juntas tóricas, pistones y aros de pistones se consideran componentes de desgaste normal. Para

obtener el rendimiento óptimo de la herramienta Bostitch siempre use fijaciones y piezas de repuesto genuinas de

Bostitch.

ESTA GARANTÍA SUSTITUYE TODA OTRA GARANTÍA, EXPRESA O IMPLÍCITA, INCLUIDAS ENTRE OTRAS,

LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD O IDONEIDAD PARA UN FIN PARTICULAR. BOSTITCH

NO SERÁ RESPONSABLE DE DAÑOS FORTUITOS O CONSECUENCIALES.

Algunos estados y países no permiten limitaciones a la duración de una garantía implícita ni la exclusión o limitación

de daños fortuitos o consecuenciales, de modo que las limitaciones o exclusiones anteriores pueden no corresponder

a su caso. Esta garantía le concede derechos legales específicos, y usted puede tener también otros derechos que

ían de un estado a otro y de un país a otro.

var

Para obtener servicio bajo garantía en los EE.UU. devuelva el producto, junto con el comprobante de compra, al

Centro de Servicio bajo Garantía Autorizado Independiente Nacional o Regional de Bostitch en los EE.UU. Dentro de

los EE.UU. usted puede llamarnos al 1-800-556-6696 o visitar www.BOSTITCH.com para ver la ubicación que más

le convenga. En Canadá llámenos al at 1-800-567-7705 o visite www.BOSTITCH.com.

9

Page 10

INSTRUCCIONES DE SEGURIDAD

Al cargar, operar o dar servicio a esta herramienta, el operador y los demás presentes en el

á

rea de trabajo deben usar SIEMPRE PROTECCIÓN DE LOS OJOS en conformidad con las

especificaciones ANSI y que proteja contra partículas que vuelen por DELANTE y por el

LADO. Se exige protegerse la vista para resguardarse contra fijaciones o residuos que

vuelen, lo cual puede causar lesiones graves a los ojos.

E

l empleador o el usuario deben asegurar que se protejan debidamente los ojos. El equipo

d

e protección ocular debe estar en conformidad con los requisitos del Instituto Nacional

A

mericano de Normas (American National Standards Institute), ANSI Z87.1 y proteger por

delante y por el costado. NOTA: Los anteojos o máscaras sin protección lateral por sí solos

no dan una protección adecuada.

PRECAUCIÓN: En algunos entornos será necesaria protección de seguridad adicional.Por ejemplo, es

p

osible que el área de trabajo incluya la exposición a niveles de ruido que pueden dañar el oído. El

empleador y el usuario deben asegurarse de que cualquier protección necesaria para los oídos sea

provista y utilizada por el operador y demás personas en el área de trabajo. Algunos entornos

requieren el uso de aparatos de protección para la cabeza. Cuando sea necesario, el empleador y el

usuario deben asegurarse de que se utilice protección para la cabeza en conformidad con la norma

A

NSI Z89.1.

NUNCA USE EL MAZO SI TIENE LA CABEZA SUELTA O EL MANGO ASTILLADO.

PRECAUCIÓN: Reemplace las piezas desgastadas o dañadas inmediatamente.

PRECAUCIÓN: Para evitar lesiones accidentales, a usted y otros, los presentes en la

cercanía deben mantenerse a distancia segura de usted durante el uso de esta herramienta

especialmente al utilizar el mazo.

PRECAUCIÓN: El operador debe usar siempre zapatos de seguridad.

PRECAUCIÓN: Use solamente clavos de Bostitch.

PRECAUCIÓN: Nunca golpee el émbolo con la cara de metal del mazo.

AL CARGAR LA HERRAMIENTA

Al cargar la herramienta: 1.) Nunca coloque una mano o cualquier otra parte del cuerpo en el

área de descarga del sujetador de la herramienta; 2.) Nunca apunte la herramienta hacia otra

persona.

OPERACIÓN

Siempre maneje la herramienta con cuidado: 1.) Nunca participe en juegos rudos; 2.) Nunca accione el

gatillo a menos que la punta esté dirigida hacia el trabajo; 3.) Mantenga a los demás a una distancia

segura de la herramienta mientras esté en funcionamiento porque puede activarse accidentalmente,

causando posibles lesiones.

Mantenga las manos y el cuerpo alejados del área de descarga de la herramienta.

No aplique fijaciones unas encima de otras ni con la herramienta en un ángulo demasiado agudo pues

esto puede ocasionar la deflexión de las fijaciones, pudiendo causar lesiones.

No aplique fijaciones cerca del borde de la pieza con la cual esté trabajando pues la madera puede

dividirse, permitiendo la deflexión de la fijación, causando posibles lesiones.

Esta clavadora produce CHISPAS durante la operación. NUNCA use la clavadora cerca de sustancias, gases

ni vapores inflamables, incluidos diluyentes, lacas, pintura, bencina, gasolina, adhesivos, mástique,

pegamentos ni ningún otro material que sea inflamable, combustible o explosivo -- o vapores, emanaciones

o subproductos que puedan serlo. Si se usa la clavadora en cualquier ambiente de este tipo podría causar

una EXPLOSION produciendo lesiones físicas o fatales para el usuario y las personas en la cercanía.

MANTENIMIENTO DE LA HERRAMIENTA

Al trabajar con herramientas, observe las advertencias de este manual y tenga sumo

cuidado al evaluar herramientas con problemas.

10

Page 11

ESPECIFICACIONES DE LA HERRAMIENTA MFN-200

T

odas las dimensiones están en pulgadas a menos que se especifique lo contrario

MMFFNN--220000

D

escripción Clavadora manual para pesos

T

ipo de fijación Clavos para pisos tipo “L” calibre 16

C

apacidad del depósito 150

L

argo 342.9mm (13-1/2 pulgadas)

Ancho 89mm (3-1/2 pulgadas )

A

ltura 444.5mm (17-1/2 pulgadas)

Peso 4.4kg (9.71lbs)

ESPECIFICACIONES DE FIJACIONES MFN-200

Modelo de SKU de

herramienta Tipo de fijación la fijación Calibre Largo

MFN-200 Clavadora FLN-150 16 38.1 mm

Manual Para Pesos FLN-200 16 50.8 mm

NOTA:

Las herramientas BOSTITCH se han diseñado para brindar una satisfacción excelente al cliente y

rar máximo rendimiento al utilizarse con fijaciones de precisión BOSTITCH diseñadas con las

log

mismas normas estrictas. BOSTITCH no puede asumir responsabilidad alguna por el rendimiento

del producto si se utilizan nuestras herramientas con fijaciones o accesorios que no reúnen los

requisitos específicos establecidos para fijaciones y accesorios genuinos de BOSTITCH.

11

Page 12

CARGA DE MFN-200

A

l cargar, operar o dar servicio a esta herramienta, el operador y los demás presentes en el

área de trabajo deben usar SIEMPRE PROTECCIÓN DE LOS OJOS en conformidad con las

e

specificaciones ANSI y que proteja contra partículas que vuelen por DELANTE y por el

LADO. Se exige protegerse la vista para resguardarse contra fijaciones o residuos que

vuelen, lo cual puede causar lesiones graves a los ojos.

E

l empleador o el usuario deben asegurar que se protejan debidamente los ojos. El equipo de

protección ocular debe estar en conformidad con los requisitos del Instituto Nacional

A

mericano de Normas (American National Standards Institute), ANSI Z87.1 y proteger por

d

elante y por el costado. NOTA: Los anteojos o máscaras sin protección lateral por sí solos

no dan una protección adecuada.

PARA PREVENIR LESIONES ACCIDENTALES:

• Nunca coloque la mano ni ninguna otra parte del cuerpo en el área de descarga de clavos de la

herramienta.

• Nunca apunte la herramienta hacia una persona.

• Nunca participe en juegos rudos.

• Siempre maneje la herramienta con cuidado.

• No contacte el activador al cargar la herramienta.

CARGA DE LA HERRAMIENT

1. Libere el clip con resorte del empujador y retire la hoja del empujador.

2. Cargue las fijaciones en el canal guía.

3. Inserte el extremo redondeado de la hoja del empujador dentro del canal para retener las fijaciones.

4. Enganche el clip con resorte del empujador al extremo con muesca de la hoja del empujador. Asegure el

enganche suficiente de la hoja del empujador para alimentar suavemente las fijaciones.

A:

1.

2.

3.

NOTA: ES POSIBLE QUE LAS FIJACIONES NO SE ALIMENTEN UNIFORMEMENTE SI NO SE INSTALA

LA HOJA DEL EMPUJADOR.

ANTES DE MANIPULAR U OPERAR ESTA HERRAMIENTA, LEA DETALLADAMENTE LAS

ADVERTENCIAS CONTENIDAS EN ESTE MANUAL.

4.

12

Page 13

FUNCIONAMIENTO

Al cargar, operar o dar servicio a esta herramienta, el operador y los demás presentes en el

área de trabajo deben usar SIEMPRE PROTECCIÓN DE LOS OJOS en conformidad con las

especificaciones ANSI y que proteja contra partículas que vuelen por DELANTE y por el

L

ADO. Se exige protegerse la vista para resguardarse contra fijaciones o residuos que

v

uelen, lo cual puede causar lesiones graves a los ojos.

El empleador o el usuario deben asegurar que se protejan debidamente los ojos. El equipo

de protección ocular debe estar en conformidad con los requisitos del Instituto Nacional

Americano de Normas (American National Standards Institute), ANSI Z87.1 y proteger por

delante y por el costado. NOTA: Los anteojos o máscaras sin protección lateral por sí solos

n

o dan una protección adecuada.

El modelo MFN-200 fue diseñado para instalar pisos de madera machihembrada de 19 mm (3/4”).

NOTA: Siempre pruebe en un trozo de piso de muestra.

CIÓN: NUNCA GOLPEE EL ÉMBOLO CON EL EXTREMO DE METAL DEL MAZO.

PRECAU

1. Posicione el piso siguiendo las especificaciones del fabricante.

2. Ponga la herramienta con la placa guía encima de la lengüeta y firmemente contra la cara delantera del

material de piso.

3. Asegúrese de que la pata compuesta quede firmemente sujeta contra la superficie superior del piso.

4. Usando la cara de caucho del mazo golpee el extremo superior del émbolo de metal.

2.

NOTA: Se requiere suficiente fuerza para instalar completamente una sola fijación con un golpe del

mazor.

4.

NOTA: CON RESPECTO AL USO DE ESTA HERRAMIENTA PARA INSTALAR

PISOS PRETERMINADOS

La BOSTITCH MFN-200 se ha diseñado precisamente para ser compatible con la amplia gama de productos

de pisos de madera actuales, incluyendo los pisos preterminados.Debido a los productos siempre cambiantes

y a los procesos de manufactura que se emplean al producir los pisos de madera preterminados, debe tenerse

cuidado para asegurar que no se dañe el acabado del piso con la herramienta. Siempre pruebe la

herramienta y la técnica de instalación en una sección de muestra del piso para tener la certeza de que ni la

herramienta ni la técnica de instalación vayan a dañar el piso preterminado. Debe seguirse este procedimiento

antes de cada trabajo debido a variaciones en pisos y condiciones de la herramienta.

asumir responsabilidad por ningún daño a los pisos.

13

BOSTITCH no puede

Page 14

LA PROFUNDIDAD DE LA FIJACIÓN

IJACIÓN MAL INSTALADA

F

FIJACIÓN BIEN INSTALADA

Piso

i el émbolo no se devuelve totalmente, no se ha instalado completamente el clavo. Cuando ocurre esto,

S

se la cara de caucho del mazo para golpear de nuevo el extremo superior del émbolo de metal. Cuando

u

se instale completamente el clavo, el mecanismo de trinquete permitirá que se devuelva el émbolo.

Fijación

Subpiso

MANTENIMIENTO

Herramienta

Al igual que con cualquier herramienta de calidad, el mantenimiento mejorará su funcionamiento y duración.

Se recomienda usar repuestos BOSTITCH. No use piezas modificadas ni componentes que no tengan un

rendimiento equivalente al equipo original.

1. Para inspecciones o reemplazar componentes del émbolo, quite primero el clip de retención y extraiga

el pasador de seguridad.

2. Extraiga el ensamblaje del émbolo.

3. Limpie la grasa vieja, la suciedad y las partículos abrasivas de todas las piezas.

4. Engrase ligeramente el émbolo y el resorte del mismo.

5. Reemplace todas las piezas dañadas o desgastadas.

PRECAUCIÓN: AL REEMPLAZAR LA HOJA IMPULSORA, REVISE QUE SE VEA LA PALABRA

“FRONT” ESTAMPADA EN LA HOJA DESPUÉS DE HABERLA INSTALADO EN EL ÉMBOLO.

Mazo

Con el tiempo la cara de caucho en el mazo puede desgastarse, agrietarse o picarse. Estas son señales de

que se necesita instalar una nueva cara de caucho.

Retire la cara de caucho desgastada:

1. Asegúrela en un tornillo de banco.

2. Mueva hacia arriba el mango hasta que se libere la cara de

caucho del perno de acero.

Para instalar una nueva cara de caucho en el mazo, recomendamos

hacerlo en el taller y usando una prensa de árbol. Si debe hacerlo

manualmente, siga estas instrucciones.

1. Asegure la cabeza del mazo en un tornillo de banco.

2. Ponga la tapa de caucho ligeramente inclinada encima del

perno de acero, y hacia abajo con un movimiento de giro para

enganchar la cavidad de caucho sobre el borde del perno de

acero.

3. Una vez totalmente enganchada encima del borde, puede

soltar el mazo del tornillo de banco y golpearlo sobre una

superficie sólida para asentar debidamente la cara de caucho

en la cabeza del mazo.

14

Page 15

PRODUCTOS BOSTITCH PARA PISOS

MIIIFS/MIIIFN

Herramienta neumática para

pisos

SX150-BHF-2

Engrapadora para pisos de

madera calibre 18

LHF97125

Engrapadora para pisos de

madera calibre 20

MIIIFN-KIT

Paquete de conversión de

clavadora MIIIFS

MIIIFOOT-KIT

Juego de pata adaptadora

MIIIFS/MIIIFN para pisos

preterminados

Para obtener más información visite:

www.BOSTITCH.com

N62FNK-2

Paquete de clavadora calibre 15

sin aceite

15

Page 16

INTRODUCTION

Les outils BOSTITCH sont des outils de précision conçus pour un clouage exact et à haut rendement. Ces outils

ffrent un service efficace et fiable lorsque utilisés correctement et avec soin. Comme pour tout outil de précision, il

o

st nécessaire de suivre les instructions du fabricant pour obtenir de meilleures performances. Prière d'étudier ce

e

manuel avant la mise en fonction de l’outil, et s'assurer d’avoir compris les avertissements et consignes de sécurité

inclus. Lire avec précaution les instructions d’installation, de fonctionnement et de maintenance; conserver le manuel

our référence ultérieure. REMARQUE : Des mesures de sécurité supplémentaires peuvent être requises en fonction

p

e votre utilisation particulière de l’outil. Pour toute question concernant l’outil et son utilisation, contacter un

d

représentant ou distributeur BOSTITCH. BOSTITCH, East Greenwich, Rhode Island 02818, États-Unis.

INDEX

Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

S

pecifications de l’outil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chargement de l’outil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fonctionnement de l’outil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Profondeur de fixation & maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Autres produits BOSTITCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

REMARQUE:

Les outils BOSTITCH répondent aux attentes des consommateurs et offrent des performances optimales,

lorsqu’ils sont utilisés en conjonction avec les dispositifs de fixation Bostitch obéissant au même standard.

BOSTITCH ne garantit pas les performances de vos outils s’ils sont utilisés avec des dispositifs de

fixation ou accessoires ne répondant pas strictement aux exigences établies en matière de clous,

agrafes et accessoires.

GARANTIE LIMITÉE 7 ANS — États-Unis et Canada seulement

À partir du 1er décembre 2005, Bostitch, L.P. garantit à l’acheteur d’origine au détail que ce produit est exempt de

tout défaut de matériaux et de fabrication et accepte, le cas échéant, de réparer ou de remplacer, à la discrétion de

Bostitch, toute agrafeuse ou cloueuse de marque Bostitch défectueuse pour une période de sept (7) ans à partir de

la date d’achat (1 (un) an à partir de la date d’achat pour les compresseurs et les outils utilisés dans des applications

de production). Cette garantie n’est pas cessible. Une preuve de la date d’achat est requise. Cette garantie couvre

uniquement les dommages résultant de défaut de matériaux et de fabrication, et ne couvre pas les conditions ou

défauts de fonctionnement résultant d’une usure normale, d’une négligence, d’un usage abusif, d’un accident, d’une

réparation ou d’une tentative de réparation par une entité autre que notre Centre de réparation national ou l’un de

nos Centres de service de garantie autorisé. Les lames du mandrin, les amortisseurs, les joints toriques, les pistons

et les garnitures de piston sont considérés comme des pièces normales d’usure. Pour une performance optimale de

votre outil Bostitch, utilisez toujours des attaches et des pièces de rechange Bostitch d’origine.

CETTE GARANTIE REMPLACE TOUTE AUTRE GARANTIE, IMPLICITE OU EXPLICITE, COMPRENANT, MAIS

SANS S’Y LIMITER, LES GARANTIES IMPLICITES DE COMMERCIALISATION OU D’ADAPTATION À UN

USAGE PARTICULIER. BOSTITCH NE SERA PAS TENUE RESPONSABLE DES DOMMAGES INDIRECTS OU

ACCESSOIRES.

Les limitations imposées par la durée d’une garantie implicite ou l’exclusion des dommages accessoires ou indirects

n’étant pas reconnues dans certains États et pays, les limitations ou exclusions précitées peuvent ne pas vous être

adressées.Cette garantie vous confère des droits juridiques spécifiques qui s’ajoutent aux autres droits éventuels qui

peuvent varier d’une province, d’un État ou d’un pays à l’autre.

Pour obtenir aux États-Unis des services liés à la garantie, retournez le produit à vos frais accompagné de la preuve

d’achat à v

autorisé. Aux États-Unis, appelez-nous au 1-800-556-6696 ou visitez le www.BOSTITCH.com pour connaître

l’emplacement du Centre le plus près de chez vous. Au Canada, appelez-nous au 1-800-567-7705 ou visitez le

www.BOSTITCH.com.

otre Centre de service national américain ou à un Centre de service régional indépendant de garantie

16

Page 17

CONSIGNES DE SÉCURITÉ

UNE PROTECTION DES YEUX, conforme aux normes ANSI et fournissant une protection

contre les projectiles en provenance de l’AVANT et des CÔTÉS, doit TOUJOURS être portée

par l’opérateur et les personnes présentes dans la zone de travail, lors du chargement, du

fonctionnement et de la maintenance de l’outil. Une telle protection est indispensable pour

vous protéger contre les attaches et débris projetés, susceptibles d’entraîner des blessures

sérieuses.

L

’employeur et/ou l’utilisateur doivent s’assurer de l'utilisation d'une bonne protection

o

culaire. L’équipement de protection doit être conforme à la norme ANSI Z87.1 et fournir une

p

rotection frontale et latérale. REMARQUE : Des lunettes sans protection latérale et des

masques faciaux ne fournissent pas la protection nécessaire.

A

TTENTION : Des mesures de sécurité supplémentaires seront nécessaires dans certains

environnements. Par exemple, la zone de travail peut comporter une exposition à des niveaux

d

e bruit pouvant conduire à un dommage auditif. L'employeur et l'utilisateur doivent alors

s

'assurer qu'une protection auditive adéquate est offerte et utilisée par l'opérateur et toute autre

personne se trouvant dans la zone de travail.Certains environnements de travail nécessitent le

port d'un casque de sécurité. Dans ce cas, l'employeur et l'utilisateur doivent s'assurer qu'un

casque de sécurité conforme à la norme ANSI Z89.1 est toujours porté.

NE JAMAIS UTILISER LE MAILLET SI SA TÊTE EST DESSERRÉE OU QUE SON MANCHE

EST FÊLÉ.

ATTENTION : Remplacer immédiatement toute pièce usée ou endommagée.

ATTENTION : Afin d’éviter les blessures à l’utilisateur et aux autres, assurez-vous que toute

tierce personne garde ses distances durant l’utilisation de l’outil, particulièrement au

moment d’élancer le maillet.

ATTENTION : L’opérateur doit toujours porter des chaussures de sécurité.

ATTENTION : N’utiliser que des crampons de Bostitch.

ATTENTION : Ne jamais frapper le plongeur avec la face métallique du maillet.

CHARGEMENT DE L’APPAREIL

Lors du chargement de l’appareil : 1) Ne jamais placer la main ou toute autre partie du corps

dans la direction de projection de l’élément d’assemblage de l’outil; 2) Ne jamais pointer

s quelqu’un.

l’outil ver

FONCTIONNEMENT

Manipuler l’appareil avec précaution : 1) Ne pas jouer ou chahuter avec l’appareil; 2) Ne

jamais appuyer sur la détente tant que le nez de l’appareil n’est pas dirigé vers la pièce à

assembler; 3) Tenir les autres personnes à distance raisonnable de l’outil lors de l’utilisation

de celui-ci, car un déclenchement accidentel peut se produire et causer des blessures.

Garder le corps et les mains à l’écart de la trajectoire de sortie des attaches.

Ne pas enfoncer des attaches lorsque l'outil est trop penché ou par-dessus d'autres

attaches car cela pourrait faire dévier ces dernières et entraîner des blessures.

Ne pas enfoncer des attaches près du bord de la pièce car le bois pourrait se fendre et faire

dévier les attaches, entraînant ainsi des blessures.

Pendant son fonctionnement, cette cloueuse génère des ÉTINCELLES. NE JAMAIS utiliser la

cloueuse près de substances, gaz ou vapeurs inflammables, y compris : laque, peinture,benzène,

solvant, essence

brumes ou produits dérivés,

dans un tel environnement pourrait mener à une EXPLOSION pouvant causer des blessures ou

, adhésifs, mastics,colles ou tous autres pr

inflammables, combustibles ou explosifs. L’utilisation de la cloueuse

oduits qui sont, eux ou leurs vapeurs,

ENTRETIEN DE L’APPAREIL

ailler avec des outils, s'assurer d'observer les avertissements contenus

Au moment de tra

dans ce manuel et prêter une attention redoublée en cas de problème.

v

17

Page 18

SPÉCIFICATIONS DES OUTIL MFN-200

T

outes les dimensions sont en métrique (impérial) sauf avis contraire

MMFFNN--220000

D

escription Outil pour revêtement de plancher

T

ype d’attache Crampons pour planchar type “L” calibre 16

C

apacité du magasin 150

Longeur 342.9mm (13-1/2 po)

Largeur 89mm (3-1/2 po )

Hauteur 444.5mm (17-1/2 po)

Poids 4.40 kg (9,71lbs)

SPÉCIFICATIONS DES ATTACHES MFN-200

Modèle d'outil Type d'attache N° stock Calibre Longueur

de l'attache

MFN-200 Outil

Pour Revêtement

de Plancher

FLN-150 16 38,1 mm

FLN-200 16 50,8 mm

REMARQUE :

Les outils BOSTITCH répondent aux attentes des consommateurs et offrent des performances

supérieures lorsqu’ils sont utilisés en conjonction avec les dispositifs de fixation BOSTITCH obéissant

au même standard. BOSTITCH ne garantit pas les performances de v

avec des dispositifs de fixation ou accessoires ne répondant pas strictement aux exigences

établies pour les clous, attaches et accessoires d’origine BOSTITCH.

os outils s’ils sont utilisés

18

Page 19

CHARGEMENT DU MFN-200

U

NE PROTECTION DES YEUX, conforme aux normes ANSI et fournissant une protection

contre les projectiles en provenance de l’AVANT et des CÔTÉS, doit TOUJOURS être portée

p

ar l’opérateur et les personnes présentes dans la zone de travail, lors du chargement, du

fonctionnement et de la maintenance de l’outil. Une telle protection est indispensable pour

vous protéger contre les attaches et débris projetés, susceptibles d’entraîner des blessures

sérieuses.

L’employeur et/ou l’utilisateur doivent s’assurer de l'utilisation d'une bonne protection

o

culaire. L’équipement de protection doit être conforme à la norme ANSI Z87.1 et fournir une

p

rotection frontale et latérale. REMARQUE : Des lunettes sans protection latérale et des

masques faciaux ne fournissent pas la protection nécessaire.

OUR PRÉVENIR TOUT ACCIDENT :

P

• Ne jamais placer une main ou une partie quelconque du corps sur la trajectoire de sortie des

attaches.

• Ne jamais pointer l’outil vers une autre personne.

• Ne jamais chahuter.

• Veiller à toujours manipuler l’outil avec précaution.

• Ne jamais appuyer sur l’activateur en chargeant l’outil.

CHARGEMENT DE L’OUTIL :

1. Dégager la pince du ressort-poussoir puis retirer la lame du poussoir.

2. Charger les attaches dans la rainure-guide.

3. Insérer l’extrémité arrondie de la lame du poussoir dans la rainure pour

maintenir les attaches en place.

4. Enclencher la pince du ressort-poussoir sur l’extrémité encochée de la lame

du poussoir. S’assurer que la lame du poussoir s’enfonce suffisamment pour assurer une avance des

attaches en douceur.

1.

3.

REMARQUE : LES ATTACHES N’AVANCERONT PAS UNIFORMÉMENT SI LA LAME DU POUSSOIR N’EST PAS

INSTALLÉE.

AVANT DE MANIPULER OU D’UTILISER CET OUTIL, VEILLER À LIRE ET COMPRENDRE LES

AVERTISSEMENTS CONTENUS DANS CE MANUEL.

2.

4.

19

Page 20

FONCTIONNEMENT

UNE PROTECTION DES YEUX, conforme aux normes ANSI et fournissant une protection

contre les projectiles en provenance de l’AVANT et des CÔTÉS, doit TOUJOURS être portée

par l’opérateur et les personnes présentes dans la zone de travail, lors du chargement, du

f

onctionnement et de la maintenance de l’outil. Une telle protection est indispensable pour

v

ous protéger contre les attaches et débris projetés, susceptibles d’entraîner des blessures

s

érieuses.

L’employeur et/ou l’utilisateur doivent s’assurer de l'utilisation d'une bonne protection

oculaire. L’équipement de protection doit être conforme à la norme ANSI Z87.1 et fournir

une protection frontale et latérale. REMARQUE : Des lunettes sans protection latérale et

d

es masques faciaux ne fournissent pas la protection nécessaire.

Le MFN-200 a été conçu pour la pose de plancher 19 mm (3/4 po) à emboîtement double (rainure et

anguette).

l

REMARQUE : Faites toujours un essai sur une retaille de plancher.

ATTENTION :NE JAMAIS FRAPPER LE PLONGEUR AVEC LA FACE MÉTALLIQUE DU MAILLET.

1. Placer le revêtement de plancher selon les instructions du fabricant.

2. Placer l’outil, la plaque-guide au-dessus de la languette, fermement contre la face avant du revêtement de

plancher.

3. S’assurer que le pied composite est bien maintenu contre la surface supérieure du revêtement de plancher.

4. À l’aide de la face caoutchoutée du maillet, frapper l’extrémité supérieure du plongeur en métal.

2.

REMARQUE : Une certaine force est requise pour enfoncer complètement une attache d’un seul coup

de maillet.

REMARQ

UE : À PROPOS DE L'UTILISATION DE CET OUTIL POUR INSTALLER

4.

UN PLANCHER PRÉFINI

Le MFN-200 de BOSTITCH a été conçu avec soin pour être compatible avec la vaste gamme des produits

actuels de plancher en bois dur, y compris les planchers préfinis. Étant donné le renouvellement constant des

produits et procédés de fabrication des planchers préfinis de bois dur, veiller à ce que l’outil n’endommage pas

le fini du plancher. Tester toujours l’outil et la technique d’installation sur un échantillon pour vous assurer

qu’aucun de ces deux aspects ne cause de dommages au plancher préfini. Cette vérification doit être

effectuée avant chaque ouvrage, étant donné les variations dans les revêtements de plancher et l’état de

BOSTITCH n’est aucunement responsable de quelque dommage à un revêtement de plancher.

l’outil.

20

Page 21

PROFONDEUR DE FIXATION

ATTACHE PAS SUFFISAMMENT

Si le plongeur ne retourn

nsuffisant. Dans un tel cas, frapper l’extrémité supérieure du plongeur en métal à l’aide de la face

i

aoutchoutée du maillet. Une fois l’attache complètement enfoncée, le mécanisme à cliquet permettra le

c

retour du plongeur.

e pas complètement à sa position originale, l’enfoncement de l’attache est

ATTACHE CORRECTEMENT ENFONCÉE

Plancher

Attache

Sous-plancher

MAINTENANCE

Outil

Comme pour n’importe quel outil, un entretien régulier améliorera sa qualité de fonctionnement et

prolongera sa durée de vie. Nous recommandons les pièces de rechange BOSTITCH. Ne pas utiliser de

pièces modifiées ou ne fournissant pas une performance équivalente à celle de l’équipement d’origine.

1. Pour inspecter ou remplacer toute pièce du plongeur, retirer d’abord la pince de retenue puis enlever la

goupille d’arrêt.

2. Retirer le montage du plongeur.

3. Nettoyer la vieille graisse, la saleté et les particules abrasives de toutes les pièces.

4. Graisser légèrement le plongeur et son ressort.

5. Remplacer immédiatement toute pièce usée ou endommagée.

ATTENTION : AU MOMENT DE REMPLACER LA LAME DU MANDRIN, S’ASSURER QUE LE MOT «

FRONT », ESTAMPILLÉ SUR LA LAME, EST VISIBLE UNE FOIS CETTE DERNIÈRE INSTALLÉE SUR

LE PLONGEUR.

Maillet

Avec le temps, la face de caoutchouc du maillet peut s’user, se fissurer ou s’écailler. Cela indique qu’il faut

remplacer la face du maillet.

Démontage de la vieille face de caoutchouc :

1. Immobiliser la face de caoutchouc dans un étau d’établi.

2. Tirer le manche vers le haut jusqu’à ce que la face de caoutchouc

se dégage du goujon d’acier.

Nous recommandons d’installer la nouvelle face en atelier, à l’aide

d’une perceuse à colonne. Si l’installation se fait à la main, suivre les

instructions suivantes :

1. Immobiliser la tête du maillet dans un étau d’établi.

2. Placer le capuchon de caoutchouc legerement incline sur dessus

du goujon d’acier, puis pousser vers le bas avec un mouvement de

torsion pour placer la cavite de caoutchouc au-dessus du rebord du

goujon.

3. Une fois complètement sur le rebord, relâcher le maillet de l’étau

puis le cogner sur une surface solide afin de bien appuyer la face

de caoutchouc sur la tête du maillet.

21

Page 22

PRODUITS BOSTITCH POUR PLANCHER

MIIIFS/MIIIFN

Outils pneumatiques pour

revêtement de plancher

SX150-BHF-2

Agrafeuse à plancher de bois dur,

calibre 18

LHF97125

Agrafeuse à plancher de bois dur,

calibre 20

MIIIFN-KIT

MIIIFS Ensemble de conversion

pour cloueuse à crampons

MIIIFOOT-KIT

MIIIFS/MIIIFN Ensemble de pied

adaptateur pour plancher préfini

Pour plus de renseignements, allez au :

www.BOSTITCH.com

N62FNK-2

Ensemble de cloueuse sans

huile, calibre 15

22

Page 23

NOTES AND RECORDS

NOTAS Y REGISTROS

REMARQUES ET RAPPORTS

23

Loading...

Loading...