Page 1

Contents

Safety Information............................................................................................................................ 2

Electrostatic Discharge Sensitive (ESDS) Device Handling ........................................................ 2

Jukebox Disassembly/Assembly Procedures............................................................................ 3-4

Jukebox Remote control ................................................................................................................. 5

Disassembly/Assembly Procedures .............................................................................................. 5

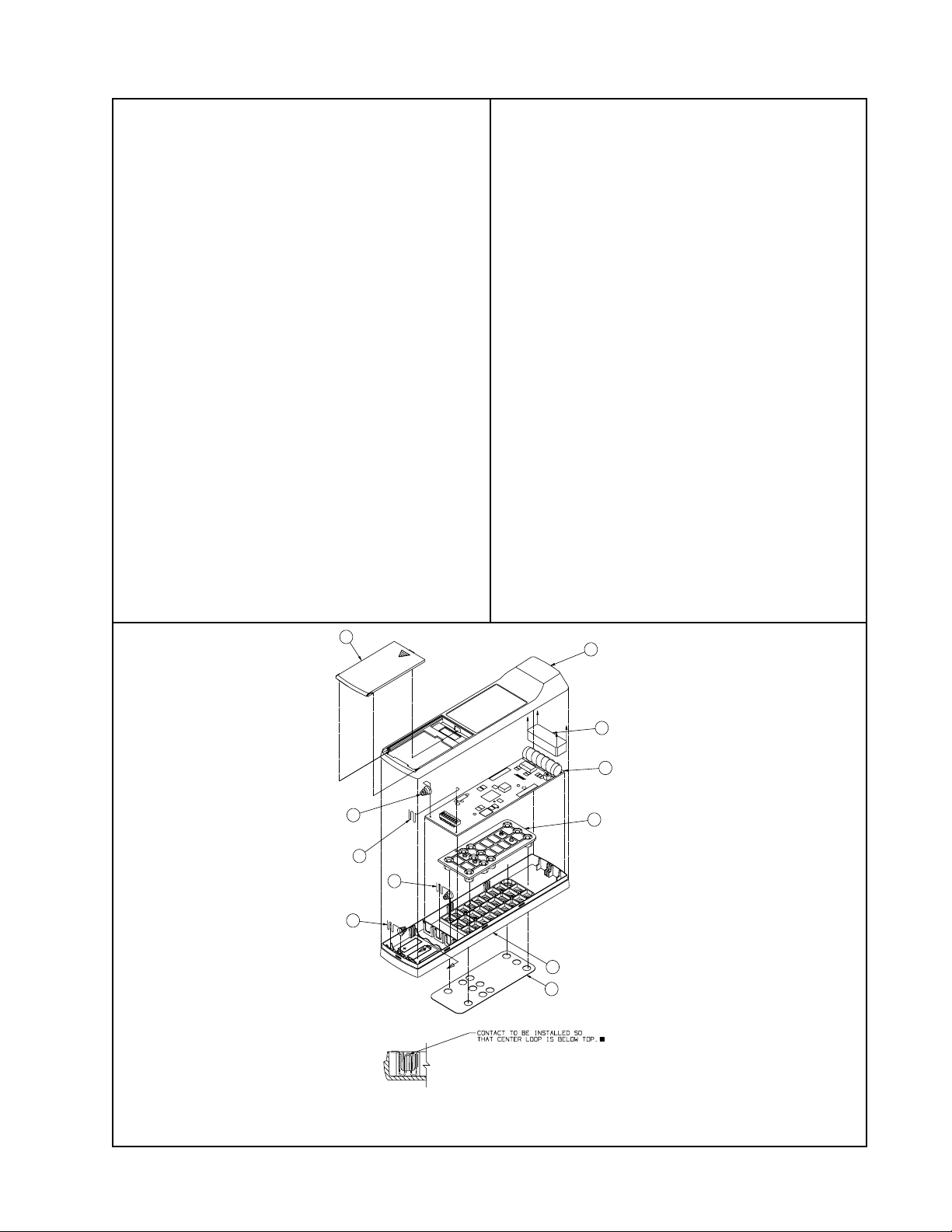

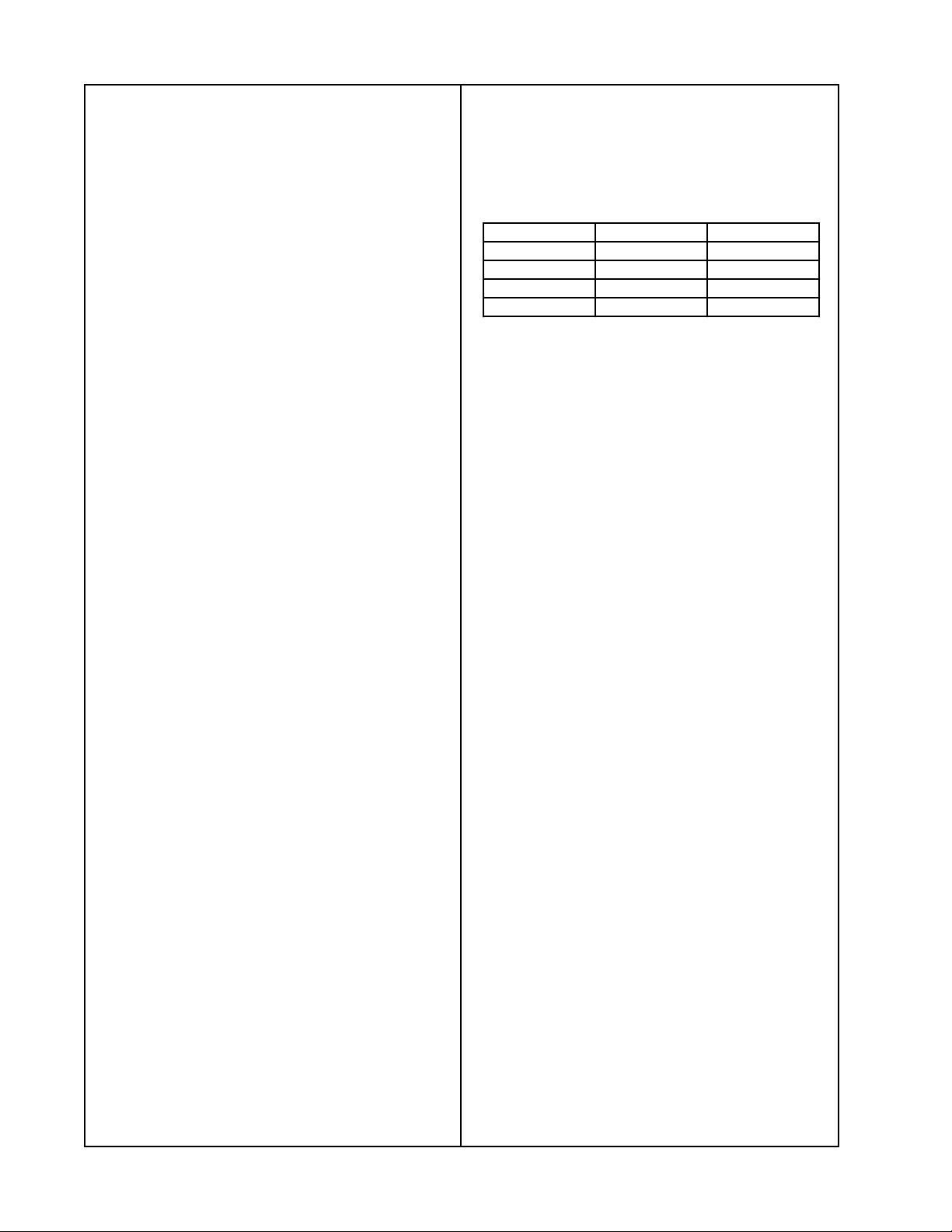

Figure 1. Remote Control Assembly Exploded View........................................................................ 5

Test Procedures ............................................................................................................................ 6-8

Part List Notes.................................................................................................................................. 9

Main Part List.................................................................................................................................... 9

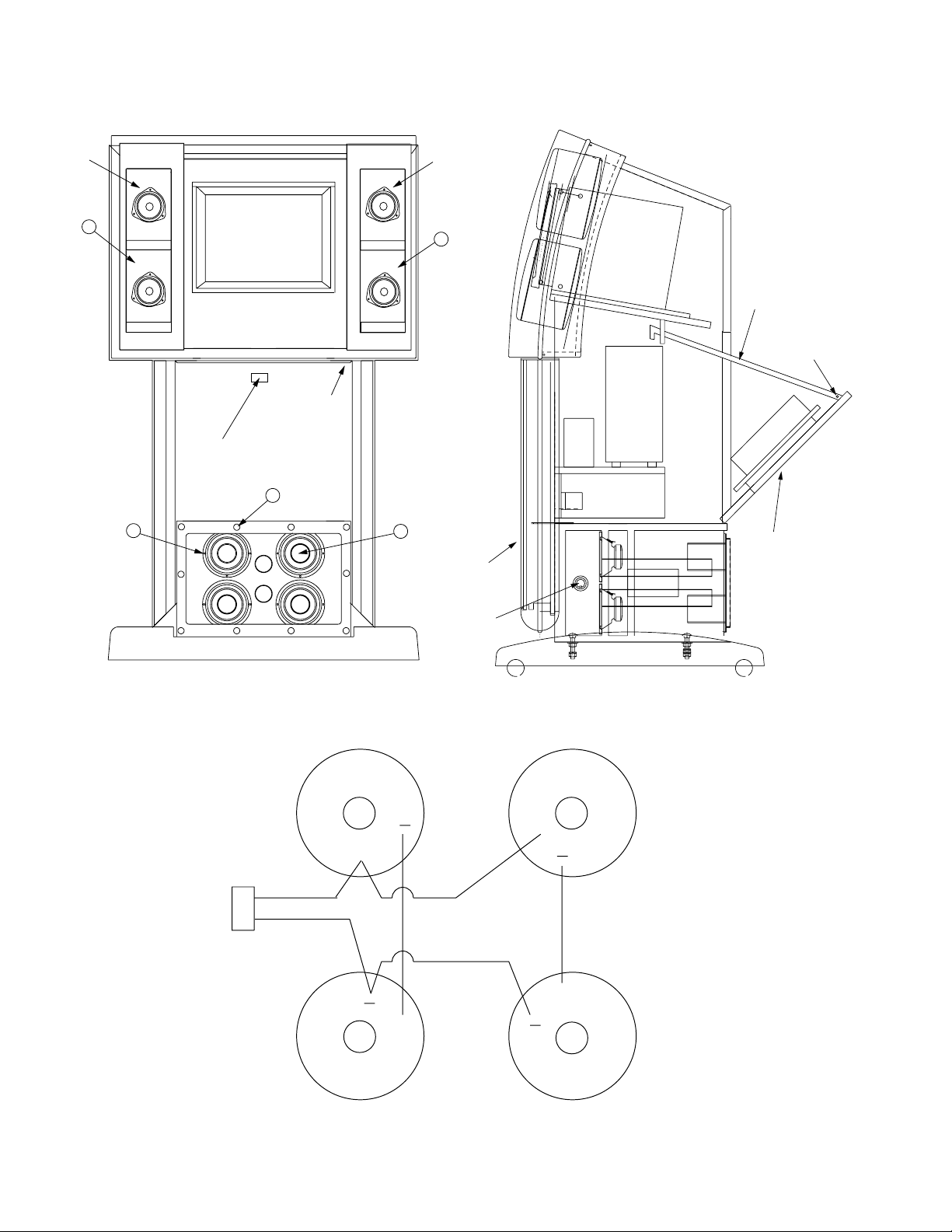

Figure 2. Jukebox Assembly .......................................................................................................... 10

Figure 3. Woofer Wiring Diagram................................................................................................... 10

Figure 4. Rear Panel Assembly...................................................................................................... 11

Zone 1 Amp Electrical Part List ............................................................................................... 12-16

Zone 2 Amp Electrical Part List ............................................................................................... 17-19

I/O PCB Part List ....................................................................................................................... 20-22

Remote Control Part List............................................................................................................... 23

Figure 5. Remote Control Exploded View ...................................................................................... 23

®

JB Part List.............................................................................................................................. 24

141

Figure 6. 141JB Exploded View ..................................................................................................... 24

ZONE 2 Speaker Connections Greater Than 3.2

Figure 7. Zone 2 External Speaker Connections ........................................................................... 25

ZONE 2 Speaker Connections Less Than 3.2

Figure 8. Low DC Resistance Connections ................................................................................... 26

Figure 9. Low DC Resistance Connections ................................................................................... 26

Troubleshooting Tips..................................................................................................................... 27

Figure 10. Audio Section Wiring/Block Diagram ............................................................................ 28

Figure 11. Control Section Wiring/Block Diagram .......................................................................... 29

Cable Drawings ......................................................................................................................... 30-31

Ω ..................................................................... 25

Ω.......................................................................... 26

Caution: The TouchTunes Digital Jukebox contains no user serviceable parts. To prevent warranty infractions, refer servicing to warranty service stations or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE® CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE

BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR USED

FOR ANY OTHER PURPOSE.

1

Page 2

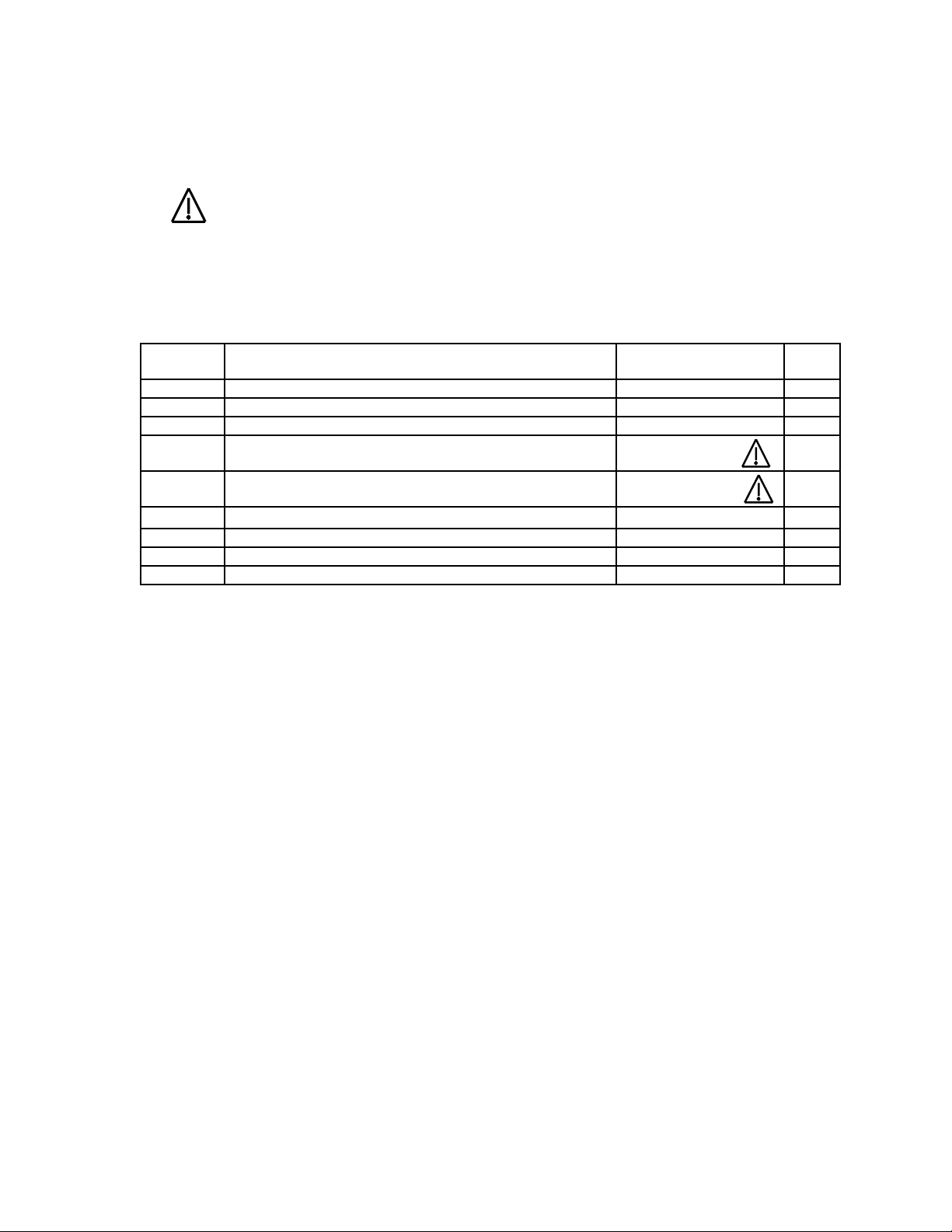

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on

schematics or by special notes in the part lists. Use only replacement parts that

have critical characteristics recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed

parts are acceptably insulated from the supply circuit before returning the unit

to the customer. Use the following checks to perform these measurements:

A. Leakage Current Hot Check: With the unit completely assembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a

leakage current tester or a metering system that complies with American National Standards

Institute (ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL)

813. With the unit's AC switch first in the ON position and then in the OFF position, measure

from a known earth ground (metal water pipe, conduit, etc.) to all exposed metal parts of the

unit (antennas, handle bracket, metal cabinet, screw-heads, metallic overlays, control shafts,

etc.), especially any exposed metal parts that offer an electrical return path to the chassis. Any

current measured must not exceed 0.75 milliamp. Reverse the unit's power cord plug in the

outlet and repeat the test. ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED

HEREIN INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE ELIMINATED BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check: (1) Unplug the power cord from the wall outlet

and connect a jumper wire between the two prongs of the plug. (2) Turn on the power switch of

the unit. (3) Measure the resistance with an ohmmeter between the jumpered AC plug and

each exposed metallic cabinet part on the unit. The reading should be between infinite. When

there is no return path to the chassis, the reading must be "infinite". If it is not within the limits

specified, there is the possibility of a shock hazard, and the unit must be repaired and rechecked before it is returned to the customer.

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive floor

mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap or plastic trays.

2

Page 3

JUKEBOX DISASSEMBLY/ASSEMBLY PROCEDURES

Note: Refer to Figures 2 and 4.

1. Rear Panel Access

1.1 Using the Jukebox key, unlock the front

drawer and slide the front drawer out.

Note: Make sure that the shipping screw

has been removed.

1.2 Lift up the rear panel release handle

and push the handle toward the rear until

the handle locks into place.

Note: The rear panel can be fully opened

by removing the locking pin that secures

the rear panel release handle to the rear

panel.

2. Rear Panel Closure

2.1 Pull the rear panel release handle

forward until the rear panel is fully seated

and the release handle is locked in the

catch.

2.2 Slide the front drawer back into the

Jukebox and with the key, lock it into place.

3. Amplifier/EQ Module Removal

3.1 Perform procedure 1.

3.2 Remove the four screws (11) that

secure the bracket adaptor to the rear

panel and the lift off the bracket adaptor.

Note: If you are replacing the amplifier

assembly, perform procedure 5.2-5.3 and

save the adaptor bracket.

3.3 Located under the equalizer PCB and

the adaptor bracket is the amplifier assembly. Lift up the amplifier assembly to remove it.

3.4 Disconnect the transformer primary

(J7), transformer secondary (J1), RCA

output plugs (J9), DIN input plug (J5), AC

plug (J6) and the woofer output cable (J3)

(ZONE 1 only). Don't remove the interconnect cable between the equalizer PCB and

the amplifier assembly. Remove the entire

amplifier module (1, 2).

4. Amplifier/EQ Module Replacement

4.1 Align the amplifier assembly so that the

two posts on the rear panel line up with the

two grommets on the amplifier assembly.

Press firmly down on the amplifier assembly so that the two posts are fully inserted

into the two grommets.

4.2 Align the adaptor bracket with the screw

holes in the rear panel. See Figure 2 for the

correct position.

4.3 Connect all the connectors that were

removed in procedure 3.4.

4.4 Replace the four screws (11) that

secure the adaptor bracket to the rear

panel.

5. Fuse Access/EQ PCB Removal

5.1 Perform procedure 1.

5.2 Remove the screw (14) that secures

the equalizer PCB to the bracket adaptor.

5.3 Press outward on the four tabs that

secure the equalizer PCB to the bracket

adaptor. Lift off the equalizer PCB. The

fuse is located on the under side of the

equalizer PCB.

6. EQ PCB Replacement

6.1 Line up the slots on the equalizer PCB

with the tabs on the adaptor bracket.

6.2 Replace the screw (14) that secures the

equalizer PCB to the adaptor bracket.

7. I/O PCB Removal

7.1 Perform procedure 1.

7.2 Remove the four screws (12) that

secure the I/O PCB to the rear panel.

7.3 Remove all the connectors from the I/O

PCB. Make a note of the wire configuration.

Lift up the I/O PCB.

3

Page 4

JUKEBOX DISASSEMBLY/ASSEMBLY PROCEDURES

Note: Some units have the antenna cable

soldered to the I/O PCB.

8. I/O PCB Replacement

8.1 Align the I/O PCB so that the holes in the

I/O PCB align with the locator pins on the

rear panel. Press down on the I/O PCB until

the locator pins are fully inserted through the

holes in the I/O PCB.

8.2 Replace the four screws (12) that secure

the I/O PCB to the rear panel.

8.3 Connect all the connectors that were

removed in procedure 5.3.

Note: The modem plug that connects to the

computer connects to J9. Solder the antenna cable to the I/O PCB if it was initially

soldered.

9. Transformer Removal

11.2 Lift the 141JB out of the Jukebox and

remove the wires from the rear of the

enclosure.

12. 141JB Replacement

12.1 Attach the wires to the rear of the

141JB (6).

12.2 Line up the inserts in the 141JB with

the screw holes in the Jukebox.

12.3 Replace the two wing nuts that secure

the 141JB to the Jukebox.

13. Woofer Removal

13.1 Perform Procedure 1.1.

13.2 Remove the 10 screws (10) that

secure the woofer access panel to the

Jukebox. Pull off the access panel.

9.1 Cut the wire ties that secure the transformer wire harness.

9.2 Disconnect the primary (J7) and secondary (J1) connectors from the amplifier

module (1, 2).

9.3 Remove the four nuts (13) that secure

the transformer to the rear panel. Lift the

transformer up (4).

10. Transformer Replacement

10.1 Align the transformer with the screw

posts on the rear panel.

10.2 Replace the four nuts (13) that secure

the transformer to the rear panel.

10.3 Connect the primary (J7) and secondary (J1) connectors to the amplifier module

(1, 2). Replace the wire ties that were

removed in procedure 7.1.

®

11. Detachable 141

JB Removal

13.3 Remove the four screws (9) that

secure the woofer (8) to the Jukebox.

13.4 Lift the woofer out of the Jukebox and

cut the wires as close as possible to the

woofer. Make a note of the wire configuration.

14. Woofer Replacement

14.1 Attach the wires to the replacement

woofer (8) referring to the wire configuration notes taken in procedure 11.4 and

figure 3.

14.2 Align the woofer to the Jukebox and

twist any excess wire to prevent wire

buzzes.

14.3 Replace the four screws (9) that

secure the woofer to the Jukebox.

14.4 Align the woofer access panel to the

Jukebox and replace the 10 screws (10)

that secure it to the Jukebox.

11.1 Remove the two wing nuts located on

the side of the 141JB (6).

4

Page 5

JUKEBOX REMOTE CONTROL

DISASSEMBLY/ASSEMBLY PROCEDURES

1. Enclosure Disassembly

1.1 Slide off the battery compartment door

(5) and remove the batteries.

1.2 While holding the top cover (4) with one

hand, place your fingers of your other hand

in the battery compartment and grasp the

lower part of the bottom cover (3) with your

fingers.

1.3 With your fingertips in the battery compartment, first pull parallel to the unit and

then pull perpendicular.

1.4 With the catches released at the bottom,

work your fingers up the sides to release

the rest of the catches.

2. Enclosure Assembly

2.1 Lower the bottom cover (3) onto the top

cover (4) so that the bottom cover's lip fits

over the top cover.

2.2 Press the top cover and the bottom

cover together until they snap into place.

3. PCB Removal

3.1 Lift the PCB (1) straight up. The springs

will come up with the PCB.

4. PCB Replacement

4.1 Lower the PCB (1) into the top cover (4)

so that the springs are in the battery compartment.

5. Pad Removal

5.1 The pad (2) is not secured. Grasp a

corner of the pad and lift it out.

6. Pad Replacement

6.1 Lower the pad (2) into the top cover (4)

so that the buttons line up with the holes in

the top cover.

5

6

7

9

8

B

B

3

12

1

2

4

10

SECTION B-B

Figure 1. Remote Control Assembly Exploded View

5

Page 6

TEST PROCEDURES

Note: The following tests are intended to

be used by a qualified electronic technician

to service an amplifier module. These

procedures are not intended to be used in

the field.

ZONE 1 Bass Channel Test Procedures

Note: Use the AM-5

number 172296, to connect the test equipment to the input (J5) of the amplifier. Disconnect the speakers from the amplifier outputs

and do not load the outputs unless otherwise

noted.

Unit Turn On Procedure

Apply 12 VDC to J5 pin1 (refer to the

schematic). This will simulate the turn-on

signal the amplifier receives from the

computer.

1. Bass Channel DC Offset

®

P audio input cable, part

4.2 Reference a dB meter to the woofer

channel output.

4.3 Measure the woofer output according to

the following table.

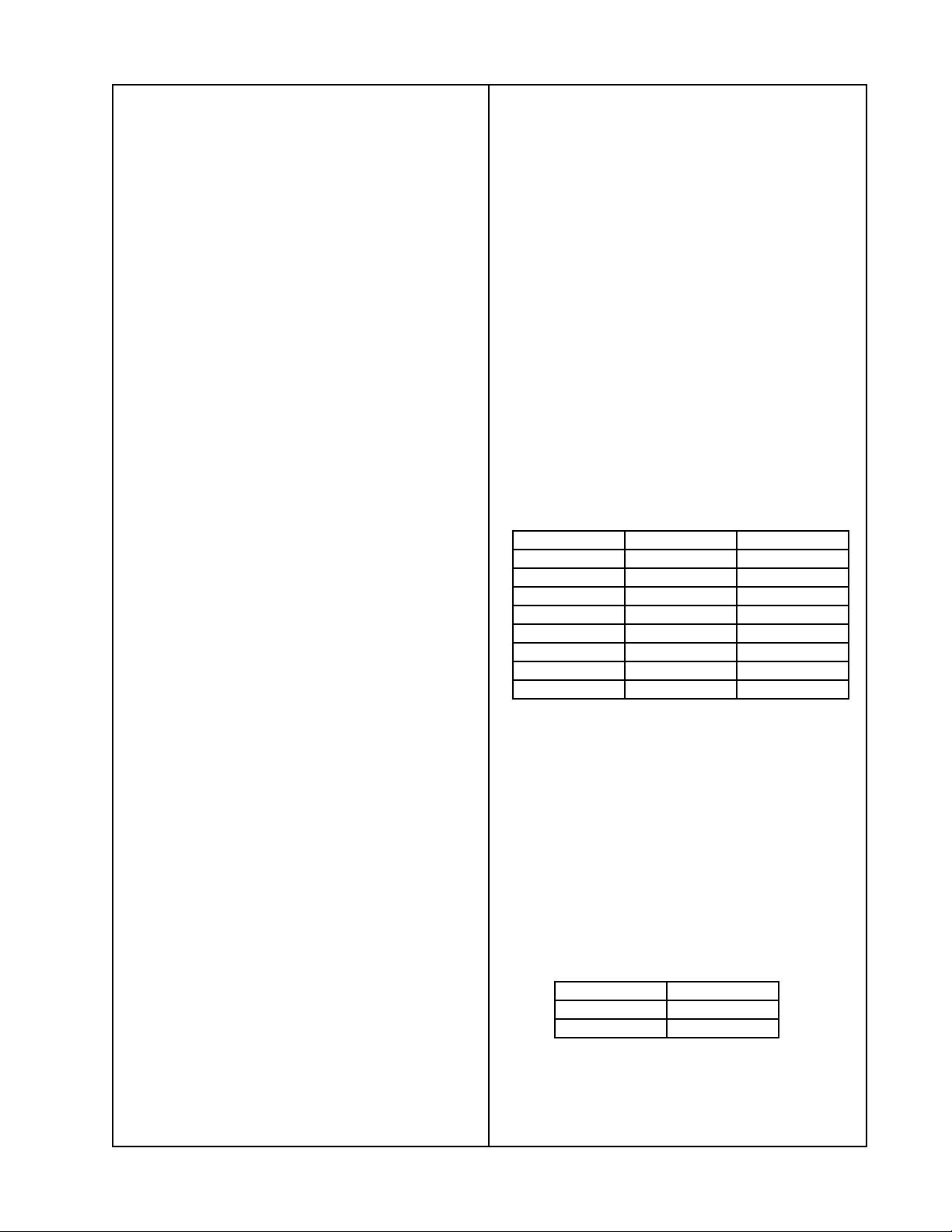

Frequency Output Tolerance

20 Hz -21.3 dB ± 2.0 dB

40 Hz +3.0 dB ± 1.5 dB

100 Hz Reference 200 Hz -24.5 dB ± 2.0 dB

5. Bass Channel Dynamic Equalizer Gain

5.1 Apply a 2.4 mVrms, 50 Hz signal to the

left and right input.

5.2 Reference a dB meter to the bass

channel output.

5.3 Apply a 240 mVrms, 50 Hz signal to the

left and right input.

1.1 Disconnect all audio input signals.

1.2 Measure the woofer channel output. It

should be 0 ± 70 mVDC.

2. Bass Channel Output Noise

2.1 Short all audio inputs.

2.2 Measure the woofer channel output. It

should be <10 mVrms.

3. Bass Channel Reference Gain

3.1 Apply a 200 mVrms, 100 Hz signal to

the left and right input.

3.2 Reference a dB meter to the applied

signal.

3.2 Measure the bass channel output. It

should be 28.3 dB ± 1.5 dB.

5.4 Measure the bass channel output. It

should be 26.3 dB ± 1.5 dB (referenced to

the measurement taken in 5.2).

6. Bass Channel Small Signal Distortion at

0.5 W (1.414 Vrms)

6.1 Connect the speaker or a 6 Ω, 1%,

100 W resistive load to the bass channel

output.

6.2 Apply a 54 mVrms, 100 Hz signal to the

left and right input.

6.3 Measure the distortion at the bass

channel output. It should be <0.5% THD.

7. Bass Channel Large Signal Distortion at

80 W (17.9 Vrms)

7.1 Connect the speaker or a 6 Ω, 1%,

resistive load to the bass channel output.

4. Bass Channel Relative Frequency

Response

4.1 Apply a 200 mVrms, 100 Hz signal to

the left and right input.

7.2 Apply a 685 mVrms, 100 Hz signal to

the left and right input.

7.3 Measure the distortion at the bass

channel output. It should be <0.2% THD.

6

Page 7

TEST PROCEDURES

8. Bass Control Test

8.1 Apply a 50 mVrms, 100 Hz signal to the

left and right input.

8.2 Adjust R302 to center. Reference a dB

meter to the bass channel output.

8.3 Adjust R302 to maximum. Measure the

bass channel output. It should be +2.5 dB ±

1.5 dB.

8.4 Adjust R302 to minimum. Measure the

bass channel output. It should be -2.8 dB ±

1.5 dB.

9. Bass Compressor Test

9.1 Apply a 1.4 mV rms, 100 Hz signal to

the left and right input.

9.2 Measure the distortion at the bass

channel output. It should be <10% THD.

ZONE 1 and 2 Left/Right Channel Tests

Note: Unload the amplifier outputs unless

otherwise noted.

Unit Turn On Procedure

Apply 12 VDC to J5 pin1. This will simulate

the turn on signal the amplifier receives

from the computer.

12. Left/Right Reference Gain

12.1 Apply a 200 mVrms, 1.0 kHz signal to

the left/right input.

12.2 Measure the left/right channel output.

It should be (19.2 dB ± 1.5 dB, ZONE 1)

(34.0 dB ± 1.5 dB, ZONE 2).

13. ZONE 1 Left/Right Channel Relative

Frequency Response

13.1 Apply a 200 mVrms, 1.0 kHz signal to

the left/right channel output.

13.2 Reference a dB meter to the left/right

channel output.

13.3 Measure the left/right channel output

according to the following table.

Frequency Output Tolerance

100 Hz -1.8 dB ± 2.5 dB

170 Hz +6.4 dB ± 1.0 dB

600 Hz +2.5 dB ± 1.0 dB

1 kHz Reference -

1.4 kHz +0.6 dB ± 1.0 dB

6.0 kHz +10.5 dB ± 1.0 dB

12 kHz +14.2 dB ± 1.5 dB

20 kHz +6.6 dB ± 3.0 dB

14. ZONE 2 Left/Right Channel Relative

Frequency Response

10. Left/Right DC Offset

10.1 Disconnect all audio input signals.

10.2 Measure the left/right channel output.

It should be 0 ± 70 mV.

11. Left/Right Output Noise

11.1 Disconnect all audio input signals.

11.2 Measure the left/right channel output.

It should be ≤500 µV un-weighted.

14.1 Apply a 50 mVrms, 1 kHz signal to left/

right channel input.

14.2 Reference a dB meter to the left/right

channel output.

14.3 Measure the left/right channel output

according to the following table.

Frequency Output

20 Hz -0.6 ± 1.0 dB

20 kHz -0.6 ± 1.0 dB

7

Page 8

TEST PROCEDURES

15. Left/Right Channel Small Signal Distortion at (0.1 W, 632 mVrms ZONE 1) (0.5

W, 1.4 Vrms ZONE 2)

15.1 Connect a 4 Ω, 1%, 50 W resistive

load to the left/right channel output.

15.2 Apply a (25 mVrms ZONE 1) (28

mVrms ZONE 2), (4 kHz ZONE 1) (9 kHz

ZONE 2) signal to the left/right input.

15.3 Measure the distortion at the left/right

channel output. It should be <0.2% THD.

16. Left/Right Channel Large Signal Distortion at (30 W, 15.5 Vrms ZONE 1) (30 W,

11.0 Vrms ZONE 2)

16.1 Connect a 4 Ω, 1%, 50 W resistive

load to the left/right channel output.

16.2 Apply a (1.7 Vrms ZONE 1) (220

mVrms ZONE 2), 1 kHz signal to the left/

right input.

19. Short Circuit Protection Test

19.1 Apply a (1 Vrms ZONE 1) (0.35

mVrms ZONE 2), 1 kHz signal to the left/

right channel input.

19.2 Momentarily short the left channel.

19.3 Verify that the mute line (J2 pin 5)

goes low (<0.2 V). Wait three seconds and

repeat for the right channel.

16.3 Measure the distortion at the left/right

channel output. It should be <0.2% THD.

17. Left/Right Channel Separation

17.1 Apply a 100 mVrms, 10 kHz signal to

the right (left) channel only. Short the left

(right) channel input.

17.2 Reference a dB meter to the right (left)

channel.

17.3 Measure the left (right) channel output. It should be <-30 dB.

18. Compressor Test

18.1 Apply a (1.9 Vrms ZONE 1) (0.70

Vrms ZONE 2), 1 kHz, signal to the left and

right channel input.

18.2 Measure the distortion at the left and

right output. It should be <6.0%

8

Page 9

PART LIST NOTES

AMP ASSY, ZONE 1, 115V PART NUMBER 199018-9014 USES PCB ASSY 195225

AMP ASSY, ZONE 2, 115V PART NUMBER 199019-9014 USES PCB ASSY 195178

1. This part is not normally available from customer service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCB are listed in the part list.

3. This part is critical for safety purposes. Failure to use a substitute replacement with

the same safety characteristics as the recommended replacement part might create shock, fire

and/or other hazards.

MAIN PART LIST

Item

Number

1 AMP ASSY, ZONE 1, 115VAC 199018-9014

2 AMP ASSY, ZONE 2, 115VAC 199019-9014

3 PCB ASSY, I/O 250636-9014

4 TRANSFORMER, 120V 196196 3

5 FAN, 115VAC 196882 3

6

7 WOOFER 190170

- FILTER, FAN 196829-001

- REMOTE CONTROL 199640-9014

®

141

JB, PAIR, DETACHABLE

Description Part Number Note

250637-9014

9

Page 10

Fixed

Fixed

Detachable

6

Top Panel

Latch (x2)

Rear Panel

Release Handle

10

9

View without Front Drawer

8

6

Detachable

Front

Drawer

Front

Drawer

Lock

UPS

Computer

Rear Panel

Release Bar

Retaining Pin

AMP

Rear Panel

Assembly

red

black

Figure 2. Jukebox Assembly

+

+

yellow

grey

green

grey

+

+

Figure 3. Woofer Wiring Diagram

10

Page 11

4

4

WOOFER

OUTPUT

(J3)

(ZONE 1 ONLY)

13

Locator

Pin

12

ZONE 2

XFORMER

AC

3

I/O PCB

ZONE 1

XFORMER

FAN

5

XFORMER

INPUT

RCA

OUTPUT

PRIMARY

(J7)

DIN

(J5)

(J9)

ZONE 1

AMP

FUSE

(bottom side)

INPUT

14

ZONE 2

AMP

AC

(J6)

1

Bracket

Adaptor

2

11

Locator

Pin

11

12

XFORMER

SECONDARY

(J1)

Figure 4. Rear Panel Assembly

11

Page 12

ZONE 1 AMP ELECTRICAL PART LIST

Resistors

Reference Designator Description Part Number Note

R2, 10, 375 14.3k, 1206, 1/8W, 1% 124894-1432

R3, 4, 8, 12, 22, 23, 176, 190, 192,

276, 290, 292, 384

R5, 6, 393 5.1Ω, LEADED, FUSE,

R7, 24, 25 20.0k, 1206, 1/8W, 5% 124895-2035

R9 30.1k, 1206, 1/8W, 1% 124894-3012

R11 THERMISTOR, 20k, ERT-

R101, 102, 103, 104, 115, 201, 202,

203, 204, 215, 417, 422, 425, 439, 459,

460

R105, 106, 205, 206 2.49k, 0805, 1/10W, 1% 133625-2491

R107, 120, 140, 207, 220, 240, 414,

419, 433

R108, 208, 317 147Ω, 0805, 1/10W, 1% 133625-1470

R109, 129, 138, 196, 209, 229, 238,

296, 322, 331, 333, 346

R110, 210 2.55k, CHIP, 0805, 1/10W,

R111, 112, 211, 212 10.0k, 0805, 1/10W, 1% 133625-1002

R114, 214, 312 22.1k, 0805, 1/10W, 1% 133625-2212

R116, 216 5.11k, CHIP, 0805, 1/10W,

R117, 139, 217, 239 1.54k, 0805, 1/10W, 1% 133625-1541

R118, 126, 133, 134, 218, 226, 233,

234

R119, 219 3.16k, 0805, 1/10W, 1% 133625-3161

R121, 221 1.05k, 0805, 1/10W, 1% 133625-1051

R122, 137, 222, 237 10Ω, CHIP, 0805, 5% 133626-1005

R124, 224 7.15k, 0805, 1/10W, 1% 133625-7151

R125, 130, 225, 230 9.09k, 0805, 1/10W, 1% 133625-9091

R127, 227 681Ω, CHIP, 0805, 1/10W,

R131, 231, 432 20.0k, CHIP, 0805, 1/10W,

R132, 232 432Ω, CHIP, 0805, 1/10W,

R135, 136, 235, 236, 304, 329, 330,

411

R141, 241, 323, 324, 327, 328 100k, 0805, 1/10W, 1% 133625-1003

R143, 149, 243, 249, 303, 305, 337,

344, 404, 415, 416, 418, 420, 421, 423,

429, 431, 457, 458

R174, 274, 374 5.90k, 1206, 1/8W, 1% 124894-5901

R175, 275 1.80k, 1206, 1/8W, 5% 124895-1825

R177, 277, 381, 385 2.49k, 1206, 1/8W, 1% 124894-2491

R178, 179, 278, 279, 399 49.9k, 1206, 1/8W, 1% 124894-4992

R180, 185, 280, 285, 378, 380, 387,

394

R181, 183, 186, 188, 189, 191, 281,

283, 286, 288, 289, 291, 388, 389, 396,

397

R182, 187, 282, 287 7.50k, 1206, 1/8W, 1% 124894-7501

R184, 193, 284, 293, 392 220Ω, CF, 5%, 52mm 121243-1212215

10.0k, 1206, 1/8W, 5% 124895-1035

130102-5R1 3

1/4W

177557

D3FHL203S

1.00k, CHIP, 0805, 1/10W,

1%

10.0k, 0805, 1/10W, 5% 133626-1035

JUMPER, CHIP, 0805 133627

1%

1%

11.8k, 0805, 1/10W, 1% 133625-1182

1%

1%

1%

330Ω, 0805, 1/10W, 5% 133626-3315

100k, 0805, 1/10W, 5% 133626-1045

100k, 1206, 1/8W, 5% 124895-1045

1.00k, 1206, 1/8W, 5% 124895-1025

133625-1001

133625-2551

133625-5111

133625-6810

133625-2002

133625-4320

12

Page 13

ZONE 1 AMP ELECTRICAL PART LIST

Resistors (continued)

Reference Designator Description Part Number Note

R194, 294 0.1Ω, 2512, 1W, 5% 149322-100

R301 18.7k, CHIP, 0805, 1/10W,

1%

R302 POT., DUAL, 10k,

DETENT.

R306, 376, 424, 430 1M, 0805, 1/10W, 5% 133626-1055

R309, 434, 436 2.00k, 0805, 1/10W, 1% 133625-2001

R310 86.6k, 0805, 1/10, 1% 133625-8662

R311, 315 23.7k, 0805, 1/10W, 1% 133625-2372

R313, 413 12.1k, 0805, 1/10W, 1% 133625-1212

R314, 401, 410 100Ω, CHIP, 0805, 1/10W,

5%

R316, 318, 402 1.62k, 0805, 1/10W, 1% 133625-1621

R320 5.36k, 0805, 1/10W, 1% 133625-5361

R321 23.2k, 0805, 1/10W, 1% 133625-2322

R325 4.75k, 0805, 1/10W, 1% 133625-4751

R326 17.4k, 0805, 1/10W, 1% 133625-1742

R336 3.0k, CHIP, 0805, 1/10W,

5%

R377 301Ω, 1206, 1/8W, 1% 124894-3010

R379 10M, 1206, 1/8W, 5% 124895-1065

R382 200Ω, 1206, 1/8W, 5% 124895-2015

R383 200k, 1206, 1/8W, 1% 124894-2003

R386 4.22k, 1206, 1/8W, 1% 124894-4221

R390, 395 75Ω, CF, 5%, 1/4W, 52mm 121243-1217505

R398 33.2k, 1206, 1/8W, 1% 124894-3322

R412 39Ω, CF, 1/4W, 5%, 52mm 121243-1213905 3

133625-1872

185173

133626-1015

133626-3025

R426, 428, 435 20k, CHIP, 0805, 5% 133626-2035

R432 3.01k, 0805, 1/10W, 1% 133625-3011

R438 196Ω, 0805, 1/10W, 1% 133625-1960

R448 14.3k, 0805, 1/10W, 1% 133625-1432

R455 36.5k, 0805, 1/10W, 1% 133625-3652

R456 SUPPRESSOR 180580-01 3

Capacitors

Reference Designator Description Part Number Note

C1, 5, 6, 11, 12, 15, 16, 17, 18, 185,

285, 379, 380, 381

C3, 4 4700uF, EL, BP, 85, 50V,

C7, 8 4700uF, EL, 85, 25V, 20% 170216

C9, 10, 13, 14, 101, 102, 175, 176,

201, 202, 275, 276, 302, 303, 304, 409,

427

C103, 130, 131, 203, 230, 231, 301,

426

C104, 204 47uF, EL, 105, 16V, 20% 137126-470

C106, 206 .015uF, BOX, 85, 100V, 5% 137127-153

C107, 108, 207, 208, 309, 310, 314,

315

C109, 110, 209, 210 .018uF, BOX, 85, 100V, 5% 137127-183

.1uF, 1206, Y5V, 50V, 80% 138551-104

187394

20%

10uF, EL, 105, 16V, 20% 137126-100

100pF, 0805, COG, 50V,

5%

.47uF, BOX, 85, 50V, 5% 137127-474

133622-101

13

Page 14

ZONE 1 AMP ELECTRICAL PART LIST

Capacitors (continued)

Reference Designator Description Part Number Note

C112, 212 .18uF, BOX, 85, 50V, 5% 137127-184

C113, 114, 118, 119, 213, 214, 218,

219

C115, 116, 215, 216 .0082uF, BOX, 85, 100V,

C120, 220 .0033uF, BOX, 85, 100V,

C121, 221 330pF, MONO, COG, 50V,

C122, 124, 125, 222, 224, 225, 318,

401, 415, 416, 418, 428

C123, 126, 127, 128, 129, 223, 226,

227, 228, 229, 308

C177, 178, 180, 182, 186, 277, 278,

280, 282, 286, 383, 386

C179, 183, 279, 283, 384 10000pF, CHIP, 5% 124959-103

C181, 281 22uF, EL, 105, 16V, 20% 137126-220

C195, 295, 385, 391 JUMPER, CHIP, 1206 124896

C306, 307 .15uF, BOX, 85, 50V, 5% 137127-154

C312, 316 .27uF, BOX, 85, 50V, 5% 137127-274

C313, 317 820pF, MONO, COG, 50V,

C319, 320, 412, 413 .10uF, 0805, Y5V, 25V,

C373, 405 100uF, EL, 105, 16V, 20% 139734-101

C377, 390 1uF, 1206, Y5V, 16V, 80% 173383-105

C378 .1uF, BOX, 85, 50V, 5% 137127-104

C382, 387 .0033uF, 1206, Y5V, 50V,

C388, 408 1.0uF, EL, 105, 50V, 20% 137126-1R0

C389, 420 270pF, 0805, COG, 50V,

C404 .0047uF, DISC, 60, AC,

C410, 411 2.2uF, EL, 105, 50V, 20% 137126-2R2

.33uF, BOX, 85, 50V, 5% 137127-334

137127-822

5%

137127-332

5%

140564-331

5%

3300pF, 0805, X7R, 50V,

10%

.033uF, 0805, X7R, 50V,

10%

1000pF, 1206, COG, 50V,

10%

5%

80%

80%

5%

100%

133623-332

133623-333

124956-1022

140564-821

133624

124959-332

133622-271

149016 3

Diodes

Reference Designator Description Part Number Note

D1, 175, 178, 182, 275, 278, 282, 403,

406, 407, 421

D21, 22, 101, 102, 181, 201, 202, 281,

302, 375, 402, 405, 410, 411, 414

D23 SWITCHING, 75V, 300mA 121501

D24, 25, 176, 179, 276, 279, 416 ZENER, 6.8V, 225mW 135247-5235

D177, 180, 277, 280 1N5393, AXIAL 177961

D301, 401, 412 DUAL, SOT-23, BAV70 147249

D376, 377 1N5402 170219

D380 ZENER, SOT23, 5%, 5.1V 135247-5231

Z1, 2 RECTIFIER, BRIDGE 170214 3

SWITCHING, 75V, 200mA 136603

DUAL, SOT-23, BAV99 147239

14

Page 15

ZONE 1 AMP ELECTRICAL PART LIST

2/02

Transistors

Reference Designator Description Part Number Note

Q175, 180, 275, 280, 377, 380, 383,

384

Q176, 276, 381, 382 DARL, P, TIP146T 172285

Q177, 179, 277, 279, 379, 385, 386 BPLR, P, 60V, 200mA, TO-

Q178, 278, 387, 388 DARL, N, TIP141T 172284

Q181, 281 BPLR, N, 50V, 100mA,

Q301, 401, 403, 404, 405, 406, 408 BPLR, N, 55V, 150mA,

Q302, 303, 376, 407, 410 BPLR, P, 55V, 150mA,

Q375 TRANS, JFET, SOT,

Q378 PNP, (2SB560F) 140349

Q400 TRIAC 178807 3

BPLR, N, 60V, 200mA, TO-

92

92

SOT23

SOT23

SOT23

MMBF4392

Integrated Circuits

117921

119168

146817

134741

258007 Alt.134743

134738

Reference Designator Description Part Number Note

U1 VOLT REG, 12V, POS

TO2

U2 VOLT REG, 12V, NEG

TO2

U101, 301 OPAMP, DUAL, DIP-8,

RC4559

U102, 103, 104, 105, 303, 304 OPAMP, DUAL, DIP-8,

LF353

U175, 275 50W AMP, CUT LEADS 170156

U302 OPAMP, SNGL, DIP-8,

CA3080

U375 OPAMP, SNGL, DIP-8,

LF351N

U402 OPTO-TRIAC, PDIP-6,

MOC3023T

U403 QUAD TRANSISTOR

ARRAY, NPN

U404 VOLTAGE

COMPARATOR, DIP-14

Miscellaneous

Reference Designator Description Part Number Note

F1 FUSE, 5X20mm, SLO-

BLO, 3A

J1 CONN, HEADER, RTANG,

5 POS

J2 CONN, HEADER, RTANG,

2.5MM, 14POS

J3 2 PIN HEADER 134290-02

J5 CONNECTOR, DIN,

PCMOUNT, 5PIN

116736

149009-12

108568

110698

119834

132604

190334-001 3

145317

137929

181561-3000 3

134290-05

145402-14

170135

15

Page 16

ZONE 1 AMP ELECTRICAL PART LIST

Miscellaneous (continued)

Reference Designator Description Part Number Note

J6 CONN, HOUSING, AC,

2POS, FEMALE

J7 CONN, HEADER, 5 POS. 178742-5

J8 CONN, HEADER,

PCBMNT, 14POS, M

J9 CONN, RCA JACK,

2POS, GREEN

Y1 JUMPER, 22AWG, NON-

INSUL, 20.0mm

Y2 JUMPER, 22AWG, NON-

INSUL, 7.5mm

Y4, 5, 6 JUMPER, 22AWG, NON-

INSUL, 10.0mm

F601 FUSECLIP, 5mm 178548

SHIELD, MICRO 177564

146563 3

133224-14

182495-1

148242-200

148242-075

148242-100

16

Page 17

ZONE 2 AMP ELECTRICAL PART LIST

Resistors

Reference Designator Description Part Number Note

R2, 10 14.3k, 1206, 1/8W, 1% 124894-1432

R3, 4, 8, 12, 22, 23, 176, 190, 192,

276, 290, 292

R5, 6 5.1Ω, LEADED, FUS, 1/4W 130102-5R1 3

R7, 24, 25 20.0k, 1206, 1/8W, 5% 124895-2035

R9 30.1k, 1206, 1/8W, 1% 124894-3012

R11 THERMISTOR, 20k, ERT-

R101, 102, 103, 104, 201, 202, 203,

204, 417, 422, 425, 439, 459, 460

R105, 106, 205, 206 8.25k, CHIP, 0805, 1/10W,

R107, 112, 117, 207, 212, 217, 414,

419, 433

R108, 208 147Ω, 0805, 1/10W, 1% 133625-1470

R111, 211, 413 12.1k, 0805, 1/10W, 1% 133625-1212

R116, 216 30.1k, 0805, 1/10W, 1% 133625-3012

R114, 115, 121, 122, 123, 127, 132,

196, 214, 215, 221, 222, 223, 227, 232,

296

R135, 136, 235, 236, 411 330Ω, 0805, 1/10W, 5% 133626-3315

R137, 237 10Ω, CHIP, 0805, 5% 133626-1005

R143, 243, 404, 415, 416, 418, 420,

421, 423, 429, 431, 457, 458

R149, 249 200k, 0805, 1/10W, 5% 133626-2045

R174, 274 5.90k, 1206, 1/8W, 1% 124894-5901

R175, 177, 275, 277 2.49k, 1206, 1/8W, 1% 124894-2491

R178, 179, 278, 279 49.9k, 1206, 1/8W, 1% 124894-4992

R180, 185, 280, 285 100k, 1206, 1/8W, 5% 124895-1045

R181, 183, 186, 188, 189, 191, 281,

283, 286, 288, 289, 291

R182, 187, 282, 287 7.50k, 1206, 1/8W, 1% 124894-7501

R184, 193, 284, 293 220Ω, CF, 5%, 52mm 121243-1212215

R194, 294 0.1Ω, 2512, 1W, 5% 149322-100

R195, 295 JUMPER, CHIP, 1206 124896

R401, 410 100Ω, CHIP, 0805, 1/10W,

R402 1.50k, CHIP, 0805, 1/10W,

R412 39Ω, CF, 1/4W, 5%, 52mm 121243-1213905 3

10.0k, 1206, 1/8W, 5% 124895-1035

177557

D3FHL203S

1.00k, CHIP, 0805, 1/10W,

1%

1%

10.0k, 0805, 1/10W, 5% 133626-1035

JUMPER, CHIP, 0805 133627

100k, 0805, 1/10W, 5% 133626-1045

1.00k, 1206, 1/8W, 5% 124895-1025

5%

1%

133625-1001

133625-8251

133626-1015

133625-1501

R424, 430 1M, 0805, 1/10W, 5% 133626-1055

R426, 428, 435 20k, CHIP, 0805, 5% 133626-2035

R432 3.01k, 0805, 1/10W, 1% 133625-3011

R434, 436 2.00k, 0805, 1/10W, 1% 133625-2001

R438 196Ω, 0805, 1/10W, 1% 133625-1960

R448 14.7k, CHIP, 0805, 1% 133625-1472

R455 36.5k, 0805, 1/10W, 1% 133625-3652

R456 SUPPRESSOR 180580-01 3

17

Page 18

ZONE 2 AMP ELECTRICAL PART LIST

Capacitors

Reference Designator Description Part Number Note

C1, 5, 6, 11, 12, 15, 16, 17, 18, 185,

285

C3, 4 4700uF, EL, BP, 85, 50V,

C7, 8 4700uF, EL, 85, 25V, 20% 170216

C9, 10, 13, 14, 101, 102, 175, 176,

201, 202, 275, 276, 409, 427

C103, 130, 203, 230, 426 100pF, 0805, COG, 50V,

C104, 204 47uF, EL, 105, 16V, 20% 137126-470

C107, 108, 207, 208 .33uF, BOX, 85, 50V, 5% 137127-334

C115, 118, 215, 218 JUMPER, 22AWG, INSUL,

C122, 124, 125, 222, 224, 225, 401,

415, 416, 418, 428

C123, 126, 127, 128, 129, 223, 226,

227, 228, 229

C177, 178, 180, 182, 186, 277, 278,

280, 282, 286

C179, 183, 279, 283 10000pF, CHIP, 5% 124959-103

C181, 281 22uF, EL, 105, 16V, 20% 137126-220

C404 .0047uF, DISC, 60, AC,

C405 100uF, EL, 105, 16V, 20% 139734-101

C408 1.0uF, EL, 105, 50V, 20% 137126-1R0

C410, 411 2.2uF, EL, 105, 50V, 20% 137126-2R2

C412, 413 .10uF, 0805, Y5V, 25V,

C420 270pF, 0805, COG, 50V,

.1uF, 1206, Y5V, 50V, 80% 138551-104

187394

20%

10uF, EL, 105, 16V, 20% 137126-100

133622-101

5%

179645

5MM

3300pF, 0805, X7R, 50V,

10%

.033uF, 0805, X7R, 50V,

10%,

1000pF, 1206, COG, 50V,

10%

100%

80%

5%

133623-332

133623-333

124956-1022

149016 3

133624

133622-271

Diodes

Reference Designator Description Part Number Note

D1, 175, 178, 182, 275, 278, 282, 403,

406, 407, 421

D21, 22, 101, 102, 181, 201, 202, 281,

402, 405, 410, 411, 414

D23 SWITCHING, 75V, 300mA 121501

D24, 25, 176, 179, 276, 279, 416 ZEN, 6.8V, 225mW 135247-5235

D177, 180, 277, 280 1N5393, AXIAL 177961

D401, 412 DUAL, SOT-23, BAV70 147249

B1, 2 RECTIFIER, BRIDGE 170214 3

Reference Designator Description Part Number Note

Q175, 180, 275, 280 BPLR, N, 60V, 200mA, TOQ176, 276 DARL, P, TIP146T 172285

Q177, 179, 277, 279 BPLR, P, 60V, 200mA, TOQ178, 278 DARL, N, TIP141T 172284

SWITCHING, 75V, 200mA 136603

DUAL, SOT-23, BAV99 147239

Transistors

117921

92

119168

92

18

Page 19

ZONE 2 AMP ELECTRICAL PART LIST

2/02

Transistors (continued)

Reference Designator Description Part Number Note

Q181, 281 BPLR, N, 50V, 100mA,

SOT23

Q400 TRIAC 178807 3

146817

Q401, 403, 404, 405, 406, 408 BPLR, N, 55V, 150mA,

SOT23

Q407, 410 BPLR, P, 55V, 150mA,

SOT23

Integrated Circuits

Reference Designator Description Part Number Note

U1 VOLT REG, 12V, POSTO2 116736

U2 VOLT REG, 12V, NEGTO2 149009-12

U101, 103, 301 OPAMP, DUAL, DIP-8,

RC4559

U102 OPAMP, DUAL, DIP-8,

LF353

U175, 275 50WAMP, CUT LEADS 170156

U402 OPTO-TRIAC, P DIP-6,

MOC3023T

U403 QUAD TRANSISTOR

ARRAY, NPN

U404 VOLTAGE

COMPARATOR, DIP-14

Miscellaneous

134741

258007 Alt. 134743

108568

110698

190334-001 3

145317

137929

Reference Designator Description Part Number Note

F1 FUSE, 5X20mm, SLO-

BLO, 3A

F601 FUSECLIP, 5MM 178548

J1 CONN, HEADER, RTANG,

5POS

J2 CONN, HEADER, RTANG,

2.5MM, 14POS

J5 CONNECTOR, DIN,

PCMOUNT, 5PIN

J6 CONN, HOUSING, AC,

2POS, FEMALE

J7 CONN, HEADER, 5POS. 178742-5

J8 CONN, HEADER,

PCBMNT, 14POS, M

J9 CONNECTOR, RCA,

JACK, 2POS, BLUE

Y1 JUMPER, 22AWG, NON-

INSUL, 20.0mm

Y2 JUMPER, 22AWG, NON-

INSUL, 7.5mm

Y4, 5, 6 JUMPER, 22AWG, NON-

INSUL, 10.0mm

181561-3000 3

134290-05

145402-14

170135

146563 3

133224-14

182495-2

148242-200

148242-075

148242-100

19

Page 20

I/O PCB PART LIST

Resistors

Reference Designator Description Part Number Note

R5, 8, 29, 107, 207 10.0k, CHIP, 0805, 1% 133625-1002

R6, 19 27Ω, CHIP, CF, 0805, 5% 133626-2705

R7 14.0k, CHIP, 0805, 1% 133625-1402

R9, 16, 18, 30, 31, 102, 202 100k, CHIP, 0805, 5% 133626-1045

R10 24.3k, CHIP, 0805, 1% 133625-2432

R11 1M, CHIP, 0805, 5% 133626-1055

R12, 105, 205 6.19k, CHIP, 0805, 1/10W,

1%

R13, 20, 21 4.02k, 0805, 1/10W, 1% 133625-4021

R14 THERMISTOR, 20k, ERT-

D3FHL203S

R15, 106, 206 4.99k, CHIP, 0805, 1% 133625-4991

R17 200k, CHIP, 0805, 1/10W,

5%

R22, 23, 27, 28 47.0k, 0805, 1/10W, 5% 133626-4735

R24, 25, 26 330Ω, CHIP, 0805, 1/10W,

5%

R101, 201 1k, CHIP, 0805, 5% 133626-1025

R108, 208 5.62k, CHIP, 0805, 1/10W,

1%

133625-6191

177557

133626-2045

133626-3315

133625-5621

Capacitors

Reference Designator Description Part Number Note

C1, 3, 6, 12 1.0uF, EL, 20% 137126-1R0

C2 .01uF, 0805, X7R, 50V,

10%

C4, 5, 10 .10uF, 0805, Y5V, 25V,

80%

C7, 8 270pF, 0805, X7R, 50V,

10%

C9, 11, 205 10uF, EL, 20% 137126-100

C103, 104, 203, 204 .1uF, BOX, 85, 50V, 5% 137127-104

Diodes

Reference Designator Description Part Number Note

D3, 4, 5, 6 BAV99, SOT23 147239

D7 SOT-23, BAV70 147249

D8 ZENER, 5.6V, 225mW,

1N5232

D10 RECTIFIER, 400V, 1A,

1N4004

Transistors

133623-103

133624

133623-271

135247-5232

116996-4

Reference Designator Description Part Number Note

Q 1 TRANS, 2SC2812SOT23 134741

20

Page 21

I/O PCB PART LIST

Integrated Circuits

Reference Designator Description Part Number Note

U2 CLIP, I-BUTTON,

DS9094F

U3 DUAL COMPARITOR,

SO-8, LM393

U4 VOLTAGE REG, TO-92,

+8V

U5 OPAMP, DUAL, SO-8,

NJM4556

U6 QUAD OPAMP, TLO74D,

SOIC

U7 ANALOG SW, SOIC,

74HC4066D

U8 VOLTAGE REG, TO-92,

-8V

U9 OPTO ISOLATOR,

MOTOROLA 4N32T

Miscellaneous

195236

148584

146234

148598

186112

187766

146235

172298 3

Reference Designator Description Part Number Note

RR1 RECEIVER, RF REMOTE,

27.145MHZ

VR1, 2 VARISTOR, METOX,

150V, 45JOULE

F1 CONN, FM ANTENNA 178354

J1, 25 CONN, HEADER,

PCBMNT, 4POS, MALE

J2 CONN, D-SUB, R/A,

FEMALE, 25PIN

J3 CONN, DUAL, DIN, 8POS 178355

J4 CONNECTOR, 15PIN 194447-002

J5 CONN, HOUSING,

PHONO, QUAD, 8POS

J6 CONN, HEADER, JSTRF-

H16-1190

J7, 8 CONN, HEADER,

PCBMNT, 5POS, MALE

J9, 10 JACK, TELEPHONE,

VERTICAL MOUNT

J11 CONN, RCA QUAD,

VERT, EMUDT6027

J12, 13 CONN, BARRIER,

BEAU69-5-4-50C

J14 CONN, BARRIER,

BEAU70-D-16-50

J15 CONN, HEADER,

PCBMNT, 2POS, MALE

J16 CONN, AC PWR, PCB

MNT, 3POS

J16_BOTTOM SCREW, TAPP, 6-13x.5,

PAN, XREC/SQ

J17 JACK, AC INLET, 3

CONDUCTOR

191401-001

170186

133224-04

194447-003

147227

198067-16

133224-05

195240-04

197863

197865-4

197862-16

133224-02

170176 3

172783-08

195245 3

21

Page 22

I/O PCB PART LIST

Miscellaneous (continued)

Reference Designator Description Part Number Note

J19 CONN, AC OUTLET,

DUAL, RTANG, SMK

J21, 22 CONN, HEADER,

LOCKING, TOP ENTRY

J23 CONN, HEADER,

PCBMNT, 3 POS, MALE

J26, 27 CONN, HEADER, INLINE,

PCBMNT, 4P

SW1, 2, 3 SWITCH, MOMENTARY,

SPST, RTANG

SW 4 SWITCH, AC, POWER,

RTANGLE

SW 5 SWITCH, SLIDE, DPDT,

3A, VERTICAL

W1 WIRE, 18AWG, RING

TERMINAL/STRIP

PAD_3/4 CABLE, 2 COND, JSTEH

TO STRIP

197867 3

193369-002

133224-03

133220-04

195246

178792 3

195243

198582

198068

22

Page 23

REMOTE CONTROL PART LIST

Item

Description Part Number Note

Number

1 PCB ASSY, RC9 176335

2 PAD, SWITCH, JUKEBOX REMOTE 195230

3 COVER, BOTTOM, CS6 182635

4 COVER, TOP, CS-6 182636

5 DOOR, BATTERY, CS-6 182637

6 CONTACT, BATTERY, CONE 174001

7 CONTACT, BATTERY, FLAT 174000

8 CONTACT, BATTERY, CONE/FLAT 174002-01

9 CONTACT, BATTERY, FLAT/CONE 174002-02

10 LABEL, APPLIQUE 195229

11 POLYBAG, REMOTE, 3.50X10.50 189252-001

12 SPACER, PAD 173605

13 CARTON, RSC, 22.88x12.43x8.75 179978

5

3

13

12

1

6

7

8

9

B

SECTION B-B

2

B

4

10

Figure 5. Remote Control Exploded View

11

23

Page 24

141®JB PART LIST

Item

Number

1 DRIVER, SHIELDED, 4.5" 123985-001

2 DRIVER GASKET, 4.5" 104794-02

3 GRILLE, PRO GRAY 176541-02

4 TRIM PLATE, PRO GRAY 176542-02 4

5 SCREW, TAPP, 8-11x1, PAN,

XREC/SQ

6 INSERT, THREADED, EXT/INTL 121690 4

7 NUT, LOCK, FLANGE, M8 121691 4

8 WASHER, LOCK, .326, 5/16, INTL T 121692-31 4

Note 4: This part is used on the detachable speaker only

Description Part Number Note

172672-16

8

6

7

2

1

5

4

Figure 6. 141JB Exploded View

3

24

Page 25

ZONE 2 SPEAKER CONNECTIONS GREATER THAN 3.2 Ω

From zone 2 amp

J5

Z2R-OUT

(Z2L-OUT)

From zone 2 amp

Z2R-OUT

(Z2L-OUT)

Right (Left)

8

(16)

7

(15)

6

(14)

single 4 ohm or 8 ohm (per channel)

5

100W @ 4 ohm or 50W @ 8 ohm

(13)

4

(12)

3

(11)

2

+

_

(10)

1

(9)

J5

Right (Left)

8

+

(16)

_

7

(15)

6

(14)

+

_

5

(13)

4

+

(12)

_

3

(11)

2

+

(10)

_

1

(9)

Four 4 ohm or 8 ohm (per channel)

100W @ 4 ohm or 50W @ 8 ohm

From zone 2 amp

J5

Z2R-OUT

(Z2L-OUT)

Right (Left)

8

(16)

7

(15)

6

Two 4 ohm (per channel)

(14)

5

(13)

4

(12)

3

(11)

2

(10)

1

(9)

50W @ 8 ohm

+

_

+

_

From zone 2 amp

J5

Z2R-OUT

(Z2L-OUT)

Right (Left)

8

(16)

7

(15)

6

+

_

(14)

5

(13)

Two 8 ohm (per channel)

4

(12)

3

(11)

2

(10)

1

(9)

100W @ 4 ohm

+

_

Figure 7. Zone 2 External Speaker Connections

25

Page 26

ZONE 2 SPEAKER CONNECTIONS LESS THAN 3.2 Ω

+

R1

LEFT

15

14

13

12

11

10

9

16

+

LEFT

15

13

12

10

9

16

R1

14

11

R2

If a pre-installed speaker system is connected to the Zone 2 amplifier and it measures less

than 3.2 Ω (DC resistance), add resistors according to the table below before operating the

system. This will prevent the amplifier's short circuit protection from activating during loud

music. If the pre-installed speaker system measures less than 2.20 Ω, the speaker system

must be rewired for higher resistance. This can be achieved by wiring the individual speakers

in series or in a series parallel combination instead of all in parallel.

Speaker's Measured DC Resistance R 1 R 2 Figure

3.20 Ω or Greater Not Applicable

Between 2.95 Ω and 3.20 Ω .25 Ω N/A 8

Between 2.70 Ω and 2.95 Ω .50 Ω N/A 8

Between 2.45 Ω and 2.70 Ω .25 Ω .50 Ω 9

Between 2.20 Ω and 2.45 Ω .50 Ω .50 Ω 9

Less than 2.20 Ω Rewire System

8

ZONE 2

AUDIO

AMPLIFIER

OUTPUT

ZONE 2

AUDIO

AMPLIFIER

OUTPUT

7

6

5

4

3

2

1

RIGHT

R1

+

Figure 8. Low DC Resistance Connections

R1

8

7

R2

6

5

4

3

2

1

RIGHT

+

Figure 9. Low DC Resistance Connections

26

Page 27

TROUBLESHOOTING TIPS

1. The amplifier fault protection circuit can trip causing no audio output. To reset the Zone 1

and 2 amplifier fault protection circuit, turn off the power switch located in the rear of the unit,

wait five seconds and the turn-on the power switch.

2. Disconnect the power to the Jukebox. Open the rear panel and make sure that all the

connectors to the amplifier module and the I/O PCB are fully inserted. Close the back panel

and apply power to the Jukebox. If the Jukebox still does not operate properly, disconnect the

power from the Jukebox and perform the following procedures to isolate the failure.

3. Check the fuse that is located on the equalizer PCB (top PCB). See Figure 4 and procedure

5 in the disassembly/assembly section.

4. Disconnect the ZONE 1 or ZONE 2 transformer and measure the DC resistances of the

transformer primary (J7). It should be approximately 1.4 Ω. Replace the transformer if the

resistance is out of range.

5. If the transformer measures good, swap the ZONE 1 and ZONE 2 DIN input cable (J5). If

the problem switches (i.e. ZONE 1 has output now and ZONE 2 has no output) the problem is

with the I/O PCB. Replace the I/O PCB.

6. If the problem does not switch when the DIN input cable is swapped between ZONE 1 and

ZONE 2 and the problem is with ZONE 1, disconnect the woofer output cable (J3) from the

ZONE 1 amplifier module. Measure the DC resistance between the black and red wire. It

should be 5.3 Ω. If the DC resistance is out of range, a woofer is defective. Remove each

woofer and check its DC resistance. Each woofer should measure 5.3 Ω. Replace the defective woofer(s).

7. If the DC resistance of the woofer measures good, disconnect the RCA plugs (J9) from the

amplifier module. Measure the DC resistance between the tip and sleeve of the RCA plug (red

and white). It should be 2.8 Ω. If it measures out of range, remove the 141

measure the DC resistance of each speaker (right side only if the red RCA plug is out of range,

left side only if the white RCA plug measures out of range). Each speaker should measure

1.4 Ω. Replace the defective 141JB speaker(s).

8. If the failure is not identified using procedures 1 through 6, the problem is with the amplifier

module. Replace the amplifier module.

®

JB speakers and

27

Page 28

The cables referenced by their part numbers are shown at the back of this manual.

120V

PRIMARY

(RED/BLACK)

ZONE 1

POWER

TRANSFOMER

SECONDARY

POWER BOARD

AC IN

UNSWITCHED

AC OUT

SWITCHED

AC OUT

VOLUME

UP/DOWN

PWR ON/OFF

DETECT

250643

196841

196923

196837

J7

196898

196838

196838

196834

PRIMARY

(RED/BLACK)

ZONE 2

POWER

TRANSFOMER

SECONDARY

FAN

UPS

MONITOR

LIGHT

TO

COMPUTER

J1

DC

POWER

SUPPLY

196844

PWR IN

J8

AUDIO OUT

AUDIO IN

ZONE 1

AMPLIFIER MODULE

AMPLIFIER PCB (BOTTOM)

L

R

AUDIO IN

EQUALIZER PCB (TOP)

SPKR OUT AC IN

J5 J9 J6

SPKR OUT

J2

EQ

BASS

SPKR

BASS

AC OUT

TURN-ON

196840

J3

J7

J13

J14

J11

J12

J10

SW5

ZONE 1

EXTERNAL

L/R SPKR

OUTPUTS

ZONE 2

SPEAKER

OUTPUTS

DUAL

BARRIER

STRIP

LINE IN

LINE OUT

MIC

21dB

IN

MODEM

IN

MODEM

OUT

F1

J9

196847

J5

196843

J26/

J27

196843

I/O BOARD

J5

196836

PWR

REG

ZONE 1

EXT EQ

SURGE

PROTECT

REMOTE

RCVR

199020

196836

TOP

BOT

RL

FRONT

SPKRS

J3J23

AUDIO

OUT

TO ANTENNA

TO COMPUTER

J25

AUDIO

IN

J8

TEMP

SENSE

AC IN

J7

AC OUT

196839

196839

J2

MGR

SWITCH

J1

J4

PCB

DB-25 196845

DB-15 196846

I-BUTTON

PCB

ZONE 2 AMPLIFIER MODULE

TURN-ON

EQUALIZER PCB (TOP)

SPKR OUT AUDIO IN

AMPLIFIER PCB (BOTTOM)

TO COMPUTER

JUKEBOX BLOCK DIAGRAM

Figure 10. Audio Section Wiring/Block Diagram

ZONE 2

AMPLIFIER MODULE

J5J9J6

SPKR OUT AUDIO IN

20 Hz HPF AUDIO OUT

PWR IN

172293

J2

R

L

DC

POWER

SUPPLY

J1

J8

28

Page 29

The cables referenced by their part numbers are shown at the back of this manual.

COUNTER

COIN

ACCEPTOR

(FAST-ON X 4)STRIPPED X 2

1/2 195270

195271

TO

TOUCH SCREEN

DB-15

COMPUTER

(BACK VIEW)

DB-9

XCP CARD

MONITOR

POWER

DB-25

199625

2X6

BILL

ACCEPTOR

2X9

FROM / TO

I/O BOARD

196846

196845

196847

TO

MONITOR

DB-15

DB-15 3X5

SOUND CARD

DB-25

MODEM

LINE PHONE

1/2 195270

DB-9

UPS

XFMR

22 VAC

120V

FUSE

FROM

LIGHT

120V FROM

POWER BOARD

Figure 11. Control Section Wiring/Block Diagram

29

POWER

Page 30

CABLE DRAWINGS

(referenced in Figures 10 and 11)

14

1

14

1

172293

196834

SHIELD

(SHELL)

8-PIN

MINI-DIN

(PLUG 1B)

6

7

8

3

45

1

2

RED

RED

BLACK

WHITE

WHITE

RED

NO ELECTRICAL CONNECTIONS TO

THE SHELL OF EITHER PLUG.

196836

3

1

5-PIN DIN

4

5

2

SHIELD

1

2

(SHELL)

(PLUG 1A)

196840

196839

PIN 1= WHITE, PIN 2= BLACK

196841

ORANGE

BROWN

RED

BLACK

PIN 1

196843

14

13

12

11

10

9

8

7

6

5

4

3

2

1

3

2

14

1

14

13

12

11

10

9

8

7

6

5

4

3

2

1

14

1

1

1

196844

30

Page 31

CABLE DRAWINGS

(referenced in Figures 10 and 11)

196845

PIN 1

8

15

7

14

6

13

5

12

4

11

3

10

2

9

1

8

7

15

6

14

5

13

12

4

3

11

2

10

9

1

196846

4-YELLOW

4

3-GREEN

3

2

2-RED

1

1-BLACK

6 CONDUCTOR

CABLE TO

18 POS.

CONNECTOR

3 CONDUCTOR

CABLE TO DB9

PIN #1-BLUE/MICROSWITCH

PIN #2-GREEN/MICROSWITCH

PIN #10-BROWN/SOLENOID

PIN #11-WHITE AND RED/

+12 VDC(PROTECTED)

PIN #14-BLACK/CASH COUNT

PIN 1= WHITE, PIN 2= BLACK

196898

PIN #1-GREEN/GROUND

PIN #2-BLUE/DATA

PIN #3-BROWN/ENABLE

PIN #4-BLACK/SEND

PIN #5-WHITE/IRQ

PIN #6-RED/OOS

PIN #20-RED/RTS

PIN #22-WHITE/CTS

PIN #25-BLACK/GROUND

PIN 1

PIN 1

196270

196271

31

196847

PIN 1

PIN #15-GREEN/GROUND

PIN #14-BLUE/DATA

PIN #7--BROWN/ENABLE

PIN #5--BLACK/SEND

PIN #17-WHITE/IRQ

PIN #9--RED/OOS

PIN #1-RED/RTS

PIN #3-WHITE/CT

PIN #9-BLACK/GROUND

PIN 1

BLUE/MICROSWITCH

GREEN/MICROSWITCH

BROWN/SOLENOID

RED/+12 VDC/SOLENOID

WHITE/+12 VDC/METER

BLACK/CASH COUNT

Page 32

TouchTunes

Digital Jukebox

(Bose Audio Portion Only)

©

1999 Bose Corporation

Service Manual

Part Number 198974 REV. J

Page 33

SPECIFICATIONS AND FEATURES SUBJECT TO CHANGE WITHOUT NOTICE

Bose Corporation

The Mountain

Framingham Massachusetts USA 01701

P/N 198974 REV. J 1/99

Loading...

Loading...