Boss DR-110 MIDI Interface Manual

1 V1.1

Assembly

The converter comes in two parts - the unit itself and the connector to be installed in the DR-

110. The main unit comes either assembled or as a kit. With both, the connector needs to be

installed in the DR-110.

Tools required

• Screwdriver

• Soldering iron

• Drill

• File or preferably rotary tool

• Multimeter (recommended)

Constructing the Unit

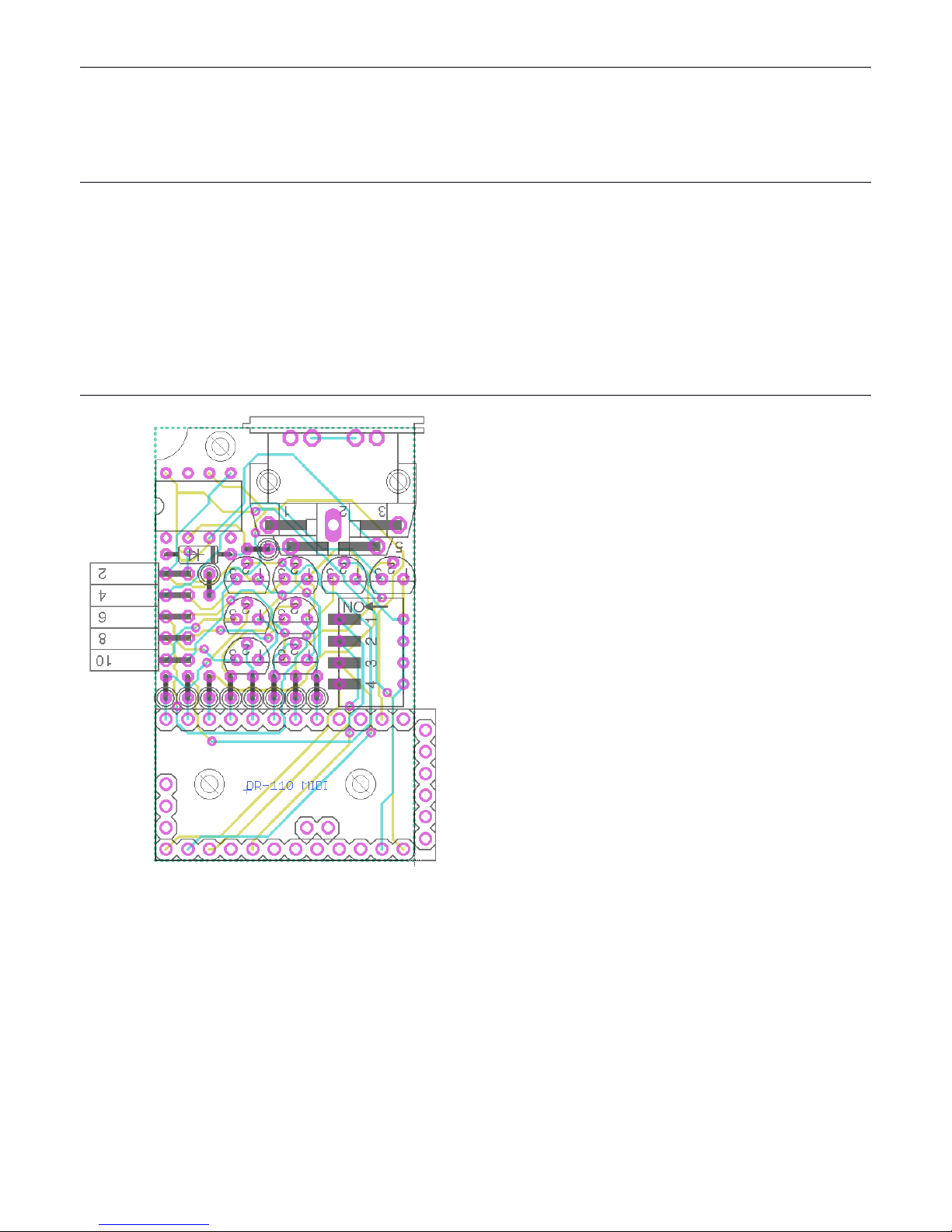

Solder the components to the PCB as per the

diagram to the left. The order of soldering is

not particularly important, but a good order

would be: large chip socket, 8 trigger resistors,

8 transistors, the diode, the 2 other resistors,

then the remaining chip, switch, MIDI port and

10-way connector.

The 8 resistors beside the chip and the one

beside the 10-way connector should all be

10kΩ (Brown Black Orange). The resistor

beside the MIDI port should 220Ω (Red Red

Brown).

The legs of the transistors must be bent to fit

in the holes. The easiest way is to line up two

legs into the correct holes and then turn the

transistor until the third lines up. The

transistors may sit at different heights

depending on how far they are pushed in.

The resistors can be inserted in either

direction, but the other components must be

inserted in the direction shown. Ensure the

black band of the diode faces towards the MIDI

port and the 8 pin chip has its dot aligned

towards the semicircle in the picture.

The controller chip can now be inserted for

testing.

2 V1.1

To ensure the PCB has been soldered correctly,

the next step is to make and then install the

connector for the DR-110 and check the two

units work together. This step is very delicate

and involves separating and stripping the end

of the wires of the ribbon cable so they line up

with the pins mentioned in the next section.

Refer to the next section for fitting it in the

unit.

The final step is to affix the PCB to the

enclosure. The controller chip will need to be

removed for this.

The PCB should be aligned with the enclosure

lid so the edge of the PCB is just within the lip

of the lid, as shown to the left. Guide marks

should be drawn onto the lid through the bolt

holes. These holes should then be drilled and

the PCB bolted in place. The three short bolts

included are for this. Care must be taken not to

tighten them too much as that could

potentially damage the board.

Once this is done, the controller chip can be

inserted into the socket.

Then the lid can be aligned with the case and

guide marks for the 10-way connector slot can

be made. There are many ways to remove the

plastic of the slot, but the fastest seems to be

to use wire cutters to cut away as much plastic

as possible and then file it down to neaten it

up. Once that is removed, the lid should fit into

the case.

Next, a hole can be made in the case for the

MIDI port. There is no simple way to locate the

hole other than measuring or estimating its

position. A stepped drill bit is the best way to

make the hole.

Finally, the lid and PCB can be screwed in place

onto the case.

3 V1.1

Installing the Connector

[!] Any user patterns saved in memory will be erased so write them down if you want to keep

them.

Remove the 3 screws on the base of the DR-

110. The back should now come off. Set this

aside for later.

The PCB will now be exposed. Solder the

ribbon cable so the red wire is connected to

the point labelled 6 on the image and the cable

runs towards the front of the DR-110. The wire

beside can be soldered to either point 7 or 8

and the other wires are to be soldered

sequentially from point 9 to 16. Once soldered,

it is important to check the continuity between

each adjacent pair of connections to ensure

they are not being bridged.

Once soldered, it should look similar to this. At

this stage, it is a good idea to connect the mod

to the unit to confirm it is working and

triggering the sounds properly. If it is not, the

soldering must be checked again and possibly

redone.

4 V1.1

Part of the PCB will need to be filed down

slightly to allow clearance for the bolts.

Remove a section of case and drill holes in

order to fit the connector

in the unit. The exact

position may vary based on how the cable has

been soldered so it is best to do this at this

stage.

Use the nuts and bolt to secure the connector.

Connect the DR-110 to the mod box.

5 V1.1

Operation

Playing Notes

Play notes as you would normally on your MIDI-equipped keyboard or digital sequence

generator, with the default keymapping below. By default, the unit will be set to channel 1.

Bass Drum

36

Hi-Hat Noise*

45

Rimshot

37

Open Hi-Hat

46

Snare Drum

38

Accent Hold*

47

Clap

39

Accent Trigger

48

Weak Clap

40

Cymbal

49

Snare Noise* 41 Cymbal Noise* 51

Closed Hi-Hat 42 Clap Noise* 52

Pedal Hi-Hat

44

Most sounds have no need to respond to Note Off events as they only trigger a short pulse, the

duration of which is set by the velocity of the note, creating a form of velocity sensitivity.

However, some sounds are sustained until a Note Off message is received. These sounds are

marked above with an asterisk and do not have velocity sensitivity.

Those sounds that do have velocity sensitivity are set so a velocity of 100 triggers each sound

the same way as the internal sequencer does.

Changing MIDI Channel

The MIDI channel can be set by either the internal switches, or MIDI CC.

Setting the channel by switch

The channel can be set using the switch positions below.

1

2 3 4 5 6 7

8

9

10

11

12

13

14

15

16

The position of the switches and the corresponding MIDI Channel

The unit will read these switches on startup if the channel has not been set previously by CC. It

will also be read if a CC9 with value 0 is received.

Setting the channel by CC

When a value of 1 - 16 is received on MIDI CC 9, the channel will be set to that value. Values 17+

have no effect. A value of 0 sets the MIDI channel the position of the switches. The MIDI channel

and omni status are saved when the device is switched off.

6 V1.1

Once the channel has been changed to another via CC, it will no longer respond to a CC on the

original channel. The sending equipment must have its send channel set the new channel of the

unit.

Omni mode can also be enabled or disabled, allowing the device to respond to messages sent

on any channel. To enable this, CC125 must be sent with a value of 0. To disable this, send

CC124 with a value of 0.

Changing the keymapping

To change which keys trigger which notes, send the CC in the implementation chart below

followed by the note number that should trigger it. For example, to change the open hi-hat so it

is triggered by the key to left of the default Bass Drum key, send CC46 with a value of 35. These

values are retained while the device is switched off.

MIDI Implementation

The unit does not transmit MIDI.

Channel

1-16

Mode

Omni / Mono

Note number

0-127

Velocity

0-127

CC

9

Set channel

36

Set Bass Drum note number

37

Set Rimshot note number

38

Set Snare Drum note number

39

Set Clap note number

40

Set Weak Clap note number

41 Set Snare Noise note number

42

Set Closed Hi-Hat note number

44

Set Pedal Hi-Hat note number

45

Set Hi-Hat Noise note number

46

Set Open Hi-Hat note number

47

Set Accent Hold note number

48 Set Accent Trigger note number

49

Set Cymbal note number

51

Set Cymbal Noise note number

52

Set Clap Noise note number

Aux

All notes off

7 V1.1

Loading...

Loading...