Page 1

t

A

S:

f

i

INSTRUCTIONS

AND

PARTS

LISJ

OF THE

N°

14

&

N°

14B

../•

BOSTITCH*

WIRE

STITCHERS

..

•

it;

i-4'

;v

•••,'••..•

;•..••

'jSf

^^P^MlMii

V

BELT

DRIVE

USES

Ne

15001D

HEAp

When

in

need

of

Parts

or

Service

Contact Your Bostitch

Distributor.

You

will

find

"BOSTITCH"

listed

in

phone

books

of

most

large

cities.

Fasten

It

Better

ad

Fasfer

'

5

STAPLERS

AND

STAPLES

>^

^-X/."

•:-v:\::

>M

-.•,:ra^P-,-.-:;

••• • :••

•'•'r-ftS'r^ift'^"""

Page 2

INSTALLATION,

OPERATION

AND

MAINTENANCE

of

No.

14

AND No. 14B

BOSTITCH

WIRE STITCHER

WITH

No.

15001D

HEAD

;;

CAPACITY:

9/16"

SIZE

OF

WIRE:

.017

thru

.023

Ribbon

No. 1 and 2

Hybar

No.

18x20,

19x21'/a,

20x24,

20x25

and

21x25

Flat

No.

18,

20, 22, 23, 24 and 25

thru

27

Round

CROWN

OR

STAPLE

WIDTH:

%", W (Standard),

%"

and

%"

SPEED:

Up to 300

stitches

per

minute

Note:

This

book

does

not

include

head

instructions.

It

should

be

used

in

conjunction

with

"Instructions

and

Parts

List

for No.

15001D,

18001D,

18001D27

and

19001D

Bostitch

Wire

Stitcher

Heads."

1.

INTRODUCTION

To

obtain

satisfactory

results from a wire stitcher,

as

with

any

other machine,

it is

necessary

that

it

be

properly installed

and

adjusted, regularly

lu-

bricated,

and

carefully maintained.

In

case

of any

serious

trouble, however,

you

should

notify

the

nearest

sales

office,

sending samples

of

the

defective

work

and

describing

the

trouble

in

detail,

so as to

obtain

the

benefit

of

their experience

in

arriving

at the

proper solution.

Be

sure

to

report

the

serial number

and

model

of the

machine when

corresponding

in

regard

to it, so

that

it may be

quickly identified.

2.

INSTALLATION

To

prevent

damaging

the

machine during

its

installation,

we

recommend that

the

following pro-

cedure

be

closely

followed:

a:

After

uncrating

machine, examine carefully

for

any

breakage

in

transit.

If

such

is

found,

do

not

attempt

to run

machine

but

report

at

once

to the

selling

agent.

If

service

man is

present,

let

him

examine machine

carefully

and

then

report

to

manufacturer.

b:

Examine name plate

on

motor

ana see

that

its

specifications

are the

same

as

those

of the

power

to

be

used.

If

not,

do not

attempt

to

use.

c:

Since'each machine

is

shipped with some

parts

disassembled,

it is

necessary

that

these

parts

be

reassembled onto

the

machine.

Attach

spool stud

and

disc, wire guide spring,

ad-

justing

screw

crank

arm, motor bracket,

motor,

V

belts, belt shield

and

belt guard.

The

mounting

of

motor onto

the

base

is a

simple

matter

which needs

no

explanation. When

assem-

bling-

belts, make sure

that

they-

are

only

tight

enough

to run

machine

without

slippage. Belt ten-

sion

may be

adjusted

by

moving motor bracket

up

or

clown.

d : Place machine

on

level

floor,

using shims under

base

to

prevent

any

movement

or

rocking.

e:

Lubricate machine thoroughly

as

described

in

head instructions

and as

follows:

Apply generous

supply

of oil

(S.A.E.

10) to

pulley

washer

as

this

lubricates

clutch.

Oil

drive

shaft through

oil

cups

(2) at top of

frame

and oil

universal

joints

in

drive

shaft

through large holes

(2) in

left

side

of

frame.

f:

Trip

the

clutch

by

means

of the

movable foot

pedal

at

front

of

machine

and

turn machine over

by

hand

a few

times

to see

that

everything

is

clear.

Then

take

foot

off

clutch

trip

pedal

and

rotate

clutch pulley rapidly,

so

that

clutch

will

be

entirely

disengaged.

Do not

turn

electric

switch

on

until

pulley

rotates

freely.

g:

Connect motor cord

to

power outlet

and

start

motor.

See

that large

pulley

or flywheel

turns

in

direction

of

arrow cast

on

pulley,

or

clockwise

as

viewed

from

the

front

of the

machine. Should

it

rotate counter-clockwise, motor

wiring

should

be

re-connected

by

electrician

in

order

to

reverse

direction

of

rotation.

h:

If

rotation

is

correct, push down

on

foot pedal

and

start

machine operating. Remove foot from

pedal

and

machine

will

stop. A very little practice

will

enable operator

to

know exactly

how to

stop

and

start

machine

exactly

when

desired.

The

following units

are not

standard equipment

on

No. 14

Stitcher

and are

furnished

special

to

order only.

Instructions

follow

for

installing same.

Continuous Feed

Device

or

Tucker

Unit:—This

is

attached

by

placing

groove

in

same over swivel

holder

clamp

on

bonnet

and

holding same with

one

screw provided.

Page 3

Table:—-Remove

clincher ba'r. Attach yoke

to

table,

being sure

that

thin

shim

is

attached with yoke

to

table. Place

table

on

arm, enter

lugs

on

table

in

holes

in

frame,

and

push

in

until dowel

in arm

enters

hole

in

shim.

Work

guide

can now be at-

ached.

Clamp from either end.

Parallel

Head

Attachment:—This

is

attached

in

the

following

manner : Remove head from machine

as

explained

in

head

instructions. Place

one

exten-

sion

block

on

each

of the

slides,

(adjusting driver

and

bender) over

tongues

with

screws

provided,

long

end of

block

to

left

with

oil

hole

on

top. These

blocks

should

be

tight.

Place long bonnet screws

in

frame.

These

are

special screws. Attach

the

exten-

sion

head

block

on

these screws

and

turn crank

into

vertical

position.

Attach

links

to two

lower exten-

sion

blocks.

Attach

head,

facing

the

right,

and

raise

bender

bar to top of

stroke.

Insert

crank

pin

into

hole

in

lower link. Insert

ball

end of

adjusting

link

into

upper block. Move

adjustment

screw

up

or

down

until

hole matches

ball

end. Enter bonnet

screws

in

head

and

tighten. Attach bonnet guard

— A special offset

arm is

necessary with this

attachment.

3.

OPERATION

a:

Place a spool

of

wire

of the

proper size

on

the

spool holder

located

near

the

stitching mech-

anism

or

head.

When

loading

with

wire

wound

on

paper

cores:

Remove

detachable

flange

from

spool

and

insert

coil

of

wire, replacing

flange

and

turning coil till

binding

wires

are

aligned with

slots

in flanges.

Tighten

nut

till coil

is

snugly held.

Cut

binding

wires,

except

the one

holding

the end of the

coil.

(They

may be

pulled

out

through

the

slots.) Then

grasp,

end of

coil

and cut and

remove

the

binding

wire which holds

it.

Thread

the

machine

as de-

scribed

in

head instructions.

b:

Referring

to

head

operating adjustments

in-

structions, follow procedure

for

remainder

of

operations required,

such

as

wire

straightening

and

adjustment

for

length

of

wire.

Gauge

for

thickness

by

placing work under gauge

at

left

of

head

and

adjust crank

at

right

of

head

until

work

is

tightly

pinched under gauge. After

turning pulley

by

hand

once

so as to be

sure

that

machine

is

properly

set for

tnickness

to be

stitched,

power

can be

applied.

c:

Machine

is now

ready

to do

stitching

and

with

directions

as

outlined,

above satisfactory results

should

be

obtained. Make several rows

of

stitches

in

stock

to be

used,

examining crown

and

legs

for

proper

appearance.

If not

satisfactory, adjust

machine

in

accordance

with

directions given

be-

low.

See

section 4 "Appearance

of

Stitches"

and

"Trouble

Shooting

Chart"

in

head

instructions.

d:

CAUTION: — Never

operate

machine

u-ith

U'ire

feeding

and no

stock

above

clinchers.

Serious

damage

may

result

if

this

practice

is

followed.

4.

APPEARANCE

OF

STITCHES

If

stitching

is

defective,

compare stitch

produced

with

illustrations

in

head

instruction

manual.

To

eliminate

defect, follow

instructions

given

with

illustration

that

agrees

with defect.

If

it is

necessary

to

correspond

about

any

defective

stitches

or

other

difficulties

with

the

machine,

be

sure

to

refer

by

letter

to the

illustration

in

head

•instructions

book, which shows

the

type

of

stitch

defect

and,

if

possible, send a sample

of the

work

actually

being done

on the

machine.

5.

*THE

ESSENTIAL

POINTS

OF

STITCHING

In

order

to

continue

to

obtain

satisfactory

stitches

it

is

necessary

that

the

-following

essentials

be

observed:

a: The

legs

of the

staple must

be of the

same

length.

b:

Wire must enter cutters

as

nearly straight

as

possible.

c:

The

cutters

or

knives must

be

sharp

and

prop-

erly

set so

that there

arc no

burrs

on end of

wire

and

wire

is cut

with a square

end

(not

beveled).

d:

Clincher

must

be in

good condition with

no

pitted

or

badly worn grooves.

For

best

results

in

stitching

with solid

clinchers

the

compression gen-

erally

should

be

such that

the

ends

of

bender

bar

very

slightly indent

the top of the

work.

e:

The

machine must

be

kept clean

and

properly

oiled.

f:

The

wire

must

be of the

correct size

for

stock

to be

stitched

and

must

be

used only

in

the

proper

bender

bar. Wire

fitting the

bender

bar

grooves

too

loosely

will

cause

buckling,

and too

large a wire

will

also cause buckling

in

addition

to

excess

wear

on

the

bender bars.

Be

guided

by the

operating

instructions

for the

proper

size

wire.

g:

The

wire spool must

be

free

to

turn

and the

wire

must

not be

allowed

to

become crossed. Short

staples

and

even entire

failure

to

produce

staples

may

result from crossed

or

tangled wires.

h:

The

wire feed grip must

not

have edge

badly

chipped

or

worn. Short

leg

staples

on one

side

can

be

caused

by

these

conditions.

*The

necessary

adjustments,

replacements,

etc.,

required

to

meet

conditions

as

listed

above

are

described

in

detail

in the

head

and

stitcher

instruc-

tions.

6.

MAINTENANCE

a:

Machine should

be

lubricated regularly

as de-

scribed

under heading

of

"Installation"

in

this

pamphlet

and

under

heading

of

"Maintenance"

in

head

instructions.

b: The

friction

clutch

is

adjusted

by

means

of

screw 2340B

in

brake band 2339A. Screw

in if

clutch

slips. Screw

out if

clutch

knocks. A quarter

Page 4

turn

will

make

considerable-difference

in

action

of

the

clutch.

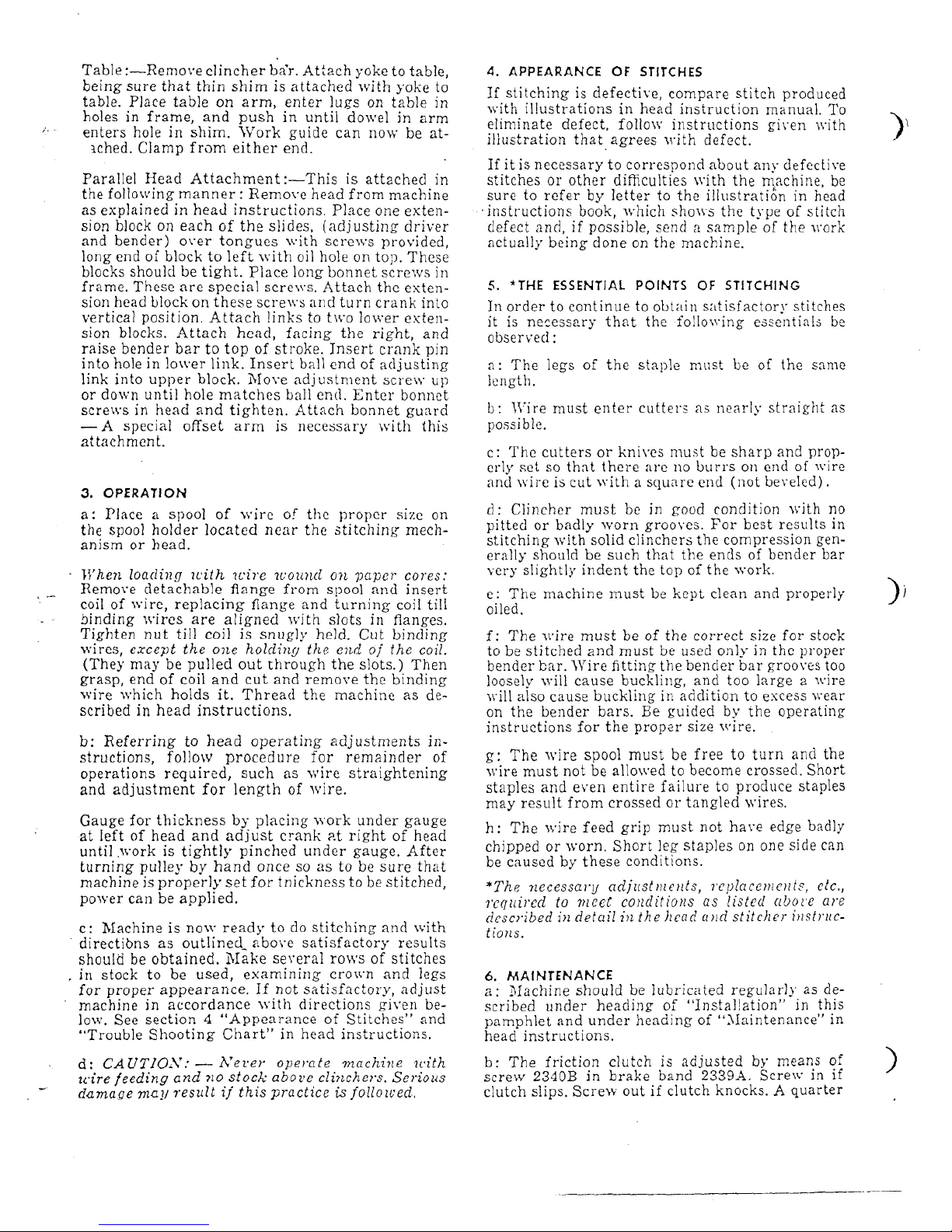

c: The

adjustment

for the

clincher

is set at the

factory

and

should

not be

altered

unless

adjust-

nt has

been

lost.

For

machines

with

arm,

readjustment from

side

to

side

may be

made

by

adjusting

hex

head

screws

(UA9132.1)

at

side

of

frame.

See

following

illus-

tration

for

vertical adjustment

of

clincher arm.

TO

RAISE

OR

LOWER CLINCHER.

1.

Loosen screw

A.

2.

Turn screw

B.

3.

Lock

screw

A.

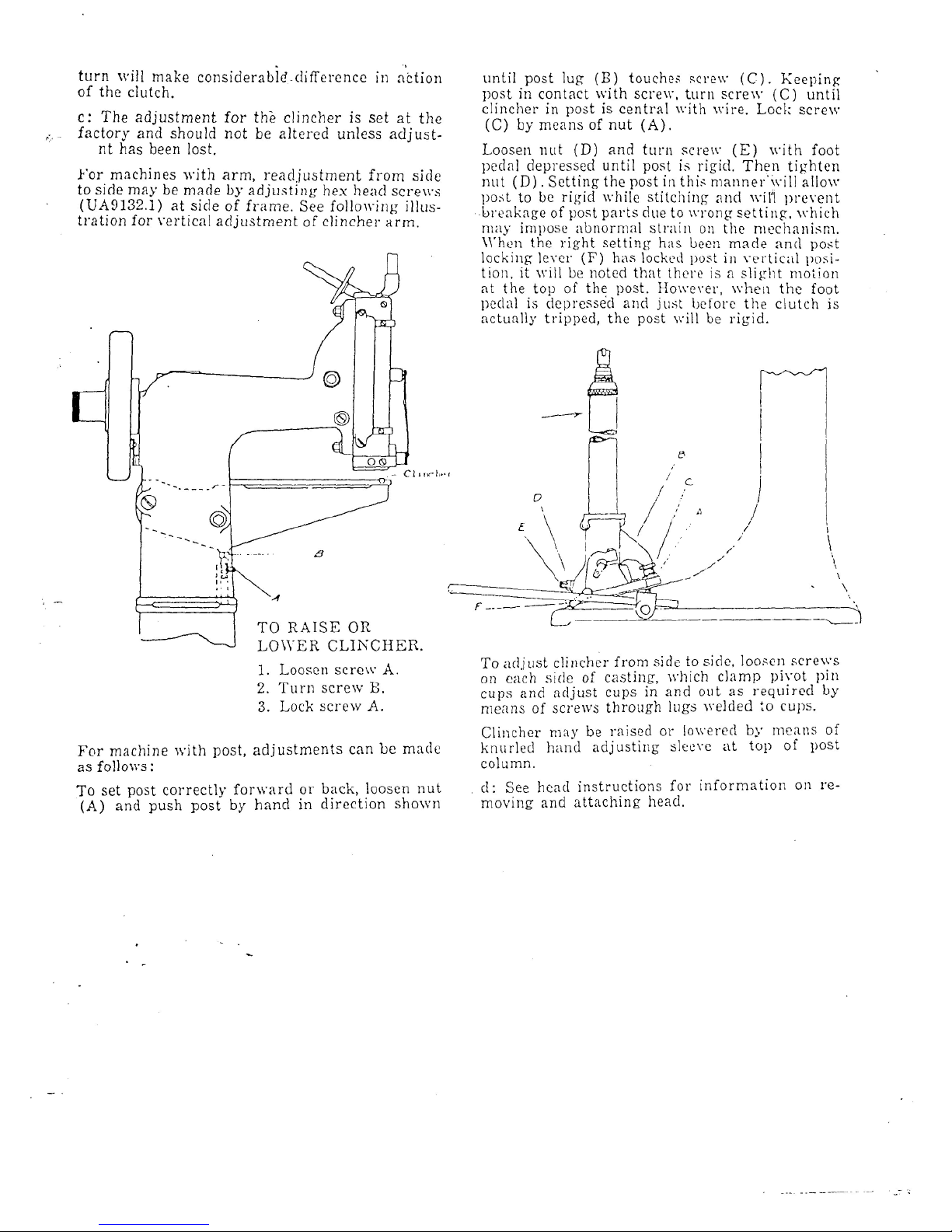

For

machine with post, adjustments

can be

made

as

follows:

To set

post correctly forward

or

back, loosen

nut

(A) and

push

post

by

hand

in

direction shown

until

post

lug

(B)

touches

screw (C).

Keeping

post

in

contact

with screw, turn screw

(C)

until

clincher

in

post

is

central with wire. Lock screw

(C) by

means

of nut

(A).

Loosen

nut (D) and

turn screw

(E)

with foot

pedal

depressed

until

post

is

rigid. Then tighten

nut

(D).

Setting

the

post

in

this

manner'will

allow

post

to be

rigid

while

stitching

and

wil'l

prevent

breakage

of

post parts

due to

wrong

setting,

which

may

impose

abnormal

strain

on the

mechanism.

When

the

right

setting

has

been

made

and

post

locking

lever

(F) has

locked

post

in

vertical

posi-

tion,

it

will

be

noted

that

there

is a slight

motion

at the top of the

post.

However,

when

the

foot

pedal

is

depressed

and

just

before

the

clutch

is

actually

tripped,

the

post

will

be

rigid.

To

adjust clincher from side

to

side, loosen

screws

on

each side

of

casting, which clamp pivot

pin

cups

and

adjust cups

in and out as

required

by

means

of

screws through lugs welded

to

cups.

Clincher

may be

raised

or

lowered

by

means

of

knurled

hand

adjusting

sleeve

at top of

post

column.

d:

See

head instructions

for

information

on re-

moving

and

attaching head.

Page 5

Page 6

NO.I4BOX'

STITCHER

N0.14B

BOTTOMING

STITCHER

Page 7

INSTRUCTIONS

FOR

OPERATING BOSTON WIRE STITCHER

HEADS

No.

15 & No. 15D

Sizes

of

Wire - Ribbon

or box

stay wire

No. 8 to No, 25 -

Rybar

wire

- No. 18 & 19

round wire

- No. 20 to 25

round

and No. 20

2:

24

& 21 x 25

flat.

Width

of

staple

1/2

regular

- 3/8 - 5/8 - 3/4

special.

Capacity

in

thickness

1/2

inch.

* No. 15D

Head.

TO

THREAD

run

v/ire

from under

side

of

spool

to

left

around spring

15151A

and

under studs

and

rolls

on

same.

Remove swivel

16066A

by

lifting lower

end of

spring

15084A

*19084A

and

swinging

to

left.

Curve wire

and

enter between

straightener

rolls

19121

and

eccentric

19128A.

Pull

wire down

until

crooked wire

has

passed through

rolls.

Cut

wire

off

with hard wire cutter just above

cutter

holder

15105B.

Enter wire

in

grip 15031

and in

tension rolls 19121 which

are

opened

by

pressing down

rod

19145A

*19147A.

Enter wire

in

slot

in

wire cut-

ter

15101

and

push down

until

wire shows through hole

in

swivel

holder

15072.

TO

STRAIGHTEN

WIRE adjust eccentric

19128A

until wire runs

straight. Start machine

and

watch wire feed past opening

in

swivel

holder. Wire should come directly

in

center

of

opening.

If

wire

curls

to

left, straightener

is not set

tight enough.

If

wire curls

to

right, straightener

is set too

tight.

When

wire runs

straight,

re-

place

swivel

and

attach spring

to

same.

OIL.

Oil

connecting

links

on

back

of

head.

Oil

swivel operating

lever

15078

*19078A.

Oil

slots

at top of

head

at

sides

of

bracket

15154.

Oil

driver

bar at top of

bender

bar

15023A.

Put

drop

of oil

in

angular

slot

in

cutter slide

15115A

*15113A

where

it can be

seen

through large

opening

in

face plate

15091A

*15135A.

Put

drop

of

-oil

on

swivel where

it

slides

in

swivel holder

15072.

TO

ADJUST

LENGTH

OF

WIRE.

To

change length

of

both

legs

of

staple, loosen screw

15088

and

push face plate

15091A

*15135A

up to

lengthen

or

down

to

shorten legs

of

staple. Tighten screw

15088

after

adjusting.

To

increase left

leg of

staple,

loosen screws 15155

and

56

near

the top of

head

and

turn

adjusting screw 15156

to

right.

To

shorten left leg, turn

to

left.

Press

down firmly

on

bracket

15154.

Tighten screws

56 and

15155.

Most adjustments

for

longer wire

can be

made

by

setting machine

for

thicker work.

WIRE

CUTTERS.

To

remove cutter

15104,

first

set

machine

at

mini-

mum

adjustment, then pull

out

slightly

on

spring 15108

and

push

the

little

pin in

cutter slide

15115A

*15113A

to top of

opening

in

face

plate. Cutter will then slide

out

easily. This

cutter

is

double

ended.

To

replace engage tongue

on

cutter

in

slot

in

slide

and

push

slide

down

to

lower

end of

stroke.

When

replacing

cutter,

trip machine

and.

turn

pulley

by

hand

to

bring

the

driver below

cutter.

To

remove

stationary cutter

15101,

loosen

screw 15102

at

left

of

cutter

holder.

Page 8

t.

COMPONENT PARTS

OF

THE

5

Q

I5D

BOSTON

WIRE

STITCHER

EADS

TRADE MARK

BOSTITCH

REG.

TJ.

S.

PAT. OFF.

BOSTON WIRE STITCHER

COMPANY

EAST

GREENWICH,

R. I.

Page 9

15283A

FOR

SHAFT

I5257A

I9283A

FOR

SHAFT

I930IA

15001

^5002

--15097B

15018A

I5283A

FOR

SHAFT I5257A

19283A

FOR

SHAFT

I930IA

-15025

„—-

15053A

15062-

BOSTITCH

LINKS

IN

PARALLEL

POSITION.

15067

BOSTON

WIRE

STITCHER

CO.

COMPONENT PARTS

OF

15

HEAD

LINKS

IN

RIGHT

ANCLE POSITION.

Page 10

I5283A--

FOR

SHAFT

I5257A

QJ|_

I9283A-.

FOR

SHAFT

I930IA

1504.5

1504-8

I5046A

15088

15155

I5094B

15093

15092

15076

I5066A

15072

320

BOSTITCH

1506219088-

9044

15077

L1KJKS

1M

PARALLEL

POSITION!

15012

15101

9057

15067

BOSTON

WIRE

STITCHER

CO.

COMPONENT

PARTS

OF

150018

15002

I5097B

15284

I9283A

FOR

SHAFT

1930

I5283A

FOR

SHAFT

1525'

15025

15027

15024

15026

15057

15056

I5053A

LINKS

IN

RIGHT ANGLE POSITION

5

D-HEAD

Page 11

PARTS

FOR NO. 15

HEAD ONLY

SEE

NO. 15

HEAD

CHART

15001

BOnnet

45.00

15018A

Driving

Slide

9.25

15019 Driving Slide Swivel Oper.

Pin .15

15078

Swivel Operating Lever 2.75

15079

Swivel Operating Lever Stud

.60

15080

Swivel Operating Lever Stop

.55

15081 Swivel Operating Lever Stop Screw

.15

15084A

Swivel Operating Spring 2.50

15091A

Face Plate - Ribbon

and

Hybar Wire 19.55

15115A

Wire Cutter Operating Slide 3.35

19091A

Face Plate - Round Wire 19.55

19145A

Tension Roll Spring

Rod .75

PARTS

FOR

NO.

15D

HEAD

ONLY

SEE NO. 15D

CHART

15001B

Bonnet

15113A

Wire Cutter Operating Slide

15135A

Face

Plate - Ribbon

and

Hybar Wire

19017A

Driving Slide

19020

Driving Slide Swivel

Oper.

Pin

19078A

Swivel Operating Lever

19079

Swivel Operating Lever Stud

19081 Swivel Operating Lever

Hub

19084A

Swivel Operating Spring

19135A

Face Plate - Round

Wire

19147A

Tension

Roll

Spring

Rod

19148 Tension

Roll

Spring

Rod

Guide

45.00

Page 12

PARTS

FOR

BOSTON WIRE

STITCHER

HEADS

NO. 15 AND NO. 15D

06

Adjusting

Screw

Binder

530

Finger Guard

5037

Driver

Retaining

Spring

Rivet

5062

Tension Roll Spring

Eod

Retainer

5160 Driver Release

Pin

7155 Spool Stud

7180

Tension Roll Spring

7224

Wire

Cutter

Slide Friction Spring

7232 Swivel

Hook

7235

Swivel

Hook

Pivot

Pin

7234

Swivel

Kook

Spring

9010 Driver Retaining

Spring

9044

Swivel Holder

Clanp

Screw

9057

Swivel Oper. Lever Stud

Screw

15002

Bonnet Screw

15011 Driver - round wire

15012 Driver - ribbon

wire

15012H

Driver - Hybar

wire

15015A

Driver

Bar

15022A

Bender

Bar -

round wire

15023A

Bender

Bar -

ribbon

wire

15023HA

Bender

Bar -

Kybar

wire

15024

Bender Slide

15025

Bender Slide

Spring

15026

Bender Slide Spring

Plunger

15027

Bender Slide Connection

Pin

15031 Grip - Ribbon Wire

15032A

Grip Holder

15033

Grip Holder Stud

.5034A

Grip

Retaining

Spring

15038

Grip Spring

15039

Grip Spring

Pin

15041 Grip Block - Ribbon

Wire

15042

Grip Block - Round Wire

15043

Grip Block Screw

15045

Grip Release Slide

15046A

Grip Release

Lever

1504S

Grip Release Lever Pivot

15055A

Supporter

15054

Supporter

Pivot

Pin

15055

Supporter Guide

Pin

15056

Supporter Spring

15057

Supporter Spring

Plunger

15061 Supporter Guide

Plate

15052

Supporter Guide Plate Screw

15056A Swivel - Ribbon Wire

15067

Swivel

Wire

Retainer

15070A

Swivel - Hybar

Wire

15072

Swivel Holder

15073A

Swivel Holder Clamp

15076

Swivel

Holder

Guard

15077 Swivel Holder Guard Screw

.05

15083

Face Plate

Adj.

Screw

.35

15089

Face Plate

Adj.

Screw

Nut

.05

15092

Face Plate

Clip

.25

15093

Face Plate

Clio

Screw

.10

15094B

Face Plate Clip

Spring

.35

15097B

Face Plate

Adj".

Slide

.10

15098

Face Plate

Adj.

Slide

Pin

.05

15100 Stationary Wire

Cutter - Hound

Y7ire

.20

15101 Stationary

Wire

Cutter - P.ibbon

Wire

.05

15102 Stationary Wire Cutter Screw

.05

15104 Sliding Wire Cutter

.05

151053

Wire Cutter

Holder

.05

15107 Wire

Cutter

Lock

Pin

.05

15108 Wire

Cutter

Lock

Pin

Spring

.40

15109 Wire

Cutter

Lock

Pin

Spring Screw

2.00

151163

Wire Cutter Slide Friction

2.00 15123 Wire

Straightener

Roll Clip

5.00 15124 Wire Straightener

Roll

Clip

Rivet

2.25 15125

Wire

Straightener

Roll

Clip

Spacer

10.00 15130 Wire Straightener

Eccentric

Block

-

10.00 Ribbon Wire

12.00 15142 Tension Roll Block - Ribbon Wire

4.20

15150A

Wire Guide Spring - Round

V.:ire

.30

15151A

Wire

Guide

Spring - Ribbon Wire

.60

15154 Wire Guide Spring Bracket

.40

15155 Wire Guide

Spring

Bracket Screw

.35

15156 Wire

Guide

Spring Bracket

Adj.

Screw

2.40 15160 Spool

Stud

Friction

Disc

.30

15161 Spool Stud Bracket

.15

15162

Spool

Stud

Bracket

Screw

•

25

15187

Parallel

Slide

Extension

.30

15188

Parallel Slide

Extension

Screw

.90

15283A

Bender Link

.90

15284

Driver

Link

.05

15286

Bender Link Connection

Pin

1.25

15287

Driver Link

Connection

Pin

1.65 19011 Driver

- 20 x 24

Wire

•20 19022A

Bender

Bar

- 20 x 24

Wire

5.25

19065A

S'.vivel - Round Wire

.15

19088

Finger

Guard

Screw

•

15

19121 Wire Straightener Roll

.15

19122 Wire Straightener Roll Stud

.20

19123A

Wire

Straightener

Eccentric

1.05 19130 Wire Straightener Eccentric

Block

-

.05

Round Wire

9.00 19133 Wire Straightener Eccentric Clip

.30

Rivet

12.00 19134 Wire Straightener Eccentric Clip

7.50 Spacer

1.05 19142 Tension Roll Block

2.25

19283A

Bender

Link

.15

1

.25

.25

.80

.20

.05

.80

.25

.00

.75

.20

.70

.50

.25

.10

.30

.15

.10

.10

.15

00

50

50

50

50

45

10

75

25

30

00

25

50

50

20

20

00

00

00

10

2o

10

75

3.00

.15

.00

.00

Loading...

Loading...